Abstract

Laser powder bed fusion (LPBF) technology is of great significance to the rapid manufacturing of high-performance metal parts. To improve the mechanical behavior of an LPBFed AlSi10Mg alloy, the influence of nano-Si3N4 reinforcement on densification behavior, microstructure, and tensile property of AlSi10Mg was studied. The experimental results show that 97% relative density of the 3 vol.% nano-Si3N4/AlSi10Mg composite was achieved via optimization of the LPBF process. With the increase in the nano-Si3N4 content, the tensile strength and the yield strength of the composite steadily increase as per the Orowan strengthening mechanism while the elongation decreases. In addition, nano-Si3N4 reinforcement reduces the width of the coarse cell structure region and the thermal influence region of the AlSi10Mg matrix. After annealing, the tensile strength of the nano-Si3N4/AlSi10Mg composite decreases and the elongation increases significantly.

1. Introduction

Additive manufacturing (AM) technology is revolutionizing the way that traditional products are manufactured, via its unique layer-by-layer superposition fabrication manner based on a 3D model [1] that can help create complex-shaped products with good physical and mechanical properties [2]. Laser powder bed fusion (LPBF) is one of the advanced AM technologies that provide outstanding advantages in combining shape forming and sintering/melting/casting in a single step. At present, it has wide application prospects in aerospace, biomedicine, automobile engineering, and other fields [3,4,5,6]. However, the bottleneck in LPBF is the relatively limited number of metals suitable for this technology, such as some aluminum, titanium, and nickel alloys and stainless steel [7]. Therefore, expanding the material range is becoming more and more important for the development of LPBF.

Due to their high specific strength, corrosion resistance, and preparation convenience, Al–Si casting alloys are now the main aluminum alloy for LPBF and have been widely investigated for applications in aerospace and automotive fields. Among all the Al–Si casting alloys, AlSi10Mg attracts the most attention [8,9]. AlSi10Mg has been proven to be a typical material suitable for LPBF due to its good weldability, admirable hardenability, high thermal conductivity, and favorable corrosion resistance. The reasons for these excellent properties are that the near-eutectic composition of Al and Si reduces the solidification range and a small amount of Mg makes AlSi10Mg suitable for heat treatment to harden and strengthen the matrix [10]. Some scholars have studied the LPBF process of AlSi10Mg, often focusing on the laser parameters, porosity, microstructure, mechanical properties, and heat treatment [11,12,13,14,15]. For example, Cauwenbergh [16] studied the threefold inter-relationship between the process (LPBF and heat treatment), the microstructure at different scales (macro-, meso-, micro-, and nano-scale), and the macroscopic material properties of AlSi10Mg. Zhou [17] investigated the effects of curvatures on the geometrical performance, defects, microstructure, and mechanical properties of as-built AlSi10Mg parts with curved surfaces.

With the development of the automobile industry and other fields, the mechanical performance requirements for aluminum alloy are getting more stringent, which makes the development of ceramic-particle-reinforced aluminum alloy matrix composites extremely urgent. Powder metallurgy was once the essential technology to make particle-enhanced metal matrix composites (MMCs), but LPBF has become an important alternative way to produce MMCs at present [18,19]. Recently, high-density ceramic-particle-reinforced aluminum composites have been successfully fabricated by LPBF. Li et al. [7] prepared an 11.6 wt.% nano-TiB2-decorated AlSi10Mg composite (NTD–Al) with a crack-free microstructure, high tensile strength, excellent plasticity, and high microhardness. Gu et al. [20] prepared nano-TiC/AlSi10Mg composites that are suitable for SLM. Wang et al. [21] also prepared 3 wt.% TiC/AlSi10Mg composites by LPBF. Their experimental results showed that nano-TiC particles can significantly improve tensile properties but increase the porosity of nano-TiC/AlSi10Mg composites. Jiang et al. [22] prepared 1 wt.% CNT AlSi10Mg via SLM and found a positive relationship between laser scanning speed and composite mechanical properties. Gao et al. [23] prepared nano-TiN-enhanced AlSi10Mg. Their tests showed that the evenly distributed particles brought about excellent microhardness and wear properties to the composite. Chang et al. [24] used micro-SiC to produce the AlSi10Mg composite by SLM, with improved wear resistance. With the help of good crystal atomic matching at the Al–LaB6 interface, Tan et al. [25] achieved high-plasticity LaB6/AlSi10Mg composites. The above research manifests that suitable ceramic particles can make metal-based composites achieve better mechanical properties through LPBF. However, among these state-of-art LPBF studies, the nano-Si3N4-particle-reinforced Al matrix composite has rarely been investigated and little attention has been paid to the effect of heat treatment on the performance of nano-scale-particle-enhanced metal-based composites.

In this work, nano-silicon nitride, due to its high strength, low thermal expansion coefficient, superior corrosion resistance, and good thermal stability [26,27], was designed as an enhancement phase for AlSi10Mg. This study was focused on the LPBF process parameters, microstructure, and mechanical properties of nano-Si3N4-enhanced AlSi10Mg composites. Moreover, the effect of heat treatment on the mechanical properties of composites was explored.

2. Materials and Methods

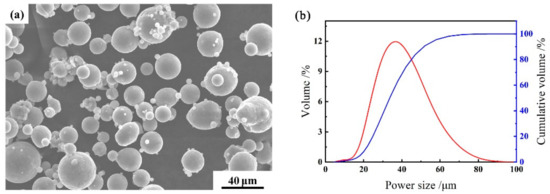

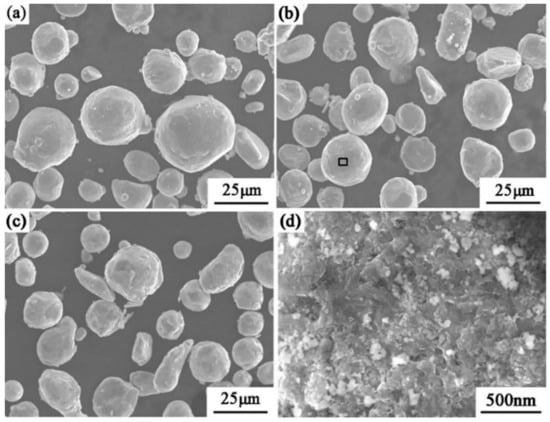

Gas-atomized AlSi10Mg powder with a median particle size of 37.43 μm, as shown in Figure 1a,c, provided by AVIC Maite Powder Metallurgy Technology (Gu’an) Co., Ltd., (Langfang, China), and nano-Si3N4 powder with a median particle size of 50 nm, provided by Beijing Guoxin Hongyu Curtain Wall Material Co., Ltd.,(Beijing, China), were used as the feedstock powders in this study. Table 1 shows the composition of AlSi10Mg powder. The contents of Si3N4 powders in nano-Si3N4/AlSi10Mg composites were set as 1, 3, and 5 vol.%, respectively. The Si3N4 and AlSi10Mg powders were mixed by ball milling, using a ball-to-powder weight ratio of 1:1, a rotation speed of 200 rpm, and a mixing time of 10 h. Figure 2 shows the SEM of mixed powders. AlSi10Mg powder maintained its original spherical shape after ball milling, while nano-Si3N4 particles were uniformly distributed on the surface of AlSi10Mg particles.

Figure 1.

The morphology of AlSi10Mg (a) and the particle size distribution of AlSi10Mg powder (b).

Table 1.

Chemical composition of AlSi10Mg powders (in wt.%).

Figure 2.

SEM images for nano-Si3N4/AlSi10Mg mixed powders with different Si3N4 contents: (a) 1 vol.%, (b) 3 vol.%, and (c) 5 vol.% Si3N4, and (d) enlarged view of (b).

Pure AlSi10Mg and nano-Si3N4/AlSi10Mg composites were produced by LPBF via SLM equipment (SLM-100C, Guangdong Hanbang 3d Tech Co., Ltd., Zhongshan, China). The substrate was sandblasted and preheated to 150 °C before LPBF. During the LPBF process, argon was continuously filled in the chamber to ensure that the oxygen content was less than 50 ppm. Various combinations of laser powers (180–300 W), scanning speeds (300–800 mm/s), hatching spaces (0.03–0.07 mm), and layer thicknesses (0.03 mm) were explored to obtain the optimal LPBF parameters in order to fabricate samples with the highest possible relative density. The chess scanning strategy was used to fabricate block samples (6 mm × 6 mm × 5 mm) and tensile bars.

The relative densities of LPBF specimens were measured using the Archimedes methods (in accordance with ASTM B962), and 4 samples were measured at a time. The microstructure was observed and analyzed by a scanning electron microscope (SEM, Gemini500). In metallographic preparation, the polished surface was etched with Keller’s reagent (95% deionized water + 1.5% hydrochloric acid + 2.5% nitric acid + 1% HF) for 10–30 s. LPBF specimens were characterized using X-ray diffraction (XRD, Bruker, D8 ADVANCE A2) with a scanning range of 20–80°. Heat treatment at 180, 230, and 280 °C annealing temperatures was applied to the LPBFed specimens, respectively. The samples were heated in the furnace for 1 h and then kept in the corresponding annealing temperature for 6 h, followed by air cooling. The micro-Vickers hardness was tested using a microhardness tester (Taiming, HXD-1000TMC/LCD) with a load of 200 g and a dwell time of 20 s. The tensile properties were evaluated using a universal testing machine (Letry, PLD-5) with a displacement speed of 0.5 mm/min.

3. Results and Discussion

3.1. Densification Behavior

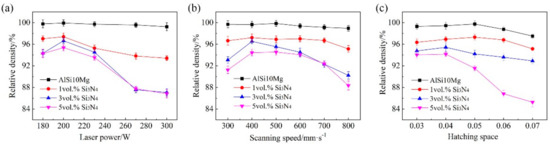

Figure 3 shows the relative density of nano-Si3N4/AlSi10Mg composites as the function of laser power (at laser scanning speed 500 mm/s and hatching space 0.05 mm), laser scanning speed (at laser power 200 W and hatching space 0.05 mm), and hatching space (at laser power 200 W and laser scanning speed 500 mm/s). It can be seen that as the content of Si3N4 nanoparticles increases, the relative density of the samples decreases and the optimum process parameter window shrinks greatly. Due to the strong agglomeration tendency caused by their high specific surface area, the nanoparticles may lead to an increase in the composite porosity. With the increase in the nanoparticle content, the fluidity of the powders becomes worse, which leads to more gas trapping between nanoparticles.

Figure 3.

Influence of process parameters on the sample’s relative density: (a) laser power, (b) scanning speed, and (c) hatching space.

For all the nano-Si3N4/AlSi10Mg composites with different nano-Si3N4 contents, laser power, laser scanning speed, as well as hatching space have optimum ranges corresponding to the peak relative density. Although the energy input during LPBF can be monotonically controlled by laser power, laser scanning speed, hatching space, and layer thickness, the relative density of the nano-Si3N4/AlSi10Mg composites does not simply increase or decrease with these LPBF parameters. If the laser power is too low, porosity and incomplete melting will lead to a low relative density. If the laser power is too high, keyhole, spheroidization, crack, and other defects can also result in a low relative density. Other LPBF parameters have a similar effect on relative density. Based on the LPBF parameter evaluation in this study, the optimum LPBF parameters of each nano-Si3N4/AlSi10Mg composite are shown in Table 2.

Table 2.

The optimum LPBF parameters for the maximum relative densities of AlSi10Mg and nano-Si3N4/AlSi10Mg composites.

3.2. Microstructure

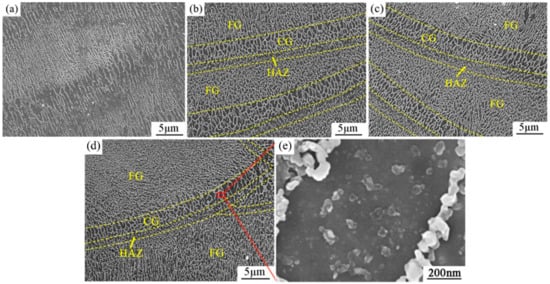

As shown in Figure 4, the microstructure of LPBFed nano-Si3N4/AlSi10Mg composites is mainly divided into three regions: (1) the inner part of the molten pool, which is a fine-cell-structure area with an average cell size of about 1 μm, (2) the boundary of the molten pool, which is a coarse-cell zone, and (3) the heat-affected zone. With the increase in the Si3N4 content, the cell structure becomes smaller. At the same time, the widths of its coarse-cell zone and heat-affected zone also decrease. Figure 4e shows that complete, undecomposed, Si3N4 particles still exist in the composite sample. From a theoretical point of view, the addition of Si3N4 particles affects the energy fluctuation and heat transfer in the molten pool and it also changes the heat transfer in the solidified region to a certain extent. Thus, it reduces the widths of the coarse-cell zone and the heat-affected zone. Furthermore, as Si3N4 particles are dispersed in the molten pool, the solid–liquid interface encounters and engulfs them during solidification at the boundary of the molten pool (see Figure 4e). Si3N4 particles hinder the movement of solid–liquid interface and eventually refine the cell structure. With the increase in the Si3N4 content, the distance between particles further decreases and the influence of refinement also increases.

Figure 4.

SEM images of nano-Si3N4/AlSi10Mg composites with different Si3N4 contents: (a) Pure AlSi10Mg, (b) 1 vol.% Si3N4, (c) 3 vol.% Si3N4, (d) 5 vol.% Si3N4, and (e) microstructure inside a single cell.

3.3. Mechanical Properties

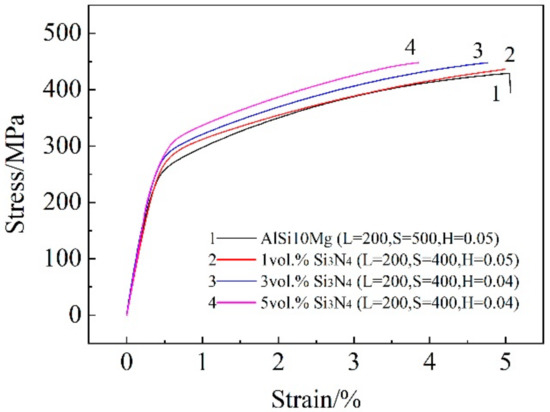

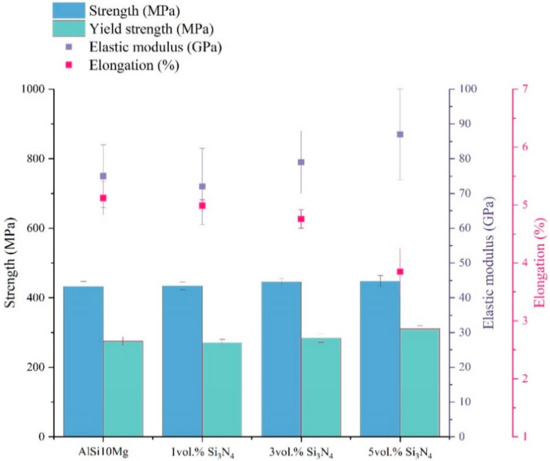

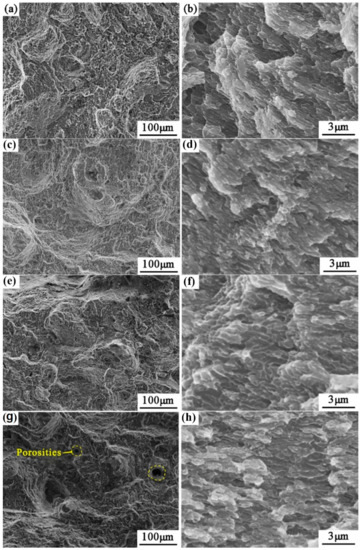

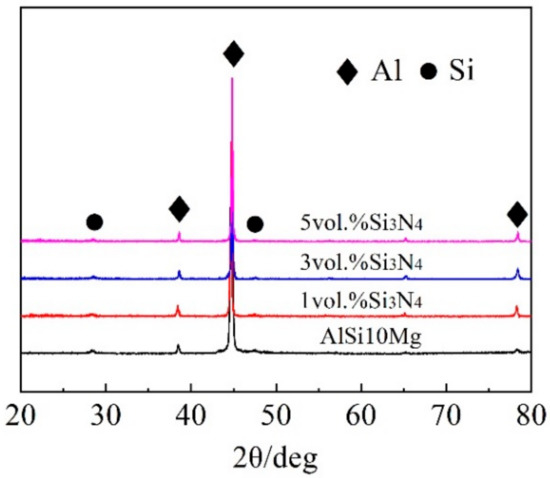

The tensile stress–strain curves of AlSi10Mg and nano-Si3N4/AlSi10Mg composites are shown in Figure 5, and the tensile test results are shown in Figure 6. The alloys tested in Figure 5 and Figure 6 were prepared using the optimized process parameters in Table 2. For example, a 1 vol.% Si3N4 sample was manufactured under the conditions of laser power = 200 W, scanning speed = 400 mm·s−1, and hatching speed = 0.05 mm. As compared with pure AlSi10Mg, 1 vol.% Si3N4 does not result in noticeable change in elastic modulus and elongation. When the Si3N4 content is increased to 3 vol.%, the strength and elastic modulus increase slightly, while the elongation decreases slightly. Compared with the test results of the nano-Si3N4/AlSi10Mg composite with 3 vol.% Si3N4, the strength and elastic modulus of the 5 vol.% Si3N4 composites increased steadily, but the relative elongation decreased. In Figure 7, we used the same batch of powder as the previous experiment. This figure shows the tensile fractograph of the composite samples. The fractographs of the composites with different Si3N4 contents are similar to that of AlSi10Mg. In addition, there are a few small tearing edges and cleavage steps, which are typical features of ductile and brittle fracture, respectively. Figure 8 shows the XRD patterns of AlSi10Mg and nano-Si3N4/AlSi10Mg samples. Because the Si3N4 content is low, the diffraction peak of the Si3N4 phase is not detected in XRD patterns. The peak intensity and angle of Al and Si phase diffraction peaks are not influenced by Si3N4 particles.

Figure 5.

Tensile stress–strain curves of pure AlSi10Mg and nano-Si3N4/AlSi10Mg composites (L represents the laser power/W, S is the scanning speed/(mm·s−1), and H is the hatching space/mm).

Figure 6.

Mechanical properties of AlSi10Mg and nano-Si3N4/AlSi10Mg composites.

Figure 7.

Tensile fractograph of pure AlSi10Mg and nano-Si3N4/AlSi10Mg composites with different Si3N4 contents, (a,b) pure AlSi10Mg, (c,d) 1 vol.% Si3N4, (e,f) 3 vol.% Si3N4, and (g,h) 5 vol.% Si3N4.

Figure 8.

XRD diffraction patterns of AlSi10Mg and nano-Si3N4/AlSi10Mg composites.

As for the composite’s strengthening mechanism, the second phase strengthening and the fine grain strengthening are included. On the one hand, the hard/brittle Si3N4 phase uniformly dispersed in the matrix and blocked dislocation movement during deformation, increasing strength and reducing elongation. That is to say, the second-phase strengthening was the main strengthening factor. Moreover, with the increase in the Si3N4 content, the more obvious the increase in strength, the more obvious the decrease in elongation. On the other hand, as shown in Figure 4, the grain size decreased to a certain extent after the addition of Si3N4 and fine grain strengthening could also improve the strength of the material. In addition, the porosities of different alloys were tested (Table 3), which indicated that the high Si3N4 content corresponds to the high porosity. The defects caused the alloy mechanical properties to deteriorate. Considering all the above factors, the strength of the alloy did not increase significantly. Therefore, the nano-Si3N4/AlSi10Mg composite with a 5 vol.% Si3N4 content shows the highest tensile strength and yield strength.

Table 3.

The relative density of Si3N4/AlSi10Mg samples.

3.4. Heating Treatment

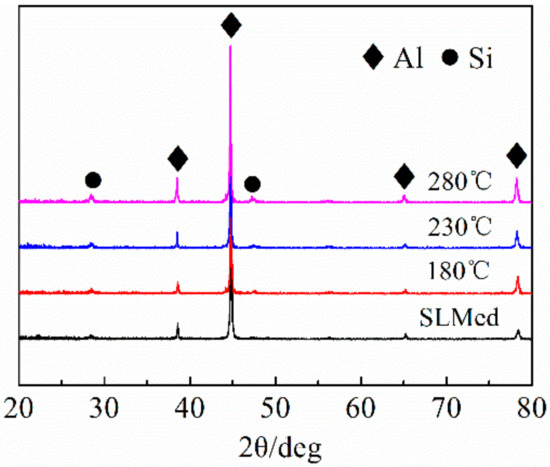

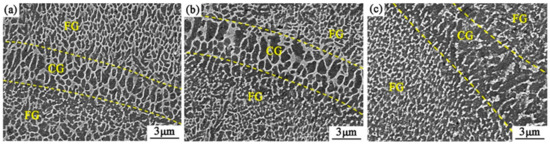

The 3 vol.% nano-Si3N4/AlSi10Mg composite was used for heat treatment tests because it had a high relative density (>97%) and better mechanical properties compared with the other nano-Si3N4/AlSi10Mg composites. Figure 9 demonstrates the XRD patterns of 3 vol.% nano-Si3N4/AlSi10Mg composite samples upon heat treatment under different annealing temperatures. The microstructure of a 3 vol.% nano-Si3N4/AlSi10Mg composite after annealing is shown in Figure 10. Annealing at 180 or 230 °C does not change the microstructure noticeably, while annealing at 280 °C seriously decomposes the eutectic structure and spheroidizes the Si phase because of the significant diffusion of the Si phase. When the annealing temperature is low, the diffusion ability of Si is not strong enough to change the eutectic structure. In fact, the meshed eutectic structure distributed along the cell boundary is not uniform and the eutectic Si phase at these locations is more likely to diffuse at a higher annealing temperature, resulting in the decomposition of the eutectic structure. In addition, Si in the solid solution begins to precipitate during annealing, contributing to the Si phase aggregation and granulation.

Figure 9.

XRD patterns of nano-Si3N4/ AlSi10Mg composites after annealing.

Figure 10.

The microstructure of a 3 vol.% nano-Si3N4/AlSi10Mg composite after annealing at (a) 180 °C, (b) 230 °C, and (c) 280 °C.

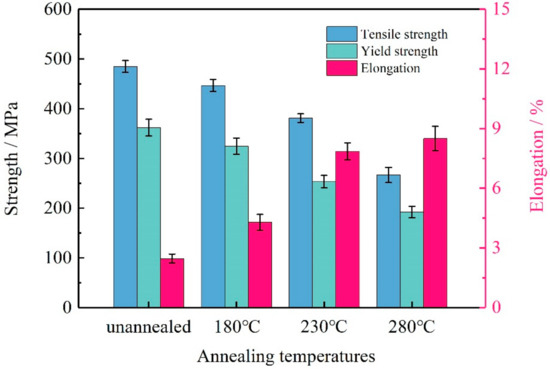

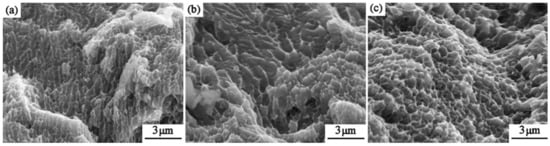

Figure 11 shows the tensile test results of an LPBFed 3 vol.% nano-Si3N4/AlSi10Mg composite at different annealing temperatures. To ensure the reliability of the data, twelve 3 vol.% Si3N4/AlSi10Mg samples were divided into four groups. One group was taken as the control group, and the rest were heat-treated at different temperatures. As the relevant changes in the mechanical properties of the sample could be clearly seen from the original experimental data, Figure 11 was drawn to show these changes: with the increase in the annealing temperature, the strength of the samples decreases while the elongation increases. The tensile fractograph is shown in Figure 12. We can see that, as the annealing temperature increases, the size and depth of the dimple increase, indicating the ductility of the composite increases. At the same time, the microhardness after annealing decreases slightly. The microhardness values of the composite after annealing at 180, 230, and 280 °C are 130 ± 1 HV, 113 ± 2 HV, and 108 ± 2 HV, respectively.

Figure 11.

Effect of annealing temperature on tensile properties of a 3 vol.% nano-Si3N4/AlSi10Mg composite.

Figure 12.

The tensile fractograph of a 3 vol.% nano-Si3N4/AlSi10Mg composite after annealing at (a) 180 °C, (b) 230 °C, and (c) 280 °C.

4. Conclusions

In this study, laser powder bed fusion (LPBF) was used to fabricate nano-Si3N4/AlSi10Mg composites with different Si3N4 contents. Firstly, the LPBF process parameters were optimized to achieve a higher density. Then, the effects of nano-Si3N4 content and heat treatment on the microstructure and mechanical properties of LPBFed composites were investigated. The main conclusions can be summarized as follows:

- (1)

- The relative density of nano-Si3N4/AlSi10Mg composites decreases with the increase in the Si3N4 content. LPBF parameters have been optimized to achieve a high relative density (above 97%) for 1–3 vol.% nano-Si3N4/AlSi10Mg composites.

- (2)

- Nano-Si3N4 particles noticeably refine the microstructure of nano-Si3N4/AlSi10Mg composites and improve the tensile strength as per the Orowan strengthening mechanism. The tensile strength, yield strength, and elongation of 5 vol.% nano-Si3N4/AlSi10Mg reach 448 ± 10 MPa, 311 ± 12 MPa, and 3.85 ± 0.16%, respectively.

- (3)

- After annealing, the strength of the 3 vol.% nano-Si3N4/AlSi10Mg composite decreases while the elongation greatly increases. Furthermore, annealing decreases the microhardness of the 3 vol.% nano-Si3N4/AlSi10Mg composite and a higher annealing temperature results in lower microhardness.

Author Contributions

Conceptualization, Z.L. and Y.H.; methodology, Z.L. and Y.H.; software, F.C. and H.Z.; validation, Z.L., Y.H. and Y.G.; formal analysis, Y.G.; investigation, F.C.; resources, Z.L., X.D. and K.M.; data curation, H.Z.; writing—original draft preparation, Z.L., Y.H. and Y.G.; writing—review and editing, Y.H., F.C. and H.Z.; supervision, D.L.; project administration, Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Science and Technology Projects of Guangdong Province, China (Grant No. 2017B090911006) and China Postdoctoral Science Foundation (Grant No. 2019M663684).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. Zhongliang Lu is a professor at Xi’an Jiaotong University. His research focus is additive manufacturing of metals and ceramics.

References

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powders. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Schanz, J.; Hofele, M.; Ruck, S.; Schubert, T.; Hitzler, L.; Schneider, G.; Merkel, M.; Riegel, H. Metallurgical investigations of laser remelted additively manufactured AlSi10Mg parts: Metallurgische Untersuchungen von laserstrahlumgeschmolzenen additiv hergestellten AlSi10Mg Bauteilen. Mater. Und Werkst. 2017, 48, 463–476. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the selective laser melting (SLM) of the AlSi10Mg alloy: Process, microstructure, and mechanical properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Emelogu, A.; Marufuzzaman, M.; Thompson, S.M.; Shamsaei, N.; Bian, L. Additive manufacturing of biomedical implants: A feasibility assessment via supply-chain cost analysis. Addit. Manuf. 2016, 11, 97–113. [Google Scholar] [CrossRef]

- Riza, S.H.; Masood, S.H.; Rashid, R.; Chandra, S. Selective laser sintering in biomedical manufacturing. Met. Biomater. Process. Med. Device Manuf. 2020, 1, 193–233. [Google Scholar]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.; Vleugels, J.; Van Humbeeck, J.; Kruth, J.-P. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, precipitates and hardness of selectively laser melted AlSi10Mg alloy before and after heat treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Qi, Y.; Hu, Z.; Zhang, H.; Nie, X.; Zhang, C.; Zhu, H. High strength Al–Li alloy development for laser powders bed fusion. Addit. Manuf. 2021, 47, 102249. [Google Scholar] [CrossRef]

- Ashkenazi, D.; Inberg, A.; Shacham-Diamand, Y.; Stern, A. Gold, Silver, and Electrum Electroless Plating on Additively Manufactured Laser Powder-Bed Fusion AlSi10Mg Parts: A Review. Coatings 2021, 11, 422–450. [Google Scholar] [CrossRef]

- Schneller, W.; Leitner, M.; Springer, S.; Grün, F.; Taschauer, M. Effect of HIP treatment on microstructure and fatigue strength of selectively laser melted AlSi10Mg. J. Manuf. Mater. Process. 2019, 3, 16. [Google Scholar] [CrossRef] [Green Version]

- Tradowsky, U.; White, J.; Ward, R.; Read, N.; Reimers, W.; Attallah, M. Selective laser melting of AlSi10Mg: Influence of post-processing on the microstructural and tensile properties development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Wang, X.; Wang, W.; Attallah, M.; Loretto, M. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Li, B.-Q.; Li, Z. Selective laser remelting of an additive layer manufacturing process on AlSi10Mg. Results Phys. 2019, 12, 982–988. [Google Scholar] [CrossRef]

- Wang, L.-Z.; Wang, S.; Wu, J.-J. Experimental investigation on densification behavior and surface roughness of AlSi10Mg powders produced by selective laser melting. Opt. Laser Technol. 2017, 96, 88–96. [Google Scholar] [CrossRef]

- Van Cauwenbergh, P.; Samaee, V.; Thijs, L.; Nejezchlebová, J.; Sedlák, P.; Iveković, A.; Schryvers, D.; Van Hooreweder, B.; Vanmeensel, K. Unravelling the multi-scale structure–property relationship of laser powder bed fusion processed and heat-treated AlSi10Mg. Sci. Rep. 2021, 11, 6423–6438. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Ning, F.; Zhang, P.; Sharma, A. Geometrical, microstructural, and mechanical properties of curved-surface AlSi10Mg parts fabricated by powder bed fusion additive manufacturing. Mater. Des. 2021, 198, 109360–109373. [Google Scholar] [CrossRef]

- Dai, D.; Gu, D. Influence of thermodynamics within molten pool on migration and distribution state of reinforcement during selective laser melting of AlN/AlSi10Mg composites. Int. J. Mach. Tools Manuf. 2016, 100, 14–24. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Mertens, R.; Hao, L.; Van Humbeeck, J.; Kruth, J.P. Selective laser melting to manufacture “in situ” metal matrix composites: A review. Adv. Eng. Mater. 2019, 21, 1801244. [Google Scholar] [CrossRef] [Green Version]

- Gu, D.; Wang, H.; Dai, D.; Yuan, P.; Meiners, W.; Poprawe, R. Rapid fabrication of Al-based bulk-form nanocomposites with novel reinforcement and enhanced performance by selective laser melting. Scr. Mater. 2015, 96, 25–28. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, J. Effect of hot isostatic pressing on nanoparticles reinforced AlSi10Mg produced by selective laser melting. Mater. Sci. Eng. A 2020, 788, 139570. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, T.; Zhang, C.; Zhang, K.; Li, M.; Ma, T.; Liao, W. Preparation and mechanical properties of CNTs-AlSi10Mg composite fabricated via selective laser melting. Mater. Sci. Eng. A 2018, 734, 171–177. [Google Scholar] [CrossRef]

- Gao, C.; Wang, Z.; Xiao, Z.; You, D.; Wong, K.; Akbarzadeh, A. Selective laser melting of TiN nanoparticle-reinforced AlSi10Mg composite: Microstructural, interfacial, and mechanical properties. J. Mater. Process. Technol. 2020, 281, 116618. [Google Scholar] [CrossRef]

- Chang, F.; Gu, D.; Dai, D.; Yuan, P. Selective laser melting of in-situ Al4SiC4+ SiC hybrid reinforced Al matrix composites: Influence of starting SiC particle size. Surf. Coat. Technol. 2015, 272, 15–24. [Google Scholar] [CrossRef]

- Tan, Q.; Zhang, J.; Mo, N.; Fan, Z.; Yin, Y.; Bermingham, M.; Liu, Y.; Huang, H.; Zhang, M.-X. A novel method to 3D-print fine-grained AlSi10Mg alloy with isotropic properties via inoculation with LaB6 nanoparticles. Addit. Manuf. 2020, 32, 101034. [Google Scholar] [CrossRef]

- Mattli, M.R.; Matli, P.R.; Shakoor, A.; Amer Mohamed, A.M. Structural and mechanical properties of amorphous Si3N4 nanoparticles reinforced Al matrix composites prepared by microwave sintering. Ceramics 2019, 2, 126–134. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Yao, D.; Yin, J.; Zuo, K.; Xia, Y.; Liang, H.; Zeng, Y.-P. Effects of β-Si3N4 whiskers addition on mechanical properties and tribological behaviors of Al matrix composites. Wear 2019, 430, 145–156. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).