Applicability Evaluation of Nano-Al2O3 Modified Sn-Ag-Cu Solder in High-Density Electronic Packaging Subjected to Thermal Cycling

Abstract

:1. Introduction

2. Experimental Methods

3. Results and Discussion

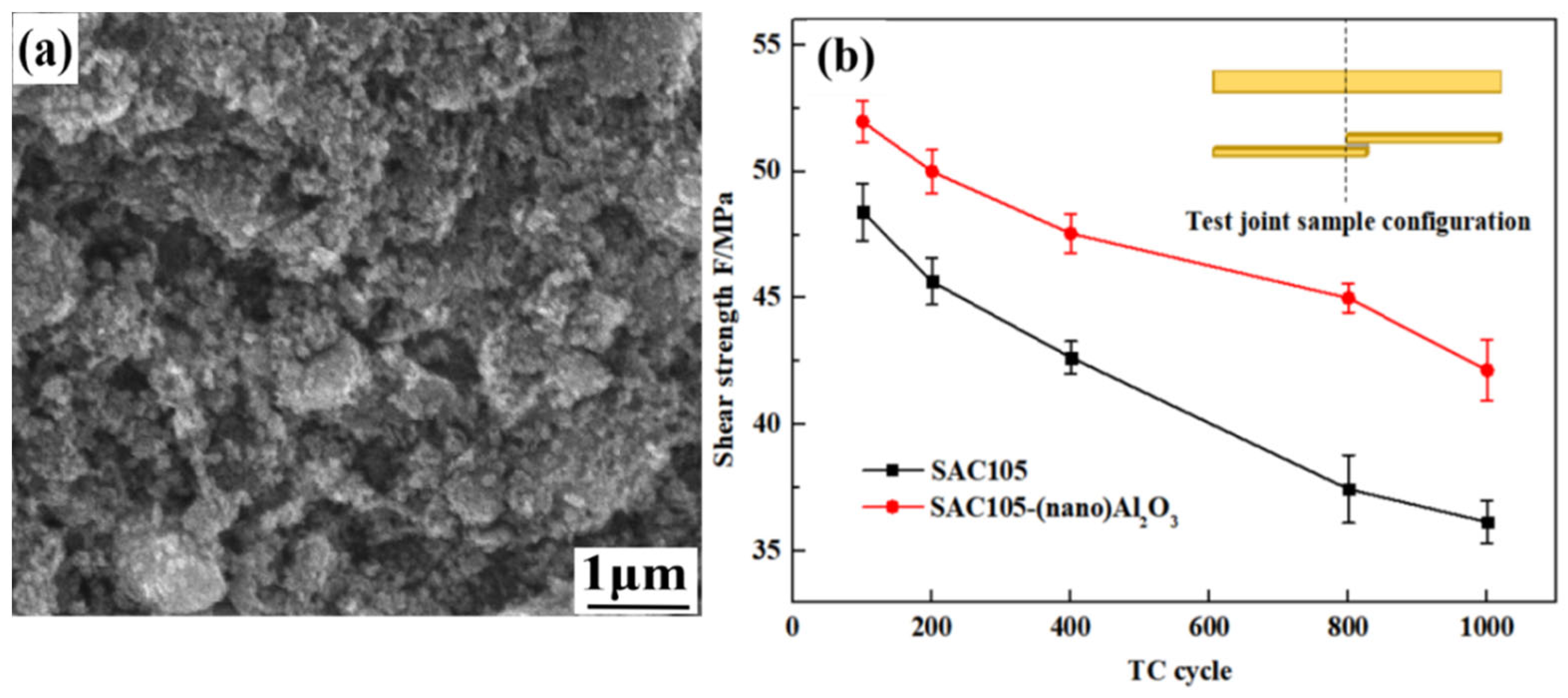

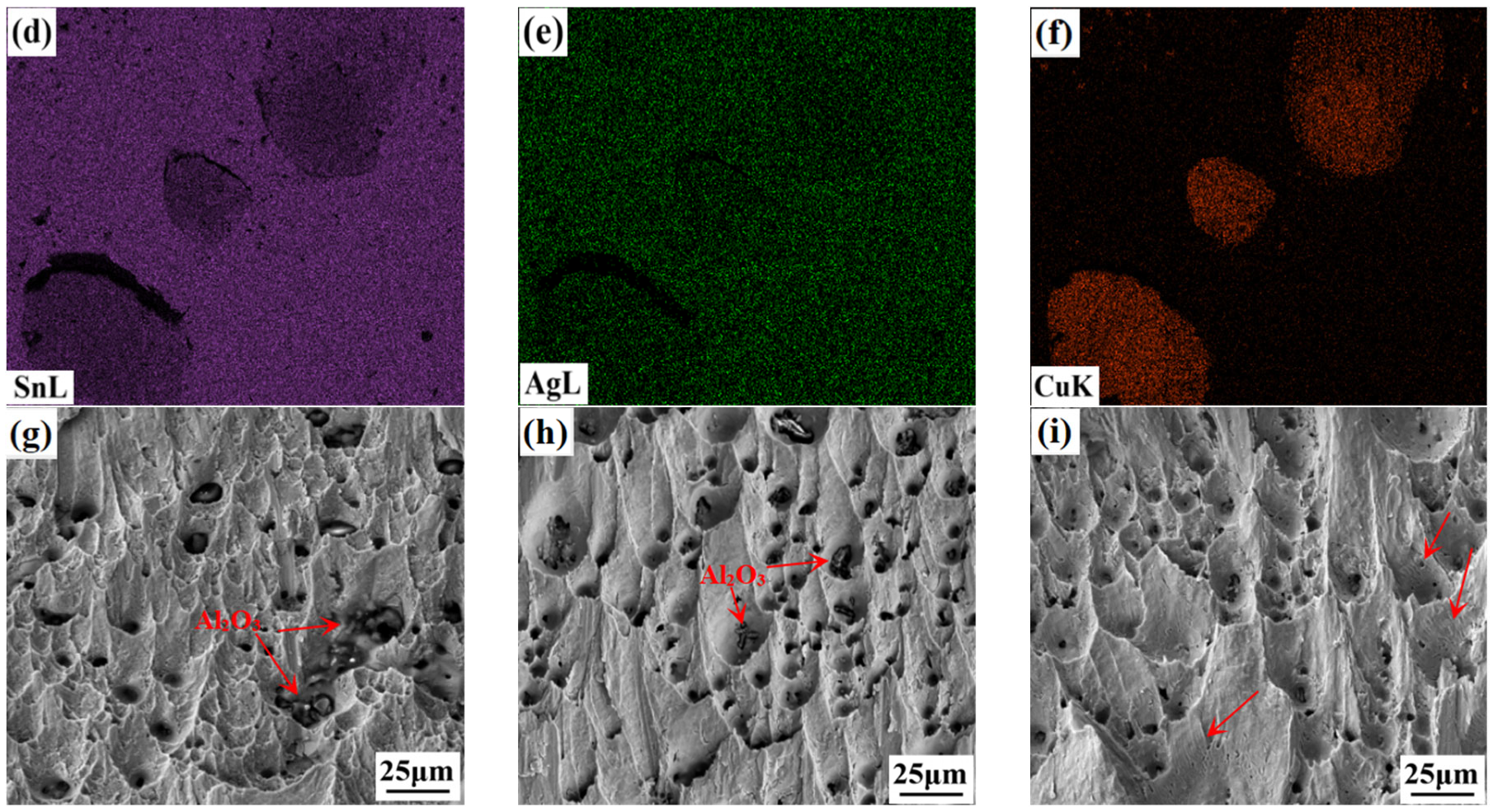

3.1. Shear Force and Fracture Morphology

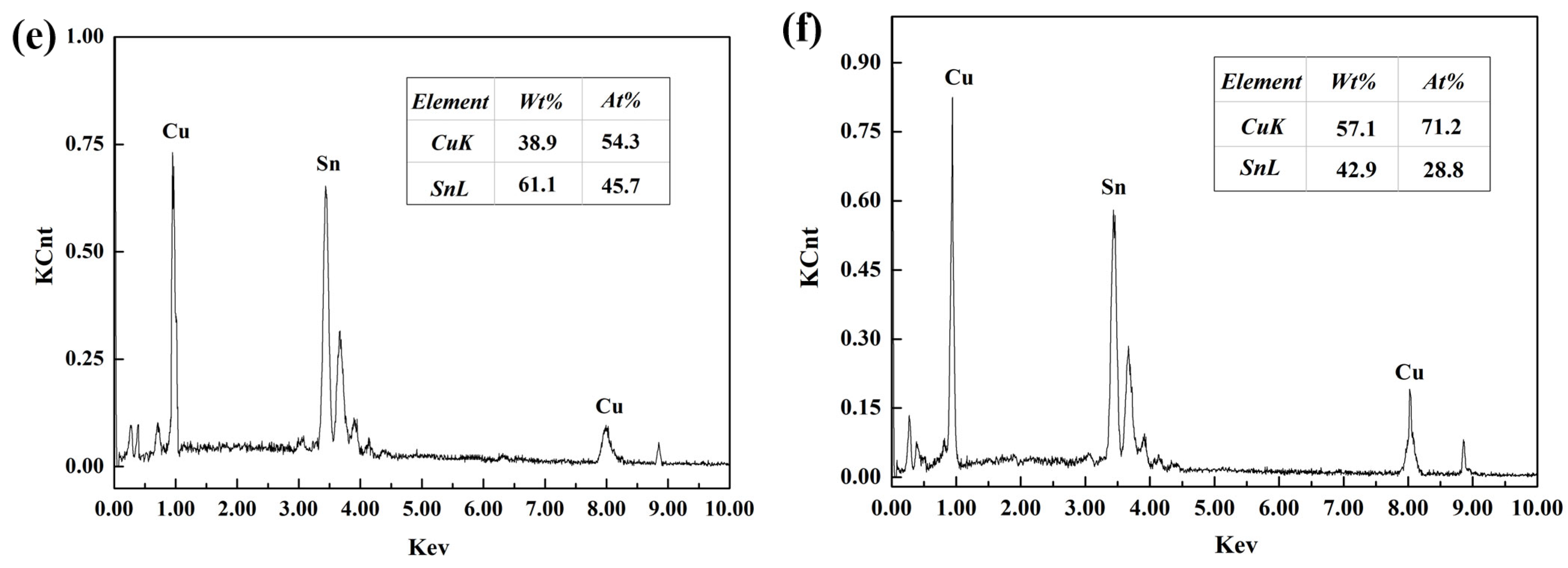

3.2. Interfacial Microstructure

3.3. Interfacial IMC Growth Kinetics

3.4. Application in High-Density Electronic Packaging

4. Conclusions

- 1.

- With nano-Al2O3 particles doped, the TC reliability of SAC105 low-Ag solder joint was enhanced, manifesting as a slower degradation in joint mechanical strength when compared to the non-modified joint. Corresponding fracture morphology also showed that SAC105-(nano)Al2O3/Cu always presented a typical ductile fracture with micro-void accumulation fracture mode.

- 2.

- The enhanced TC reliability is mainly attributed to the insoluble Al2O3 NPs absorbing on the grain surface, inhibiting the microstructure coarsening. In addition, some nano-scaled Ag3Sn particles also tended to form at the phase boundary, and contributing to decreasing the IMC coarsening rate in bulk solder.

- 3.

- Doping of nano-Al2O3 exerted a pinning effect on the interfacial IMCs due to their absorption on grain surfaces of interfacial IMCs. Thus, the flux of Cu dissolution from Cu substrate via GB channels was decreased, representing a suppressed growth of interfacial IMCs. Theoretical calculation also demonstrated a decrease in the average growth coefficients of interfacial IMCs, from 8.4 × 10−11 cm2/h to 6.5 × 10−11 cm2/h.

- 4.

- From the FEM simulation results of applying nano-Al2O3 modified solder in high-density packaging, it was clear that the induced stress and strain with TC treatment can be decreased. However, as the TC number increased, the induced stress and strain slightly increased, which was still not much more severe than that of the non-modified one.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, R.; Li, Y.C.; Cai, J.M.; Cao, K.; Lee, H.B.R. Atomic level deposition to extend Moore’s law and beyond. Int. J. Extrem. Manuf. 2020, 2, 022002. [Google Scholar] [CrossRef]

- Lu, N.; Yang, D.; Li, L. Interfacial reaction between Sn–Ag–Cu solder and Co–P films with various microstructures. Acta Mater. 2013, 61, 4581–4590. [Google Scholar] [CrossRef]

- Ajayan, J.; Nirmal, D.; Tayal, S.; Bhattacharya, S.; Arivazhagan, L.; Fletcher, A.A.; Murugapandiyan, P.; Ajitha, D. Nanosheet field effect transistors—A next generation device to keep Moore’s law alive: An intensive study. Microelectron. J. 2021, 114, 105141. [Google Scholar] [CrossRef]

- Hao, Y.; Wu, H.; Yang, Y.; Liu, Q.; Gong, X.; Han, G.; Li, M. Preface to the Special Issue on Beyond Moore: Three-Dimensional (3D) Heterogeneous Integration. J. Semicond. 2021, 42, 020101. [Google Scholar] [CrossRef]

- Chou, T.-T.; Song, R.-W.; Chen, H.; Duh, J.-G. Low thermal budget bonding for 3D-package by collapse-free hybrid solder. Mater. Chem. Phys. 2019, 238, 121887. [Google Scholar] [CrossRef]

- Spurney, R.G.; Sharma, H.; Raj, P.M.; Tummala, R.; Lollis, N.; Weaver, M.; Romig, M.; Gandhi, S.; Brumm, H. 3-D Packaging and Integration of High-Density Tantalum Capacitors on Silicon. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 1466–1472. [Google Scholar] [CrossRef]

- Lu, M.C. Advancement of Chip Stacking Architectures and Interconnect Technologies for Image Sensors. J. Electron. Packag. 2022, 144, 020801. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y.; Li, J.; Qiao, Y.; Ma, Q.; Shan, S.; Zhang, H.; Tang, X. Failure Analysis Technology for High Density Packaging and Its Application. Semicond. Technol. 2018, 43, 310–315. [Google Scholar]

- Liu, M.; Nie, J.; Liu, Y.; Sun, J.; Li, M.; Yan, C.; Yan, Q. Research on the reliability of Micro LED high-density solder joints under thermal cycling conditions. J. Phys. Conf. Ser. 2022, 2221, 012010. [Google Scholar] [CrossRef]

- Zhang, L.; Tu, K.N. Structure and properties of lead-free solders bearing micro and naXno particles. Mater. Sci. Eng. R 2014, 82, 1–32. [Google Scholar] [CrossRef]

- Li, M.L.; Gao, L.L.; Zhang, L.; Long, W.M.; Zhong, S.J.; Zhang, L. Interfacial evolution of pure Sn solder bearing silicon carbide nanowires under isothermal aging and thermal cycling. J. Mater. Res. Technol. 2021, 15, 3974–3982. [Google Scholar] [CrossRef]

- Gu, T.H.; Xu, Y.L.; Gourlay, C.M.; Britton, T.B. In-situ electron backscatter diffraction of thermal cycling in a single grain Cu/Sn-3Ag-0.5Cu/Cu solder joint. Scr. Mater. 2020, 175, 55–60. [Google Scholar] [CrossRef]

- Wang, J.H.; Xue, S.B.; Liu, L.; Zhang, P.; Nishikawa, H. Three-dimensional interface and property of SnPb solder joint under extreme thermal shocking. Sci. Technol. Weld. Join. 2022, 27, 186–196. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, L.; Zhong, S.J.; Ma, J.; Bao, L. Reliability Studies of Sn-3.0Ag-0.5Cu Solder Joints. Electron. Process Technol. 2015, 36, 187. [Google Scholar]

- Zhang, S.; Duan, R.; Xu, S.; Xue, P.; Wang, C.; Chen, J.; Paik, K.W.; He, P. Shear performance and accelerated reliability of solder interconnects for fan-out wafer-level package. J. Adv. Join Process. 2022, 5, 100076. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, X.C.; Liu, Y.; Wang, Y.; Li, D.M. Microstructure, wetting property of Sn–Ag–Cu–Bi–xCe solder and IMC growth at solder/Cu interface during thermal cycling. Rare Met. 2021, 40, 714–719. [Google Scholar] [CrossRef]

- Tikale, S.; Prabhu, K.N. Development of low-silver content SAC0307 solder alloy with Al2O3 nanoparticles. Mater. Sci. Eng. A 2020, 787, 139439. [Google Scholar] [CrossRef]

- Liu, L.; Shi, L.; Peng, J.; Jiang, B.; Liu, S.; Liu, C.; Chen, Z. Interfacial reaction between Sn-Ag solder and electroless Ni-Fe-P diffusion barriers with different internal microstructure. Mater. Res. Bull. 2022, 152, 111854. [Google Scholar] [CrossRef]

- Muhamad, M.; Masri, M.N.; Nazeri, M.F.M.; Mohamad, A.A. The Effect of Bismuth Addition on Sn-Ag-Cu Lead-Free Solder Properties: A Short Review. IOP Conf. Ser. Earth Environ. Sci. 2020, 596, 012007. [Google Scholar] [CrossRef]

- El-Daly, A.; El-Hosainy, H.; Elmosalami, T.; Desoky, W. Microstructural modifications and properties of low-Ag-content Sn–Ag–Cu solder joints induced by Zn alloying. J. Alloys Compd. 2015, 653, 402–410. [Google Scholar] [CrossRef]

- Wu, J.; Xue, S.; Huang, G.; Sun, H.; Chi, F.; Yang, X.; Xu, Y. In-situ synergistic effect of Pr and Al2O3 nanoparticles on enhancing thermal cycling reliability of Sn-0.3 Ag-0.7 Cu/Cu solder joint. J. Alloys Compd. 2022, 905, 164152. [Google Scholar] [CrossRef]

- Shnawah, D.A.; Sabri, M.F.M.; Badruddin, I.A.; Said, S.B.M.; Bashir, M.B.A.; Sharif, N.M.; Elsheikh, M.H. Study on coarsening of Ag3Sn intermetallic compound in the Fe-modified Sn–1Ag–0.5Cu solder alloys. J. Alloys Compd. 2015, 622, 184–188. [Google Scholar] [CrossRef]

- Liu, P.; Gu, X.L.; Zhong, H.F.; Jin, X.; Zhe, J. New Brazing Material and vacuum brazing: Study on novel low-Ag solder SAC0307X. Electron. Compon. Mater. 2015, 34, 129–133. [Google Scholar]

- Yang, M.; Ji, H.; Wang, S.; Ko, Y.H.; Lee, C.W.; Wu, J.; Li, M. Effects of Ag content on the interfacial reactions between liquid Sn–Ag–Cu solders and Cu substrates during soldering. J. Alloys Compd. 2016, 679, 18–25. [Google Scholar] [CrossRef]

- Illés, B.; Choi, H.; Hurtony, T.; Skwarek, A.; Dusek, K.; Busek, D. Suppression of Sn whisker growth from SnAgCu solder alloy with TiO2 and ZnO reinforcement nano-particles by increasing the corrosion resistance of the composite alloy. J. Mater. Res. Technol. 2022, 20, 4231–4240. [Google Scholar] [CrossRef]

- Sayyadi, R.; Khodabakhshi, F.; Javid, N.S.; Khatibi, G. Influence of graphene content and nickel decoration on the microstructural and mechanical characteristics of the Cu/Sn–Ag–Cu/Cu soldered joint. J. Mater. Res. Technol. 2020, 9, 8953–8970. [Google Scholar] [CrossRef]

- Xu, L.; Wang, L.; Jing, H.; Liu, X.; Wei, J.; Han, Y. Effects of graphene nanosheets on interfacial reaction of Sn-Ag-Cu solder joints. J. Alloys Compd. 2015, 650, 475–481. [Google Scholar] [CrossRef]

- Skwarek, A.; Krammer, O.; Hurtony, T.; Ptak, P.; Górecki, K.; Wroński, S.; Straubinger, D.; Witek, K.; Illés, B. Application of ZnO nanoparticles in Sn99Ag0.3Cu0.7 based composite solder alloys. Nanomaterials 2021, 11, 1545. [Google Scholar] [CrossRef] [PubMed]

- Xing, W.Q.; Yu, X.Y.; Li, H.; Ma, L.; Zuo, W.; Dong, P.; Wang, W.X.; Ding, M. Effect of nano-Al2O3 additions on the interfacial behavior and mechanical properties of eutectic Sn-9Zn solder on low temperature wetting and soldering of 6061 aluminum alloys. J. Alloys Compd. 2016, 695, 574–582. [Google Scholar] [CrossRef]

- Tsao, L.C.; Wu, R.W.; Cheng, T.H.; Fan, K.H.; Chen, R.S. Effects of nano-Al2O3 particles on microstructure and mechanical properties of Sn3.5Ag0.5Cu composite solder ball grid array joints on Sn/Cu pads. Mater. Des. 2013, 50, 774–781. [Google Scholar] [CrossRef]

- Tikale, S.; Prabhu, K.N. Performance and reliability of Al2O3 nanoparticles doped multicomponent Sn-3.0Ag-0.5Cu-Ni-Ge solder alloy. Microelectron. Reliab. 2020, 113, 113933. [Google Scholar] [CrossRef]

- Zhang, Y.; Madenci, E.; Zhang, Q. ANSYS implementation of a coupled 3D peridynamic and finite element analysis for crack propagation under quasi-static loading. Eng. Fract. Mech. 2022, 260, 108179. [Google Scholar] [CrossRef]

- Bai, T.; Qiao, Y.; Wang, X.; Zhao, N. Finite element method modeling of temperature gradient-induced Cu atomic thermomigration in Cu/Sn/Cu micro solder joint. Microelectron. Reliab. 2022, 129, 114479. [Google Scholar] [CrossRef]

- Xie, M.W.; Chen, G.; Yu, J.T.; Wu, Y.; Liu, X.; Yang, J.; Xu, W.L. A dual-phase crystal plasticity finite-element method for modeling the uniaxial deformation behaviors of thermally aged SAC305 solder. Int. J. Plast. 2022, 155, 103342. [Google Scholar] [CrossRef]

- Qiao, Y.Y.; Ma, H.T.; Yu, F.Y.; Zhao, N. Quasi-in-situ observation on diffusion anisotropy dominated asymmetrical growth of Cu-Sn IMCs under temperature gradient. Acta Mater. 2021, 217, 117168. [Google Scholar] [CrossRef]

- Qiao, C.; Sun, X.; Wang, Y.Z.; Hao, L.; An, X.Z. A perspective on effect by Ag addition to corrosion evolution of Pb-free Sn solder. Mater. Lett. 2021, 297, 129935. [Google Scholar] [CrossRef]

- Tu, K.N.; Liu, Y. Recent advances on kinetic analysis of solder joint reactions in 3D IC packaging technology. Mater. Sci. Eng. R Rep. 2019, 136, 1–12. [Google Scholar] [CrossRef]

| Analysis Technique | Brand | Test Sample |

|---|---|---|

| Drying box | DZF-6050-220V-MS, Hefei Kejing Material Technology Co., Ltd., Hefei, China | Al2O3 NPs |

| Automatic solder paste mixer | ZB500S, Huaqi Zhengbang Co., Ltd., Zhejiang, China | Solder paste |

| Thermal shock test chamber | CJ61S2, Chongqing Yinhe Test Instrument Co., Ltd., Chongqing, China | lap-shaped joint sample |

| Tensile testing machine | WEW-100B, Jinan Liling Testing Machine Co., Ltd., Jinan, China | lap-shaped joint sample subjected with different TC cycles (100, 200, 400, 800, 1000) |

| FE-SEM | Tescan Mira3 | solder joint sample subjected with different TC cycle (100, 200, 400, 800, 1000) |

| EDS | Bruker, Billerica, MA, USA | solder joint sample subjected with different TC cycles (100, 200, 400, 800, 1000) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Huang, G.; Wu, Y.; Huang, X.; Yu, R.; Yang, X.; Chen, G.; Tan, C.; Yu, Z.; Sun, H.; et al. Applicability Evaluation of Nano-Al2O3 Modified Sn-Ag-Cu Solder in High-Density Electronic Packaging Subjected to Thermal Cycling. Crystals 2022, 12, 1736. https://doi.org/10.3390/cryst12121736

Wu J, Huang G, Wu Y, Huang X, Yu R, Yang X, Chen G, Tan C, Yu Z, Sun H, et al. Applicability Evaluation of Nano-Al2O3 Modified Sn-Ag-Cu Solder in High-Density Electronic Packaging Subjected to Thermal Cycling. Crystals. 2022; 12(12):1736. https://doi.org/10.3390/cryst12121736

Chicago/Turabian StyleWu, Jie, Guoqiang Huang, Yiping Wu, Xiwu Huang, Rui Yu, Xuqi Yang, Guangyao Chen, Cheelong Tan, Zhihao Yu, Huabin Sun, and et al. 2022. "Applicability Evaluation of Nano-Al2O3 Modified Sn-Ag-Cu Solder in High-Density Electronic Packaging Subjected to Thermal Cycling" Crystals 12, no. 12: 1736. https://doi.org/10.3390/cryst12121736

APA StyleWu, J., Huang, G., Wu, Y., Huang, X., Yu, R., Yang, X., Chen, G., Tan, C., Yu, Z., Sun, H., & Xu, Y. (2022). Applicability Evaluation of Nano-Al2O3 Modified Sn-Ag-Cu Solder in High-Density Electronic Packaging Subjected to Thermal Cycling. Crystals, 12(12), 1736. https://doi.org/10.3390/cryst12121736