Effects of Annealing on the Microstructure and Wear Resistance of Laser Cladding CrFeMoNbTiW High-Entropy Alloy Coating

Abstract

:1. Introduction

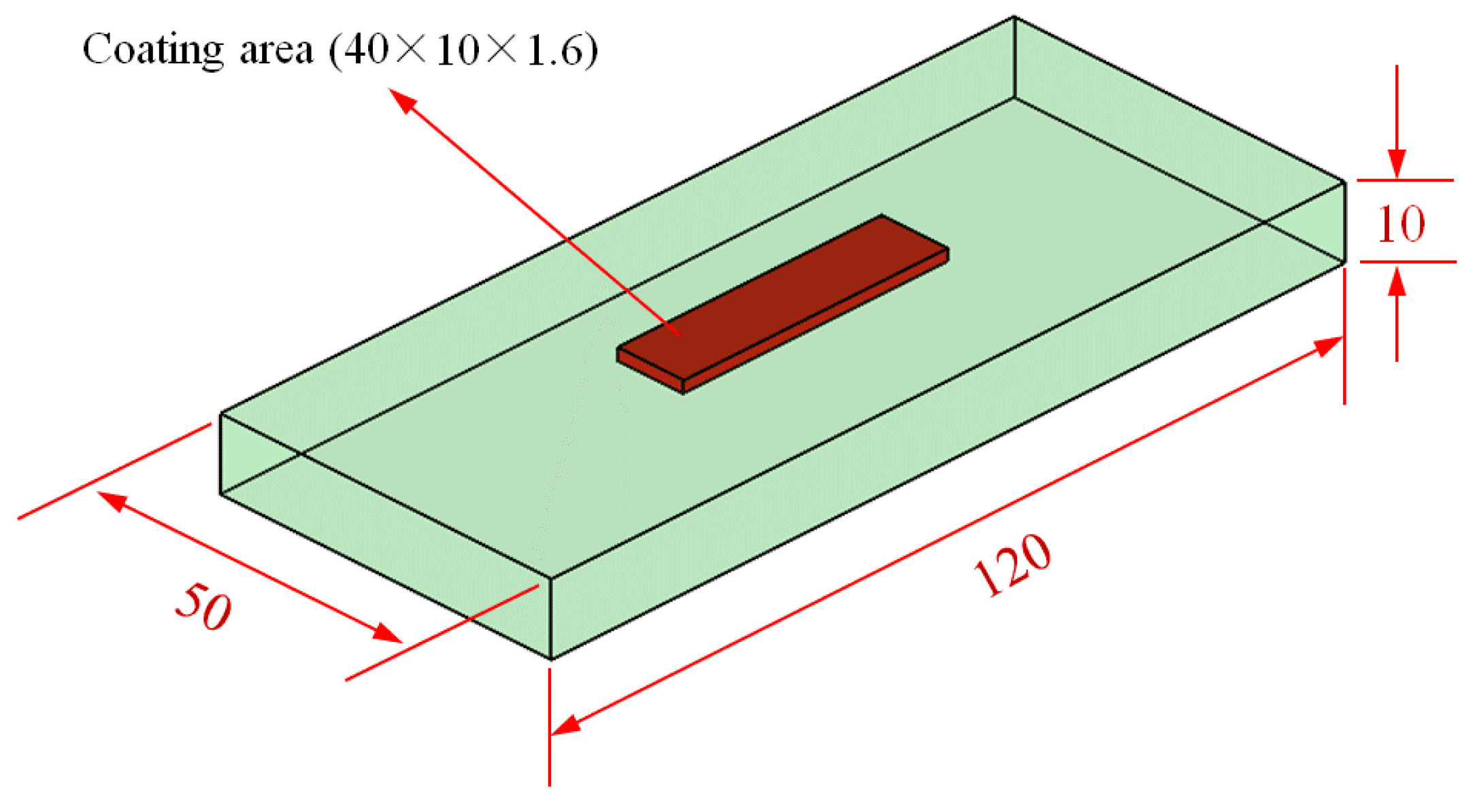

2. Materials and Methods

3. Results and Discussion

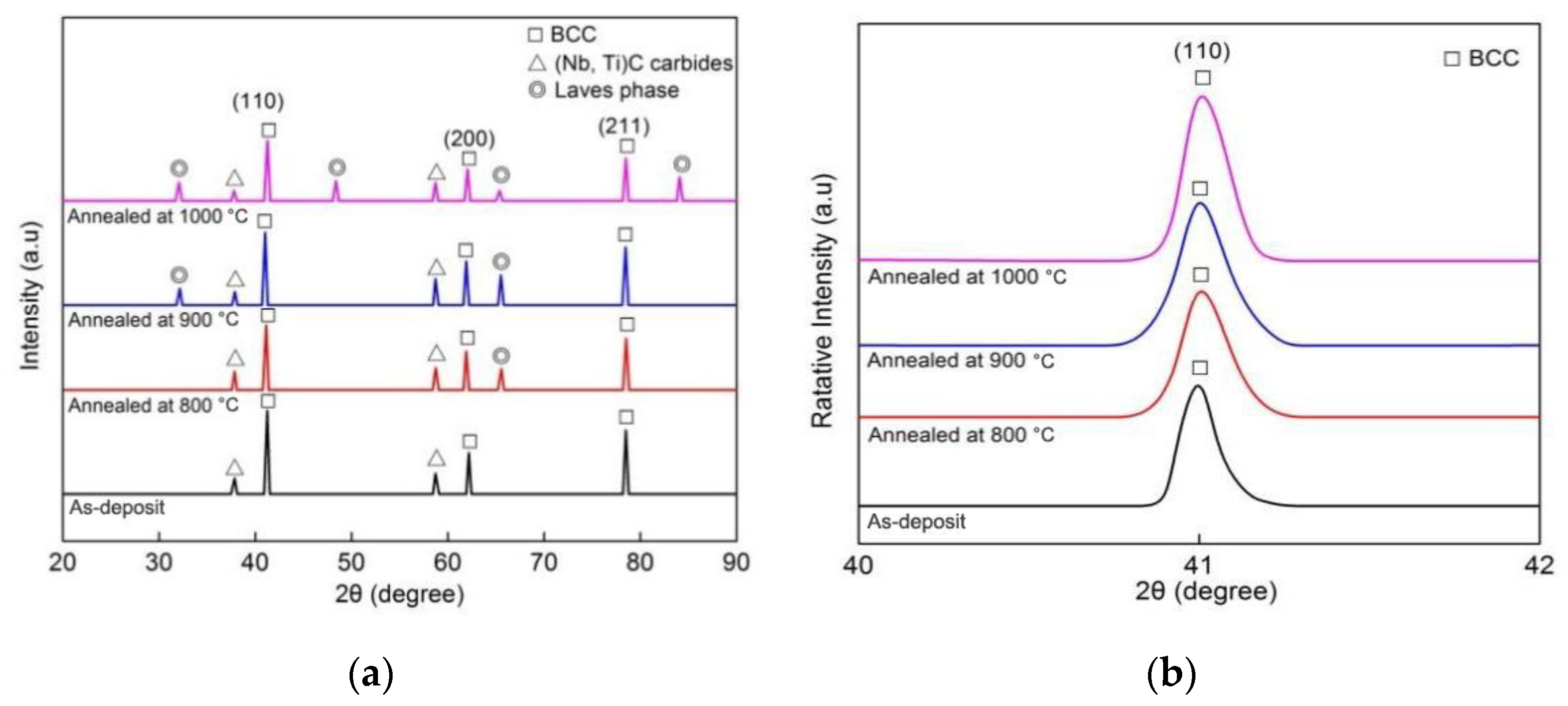

3.1. Crystal Structure Observation

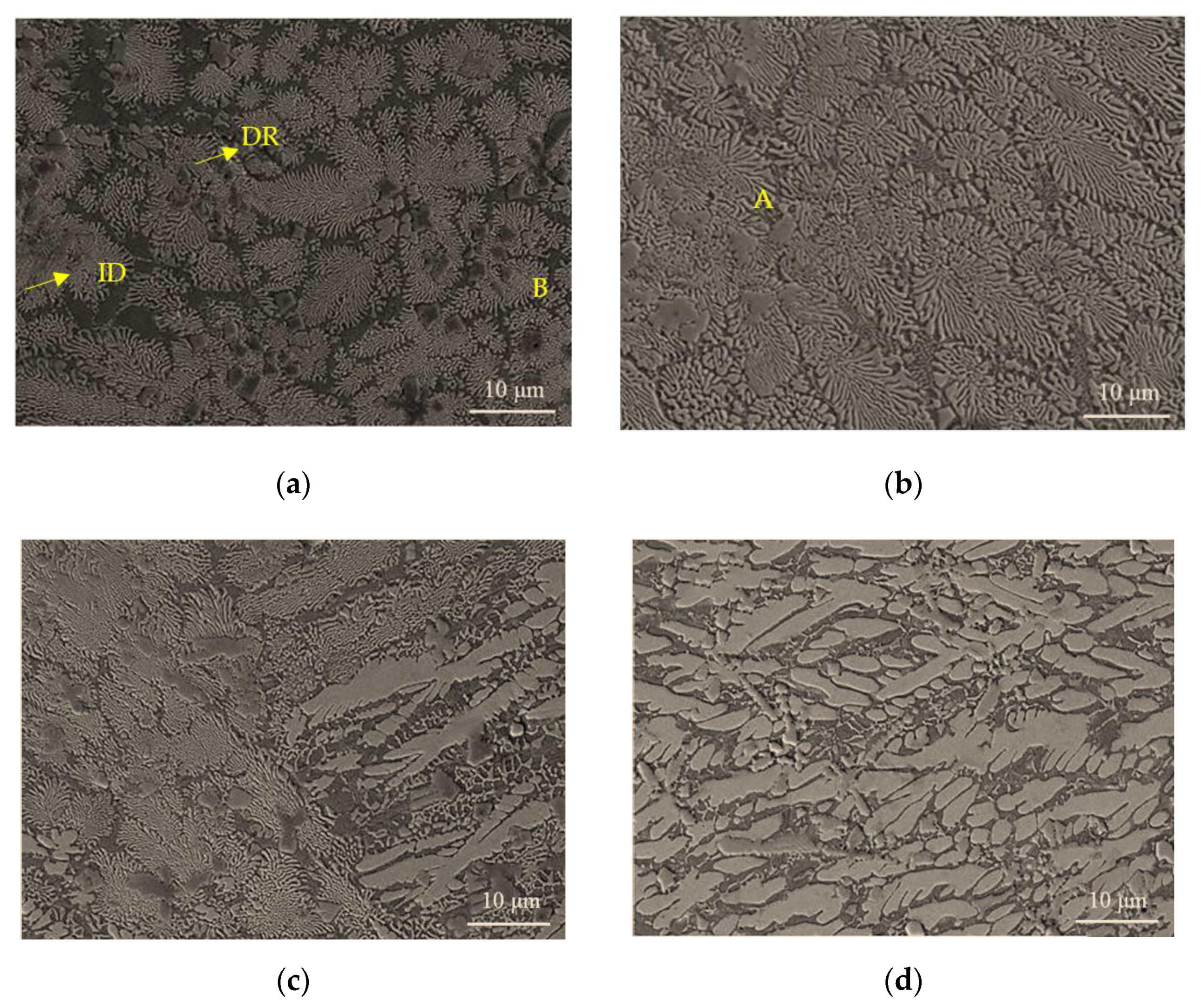

3.2. Microstructures

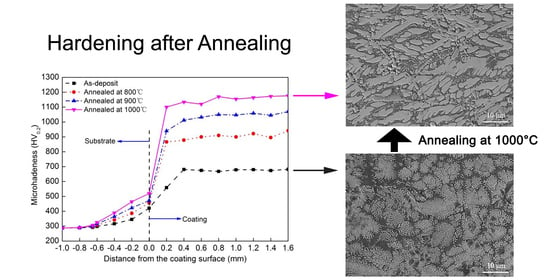

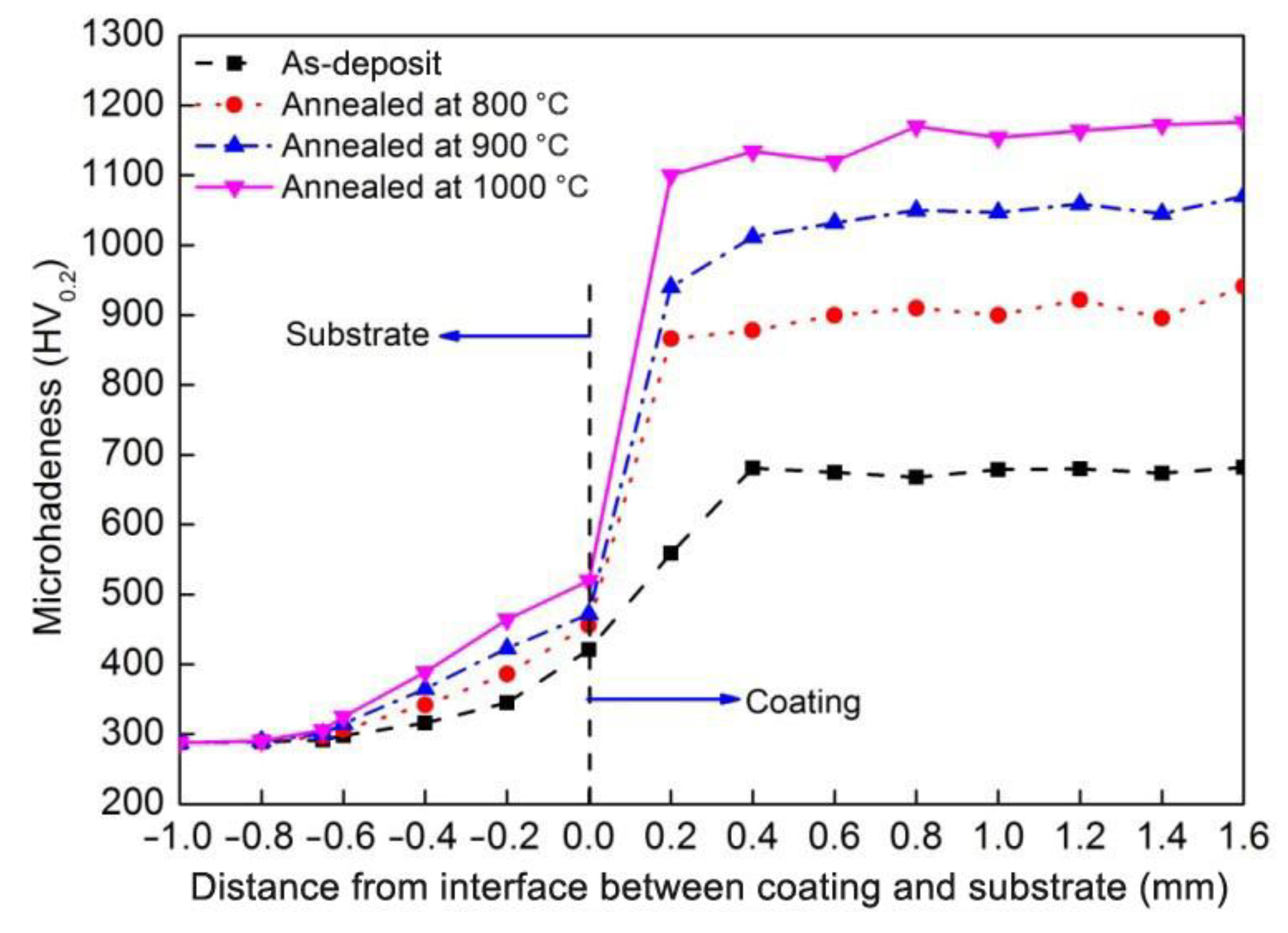

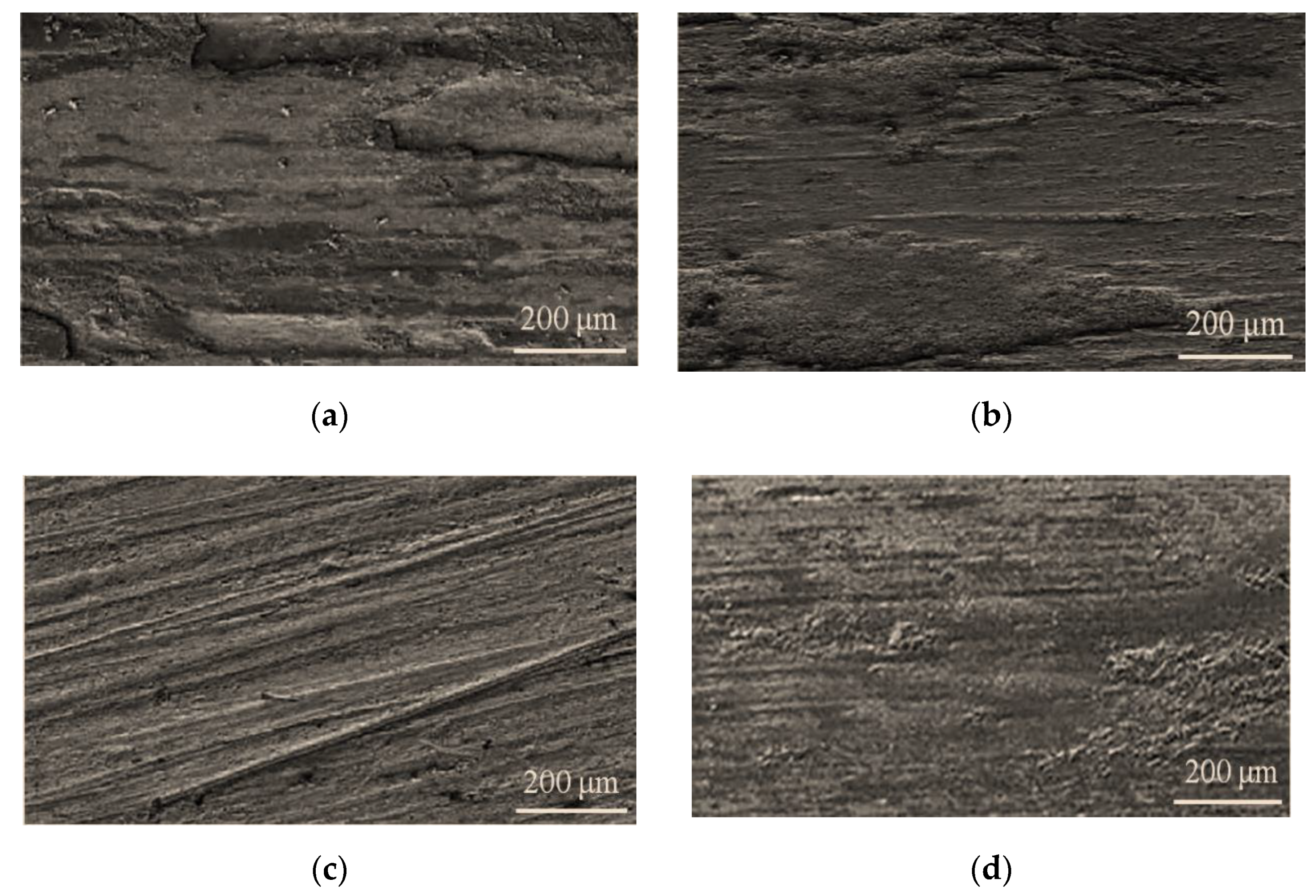

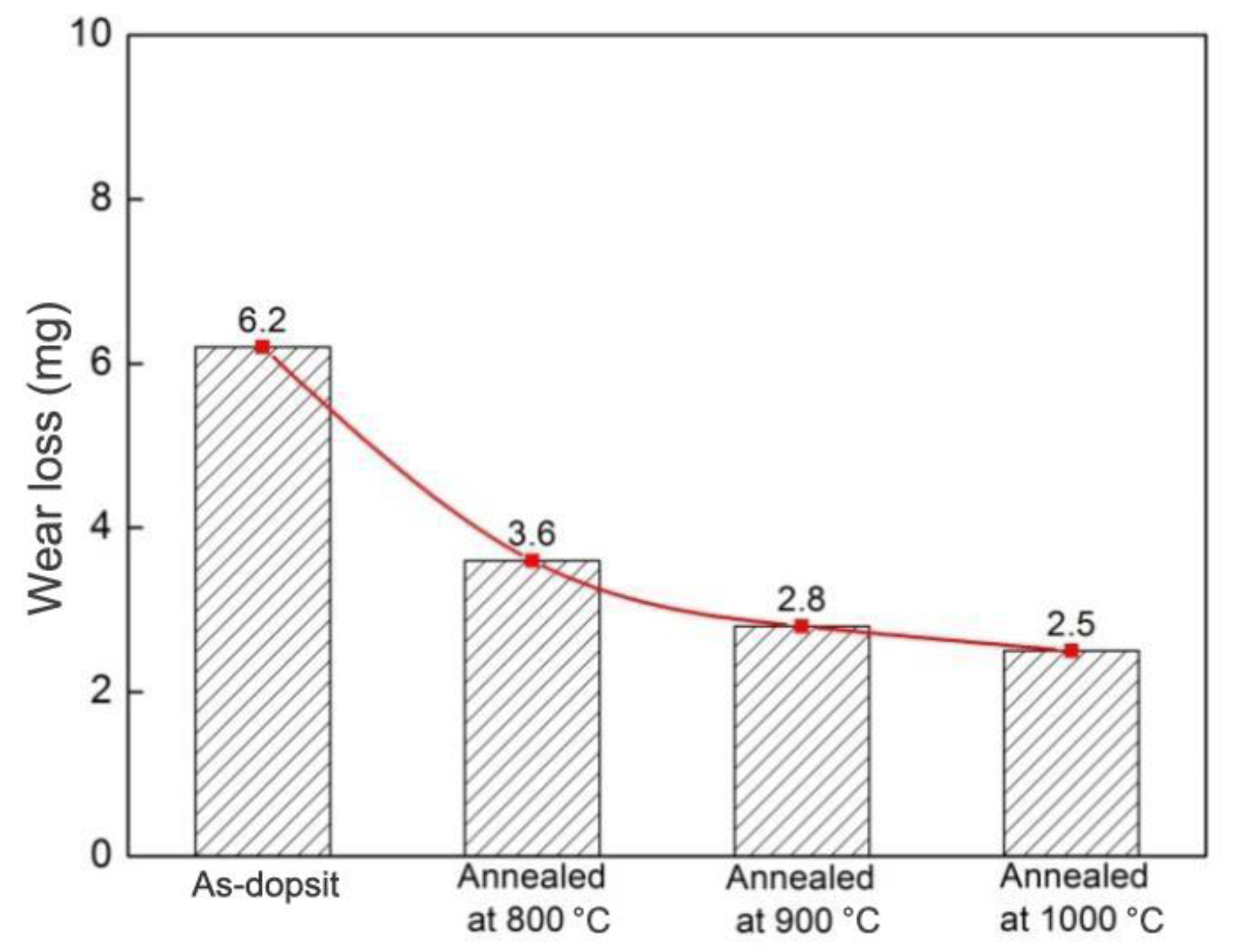

3.3. Micro-Hardness and Wear Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Gao, M.C.; Zhao, J.; Morral, J.E. The thermodynamics and kinetics of high-entropy alloys. J. Phase Equilibria Diffus. 2017, 38, 351–352. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Guan, Y.; Xia, X.; Peng, P.; Ding, Q.; Liu, X. Laser cladding of Al0.5CoCrCuFeNiSi high entropy alloy coating without and with yttria addition on H13 steel. Crystals 2020, 10, 320. [Google Scholar] [CrossRef]

- Huang, E.-W.; Hung, G.-Y.; Lee, S.Y.; Jain, J.; Chang, K.-P.; Chou, J.J.; Yang, W.-C.; Liaw, P.K. Mechanical and magnetic properties of the high-entropy alloys for combinatorial approaches. Crystals 2020, 10, 200. [Google Scholar] [CrossRef] [Green Version]

- Dobeš, F.; Hadraba, H.; Chlup, Z.; Dlouhý, A.; Vilémová, M.; Matějíček, J. Compressive creep behavior of an oxide-dispersion-strengthened CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2018, 732, 99–104. [Google Scholar] [CrossRef]

- Lindner, T.; Löbel, M.; Saborowski, E.; Rymer, L.-M.; Lampke, T. Wear and Corrosion behaviour of supersaturated surface layers in the high-entropy alloy systems CrMnFeCoNi and CrFeCoNi. Crystals 2020, 10, 110. [Google Scholar] [CrossRef] [Green Version]

- Cao, L.; Zhu, L.; Shi, H.; Wang, Z.; Yang, Y.; Meng, Y.; Zhang, L.; Cui, Y. Microstructural evolution from dendrites to core-shell equiaxed grain morphology for CoCrFeNiVx high-entropy alloys in metallic casting mold. Metals 2019, 9, 1172. [Google Scholar] [CrossRef] [Green Version]

- Oh, H.S.; Ma, D.; Leyson, G.P.; Grabowski, B.; Park, E.S.; Körmann, F.; Raabe, D. Lattice distortions in the FeCoNiCrMn high entropy alloy studied by theory and experiment. Entropy 2016, 18, 321. [Google Scholar] [CrossRef] [Green Version]

- Hou, J.; Zhang, M.; Yang, H.; Qiao, J. Deformation behavior of Al0.25CoCrFeNi high-entropy alloy after recrystallization. Metals 2017, 7, 111. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Pan, Y.; He, Y.Z. Synthesis and characterization of FeCoNiCrCu high-entropy alloy coating by laser cladding. Mater. Design. 2011, 32, 1910–1915. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Ye, H.Q.; He, C.; Zhang, H.F.; Hu, Z.Q. Wetting and interface phenomena in the molten Sn/CuFeNiCoCr high-entropy alloy system. Appl. Surf. Sci. 2015, 356, 460–466. [Google Scholar] [CrossRef]

- Zhang, M.; Zhou, X.; Yu, X.; Li, J. Synthesis and characterization of refractory TiZrNbWMo high-entropy alloy coating by laser cladding. Surf. Coat. Technol. 2017, 311, 321–329. [Google Scholar] [CrossRef]

- Jiang, H.; Han, K.; Li, D.; Cao, Z. Synthesis and characterization of AlCoCrFeNiNbx high-entropy alloy coatings by laser cladding. Crystals 2019, 9, 56. [Google Scholar] [CrossRef] [Green Version]

- Li, M.X.; He, Y.Z.; Sun, G.X. Laser cladding Co-based alloy/SiCp composite coatings on IF steel. Mater. Des. 2004, 25, 355–358. [Google Scholar] [CrossRef]

- Zhang, H.; He, Y.Z.; Yuan, X.M.; Pan, Y. Microstructure and age characterization of Cu–15Ni–8Sn alloy coatings by laser cladding. Appl. Surf. Sci. 2010, 256, 5837–5842. [Google Scholar]

- Qiu, X.W.; Zhang, Y.P.; He, L.; Liu, C.G. Microstructure and corrosion resistance of AlCrFeCuCo high entropy alloy. J. Alloys Compd. 2013, 549, 195–199. [Google Scholar] [CrossRef]

- Liu, D.; Zhao, J.; Li, Y.; Zhu, W.; Lin, L. Effects of boron content on microstructure and wear properties of FeCoCrNiBx high-entropy alloy coating by laser cladding. Appl. Sci. 2020, 10, 49. [Google Scholar] [CrossRef] [Green Version]

- Ye, X.; Ma, M.; Cao, Y.; Liu, W.; Ye, X.; Gu, Y. Synthesis and characterization of high-entropy alloy AlxFeCoNiCuCr by laser cladding. Adv. Mater. Sci. Eng. 2011, 12, 303–312. [Google Scholar]

- Huang, C.; Zhang, Y.Z.; Vilar, R.; Shen, J.Y. Dry sliding wear behavior of laser clad TiVCrAlSi high entropy alloy coatings on Ti–6Al–4V substrate. Mater. Des. 2012, 41, 338–343. [Google Scholar] [CrossRef]

- Luo, X.Y.; Liu, G.Z.; Gao, Y. Hardness and electrochemical property of as annealed multi-component AlFeCoNiCrTiV_(0.5) high-entropy alloy. Mater. Mech. Eng. 2011, 35, 87–90. [Google Scholar]

- Wang, Y.F.; Ma, S.G.; Chen, X.H.; Shi, J.Y.; Zhang, Y.; Qiao, J.W. Optimizing mechanical properties of AlCoCrFeNiTi_x high-entropy alloys by tailoring microstructures. Acta. Metall. Sin. 2013, 26, 277–284. [Google Scholar] [CrossRef] [Green Version]

- Przestacki, D.; Jankowiak, M. Surface roughness analysis after laser assisted machining of hard to cut materials. J. Phys. Conf. Ser. 2014, 483, 012019. [Google Scholar] [CrossRef]

- Przestacki, D.; Majchrowski, R.; Marcinia-podsadna, L. Experimental research of surface roughness and surface texture after laser cladding. Appl. Surf. Sci. 2016, 388, 420–423. [Google Scholar] [CrossRef]

- Arfaoui, M.; Radnóczi, G.; Kovács Kis, V. Transformations in CrFeCoNiCu high entropy alloy thin films during in-situ annealing in TEM. Coatings 2020, 10, 60. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- Lu, Y.P.; Hui, J.; Guo, S.; Wang, T.M.; Cao, Z.Q.; Li, T.G. A new strategy to design eutectic high-entropy alloys using mixing enthalpy. Intermetallics 2017, 91, 124–128. [Google Scholar] [CrossRef]

- Li, Q.T.; Lei, Y.P.; Fu, H.G.; Wu, Z.W.; Lin, J. Microstructure and mechanical properties of in situ (Ti, Nb)Cp/Fe-based laser composite coating prepared with different heat inputs. Rare Met. 2018, 10, 852–858. [Google Scholar] [CrossRef]

- Fang, W.; Chang, R.; Ji, P.; Zhang, X.; Liu, B.; Qu, X.; Yin, F. Transformation induced plasticity effects of a non-equal molar Co-Cr-Fe-Ni high entropy alloy system. Metals 2018, 8, 369. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.M.; Wang, Z.Y.; Xu, Z.Z.; Zang, X.M.; Chen, X.G. Microstructure and properties of TiNbZrMo high entropy alloy coating. Mater. Lett. 2020, 285, 129004. [Google Scholar] [CrossRef]

- Yan, G.; Zheng, M.; Ye, Z.; Gu, J.; Wang, B. In-situ Ti(C, N) reinforced AlCoCrFeNiSi-based high entropy alloy coating with functional gradient double-layer structure fabricated by laser cladding. J. Alloy. Compd. 2021, 886, 161252. [Google Scholar] [CrossRef]

- Lin, Y.C.; Cho, Y.H. Elucidating the microstructural and tribological characteristics of NiCrAlCoCu and NiCrAlCoMo multicomponent alloy clad layers in situ. Surf. Coat. Tech. 2009, 203, 1694–1701. [Google Scholar] [CrossRef]

- Hsu, C.Y.; Yeh, J.W.; Chen, S.K.; Shun, T.T. Wear resistance and high-temperature compression strength of FCC CuCoNiCrAl0.5Fe alloy with boron addition. Metall. Mater. Trans. A 2004, 35, 1065–1069. [Google Scholar] [CrossRef]

- Li, T.; Liu, Y.; Liu, B.; Guo, W.; Xu, L. Microstructure and wear behavior of FeCoCrNiMo0.2 high entropy coatings prepared by air plasma spray and the high velocity oxy-fuel spray processes. Coatings 2017, 7, 151. [Google Scholar] [CrossRef] [Green Version]

- Degtyareva, V.F.; Afonikova, N.S. Simple metal and binary alloy phases based on the fcc structure: Electronic origin of distortions, superlattices and vacancies. Crystals 2017, 7, 34. [Google Scholar] [CrossRef] [Green Version]

- Jin, G.; Cai, Z.B.; Guan, Y.J.; Cui, X.F.; Liu, Z.; Li, Y.; Dong, M.L.; Zhang, D. High temperature wear performance of laser-cladded FeNiCoAlCu high-entropy alloy coating. Appl. Surf. Sci. 2018, 445, 113–122. [Google Scholar] [CrossRef]

- Archard, J.F.; Hirst, W. The wear of metals under unlubricated conditions. Proc. Roy. Soc. Lond. A 1956, 236, 397–410. [Google Scholar]

| Annealing Temperature | 25 °C | 800 °C | 900 °C | 1000 °C |

| Lattice Constant (pm) | 289.36 | 288.24 | 287.85 | 287.32 |

| Annealing Temperature | Region | Fe | Mo | Cr | Ti | W | Nb | C | ∆Smix |

|---|---|---|---|---|---|---|---|---|---|

| As-deposit | DR | 35.85 | 10.69 | 11.86 | 14.22 | 11.76 | 15.62 | 1.68R | |

| ID | 24.59 | 11.21 | 13.61 | 16.34 | 13.71 | 17.82 | 2.72 | 1.74R | |

| Annealed at 800 °C | DR | 34.69 | 10.05 | 11.17 | 15.61 | 11.83 | 16.65 | 1.68R | |

| ID | 25.68 | 11.62 | 14.12 | 17.49 | 10.09 | 18.09 | 2.91 | 1.72R | |

| Annealed at 900 °C | DR | 31.21 | 10.56 | 12.73 | 15.65 | 12.72 | 17.13 | 1.72R | |

| ID | 21.58 | 11.02 | 14.34 | 16.36 | 13.18 | 19.21 | 4.31 | 1.73R | |

| Annealed at 1000 °C | DR | 30.06 | 11.61 | 12.85 | 15.86 | 12.16 | 17.51 | 1.73R | |

| ID | 22.11 | 12.21 | 13.31 | 17.22 | 13.03 | 18.96 | 3.16 | 1.74R |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Q.; Li, Y.; Zhao, J.; Liu, D.; Yang, Y. Effects of Annealing on the Microstructure and Wear Resistance of Laser Cladding CrFeMoNbTiW High-Entropy Alloy Coating. Crystals 2021, 11, 1096. https://doi.org/10.3390/cryst11091096

Shen Q, Li Y, Zhao J, Liu D, Yang Y. Effects of Annealing on the Microstructure and Wear Resistance of Laser Cladding CrFeMoNbTiW High-Entropy Alloy Coating. Crystals. 2021; 11(9):1096. https://doi.org/10.3390/cryst11091096

Chicago/Turabian StyleShen, Qiang, Yan Li, Jing Zhao, Dezheng Liu, and Yongsheng Yang. 2021. "Effects of Annealing on the Microstructure and Wear Resistance of Laser Cladding CrFeMoNbTiW High-Entropy Alloy Coating" Crystals 11, no. 9: 1096. https://doi.org/10.3390/cryst11091096

APA StyleShen, Q., Li, Y., Zhao, J., Liu, D., & Yang, Y. (2021). Effects of Annealing on the Microstructure and Wear Resistance of Laser Cladding CrFeMoNbTiW High-Entropy Alloy Coating. Crystals, 11(9), 1096. https://doi.org/10.3390/cryst11091096