Effects of Grain Refinement on the Low-Cycle Fatigue Behavior of IN792 Superalloys

Abstract

:1. Introduction

2. Materials and Methods

2.1. IN792 Superalloy Preparation

2.2. Microstructure Observation

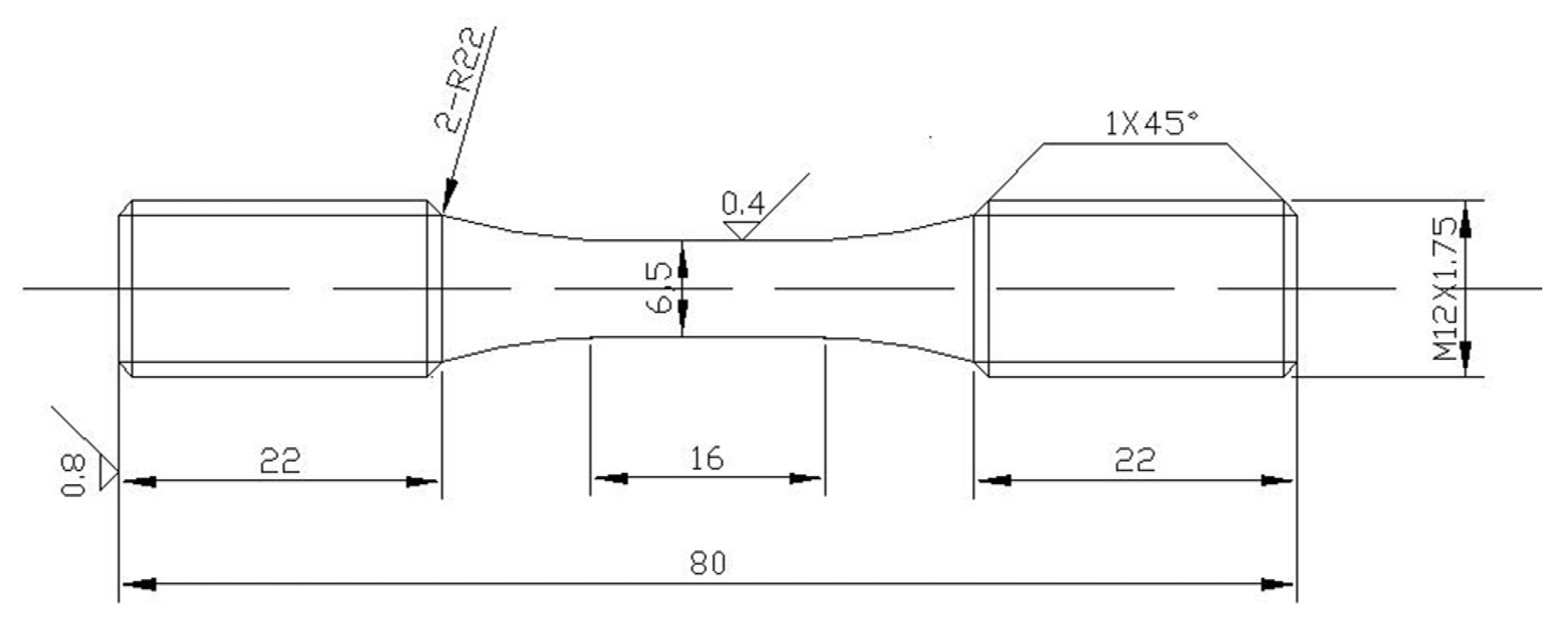

2.3. LCF Tests

2.4. Fractured Specimen Observation

3. Results

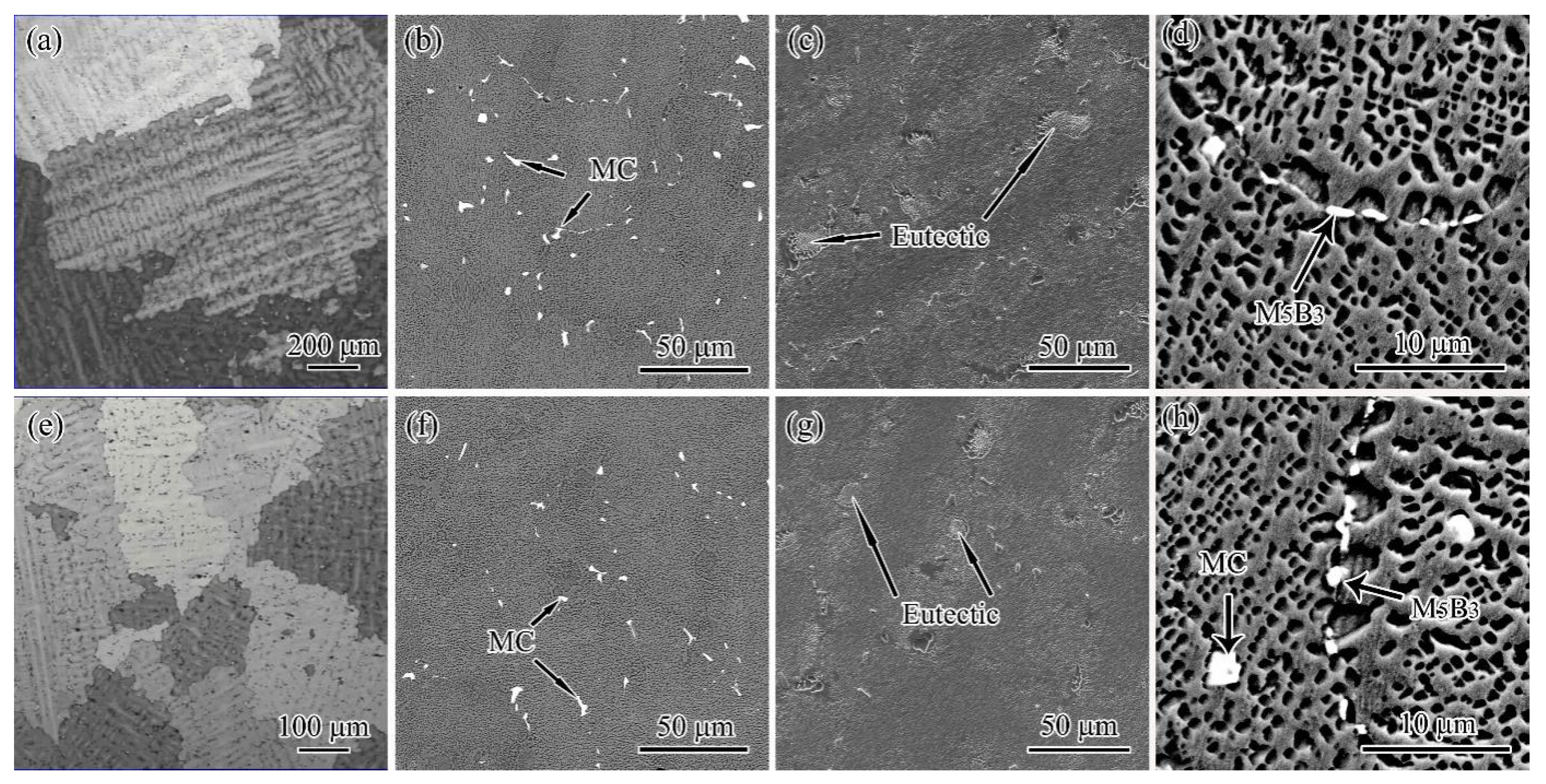

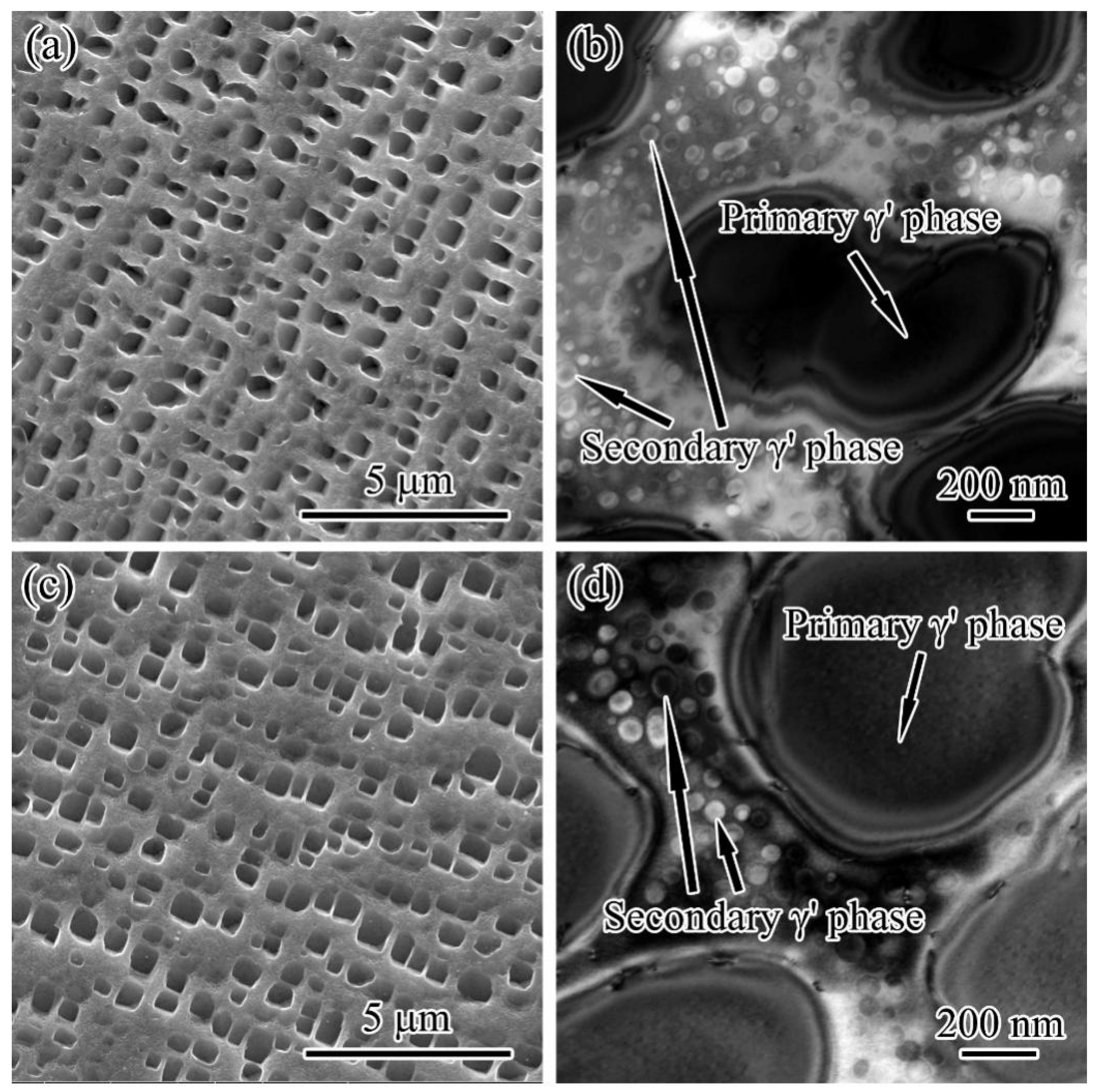

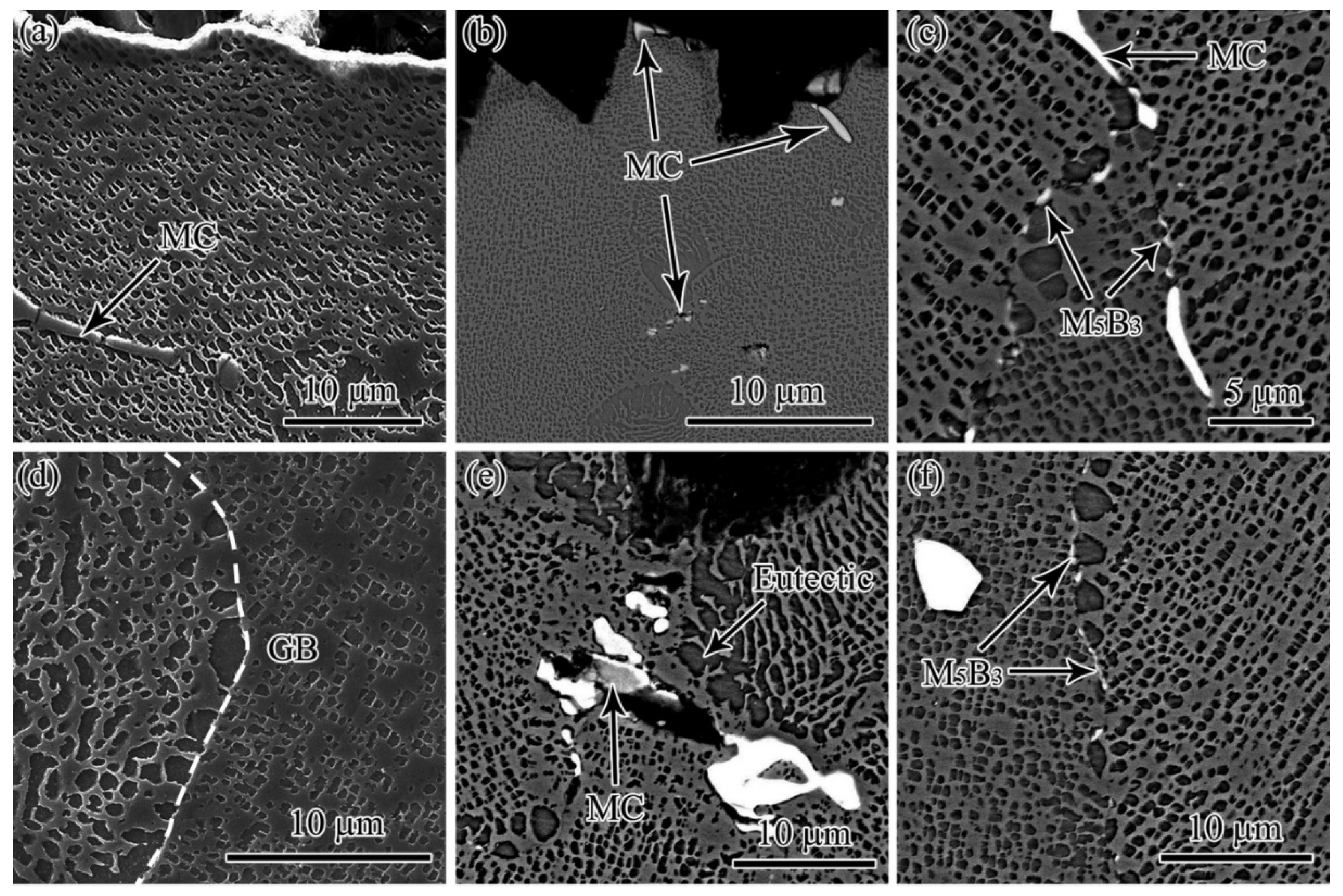

3.1. Microstructure

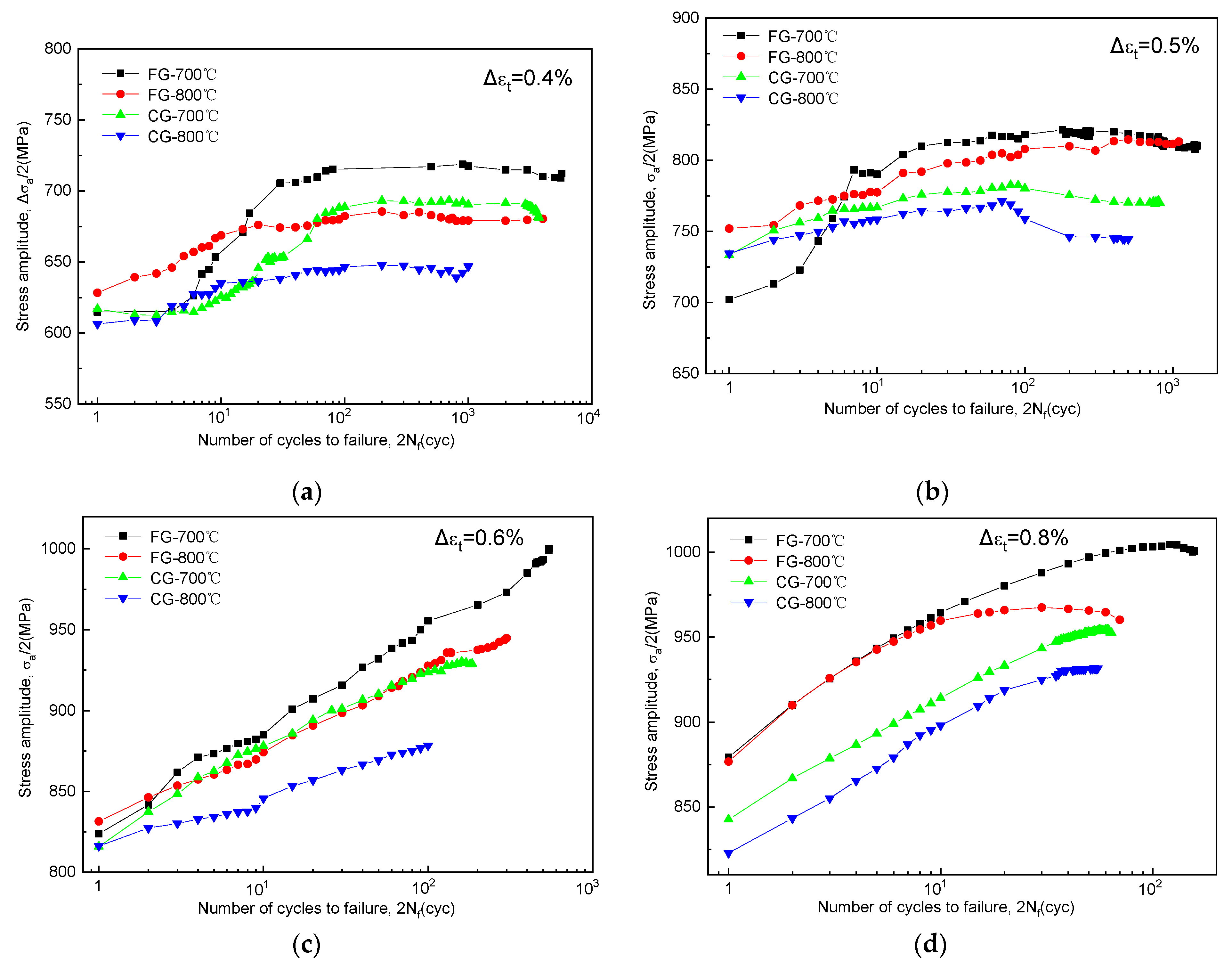

3.2. Cyclic Stress Response Behavior

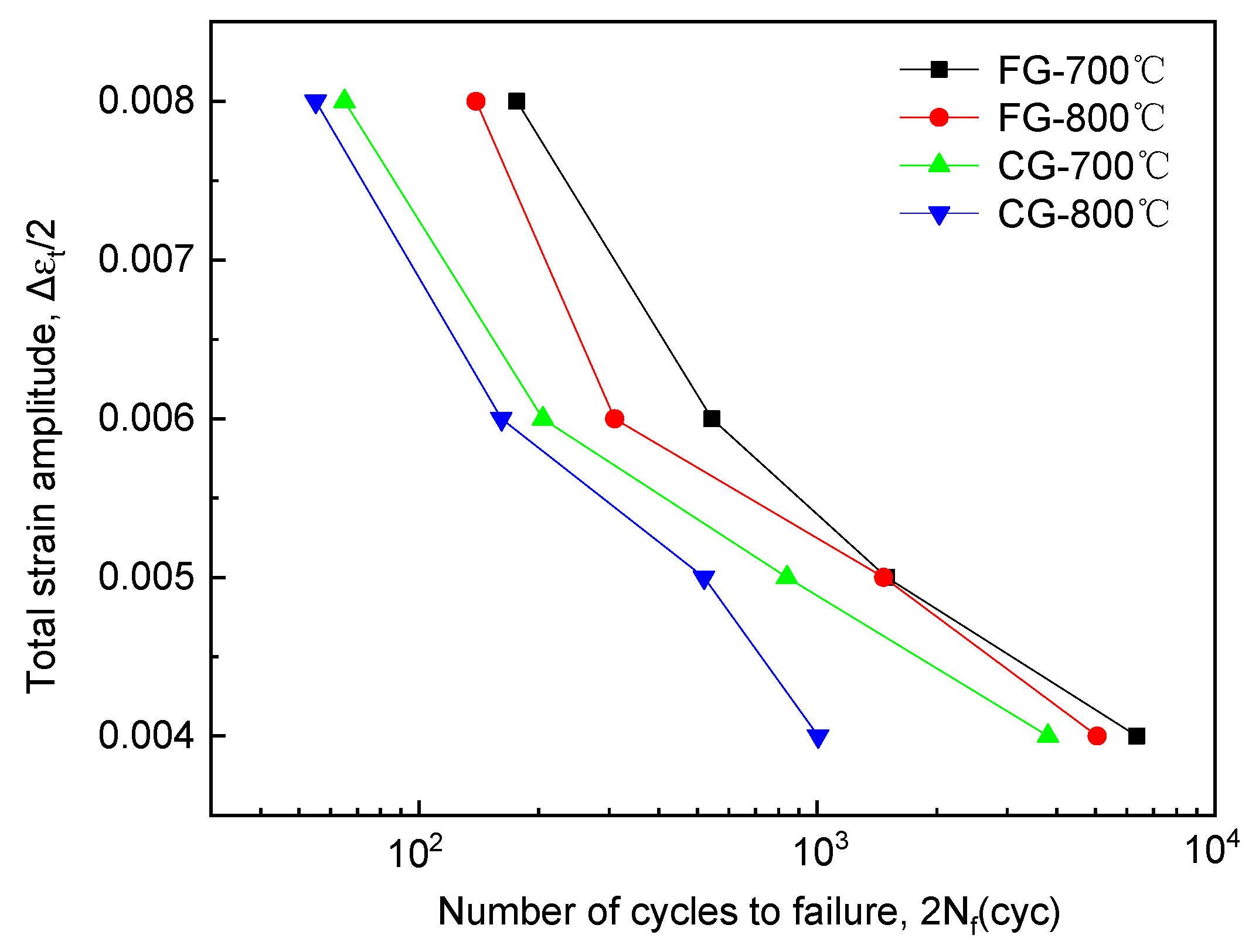

3.3. Fatigue Life Curves

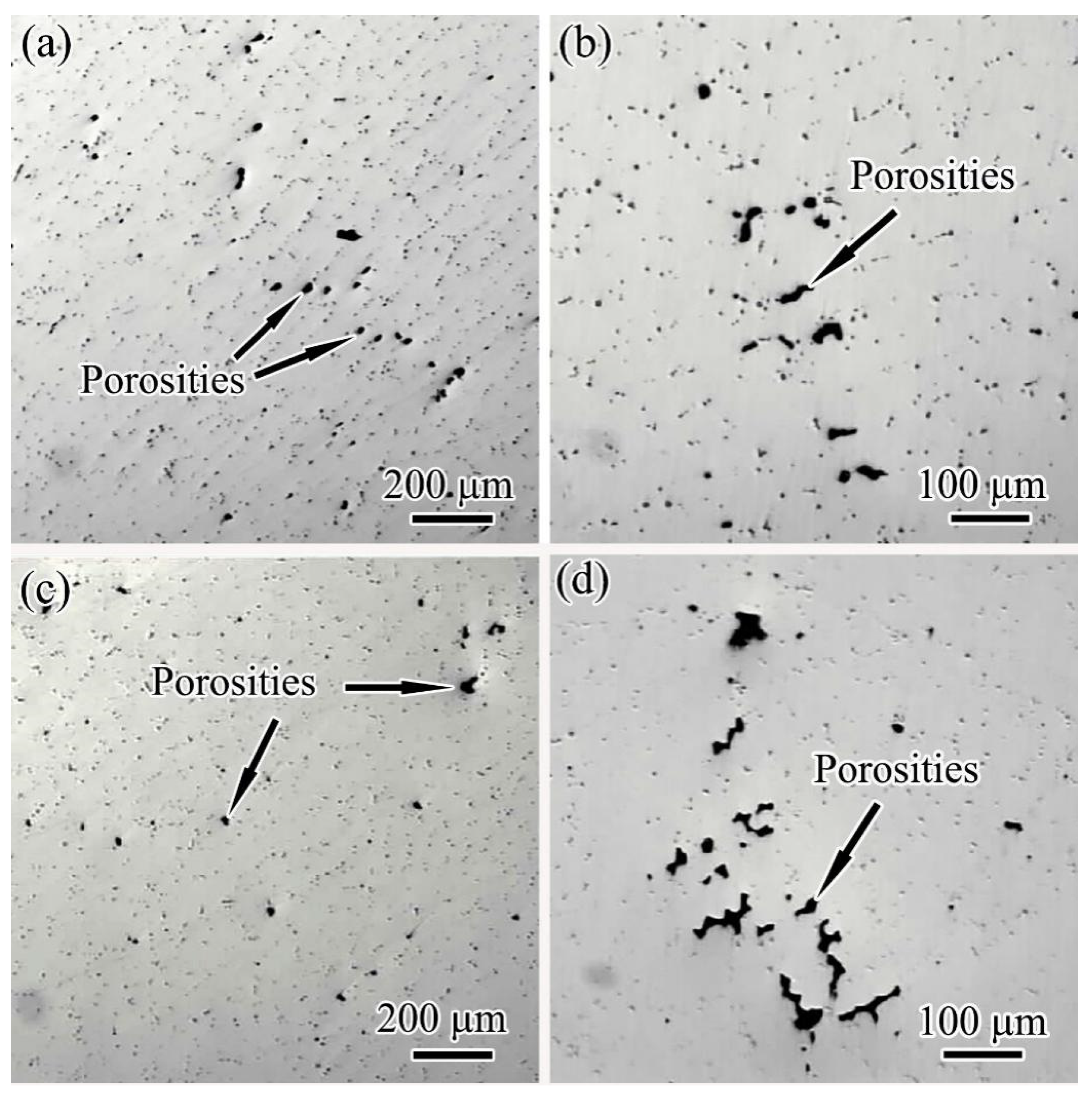

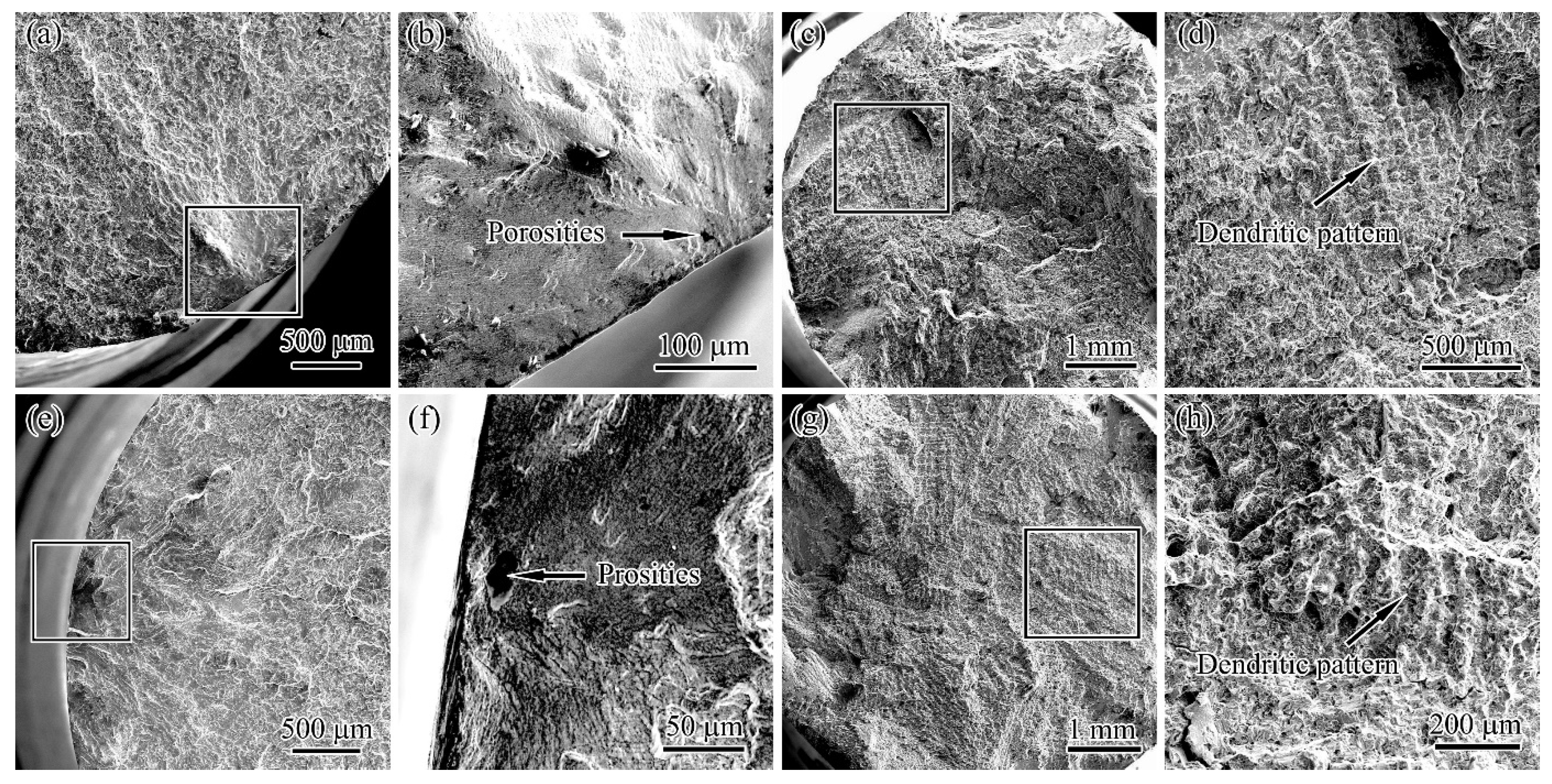

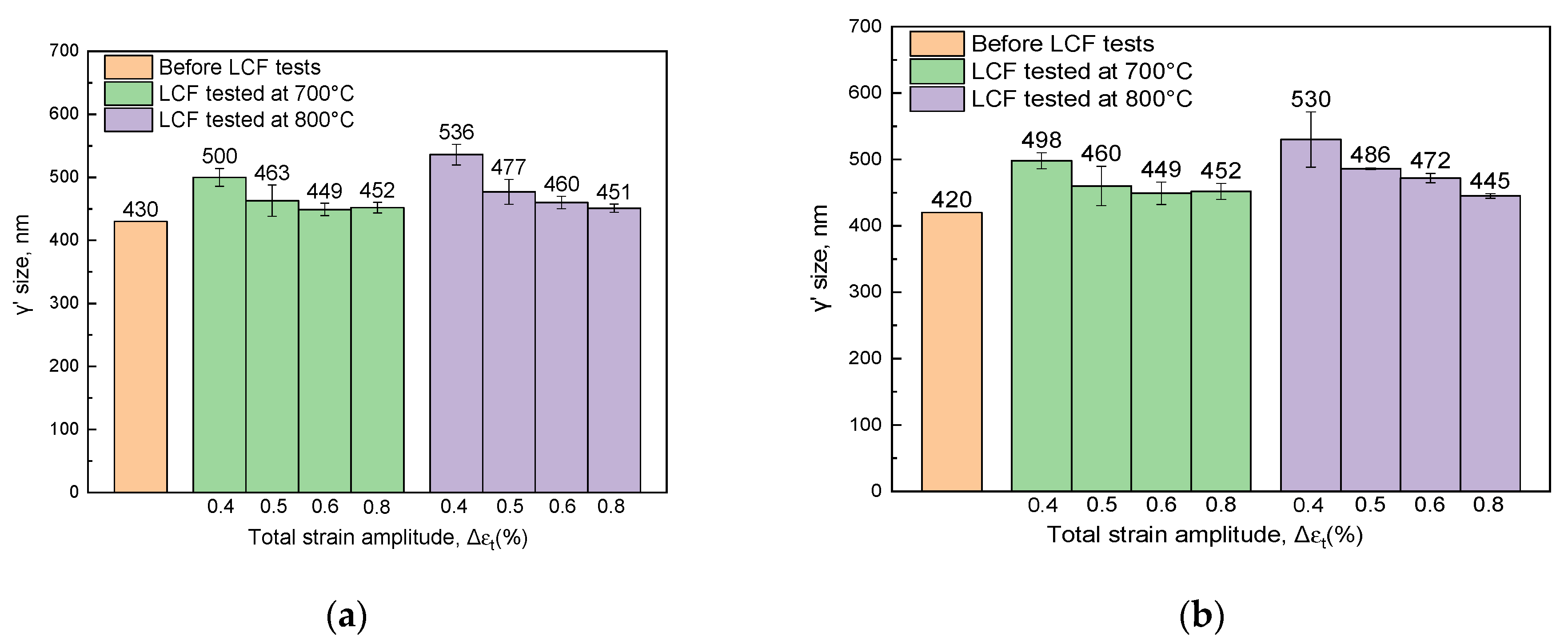

3.4. Microstructure of Fractured Specimens

3.5. Dislocation Structure after LCF Tests

4. Discussion

4.1. The Cyclic Stress Response Behavior of IN792 Superalloy

4.2. The Effect of Grain Refinement on the LCF Property and Fracture of IN792 Superalloy

5. Conclusions

- (1)

- Through decreasing melting and pouring temperatures, the grains, MC carbides, eutectic structures and dendritic structures are refined simultaneously, but the primary and secondary γ’ phases stay consistent due to the same heat treatment process.

- (2)

- The LCF properties of 700 °C and 800 °C are optimized under four different total strain amplitudes by grain refinement.

- (3)

- The LCF fracture mode is related to the applied total strain amplitude. Under low total strain amplitude, the fatigue cracks mainly initiate at the porosities near the specimen surface, while under high total strain amplitude, the fatigue cracks tend to form at the center of the specimen, and propagate along interdendritic regions.

- (4)

- When the total strain amplitude is low, the dislocations could move in the γ channel and form dislocation networks. When the total strain amplitude is high, the dislocations could shear primary γ’ phases and form stacking faults.

- (5)

- The results obtained in the present study could provide theoretical guidance for improving the service performance of IN792 superalloys.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, J.; Zhou, L.; Sheng, L.; Guo, J. The microstructure evolution and its effect on the mechanical properties of a hot-corrosion resistant Ni-based superalloy during long-term thermal exposure. Mater. Design 2012, 39, 55–62. [Google Scholar] [CrossRef]

- Phillips, P.; Unocic, R.; Mills, M. Low cycle fatigue of a polycrystalline Ni-based superalloy: Deformation substructure analysis. Int. J. Fatigue 2013, 57, 50–57. [Google Scholar] [CrossRef]

- Sheng, L.; Yang, F.; Guo, J.; Xi, T.F. Anomalous yield and intermediate temperature brittleness behaviors of directionally solidified nickel-based superalloy. Trans. Nonferrous Met. Soc. China 2014, 24, 673–681. [Google Scholar] [CrossRef]

- Unocic, R.; Viswanathan, G.; Sarosi, P.; Karthikeyan, S.; Li, J.; Mills, M. Mechanisms of creep deformation in polycrystalline Ni-base disk superalloys. Mater. Sci. Eng. A 2008, 483–484, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Sun, J.; Xie, X.; Hu, Y.; Zhao, J.; Yan, P. An investigation on fine-grain formation and structural character in cast IN718 superalloy. J. Mater. Process. Technol. 2003, 137, 35–39. [Google Scholar] [CrossRef]

- Jiang, R.; Everitt, S.; Lewandowski, M.; Gao, N.; Reed, P. Grain size effects in a Ni-based turbine disc alloy in the time and cycle dependent crack growth regimes. Int. J. Fatigue 2014, 62, 217–227. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Zhang, W.; Guo, J.T.; Wang, Z.S.; Ovcharenko, V.E.; Zhou, L.Z.; Ye, H.Q. Microstructure and mechanical properties of Ni3Al fabricated by thermal explosion and hot extrusion. Intermetallics 2009, 17, 572–577. [Google Scholar] [CrossRef]

- Wei, C.; Bor, H.; Ma, C.; Lee, T. A study of IN-713LC superalloy grain refinement effects on microstructure and tensile properties. Mater. Chem. Phys. 2003, 80, 89–93. [Google Scholar] [CrossRef]

- Torster, F.; Baumeister, G.; Albrecht, J.; Lütjering, G.; Helm, D.; Daeubler, M. Influence of grain size and heat treatment on the microstructure and mechanical properties of the nickel-base superalloy U 720 LI. Mater. Sci. Eng. A 1997, 234–236, 189–192. [Google Scholar] [CrossRef]

- Du, B.; Yang, J.; Cui, C.; Sun, X. Effects of grain size on the high-cycle fatigue behavior of IN792 superalloy. Mater. Des. 2015, 65, 57–64. [Google Scholar] [CrossRef]

- Du, B.; Yang, J.; Cui, C.; Sun, X. Effects of grain refinement on the microstructure and tensile behavior of K417G superalloy. Mater. Sci. Eng. A 2015, 623, 59–67. [Google Scholar] [CrossRef]

- Morrison, D.; Moosbrugger, J. Effects of grain size on cyclic plasticity and fatigue crack initiation in nickel. Int. J. Fatigue 1997, 19, 51–59. [Google Scholar] [CrossRef]

- Quested, P.N.; Osgerby, S. Mechanical properties of conventionally cast, directionally solidified, and single-crystal superalloys. Mater. Sci. Tech. 1986, 2, 461–475. [Google Scholar] [CrossRef]

- Jiao, J.; Zou, Q.; Ye, Y.; Xu, Z.; Sheng, L. Carbon fiber reinforced thermoplastic composites and TC4 alloy laser assisted joining with the metal surface laser plastic-covered method. Compos. Part B Eng. 2021, 213, 108738. [Google Scholar] [CrossRef]

- Larson, J.M.; Floreen, S. Metallurgical factors affecting the crack growth resistance of a superalloy. Met. Mater. Trans. A 1977, 8, 51–55. [Google Scholar] [CrossRef]

- Soula, A.; Renollet, Y.; Boivin, D.; Pouchou, J.-L.; Locq, D.; Caron, P.; Bréchet, Y. Analysis of high-temperature creep deformation in a polycrystalline nickel-base superalloy. Mater. Sci. Eng. A 2009, 510-511, 301–306. [Google Scholar] [CrossRef]

- Zhao, H.; Sheng, L. Microstructure and mechanical properties of the Ag/316L composite plate fabricated by explosive welding. J. Manuf. Process. 2021, 64, 265–275. [Google Scholar] [CrossRef]

- Thibault, K.; Locq, D.; Caron, P.; Boivin, D.; Renollet, Y.; Bréchet, Y. Influence of microstructure on local intra- and intergranular deformations during creep of a nickel-based superalloy at 700 °C. Mater. Sci. Eng. A 2013, 588, 14–21. [Google Scholar] [CrossRef]

- Shingledecker, J.; Evans, N.; Pharr, G. Influences of composition and grain size on creep–rupture behavior of Inconel® alloy 740. Mater. Sci. Eng. A 2013, 578, 277–286. [Google Scholar] [CrossRef]

- Du, B.N.; Yang, J.X.; Cui, C.Y.; Sun, X.F. Effects of Grain Refinement on Creep Properties of K417G Superalloy. Acta Metall. Sin. 2014, 50, 1384–1392. [Google Scholar]

- Kobayashi, K.; Yamaguchi, K.; Hayakawa, M.; Kimura, M. Grain size effect on high-temperature fatigue properties of alloy718. Mater. Lett. 2005, 59, 383–386. [Google Scholar] [CrossRef]

- Chan, K.S. Roles of microstructure in fatigue crack initiation. Int. J. Fatigue 2010, 32, 1428–1447. [Google Scholar] [CrossRef]

- Du, B.; Shi, Z.; Yang, J.; Chu, Z.; Cui, C.; Sun, X.; Sheng, L.; Zheng, Y. M5B3 Boride at the Grain Boundary of a Nickel-based Superalloy. J. Mater. Sci. Technol. 2016, 32, 265–270. [Google Scholar] [CrossRef]

- Du, B.; Sheng, L.; Cui, C.; Yang, J.; Sun, X. Precipitation and evolution of grain boundary boride in a nickel-based superalloy during thermal exposure. Mater. Charact. 2017, 128, 109–114. [Google Scholar] [CrossRef]

- Du, B.; Hu, Z.; Sheng, L.; Cui, C.; Yang, J.; Zheng, Y.; Sun, X. Tensile, creep behavior and microstructure evolution of an as-cast Ni-based K417G polycrystalline superalloy. J. Mater. Sci. Technol. 2018, 34, 1805–1816. [Google Scholar] [CrossRef]

- Kunz, L.; Lukáš, P.; Konečná, R.; Fintová, S. Casting defects and high temperature fatigue life of IN713LC superalloy. Int. J. Fatigue 2012, 41, 47–51. [Google Scholar] [CrossRef]

- Collini, L.; Pirondi, A.; Bianchi, R.; Cova, M.; Milella, P. Influence of casting defects on fatigue crack initiation and fatigue limit of ductile cast iron. Procedia Eng. 2011, 10, 2898–2903. [Google Scholar] [CrossRef]

- He, L.; Zheng, Q.; Sun, X.; Guan, H.; Hu, Z.; Tieu, A.; Lu, C.; Zhu, H. High temperature low cycle fatigue behavior of Ni-base superalloy M963. Mater. Sci. Eng. A 2005, 402, 33–41. [Google Scholar] [CrossRef]

- Du, B.; Sheng, L.; Hu, Z.; Cui, C.; Yang, J.; Sun, X. Investigation on the microstructure and tensile behavior of a Ni-based IN792 superalloy. Adv. Mech. Eng. 2018, 10, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Caron, P.; Khan, T.; Veyssière, P. On precipitate shearing by superlattice stacking faults in superalloys. Philos. Mag. A 1988, 57, 859–875. [Google Scholar] [CrossRef]

- Wang, K.; Jing, H.; Xu, L.; Han, Y.; Zhao, L.; Song, K. Cyclic response and dislocation evolution of a nickel-based superalloy under low cycle fatigue deformation. Mater. Sci. Eng. A 2021, 814, 141225. [Google Scholar] [CrossRef]

- Chen, L.J.; Wang, Z.G.; Yao, G.; Tian, J.F. Investigation on high temperature low cycle fatigue properties of a casting nickel base superalloy K417. Acta Metall. Sin. 1999, 35, 1144–1150. [Google Scholar]

- Yao, J.; Guo, J.T.; Yuan, C.; Li, Z.J. Low cycle fatigue behavior of cast nickel base superalloy K52. Acta Metall. Sin. 2005, 41, 357–362. [Google Scholar]

- Liu, L.; Meng, J.; Liu, J.; Zhang, H.; Sun, X.; Zhou, Y. Investigation on low cycle fatigue behaviors of the [001] and [011] oriental single crystal superalloy at 760 °C. Mater. Sci. Eng. A 2018, 734, 1–6. [Google Scholar] [CrossRef]

- Du, B.; Hu, Z.; Sheng, L.; Xu, D.; Qiao, Y.; Wang, B.; Wang, J.; Zheng, Y.; Xi, T. Microstructural characteristics and mechanical properties of the hot extruded Mg-Zn-Y-Nd alloys. J. Mater. Sci. Technol. 2021, 60, 44–55. [Google Scholar] [CrossRef]

- Du, B.; Hu, Z.; Wang, J.; Sheng, L.; Zhao, H.; Zheng, Y.; Xi, T. Effect of extrusion process on the mechanical and in vitro degradation performance of a biomedical Mg-Zn-Y-Nd alloy. Bioact. Mater. 2020, 5, 219–227. [Google Scholar] [CrossRef]

- Qin, X.; Guo, J.; Yuan, C.; Chen, C.; Hou, J.; Ye, H. Decomposition of primary MC carbide and its effects on the fracture behaviors of a cast Ni-base superalloy. Mater. Sci. Eng. A 2008, 485, 74–79. [Google Scholar] [CrossRef]

- Liu, L.; Jin, T.; Zhao, N.; Sun, X.; Guan, H.; Hu, Z. Formation of carbides and their effects on stress rupture of a Ni-base single crystal superalloy. Mater. Sci. Eng. A 2003, 361, 191–197. [Google Scholar] [CrossRef]

- He, L.; Zheng, Q.; Sun, X.; Guan, H.; Hu, Z.; Tieu, A.; Lu, C.; Zhu, H. Effect of carbides on the creep properties of a Ni-base superalloy M963. Mater. Sci. Eng. A 2005, 397, 297–304. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, L.; Qin, X.; Sheng, L.; Hou, J.; Guo, J. Primary MC decomposition and its effects on the rupture behaviors in hot-corrosion resistant Ni-based superalloy K444. Mater. Sci. Eng. A 2012, 553, 14–21. [Google Scholar] [CrossRef]

| C | Cr | Co | Mo | W | Ta | Al | Ti | B | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.089 | 12.60 | 8.99 | 1.97 | 3.98 | 4.25 | 3.43 | 3.92 | 0.014 | 0.030 | Balance |

| Average Grain Size (μm) | Average Size of MC Carbide (μm) | Average Size of Eutectic (μm) | Average Size of γ’ Phase in the Dendrite Core (nm) | |

|---|---|---|---|---|

| CG | 2300 | 2.6 | 10.7 | 430 |

| FG | 400 | 1.9 | 8.1 | 420 |

| b | c | |||

|---|---|---|---|---|

| FG-700 °C | 1710 | 0.114 | 0.238 | 0.912 |

| CG-700 °C | 1568 | 0.110 | 0.085 | 0.901 |

| FG-800 °C | 1524 | 0.099 | 0.742 | 1.188 |

| CG-800 °C | 1423 | 0.110 | 0.503 | 1.285 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, B.; Sheng, L.; Cui, C.; Hu, Z.; Sun, X. Effects of Grain Refinement on the Low-Cycle Fatigue Behavior of IN792 Superalloys. Crystals 2021, 11, 892. https://doi.org/10.3390/cryst11080892

Du B, Sheng L, Cui C, Hu Z, Sun X. Effects of Grain Refinement on the Low-Cycle Fatigue Behavior of IN792 Superalloys. Crystals. 2021; 11(8):892. https://doi.org/10.3390/cryst11080892

Chicago/Turabian StyleDu, Beining, Liyuan Sheng, Chuanyong Cui, Ziyang Hu, and Xiaofeng Sun. 2021. "Effects of Grain Refinement on the Low-Cycle Fatigue Behavior of IN792 Superalloys" Crystals 11, no. 8: 892. https://doi.org/10.3390/cryst11080892

APA StyleDu, B., Sheng, L., Cui, C., Hu, Z., & Sun, X. (2021). Effects of Grain Refinement on the Low-Cycle Fatigue Behavior of IN792 Superalloys. Crystals, 11(8), 892. https://doi.org/10.3390/cryst11080892