Abstract

Recently, soil improvement using EICP (Enzyme-Induced Carbonate Precipitation) methods in the geotechnical and geo-environmental field has become a prominent interest worldwide. The objective of this study was to develop an improved extraction technique of crude urease from watermelon seeds in both dry and germinated conditions. Subsequently, this study also analyzed the improvement methodology of crystal polymorphs and soil bonding incorporation of various Mg2+/Ca2+ ratios. The optimization of enzyme-mediated carbonate precipitation was also investigated by Scanning Electron Microscope (SEM) and X-ray Diffraction (XRD) analysis. Results confirmed that the precipitated crystals are mainly calcite, vaterite and aragonite primarily (depending on the Mg2+/Ca2+ ratios). Therefore, to improve the bonding capacity in between the sand particles a novel improvement methodology was investigated by adding various Mg2+/Ca2+ ratios. The mechanical properties of the treated soil (Mikawa Sand, D50 = 0.870 mm) specimens were tested by unconfined compressive strength (UCS) and this confirmed the effectiveness of adding various Mg2+/Ca2+ ratios. The results of the UCS tests showed that, the lower molar ratios of Mg2+/Ca2+ can significantly improve the UCS of the specimen (up to 50%) which could be considered a significant outcome for different bio-geotechnical applications.

1. Introduction

Enzyme-induced carbonate precipitation (EICP) is an innovative, bio-inspired soil stabilization technique [1,2] in which calcium carbonate (CaCO3) crystals are enzymatically precipitated and bind the soil particles and enhancing the soil engineering properties. In recent years, soil improvement through calcium carbonate (CaCO3) precipitation by a biological approach (bio-calcification, bio-grouting, biomineralization, bio-cement) has emerged as a potential strategy for soil stabilization [3,4,5] and has been studied intensively throughout the world over the last two decades. Most of the previous work published on the microbial induced carbonate precipitation (MICP) method is based on microorganisms (ureolytic bacteria, fungi, etc.) [6,7,8] that precipitated CaCO3 via urea hydrolysis in the presence of Ca2+ ion at favorable conditions (e.g., pH, temperature, bacterial culture/duration/population, the interval of injection, etc.). These minerals of carbonate (CaCO3) serve as the main binding agent inside the pores of the soil, bridging the particles of the soil and giving complete cohesion to the soil structure and thus enhance the soil stability [9,10]. However, bacteria’s cultivation and its storage at a large scale is a complex process that challenges the use of MICP [11] in real field application. Nevertheless, the screening, isolation, cultivation and controlling of ureolytic bacteria, physical non/homogeneity, oxygen availability and their enzymatic activity, bacterial cell attachment to soil particles, and their interaction between other species in the soil is a complex process [12] and their large-scale preservation is also a challenging method that threatens the use of MICP in actual field application. However, some researchers have tried to overcome some of these challenges [13], but some inconclusive issues related to MICP still persist, for instance survivability of the bacteria, culture and nutrition supply to the bacteria, etc. [14]. Additionally, the use of urease enzymes obtained from non-microbial sources such as jack bean seeds, watermelon seeds, etc., is also known as enzyme-induced carbonate precipitation (EICP). In recent years, EICP has drawn the interests of numerous researchers [15] to a successful investigation and explored the feasibility of using this method on a laboratory scale. At present, commercially available urease enzyme is expensive, because it is produced in small quantities at high levels of purity for use in sensitive applications (e.g., food and medical applications). To overcome some of the above leading limitations, this study focused on using an EICP method which is considered a low cost, sustainable, and eco-friendly method in improving the geotechnical properties of soil. Using crude extract from different plant urease, considered a promising alternative to microbial urease. Considering cost effectiveness and waste utilization, this study focused on using watermelon seeds (Citrullus lanatus) because watermelon seeds are considered “food waste material” and a promising alternative to other plant derivative urease [16].

However, under a controlled laboratory condition and soil improvement technique using the EICP method (extracted crude urease from watermelon seeds) urea hydrolysis reaction rate, various in situ factors (temperature, pH) that can influence the urease activity and morphology of calcium carbonate crystals (considering Mg2+/Ca2+ ratios) were not investigated extensively, since Mg2+ is one of the most vital modifiers of CaCO3 morphology [17] found in the natural environment. In contrast to previous research work available for soil improvement by carbonate precipitation, no attention has been paid to understanding the effect of magnesium-modified CaCO3 crystals on the variation of the unconfined compressive strength of the soil. Hence, considering the limitations in the previous understanding of magnesium modified calcium carbonate precipitation for soil improvement, this study tried to evaluate the following parameters as discussed below considering different Mg2+/Ca2+ ratios (from 0 to 1).

- Extraction and evaluation of urease activity of the crude enzyme (dry condition and germinated condition) and their subsequent effects on temperature and pH.

- Evaluation of urea hydrolysis rate with time considering different Mg2+/Ca2+ ratios.

- Mineralogical and morphological characterization of precipitated carbonate crystals by X-ray powder diffraction test (XRD) and scanning electron microscopy (SEM).

- Finally, evaluation of the unconfined compressive strengths (UCS) of the soil.

- specimens treated with EICP solution at various Mg2+/Ca2+ ratios and subsequent evaluation of the effective bonding patterns in between the sand particles.

2. Materials and Methods

2.1. Extraction of Crude Urease

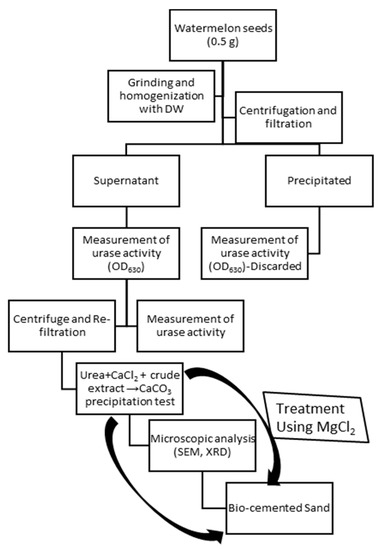

Dry and germinated (0–4 days) watermelons seeds (0.5 g) were finely crushed with a kitchen blender using 10 mL of distilled water (concentration 50 g seeds/L) and then stirred at 500 rpm for around 1 h. One portion of the collected crude extract was used directly to measure the urease activity and the other portion of the crude extract was filtered and centrifuged at 10,000 rpm for 5 min at 25 °C and the collected supernatant was used to assess the urease activity considering several environmental parameters (temperature and pH, etc.) followed by the indophenol method [18]. The effects of pH were studied at room temperature (25 °C) and the effects of temperature were studied at neutral pH condition (pH 7). The flow chart of the extraction procedure of crude urease solution from watermelon seeds is presented in Figure 1. The urease activity of the enzyme (crude extracts) solution was calculated (absorbance at OD630 nm) by measuring the released NH4+ ions (described by indophenol method) as a result of urea hydrolysis. The measuring time interval for urease activity was 0 min, 5 min, 10 min and 15 min. The overall experimental procedure illustrated in Figure 2.

Figure 1.

Extraction procedures of crude urease solution from watermelon seeds. (1) Dry seeds, (2) germinated seeds at 48 h, (3) germinated seeds at 96 h, (4) crushed and blended watermelon seeds, (5) filtration of the crude extract, (6) after subsequent filtration translucent crude extract obtained, (7) constant temperature water bath for urease activity investigation, (8) UV-vis spectrophotometer, (9) intensity of dye-solution measured at OD630.

Figure 2.

Experimental procedure used in this study (DW—distilled water; SEM—Scanning Electron Microscope; XRD—X-ray Diffraction).

2.2. Enzyme Catalyzedreaction Rate and CaCO3 Precipitation Test

To evaluate the urea hydrolysis reaction rate and to confirm the morphology of CaCO3 precipitation and its precipitation trend, a series of experiments were conducted by various combinations of CaCl2–urea and urease directly in transparent polypropylene tubes. Subsequently, the rate of CaCO3 precipitation in combinations with CaCl2–urea and crude urease was measured directly by evaluating Ca2+ concentration with time. The concentration of the crude urease was 50 g seeds/L. MgCl2 was mixed with CaCl2–urea–crude urease solutions counting various molar ratios from 0 to 1 (Table 1). The adjusted solution was then added to the test tube and kept in a shaker at 30 °C for 48 h. The obtained precipitation (CaCO3) was separated from the solution using filter paper and kept in an oven drier for about 24 h at 100 °C. Finally, precipitated CaCO3 was weighed to determine the total carbonate precipitate mass. To check the reproducibility of the test three samples of each conditions were evaluated. Scanning Electron Microscope (SEM) (TM3000, Hitachi, Tokyo, Japan) and X-ray diffraction (XRD) (MiniFlex™, Rigaku Co., Ltd., Tokyo, Japan)-analysis were also conducted to investigate the morphology of the precipitated carbonates.

Table 1.

Testing conditions for the CaCO3 precipitation test.

2.3. Sand Solidification (Syringe) Test

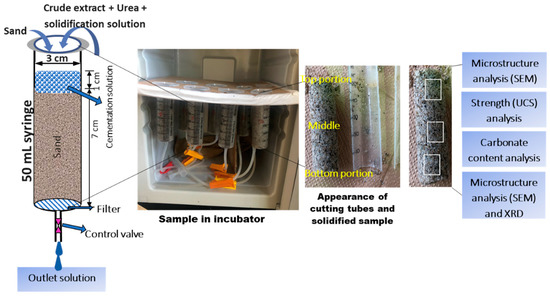

Dried “Mikawa” sand (commercially available) was placed at 110 °C for 1 day and then transferred (85 g) into a 50 mL syringe (diameter, φ = 3 cm, height h = 7.1 cm) and compacted gently. The physical properties of “Mikawa” sand used in this study are outlined in Table 2. Prepared samples were placed in an incubator (30 °C). Subsequently, 26 mL of prepared urea–CaCl2–urease solution (maintaining Mg2+/Ca2+ ratios) was added to the syringe and the final level of the solution maintained above the top surface of the sand sample. A new solidification solution was injected into the samples (48 h intervals) with the same volume and concentration and drained the previously injected solution gradually. To avoid clogging and considering the fast reaction rate, the crude urease injection interval was decided (48 h). To investigate the temporal variations of these parameters within the specimen, the concentration of Ca2+ and the pH of the outlet was observed regularly (48 h intervals). The experimental protocol used in this study illustrated in Figure 3. Finally, using a needle penetration device, a value for approximate UCS (unconfined compressive strength) was measured after 14 days of curing. The microstructure and morphology analysis were conducted by SEM and XRD analysis. The condition of the syringe solidification test outlined in Table 3.

Table 2.

Physical properties of “Mikawa” sand used in this study.

Figure 3.

Experimental protocol used in this study (UCS—unconfined compressive strength).

Table 3.

Testing conditions for sand solidification.

3. Results and Discussion

3.1. Extraction of Cruse Urease

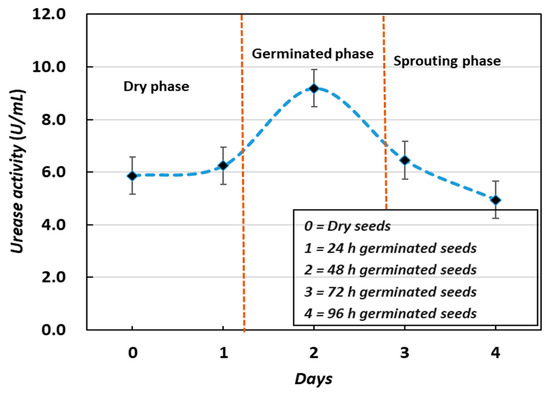

Urease activity (U/mL) of the extracted enzyme from watermelon seeds is shown in Figure 4 corresponding with dry seed condition and germinated seed condition with time. Results showed that, for the case of dry seed crude extract solution, the urease activity was 6 U/mL and gradually increased with time (germinated condition). After several consecutive days (48 h) the urease activity reached to its peak (9 U/mL) and then the urease activity declined (5 U/mL) after 96 h and showed a bell shape curve. The fluctuation of the urease activity was influenced by some metabolic factors, biological reactions and functional proteins [19,20] which triggered the enzymatic activity of the seed. The obtained urease activity (in the case of dry seeds) in this study was equivalent to some previous studies that mainly focused on crude solution extracted from crushed watermelon seeds [21,22]. In addition, this study also revealed higher urease activity extracted from germinated watermelon seeds, which allows gaining of an additional 50% urease activity from the same mass of seed used, for improving the enzyme-induced bio-cementation method and its application. Therefore, germinated seeds (48 h) were used for rest of the study.

Figure 4.

Urease activity of different conditions of seed.

The successful implementation of the EICP technique for soil improvement was likely dependent on several environmental factors including urease activity, temperature, pH, etc. [23], which were also evaluated in this study. Figure 5 showed the interdependent changes of urease activity from the initial phase to the declining phase (10 °C to 60 °C) and the fluctuation of urease activity was temperature dependent. From the results (Figure 5), the urease activity was lower at 10 °C and increased progressively with increasing temperature for both non-treated and treated cases (before centrifuge and after centrifuge). Subsequently, the urease activity reached a stable phase at 30 °C and the urease activity dropped with further increase in temperature. Compared with some of the previous studies, the maximum urease activity was obtained at 65 °C (jack bean seeds) and was deactivated at 70 °C [23,24]. It was reported that, at low temperature (below 10 °C) and at high temperature (above 70 °C), the free enzyme easily denatured [25]. The possible reason was that the molecules of the enzyme exceed the barrier of energy and the breakage of the hydrogen and hydrophobic bonds [26] that were responsible for maintaining the structure of the enzyme [27]. Finally, because of the broken structure of the enzyme, further ureolysis potentiality also dropped. From this study, it is obvious that, to obtain maximum urease activity from crude extract, i.e., plant sources (watermelon seeds), retaining moderate temperature is recommended.

Figure 5.

Urease activity varying with temperature.

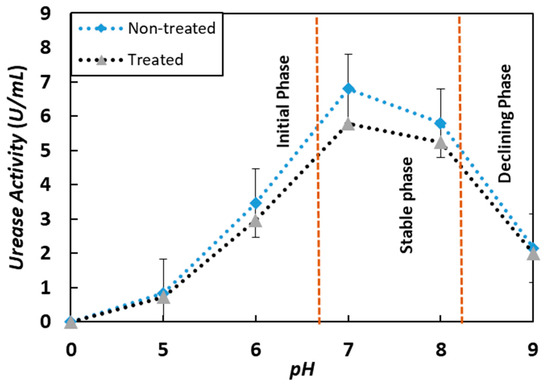

The pH values played an important role in the urease activity of crude urease. Previous research reported that the pH of the reaction medium is a significant abiotic factor that affects the urease activity during urea hydrolysis [28]. In this study, the urease activity of the extracted crude urease from watermelon seed was found to yield maximum activity at pH 7.5 (Figure 6), which means that the watermelon urease may belong to the category of basic urease. The pH value of the test condition was set from slightly acidic (pH 5) to slightly alkaline (pH 9). The results of pH dependency showed that variation of pH was evidently sensitive for urease activity. The urease activity was below 1 U/mL at pH 5. The maximum urease activity (7.5 U/mL) was observed with increasing pH (7.5) and with further increase in pH (9), the urease activity declined (2 U/mL). Similarly, several other studies reported basic pH as an optimum value for the urease activity of extracted crude urease [29]. These findings may be clarified by the fact that the acidic or alkaline pH inhibits the enzyme, decreasing its activity. The presence of active sites in amino acids can also be affected by changes in pH, which may alter their ionization and consequences on urease activity [30]. Studies also observed that an acidic reaction medium delayed the EICP reaction rate [31], which was also consistent with the results from bio-treated soil stabilization [32].

Figure 6.

Urease activity varying with pH.

3.2. CaCO3 Precipitation Test

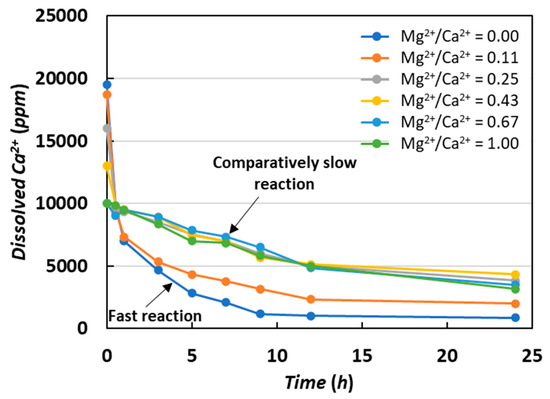

It’s well established that CaCO3 serves as the primary binding materials in between the sand particles to stabilize the soil [33]. The effects of different Mg2+/Ca2+ ratios and subsequent hydrolysis with time were studied and the results are shown in Figure 7. Figure 7 showed that the urea hydrolysis rate of among the different Mg2+/Ca2+ ratios demonstrated a significant difference. Notably, when the Mg2+/Ca2+ = 0 the urea hydrolysis rate was very fast, the urea hydrolysis mostly occurs in between 0 and 5 h. With increase in Mg2+/Ca2+ ratios, the urea hydrolysis rate tends to be slower and delayed the urea hydrolysis rate up to 24 h. The variation of the reaction rate was determined by the Mg2+/Ca2+ ratios [34]. Since Mg2+ ion has a greater solubility than Ca2+ ion [34], therefore, during the urea hydrolysis process, the supersaturation of calcium carbonate occurred by interfering with the nucleation sites [35], resulting in formation of calcite, aragonite and/or vaterite depending on the Ca2+ and Mg2+ reaction equilibrium.

Figure 7.

Urea hydrolysis rate with time.

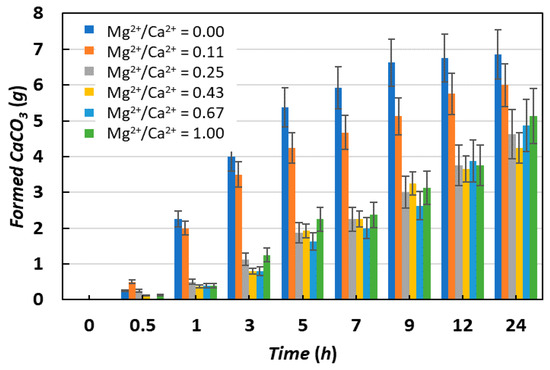

Furthermore, the amount of formed CaCO3 precipitated crystals were also highly influenced by Mg2+/Ca2+ ratios. Based on the results of test-tube experiments, Figure 8 illustrates the effect of various Mg2+/Ca2+ ratios on the formed CaCO3 crystals. The results showed that, as the Mg2+/Ca2+ ratios increased, the CaCO3 crystals were decreased. The possible reason for varying CaCO3 precipitation was unstable pH and the duration of urea hydrolysis which occurred. Under a certain pH change or during the hydrolysis process, the shape of precipitated crystals changed and extended through the crystallization or re-crystallization process until a more stable form was obtained [36]. The re-crystallization process triggered the system to lose energy by forming an unstable crystal structure [37], which could be one of the reasons for the decreased CaCO3 precipitation amount. The result of this study is in accordance with some of the previous studies as well [38].

Figure 8.

Amount of CaCO3 precipitated with time.

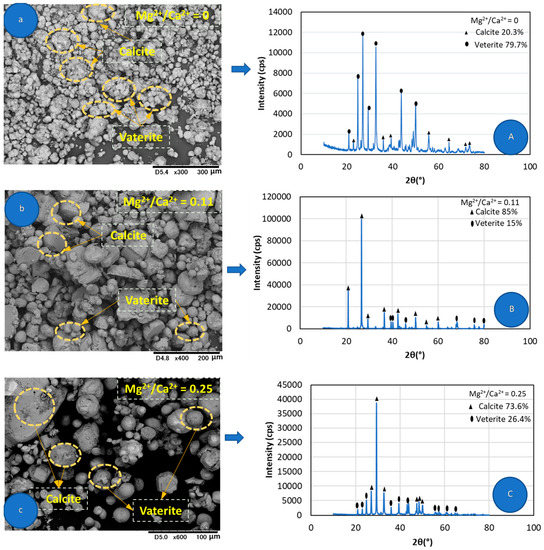

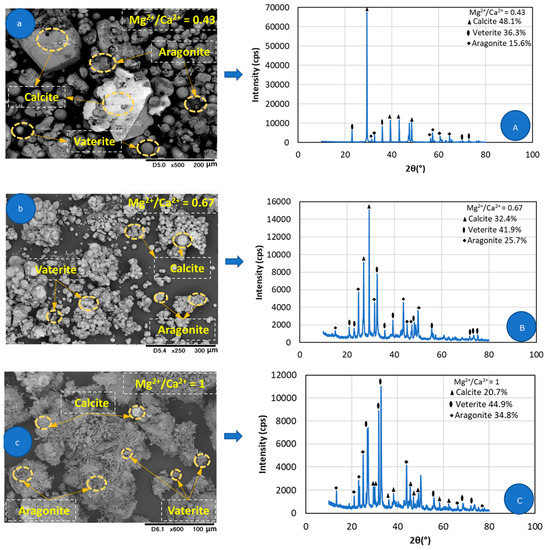

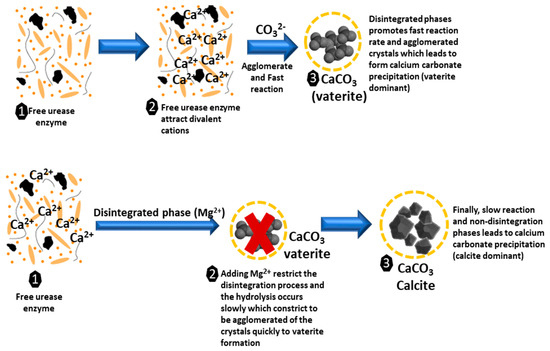

The evolution of the crystals’ morphology and shapes obtained from the SEM and XRD analysis is shown in Figure 9 and Figure 10. The crystal structure of the image showed a rhombohedral shape without the magnesium (Mg2+/Ca2+ = 0), which is also confirmed as calcite (20.3%) and vaterite (79.7%) by XRD analysis. With increasing Mg2+/Ca2+ ratios, the precipitation tendency and crystal morphology were also observed to change from rhombohedral (vaterite) to hexagonal (calcite) and orthorhombic (aragonite) [39,40]. When Mg2+/Ca2+ = 0.11 and 0.25, results showed an effective transformation of calcite (85%) and vaterite (15%) (Figure 9b-B). Furthermore, due to metastable nucleation [41] and increased Mg2+/Ca2+ ratios (Mg2+/Ca2+ = 1) orthorhombic (aragonite) crystals are evident from figure (Figure 10c-C). The overall mechanism of transformation of crystals is illustrated in Figure 11.

Figure 9.

SEM images of the precipitated CaCO3 crystals with different Mg2+/Ca2+ ratios (a–c) and their subsequent XRD analysis to confirm the polymorph of the crystals (A–C).

Figure 10.

SEM images of the precipitated CaCO3 crystals with different Mg2+/Ca2+ ratios (a–c) and their subsequent XRD analysis to confirm the polymorph of the crystals (A–C).

Figure 11.

Schematic illustration of the CaCO3 formation mechanism (calcite and vaterite) in contract with Mg2+/Ca2+ ratios.

3.3. Sand Solidification (Syringe) Test

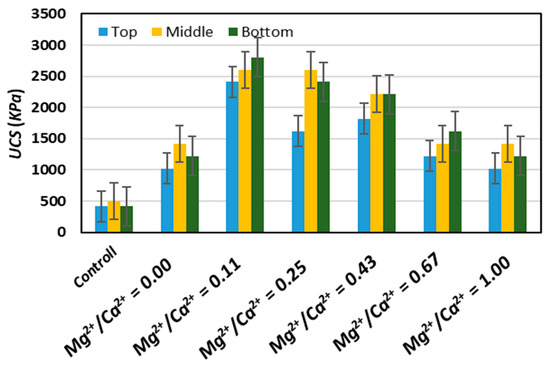

Figure 12 shows the UCS value resulting from the specimens of soil treated with crude extract solution containing various Mg2+/Ca2+ molar ratios. According to the UCS results, a moderate UCS (1.2 MPa) was obtained using only crude extract enzyme solution (Mg2+/Ca2+ = 0). Moreover, a higher UCS (2.5 MPa) was obtained when Mg2+/Ca2+ ratios increased at 0.11 and cured for 14 days. After subsequent increase in Mg2+/Ca2+ = 0.43–1.00, the UCS values declined gradually and reached a lower UCS (1.5 MPa) value compared to other testing cases.

Figure 12.

UCS of the solidified sand.

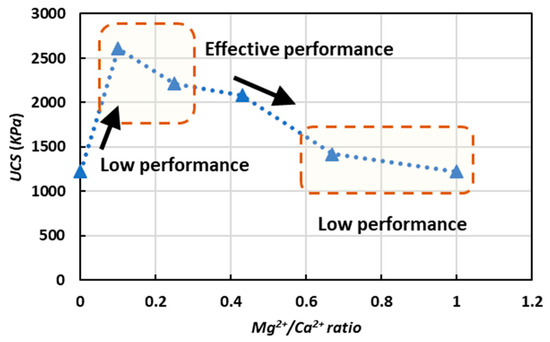

Figure 13 shows the overall improvement tendency of using Mg2+/Ca2+ ratios over estimated UCS. The results showed that Mg2+/Ca2+ ratios are a significant factor for EICP treated sand improvement. Minimal performance observed at higher (Mg2+/Ca2+ = 1) or lower Mg2+/Ca2+ ratios (Mg2+/Ca2+ = 0). Optimum Mg2+/Ca2+ ratios were favored to obtain an effective treatment of the EICP-treated specimens.

Figure 13.

Improvement tendency of the solidified sand (UCS) with different Mg2+/Ca2+ ratios.

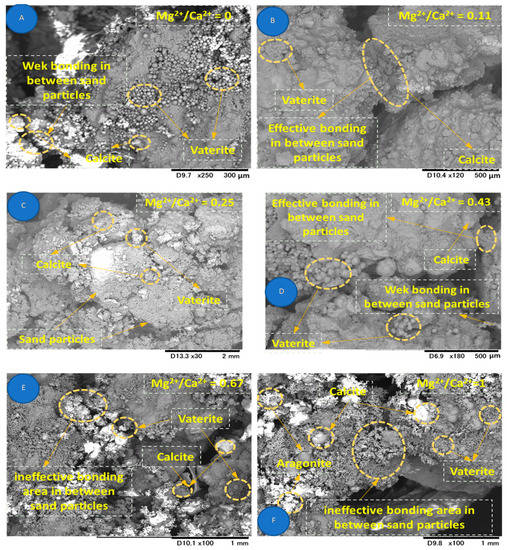

From the SEM observation results, it is obvious that, in the case of only crude extract enzyme–CaCl2–urea solution, the crystals (mostly vaterite) remained on the sand particles, and their bonding capacity between the sand particles remains very weak (Figure 14). Furthermore, the promotion of the newly added solution (depending on the Mg2+/Ca2+ ratios), the transformation of the crystal occurred (mostly calcite) and the strength of the sand sample was significantly increased. The effectiveness of the bonding pattern and agglomeration of CaCO3 crystals in between the sand particles shown in Figure 14A–F. The results clearly reflect the presence of calcite in between the sand particles and void space which is mainly responsible for the increase in the strength of the treated samples. The results of this study are in accordance with [42,43,44].

Figure 14.

SEM images showing the efficacy and bonding patterns of CaCO3 crystals in between the sand particles (A–F).

4. Conclusions

This study explained the successful extraction of urease enzymes (from germinated watermelon seeds), the effects of Mg2+/Ca2+ ratios on carbonate precipitation and their morphology and described the overall process of soil improvement methods using sustainable, cost-effective, and environmentally friendly bio-mediated techniques. Considering the results performed in this study, the following conclusion can be drawn:

- Crude extracts from seeds germinated for two days showed a 50% higher urease activity than that extracted from dry seeds.

- It was detected that the Mg2+/Ca2+ ratios are a significant factor influencing both the amount of carbonate precipitation and the ratios of the calcium carbonate polymorphs (calcite, vaterite, aragonite) in EICP process.

- The Mg2+/Ca2+ ratios influence the UCS value of the treated samples. For Mg2+/Ca2+ ratios = 0.11, an improvement of UCS of 50% compared to Mg/Ca = 0 could be demonstrated.

- Our results suggest that calcite is more efficient in binding the sand particles compared to vaterite. Adding a small amount of MgCl2 has a significant effect on the CaCO3 precipitation pattern and bonding between the sand particles during EICP, as it increases the proportion of calcite. However, some major challenges for field implementations of this EICP method still remain in this novel area.

- Nevertheless, the findings of these studies could play a significant role for sand stabilization and other applications in the geotechnical sectors.

Author Contributions

M.A.I. conceptualized the methodology and performed all the experiments, analyzed the data and prepared original draft of this manuscript; K.N. has suggested how to improve the methodology and edited the manuscript; S.K. was responsible for fund acquisition and supervised the work, partly conducted the experiments and analyzed the data. All authors have read and agreed to the published version of the manuscript.

Funding

This work was partly supported by JSPS KAKENHI, grant number JP19H02229.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declared no conflict of interest.

References

- Putra, H.; Yasuhara, H.; Erizal; Sutoyo; Fauzan, M. Review of Enzyme-Induced Calcite Precipitation as a Ground-Improvement Technique. Infrastructures 2020, 5, 66. [Google Scholar] [CrossRef]

- Hamed Khodadadi, T.; Kavazanjian, E.; van Paassen, L.; DeJong, J. Bio-Grout Materials: A Review. In Proceedings of the Grouting 2017; American Society of Civil Engineers: Reston, VA, USA, 2017; pp. 1–12. [Google Scholar]

- Miftah, A.; Khodadadi Tirkolaei, H.; Bilsel, H. Bio-precipitation of CaCO3 for soil improvement: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 800, 012037. [Google Scholar] [CrossRef]

- Ahenkorah, I.; Rahman, M.M.; Karim, M.R.; Beecham, S.; Saint, C. A Review of Enzyme Induced Carbonate Precipitation (EICP): The Role of Enzyme Kinetics. Sustain. Chem. 2021, 2, 7. [Google Scholar] [CrossRef]

- Kavazanjian, E.; Hamdan, N. Enzyme Induced Carbonate Precipitation (EICP) Columns for Ground Improvement. In Proceedings of the IFCEE 2015; American Society of Civil Engineers: Reston, VA, USA, 2015; Volume GSP 256, pp. 2252–2261. [Google Scholar]

- Mujah, D.; Shahin, M.A.; Cheng, L. State-of-the-Art Review of Biocementation by Microbially Induced Calcite Precipitation (MICP) for Soil Stabilization. Geomicrobiol. J. 2017, 34, 524–537. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hora, R.N.; Ahenkorah, I.; Beecham, S.; Karim, M.R.; Iqbal, A. State-of-the-Art Review of Microbial-Induced Calcite Precipitation and Its Sustainability in Engineering Applications. Sustainability 2020, 12, 6281. [Google Scholar] [CrossRef]

- De Muynck, W.; De Belie, N.; Verstraete, W. Microbial carbonate precipitation in construction materials: A review. Ecol. Eng. 2010, 36, 118–136. [Google Scholar] [CrossRef]

- Tang, C.-S.; Yin, L.; Jiang, N.; Zhu, C.; Zeng, H.; Li, H.; Shi, B. Factors affecting the performance of microbial-induced carbonate precipitation (MICP) treated soil: A review. Environ. Earth Sci. 2020, 79, 94. [Google Scholar] [CrossRef]

- Al-Salloum, Y.; Hadi, S.; Abbas, H.; Almusallam, T.; Moslem, M.A. Bio-induction and bioremediation of cementitious composites using microbial mineral precipitation–A review. Constr. Build. Mater. 2017, 154, 857–876. [Google Scholar] [CrossRef]

- Putri, P.Y.; Ujike, I.; Sandra, N.; Rifwan, F.; Andayono, T. Calcium Carbonate in Bio-Based Material and Factor Affecting Its Precipitation Rate for Repairing Concrete. Crystals 2020, 10, 883. [Google Scholar] [CrossRef]

- Arias, D.; Cisternas, L.; Rivas, M. Biomineralization Mediated by Ureolytic Bacteria Applied to Water Treatment: A Review. Crystals 2017, 7, 345. [Google Scholar] [CrossRef]

- Osinubi, K.J.; Eberemu, A.O.; Ijimdiya, T.S.; Yakubu, S.E.; Gadzama, E.W.; Sani, J.E.; Yohanna, P. Review of the use of microorganisms in geotechnical engineering applications. SN Appl. Sci. 2020, 2, 207. [Google Scholar] [CrossRef]

- Lee, Y.S.; Park, W. Current challenges and future directions for bacterial self-healing concrete. Appl. Microbiol. Biotechnol. 2018, 102, 3059–3070. [Google Scholar] [CrossRef]

- Putra, H.; Yasuhara, H.; Kinoshita, N.; Hirata, A. Optimization of Enzyme-Mediated Calcite Precipitation as a Soil-Improvement Technique: The Effect of Aragonite and Gypsum on the Mechanical Properties of Treated Sand. Crystals 2017, 7, 59. [Google Scholar] [CrossRef]

- Nam, I.H.; Chon, C.M.; Jung, K.Y.; Choi, S.G.; Choi, H.; Park, S.S. Calcite precipitation by ureolytic plant (Canavalia ensiformis) extracts as effective biomaterials. KSCE J. Civ. Eng. 2015, 19, 1620–1625. [Google Scholar] [CrossRef]

- Davis, K.J. The Role of Mg2+ as an Impurity in Calcite Growth. Science 2000, 290, 1134–1137. [Google Scholar] [CrossRef]

- Natarajan, K.R. Kinetic study of the enzyme urease from Dolichos biflorus. J. Chem. Educ. 1995, 73, 556–557. [Google Scholar] [CrossRef]

- Wani, A.A.; Sogi, D.S.; Singh, P.; Wani, I.A.; Shivhare, U.S. Characterisation and functional properties of watermelon (Citrullus lanatus) seed proteins. J. Sci. of Food Agric. 2011, 91, 113–121. [Google Scholar] [CrossRef]

- Abas Wani, A.; Sogi, D.S.; Grover, L.; Saxena, D.C. Effect of Temperature, Alkali Concentration, Mixing Time and Meal/Solvent Ratio on the Extraction of Watermelon Seed Proteins—A Response Surface Approach. Biosyst. Eng. 2006, 94, 67–73. [Google Scholar] [CrossRef]

- Javadi, N.; Khodadadi, H.; Hamdan, N.; Kavazanjian, E. EICP Treatment of Soil by Using Urease Enzyme Extracted from Watermelon Seeds. In Proceedings of the IFCEE 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 115–124. [Google Scholar]

- Dilrukshi, R.A.N.; Nakashima, K.; Kawasaki, S. Soil improvement using plant-derived urease-induced calcium carbonate precipitation. Soils Found. 2018, 58, 894–910. [Google Scholar] [CrossRef]

- Feder, M.J.; Akyel, A.; Morasko, V.J.; Gerlach, R.; Phillips, A.J. Temperature-dependent inactivation and catalysis rates of plant-based ureases for engineered biomineralization. Eng. Rep. 2021, 3. [Google Scholar] [CrossRef]

- Blakeley, R.L.; Zerner, B. Jack bean urease: The first nickel enzyme. J. Mol. Catal. 1984, 23, 263–292. [Google Scholar] [CrossRef]

- Dixon, N.E.; Gazzola, C.; Blakeley, R.L.; Zerner, B. Jack bean urease (EC 3.5.1.5). Metalloenzyme. Simple biological role for nickel. J. Am. Chem. Soc. 1975, 97, 4131–4133. [Google Scholar] [CrossRef]

- Weber, M.; Jones, M.J.; Ulrich, J. Optimisation of isolation and purification of the jack bean enzyme urease by extraction and subsequent crystallization. Food Bioprod. Process. 2008, 86, 43–52. [Google Scholar] [CrossRef]

- EL-Hefnawy, M.E.; Sakran, M.; Ismail, A.I.; Aboelfetoh, E. Extraction, purification, kinetic and thermodynamic properties of urease from germinating Pisum Sativum L. seeds. BMC Biochem. 2014, 15, 15. [Google Scholar] [CrossRef] [PubMed]

- Labana, S.; Singh, O.V.; Basu, A.; Pandey, G.; Jain, R.K. A microcosm study on bioremediation of p-nitrophenol-contaminated soil using Arthrobacter protophormiae RKJ100. Appl. Microbiol. Biotechnol. 2005, 68, 417–424. [Google Scholar] [CrossRef] [PubMed]

- Neupane, D.; Yasuhara, H.; Kinoshita, N.; Unno, T. Applicability of Enzymatic Calcium Carbonate Precipitation as a Soil-Strengthening Technique. J. Geotech. Geoenviron. Eng. 2013, 139, 2201–2211. [Google Scholar] [CrossRef]

- Cui, M.-J.; Lai, H.-J.; Hoang, T.; Chu, J. One-phase-low-pH enzyme induced carbonate precipitation (EICP) method for soil improvement. Acta Geotech. 2021, 16, 481–489. [Google Scholar] [CrossRef]

- Rohy, H.; Arab, M.; Zeiada, W.; Omar, M.; Almajed, A.; Tahmaz, A. One Phase Soil Bio-Cementation with EICP-Soil Mixing. In Proceedings of the World Congress on Civil, Structural, and Environmental Engineering, Rome, Italy, 7–9 April 2019. [Google Scholar]

- Cheng, L.; Shahin, M.A.; Asce, M.; Mujah, D. Influence of Key Environmental Conditions on Microbially Induced Cementation for Soil Stabilization. J. Geotech. Geoenviron. Eng 2017, 143, 1–11. [Google Scholar] [CrossRef]

- Khodadadi Tirkolaei, H.; Javadi, N.; Krishnan, V.; Hamdan, N.; Kavazanjian, E. Crude Urease Extract for Biocementation. J. Mater. Civ. Eng. 2020, 32, 04020374. [Google Scholar] [CrossRef]

- Katz, A. The interaction of magnesium with calcite during crystal growth at 25–90 °C and one atmosphere. Geochim. Cosmochim. Acta 1973, 37, 1563–1586. [Google Scholar] [CrossRef]

- Doner, H.E.; Pratt, P.F. Solubility of Calcium Carbonate Precipitated in Aqueous Solutions of Magnesium and Sulfate Salts. Soil Sci. Soc. Am. J. 1969, 33, 690–693. [Google Scholar] [CrossRef]

- Chandra, A.; Ravi, K. Effect of Magnesium Incorporation in Enzyme-Induced Carbonate Precipitation (EICP) to Improve Shear Strength of Soil. In Lecture Notes in Civil Engineering; Springer: Singapore, 2020; Volume 56, pp. 333–346. [Google Scholar]

- Xia, H.; Zhou, M.; Wei, X.; Zhang, X.; Wu, Z. Slow and Sustained Release of Carbonate Ions from Amino Acids for Controlled Hydrothermal Growth of Alkaline-Earth Carbonate Single Crystals. ACS Omega 2020, 5, 14123–14132. [Google Scholar] [CrossRef]

- Wang, Y.; Mao, X.; Xiao, W.; Wang, W. The Influence Mechanism of Magnesium Ions on the Morphology and Crystal Structure of Magnetized Anti-Scaling Products. Minerals 2020, 10, 997. [Google Scholar] [CrossRef]

- Xu, X.; Guo, H.; Cheng, X.; Li, M. The promotion of magnesium ions on aragonite precipitation in MICP process. Constr. Build. Mater. 2020, 263, 120057. [Google Scholar] [CrossRef]

- Sun, X.; Miao, L.; Wu, L.; Wang, C. Study of magnesium precipitation based on biocementation. Mar. Georesources Geotechnol. 2019, 37, 1257–1266. [Google Scholar] [CrossRef]

- Nayanthara, P.G.N.; Dassanayake, A.B.N.; Nakashima, K.; Kawasaki, S. Microbial Induced Carbonate Precipitation Using a Native Inland Bacterium for Beach Sand Stabilization in Nearshore Areas. Appl. Sci. 2019, 9, 3201. [Google Scholar] [CrossRef]

- Arab, M.G.; Rohy, H.; Zeiada, W.; Almajed, A.; Omar, M. One-Phase EICP Biotreatment of Sand Exposed to Various Environmental Conditions. J. Mater. Civ. Eng. 2021, 33, 04020489. [Google Scholar] [CrossRef]

- Sulistiawati Baiq, H. Examination Of Calcite Precipitation Using Plant-Derived Urease Enzyme For Soil Improvement. Int. J. GEOMATE 2020, 19. [Google Scholar] [CrossRef]

- Cuccurullo, A.; Gallipoli, D.; Bruno, A.W.; Augarde, C.; Hughes, P.; La Borderie, C. Earth stabilisation via carbonate precipitation by plant-derived urease for building applications. Geomech. Energy Environ. 2020, 100230. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).