Dispersion Diagram of Trigonal Piezoelectric Phononic Structures with Langasite Inclusions

Abstract

1. Introduction

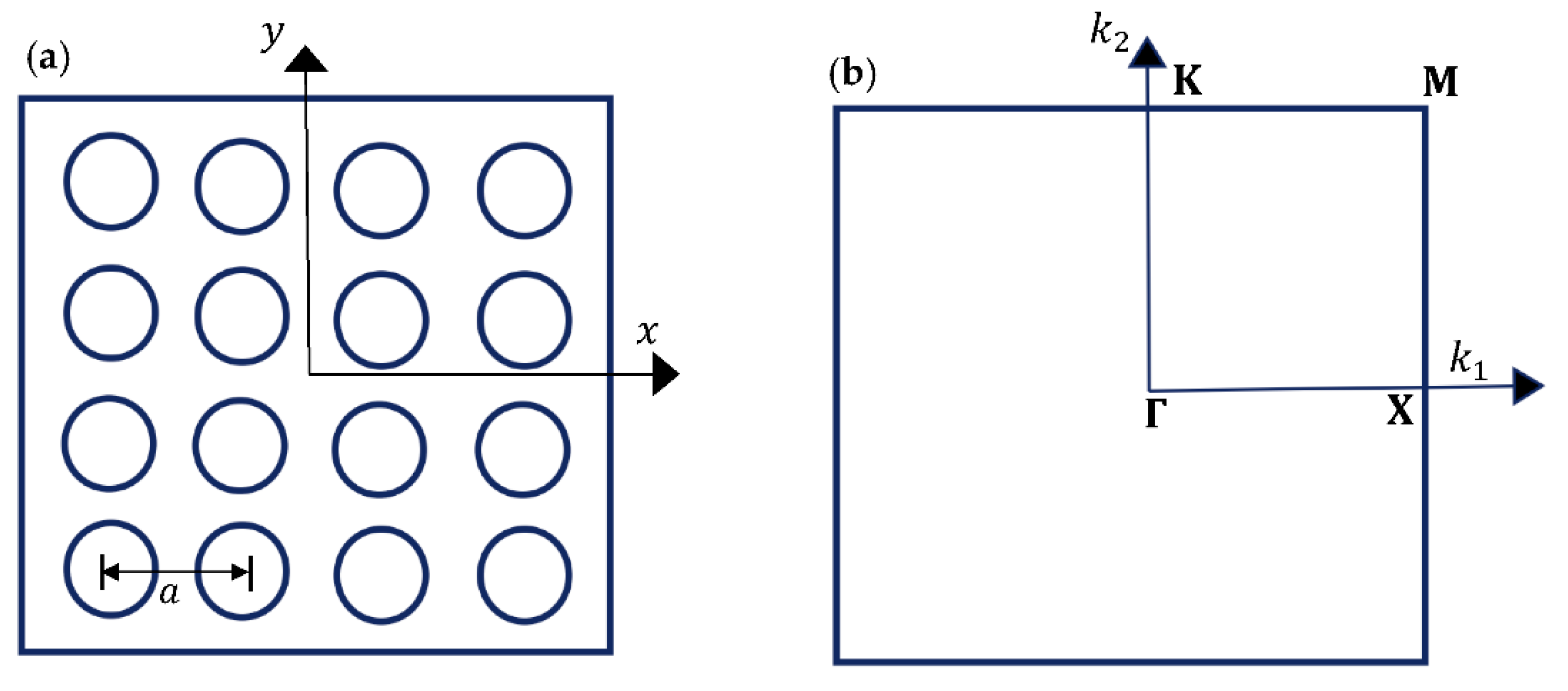

2. Langasite Phononic Structure Modelling

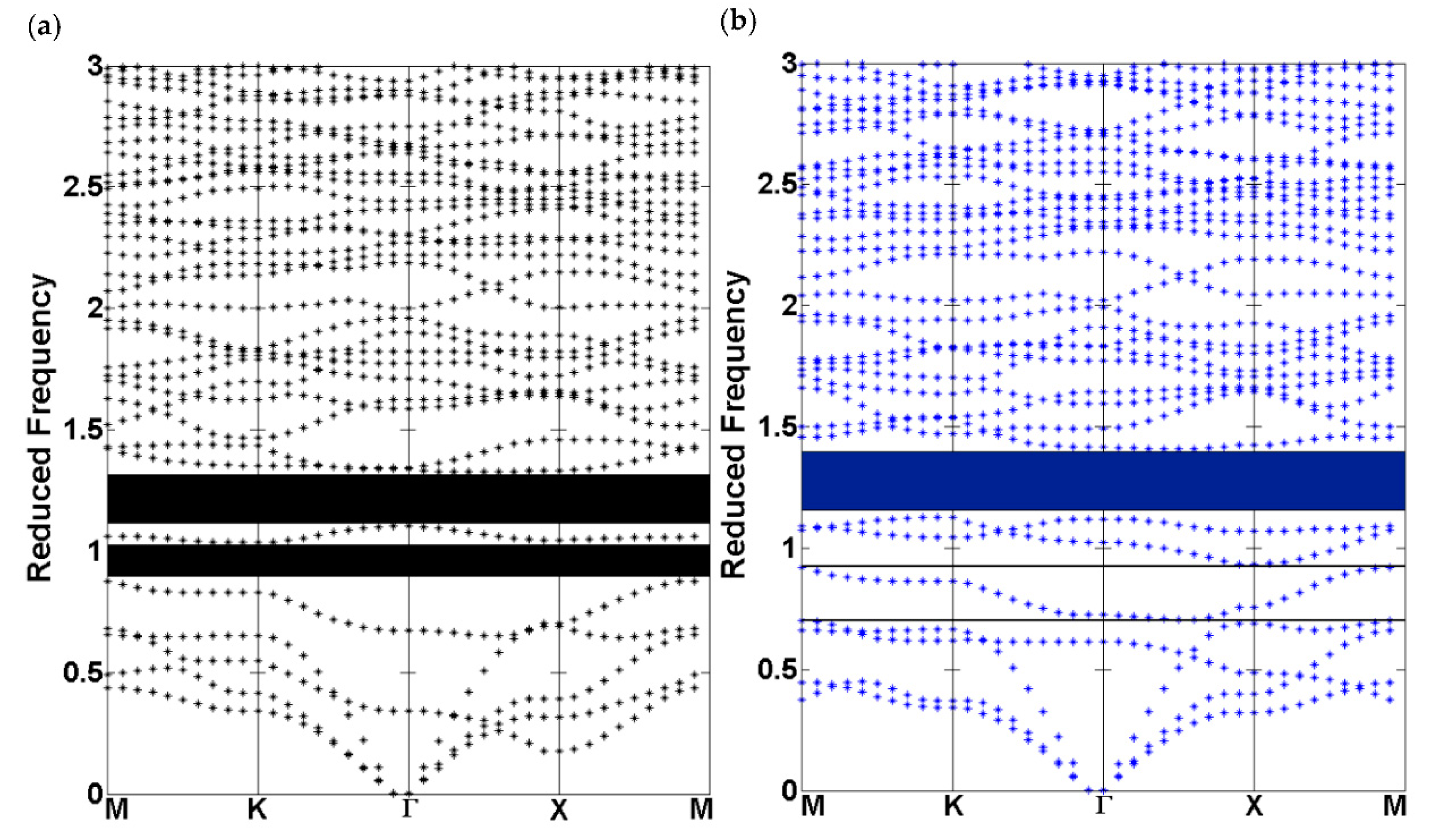

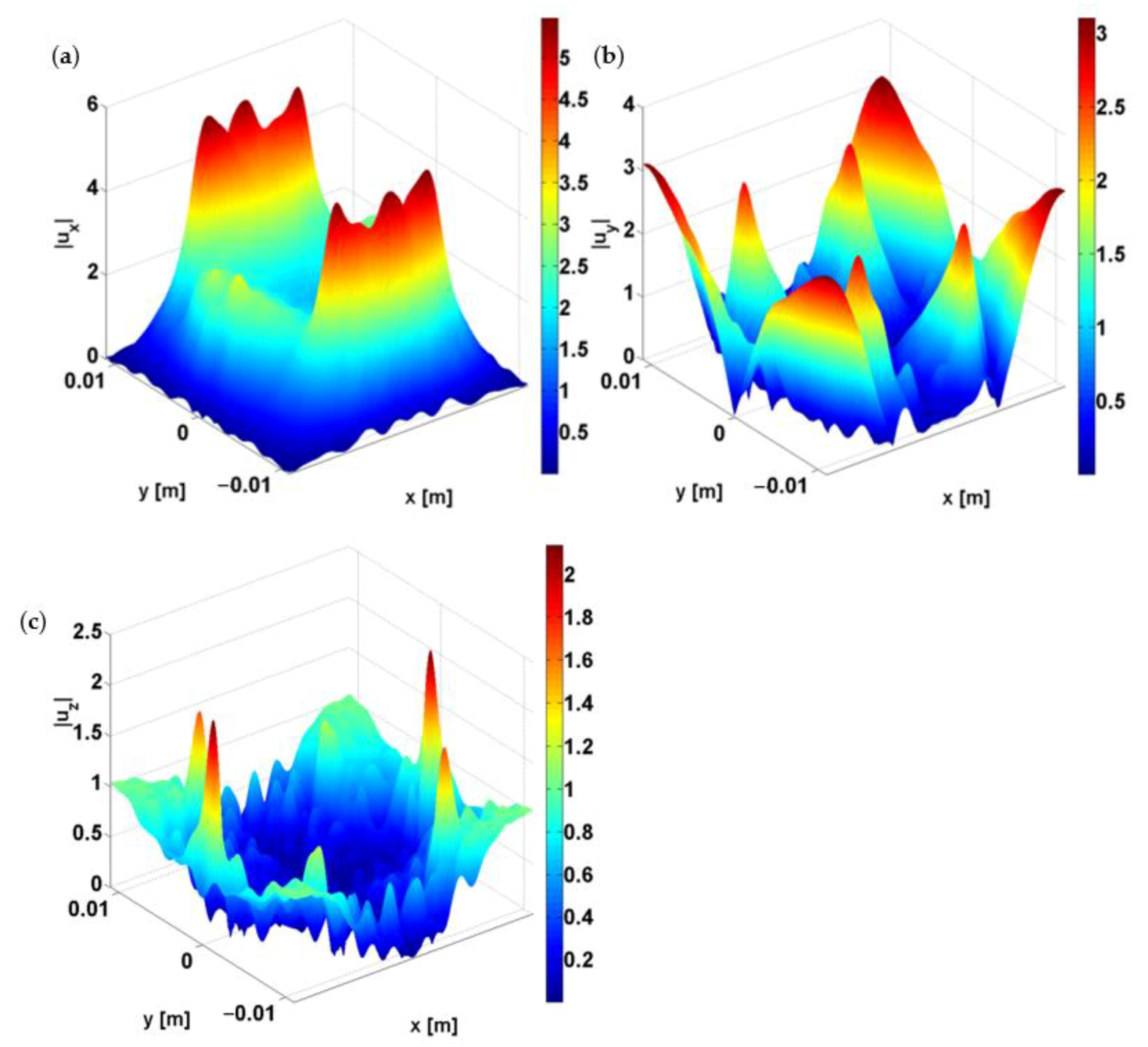

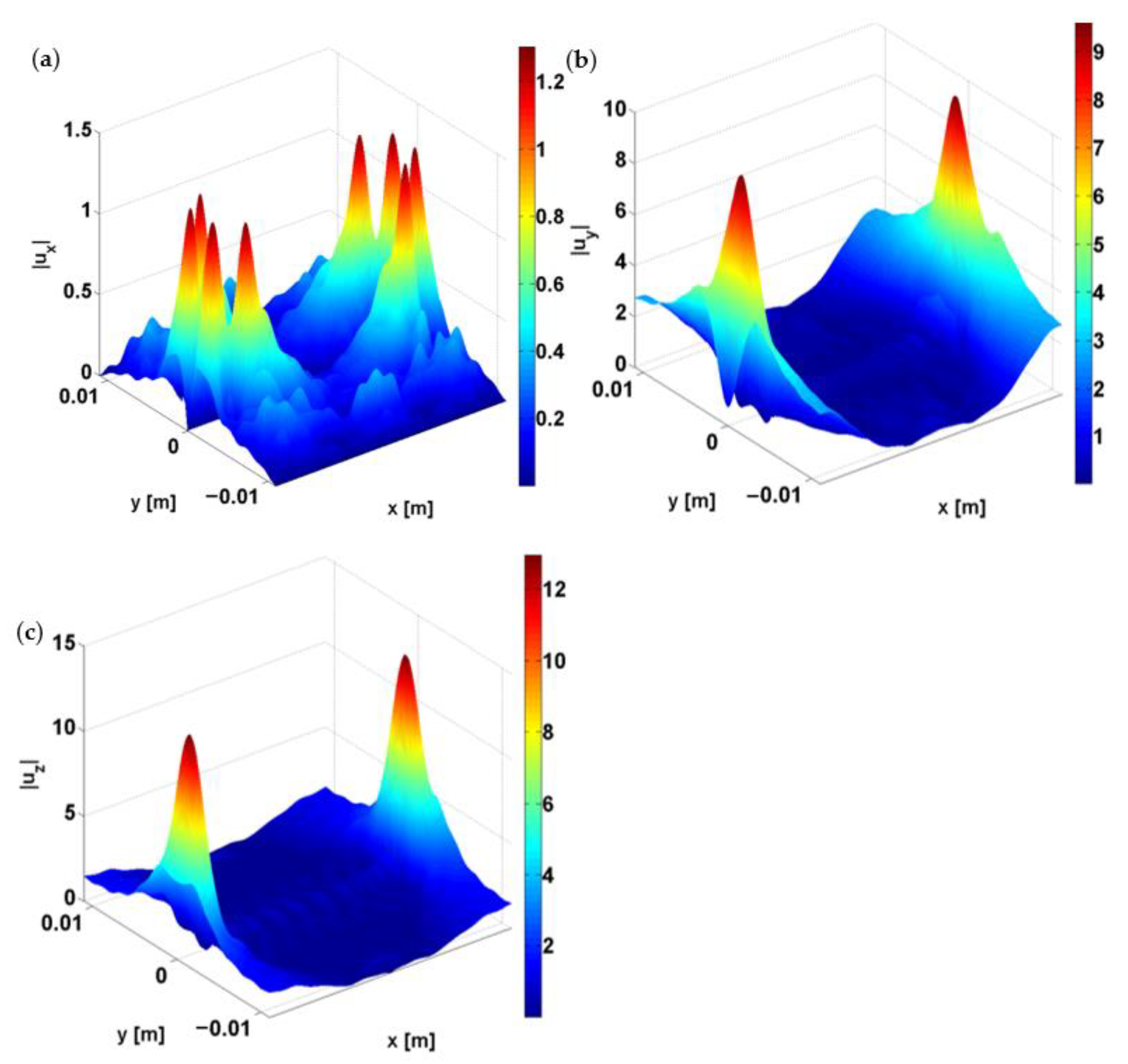

3. Simulated Examples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kushwaha, M.S.; Halevi, P.; Dobrzynski, L.; Djafari-Rouhani, B. Acoustic band structure of periodic elastic composites. Phys. Rev. Lett. 1993, 71, 2022–2025. [Google Scholar] [CrossRef]

- Dal Poggetto, V.F.; Serpa, A.L. Flexural wave band gaps in a ternary periodic metamaterial plate using the plane wave expansion method. J. Sound Vib. 2021, 495, 115909. [Google Scholar] [CrossRef]

- Chen, Y.; Meng, F.; Huang, X. Creating acoustic topological insulators through topology optimization. Mech. Syst. Signal. Process. 2021, 146, 107054. [Google Scholar] [CrossRef]

- Tang, L.; Cheng, L. Impaired sound radiation in plates with periodic tunneled Acoustic Black Holes. Mech. Syst. Signal. Process. 2020, 135, 106410. [Google Scholar] [CrossRef]

- Qian, D. Bandgap properties of a piezoelectric phononic crystal nanobeam based on nonlocal theory. J. Mater. Sci. 2019, 54, 4038–4048. [Google Scholar] [CrossRef]

- Miranda, E.J.P., Jr.; Dos Santos, J.M.C. Band structure in carbon nanostructure phononic crystals. Mat. Res. 2017, 20 (Suppl. 1), 555–571. [Google Scholar] [CrossRef]

- Jo, S.-H.; Yoon, H.; Shin, Y.C.; Youn, B.D. A graded phononic crystal with decoupled double defects for broadband energy localization. Int. J. Mech. Sci. 2020, 183, 105833. [Google Scholar] [CrossRef]

- Gupta, M.; Ruzzene, M. Dynamics of quasiperiodic beams. Crystals 2020, 10, 1144. [Google Scholar] [CrossRef]

- Sharma, G.S.; Skvortsov, A.; MacGillivray, I.; Kessissoglou, N. Acoustic performance of periodic steel cylinders embedded in a viscoelastic medium. J. Sound Vib. 2019, 443, 652–665. [Google Scholar] [CrossRef]

- Sharma, G.S.; Skvortsov, A.; MacGillivray, I.; Kessissoglou, N. Sound scattering by a bubble metasurface. Phys. Rev. B 2020, 102, 214308. [Google Scholar] [CrossRef]

- Sharma, G.S.; Skvortsov, A.; MacGillivray, I.; Kessissoglou, N. On superscattering of sound waves by a lattice of disk-shaped cavities in a soft material. Appl. Phys. Lett. 2020, 116, 041602. [Google Scholar] [CrossRef]

- Wilm, M.; Ballandras, S.; Laude, V.; Pastureaud, T. A full 3D plane-wave-expansion model for 1-3 piezoelectric composite structures. J. Acoust. Soc. Am. 2002, 112, 943–952. [Google Scholar] [CrossRef] [PubMed]

- Miranda, E.J.P., Jr.; Dos Santos, J.M.C. Complete band gaps in nano-piezoelectric phononic crystals. Mat. Res. 2017, 20 (Suppl. 1), 15–38. [Google Scholar] [CrossRef]

- Sugino, C.; Ruzzene, M.; Erturk, A. An analytical framework for locally resonant piezoelectric metamaterial plates. Int. J. Solids Struct. 2020, 182–183, 281–294. [Google Scholar] [CrossRef]

- Robillard, J.-F.; Bou Matar, O.; Vasseur, J.O.; Deymier, P.A.; Stippinger, M.; Hladky-Hennion, A.-C.; Pennec, Y.; Djafari-Rouhani, B. Tunable magnetoelastic phononic crystals. Appl. Phys. Lett. 2009, 95, 124104. [Google Scholar] [CrossRef]

- Wang, Y.-Z.; Li, F.-M.; Huang, W.-H.; Jiang, X.; Wang, Y.-S.; Kishimoto, K. Wave band gaps in two-dimensional piezoelectric/piezomagnetic phononic crystals. Int. J. Solids Struct. 2008, 45, 4203–4210. [Google Scholar] [CrossRef]

- Miranda, E.J.P., Jr.; Dos Santos, J.M.C. Evanescent Bloch waves and complex band structure in magnetoelectroelastic phononic crystals. Mech. Syst. Signal. Pr. 2018, 112, 280–304. [Google Scholar] [CrossRef]

- Miranda, E.J.P., Jr.; Rodrigues, S.F.; Aranas, C., Jr.; Silva, H.V.C.; Silva, E.S.; Reis, G.S.; Paiva, A.E.M.; Dos Santos, J.M.C. Modelling propagating Bloch waves in magnetoelectroelastic phononic structures with Kagomé lattice using the improved plane wave expansion. Crystals 2020, 10, 586. [Google Scholar] [CrossRef]

- Ronda, S.; Aragón, J.L.; Iglesias, E.; Espinosa, F.M. The use of phononic crystals to design piezoelectric power transducers. Sensors 2017, 17, 729. [Google Scholar] [CrossRef]

- Ronda, S.; Espinosa, F.M. Design of piezoelectric piston-like piezoelectric transducers based on a phononic crystal. Adv. Appl. Ceram. 2017, 117, 177–181. [Google Scholar] [CrossRef]

- Yenuganti, S.; Zhang, H.; Zhang, C. Langasite crystal based pressure sensor with temperature compensation. Sensor Actuat. A Phys. 2018, 281, 108–116. [Google Scholar] [CrossRef]

- Beli, A.J.; Comyn, T.P.; Stevenson, T.J. Expanding the application space for piezoelectric materials. APL Mater. 2021, 9, 010901. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Yu, F.; Jiang, X.; Lee, H.-Y.; Luo, J.; Shrout, T.R. Recent developments in piezoelectric crystals. J. Korean Ceram. Soc. 2018, 55, 419–439. [Google Scholar] [CrossRef]

- Zhang, H.; Turner, J.A.; Yang, J.; Kosinski, J.A. Electroelastic effect of thickness mode Langasite resonators. IEEE T Ultrason. Ferr. 2007, 54, 2120–2128. [Google Scholar] [CrossRef] [PubMed]

- Choi, G.; Yong, Y.-K. Langatate and Langasite microacoustic gyro sensors. IEEE Int. Ultrason. Symp. 2014, 54, 1480–1483. [Google Scholar]

- Heywang, W.; Lubitz, K.; Wersing, W. Piezoelectricity: Evolution and Future of a Technology, 1st ed.; Springer Series in Materials Science: Oldenburg, Germany, 2008. [Google Scholar]

- Cao, Y.; Hou, Z.; Liu, Y. Convergence problem of plane-wave expansion method for phononic crystals. Phys. Lett. A. 2004, 327, 247–253. [Google Scholar] [CrossRef]

- Xie, L.; Xia, B.; Liu, J.; Huang, G.; Lei, J. An improved fast plane wave expansion method for topology optimization of phononic crystals. Int. J. Mech. Sci. 2017, 120, 171–181. [Google Scholar] [CrossRef]

- Dal Poggetto, V.F.; Serpa, A.L. Elastic wave band gaps in a three-dimensional periodic metamaterial using the plane wave expansion method. Int. J. Mech. Sci. 2020, 184, 105841. [Google Scholar] [CrossRef]

- Ballato, A. Piezoelectricity: Old effect, new thrusts. IEEE T Ultrason. Ferr. 1995, 42, 916–925. [Google Scholar] [CrossRef]

- Wilm, M.; Khelif, A.; Ballandras, S.; Laude, V.; Djafari-Rouhani, B. Out-of-plane propagation of elastic waves in two-dimensional phononic band-gap materials. Phys. Rev. E 2003, 67, 065602(R). [Google Scholar] [CrossRef]

- Lin, S.-C.S.; Huang, T.J. Tunable phononic crystals with anisotropic inclusions. Phys. Rev. B 2011, 83, 174303. [Google Scholar] [CrossRef]

- Sharma, G.S.; Eggler, D.; Peters, H.; Kessissoglou, N.; Skvortsov, A.; MacGillivry, I. Acoustic performance of periodic composite materials. In Proceedings of the Acoustics 2015 Hunter Valley, NSW Hunter Valley, Australia, 15–18 November 2015. [Google Scholar]

- Van Dyke, K.S. Matrices of piezoelectric, elastic, and dielectric constants. J. Acoust. Soc. Am. 1950, 22, 681. [Google Scholar] [CrossRef]

- Schnepp, Z.; Mitchells, J.; Mann, S.; Hall, S.R. Biopolymer-mediated synthesis of anisotropic piezoelectric nanorods. Chem. Commun. 2010, 46, 4887–4889. [Google Scholar] [CrossRef]

- Gissibl, T.; Thiele, S.; Herkommer, A.; Giessen, H. Two-photon direct laser writing of ultracompact multi-lens objectives. Nat. Photonics. 2016, 10, 554–561. [Google Scholar] [CrossRef]

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast laser processing of materials: From science to industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef]

- Cui, H.; Hensleigh, R.; Chen, H.; Zheng, X. Additive Manufacturing and size-dependent mechanical properties of three-dimensional microarchitected, high-temperature ceramic metamaterials. J. Mater. Sci. 2018, 33, 360–371. [Google Scholar] [CrossRef]

- Surjadi, J.U.; Gao, L.; Du, H.; Li, X.; Xiong, X.; Fang, N.X.; Lu, Y. Mechanical metamaterials and their engineering applications. Adv. Eng. Mater. 2019, 21, 1800864. [Google Scholar] [CrossRef]

- Bohm, J.; Heimann, R.B.; Hengst, M.; Roewer, R.; Schindler, J. Czochralski growth and characterization of piezoelectric single crystals with langasite structure: La3Ga5SiO14 (LGS), La3Ga5.5Nb0.5O14 (LGN), and La3Ga5.5Ta0.5O14 (LGT): Part I. J. Cryst. Growth. 1999, 204, 128–136. [Google Scholar] [CrossRef]

- Bohm, J.; Chilla, E.; Flannery, C.; Flöhlich, H.-J.; Hauke, T.; Heimann, R.B.; Hengst, M.; Straube, U. Czochralski growth and characterization of piezoelectric single crystals with langasite structure: La3Ga5SiO14 (LGS), La3Ga5.5Nb0.5O14 (LGN), and La3Ga5.5Ta0.5O14 (LGT) Part II. J. Cryst. Growth. 2000, 216, 293–298. [Google Scholar] [CrossRef]

- Zhang, X.; Loiko, P.; Mateos, X.; Serres, J.M.; Ren, J.; Guo, J.; Cheng, R.; Gao, C.; Dong, Q.; Jambunathan, V.; et al. Crystal growth, low-temperature spectroscopy and multi-watt laser operation of Yb:Ca3NbGa3Si2O14. J. Lumin. 2018, 197, 90–97. [Google Scholar] [CrossRef]

- Sharma, G.S.; Faverjon, B.; Dureisseix, D.; Skvortsov, A.; MacGillivray, I.; Audoly, C.; Kessissoglou, N. Acoustic performance of a periodically voided viscoelastic medium with uncertainty in design parameters. J. Vib. Acoust. 2020, 142, 061002. [Google Scholar] [CrossRef]

- Fabro, A.T.; Meng, H.; Chronopoulos, D. Uncertainties in the attenuation performance of a multi-frequency metastructure from additive manufacturing. Mech. Syst. Signal. Pr. 2020, 138, 106557. [Google Scholar] [CrossRef]

- Hou, Z.; Wu, F.; Liu, Y. Phononic crystals containing piezoelectric material. Solid State Commun. 2004, 130, 745–749. [Google Scholar] [CrossRef]

- Zouari, S.; Brocail, J.; Génevaux, J.-M. Flexural wave band gaps in metamaterial plates: A numerical and experimental study from infinite to finite models. J. Sound Vib. 2018, 435, 246–263. [Google Scholar] [CrossRef]

| Geometry/Property | Value |

|---|---|

| 0.022 m | |

| 0.5 | |

| ) | 5739 kg/m3, 1150 kg/m3 |

| 188.49 × 109 N/m2, 7.8 × 109 N/m2 | |

| 104.07 × 109 N/m2, 4.7 × 109 N/m2 | |

| 14.15 × 109 N/m2, 0 N/m2 | |

| 53.71 × 109 N/m2, 1.6 × 109 N/m2 | |

| 42.21 × 109 N/m2, 1.55 × 109 N/m2 | |

| −0.402 C/m2, 0 C/m2 | |

| 0.13 C/m2, 0 C/m2 | |

| 0.1737 × 10−9 C2/Nm2, 0.0398 × 10−9 C2/Nm2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miranda, E.; Aranas, C.; Rodrigues, S.; Silva, H.; Reis, G.; Paiva, A.; Dos Santos, J. Dispersion Diagram of Trigonal Piezoelectric Phononic Structures with Langasite Inclusions. Crystals 2021, 11, 491. https://doi.org/10.3390/cryst11050491

Miranda E, Aranas C, Rodrigues S, Silva H, Reis G, Paiva A, Dos Santos J. Dispersion Diagram of Trigonal Piezoelectric Phononic Structures with Langasite Inclusions. Crystals. 2021; 11(5):491. https://doi.org/10.3390/cryst11050491

Chicago/Turabian StyleMiranda, Edson, Clodualdo Aranas, Samuel Rodrigues, Hélio Silva, Gedeon Reis, Antônio Paiva, and José Dos Santos. 2021. "Dispersion Diagram of Trigonal Piezoelectric Phononic Structures with Langasite Inclusions" Crystals 11, no. 5: 491. https://doi.org/10.3390/cryst11050491

APA StyleMiranda, E., Aranas, C., Rodrigues, S., Silva, H., Reis, G., Paiva, A., & Dos Santos, J. (2021). Dispersion Diagram of Trigonal Piezoelectric Phononic Structures with Langasite Inclusions. Crystals, 11(5), 491. https://doi.org/10.3390/cryst11050491