Combinatorial Materials Design Approach to Investigate Adhesion Layer Chemistry for Optimal Interfacial Adhesion Strength

Abstract

:1. Introduction

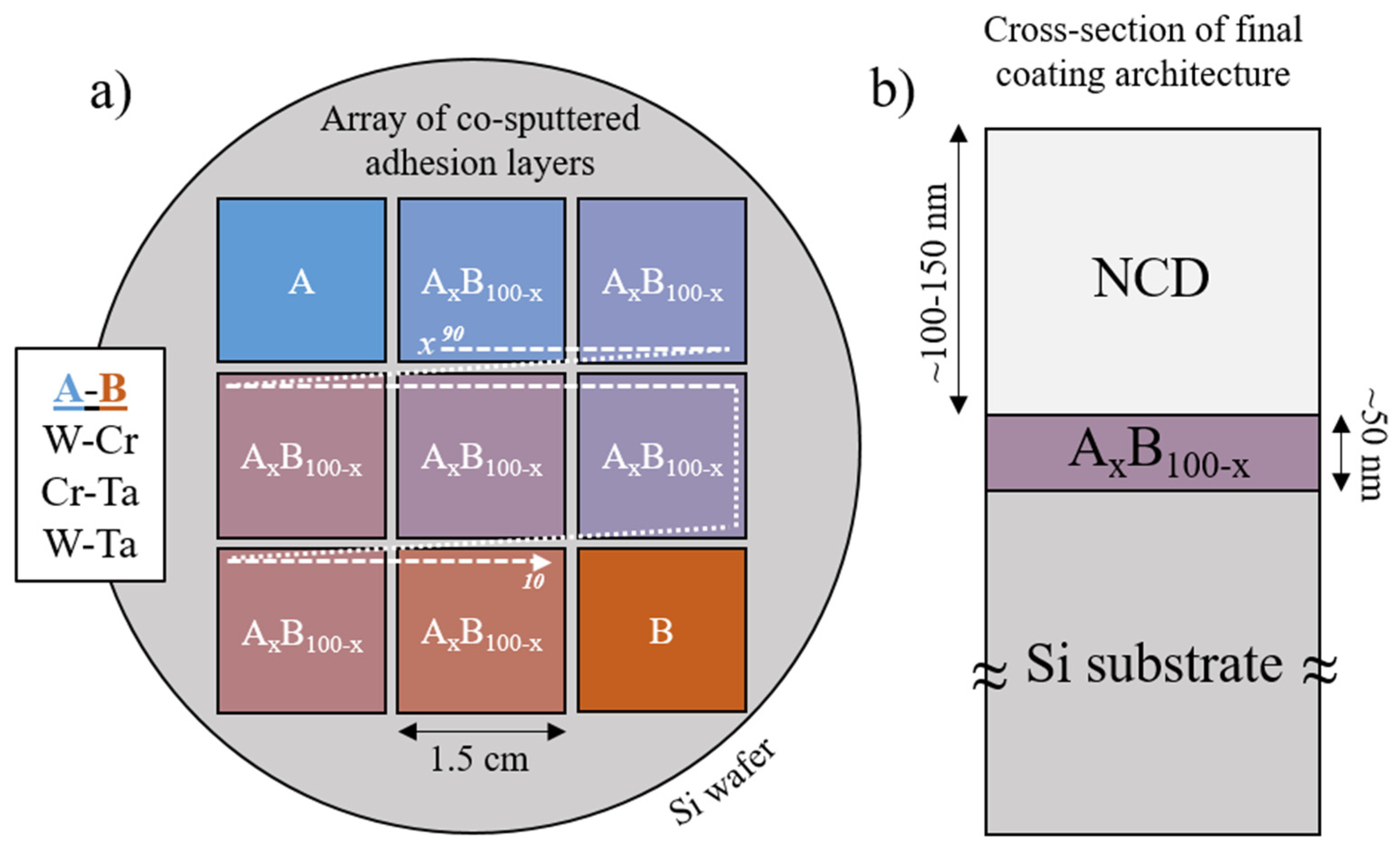

2. Materials and Methods

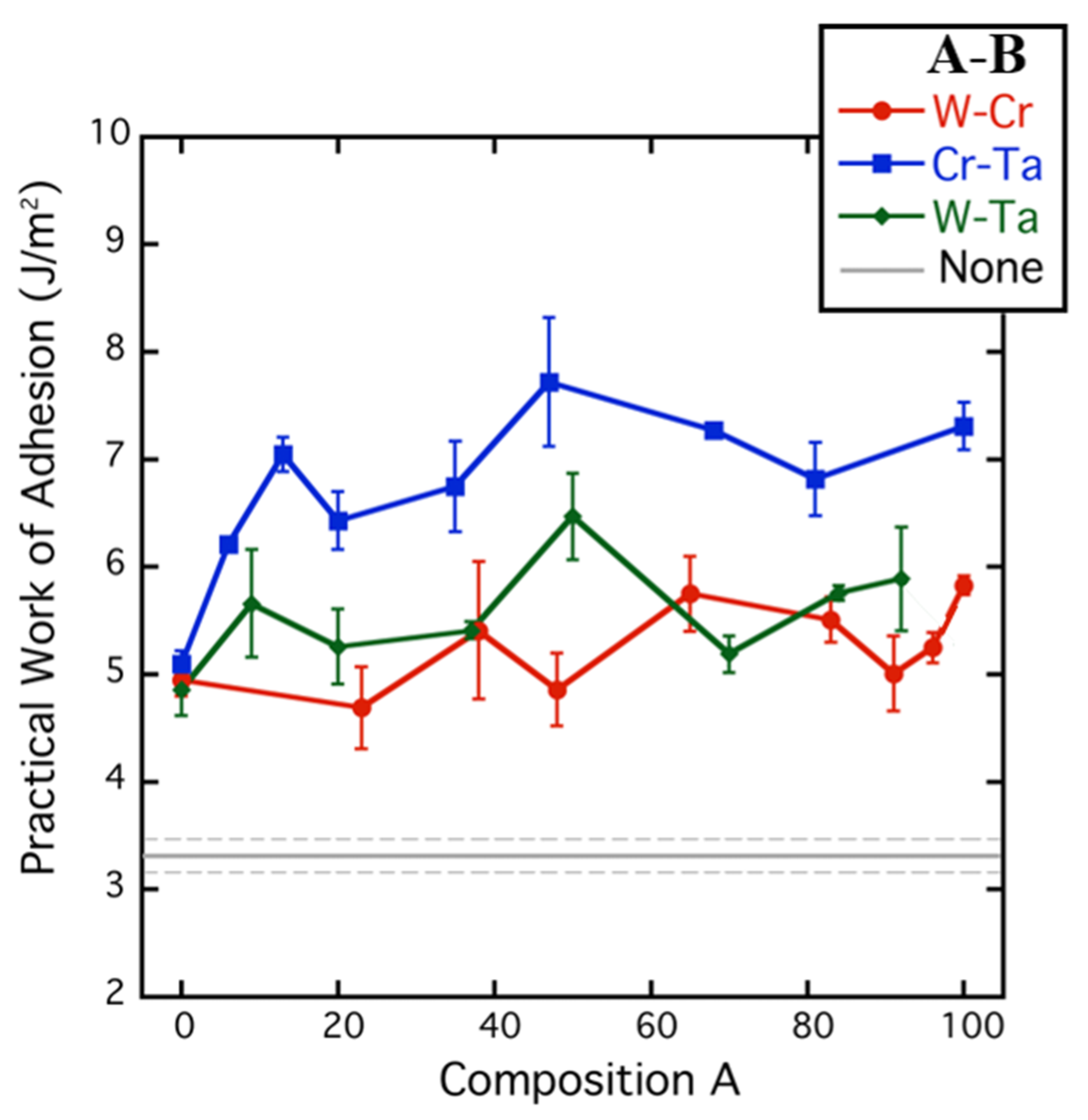

2.1. Calculation of Practical Work of Adhesion from Critical Load

2.2. Experimental Details

3. Results

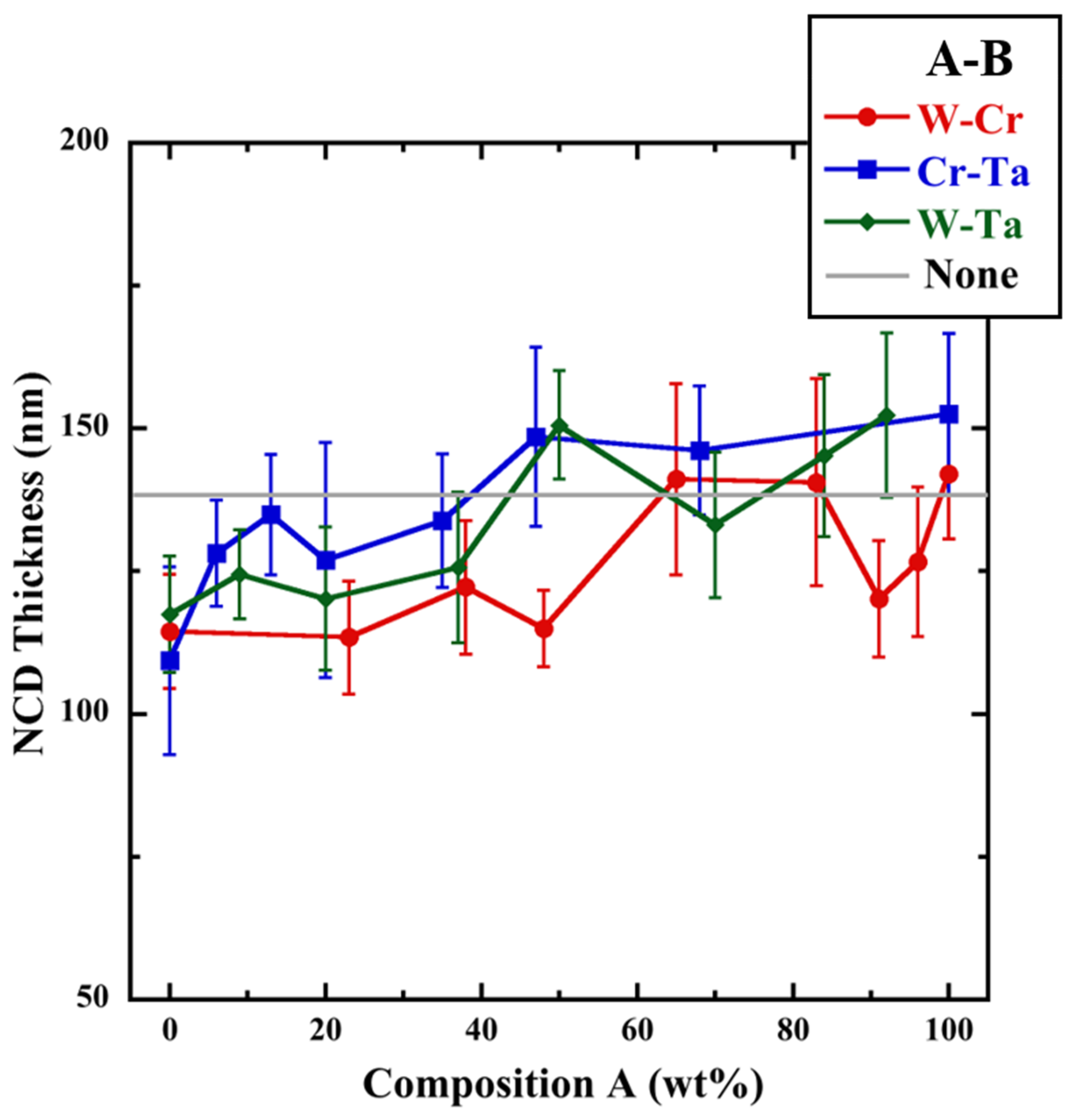

3.1. NCD Microstructure

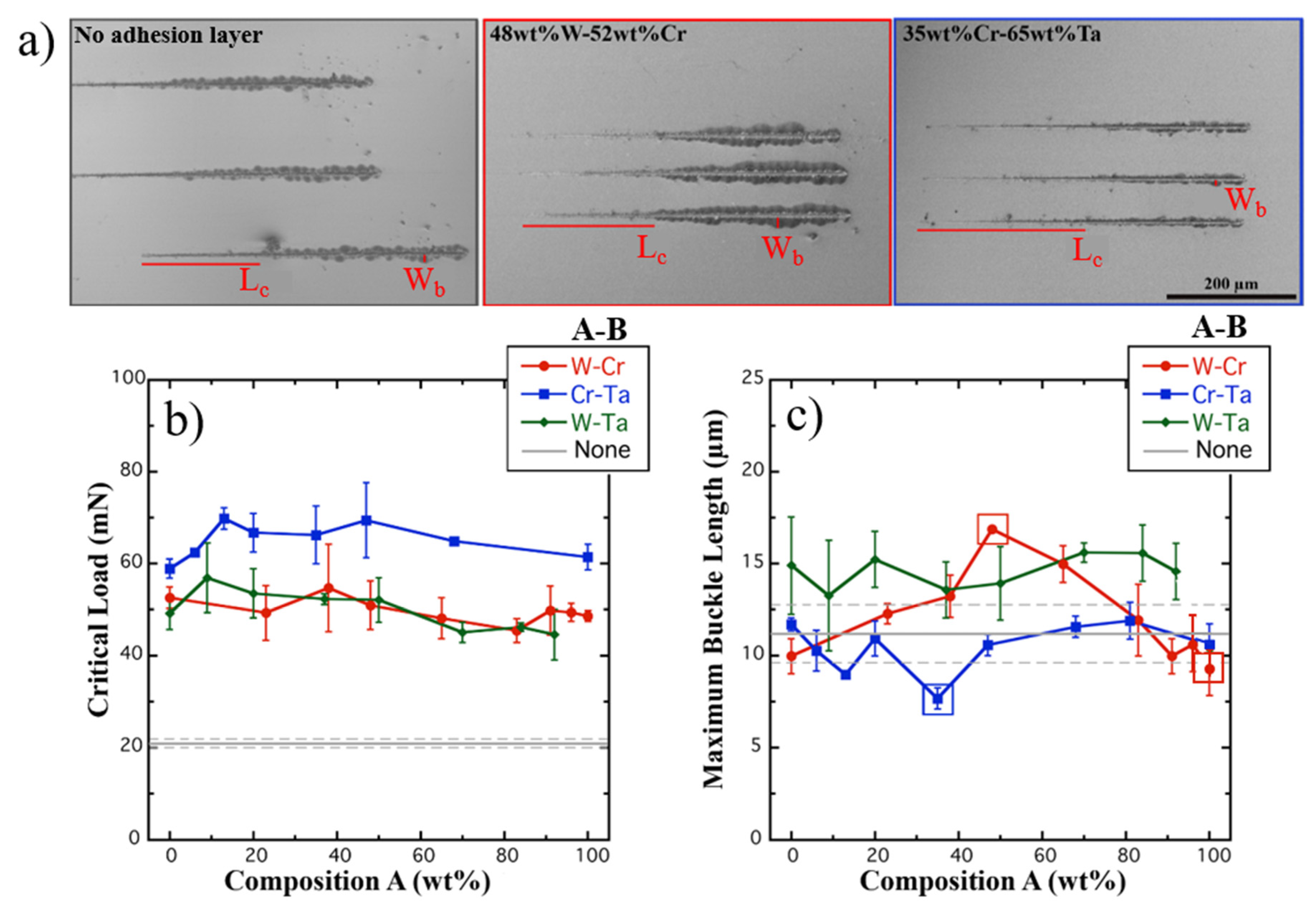

3.2. Scratch Testing: Critical Load and Buckle Length

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ludwig, A. Discovery of new materials using combinatorial synthesis and high-throughput characterization of thin-film materials libraries combined with computational methods. NPJ Comput. Mater. 2019, 5. [Google Scholar] [CrossRef]

- Alberi, K.; Nardelli, M.B.; Zakutayev, A.; Mitas, L.; Curtarolo, S.; Jain, A.; Fornari, M. The 2019 materials by design roadmap. J. Photochem. Photobiol. A Chem. 2019, 52. [Google Scholar] [CrossRef]

- Naujoks, D.; Weiser, M.; Salomon, S.; Stein, H.; Virtanen, S.; Ludwig, A. Combinatorial Study on Phase Formation and Oxidation in the Thin Film Superalloy Subsystems Co–Al–Cr and Co–Al–Cr–W. ACS Comb. Sci. 2018, 20, 611–620. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Liu, Y.; Gong, P.; Li, Y.; Moore, K.M.; Scanley, E.; Walker, F.; Broadbridge, C.C.; Schroers, J. Combinatorial exploration of color in gold-based alloys. Gold Bull. 2015, 48, 111–118. [Google Scholar] [CrossRef] [Green Version]

- Xiang, X. Combinatorial material synthesis and screening: An integrated materials chip approach to discovery and optimization of functional materials. Annu. Rev. Mater. Sci. 1999, 29, 149–171. [Google Scholar] [CrossRef]

- Schoeppner, R.; Ferguson, C.; Pethö, L.; Guerra-Nuñez, C.; Taylor, A.A.; Polyakov, M.; Putz, B.; Breguet, J.-M.; Utke, I.; Michler, J. Interfacial adhesion of alumina thin films over the full compositional range of ternary fcc alloy films: A combinatorial nanoindentation study. Mater. Des. 2020, 193. [Google Scholar] [CrossRef]

- Maier, W.F.; Stowe, K.; Sieg, S. Combinatorial and high-throughput materials science. Angew. Chem. Int. Ed. 2007, 46, 6016–6067. [Google Scholar] [CrossRef]

- Furrer, A.; Spolenak, R. Colors of thin films of binary and ternary gold- and platinum-based alloys. Acta Mater. 2014, 66, 241–250. [Google Scholar] [CrossRef]

- Guerin, S.; Hayden, B.E. Physical vapor deposition method for the high-throughput synthesis of solid-state material libraries. J. Comb. Chem. 2006, 8, 66–73. [Google Scholar] [CrossRef]

- Barber, Z.H.; Blamire, M.G. High Throughput Thin Film Materials Science. Mater. Sci. Technol. 2008, 24, 757–770. [Google Scholar] [CrossRef]

- Evertz, S.; Kirchlechner, I.; Soler, R.; Kirchlechner, C.; Kontis, P.; Bednarcik, J.; Gault, B.; Dehm, G.; Raabe, D.; Schneider, J.M. Electronic structure based design of thin film metallic glasses with superior fracture toughness. Mater. Des. 2020, 186, 108327. [Google Scholar] [CrossRef]

- Rar, A.; Frafjord, J.J.; Fowlkes, J.D.; Specht, E.D.; Rack, P.D.; Santella, M.L.; Bei, H.; George, E.P.; Pharr, G.M. PVD synthesis and high-throughput property characterization of Ni–Fe–Cr alloy libraries. Meas. Sci. Technol. 2005, 16, 46–53. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Liu, Z.; Sohn, S.; Walker, F.J.; Schroers, J.; Ding, S. Combinatorial development of bulk metallic glasses. Nat. Mater. 2014, 13, 494–500. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, K.; Lu, X.; Lam, Y.C. A review on the mechanical methods for evaluating coating adhesion. Acta Mech. 2014, 225, 431–452. [Google Scholar] [CrossRef]

- Mittal, K.L. Adhesion Measurement of Thin Films. Electrocompon. Sci. Technol. 1976, 3, 21–42. [Google Scholar] [CrossRef]

- Cailler, M.; Lee, G.H. Scratch adhesion test of magnetron-sputtered copper coatings on aluminium substrates: Effects of the surface preparation. Thin Solid Film. 1989, 168, 193–205. [Google Scholar] [CrossRef]

- Bull, S.J.; Berasetegui, E.G. An overview of the potential of quantitative coating adhesion measurement by scratch testing. Tribol. Int. 2006, 39, 99–114. [Google Scholar] [CrossRef]

- Perry, A.J. Scratch adhesion testing of hard coatings. Thin Solid Film. 1983, 107, 167–180. [Google Scholar] [CrossRef]

- Bull, S.J. Failure modes in scratch adhesion testing. Surf. Coat. Technol. 1991, 50, 25–32. [Google Scholar] [CrossRef]

- Rabe, R.; Breguet, J.-M.; Schwaller, P.; Stauss, S.; Haug, F.-J.; Patscheider, J.; Michler, J. Observation of fracture and plastic deformation during indentation and scratching inside the scanning electron microscope. Thin Solid Film. 2004, 469–470, 206–213. [Google Scholar] [CrossRef]

- Laugier, M.T. An energy approach to the adhesion of coatings using the scratch test. Thin Solid Film. 1984, 117, 243–249. [Google Scholar] [CrossRef]

- Steinmann, P.A.; Tardy, Y.; Hintermann, H.E.; Diego, S.; Aeronautics, N. Adhesion testing by the scratch test method: The influence of intrinsic and extrinsic parameters on the critical load. Thin Solid Film. 2007, 154, 333–349. [Google Scholar] [CrossRef]

- Malzbender, J.; den Toonder, J.M.J.; Balkenende, A.R.; de With, G. Measuring mechanical properties of coatings: A methodology applied to nano-particle-filled sol-gel coatings on glass. Mater. Sci. Eng. R. Rep. 2002, 36, 47–103. [Google Scholar] [CrossRef]

- Kleinbichler, A.; Pfeifenberger, M.J.; Zechner, J.; Wöhlert, S.; Cordill, M.J. Scratch induced thin film buckling for quantitative adhesion measurements. Mater. Des. 2018, 155, 203–211. [Google Scholar] [CrossRef]

- Amaral, M.; Gomes, P.S.; Lopes, M.A.; Santos, J.D.; Silva, R.F.; Fernandes, M.H. Nanocrystalline diamond as a coating for joint implants: Cytotoxicity and biocompatibility assessment. J. Nanomater. 2008, 2008. [Google Scholar] [CrossRef]

- Mitura, S.; Mitura, A.; Niedzielski, P.; Couvrat, P. Nanocrystalline diamond coatings. Chaos Solitons Fractals 1999, 10, 2165–2176. [Google Scholar] [CrossRef]

- Damm, D.D.; Contin, A.; Barbieri, F.C.; Trava-Airoldi, V.J.; Barquete, D.M.; Corat, E.J. Interlayers applied to CVD diamond deposition on steel substrate: A review. Coatings 2017, 7, 141. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; He, L.; Li, Y.; Yang, Q. Diamond deposition on iron and steel substrates: A review. Micromachines 2020, 11, 719. [Google Scholar] [CrossRef]

- Li, Y.S.; Ye, F.; Corona, J.; Taheri, M.; Zhang, C.; Sanchez-Pasten, M.; Yang, Q. CVD deposition of nanocrystalline diamond coatings on implant alloy materials with CrN/Al interlayer. Surf. Coatings Technol. 2018, 353, 364–369. [Google Scholar] [CrossRef]

- Lu, N.; Wang, X.; Suo, Z.; Vlassak, J. Metal films on polymer substrates stretched beyond 50%. Appl. Phys. Lett. 2007, 91, 2–4. [Google Scholar] [CrossRef]

- Cordill, M.J. Flexible film systems: Current understanding and future prospects. Jom 2010, 62, 9–14. [Google Scholar] [CrossRef]

- Putz, B.; Schoeppner, R.L.; Glushko, O.; Bahr, D.F.; Cordill, M.J. Improved electro-mechanical performance of gold films on polyimide without adhesion layers. Scr. Mater. 2015, 102. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Putz, B.; Glushko, O.; Marx, V.M.; Kirchlechner, C.; Toebbens, D.M.; Cordill, M.J. Electro-mechanical performance of thin gold films on polyimide. MRS Adv. 2016, 773–778. [Google Scholar] [CrossRef]

- Lassnig, A.; Putz, B.; Hirn, S.; Többens, D.M.; Mitterer, C.; Cordill, M.J. Adhesion evaluation of thin films to dielectrics in multilayer stacks: A comparison of four-point bending and stressed overlayer technique. Mater. Des. 2021, 200, 109451. [Google Scholar] [CrossRef]

- Hamilton, G.M.; Goodman, L.E. The stress field created by a circular sliding contact. J. Appl. Mech. 1966, 33, 371–376. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Hopcroft, M.A.; Nix, W.D.; Kenny, T.W. What is the Young’s Modulus of Silicon? J. Microelctromechanical Syst. 2010, 19, 229–238. [Google Scholar] [CrossRef] [Green Version]

- Mehedi, H.A.; Achard, J.; Rats, D.; Brinza, O.; Tallaire, A.; Mille, V.; Silva, F.; Provent, C.; Gicquel, A. Low temperature and large area deposition of nanocrystalline diamond films with distributed antenna array microwave-plasma reactor. Diam. Relat. Mater. 2014, 47, 58–65. [Google Scholar] [CrossRef]

- Antonin, O.; Schoeppner, R.; Gabureac, M.; Pethö, L.; Michler, J.; Raynaud, P.; Nelis, T. Nano crystalline diamond MicroWave Chemical Vapor Deposition growth on three dimension structured silicon substrates at low temperature. Diam. Relat. Mater. 2018, 83, 67–74. [Google Scholar] [CrossRef]

- Rats, D.; Provent, C. Method for a Diamond Vapor Deposition. U.S. Patent 20160032450A1, 4 February 2016. [Google Scholar]

- Latrasse, L.; Radoiu, M.; Nelis, T.; Antonin, O. Self-matching plasma sources using 2.45 GHz solid-state generators: Microwave design and operating performance. J. Microw. Power Electromagn. Energy 2017, 51, 237–258. [Google Scholar] [CrossRef]

- Zhang, J.; Yuan, Y.; Zhang, J. Cutting performance of microcrystalline, nanocrystalline and dual-layer composite diamond coated tools in drilling carbon fiber reinforced plastics. Appl. Sci. 2018, 8, 1642. [Google Scholar] [CrossRef] [Green Version]

- May, P.W.; Ludlow, W.J.; Hannaway, M.; Heard, P.J.; Smith, J.A.; Rosser, K.N. Raman and conductivity studies of boron-doped microcrystalline diamond, facetted nanocrystalline diamond and cauliflower diamond films. Diam. Relat. Mater. 2008, 17, 105–117. [Google Scholar] [CrossRef]

- Nie, A.; Bu, Y.; Li, P.; Zhang, Y.; Jin, T.; Liu, J.; Su, Z.; Wang, Y.; He, J.; Liu, Z.; et al. Approaching diamond’s theoretical elasticity and strength limits. Nat. Commun. 2019, 10. [Google Scholar] [CrossRef] [PubMed]

- Kleinbichler, A.; Zechner, J.; Cordill, M.J. Buckle induced delamination techniques to measure the adhesion of metal dielectric interfaces. Microelectron. Eng. 2017, 167, 63–68. [Google Scholar] [CrossRef]

- Guo, H.; Xiao, X.; Qi, Y.; Xu, Z.H.; Li, X. Enhance diamond coating adhesion by oriented interlayer microcracking. J. Appl. Phys. 2009, 106. [Google Scholar] [CrossRef] [Green Version]

- Hayward, I.P.; Singer, I.L.; Seitzman, L.E. Effect of roughness on the friction of diamond on cvd diamond coatings. Wear 1992, 157, 215–227. [Google Scholar] [CrossRef]

- Azevedo, A.F.; Matsushima, J.T.; Vicentin, F.C.; Baldan, M.R.; Ferreira, N.G. Surface characterization of NCD films as a function of sp2/sp3 carbon and oxygen content. Appl. Surf. Sci. 2009, 255, 6565–6570. [Google Scholar] [CrossRef]

- Cordill, M.J.; Moody, N.R.; Bahr, D.F. The effects of plasticity on adhesion of hard films on ductile interlayers. Acta Mater. 2005, 53, 2555–2562. [Google Scholar] [CrossRef]

- Brady, M.P.; Zhu, J.H.; Liu, C.T.; Tortorelli, P.F.; Walker, L.R. Oxidation resistance and mechanical properties of Laves phase reinforced Cr in-situ composites. Intermetallics 2000, 8, 1111–1118. [Google Scholar] [CrossRef]

- Koch, R. Stress in Evaporated and Sputtered Thin Films—A Comparison. Surf. Coat. Technol. 2010, 204, 1973–1982. [Google Scholar] [CrossRef]

- Hoffman, R.W. Stresses in thin films: The relevance of grain boundaries and impurities. Thin Solid Film. 1976, 34, 185–190. [Google Scholar] [CrossRef]

- Marx, V.M.; Toth, F.; Wiesinger, A.; Berger, J.; Kirchlechner, C.; Cordill, M.J.; Fischer, F.D.; Rammerstorfer, F.G.; Dehm, G. The influence of a brittle Cr interlayer on the deformation behavior of thin Cu films on flexible substrates: Experiment and model. Acta Mater. 2015, 89, 278–289. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, B.; Li, H.; Yu, B.; Huang, N.; Liu, L.; Jiang, X. Deposition of highly adhesive nanocrystalline diamond films on Ti substrates via diamond/SiC composite interlayers. Diam. Relat. Mater. 2020, 108, 107928. [Google Scholar] [CrossRef]

- Diao, D.; Kandori, A. Finite element analysis of the effect of interfacial roughness and adhesion strength on the local delamination of hard coating under sliding contact. Tribol. Int. 2006, 39, 849–855. [Google Scholar] [CrossRef]

- Packham, D.E. Surface energy, surface topography and adhesion. Int. J. Adhes. Adhes. 2003, 23, 437–448. [Google Scholar] [CrossRef] [Green Version]

- Kim, W.-S.; Yun, I.-H.; Lee, J.-J.; Jung, H.-T. Evaluation of mechanical interlock effect on adhesion strength of polymer-metal interfaces using micro-patterned surface topography. Int. J. Adhes. Adhes. 2010, 30, 408–417. [Google Scholar] [CrossRef]

- Lux, B.; Haubner, R. Diamond substrate interactions and the adhesion of diamond coatings. Pure Appl. Chem. 1994, 66, 1783–1788. [Google Scholar] [CrossRef] [Green Version]

- Haubner, R.; Lindlbauer, A.; Lux, B. Diamond deposition on chromium, cobalt and nickel substrates by microwave plasma chemical vapour deposition. Diam. Relat. Mater. 1993, 2, 1505–1515. [Google Scholar] [CrossRef]

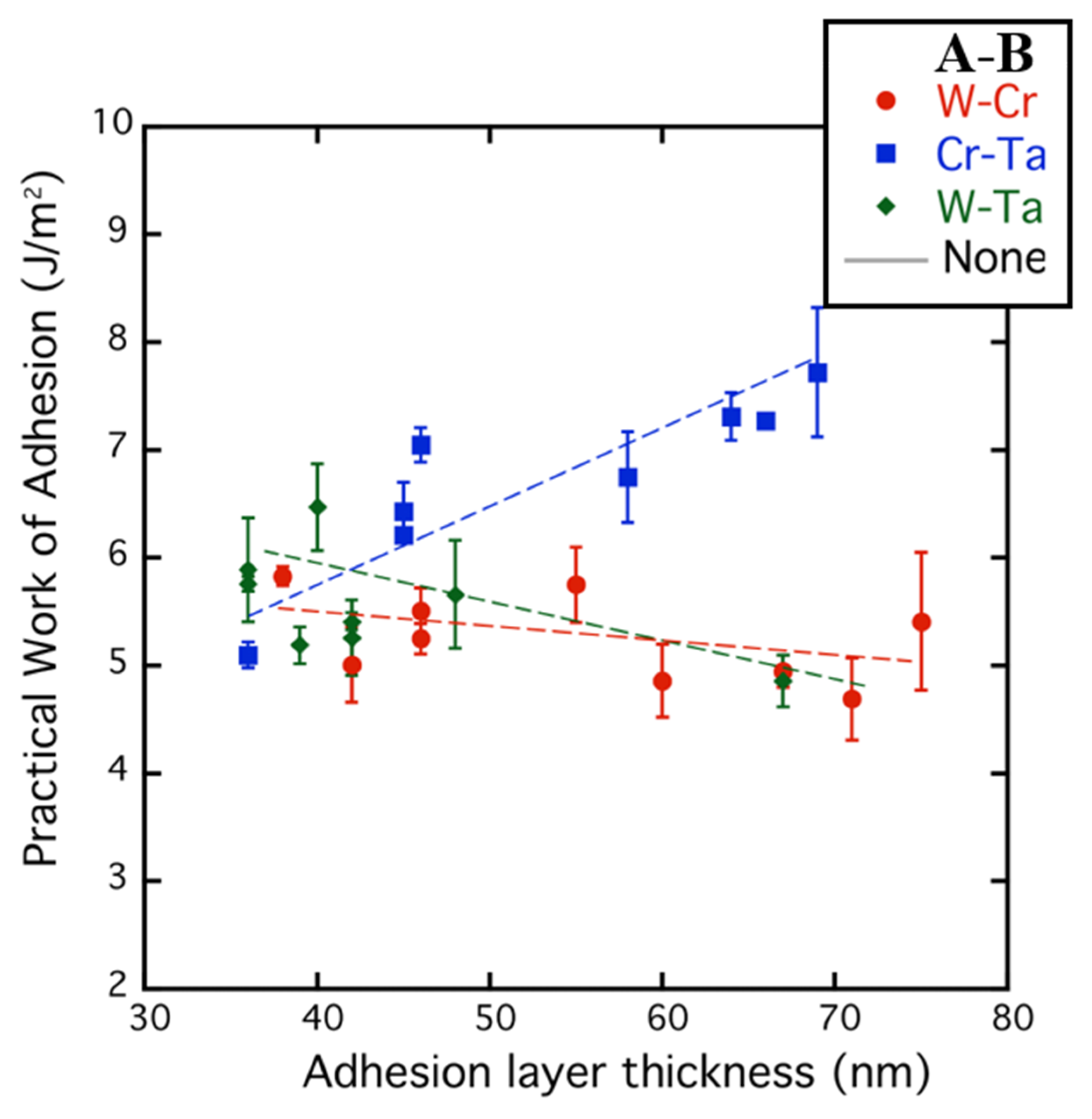

| W–Ta | |||||||||

| Composition (wt%) | 100–0 | 92–8 | 84–16 | 70–30 | 52–48 | 36–64 | 22–78 | 9–91 | 0–100 |

| Thickness (nm) | n/a | 36 | 36 | 39 | 40 | 42 | 42 | 48 | 67 |

| W–Cr | |||||||||

| Composition (wt%) | 100–0 | 94–6 | 91–9 | 83–17 | 65–35 | 48–52 | 38–62 | 23–77 | 0–100 |

| Thickness (nm) | 38 | 46 | 42 | 46 | 55 | 60 | 75 | 71 | 67 |

| Cr–Ta | |||||||||

| Composition (wt%) | 100–0 | 80–20 | 68–32 | 47–53 | 35–65 | 20–80 | 13–87 | 6–94 | 0–100 |

| Thickness (nm) | 64 | n/a | 66 | 69 | 58 | 45 | 46 | 45 | 36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schoeppner, R.L.; Putz, B.; Taylor, A.A.; Pethö, L.; Thomas, K.; Antonin, O.; Nelis, T.; Michler, J. Combinatorial Materials Design Approach to Investigate Adhesion Layer Chemistry for Optimal Interfacial Adhesion Strength. Crystals 2021, 11, 357. https://doi.org/10.3390/cryst11040357

Schoeppner RL, Putz B, Taylor AA, Pethö L, Thomas K, Antonin O, Nelis T, Michler J. Combinatorial Materials Design Approach to Investigate Adhesion Layer Chemistry for Optimal Interfacial Adhesion Strength. Crystals. 2021; 11(4):357. https://doi.org/10.3390/cryst11040357

Chicago/Turabian StyleSchoeppner, Rachel L., Barbara Putz, Aidan A. Taylor, Laszlo Pethö, Keith Thomas, Olivier Antonin, Thomas Nelis, and Johann Michler. 2021. "Combinatorial Materials Design Approach to Investigate Adhesion Layer Chemistry for Optimal Interfacial Adhesion Strength" Crystals 11, no. 4: 357. https://doi.org/10.3390/cryst11040357

APA StyleSchoeppner, R. L., Putz, B., Taylor, A. A., Pethö, L., Thomas, K., Antonin, O., Nelis, T., & Michler, J. (2021). Combinatorial Materials Design Approach to Investigate Adhesion Layer Chemistry for Optimal Interfacial Adhesion Strength. Crystals, 11(4), 357. https://doi.org/10.3390/cryst11040357