Molecular Dynamics Simulation of the Influence of RDX Internal Defects on Sensitivity

Abstract

1. Introduction

2. Materials and Methods

3. Results

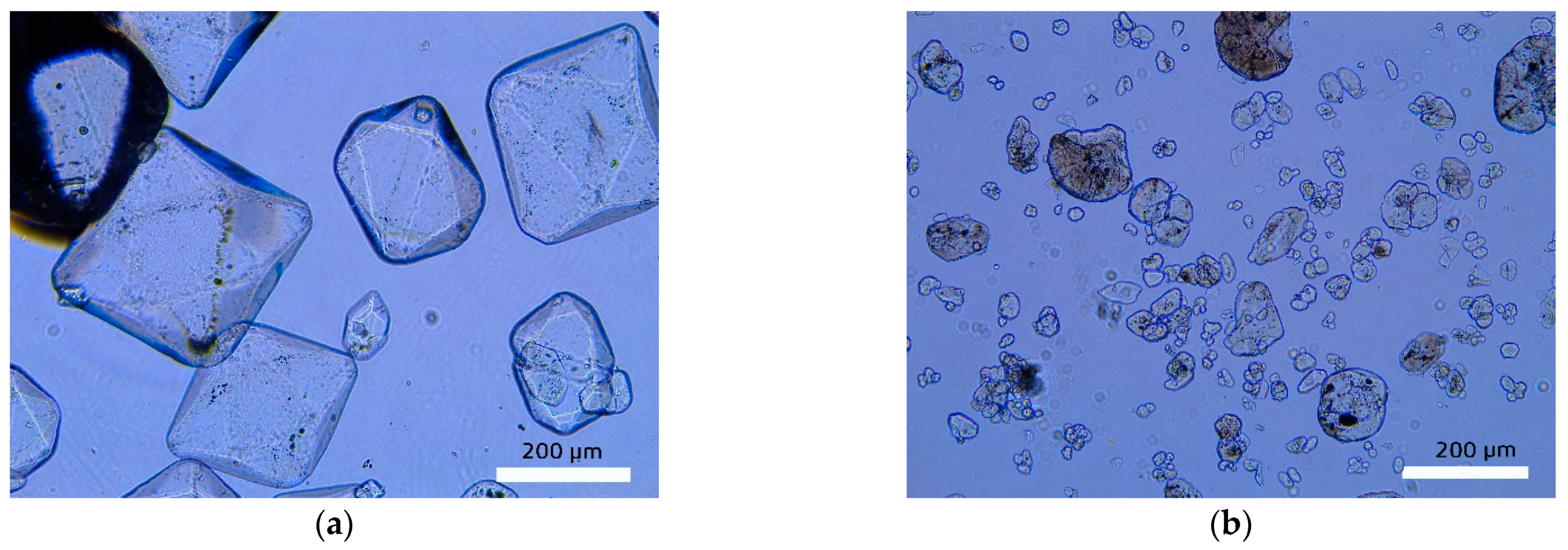

3.1. Optical Refraction Matching

3.2. Raman

3.3. Micro-CT

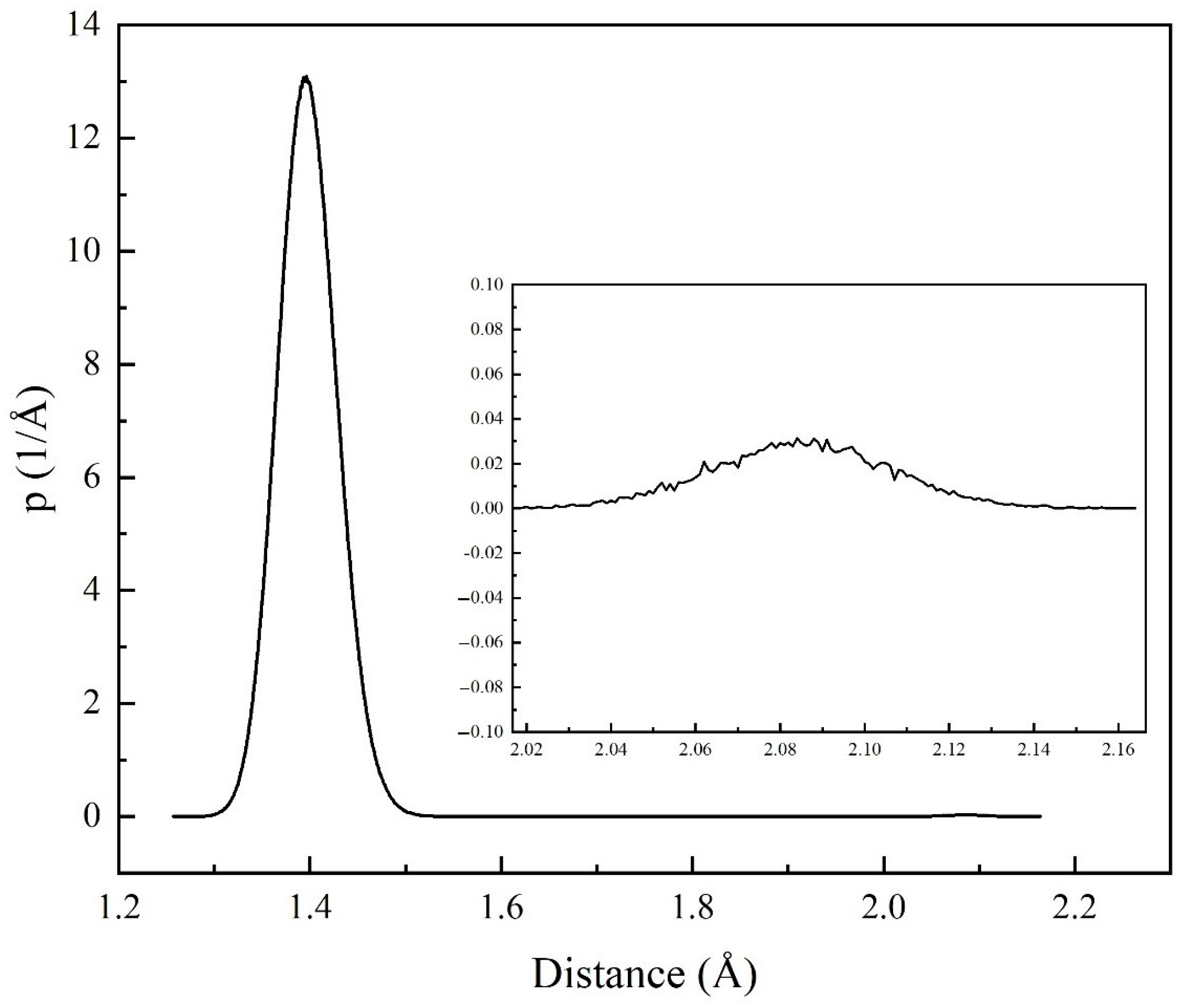

3.4. Molecular Dynamics Simulation

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Campbell, A.W.; Davis, W.C.; Ramsay, J.B.; Travis, J.R. Shock Initiation of Solid Explosives. Phys. Fluids 1961, 4, 511. [Google Scholar] [CrossRef]

- Baillou, F.; Dartyge, J.; Pyckerelle, C.; Mala, J. Influence of Crystal Defects on Sensitivity of Explosives. In Proceedings of the 10th Symposium (International) on Detonation, Boston, MA, USA, 12–16 July 1993. [Google Scholar]

- Choi, C.S.; Boutin, H.P. A Study of the Crystal Structure of β-cyclotetramethylene Tetranitramine by Neutron Diffraction. Acta Crystallogr. Sect. B 1970, 26, 1235–1240. [Google Scholar] [CrossRef]

- Klapotke, T.M. Energetic Materials Encyclopedia; De Gruyter: Berlin, Germany, 2018. [Google Scholar]

- Herrmann, M.; Förter-Barth, U.; Bohn, M.A.; Borne, L. Aging of Standard and Insensitive RDX Crystals Investigated by Means of X-ray Diffraction. Propellants Explos. Pyrotech. 2017, 42, 724–727. [Google Scholar] [CrossRef]

- Borne, L.; Patedoye, J.C.; Spyckerelle, C. Quantitative Characterization of Internal Defects in RDX Crystals. Propellants Explos. Pyrotech. 1999, 24, 255–259. [Google Scholar] [CrossRef]

- McGrane, S.D.; Grieco, A.; Ramos, K.J.; Hooks, D.E.; Moore, D.S. Femtosecond Micromachining of Internal Voids in High Explosive Crystals for Studies of Hot Spot Initiation. J. Appl. Phys. 2009, 105, 073505. [Google Scholar] [CrossRef]

- Hua, C.; Zhang, P.-J.; Lu, X.-J.; Huang, M.; Dai, B.; Fu, H. Research on the Size of Defects inside RDX/HMX Crystal and Shock Sensitivity. Propellants Explos. Pyrotech. 2013, 38, 775–780. [Google Scholar] [CrossRef]

- Cao, X.; Duan, X.; Pei, C. Study on Crystallization Kinetics and the Crystal Internal Defects of HMX. Cryst. Res. Technol. 2013, 48, 29–37. [Google Scholar] [CrossRef]

- Bouma, R.H.; Duvalois, W.; Van der Heijden, A.E. Microscopic Characterization of Defect Structure in RDX Crystals. J. Microsc. 2013, 252, 263–274. [Google Scholar] [CrossRef]

- Qi, C.B.; Wang, T.; Miao, S.; Wang, Y.L.; Hang, G.Y. Molecular Dynamics Research on Effect of Doping Defects on Properties of PETN. J. Mol. Model. 2019, 25, 287. [Google Scholar] [CrossRef]

- Sabatini, J.; Oyler, K. Recent Advances in the Synthesis of High Explosive Materials. Crystals 2015, 6, 5. [Google Scholar] [CrossRef]

- Liu, Y.; Niu, S.; Lai, W.; Yu, T.; Ma, Y.; Gao, H.; Zhao, F.; Ge, Z. Crystal Morphology Prediction of Energetic Materials Grown from Solution: Insights into the Accurate Calculation of Attachment Energies. CrystEngComm 2019, 21, 4910–4917. [Google Scholar] [CrossRef]

- Pereverzev, A.; Sewell, T. Elastic Coefficients of β-HMX as Functions of Pressure and Temperature from Molecular Dynamics. Crystals 2020, 10, 1123. [Google Scholar] [CrossRef]

- Song, L.; Zhao, F.-Q.; Xu, S.-Y.; Ju, X.-H. Prediction of Nitroguanidine Crystal Habits in Water and γ-butyrolactone by Spiral Growth Model. J. Energetic Mater. 2020, 38, 348–361. [Google Scholar] [CrossRef]

- Chen, G.; Xia, M.; Lei, W.; Wang, F.; Gong, X. Prediction of Crystal Morphology of Cyclotrimethylene Trinitramine in the Solvent Medium by Computer Simulation: A Case of Cyclohexanone Solvent. J. Phys. Chem. A 2014, 118, 11471–11478. [Google Scholar] [CrossRef] [PubMed]

- Duan, X.; Wei, C.; Liu, Y.; Pei, C. A Molecular Dynamics Simulation of Solvent Effects on the Crystal Morphology of HMX. J. Hazard. Mater. 2010, 174, 175–180. [Google Scholar] [CrossRef]

- Duan, X.H.; Li, W.P.; Pei, C.H.; Zhou, X.Q. Molecular Dynamics Simulations of Void Defects in the Energetic Material HMX. J. Mol. Model. 2013, 19, 3893–3899. [Google Scholar] [CrossRef]

- Choi, C.S.; Prince, E. The Crystal Structure of Cyclotrimethylenetrinitramine. Acta Crystallogr. Sect. B 1972, 28, 2857–2862. [Google Scholar] [CrossRef]

- Sun, H.J. COMPASS: An ab Initio Force-Field Optimized for Condensed-Phase Applications Overview with Details on Alkane and Benzene Compounds. J. Phys. Chem. B 1998, 102, 7338–7364. [Google Scholar] [CrossRef]

- Andersen, H.C. Molecular Dynamics Simulations at Constant Pressure and/or Temperature. J. Chem. Phys. 1980, 72, 2384–2393. [Google Scholar] [CrossRef]

- Parrinello, M.; Rahman, A. Strain Fluctuations and Elastic Constants. J. Chem. Phys. 1982, 76, 2662–2666. [Google Scholar] [CrossRef]

- Zhao, X.X.; Zhang, Y.A. The Critical Initiation Parameters of Hot-spots and Impact Sensitivity of Melt-cast Explosives. Chin. J. Energetic Mater. 2003, 11, 127–129. [Google Scholar]

- Xiao, J.J.; Zhao, L.; Zhu, W.; Chen, J.; Ji, G.F.; Zhao, F.; Wu, Q.; Xiao, H.M. Molecular Dynamics Study on the Relationships of Modeling, Structural and Energy Properties with Sensitivity for RDX-based PBXs. Sci. China Chem. 2012, 55, 2587–2594. [Google Scholar] [CrossRef]

- Qin, J.F.; Zhao, X.; Qian, H.; Rui, J.H. Effect of Crystal Structure of High Density Spherical RDX on Safety Performance of PBX. Acta Armamentarii 2020, 41, 481–487. [Google Scholar]

| Sample | FWHM/cm−1 | RSD/cm−1 |

|---|---|---|

| High-density RDX | 8.26 | 0.010 |

| Raw RDX | 8.31 | 0.016 |

| Grey Value | Pixel Number | Proportion |

|---|---|---|

| (10,20] | 9352 | 6.64% |

| (20,30] | 15,163 | 10.77% |

| (30,40] | 20,737 | 14.73% |

| (40,50] | 35,719 | 25.37% |

| (50,60] | 37,837 | 26.87% |

| (60,70] | 17,953 | 12.75% |

| (70,80] | 3693 | 2.62% |

| (90,100] | 337 | 0.23% |

| (100,110] | 17 | 0.01% |

| (110,120] | 2 | 0.00% |

| Model | Defect Type | Defect Rates | Crystal |

|---|---|---|---|

| (a) | None | 0 | - |

| (b) | Vacancy | 2.78% | Raw RDX |

| (c) | Vacancy | 1.85% | Raw RDX |

| (d) | Vacancy | 1.85% | High density RDX |

| Model | CED/J·cm−3 | Lmax/Å | Activation Bonds Ratio |

|---|---|---|---|

| (a) | 754.5 | 1.563 | 0 |

| (b) | 676.8 | 1.579 | 0.0018‰ |

| (c) | 687.2 | 1.575 | 0.0014‰ |

| (d) | 688.6 | 1.572 | 0.0010‰ |

| Doped Molecular | CED/J·cm−3 | Lmax/Å | Activation Bonds Ratio |

|---|---|---|---|

| H2O | 703.3 | 1.600 | 0.0018‰ |

| cyclohexanone | 692.1 | 1.589 | 0.0015‰ |

| acetone | 564.4 | 1.646 | 0.1191‰ |

| NMP | 695.1 | 1.583 | 0.0012‰ |

| butyrolactone | 693.9 | 1.591 | 0.0014‰ |

| propylene carbonate | 608.5 | 2.162 | 1.5440‰ |

| DMSO | 689.2 | 1.593 | 0.0011‰ |

| DMF | 695.1 | 1.589 | 0.0009‰ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, P.; Zhao, X.; Rui, J.; Zhao, J.; Xu, M.; Zhai, L. Molecular Dynamics Simulation of the Influence of RDX Internal Defects on Sensitivity. Crystals 2021, 11, 329. https://doi.org/10.3390/cryst11040329

Yan P, Zhao X, Rui J, Zhao J, Xu M, Zhai L. Molecular Dynamics Simulation of the Influence of RDX Internal Defects on Sensitivity. Crystals. 2021; 11(4):329. https://doi.org/10.3390/cryst11040329

Chicago/Turabian StyleYan, Pengmin, Xue Zhao, Jiuhou Rui, Juan Zhao, Min Xu, and Lizhe Zhai. 2021. "Molecular Dynamics Simulation of the Influence of RDX Internal Defects on Sensitivity" Crystals 11, no. 4: 329. https://doi.org/10.3390/cryst11040329

APA StyleYan, P., Zhao, X., Rui, J., Zhao, J., Xu, M., & Zhai, L. (2021). Molecular Dynamics Simulation of the Influence of RDX Internal Defects on Sensitivity. Crystals, 11(4), 329. https://doi.org/10.3390/cryst11040329