Improving Compactness of 3D Metallic Microstructures Printed by Laser-Induced Forward Transfer

Abstract

1. Introduction

2. Materials and Methods

3. Results

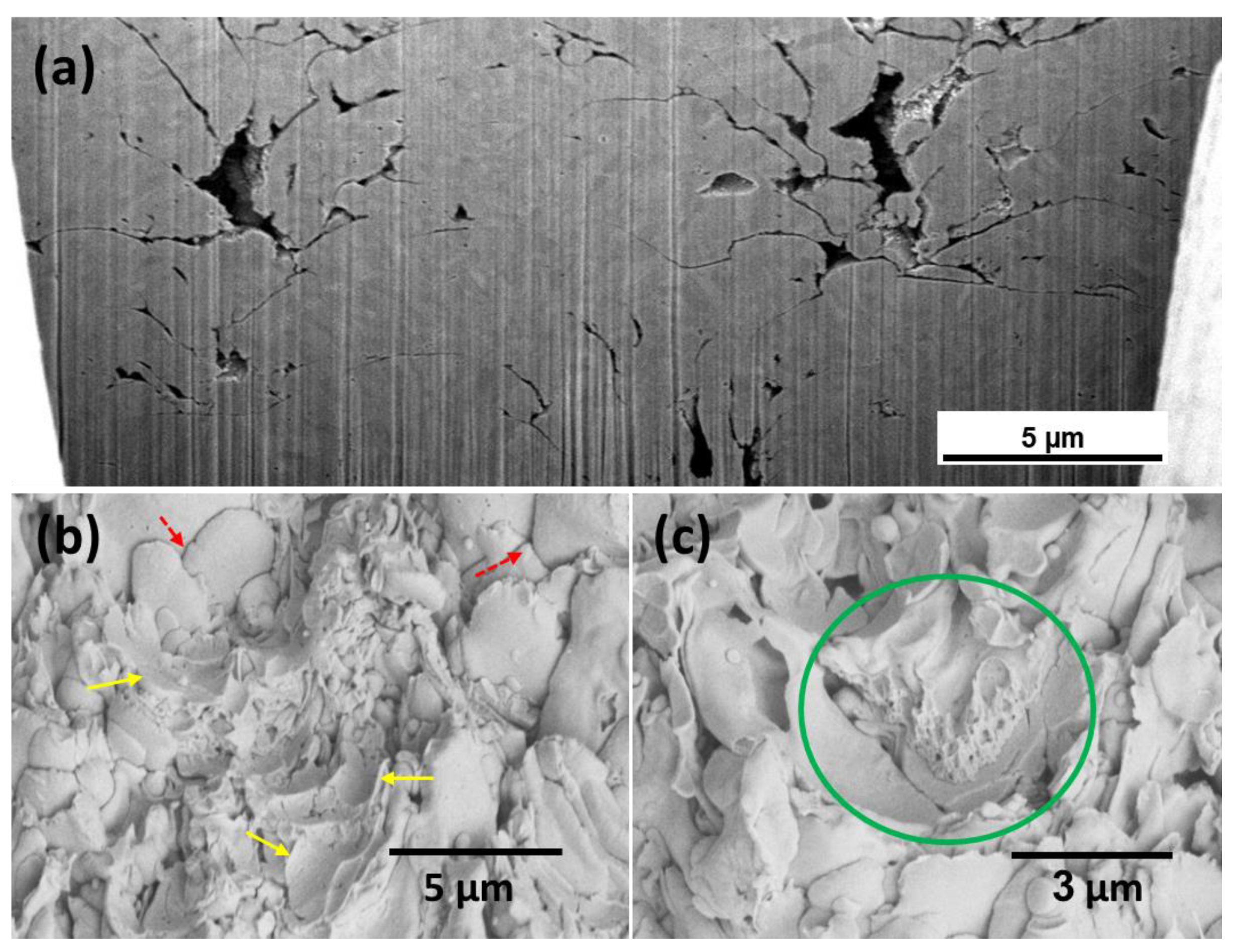

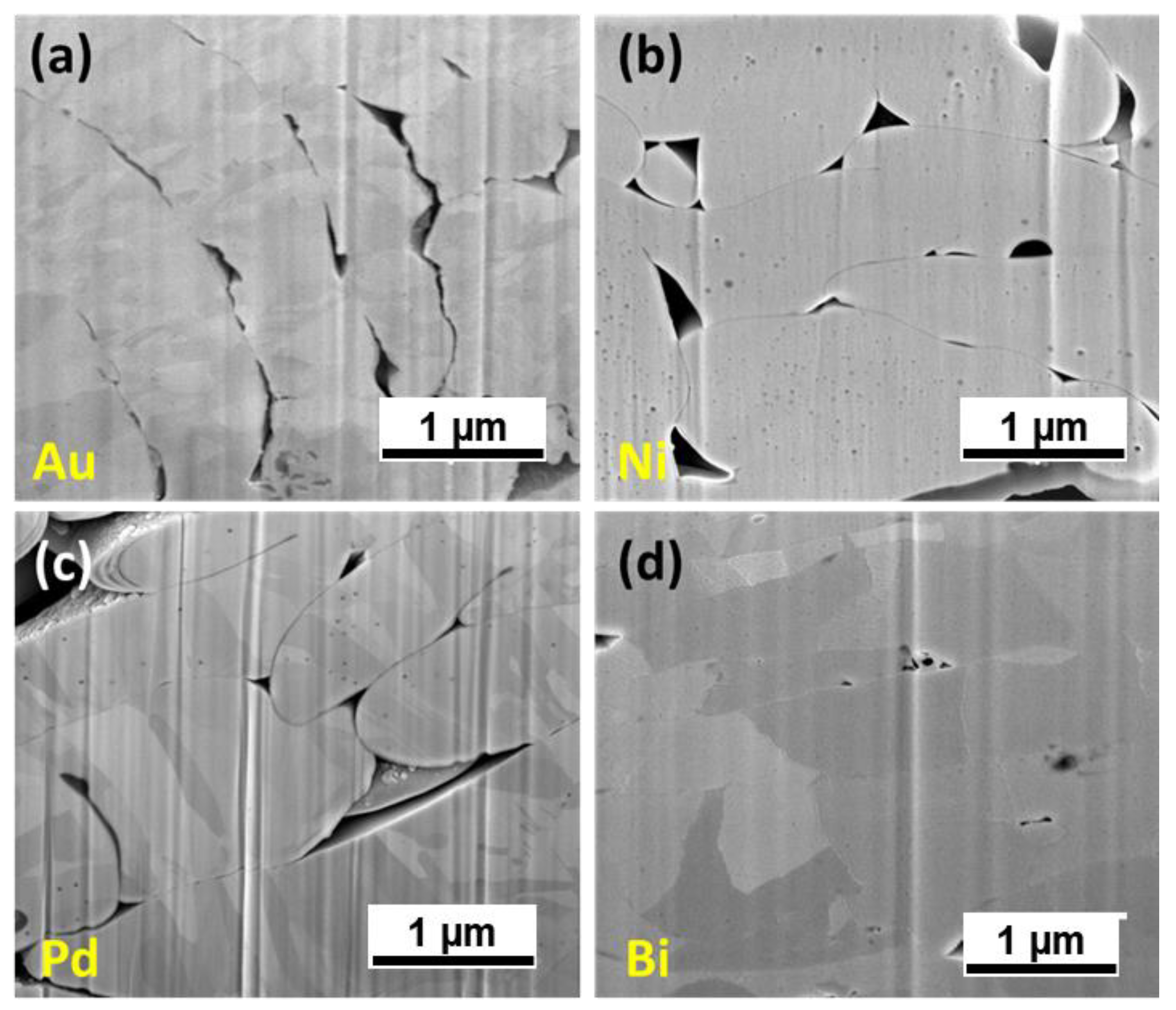

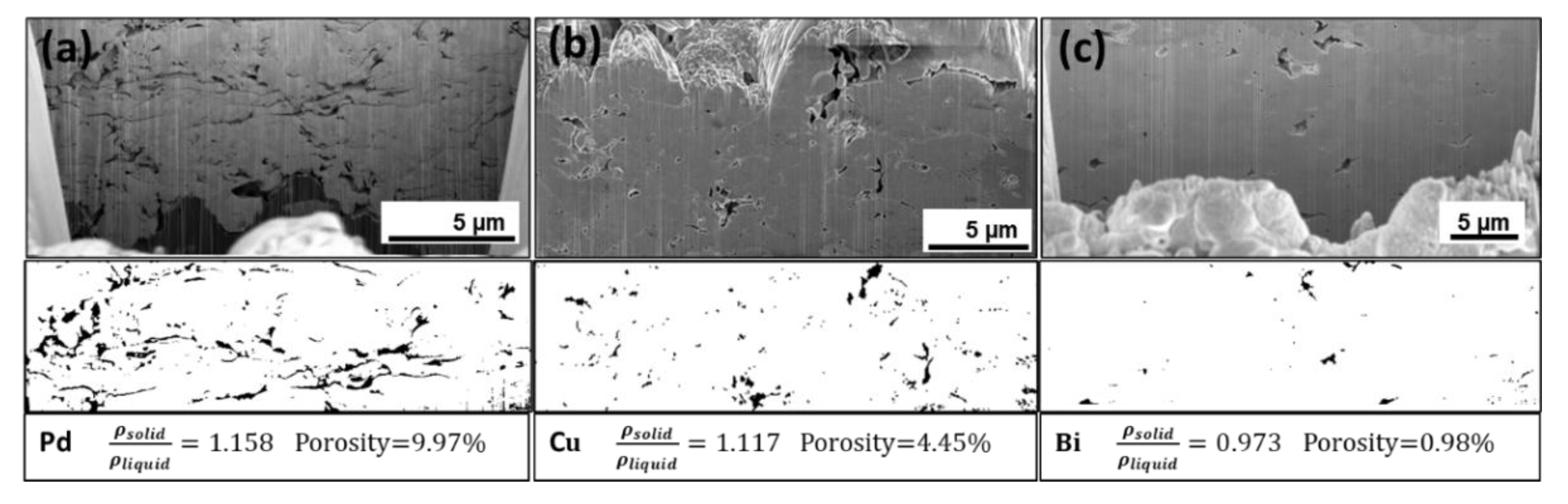

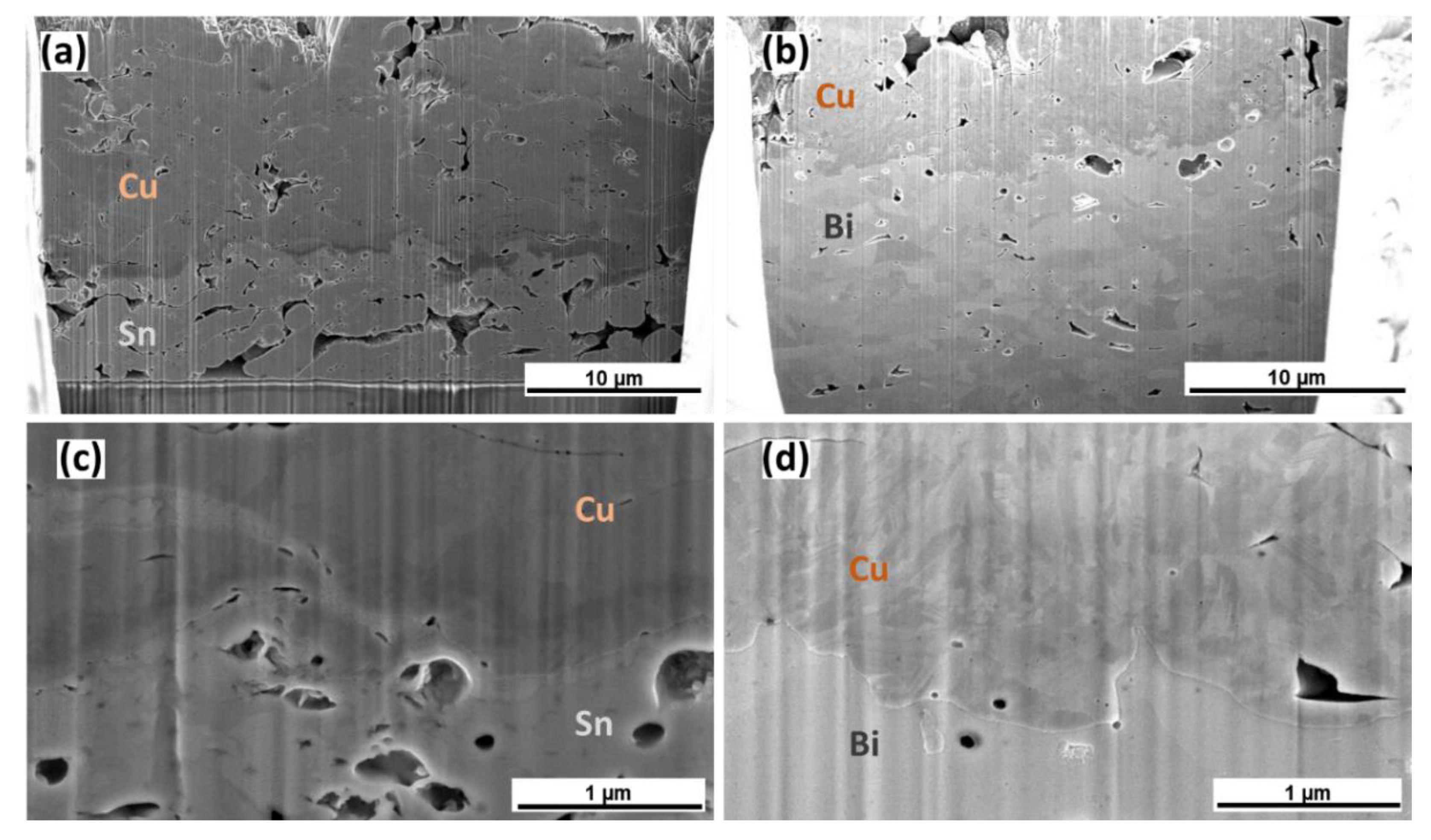

3.1. Voids and Delamination

3.2. Inter-Droplet Melting

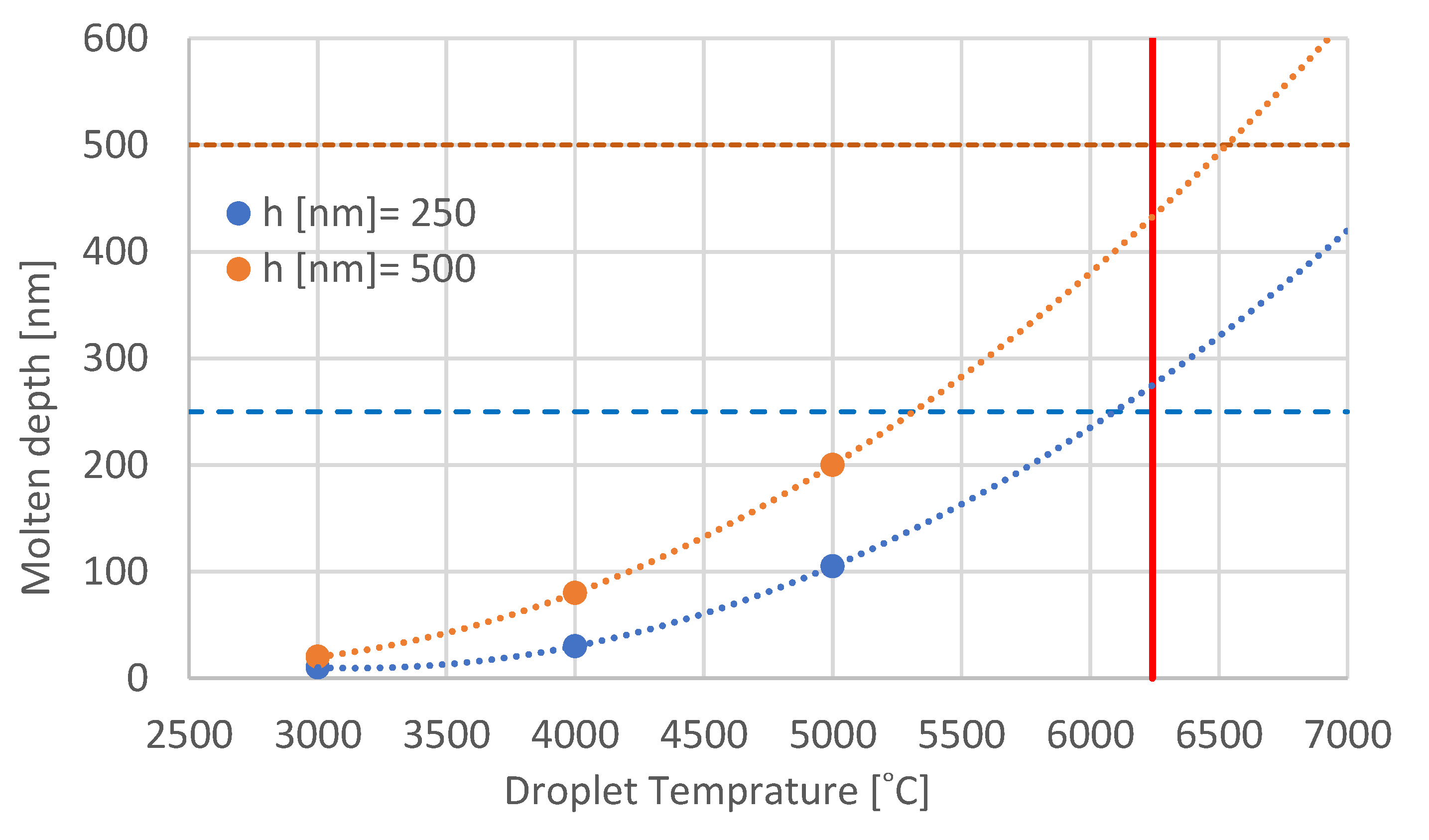

3.2.1. Theory

3.2.2. Experimental Results

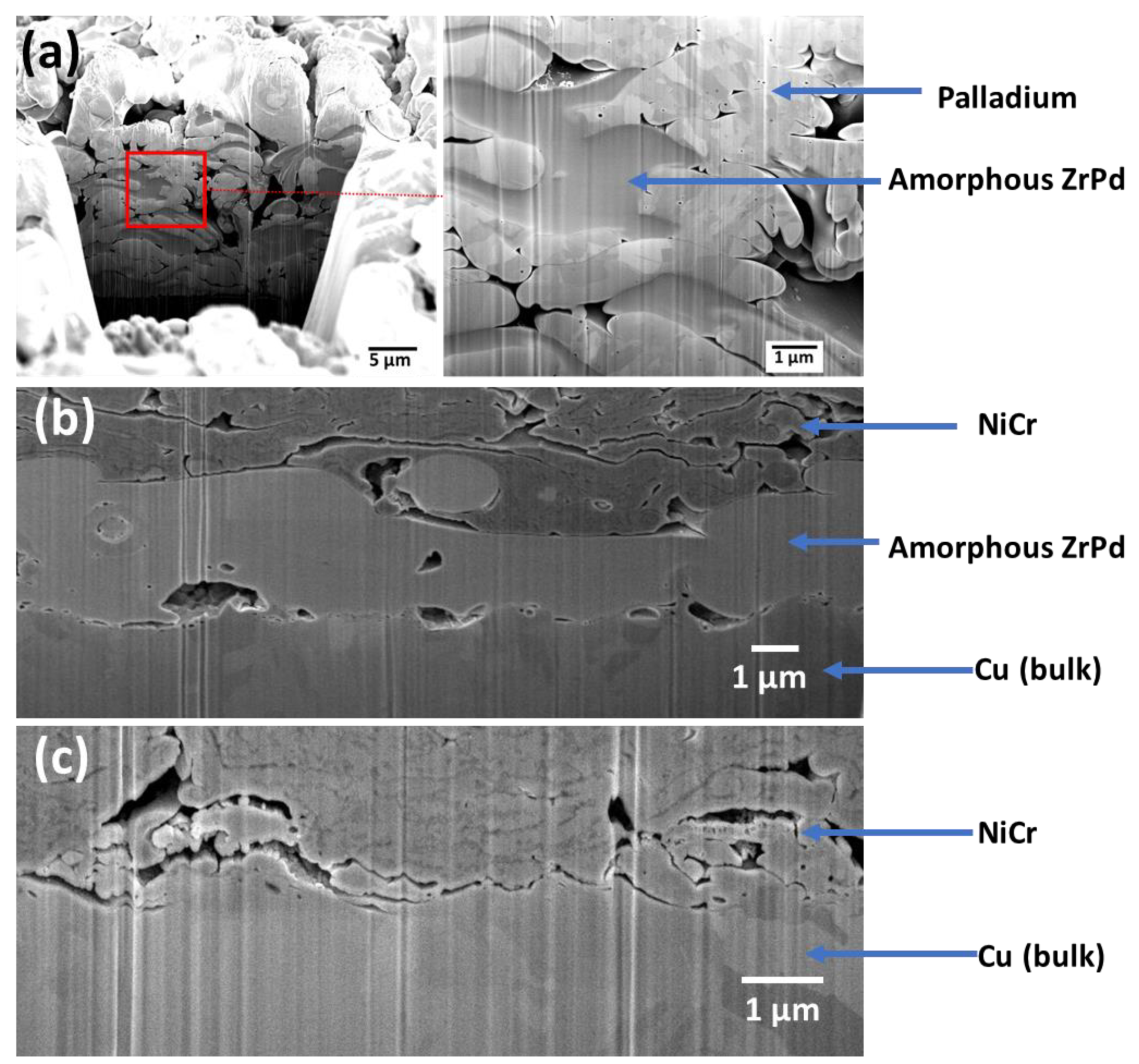

3.3. Metal Glass

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Metal | Pulse Width [ns] | Energy per Pulse [µJ] | Fluence [J/cm2] |

|---|---|---|---|

| Au | 1 | 4.25 | 0.88 |

| Ni | 5 | 6.25 | 1.3 |

| Pd | 10 | 6.5 | 1.35 |

| Bi | 1 | 0.75 | 0.16 |

| ZrPd | 20 | 6 | 1.25 |

| Metal | Reflectivity at 532 nm [%] | A ET/Ep |

|---|---|---|

| Cu | 60.1 | 0.38 |

| Au | 70.4 | 0.28 |

| Al | 91.6 | 0.08 |

| Bi | 52.5 | 0.46 |

| Ni | 63.3 | 0.35 |

| Ge | 51.5 | 0.47 |

| Pd | 69.2 | 0.3 |

| Cr | 55.6 | 0.43 |

| Material | Tm | Tb | ∆Hf | ∆Hf/Cp,s | Cp,s | Cp,l | ρ(S) | ρ(L) | k(S) | k(L) | α(S) | α(L) | ks/kl |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| °C | °C | J/gr | K | J/gr/K | J/gr/K | gr/cm3 | gr/cm3 | W/m/K | W/m/K | cm2/sec | cm2/sec | ||

| Cu | 1084 | 2567 | 204.7 | 531.7 | 0.39 | 0.49 | 8.96 | 7.9 | 401. | 165 | 1.16 | 0.43 | 2.43 |

| Au | 1064 | 2970 | 63.0 | 493.8 | 0.48 | 0.15 | 19.3 | 17.3 | 318 | 106 | 1.28 | 0.4 | 3.00 |

| Al | 660 | 2467 | 399.6 | 446.0 | 0.13 | 1.18 | 2.7 | 2.54 | 237 | 95.0 | 0.98 | 0.41 | 2.49 |

| Ti | 1668 | 3287 | 295.4 | 564.2 | 0.90 | 0.79 | 4.5 | 4.1 | 20.0 | 20 | 0.08 | 0.32 | 1.00 |

| Sn | 231 | 2602 | 59.2 | 259.3 | 0.52 | 0.24 | 7.28 | 6.98 | 66.8 | 30.0 | 0.40 | 0.06 | 2.23 |

| Bi | 271.5 | 1564 | 54.1 | 443.2 | 0.23 | 0.15 | 9.81 | 10.0 | 8.0 | 13. | 0.07 | 0.18 | 0.62 |

| Ni | 1455 | 2730 | 297.8 | 670.6 | 0.12 | 0.73 | 8.9 | 7.8 | 90.9 | 55. | 0.23 | 0.09 | 1.65 |

| Zr | 1855 | 4377 | 153.5 | 552.1 | 0.44 | 0.51 | 6.52 | 5.8 | 22.6 | 20. | 0.12 | 0.097 | 1.13 |

| Ge | 938 | 2833 | 508.6 | 1590.7 | 0.28 | 0.34 | 5.32 | 5.6 | 60.2 | 43. | 0.35 | 0.07 | 1.40 |

| Pd | 1555 | 2963 | 151. | 616.5 | 0.32 | 0.37 | 12.0 | 10.4 | 71.8 | 55 | 0.24 | 0.22 | 1.31 |

| Cr | 1907 | 2671 | 403.9 | 901.3 | 0.25 | 0.76 | 7.19 | 6.3 | 93.9 | 35 | 0.29 | 0.14 | 2.68 |

References

- Serra, P.; Piqué, A. Laser-Induced Forward Transfer: Fundamentals and Applications. Adv. Mater. Technol. 2019, 1800099. [Google Scholar] [CrossRef]

- Guo, S.; Qiu, K.; Meng, F.; Park, S.H.; Mcalpine, M.C. 3D Printed Stretchable Tactile Sensors. Adv. Mater. 2017, 29, 1701218. [Google Scholar] [CrossRef]

- Pique, A.; Auyeung, R.C.Y.; Kim, H.; Charipar, N.A.; Mathews, S.A. Laser 3D micro-manufacturing. J. Phys. D Appl. Phys. 2016, 49, 223001. [Google Scholar] [CrossRef]

- Zenou, M.; Sa’ar, A.; Kotler, Z. Laser jetting of femto-liter metal droplets for high resolution 3D printed structures. Sci. Rep. 2015, 5, 17265 . [Google Scholar] [CrossRef]

- Zenou, M.; Sa’Ar, A.; Kotler, Z. Laser Transfer of Metals and Metal Alloys for Digital Microfabrication of 3D Objects. Small 2015, 11, 4082–4089. [Google Scholar] [CrossRef]

- Zenou, M.; Kotler, Z. Printing of metallic 3D micro-objects by laser induced forward transfer. Opt. Express 2016, 24, 1431–1446. [Google Scholar] [CrossRef]

- Visser, C.W.; Pohl, R.; Sun, C.; Römer, G.W.; Huis In ’T Veld, B.; Lohse, D. Toward 3D Printing of Pure Metals by Laser-Induced Forward Transfer. Adv. Mater. 2015, 27, 4087–4092. [Google Scholar] [CrossRef]

- Feinaeugle, M.; Pohl, R.; Bor, T.; Vaneker, T.; Römer, G. Printing of complex free-standing microstructures via laser-induced forward transfer ( LIFT ) of pure metal thin films. Addit. Manuf. 2018, 24, 391–399. [Google Scholar] [CrossRef]

- Luo, J.; Pohl, R.; Qi, L.; Römer, G.; Sun, C.; Lohse, D.; Visser, C.W. Printing Functional 3D Microdevices by Laser-Induced Forward Transfer. Small 2017, 13, 1602553. [Google Scholar] [CrossRef]

- Fogel, O.; Winter, S.; Benjamin, E.; Krylov, S.; Kotler, Z.; Zalevsky, Z. 3D printing of functional metallic microstructures and its implementation in electrothermal actuators. Addit. Manuf. 2018, 21, 307–311. [Google Scholar] [CrossRef]

- Gold, U.; Kotler, Z. A Method and System for Electrical Circuit Repair. Patent WO/2010/100635, 10 September 2010. [Google Scholar]

- Winter, S.; Zenou, M.; Kotler, Z. Conductivity of laser printed copper structures limited by nano-crystal grain size and amorphous metal droplet shell. J. Phys. D Appl. Phys. 2016, 49, 465310. [Google Scholar] [CrossRef]

- Fogel, O.; Cohen, S.; Kotler, Z.; Zalevsky, Z. Mechanical properties of 3D metallic microstructures printed by laser induced forward transfer. Procedia CIRP 2018, 74, 285–289. [Google Scholar] [CrossRef]

- Zenou, M.; Sa’Ar, A.; Kotler, Z. Digital laser printing of metal/metal-oxide nano-composites with tunable electrical properties. Nanotechnology 2016, 27, 015203. [Google Scholar] [CrossRef]

- Fogel, O.; Toker, G.B.; Cohen-Taguri, G.; Gergaud, P.; Gaillard, F.; Kotler, Z.; Zalevsky, Z. An investigation of the influence of thermal process on the electrical conductivity of LIFT printed Cu structures. J. Phys. D Appl. Phys. 2019, 52, 285303. [Google Scholar] [CrossRef]

- Gorodesky, N.; Sedghani-cohen, S.; Altman, M.; Fogel, O.; Cohen-taguri, G.; Fleger, Y.; Kotler, Z.; Zalevsky, Z. Concurrent Formation of Metallic Glass During Laser Forward Transfer 3D Printing. Adv. Funct. Mater. 2020, 30, 2001260. [Google Scholar] [CrossRef]

- Kant, P.; Koldeweij, R.B.J.; Harth, K.; Van Limbeek, M.A.J.; Lohse, D. Fast-freezing kinetics inside a droplet impacting on a cold surface. Appl. Phys. Sci. 2020, 117, 2788–2794. [Google Scholar] [CrossRef]

- Gielen, M.V.; De Ruiter, R.; Koldeweij, R.B.J.; De Lohse, J.H.; Snoeijer, H. Gelderblom Solidification of liquid metal drops during impact. J. Fluid Mech. 2020, 883, 32. [Google Scholar] [CrossRef]

- De Ruiter, J.; Soto, D.; Varanasi, K.K. Self-peeling of impacting droplets. Nat. Phys. 2017, 14, 35–39. [Google Scholar] [CrossRef]

- Reiser, A.; Koch, L.; Dunn, K.A.; Matsuura, T.; Iwata, F.; Fogel, O.; Kotler, Z.; Zhou, N.; Charipar, L.; Piqué, A.; et al. Metals by Micro-Scale Additive Manufacturing: Comparison of Microstructure and Mechanical Properties. Adv. Funct. Mater. 2020, 30, 1910491. [Google Scholar] [CrossRef]

- George, A. Pantazopoulos A Short Review on Fracture Mechanisms of Mechanical Components Operated under Industrial Process Conditions: Fractographic Analysis and Selected Prevention Strategies. Metals 2019, 9, 148. [Google Scholar] [CrossRef]

- Stefun, J. Uber die Diffusion von Sauren und Basen gegen einander. Akad. Mat. Nat. 1889, 98, 473–484. [Google Scholar]

- Esen, A.; Kutluay, S. A numerical solution of the Stefan problem with a Neumann-type boundary condition by enthalpy method. Appl. Math. Comput. 2004, 148, 321–329. [Google Scholar] [CrossRef]

- Hu, H.; Argyropoulos, S.A.; Simul, M.; Sci, M.; Hu, H.; Argyropoulos, S.A. Mathematical modelling of solidification and melting: A review. Model. Simul. Mater. Sci. Eng. 1996, 4, 371. [Google Scholar] [CrossRef]

- Hendersont, S.J.; Speedy, R.J. Melting Temperature of Ice at Positive and Negative Pressures. J. Phys. Chem. 1987, 91, 3069–3072. [Google Scholar] [CrossRef]

- Waterstrat, R.M.; Shapiro, A.; Jeremie, A. The palladium–zirconium phase diagram. J. Alloys Compd. 1999, 290, 63–70. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Calculations of Mixing Enthalpy and Mismatch Entropy for Ternary Amorphous Alloys. Mater. Trans. 2000, 41, 1372–1378. [Google Scholar] [CrossRef]

- Jiang, J.Z.; Saksl, K.; Saida, J.; Inoue, A.; Franz, H.; Messel, K.; Lathe, C. Evidence of polymorphous amorphous-to-quasicrystalline phase transformation in Zr66.7Pd33.3 metallic glass Evidence of polymorphous amorphous-to-quasicrystalline phase. Appl. Phys. Lett. 2011, 781, 2000–2003. [Google Scholar] [CrossRef][Green Version]

- Telford, M. The case for bulk metallic glass. Mater. Today 2004, 7, 36–43. [Google Scholar] [CrossRef]

| Material | Tm | ∆TL (ks,d = ks,bulk) | ∆TL* (ks,d = ks,bulk/2) | Tb |

|---|---|---|---|---|

| °C | °C | °C | °C | |

| Cu | 1084 | 5158 | 2579 | 2575 |

| Au | 1064 | 6080 | 3040 | 2800 |

| Al | 660 | 3809 | 1905 | 2470 |

| Sn | 231 | 1613 | 807 | 2600 |

| Bi | 271 | 697 | 349 | 1564 |

| Ni | 1455 | 4580 | 2290 | 2800 |

| Ge | 938 | 5732 | 2866 | 2833 |

| Pd | 1555 | 3607 | 1803 | 2963 |

| Cr | 1907 | 9885 | 4943 | 2670 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gorodesky, N.; Sedghani-Cohen, S.; Fogel, O.; Silber, A.; Tkachev, M.; Kotler, Z.; Zalevsky, Z. Improving Compactness of 3D Metallic Microstructures Printed by Laser-Induced Forward Transfer. Crystals 2021, 11, 291. https://doi.org/10.3390/cryst11030291

Gorodesky N, Sedghani-Cohen S, Fogel O, Silber A, Tkachev M, Kotler Z, Zalevsky Z. Improving Compactness of 3D Metallic Microstructures Printed by Laser-Induced Forward Transfer. Crystals. 2021; 11(3):291. https://doi.org/10.3390/cryst11030291

Chicago/Turabian StyleGorodesky, Niv, Sharona Sedghani-Cohen, Ofer Fogel, Amir Silber, Maria Tkachev, Zvi Kotler, and Zeev Zalevsky. 2021. "Improving Compactness of 3D Metallic Microstructures Printed by Laser-Induced Forward Transfer" Crystals 11, no. 3: 291. https://doi.org/10.3390/cryst11030291

APA StyleGorodesky, N., Sedghani-Cohen, S., Fogel, O., Silber, A., Tkachev, M., Kotler, Z., & Zalevsky, Z. (2021). Improving Compactness of 3D Metallic Microstructures Printed by Laser-Induced Forward Transfer. Crystals, 11(3), 291. https://doi.org/10.3390/cryst11030291