In-Situ Formed Al3Zr Compounds Reinforced Al Composites and Tribological Application

Abstract

1. Introduction

2. Materials and Methods

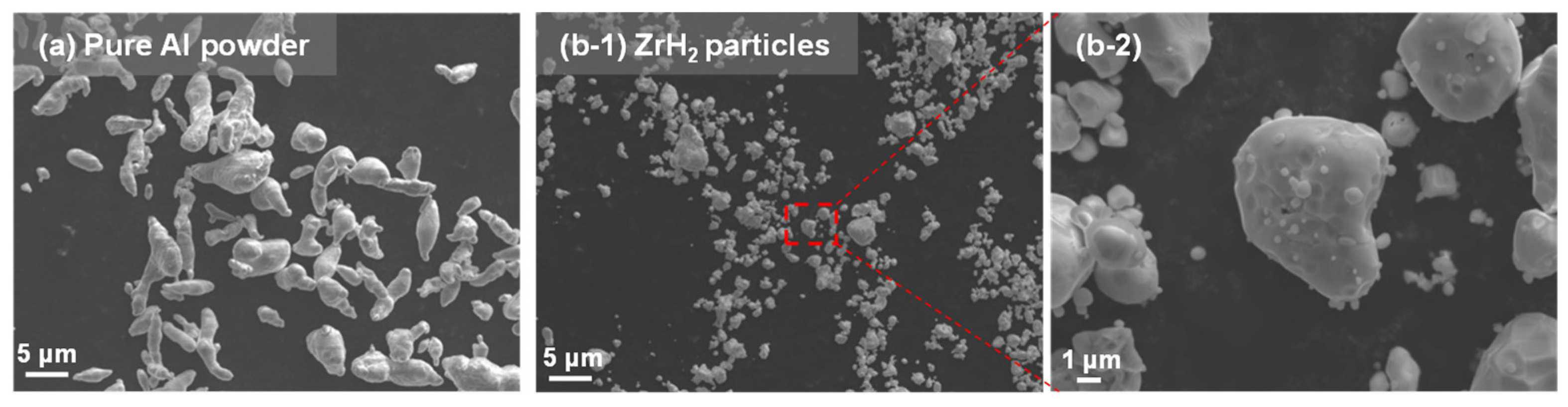

2.1. Materials Fabrication

2.2. Materials Characterization

2.3. Wear Test

3. Results

3.1. Materials Characterisation

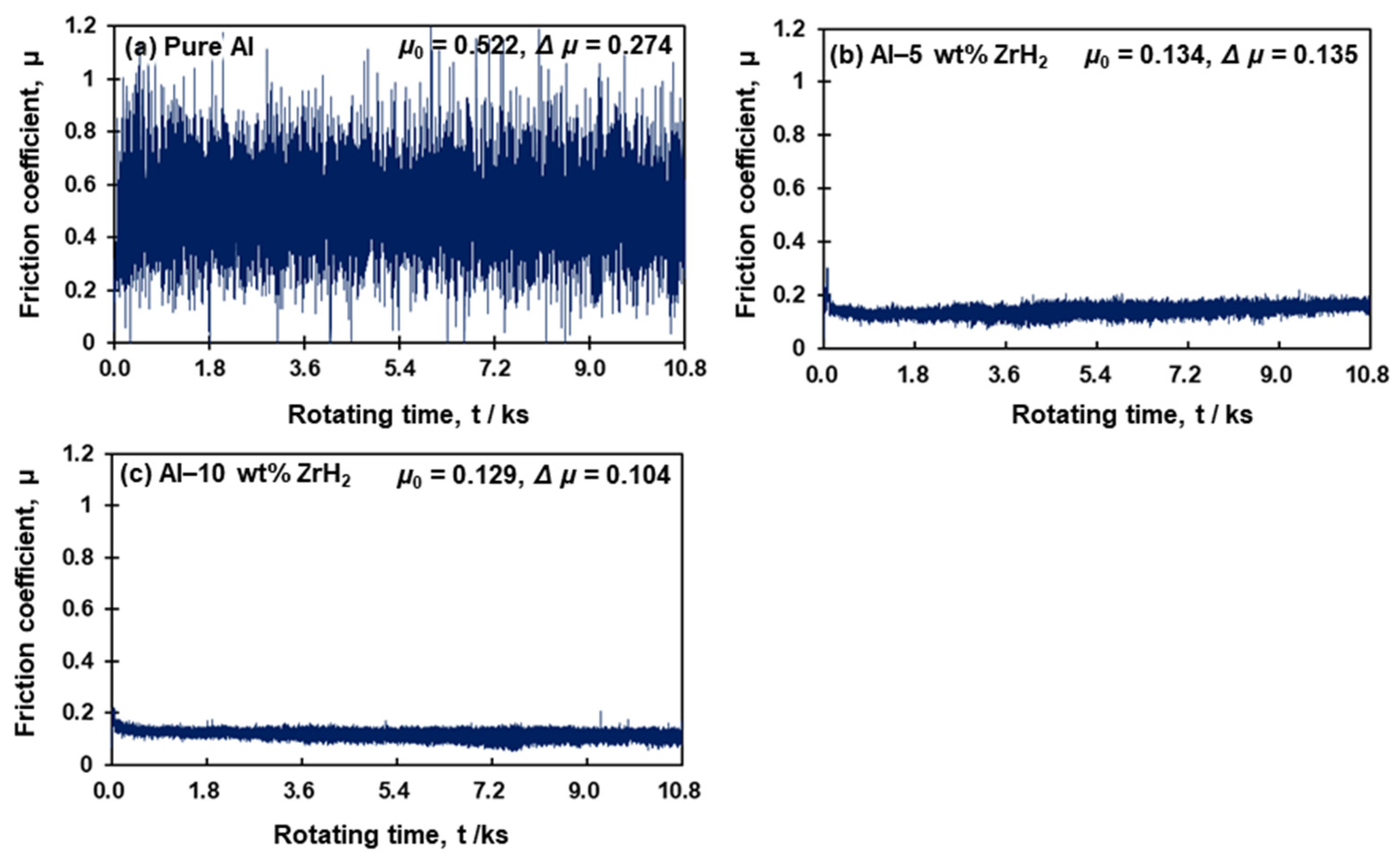

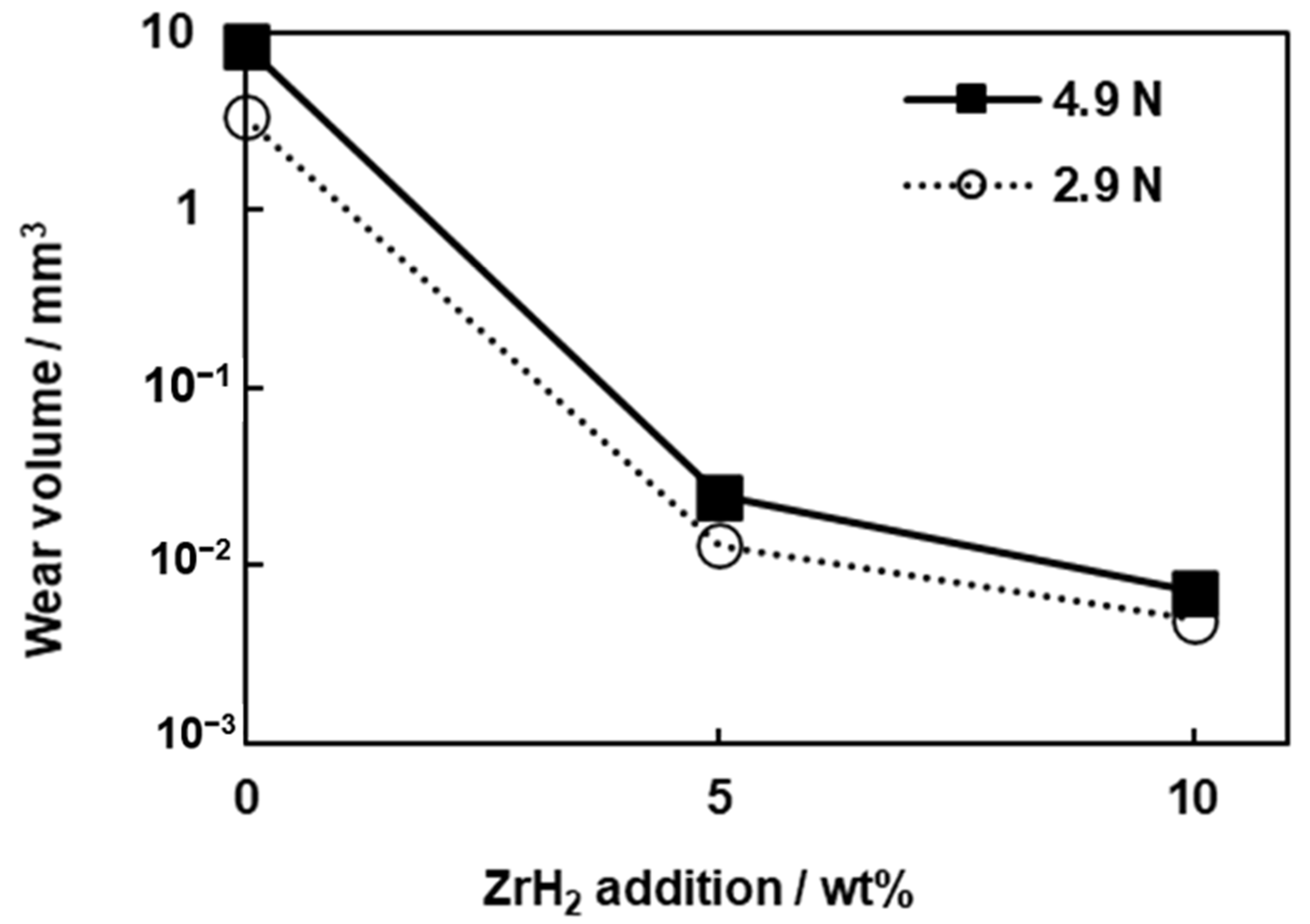

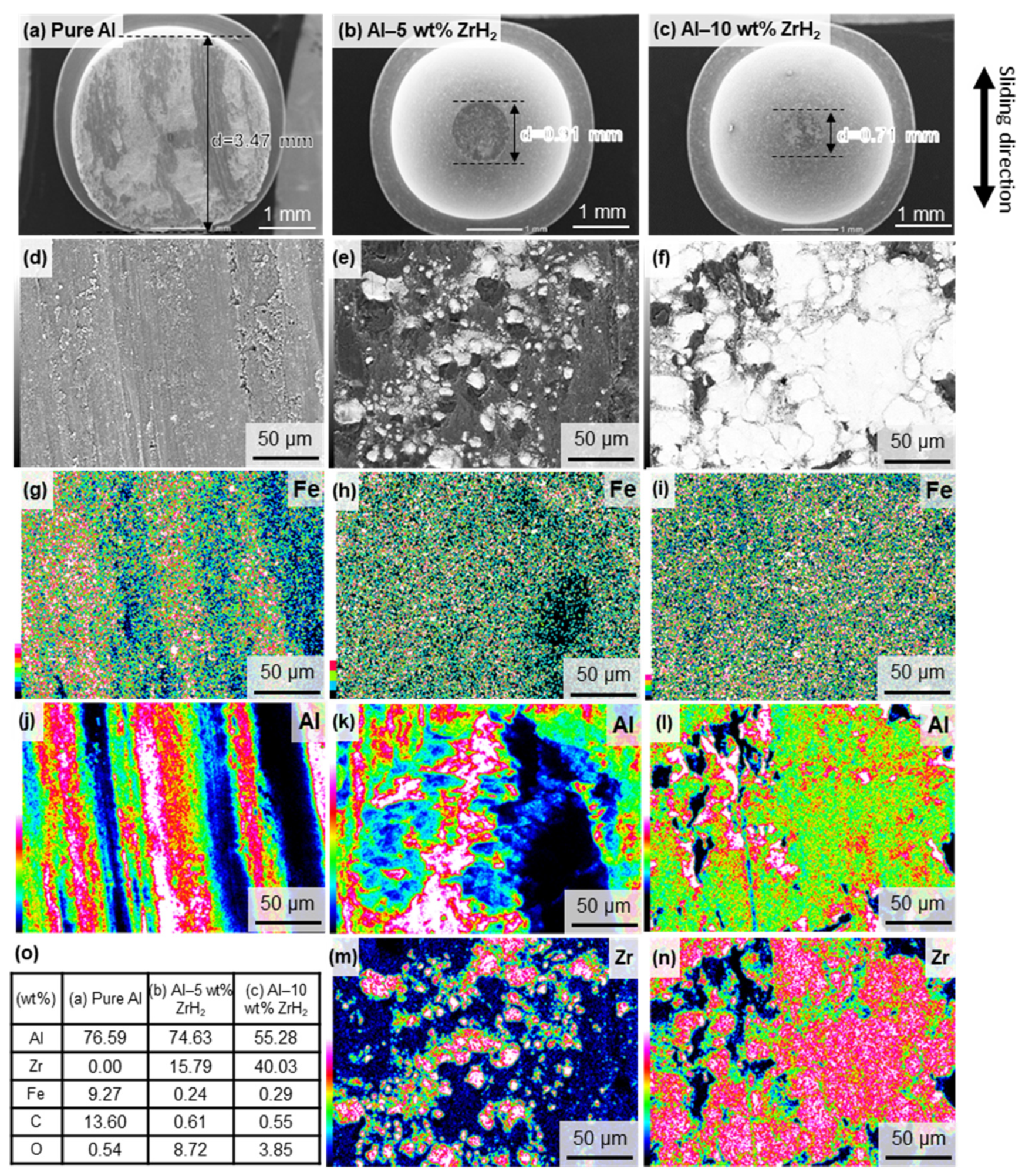

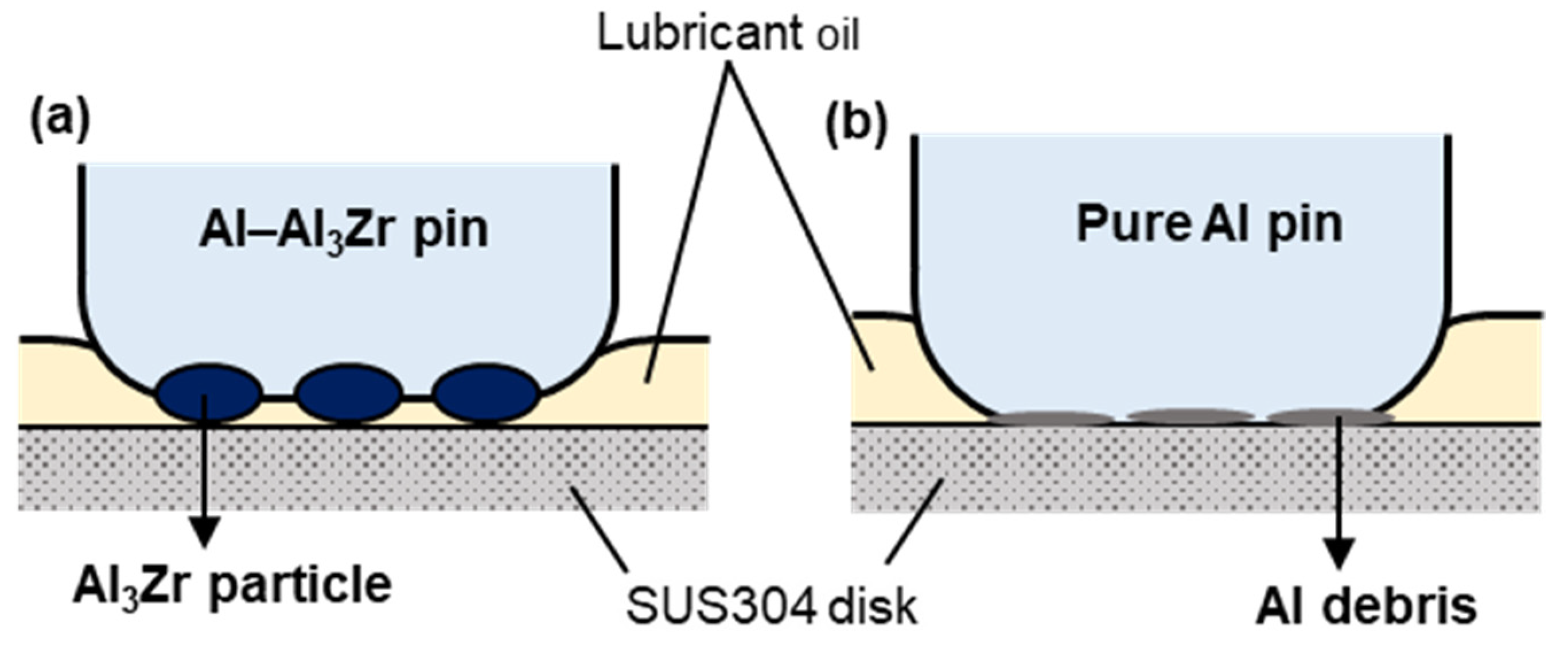

3.2. Friction and Wear Behaviour

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Starke, E.A.; Staley, J.T. Application of modern aluminium alloys to aircraft. In Fundamentals of Aluminium Metallurgy: Production, Processing and Applications; Lumley, R., Ed.; Woodhead Publishing: Cambridge, UK, 2010; pp. 747–783. [Google Scholar]

- Hirsch, J. Recent development in aluminium for automotive applications. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2014, 24, 1995–2002. [Google Scholar] [CrossRef]

- Huang, X.; Famiyeh, L. Plasma Electrolytic Oxidation Coatings on Aluminium Alloys: Microstructures, Properties, and Applications. Mod. Concepts Mater. Sci. 2019, 2, 000526. [Google Scholar]

- Chu, H.; Lin, J. Experimental analysis of the tribological behavior of electroless nickel-coated graphite particles in aluminium matrix composites under reciprocating motion. Wear 2000, 239, 126–142. [Google Scholar] [CrossRef]

- Li, N.; Zhang, L.; Xu, M.; Xia, T.; Ruan, X.; Song, S.; Ma, H. Preparation and mechanical property of electrodeposited Al-graphene composite coating. Mater. Des. 2016, 111, 522–527. [Google Scholar] [CrossRef]

- Tabandeh-Khorshid, M.; Omrani, E.; Menezes, P.; Rohatgi, P. Tribological performance of self-lubricating aluminum matrix nanocomposites: Role of graphene nanoplatelets. Eng. Sci. Technol. Int. J. 2016, 19, 463–469. [Google Scholar] [CrossRef]

- Kondoh, K.; Umeda, J.; Watanabe, R. Cavitation resistance of powder metallurgy aluminum matrix composite with AlN dispersoids. Mater. Sci. Eng. A 2009, 499, 440–444. [Google Scholar] [CrossRef]

- Chen, B.; Shen, J.; Ye, X.; Imai, H.; Umeda, J.; Takahashi, M.; Kondoh, K. Solid-state interfacial reaction and load transfer efficiency in carbon nanotubes (CNTs)-reinforced aluminium matrix composites. Carbon 2017, 114, 198–208. [Google Scholar] [CrossRef]

- Bakshi, S.; Singh, V.; Balani, K.; McCartney, D.; Seal, S.; Agarwal, A. Carbon nanotube reinforced aluminium composite coating via cold spraying. Surf. Coat. Technol. 2008, 202, 5162–5169. [Google Scholar] [CrossRef]

- Wang, L.; Wan, S.; Wang, S.C.; Wood, R.J.K.; Xue, Q.J. Gradient DLC-based nanocomposite coatings as a solution to improve tribological performance of aluminium alloy. Tribol. Lett. 2010, 38, 155–160. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Matsumoto, Y. Electrodeposition of TiO2 photocatalyst into nano-pores of hard alumite. Electrochim. Acta 2001, 46, 2819–2824. [Google Scholar] [CrossRef]

- Noordhuis, J.; Hosson, J. Surface modification by means of laser melting combined with shot peening: A novel approach. Acta Metall. Mater. 1992, 40, 3317–3324. [Google Scholar] [CrossRef]

- Wu, X.; Qin, W.; Guo, Y.; Xie, Z. Self-lubricative coating grown by micro-plasma oxidation on aluminium alloys in the solution of aluminate-graphite. Appl. Surf. Sci. 2008, 254, 6395–6399. [Google Scholar] [CrossRef]

- Chen, B.; Kondoh, K.; Umeda, J.; Li, S.; Jia, L.; Li, J. Interfacial in-situ Al2O3 nanoparticles enhance load transfer in carbon nanotube (CNT)-reinforced aluminium matrix composites. J. Alloys Compd. 2019, 789, 25–29. [Google Scholar] [CrossRef]

- Hossein-Zadeh, M.; Mirzaee, O.; Saidi, P. Structural and mechanical characterization of Al-based composite reinforced with heat treated Al2O3 particles. Mater. Des. 2014, 54, 245–250. [Google Scholar] [CrossRef]

- Dey, S.K.; Perry, T.A.; Alpas, A.T. Micromechanisms of low load wear in an Al-18.5% Si alloy. Wear 2009, 267, 515–524. [Google Scholar] [CrossRef]

- Kori, S.A.; Chandrashekharaiah, T.M. Studies on the dry sliding wear behaviour of hypoeutectic and eutectic Al-Si alloys. Wear 2007, 263, 745–755. [Google Scholar] [CrossRef]

- Mousavia, R.T.; Khosroshahi, R.A.; Yazdani, S.; Brabazon, D.; Boostani, A.F. Fabrication of aluminum matrix composites reinforced with nano- to micrometer-sized SiC particles. Mater. Des. 2016, 89, 58–70. [Google Scholar] [CrossRef]

- Ghasali, E.; Pakseresht, A.; Rahbari, A.; Eslami-Shahed, H.; Alizadeh, M.; Ebadzadeh, T. Mechanical properties and microstructure characterization of spark plasma and conventional sintering of Al-SiC-TiC composites. J. Alloys Compd. 2016, 666, 366–371. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Haseeb, A.; Celis, J.P. Tribo-surface characteristics of Al-B4C and Al-SiC composites worn under different contact pressures. Wear 2006, 261, 634–641. [Google Scholar] [CrossRef]

- Harichandran, R.; Selvakumar, N. Effect of nano/micro B4C particles on the mechanical properties of aluminium metal matrix composites fabricated by ultrasonic cavitation-assisted solidification process. Arch. Civ. Mech. Eng. 2016, 16, 147–158. [Google Scholar] [CrossRef]

- Vivekananda, A.S.; Prabu, S.B. Wear Behaviour of In Situ Al/TiB2 Composite: Influence of the Microstructural Instability. Tribol. Lett. 2018, 66, 1–14. [Google Scholar] [CrossRef]

- Krishnamurthy, K.; Venkatesh, J. Assessment of Surface Roughness and Material Removal Rate on Machining of TIB2 Reinforced Aluminium 6063. Composites: A Taguchi’s Approach. Int. J. Sci. Res. 2013, 3, 1–6. [Google Scholar]

- Popov, V.A.; Shelekhov, E.V.; Prosviryakov, A.S.; Presniakov, M.Y.; Senatulin, B.R.; Kotov, A.D.; Khomutov, M.G. Particulate metal matrix composites development on the basis of in situ synthesis of TiC reinforcing nanoparticles during mechanical alloying. J. Alloys Compd. 2017, 707, 365–370. [Google Scholar] [CrossRef]

- Baskaran, S.; Anandakrishnan, B.; Duraiselvam, M. Investigations on dry sliding wear behavior of in situ casted AA7075-TiC metal matrix composites by using Taguchi technique. Mater. Des. 2014, 60, 184–192. [Google Scholar] [CrossRef]

- Landolt, D.; Mischler, S.; Stemp, M.; Barril, S. Third body effects and material fluxes in tribocorrosion systems involving a sliding contact. Wear 2004, 256, 517–524. [Google Scholar] [CrossRef]

- Vivekananda, A.S.; Balasivanandha, P.S.; Paskaramoorthy, R. Combined effect of process parameters during aluminothermic reaction process on the microstructure and mechanical properties of in situ Al/TiB2 composite. J. Alloys Compd. 2018, 735, 619–634. [Google Scholar] [CrossRef]

- Varin, R.V. Intermetallic-reinforced light-metal matrix in-situ composites. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2002, 33, 193–201. [Google Scholar] [CrossRef]

- Dufaud, O.; Bideau, D.; Guyadec, F.; Corriou, J.P.; Perrin, L.; Caleyron, A. Self ignition of layers of metal powder mixtures. Powder Technol. 2014, 254, 160–169. [Google Scholar] [CrossRef]

- Kondoh, K.; Takeda, Y. Tribological property of in situ directly nitrided and sintered Al/AlN composite. Powder Metall. 2000, 43, 69–75. [Google Scholar] [CrossRef]

- Laik, A.; Bhanumurthy, K.; Kale, G.B. Intermetallics in the Zr-Al diffusion zone. Intermetallics 2004, 12, 69–74. [Google Scholar] [CrossRef]

- Okamoto, H. Al-Zr (aluminum-zirconium). J. Phase Equilibria 1993, 14, 259–260. [Google Scholar] [CrossRef]

- Kumar, P.; Wani, M.F. Tribological Characterisation of Hypereutectic Al-25Si Alloy under Dry and Lubricated Sliding Conditions. J. Tribol. 2018, 140, 1–19. [Google Scholar] [CrossRef]

| Materials | Pure Al | Al-Al3Zr | Al3Zr IMC * | SUS304 Disk | |

|---|---|---|---|---|---|

| Al3Zr | Al Matrix | ||||

| Micro-hardness (HV) | 33 | 545 | 35 | 645 | 291 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Umeda, J.; Nishimura, N.; Fujii, H.; Jia, L.; Kondoh, K. In-Situ Formed Al3Zr Compounds Reinforced Al Composites and Tribological Application. Crystals 2021, 11, 227. https://doi.org/10.3390/cryst11030227

Umeda J, Nishimura N, Fujii H, Jia L, Kondoh K. In-Situ Formed Al3Zr Compounds Reinforced Al Composites and Tribological Application. Crystals. 2021; 11(3):227. https://doi.org/10.3390/cryst11030227

Chicago/Turabian StyleUmeda, Junko, Nodoka Nishimura, Hiroko Fujii, Lei Jia, and Katsuyoshi Kondoh. 2021. "In-Situ Formed Al3Zr Compounds Reinforced Al Composites and Tribological Application" Crystals 11, no. 3: 227. https://doi.org/10.3390/cryst11030227

APA StyleUmeda, J., Nishimura, N., Fujii, H., Jia, L., & Kondoh, K. (2021). In-Situ Formed Al3Zr Compounds Reinforced Al Composites and Tribological Application. Crystals, 11(3), 227. https://doi.org/10.3390/cryst11030227