Impact Response of Preplaced Aggregate Fibrous Concrete Hammerhead Pier Beam Designed with Topology Optimization

Abstract

1. Introduction

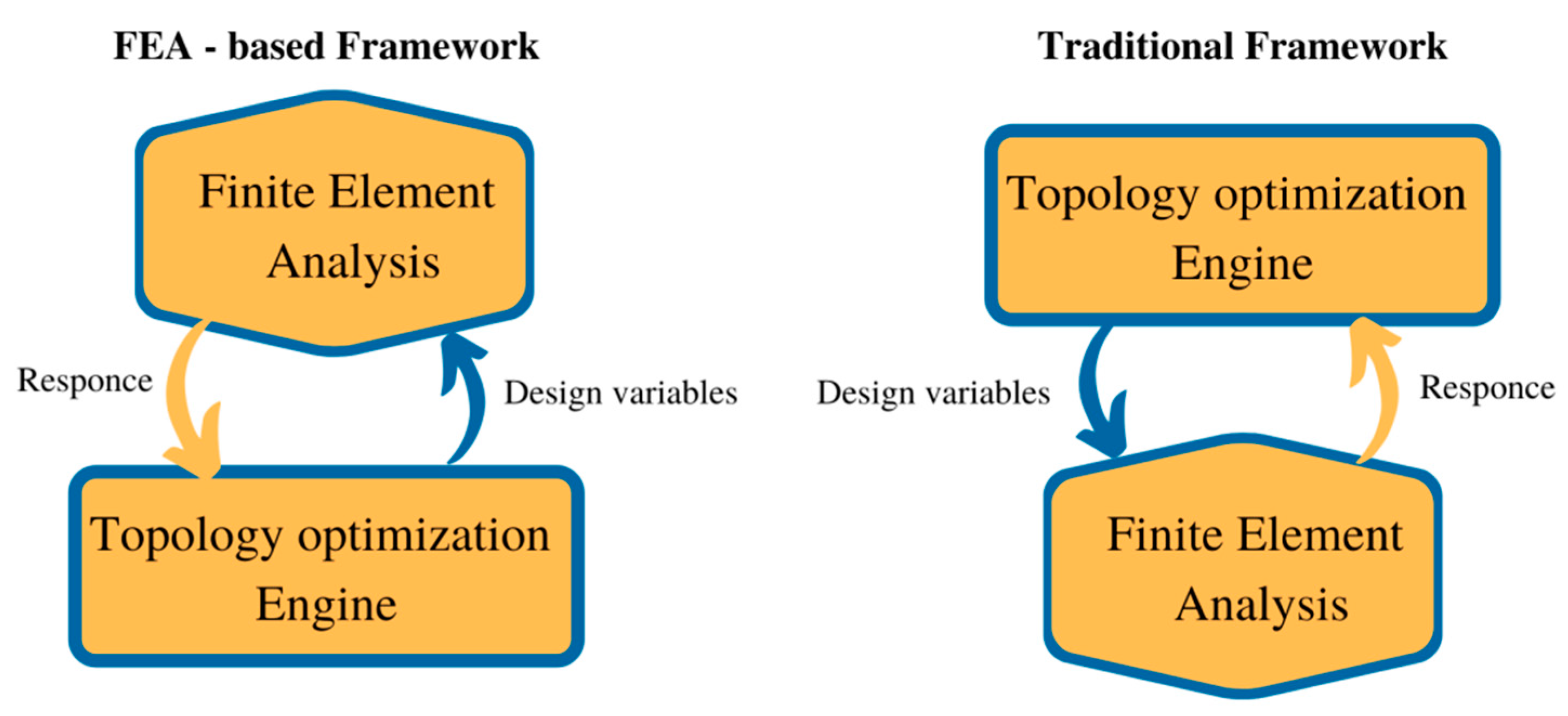

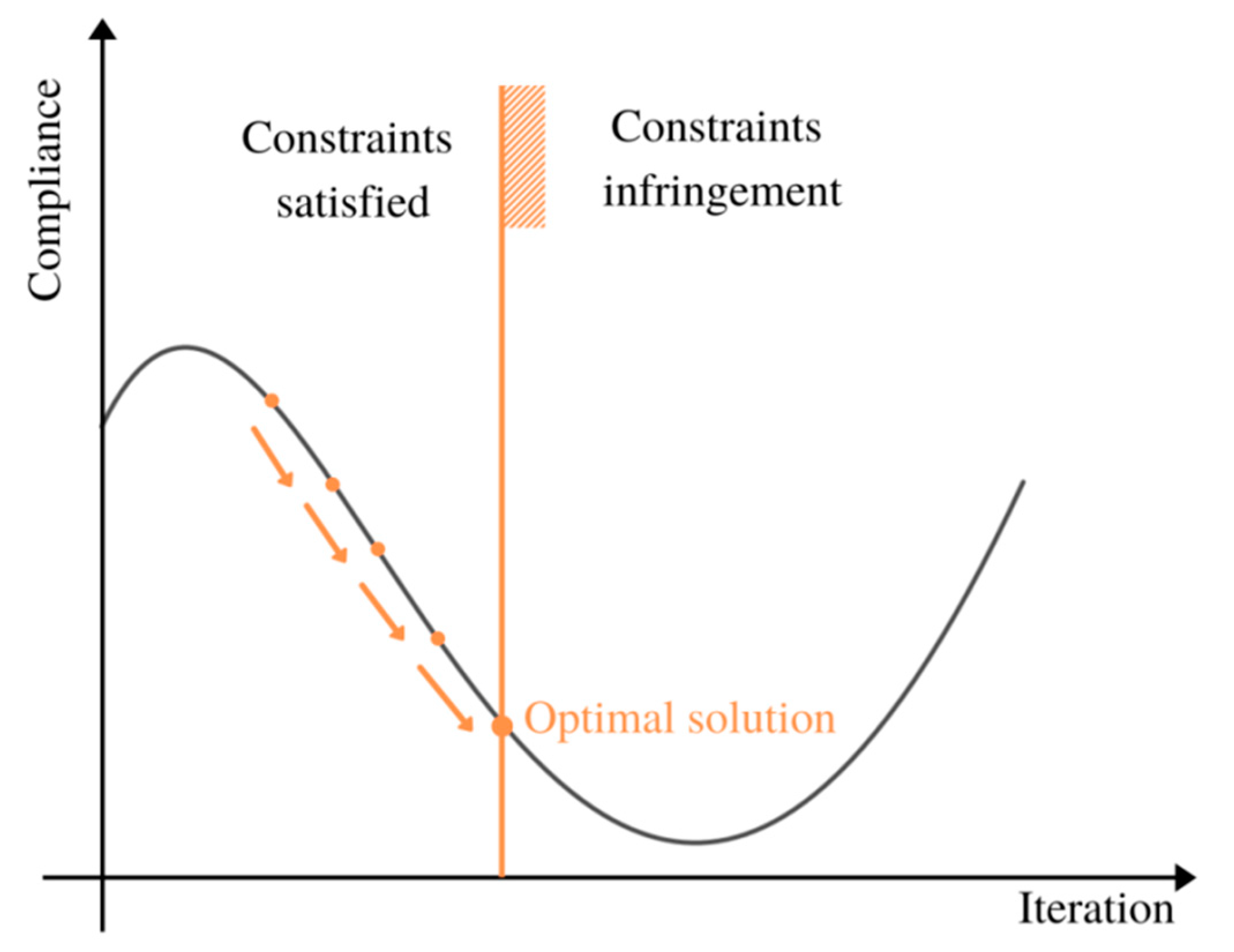

2. Materials and Methods

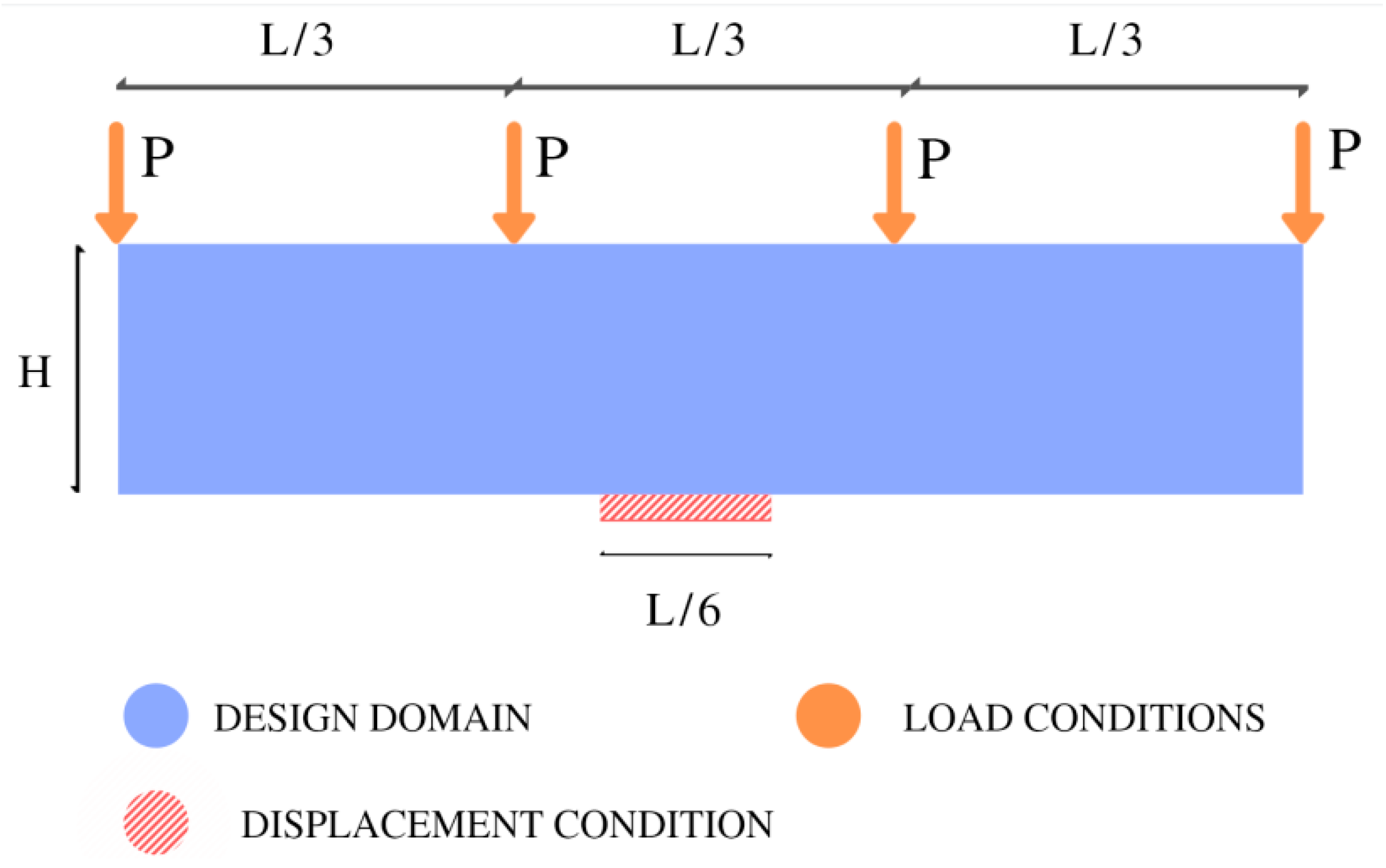

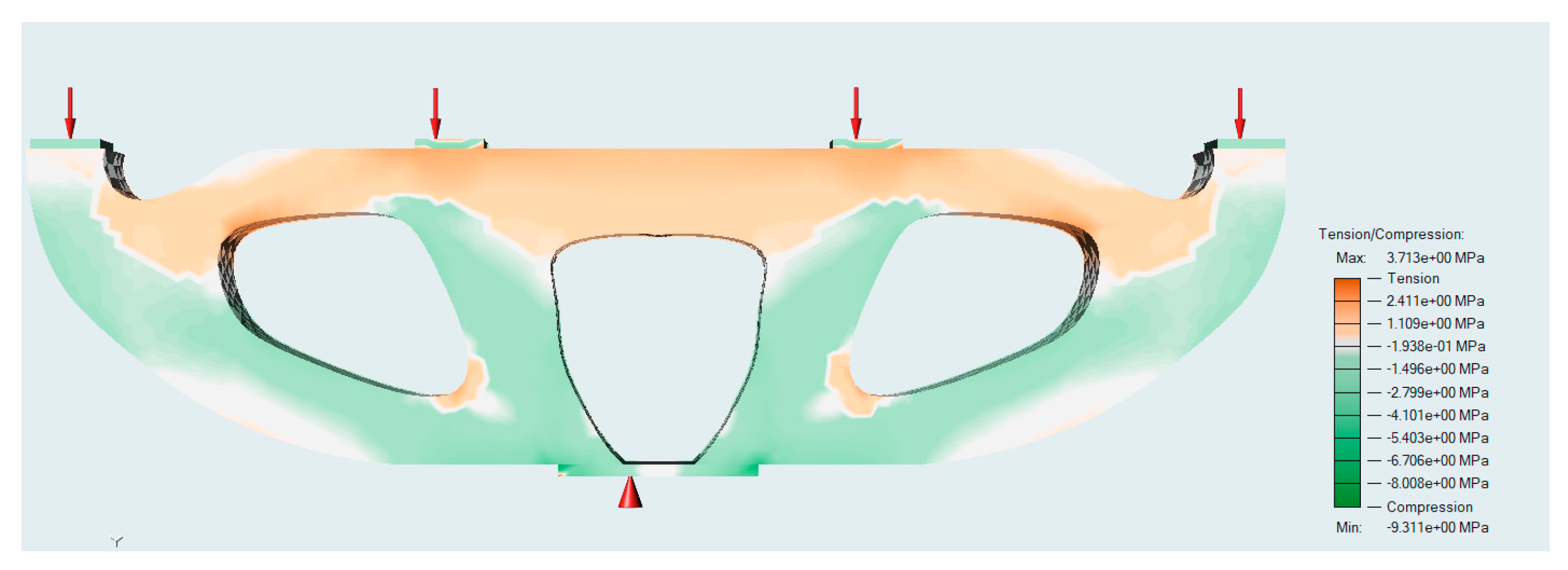

2.1. The Specimen

2.2. Cementitious Materials

2.3. Mixture Composition

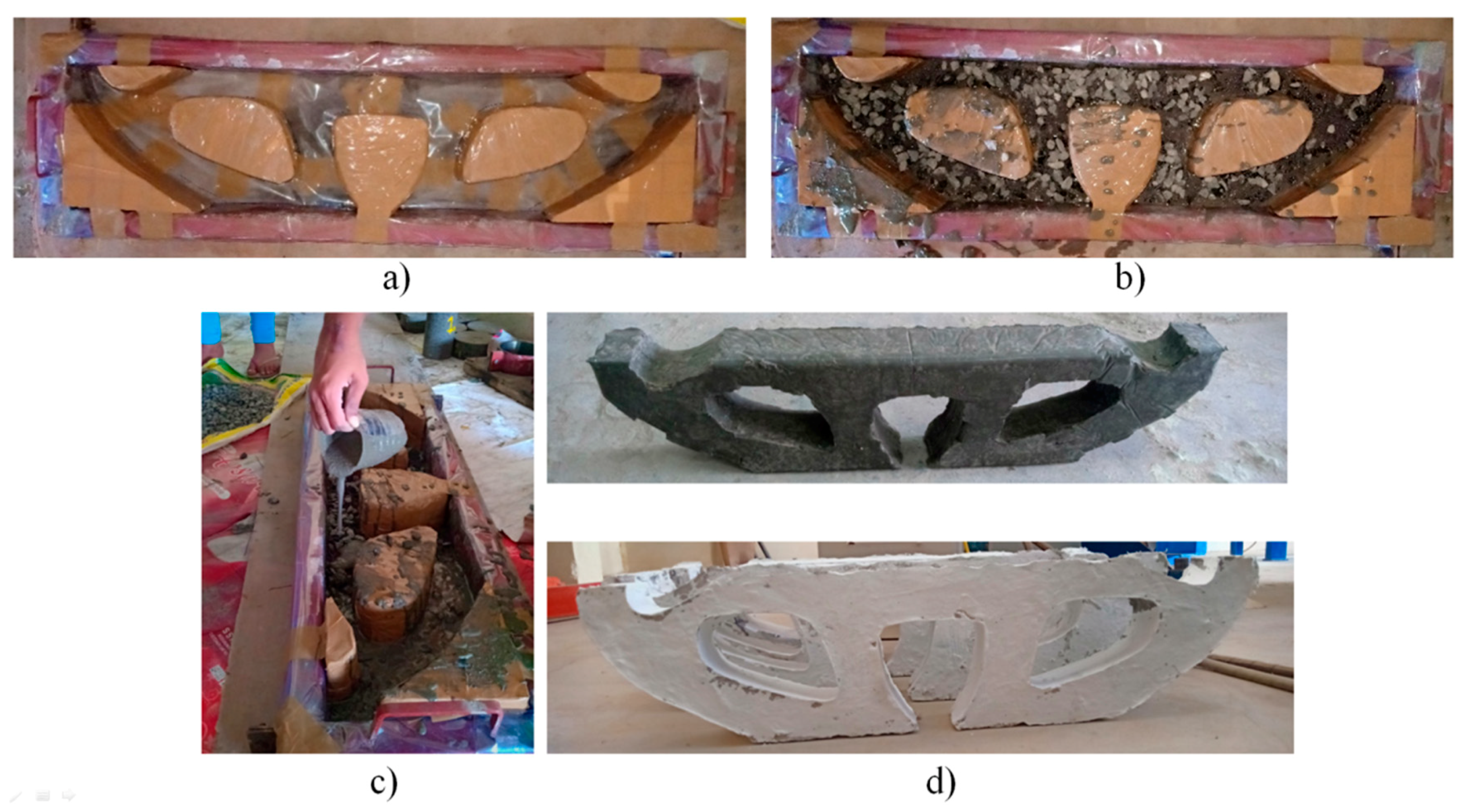

2.4. Process of TOHPB Preparation

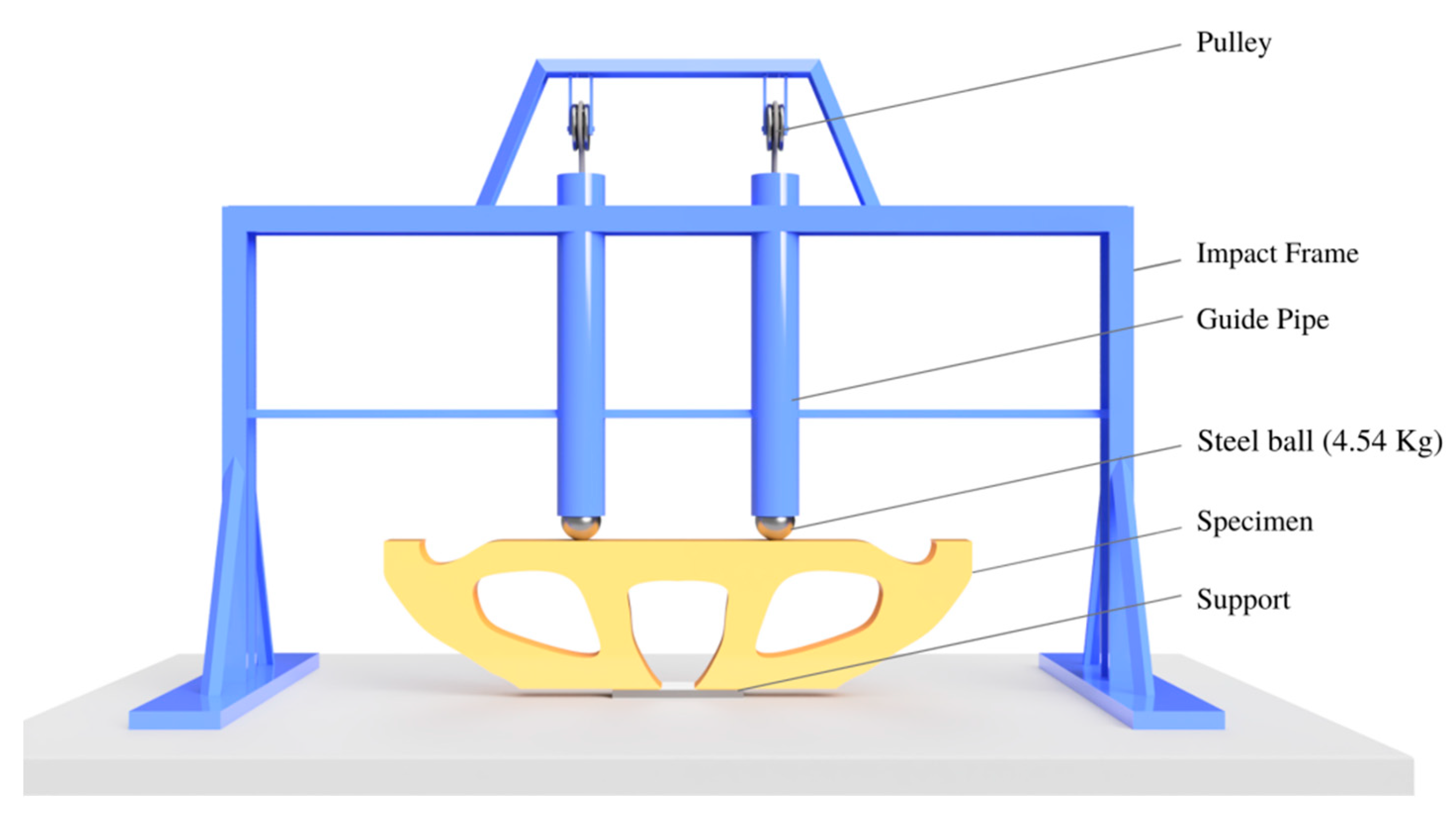

2.5. Test Setup

3. Results and Discussion

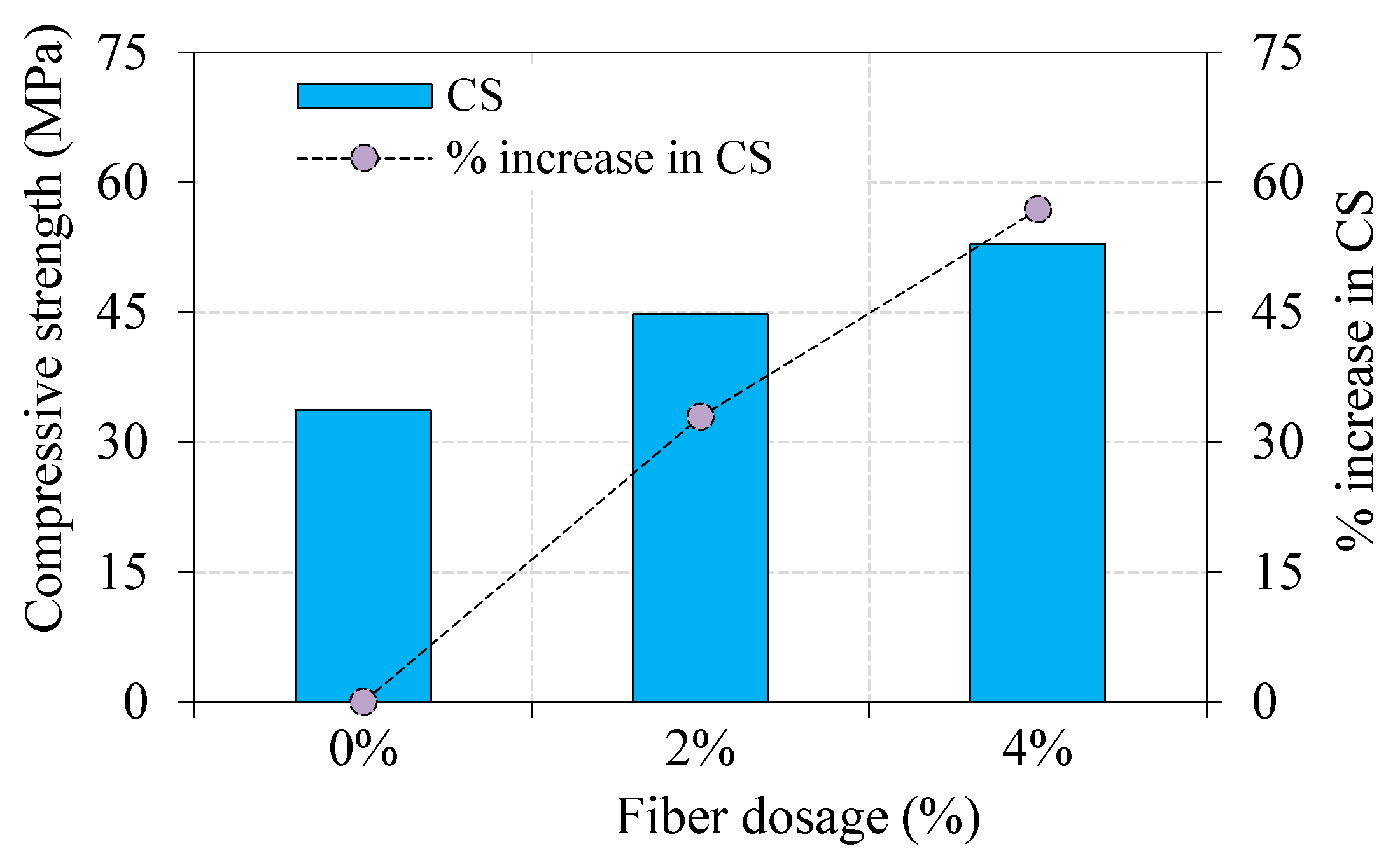

3.1. Compressive Strength of PAFC

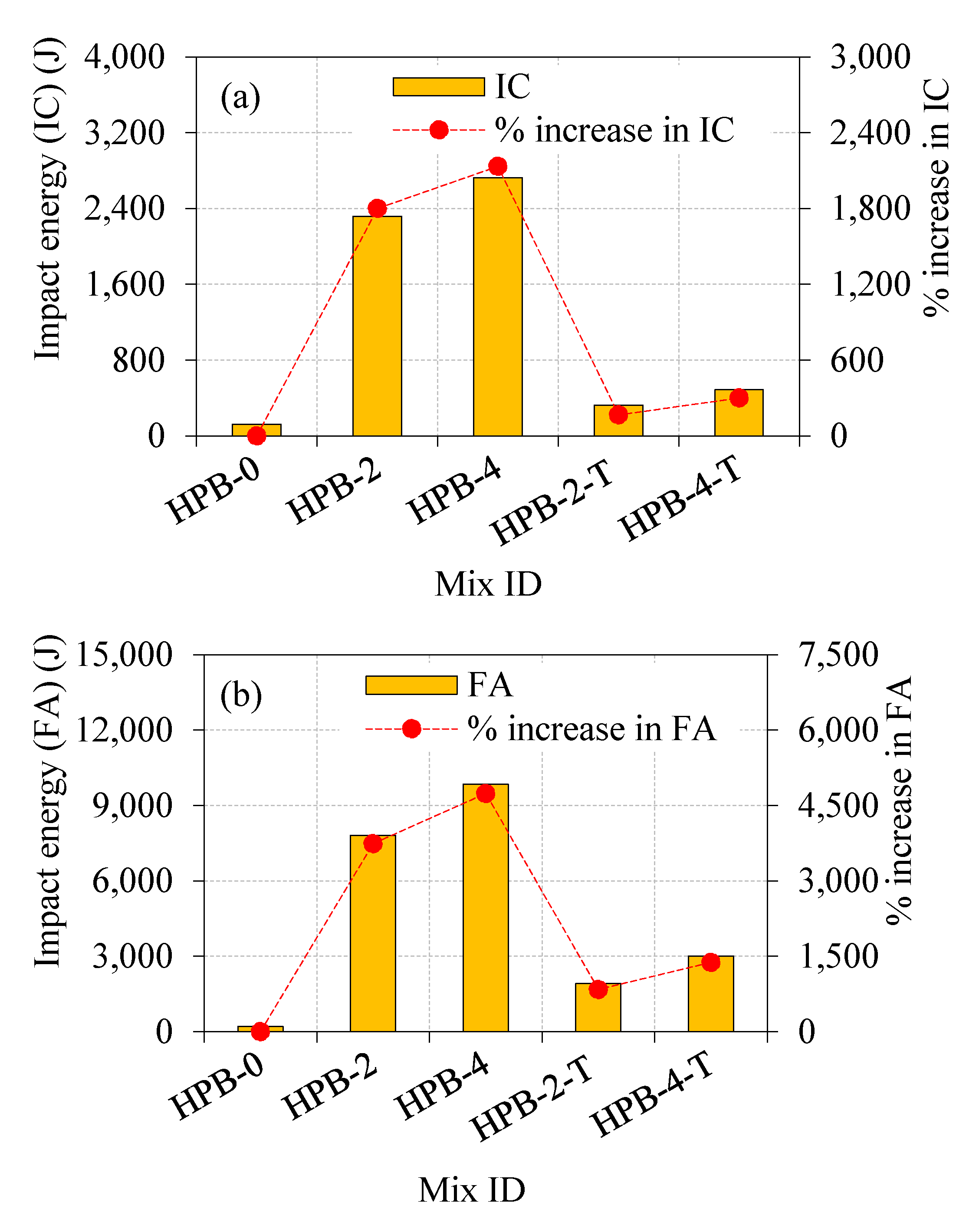

3.2. Impact Test Results

3.3. Impact Ductility Index (IDI)

3.4. Failure Mechanism

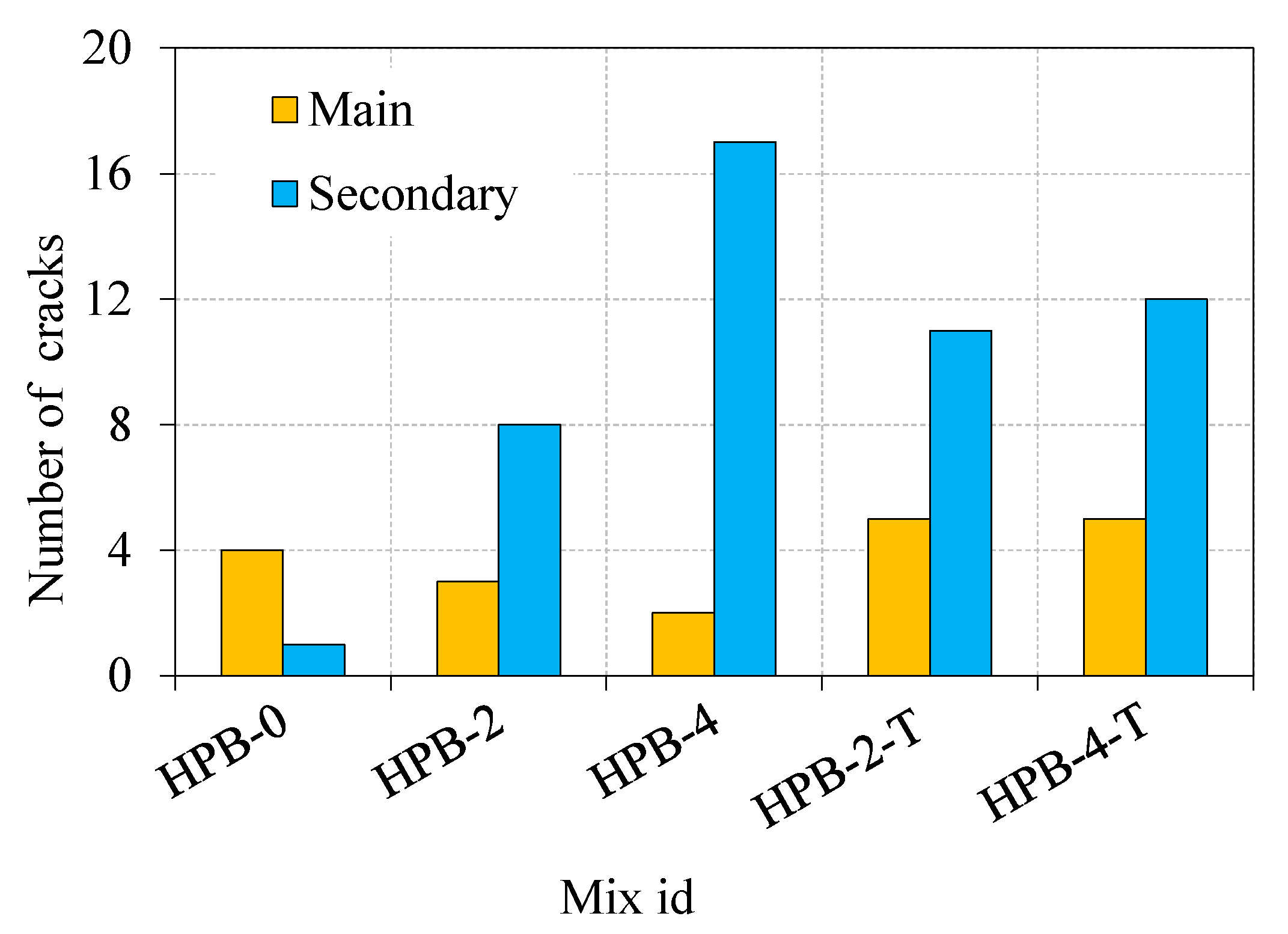

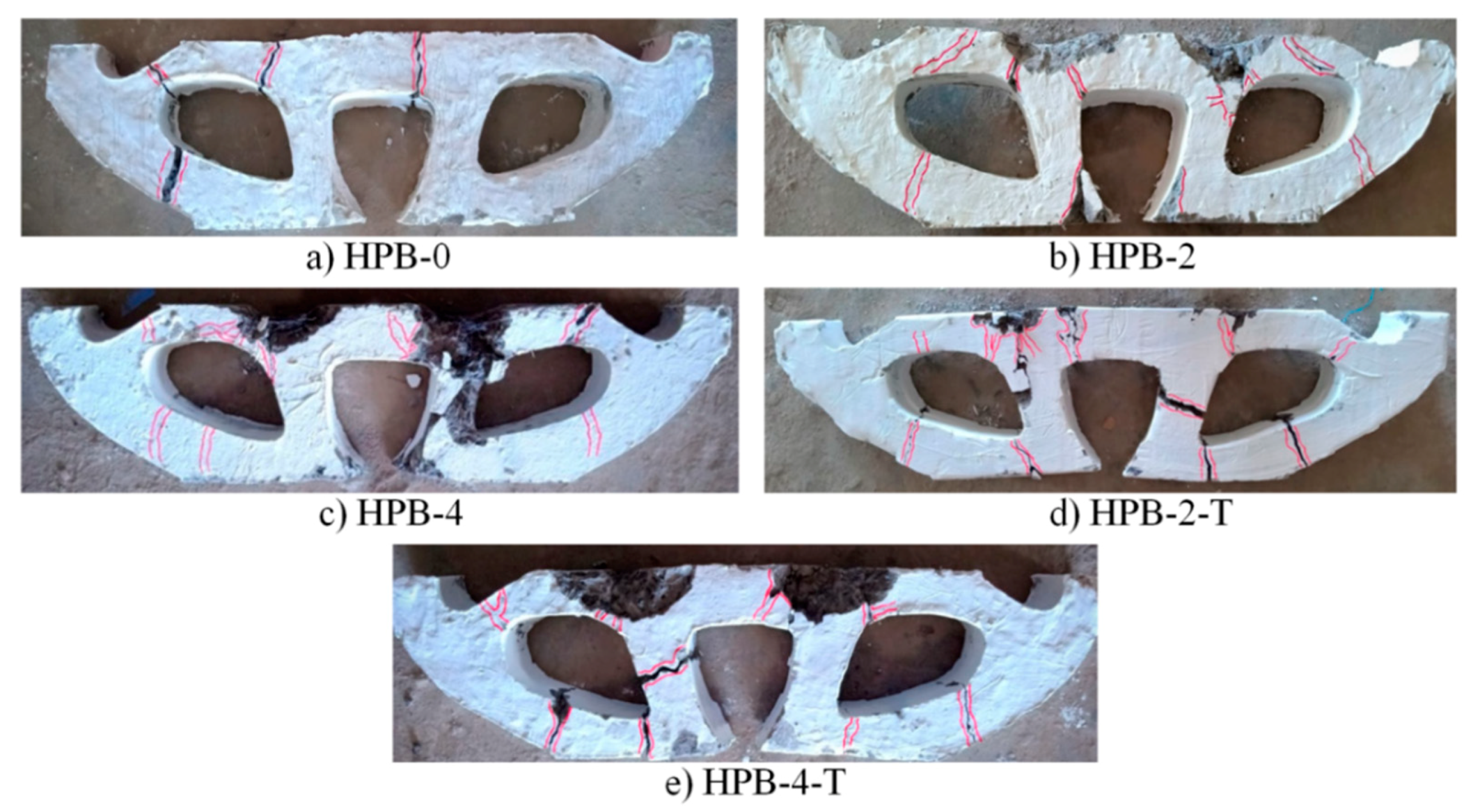

3.5. Number of Cracks and Failure Pattern

4. Conclusions

- The compressive strength of concrete is increased when the dosage of fiber is increased. For instance, the compressive strength is increased by about 56.9%, when the corresponding dosage of steel fiber was 4%. Besides, the fiber balling is wholly eradicated due to the new casting techniques adopted for producing PAFC.

- It is found that when the HPB-4 contained a 4% fiber dosage in full cross-section, the impact energy at initial crack and failure were 2725.1 J and 3009.8 J, respectively. This phenomenon is attributed to fiber steel fibers, which plays a crucial part in improving the impact energy absorbance of the cracking zone and adjoining crack tip by the action of fiber bridging, thus arresting cracks.

- The highest impact ductility index was observed in HPB-4-T, followed by HPB-2-T due to the tensile strength of fiber and bridging action. The post crack resistance against impact load is much higher in the beam reinforced in the tensile zone than the beam reinforced in the full cross-section because of the more fibers provided at tensile zone.

- Two different failure modes were observed. First, brittle failure was observed in the non-fibrous beam due to the fibre’s absence. Second, all fibrous beams experienced a ductile failure resulting from fiber bridging action, which leads to multiple micro-cracks, thereby delaying the failure.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bhattacherjee, S.; Rahul, A.V.; Santhanam, M. 3D Printing—Progress Worldwide. Indian Concr. J. 2020, 94, 8–25. [Google Scholar]

- Veenendaal, D.; West, M.; Block, P. History and overview of fabric formwork: Using fabrics for concrete casting. Struct. Concr. 2011, 12, 164–177. [Google Scholar] [CrossRef]

- Srivastava, S.; Salunkhe, S.; Pande, S.; Kapadiya, B. Topology optimization of steering knuckle structure. Int. J. Simul. Multidiscip. Des. Optim. 2020, 11, 4. [Google Scholar] [CrossRef]

- Shi, J.-F.; Sun, J.-H. Overview on Innovation of Topology Optimization in Vehicle CAE. In Proceedings of the 2009 International Conference on Electronic Computer Technology (ICECT 2009), Macau, China, 20–22 February 2009; pp. 457–460. [Google Scholar] [CrossRef]

- Yu, M.; Ruan, S.; Gu, J.; Ren, M.; Li, Z.; Wang, X.; Shen, C. Three-dimensional topology optimization of thermal-fluid-structural problems for cooling system design. Struct. Multidiscip. Optim. 2020, 62, 3347–3366. [Google Scholar] [CrossRef]

- Ruan, X.; Jiang, P.; Zhou, Q.; Hu, J.; Shu, L. Variable-fidelity probability of improvement method for efficient global optimization of expensive black-box problems. Struct. Multidiscip. Optim. 2020, 62, 3021–3052. [Google Scholar] [CrossRef]

- Vantyghem, G.; De Corte, W.; Steeman, M.; Boel, V. Density-based topology optimization for 3D-printable building structures. Struct. Multidiscip. Optim. 2019, 60, 2391–2403. [Google Scholar] [CrossRef]

- Carstensen, J.V. Topology optimization with nozzle size restrictions for material extrusion-type additive manufacturing. Struct. Multidiscip. Optim. 2020, 62, 2481–2497. [Google Scholar] [CrossRef]

- Liu, J.; Gaynor, A.T.; Chen, S.; Kang, Z.; Suresh, K.; Takezawa, A.; Li, L.; Kato, J.; Tang, J.; Wang, C.C.L.; et al. Current and future trends in topology optimization for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 2457–2483. [Google Scholar] [CrossRef]

- Schmidt, M.-P.; Couret, L.; Gout, C.; Pedersen, C.B.W. Structural topology optimization with smoothly varying fiber orientations. Struct. Multidiscip. Optim. 2020, 62, 3105–3126. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.-F.M. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Tajs-Zielińska, K.; Bochenek, B. Topology Optimization—Engineering Contribution to Architectural Design. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 082057. [Google Scholar] [CrossRef]

- Beghini, L.L.; Beghini, A.; Katz, N.; Baker, W.F.; Paulino, G. Connecting architecture and engineering through structural topology optimization. Eng. Struct. 2014, 59, 716–726. [Google Scholar] [CrossRef]

- D’Uva, D. Handbook of Research on form and Morphogenesis in Modern Architectural Contexts; IGI Global: Hershe, PA, USA, 2018; pp. 1–493. [Google Scholar] [CrossRef]

- Montes, M.A.O.; Ivvan, S.; Pe, V.; Rionda, S.B. Topology Optimization Algorithms for the Solution of Compliance and Volume Problems in 2D; Topology; Centro de Investigaci´on en Matem´aticas A.C.: Guanajuato, México, 2016. [Google Scholar]

- Sigmund, O.; Maute, K. Topology optimization approaches: A comparative review. Struct. Multidiscip. Optim. 2013, 48, 1031–1055. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Duysinx, P. Topology Optimizatin of Continuum Structures with Local Stress Constraints. Int. J. Numer. Methods Eng. 1998, 43, 1453–1478. [Google Scholar] [CrossRef]

- Bendsoe, M.P.; Sigmund, O. Topology Optimization Theory, Methods and Applications; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Polajnar, M.; Kosel, F.; Drazumeric, R. Structural optimization using global stress-deviation objective function via the level-set method. Struct. Multidiscip. Optim. 2016, 55, 91–104. [Google Scholar] [CrossRef]

- Deaton, J.D.; Grandhi, R.V. A survey of structural and multidisciplinary continuum topology optimization: Post 2000. Struct. Multidiscip. Optim. 2014, 49, 1–38. [Google Scholar] [CrossRef]

- Picelli, R.; Townsend, S.; Brampton, C.; Norato, J.; Kim, H. Stress-based shape and topology optimization with the level set method. Comput. Methods Appl. Mech. Eng. 2018, 329, 1–23. [Google Scholar] [CrossRef]

- Jeong, S.H.; Yoon, G.H.; Takezawa, A.; Choi, D.-H. Development of a novel phase-field method for local stress-based shape and topology optimization. Comput. Struct. 2014, 132, 84–98. [Google Scholar] [CrossRef]

- Salaimanimagudam, M.P.; Suribabu, C.R.; Murali, G.; Abid, S.R. Impact Response of Hammerhead Pier Fibrous Concrete Beams Designed with Topology Optimization. Period. Polytech. Civ. Eng. 2020, 18, 1244–1258. [Google Scholar] [CrossRef]

- Xia, Y.; Langelaar, M.; Hendriks, M.A. Optimization-based three-dimensional strut-and-tie model generation for reinforced concrete. Comput. Aided Civ. Infrastruct. Eng. 2020, 1–18. [Google Scholar] [CrossRef]

- Xia, Y.; Langelaar, M.; Hendriks, M.A. A critical evaluation of topology optimization results for strut-and-tie modeling of reinforced concrete. Comput. Aided Civ. Infrastruct. Eng. 2020, 5, 850–869. [Google Scholar] [CrossRef]

- Jewett, J.L.; Carstensen, J.V. Topology-optimized design, construction and experimental evaluation of concrete beams. Autom. Constr. 2019, 102, 59–67. [Google Scholar] [CrossRef]

- Nehdi, M.L.; Najjar, M.F.; Soliman, A.M.; Azabi, T.M. Novel steel fibre-reinforced preplaced aggregate concrete with superior mechanical performance. Cem. Concr. Compos. 2017, 82, 242–251. [Google Scholar] [CrossRef]

- Najjar, M.F.; Soliman, A.M.; Nehdi, M. Critical overview of two-stage concrete: Properties and applications. Constr. Build. Mater. 2014, 62, 47–58. [Google Scholar] [CrossRef]

- Bras, A.; Gião, A.R.F.C.D.S.; Lúcio, V.; Chastre, C. Development of an injectable grout for concrete repair and strengthening. Cem. Concr. Compos. 2013, 37, 185–195. [Google Scholar] [CrossRef]

- Lee, S.; Jang, S.Y.; Kim, C.Y.; Ahn, E.J.; Kim, S.P.; Gwon, S.; Shin, M. Effects of Redispersible Polymer Powder on Mechanical and Durability Properties of Preplaced Aggregate Concrete with Recycled Railway Ballast. Int. J. Concr. Struct. Mater. 2018, 12, 69. [Google Scholar] [CrossRef]

- An, X.; Wu, Q.; Jin, F.; Huang, M.; Zhou, H.; Chen, C.; Liu, C. Rock-filled concrete, the new norm of SCC in hydraulic engineering in China. Cem. Concr. Compos. 2014, 54, 89–99. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, T.; Li, K. Development and Investigation of a New Low-Cement-Consumption Concrete—Preplaced Aggregate Concrete. Sustainability 2020, 12, 1080. [Google Scholar] [CrossRef]

- Stempkowska, A.; Gawenda, T.; Naziemiec, Z.; Ostrowski, K.A.; Saramak, D.; Surowiak, A. Impact of the Geometrical Parameters of Dolomite Coarse Aggregate on the Thermal and Mechanic Properties of Preplaced Aggregate Concrete. Materials 2020, 13, 4358. [Google Scholar] [CrossRef]

- Yoon, J.; Kim, H.; Shin, S.W.; Sim, S.-H. Rheology-based determination of injectable grout fluidity for preplaced aggregate concrete using ultrasonic tomography. Constr. Build. Mater. 2020, 260, 120447. [Google Scholar] [CrossRef]

- Zhang, C.; Gholipour, G.; Mousavi, A.A. State-of-the-Art Review on Responses of RC Structures Subjected to Lateral Impact Loads. Arch. Comput. Methods Eng. 2020, 1–31. [Google Scholar] [CrossRef]

- Manohar, T.; Suribabu, C.R.; Murali, G.; Salaimanimagudam, M.P. A novel steel-PAFRC composite fender for bridge pier protection under low velocity vessel impacts. Structures 2020, 26, 765–777. [Google Scholar] [CrossRef]

- Zhang, C.; Gholipour, G.; Mousavi, A.A. Nonlinear dynamic behavior of simply-supported RC beams subjected to combined impact-blast loading. Eng. Struct. 2019, 181, 124–142. [Google Scholar] [CrossRef]

- Bruggi, M.; Taliercio, A. Topology optimization of the fiber-reinforcement retrofitting existing structures. Int. J. Solids Struct. 2013, 50, 121–136. [Google Scholar] [CrossRef]

- Bruggi, M. Topology optimization with mixed finite elements on regular grids. Comput. Methods Appl. Mech. Eng. 2016, 305, 133–153. [Google Scholar] [CrossRef][Green Version]

- Osanov, M.; Carstensen, J.V.; Tromme, E.M.; Guest, J.K.; Williams, C. Topology Optimization for Additive Manufacturing: New Projection-based Design Algorithms. In Proceedings of the 17th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, Washington, DC, USA, 13–17 June 2016; pp. 1–9. [Google Scholar] [CrossRef]

- Jaishankar, P.; Murali, G.; Salaimanimagudam, M.P.; Amran, Y.H.; Fediuk, R.; Karthikeyan, K. Study of Topology Optimized Hammerhead Pier Beam Made with Novel Preplaced Aggregate Fibrous Concrete. Period. Polytech. Civ. Eng. 2020, 65, 287–298. [Google Scholar] [CrossRef]

- IS 1489-1. Specification for Portland Pozzolana Cement. India. 1991. Available online: https://archive.org/details/gov.in.is.1489.1.1991/page/n7/mode/2up (accessed on 31 January 2021).

- IS:383-2016. Coarse and Fine Aggregate for Concrete—Specification, (Third Revision), India. 2016. Available online: http://skgcgroup.com/wp-content/uploads/2020/02/IS%20383-2016.pdf (accessed on 31 January 2021).

- American Society for Testing and Materials (ASTM). Sandard Test Methods for Flow of Grout for Preplaced-Aggregate Concrete (Flow Cone Method); ASTM: West Conshohocken, PA, USA, 2010. [Google Scholar]

- ACI544.2R-89. Measurement of Properties of Fibber Reinforced Concrete; ACI: West Conshohocken, PA, USA, 1999. [Google Scholar]

- Abid, S.R.; Hussein, M.L.A.; Ali, S.H.; Kazem, A.F. Suggested modified testing techniques to the ACI 544-R repeated drop-weight impact test. Constr. Build. Mater. 2020, 244, 118321. [Google Scholar] [CrossRef]

- Rithanyaa, R.; Murali, G.; Salaimanimagudam, M.; Fediuk, R.; Abdelgader, H.S.; Siva, A. Impact response of novel layered two stage fibrous composite slabs with different support type. Structures 2021, 29, 1–13. [Google Scholar] [CrossRef]

- Abid, S.R.; Murali, G.; Amran, M.; Vatin, N.; Fediuk, R.; Karelina, M. Evaluation of Mode II Fracture Toughness of Hybrid Fibrous Geopolymer Composites. Materials 2021, 14, 349. [Google Scholar] [CrossRef]

- Abid, S.R.; Gunasekaran, M.; Ali, S.H.; Kadhum, A.L.; Al-Gasham, T.S.; Fediuk, R.; Vatin, N.; Karelina, M. Impact Performance of Steel Fiber-Reinforced Self- Compacting Concrete against Repeated Drop Weight Impact. Crystals 2021, 11, 91. [Google Scholar] [CrossRef]

- Prasad, N.; Murali, G.; Fediuk, R.; Vatin, N.; Karelina, M. Response of Novel Functionally-Graded Prepacked Aggregate Fibrous Concrete against Low Velocity Repeated Projectile Impacts. Materials 2021, 14, 280. [Google Scholar] [CrossRef] [PubMed]

- Loganaganandan., M.; Murali, G.; Salaimanimagudam, M.P.; Haridharan, M.P.; Karthikeyan, K. Experimental Study on GFRP Strips Strengthened New Two Stage Concrete Slabs under Falling Mass Collisions. KSCE J. Civ. Eng. 2021, 25, 235–244. [Google Scholar] [CrossRef]

- Murali, G.; Amran, M.; Fediuk, R.; Vatin, N.; Raman, S.N.; Maithreyi, G.; Sumathi, A. Structural Behavior of Fibrous-Ferrocement Panel Subjected to Flexural and Impact Loads. Materials 2020, 13, 5648. [Google Scholar] [CrossRef] [PubMed]

- Prasad, N.; Murali, G. Exploring the impact performance of functionally-graded preplaced aggregate concrete incorporating steel and polypropylene fibres. J. Build. Eng. 2021, 35, 102077. [Google Scholar] [CrossRef]

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vatin, N.; Promakhov, V.; Vasilev, Y. Experimental Tests and Reliability Analysis of the Cracking Impact Resistance of UHPFRC. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, Y.H.M.; Abdelgader, H.S.; Fediuk, R.; Susrutha, A.; Poonguzhali, K. Impact performance of novel multi-layered prepacked aggregate fibrous composites under compression and bending. Structures 2020, 28, 1502–1515. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Vatin, N.; Huei Lee, Y.; Murali, G.; Ozbakkaloglu, T.; Klyuev, S.; Alabduljabber, H. Fibre-Reinforced Foamed Concretes: A Review. Materials 2020, 13, 4323. [Google Scholar] [CrossRef]

- Haridharan, M.K.; Matheswaran, S.; Murali, G.; Abid, S.R.; Fediuk, R.; Amran, Y.H.M.; Abdelgader, H.S. Impact response of two-layered grouted aggregate fibrous concrete composite under falling mass impact. Constr. Build. Mater. 2020, 263, 120628. [Google Scholar] [CrossRef]

- Abirami, T.; Murali, G.; Saravana Raja Mohan, K.; Salaimanimagudam, M.P.; Nagaveni, P.; Bhargavi, P. Multi-layered two stage fibrous composites against low-velocity falling mass and projectile impact. Constr. Build. Mater. 2020, 248, 118631. [Google Scholar] [CrossRef]

- Murali, G.; Fediuk, R. A Taguchi approach for study on impact response of ultra-high-performance polypropylene fibrous cementitious composite. J. Build. Eng. 2020, 30, 101301. [Google Scholar] [CrossRef]

- Murali, G.; Laxminadh, P.; Parthiban, K.; Haridharan, M.K.; Siva, A. Impact Response of Novel Fibre-Reinforced Grouted Aggregate Rubberized Concrete. Arab. J. Sci. Eng. 2019, 44, 8451–8463. [Google Scholar] [CrossRef]

- Abirami, T.; Loganaganandan, M.; Murali, G.; Fediuk, R.; Vickhram Sreekrishna, R.; Vignesh, T.; Januppriya, G.; Karthikeyan, K. Experimental research on impact response of novel steel fibrous concretes under falling mass impact. Constr. Build. Mater. 2019, 222, 447–457. [Google Scholar] [CrossRef]

- Ramkumar, V.R.; Murali, G.; Asrani, N.P.; Karthikeyan, K. Development of a novel low carbon cementitious two stage layered fibrous concrete with superior impact strength. J. Build. Eng. 2019, 25, 100841. [Google Scholar] [CrossRef]

- Asrani, N.P.; Murali, G.; Parthiban, K.; Surya, K.; Prakash, A.; Rathika, K.; Chandru, U. A feasibility of enhancing the impact resistance of hybrid fibrous geopolymer composites: Experiments and modelling. Constr. Build. Mate. 2019, 203, 56–68. [Google Scholar] [CrossRef]

- Murali, G.E.; Vinodha, E. Experimental and Analytical Study of Impact Failure Strength of Steel Hybrid Fibre Reinforced Concrete Subjected to Freezing and Thawing Cycles. Arab. J. Sci. Eng. 2018, 43, 5487–5497. [Google Scholar] [CrossRef]

- Murali, G.; Ramprasad, K. A feasibility of enhancing the impact strength of novel layered two stage fibrous concrete slabs. Eng. Struct. 2018, 175, 41–49. [Google Scholar] [CrossRef]

- Murali, G.; Venkatesh, J.; Lokesh, N.; Reddy, N.T.; Karthikeyan, K. Comparative Experimental and Analytical Modeling of Impact Energy Dissipation of Ultra-High Performance Fibre Reinforced Concrete. KSCE J. Civ. Eng. 2018, 22, 3112–3119. [Google Scholar] [CrossRef]

| Type | Physical Quantity | Similitude Relation | Similitude Parameter |

|---|---|---|---|

| Geometry | Length (L) | 1:20 | |

| Displacement (δ) | 1:20 | ||

| Material properties | Elastic modulus, (E) | 1 | |

| Stress (σ) | 1 | ||

| Loads | Strain (ε) | 1 | |

| Force (F) | 1:400 |

| Fiber Type | Tensile Strength (MPa) | Diameter (mm) | Length (mm) |

|---|---|---|---|

| Hybrid hooked end-crimped | 1150 | 1 | 50 |

| Mixture ID | W/B | S/B | t (Sec) | Fiber Dosage (%) | SP (%) | |

|---|---|---|---|---|---|---|

| Tension Region | Compression Region | |||||

| HPB-0 | 0.42 | 1.0 | 36 | 0 | 0 | 0.3 |

| HPB-2 | 39 | 2 | 2 | 0.5 | ||

| HPB-4 | 39 | 4 | 4 | |||

| HPB-2-T | 39 | 2 | 0 | |||

| HPB-4-T | 39 | 4 | 0 | |||

| Mix Id | Number of Hits | Impact Energy (J) | Impact Ductility Index | No of Cracks | |||

|---|---|---|---|---|---|---|---|

| IC | FA | IC | FA | Major | Minor | ||

| HPB-0 | 3 | 5 | 122.0 | 203.4 | 1.7 | 4 | 1 |

| HPB-2 | 57 | 192 | 2318.4 | 7809.2 | 3.4 | 3 | 8 |

| HPB-4 | 67 | 242 | 2725.1 | 9842.9 | 3.6 | 2 | 17 |

| HPB-2-T | 8 | 47 | 325.4 | 1911.6 | 5.9 | 5 | 11 |

| HPB-4-T | 12 | 74 | 488.1 | 3009.8 | 6.2 | 5 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salaimanimagudam, M.P.; Murali, G.; Vardhan, C.M.V.; Amran, M.; Vatin, N.; Fediuk, R.; Vasilev, Y. Impact Response of Preplaced Aggregate Fibrous Concrete Hammerhead Pier Beam Designed with Topology Optimization. Crystals 2021, 11, 147. https://doi.org/10.3390/cryst11020147

Salaimanimagudam MP, Murali G, Vardhan CMV, Amran M, Vatin N, Fediuk R, Vasilev Y. Impact Response of Preplaced Aggregate Fibrous Concrete Hammerhead Pier Beam Designed with Topology Optimization. Crystals. 2021; 11(2):147. https://doi.org/10.3390/cryst11020147

Chicago/Turabian StyleSalaimanimagudam, Meivazhisalai Parasuraman, Gunasekaran Murali, C. M. Vivek Vardhan, Mugahed Amran, Nikolai Vatin, Roman Fediuk, and Yuriy Vasilev. 2021. "Impact Response of Preplaced Aggregate Fibrous Concrete Hammerhead Pier Beam Designed with Topology Optimization" Crystals 11, no. 2: 147. https://doi.org/10.3390/cryst11020147

APA StyleSalaimanimagudam, M. P., Murali, G., Vardhan, C. M. V., Amran, M., Vatin, N., Fediuk, R., & Vasilev, Y. (2021). Impact Response of Preplaced Aggregate Fibrous Concrete Hammerhead Pier Beam Designed with Topology Optimization. Crystals, 11(2), 147. https://doi.org/10.3390/cryst11020147