Investigation of the Optimum Mg Doping Concentration in p-Type-Doped Layers of InGaN Blue Laser Diode Structures

Abstract

:1. Introduction

2. Materials and Methods

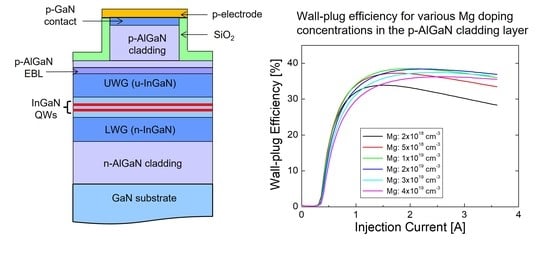

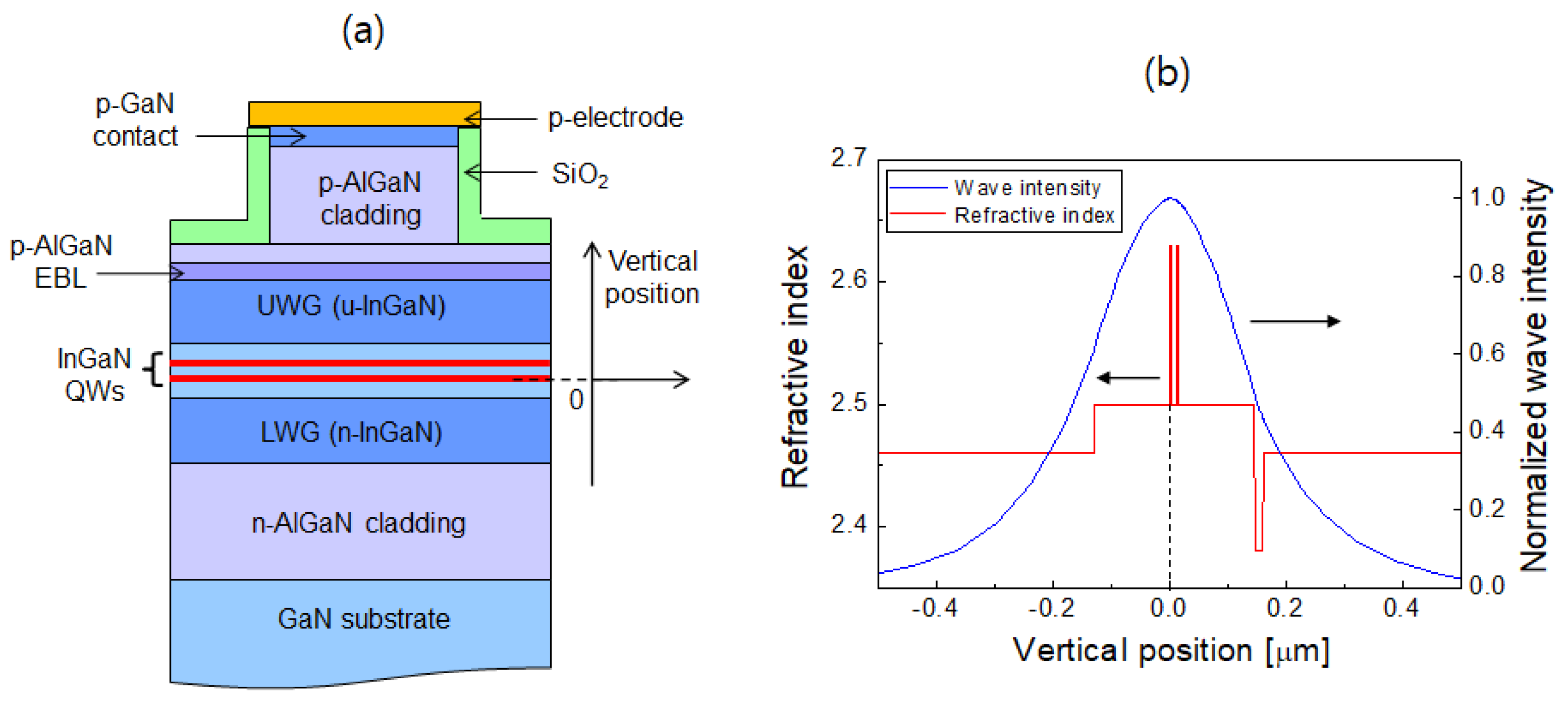

2.1. Laser Diode Structure

2.2. Simulation Methods

3. Results and Discussion

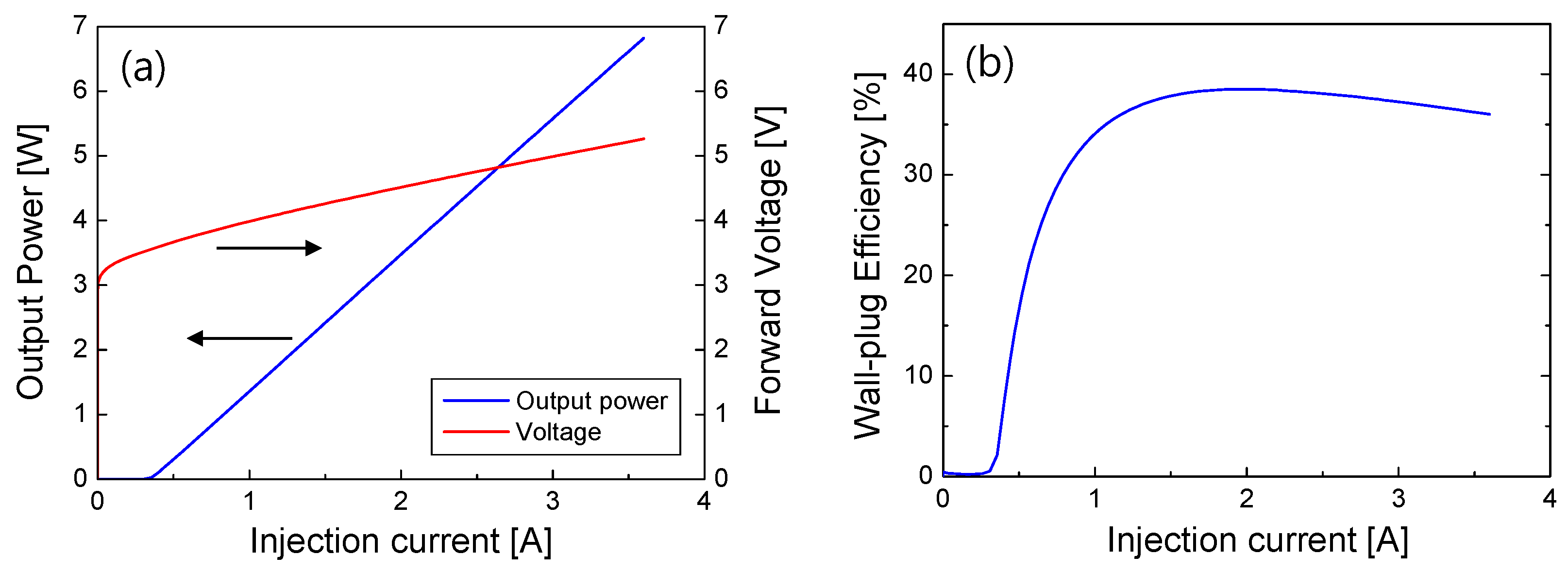

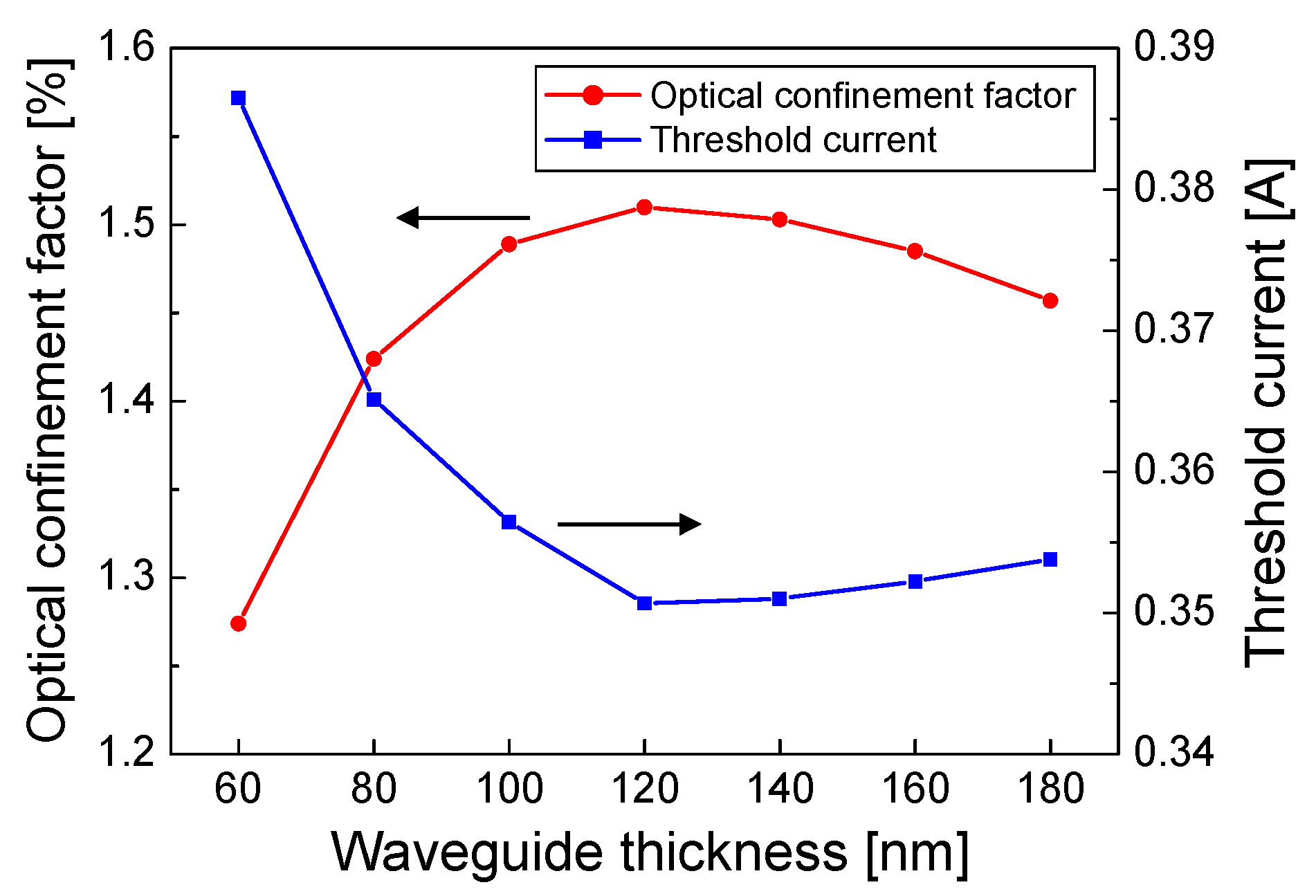

3.1. Optimum Thickness of LWG and UWG

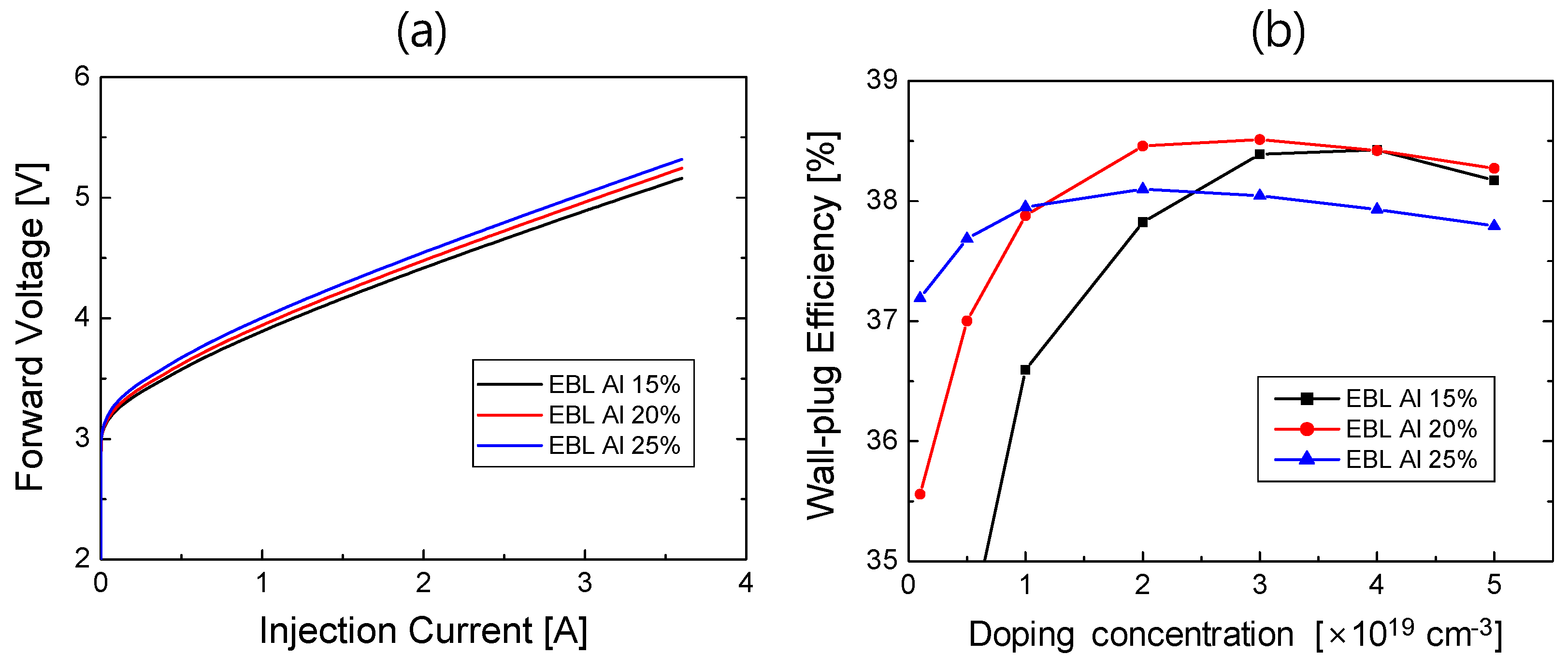

3.2. Optimization of EBL

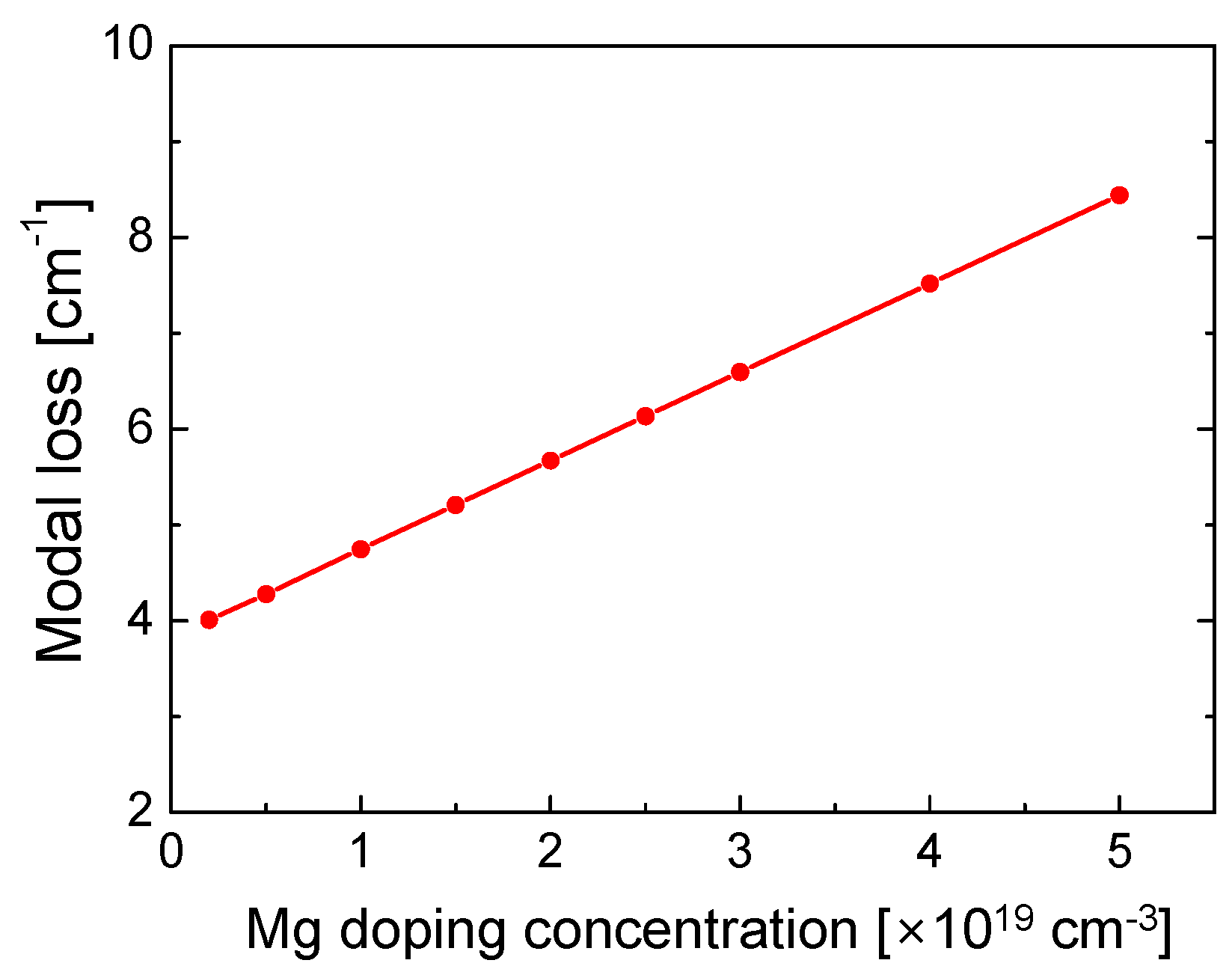

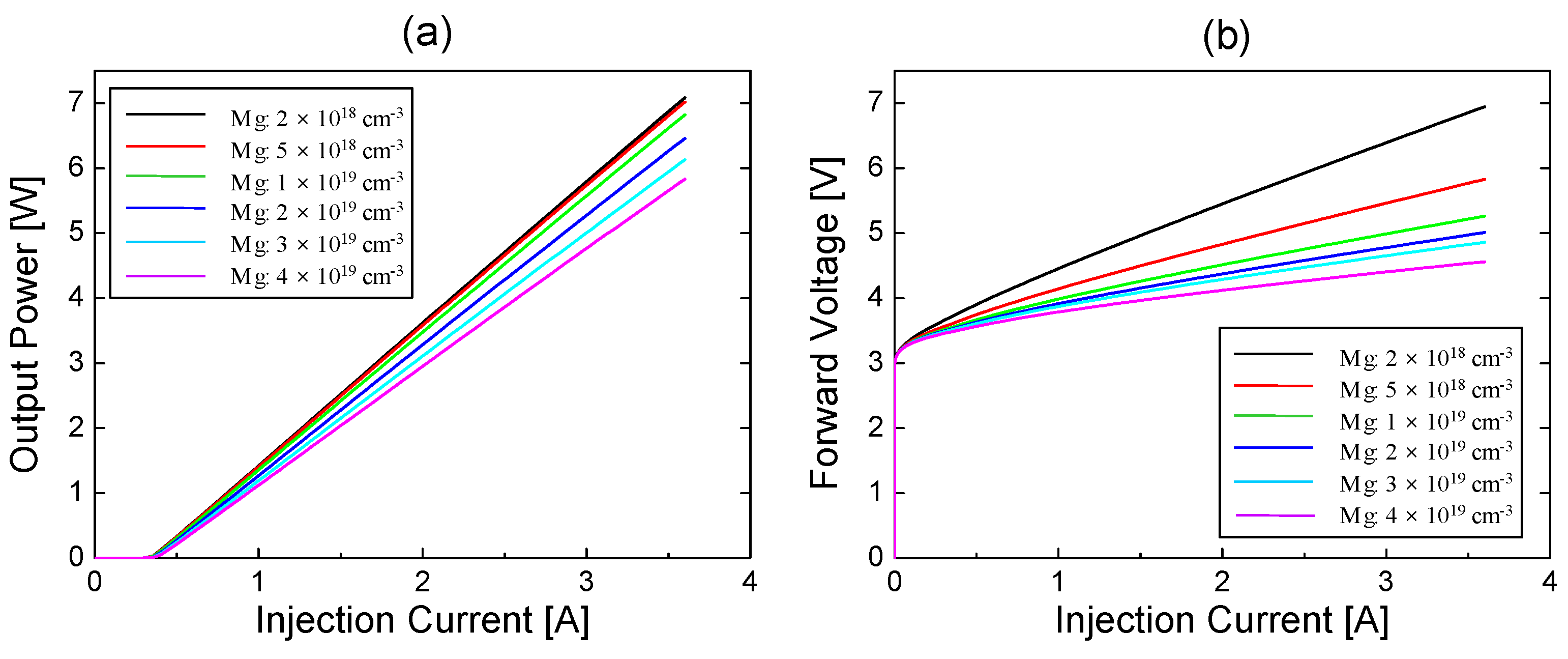

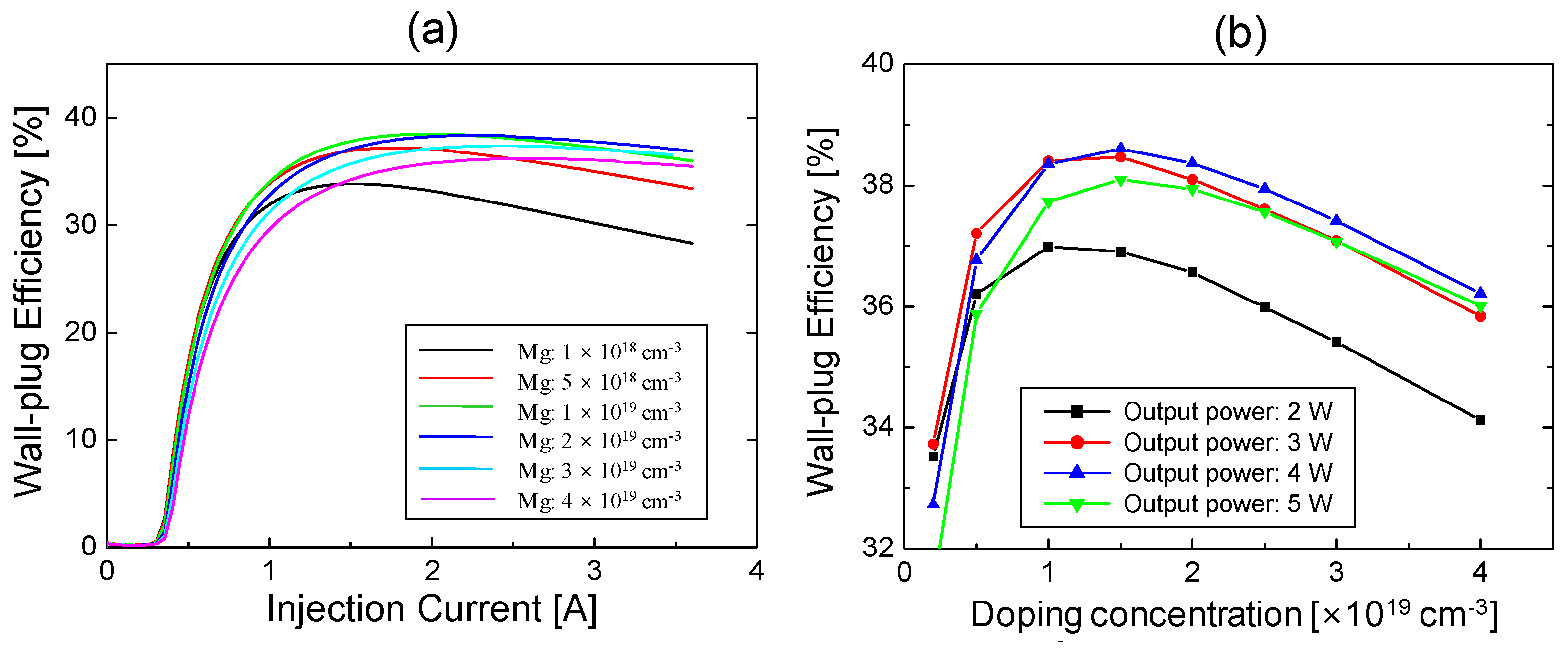

3.3. Optimum Mg Doping Concentration in the p-AlGaN Cladding Layer

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nakamura, S.; Senoh, M.; Nagahama, S.; Iwasa, N.; Yamada, T.; Matsushita, T.; Kiyoku, H.; Sugimoto, Y. InGaN-based multi-quantum-well-structure laser diodes. Jpn. J. Appl. Phys. 1996, 35, L74–L76. [Google Scholar] [CrossRef]

- Nagahama, S.; Yanamoto, T.; Sano, M.; Mukai, T. Wavelength dependence of InGaN laser diode characteristics. Jpn. J. Appl. Phys. 2001, 40, 3075–3081. [Google Scholar] [CrossRef]

- Nakatsu, Y.; Nagao, Y.; Hirao, T.; Hara, Y.; Masui, S.; Yanamoto, T.; Nagahama, S. Blue and green InGaN semiconductor lasers as light sources for displays. Proc. SPIE 2020, 11280, 112800S. [Google Scholar]

- Murayama, M.; Nakayama, Y.; Yamazaki, K.; Hoshina, Y.; Watanabe, H.; Fuutagawa, N.; Kawanishi, H.; Uemura, T.; Narui, H. Watt-class green (530 nm) and blue (465 nm) laser diodes. Phys. Status Solidi A 2018, 215, 1700513. [Google Scholar] [CrossRef]

- Buckley, E. Laser wavelength choices for pico-projector applications. J. Disp. Technol. 2011, 7, 402. [Google Scholar] [CrossRef]

- Wierer, J.J.; Tsao, J.Y.; Sizov, D.S. Comparison between blue lasers and light-emitting diodes for future solid-state lighting. Laser Photonics Rev. 2013, 7, 963–993. [Google Scholar] [CrossRef]

- Ryu, H.Y.; Kim, D.H. High-brightness phosphor-conversion white light source using InGaN blue laser diode. J. Opt. Soc. Korea 2010, 14, 415–419. [Google Scholar] [CrossRef] [Green Version]

- Chi, Y.C.; Hsieh, D.H.; Lin, C.Y.; Chen, H.Y.; Huang, C.Y.; He, J.H.; Ooi, B.; DenBaars, S.P.; Nakamura, S.; Kuo, H.C.; et al. Phosphorous diffuser diverged blue laser diode for indoor lighting and communication. Sci. Rep. 2015, 5, 18690. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Watson, S.; Tan, M.; Najda, S.P.; Perlin, P.; Leszczynski, M.; Targowaski, G.; Grzanka, S.; Kelly, A.E. Visible light communications using a directly modulated 422 nm GaN laser diode. Opt. Lett. 2013, 38, 3792–3794. [Google Scholar] [CrossRef]

- Lee, C.; Zhang, C.; Cantore, M.; Farrell, R.M.; Oh, S.H.; Margalith, T.; Speck, J.S.; Nakamura, S.; Bowers, J.E.; DenBaars, S.P. 4 Gbps direct modulation of 450 nm GaN laser for high-speed visible light communication. Opt. Express 2015, 23, 16232–16237. [Google Scholar] [CrossRef]

- Wu, T.C.; Chi, Y.C.; Wang, H.Y.; Tsai, C.T.; Lin, G.R. Blue laser diode enables underwater communication at 12.4 Gbps. Sci. Rep. 2017, 7, 40480. [Google Scholar] [CrossRef] [PubMed]

- Baumann, M.; Balck, A.; Malchus, J.; Chacko, R.V.; Marfels, S.; Witte, U.; Dinakaran, D.; Ocylok, S.; Weinbach, M.; Bachert, C.; et al. 1000 W blue fiber-coupled diode laser emitting at 450 nm. Proc. SPIE 2019, 10900, 1090005. [Google Scholar]

- Coffey, V.C. High-powered diode lasers—New, bright and blue. Opt. Photonics News. 2020, 28–35. [Google Scholar] [CrossRef]

- Hagino, H.; Kawaguchi, M.; Nozaki, S.; Mochida, A.; Kano, T.; Takigawa, S.; Katayama, T.; Tanaka, T. High-power InGaN laser array with advanced lateral-corrugated waveguides. IEEE J. Quantum Electron. 2021, 57, 2600107. [Google Scholar] [CrossRef]

- Zhong, Z.; Lu, S.; Li, J.; Lin, W.; Huang, K.; Li, S.; Cai, D.; Kang, J. Design and fabrication of high power InGaN blue laser diode over 8 W. Opt. Laser Technol. 2021, 139, 106985. [Google Scholar] [CrossRef]

- Crump, P.; Wang, J.; Das, S.; Grimshaw, M.; Farmer, J.; DeVito, M.; Dong, W.; Crum, T.; Wise, D.; Feng, Y. >360 W and >70% efficient GaAs-based diode lasers. Proc. SPIE 2005, 5711, 21–29. [Google Scholar]

- Piprek, J. Comparative efficiency analysis of GaN-based light-emitting diodes and laser diodes. Appl. Phys. Lett. 2016, 109, 021104. [Google Scholar] [CrossRef]

- Piprek, J. Analysis of efficiency limitations in high-power InGaN/GaN laser diodes. Opt. Quantum Electron. 2016, 48, 471. [Google Scholar] [CrossRef]

- Uchida, S.; Takeya, M.; Ikeda, S.; Mizuno, T.; Fujimoto, T.; Matsumoto, O.; Goto, S.; Tojyo, T.; Ikeda, M. Recent progress in high-power blue-violet lasers. IEEE J. Sel. Top. Quantum Electron. 2003, 9, 1252–1259. [Google Scholar] [CrossRef]

- Ryu, H.Y.; Ha, K.H.; Son, J.K.; Paek, H.S.; Sung, Y.J.; Kim, K.S.; Kim, H.K.; Park, Y.; Lee, S.N.; Nam, O.H. Comparison of output power of InGaN laser diodes for different Al compositions in the AlGaN n-cladding layer. J. Appl. Phys. 2009, 105, 103102. [Google Scholar] [CrossRef]

- Chen, P.; Feng, M.X.; Jiang, D.S.; Zhao, D.G.; Liu, Z.S.; Li, L.; Wu, L.L.; Le, L.C.; Zhu, J.J.; Wang, H.; et al. Improvement of characteristics of InGaN-based laser diodes with undoped InGaN upper waveguide layer. J. Appl. Phys. 2012, 112, 113105. [Google Scholar] [CrossRef]

- Liang, F.; Zhao, D.; Jiang, D.; Liu, Z.; Zhu, J.; Chen, P.; Yang, J.; Liu, W.; Li, X.; Liu, S.; et al. New design of upper waveguide with unintentionally doped InGaN layer for InGaN-based laser diode. Opt. Laser Technol. 2017, 97, 284–289. [Google Scholar] [CrossRef]

- Kawaguchi, M.; Imafuji, O.; Nozaki, S.; Hagino, H.; Takigawa, S.; Katayama, T.; Tanaka, T. Optical-loss suppressed InGaN laser diodes using undoped thick waveguide structure. Proc. SPIE 2016, 9748, 974818. [Google Scholar]

- Hou, Y.; Zhao, D.; Liang, F.; Liu, Z.; Yang, J.; Chen, P. Enhancing the efficiency of GaN-based laser diodes by the designing of a p-AlGaN cladding layer and an upper waveguide layer. Opt. Mater. Express 2021, 11, 1780–1790. [Google Scholar] [CrossRef]

- Schubert, E.F. Light-Emitting Diodes, 2nd ed.; Cambridge University Press: Cambridge, UK, 2006; pp. 145–149. [Google Scholar]

- Kioupakis, E.; Rinke, P.; Van de Walle, C.G. Determination of internal loss in nitride lasers from first principles. Appl. Phys. Express 2010, 3, 082101. [Google Scholar] [CrossRef]

- Pourhashemi, A.; Farrell, R.M.; Cohen, D.A.; Speck, J.S.; DenBaars, S.P.; Nakamura, S. High-power blue laser diodes with indium tin oxide cladding on semipolar (202-1-) GaN substrates. Appl. Phys. Lett. 2015, 106, 111105. [Google Scholar] [CrossRef]

- Li, X.; Zhao, D.G.; Jiang, D.S.; Chen, P.; Liu, Z.S.; Zhu, J.J.; Yang, J.; Liu, W.; He, X.G.; Li, X.J.; et al. The effectiveness of electron blocking layer in InGaN-based laser diodes with different indium content. Phys. Status Solidi A 2016, 213, 2223–2228. [Google Scholar] [CrossRef]

- Wang, W.; Xie, W.; Deng, Z.; Liao, M. Improving output power of InGaN laser diode using asymmetric In0.15Ga0.85N/In0.02Ga0.98N multiple quantum wells. Micromachines 2019, 10, 895. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cheng, L.; Li, Z.; Zhang, J.; Lin, X.; Yang, D.; Chen, H.; Wu, S.; Yao, S. Advantages of InGaN-GaN-InGaN delta barriers for InGaN-based laser diodes. Nanomaterials 2021, 11, 2070. [Google Scholar] [CrossRef] [PubMed]

- LASTIP by Crosslight Software Inc Burnaby Canada. Available online: http://crosslight.com (accessed on 1 October 2021).

- Chang, Y.L.; Ludowise, M.; Lefforge, D.; Perez, B. Study of Mg diffusion during metalorganic chemical vapor deposition of GaN and AlGaN. Appl. Phys. Lett. 1999, 74, 688–690. [Google Scholar] [CrossRef]

- Köhler, K.; Gutt, R.; Wiegert, J.; Kirste, L. Diffusion of Mg dopant in metal-organic vapor-phase epitaxy grown GaN and AlxGa1-xN. J. Appl. Phys. 2013, 113, 073514. [Google Scholar] [CrossRef]

- Nam, O.H.; Ha, K.H.; Kwak, J.S.; Lee, S.N.; Choi, K.K.; Chang, T.H.; Chae, S.H.; Lee, W.S.; Sung, Y.J.; Paek, H.S.; et al. Characteristics of GaN-based laser diodes for post-DVD applications. Phys. Status Solidi A 2004, 201, 2717–2720. [Google Scholar] [CrossRef]

- Fiorentini, V.; Bernardini, F.; Ambacher, O. Evidence for nonlinear macroscopic polarization in III-V nitride alloy heterostructures. Appl. Phys. Lett. 2002, 80, 1204–1206. [Google Scholar] [CrossRef]

- Flory, C.A.; Hasnain, G. Modeling of GaN optoelectronic devices and strain-induced piezoelectric effects. IEEE J. Quantum Electron. 2001, 37, 244–253. [Google Scholar] [CrossRef]

- Piprek, J. AlGaN polarization doping effects on the efficiency of blue LEDs. Proc. SPIE 2012, 8262, 82620E. [Google Scholar]

- Park, S.I.; Lee, J.I.; Jang, D.H.; Kim, H.S.; Shin, D.S.; Ryu, H.Y.; Shim, J.I. Measurement of internal electric field in GaN-based light-emitting diodes. IEEE J. Quantum Electron. 2012, 48, 500–506. [Google Scholar] [CrossRef]

- Ryu, H.Y.; Jeon, K.S.; Kang, M.G.; Yuh, H.K.; Choi, Y.H.; Lee, J.S. A comparative study of efficiency droop and internal electric field for InGaN blue light-emitting diodes on silicon and sapphire substrates. Sci. Rep. 2017, 7, 44814. [Google Scholar] [CrossRef]

- Farahmand, M.; Garetto, C.; Bellotti, E.; Brennan, K.F.; Goano, M.; Ghillino, E.; Ghione, G.; Albrecht, J.D.; Ruden, P.P. Monte Carlo simulation of electron transport in the III-nitride wurtzite phase materials system: Binaries and ternaries. IEEE Trans. Electron. Devices 2001, 48, 535–542. [Google Scholar] [CrossRef] [Green Version]

- Piprek, J. Semiconductor Optoelectronic Devices; Academic Press: London, UK, 2003; pp. 187–211. [Google Scholar]

- Chen, J.R.; Wu, Y.C.; Ling, S.C.; Ko, T.S.; Lu, T.C.; Kuo, H.C.; Kuo, Y.K.; Wang, S.C. Investigation of wavelength-dependent efficiency droop in InGaN light-emitting diodes. Appl. Phys B 2010, 98, 779–789. [Google Scholar] [CrossRef]

- Zhang, L.Q.; Jiang, D.S.; Zhu, J.J.; Zhao, D.G.; Liu, Z.S.; Zhang, S.M.; Yang, H. Confinement factor and absorption loss of AlInGaN based laser diodes emitting from ultraviolet to green. J. Appl. Phys. 2009, 105, 023104. [Google Scholar] [CrossRef]

- Muziol, G.; Turski, H.; Siekacz, M.; Sawicka, M.; Wolny, P.; Perlin, P.; Skierbiszewski, C. Determination of gain in AlGaN cladding free nitride laser diodes. Appl. Phys. Lett. 2013, 103, 061102. [Google Scholar] [CrossRef]

- Ryu, H.Y. Investigation into the anomalous temperature characteristics of InGaN double quantum well blue laser diodes using numerical simulation. Nanoscale Res. Lett. 2017, 12, 366. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Piprek, J.; Li, S. Electron leakage effects on GaN-based light-emitting diodes. Opt. Quantum Electron. 2011, 42, 89–95. [Google Scholar] [CrossRef]

- Neamen, D.A. Semiconductor Physics and Devices, 4th ed.; McGraw Hill: New York, NY, USA, 2012; pp. 131–135. [Google Scholar]

- Xi, Y.; Gessmann, T.; Xi, J.; Kim, J.K.; Shah, J.M.; Schubert, E.F.; Fischer, A.J.; Crawford, M.H.; Bogart, K.H.; Allerman, A.A. Junction temperature in ultraviolet light-emitting diodes. Jpn. J. Appl. Phys. 2005, 44, 7260–7266. [Google Scholar] [CrossRef] [Green Version]

- Ryu, H.Y.; Ha, K.H.; Chae, J.H.; Nam, O.H.; Park, Y.J. Measurement of junction temperature in GaN-based laser diodes using voltage-temperature characteristics. Appl. Phys. Lett. 2005, 87, 093506. [Google Scholar] [CrossRef]

- Onwukaeme, C.; Choi, W.J.; Ryu, H.Y. Accurate determination of junction temperature in a GaN-based blue light-emitting diode using nonlinear voltage-temperature relation. Opt. Quantum Electron. 2021, 53, 513. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onwukaeme, C.; Ryu, H.-Y. Investigation of the Optimum Mg Doping Concentration in p-Type-Doped Layers of InGaN Blue Laser Diode Structures. Crystals 2021, 11, 1335. https://doi.org/10.3390/cryst11111335

Onwukaeme C, Ryu H-Y. Investigation of the Optimum Mg Doping Concentration in p-Type-Doped Layers of InGaN Blue Laser Diode Structures. Crystals. 2021; 11(11):1335. https://doi.org/10.3390/cryst11111335

Chicago/Turabian StyleOnwukaeme, Chibuzo, and Han-Youl Ryu. 2021. "Investigation of the Optimum Mg Doping Concentration in p-Type-Doped Layers of InGaN Blue Laser Diode Structures" Crystals 11, no. 11: 1335. https://doi.org/10.3390/cryst11111335

APA StyleOnwukaeme, C., & Ryu, H.-Y. (2021). Investigation of the Optimum Mg Doping Concentration in p-Type-Doped Layers of InGaN Blue Laser Diode Structures. Crystals, 11(11), 1335. https://doi.org/10.3390/cryst11111335