Effect of A Limited Amount of D-Sorbitol on Pitch and Mechanical Properties of Cellulose Nanocrystal Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of the CNC Suspension

2.2.2. Preparation of Pure CNC and CNC/DS Films

2.2.3. Characterization

3. Results

3.1. Structure Characterizations of CNC and CNC/DS Films

3.2. Optical Properties of the CNC and CNC/DS Films

3.3. Mechanical Properties of CNC/DS Films

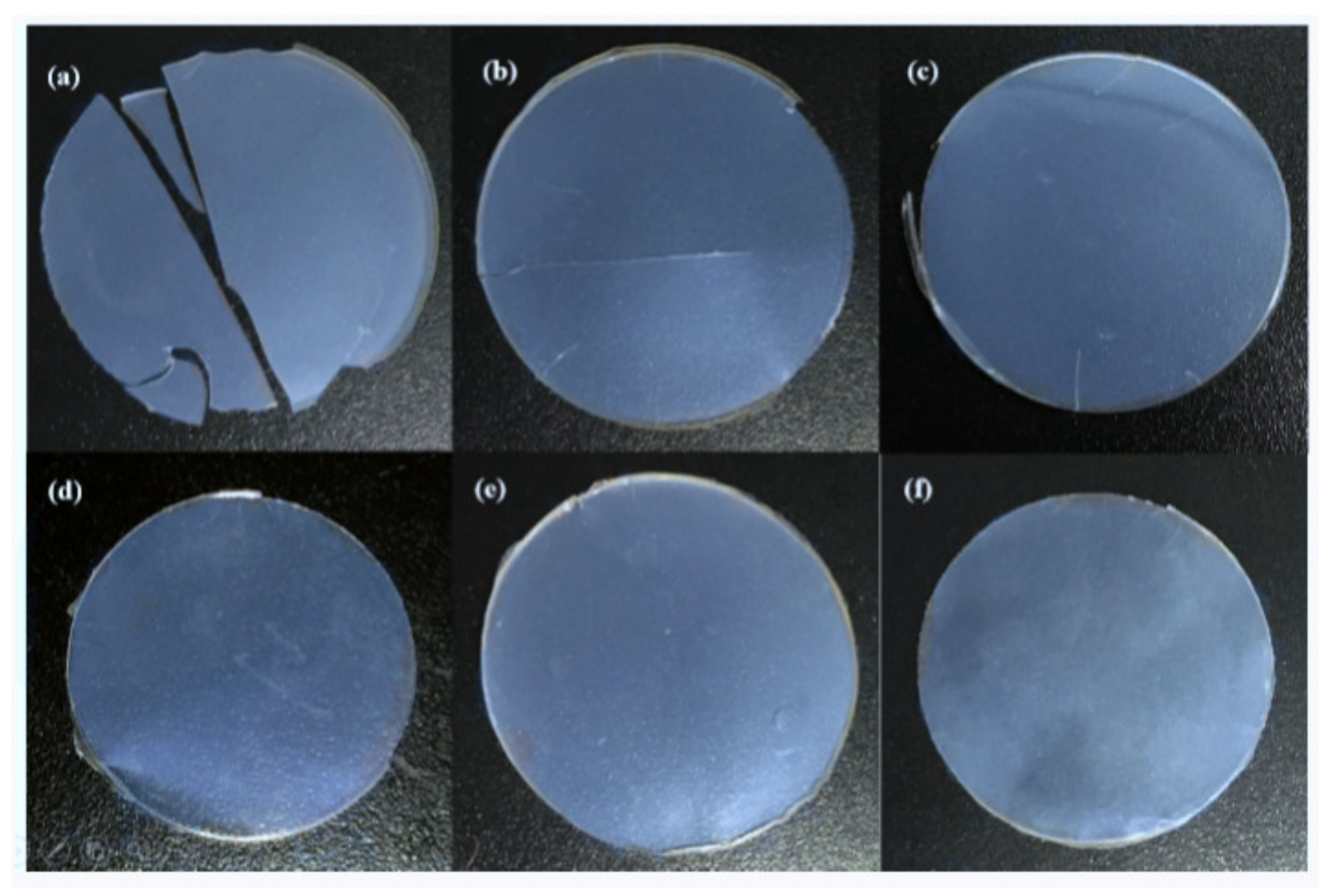

3.4. Morphology of the CNC and CNC/DS4 Film

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Collings, P.J. Introduction to liquid crystals: Chemistry and physics. Am. J. Phys. 1998, 66, 551. [Google Scholar] [CrossRef]

- Mitov, M. Cholesteric liquid crystals in living matter. Soft. Mater. 2017, 13, 4176–4209. [Google Scholar] [CrossRef]

- Mathews, M.; Zola, R.S.; Hurley, S.; Yang, D.K.; White, T.J.; Bunning, T.J.; Li, Q. Light-driven reversible handedness Inversion in self-organized helical superstructures. J. Am. Chem. Soc. 2010, 132, 18361–18366. [Google Scholar] [CrossRef]

- Li, Y.; Wang, M.; White, T.J.; Bunning, T.J.; Li, Q. Azoarenes with opposite chiral configurations: Light-driven reversible Handedness inversion in self-organized helical superstructures. Angew. Chem. Int. Edit. 2013, 125, 9093–9097. [Google Scholar] [CrossRef]

- Takezoe, H.; Eremin, A. Bent-Shaped Liquid Crystals: Structures and Physical Properties; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Zheng, Z.-G.; Yuan, C.-L.; Hu, W.W.; Bisoyi, H.K.; Li, Q. Light-patterned crystallographic direction of a self-organized 3D soft photonic crystal. Adv. Mater. 2017, 29, 1703165. [Google Scholar] [CrossRef]

- Hu, Q.-Z.; Jang, C.H. Using liquid crystals for the real-time detection of urease at aqueous/liquid crystal interfaces. J. Mater. Sci. 2012, 47, 969–975. [Google Scholar] [CrossRef]

- Inui, S.; Iimura, N.; Suzuki, T.; Iwane, H.; Miyachi, K.; Takanishi, Y.; Fukuda, A. Thresholdless antiferroelectricity in liquid crystals and its application to displays. J. Mater. Chem. 1996, 6, 671–673. [Google Scholar] [CrossRef]

- Ma, L.-L.; Li, S.-S.; Li, W.-S. Rationally designed dynamic superstructures enabled by photoaligning cholesteric liquid crystals. Adv. Opt. Mater. 2015, 3, 1691–1696. [Google Scholar] [CrossRef]

- Chigrinov, V.G. Photoaligning and photopatterning-a new challenge in liquid crystal photonics. Crystals 2013, 3, 149–162. [Google Scholar] [CrossRef] [Green Version]

- Dufresne, A. Nanocellulose: A new ageless, bionanomateria. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Kelly, J.A.; Giese, M.; Shopsowitz, K.E.; Hamad, W.Y.; Maclachlan, M.J. The development of chiral nematic mesoporous materials. Acc. Chem. Res. 2014, 47, 1088–1096. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating niopolymer and sustainable raw material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Li, N.; Zong, L.; Zhang, J. Recent advances in vacuum assisted self-assembly of cellulose nanocrystals. Curr. Opin. Solid. State. Mater. Sci. 2019, 23, 142–148. [Google Scholar] [CrossRef]

- Gray, D.G. Recent advances in chiral nematic structure and iridescent color of cellulose nanocrystal films. Nanomaterials 2016, 6, 213. [Google Scholar] [CrossRef]

- Sun, C.; Lu, J. Effect of sectional polymerization process on tunable twist structure liquid crystal filters. Crystals 2019, 9, 268. [Google Scholar] [CrossRef] [Green Version]

- Edgar, C.D.; Gray, D.G. Induced circular dichroism of chiral nematic cellulose films. Cellulose 2001, 8, 5–12. [Google Scholar] [CrossRef]

- Wei, X.-Y.; Lin, T.; Duan, M.; Du, H.-L.; Yin, X.-F. Cellulose nanocrystal-based liquid crystal structures and the unique optical characteristics of cellulose nanocrystal films. Bioresources 2021, 16, 2116–2137. [Google Scholar] [CrossRef]

- Beck, S.; Bouchard, J.; Berry, R. Controlling the reflection wavelength of iridescent solid films of nanocrystalline cellulose. Biomacromolecules 2011, 12, 167–172. [Google Scholar] [CrossRef]

- Bardet, R.; Roussel, F.; Coindeau, S.; Belgacem, N.; Bras, J.J. Engineered pigments based on iridescent cellulose nanocrystal films. Carbohyd. Polym. 2015, 122, 367–375. [Google Scholar] [CrossRef] [PubMed]

- Gan, L.; Feng, N.; Liu, S.; Zheng, S.; Li, Z.; Huang, J. Assembly-induced emission of cellulose nanocrystals for hiding information. particle and particle systems characterization. Part. Part. Syst. Charact. 2019, 36, 1800412. [Google Scholar] [CrossRef]

- Kim, J.; Jayaramudu, T.; Zhai, L.; Kim, H.C.; Agumba, D.O. Preparation of cellulose nanocrystal-reinforced physical hydrogels for actuator application. Crystals 2020, 10, 969. [Google Scholar] [CrossRef]

- Zhao, G.-M.; Zhang, Y.; Zhai, S.-C.; Sugiyama, J.; Pan, M.-Z.; Shi, J.-B.; Lu, H.Y. Dual response of photonic film with chiral nematic cellulose nanocrystal: Humidity and formaldehyde. ACS Appl. Mater. Inter. 2020, 12, 17833–17844. [Google Scholar] [CrossRef] [PubMed]

- Grey, P.; Fernandes, S.N.; Gaspar, D.; Fortunato, E.; Martins, R.; Godinho, M.H.; Pereira, L. Field-effect transistors on photonic cellulose nanocrystal solid electrolyte for circular polarized light sensing. Adv. Funct. Mater. 2019, 29, 1805279. [Google Scholar] [CrossRef]

- Wang, B.; Walther, A. Self-assembled, iridescent, crustacean-mimetic nanocomposites with tailored periodicity and layered cuticular structure. ACS Nano. 2015, 9, 10637–10646. [Google Scholar] [CrossRef]

- Tatsumi, M.; Teramoto, Y.; Nishio, Y. Polymer composites reinforced by locking-in a liquid-crystalline assembly of cellulose nanocrystallites. Biomacromolecules 2012, 13, 1584–1591. [Google Scholar] [CrossRef]

- He, Y.-D.; Zhang, Z.-L.; Xue, J.; Wang, X.-H.; Song, F.; Wang, X.-L.; Zhu, L.-L.; Wang, Y.-Z. Biomimetic optical cellulose nanocrystal films with controllable iridescent color and environmental stimuli-responsive chromism. ACS Appl. Mater. Interfaces 2018, 10, 5805–5811. [Google Scholar] [CrossRef] [PubMed]

- Mathew, A.P.; Thielemans, W.; Dufresne, A. Mechanical properties of nanocomposites from sorbitol plasticized starch and tunicin whiskers. J. Appl. Polym. Sci. 2010, 109, 4065–4074. [Google Scholar] [CrossRef]

- Gaudin, S.; Lourdin, D.; Botlan, D.L. Plasticisation and mobility in starch-sorbitol films. J. Cereal Sci. 1999, 29, 273–284. [Google Scholar] [CrossRef]

- Csiszár, E.; Nagy, S. A comparative study on cellulose nanocrystals extracted from bleached cotton and flax and used for casting films with glycerol and sorbitol plasticisers. Carbohyd. Polym. 2017, 174, 740–749. [Google Scholar] [CrossRef]

- Lin, N.; Huang, J.; Chang, P.-R. Surface acetylation of cellulose nanocrystal and its reinforcing function in poly (lactic acid). Carbohydr. Polym. 2012, 83, 1834–1842. [Google Scholar] [CrossRef]

- Lu, Q.; Tang, L.; Lin, F.; Wang, S.; Chen, Y.; Chen, X.; Huang, B. Preparation and characterization of cellulose nanocrystals via ultrasonication-assisted FeCl3-catalyzed hydrolysis. Cellulose 2014, 21, 3497–3506. [Google Scholar] [CrossRef]

- Lojewska, J.; Miskowiec, P.; Lojewski, T.; Pronewicz, L.M. Cellulose oxidative and hydrolysis degradation: In situ FTIR approach. Degrad. Stab. 2005, 88, 512–520. [Google Scholar] [CrossRef]

- Johar, N.; Ahmad, I.; Dufresne, A. Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind. Crops. Prod. 2012, 37, 93–99. [Google Scholar] [CrossRef]

- Jahan, M.S.; Saeed, A.; He, Z.; Ni, Y. Jute as raw material for the preparation of microcrystalline cellulose. Cellulose 2011, 18, 451–459. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, X.-Y.; Lin, T.; Wang, L.; Yin, X.-F. Effect of A Limited Amount of D-Sorbitol on Pitch and Mechanical Properties of Cellulose Nanocrystal Films. Crystals 2021, 11, 1324. https://doi.org/10.3390/cryst11111324

Wei X-Y, Lin T, Wang L, Yin X-F. Effect of A Limited Amount of D-Sorbitol on Pitch and Mechanical Properties of Cellulose Nanocrystal Films. Crystals. 2021; 11(11):1324. https://doi.org/10.3390/cryst11111324

Chicago/Turabian StyleWei, Xiao-Yao, Tao Lin, Le Wang, and Xue-Feng Yin. 2021. "Effect of A Limited Amount of D-Sorbitol on Pitch and Mechanical Properties of Cellulose Nanocrystal Films" Crystals 11, no. 11: 1324. https://doi.org/10.3390/cryst11111324

APA StyleWei, X.-Y., Lin, T., Wang, L., & Yin, X.-F. (2021). Effect of A Limited Amount of D-Sorbitol on Pitch and Mechanical Properties of Cellulose Nanocrystal Films. Crystals, 11(11), 1324. https://doi.org/10.3390/cryst11111324