Wear Behavior of Commercial Copper-Based Aircraft Brake Pads Fabricated under Different SPS Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Tribological Test

2.3. Analysis of Worn Surface

3. Results and Discussion

3.1. Characterization of Cu-Based Brake Pads

3.1.1. Composition and Microstructure

3.1.2. Density and Mechanical Properties

3.2. Dry Sliding Wear

3.2.1. Coefficient of Friction (COF)

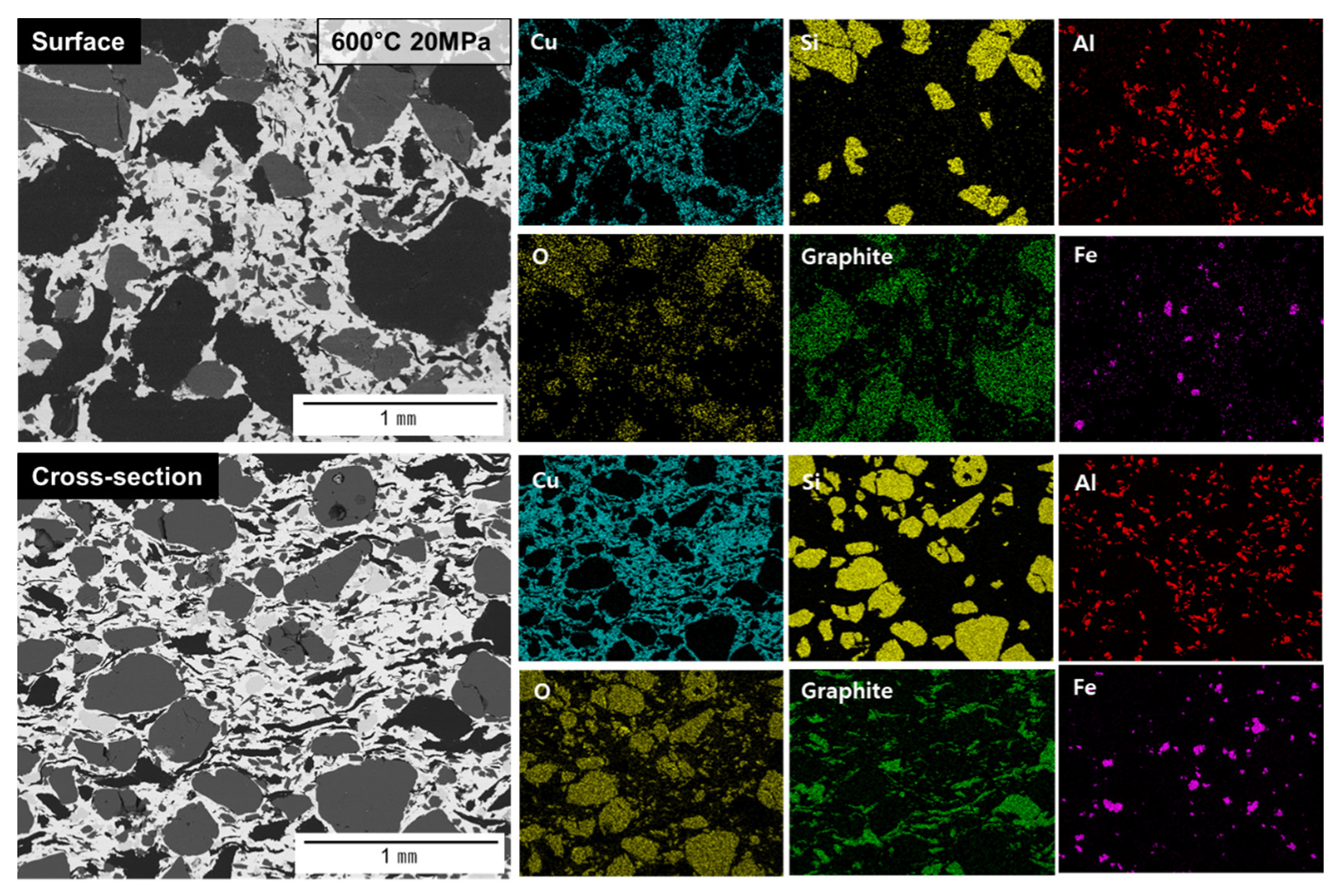

3.2.2. Morphology of Worn Surface

3.2.3. Wear Mechanism

3.2.4. Dynamometer Test

4. Conclusions

- (1)

- The Cu-based brake pads fabricated under the different SPS conditions showed different relative densities and hardnesses, which varied with the sintering temperature and pressure used. This was owing to the differences in the tribofilm formation mechanism and the COF values during the tribological test. The COF value increased from 0.18 to 0.3 in the following order: 600-20, 800-20, and 800-40.

- (2)

- Based on the sintering temperature and pressure used, the Cu-based brake pads exhibited different wear mechanisms. Sample 600-20 showed abrasive wear while sample 800-20 showed both abrasive and adhesive wear. Finally, sample 800-40 primarily showed adhesive wear. This is because the differences in the hardnesses and relative densities of the samples affected the size and amount of debris produced during the wear test.

- (3)

- During the tribological test, a higher load resulted in a greater degree of oxidation. This is because as a greater load was applied, more heat was generated, accelerating the oxidation process and contributing to the formation of the oxide film. As a result, the samples with high oxidation wear exhibited low COF values.

- (4)

- The dynamometer test was performed on the 800-40 sample, which showed the best friction characteristics in this study. It was confirmed that the dynamometer test resulted in the same wear mechanism as the ball-on-disc test.

- (5)

- The temperature and pressure used during the sintering of brake pads have a determining effect on their friction and wear characteristics. In particular, in the case of the commercial Cu-based brake pads used in aircraft, a temperature and pressure of 800 °C and 40 MPa, respectively, would result in the best wear characteristics. Furthermore, the results of the wear mechanism analysis performed in this study should aid the development of improved Cu-based friction pads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Osterle, W.; Prietzel, C.; Kloss, H.; Dmitriev, A.I. On the role of copper in brake friction materials. Tribol. Int. 2010, 43, 2317–2326. [Google Scholar] [CrossRef]

- Kukutschova, J.; Roubicek, V.; Malachova, K.; Pavlickova, Z.; Holusa, R.; Kubackova, J.; Micka, V.; MacCrimmon, D.; Filip, P. Wear mechanism in automotive brake materials, wear debris and its potential environmental impact. Wear 2009, 267, 807–817. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.B.; Yao, P.P.; Xiao, Y.L.; Fan, K.Y.; Zhang, Z.Y.; Gong, T.M.; Zhao, L.; Deng, M.W.; Liu, C.; Ling, P. Friction and wear maps of copper metal matrix composites with different iron volume content. Tribol. Int. 2019, 132, 199–210. [Google Scholar] [CrossRef]

- Cheng, J.B.; Liang, X.B.; Xu, B.S. Devitrification of arc-sprayed FeBSiNb amorphous coatings: Effects on wear resistance and mechanical behavior. Surf. Coat. Technol. 2013, 235, 720–726. [Google Scholar] [CrossRef]

- Hong, S.; Lin, J.; Wu, Y.; Wu, J.; Zheng, Y.; Zhang, Y.; Cheng, J.; Sun, W. Cavitation erosion characteristics at various flow velocities in NaCl medium of carbide-based cermet coatings prepared by HVOF spraying. Ceram. Int. 2021, 47, 1929–1939. [Google Scholar] [CrossRef]

- Shaik, M.A.; Golla, B.R. Densification, microstructure and properties of mechanically alloyed and hot-pressed Cu-15 wt% Al alloy. J. Mater. Sci. 2018, 53, 14694–14712. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Q.J. Lubrication regimes. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.-W., Eds.; Springer: New York, NY, USA, 2013; pp. 2110–2113. ISBN 978-0-387-92898-2. [Google Scholar]

- Zhang, P.; Zhang, L.; Wei, D.B.; Wu, P.F.; Cao, J.W.; Shijia, C.R.; Qu, X.H. A high-performance copper-based brake pad for high-speed railway trains and its surface substance evolution and wear mechanism at high temperature. Wear 2020, 444, 203182. [Google Scholar] [CrossRef]

- Sun, Q.C.; Wang, Z.X.; Yin, B.; Yang, J.; Liu, J.J.; Liu, Y.L.; Cheng, J.; Zhu, S.Y.; Qiao, Z.H. The tribological properties and wear mechanism of copper coated graphite doped Sialon ceramic composites at wide range temperature from 25 to 800 °C. Tribol. Int. 2018, 123, 10–16. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Fu, K.; Cao, J.; Shijia, C.; Qu, X. Effects of different forms of Fe powder additives on the simulated braking performance of Cu-based friction materials for high-speed railway trains. Wear 2018, 414, 317–326. [Google Scholar] [CrossRef]

- Xiong, X.; Chen, J.; Yao, P.; Li, S.; Huang, B. Friction and wear behaviors and mechanisms of Fe and SiO2 in Cu-based P/M friction materials. Wear 2007, 262, 1182–1186. [Google Scholar] [CrossRef]

- Sun, W.; Zhou, W.; Liu, J.; Fu, X.; Chen, G.; Yao, S. The Size Effect of SiO2 Particles on Friction Mechanisms of a Composite Friction Material. Tribol. Lett. 2018, 66, 35. [Google Scholar] [CrossRef]

- Peng, T.; Yan, Q.; Li, G.; Zhang, X. The Influence of Cu/Fe Ratio on the Tribological Behavior of Brake Friction Materials. Tribol. Lett. 2018, 66, 18. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Fu, K.; Wu, P.; Cao, J.; Shijia, C.; Qu, X. The effect of Al2O3 fiber additive on braking performance of copper-based brake pads utilized in high-speed railway train. Tribol. Int. 2019, 135, 444–456. [Google Scholar] [CrossRef]

- Chen, B.; Bi, Q.; Yang, J.; Xia, Y.; Hao, J. Tribological properties of solid lubricants (graphite, h-BN) for Cu-based P/M friction composites. Tribol. Int. 2008, 41, 1145–1152. [Google Scholar] [CrossRef]

- Kovalchenko, A.M.; Fushchich, O.I.; Danyluk, S. The tribological properties and mechanism of wear of Cu-based sintered powder materials containing molybdenum disulfide and molybdenum diselenite under unlubricated sliding against copper. Wear 2012, 290, 106–123. [Google Scholar] [CrossRef]

- Senouci, A.; Frene, J.; Zaidi, H. Wear mechanism in graphite-copper electrical sliding contact. Wear 1999, 225, 949–953. [Google Scholar] [CrossRef]

- Xiao, Y.; Yao, P.; Zhou, H.; Zhang, Z.; Gong, T.; Zhao, L.; Deng, M. Investigation on Speed-Load Sensitivity to Tribological Properties of Copper Metal Matrix Composites for Braking Application. Metals 2020, 10, 889. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhang, Z.; Yao, P.; Fan, K.; Zhou, H.; Gong, T.; Zhao, L.; Deng, M. Mechanical and tribological behaviors of copper metal matrix composites for brake pads used in high-speed trains. Tribol. Int. 2018, 119, 585–592. [Google Scholar] [CrossRef]

- Peng, T.; Yan, Q.; Zhang, X. Stability of Metal Matrix Composite Pads During High-Speed Braking. Tribol. Lett. 2018, 66. [Google Scholar] [CrossRef]

- Xiao, J.-K.; Xiao, S.-X.; Chen, J.; Zhang, C. Wear mechanism of Cu-based brake pad for high-speed train braking at speed of 380 km/h. Tribol. Int. 2020, 150, 106357. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Wei, D.; Wu, P.; Cao, J.; Shijia, C.; Qu, X. Adjusting function of MoS2 on the high-speed emergency braking properties of copper-based brake pad and the analysis of relevant tribo-film of eddy structure. Compos. Part B Eng. 2020, 185, 107779. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, L.; Wu, P.; Cao, J.; Shijia, C.; Wei, D.; Qu, X. Effect of carbon fiber on the braking performance of copper-based brake pad under continuous high-energy braking conditions. Wear 2020, 458, 203408. [Google Scholar] [CrossRef]

- Akhtar, F.; Askari, S.J.; Shah, K.A.; Du, X.L.; Guo, S.J. Microstructure, mechanical properties, electrical conductivity and wear behavior of high volume TiC reinforced Cu-matrix composites. Mater. Charact. 2009, 60, 327–336. [Google Scholar] [CrossRef]

- Gupta, P.; Kumar, D.; Parkash, O.; Jha, A.K.; Sadasivuni, K.K. Dependence of wear behavior on sintering mechanism for Iron-Alumina Metal Matrix Nanocomposites. Mater. Chem. Phys. 2018, 220, 441–448. [Google Scholar] [CrossRef]

- Zhan, Y.Z.; Zhang, G.D. Friction and wear behavior of copper matrix composites reinforced with SiC and graphite particles. Tribol. Lett. 2004, 17, 91–98. [Google Scholar] [CrossRef]

- Dudina, D.V.; Bokhonov, B.B. Elimination of oxide films during Spark Plasma Sintering of metallic powders: A case study using partially oxidized nickel. Adv. Powder Technol. 2017, 28, 641–647. [Google Scholar] [CrossRef]

- Jayashree, P.; Menapace, C.; Turani, S.; Straffelini, G. Dry sliding behaviour of composite friction materials with varying iron and copper content prepared using the spark plasma sintering technique. Powder Metall. 2021, 1–13. [Google Scholar] [CrossRef]

- Ayyappadas, C.; Muthuchamy, A.; Raja Annamalai, A.; Agrawal, D.K. An investigation on the effect of sintering mode on various properties of copper-graphene metal matrix composite. Adv. Powder Technol. 2017, 28, 1760–1768. [Google Scholar] [CrossRef]

- Dash, K.; Ray, B.C.; Chaira, D. Synthesis and characterization of copper–alumina metal matrix composite by conventional and spark plasma sintering. J. Alloys Compd. 2012, 516, 78–84. [Google Scholar] [CrossRef]

- Ikeuchi, K.; Handa, K.; Lunden, R.; Vernersson, T. Wheel tread profile evolution for combined block braking and wheel-rail contact: Results from dynamometer experiments. Wear 2016, 366, 310–315. [Google Scholar] [CrossRef]

- Efe, G.C.; Yener, T.; Altinsoy, I.; Ipek, M.; Zeytin, S.; Bindal, C. The effect of sintering temperature on some properties of Cu-SiC composite. J. Alloys Compd. 2011, 509, 6036–6042. [Google Scholar] [CrossRef]

- Wang, X.J.; Yao, X.M.; Zhang, H.; Liu, X.J.; Huang, Z.R. Tribological properties and wear mechanisms of hot-pressed sintering mesocarbon microbeads (MCMBs)-SiC composites against different counterparts. Ceram. Int. 2020, 46, 3896–3903. [Google Scholar] [CrossRef]

- Liew, K.W.; Nirmal, U. Frictional performance evaluation of newly designed brake pad materials. Mater. Des. 2013, 48, 25–33. [Google Scholar] [CrossRef]

- Uyyuru, R.K.; Surappa, M.K.; Brusethaug, S. Tribological behavior of Al-Si-SiCp composites/automobile brake pad system under dry sliding conditions. Tribol. Int. 2007, 40, 365–373. [Google Scholar] [CrossRef]

- Rodrigues, A.C.P.; Österle, W.; Gradt, T.; Azevedo, C.R.F. Impact of copper nanoparticles on tribofilm formation determined by pin-on-disc tests with powder supply: Addition of artificial third body consisting of Fe3O4, Cu and graphite. Tribol. Int. 2017, 110, 103–112. [Google Scholar] [CrossRef]

- Ma, C.; Wang, S.C.; Wang, L.P.; Walsh, F.C.; Wood, R.J.K. The role of a tribofilm and wear debris in the tribological behaviour of nanocrystalline Ni-Co electrodeposits. Wear 2013, 306, 296–303. [Google Scholar] [CrossRef]

- Biswas, S.K. Some mechanisms of tribofilm formation in metal/metal and ceramic/metal sliding interactions. Wear 2000, 245, 178–189. [Google Scholar] [CrossRef]

- Nan, F.; Xu, Y.; Xu, B.S.; Gao, F.; Wu, Y.X.; Tang, X.H. Effect of natural attapulgite powders as lubrication additive on the friction and wear performance of a steel tribo-pair. Appl. Surf. Sci. 2014, 307, 86–91. [Google Scholar] [CrossRef]

- Berger, H.R.; Heinrich, G. Friction effects in the contact area of sliding rubber: A generalized Schallamach model. Kautsch. Gummi Kunstst. 2000, 53, 200–205. [Google Scholar]

| Number | Processing Condition | Relative Density (%) | Hardness (HRR) | |||

|---|---|---|---|---|---|---|

| Heating Rate (°C/min) | Sintering Temp. (°C) | Pressure (MPa) | Time (min) | |||

| 1 | 50 | 800 | 20 | 10 | 95.59 | 101.2 |

| 2 | 40 | 97.65 | 108.3 | |||

| 3 | 700 | 20 | 20 | 95.59 | 102.5 | |

| 4 | 600 | 10 | 20 | 82.20 | 61.6 | |

| 5 | 20 | 10 | 94.36 | 101.4 | ||

| 6 | 20 | 92.71 | 98.2 | |||

| 7 | 400 | 20 | 10 | 83.44 | 89.8 | |

| 8 | 40 | 89.41 | 105.5 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, K.I.; Lee, H.; Kim, J.; Oh, K.H.; Kim, K.T. Wear Behavior of Commercial Copper-Based Aircraft Brake Pads Fabricated under Different SPS Conditions. Crystals 2021, 11, 1298. https://doi.org/10.3390/cryst11111298

Kim KI, Lee H, Kim J, Oh KH, Kim KT. Wear Behavior of Commercial Copper-Based Aircraft Brake Pads Fabricated under Different SPS Conditions. Crystals. 2021; 11(11):1298. https://doi.org/10.3390/cryst11111298

Chicago/Turabian StyleKim, Kyung Il, Hyunjong Lee, Jongbeom Kim, Kyu Hwan Oh, and Kyung Taek Kim. 2021. "Wear Behavior of Commercial Copper-Based Aircraft Brake Pads Fabricated under Different SPS Conditions" Crystals 11, no. 11: 1298. https://doi.org/10.3390/cryst11111298

APA StyleKim, K. I., Lee, H., Kim, J., Oh, K. H., & Kim, K. T. (2021). Wear Behavior of Commercial Copper-Based Aircraft Brake Pads Fabricated under Different SPS Conditions. Crystals, 11(11), 1298. https://doi.org/10.3390/cryst11111298