Kinetics of Capability Aging in Ti-13Nb-13Zr Alloy

Abstract

1. Introduction

2. Materials and Methods

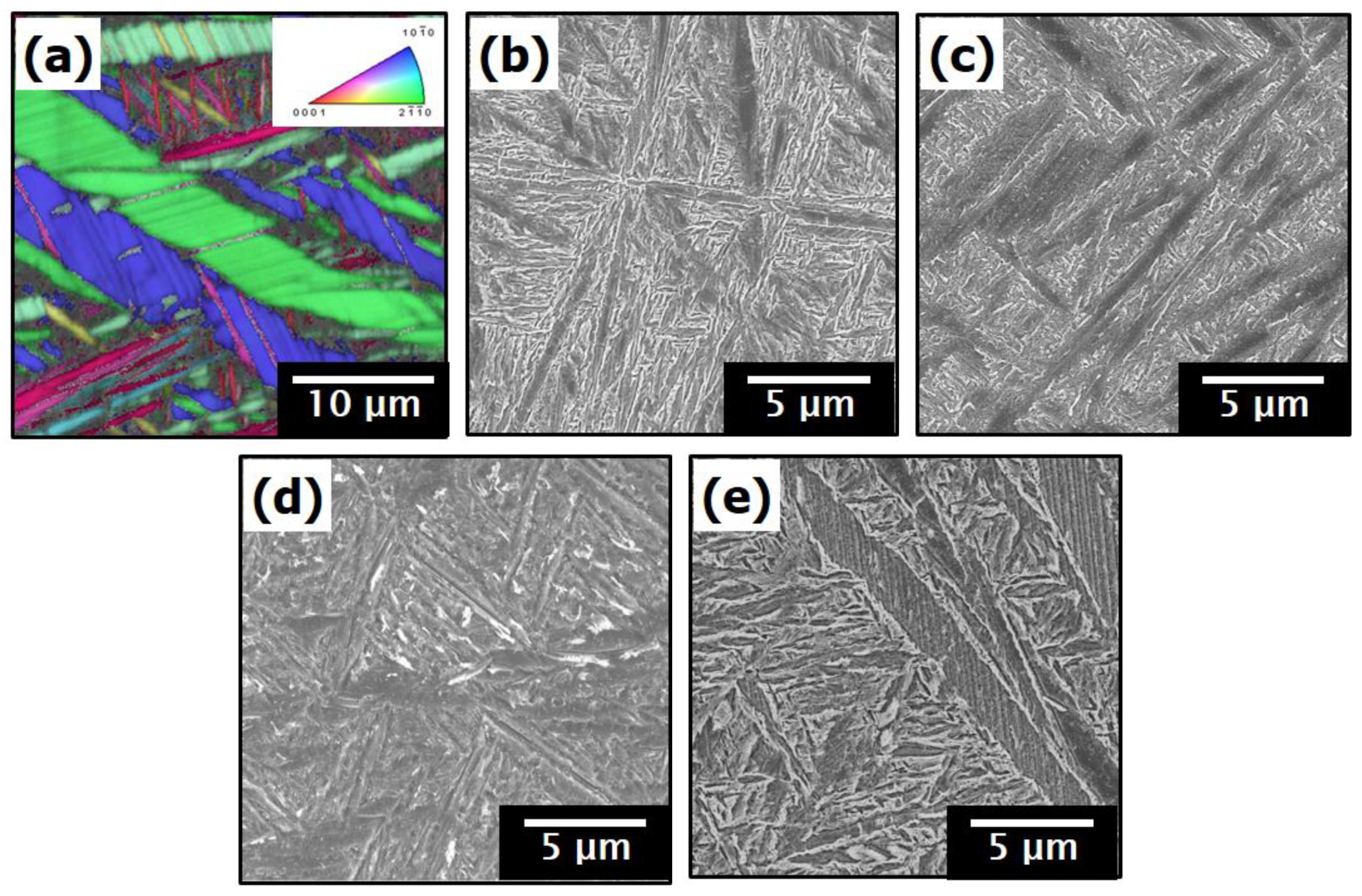

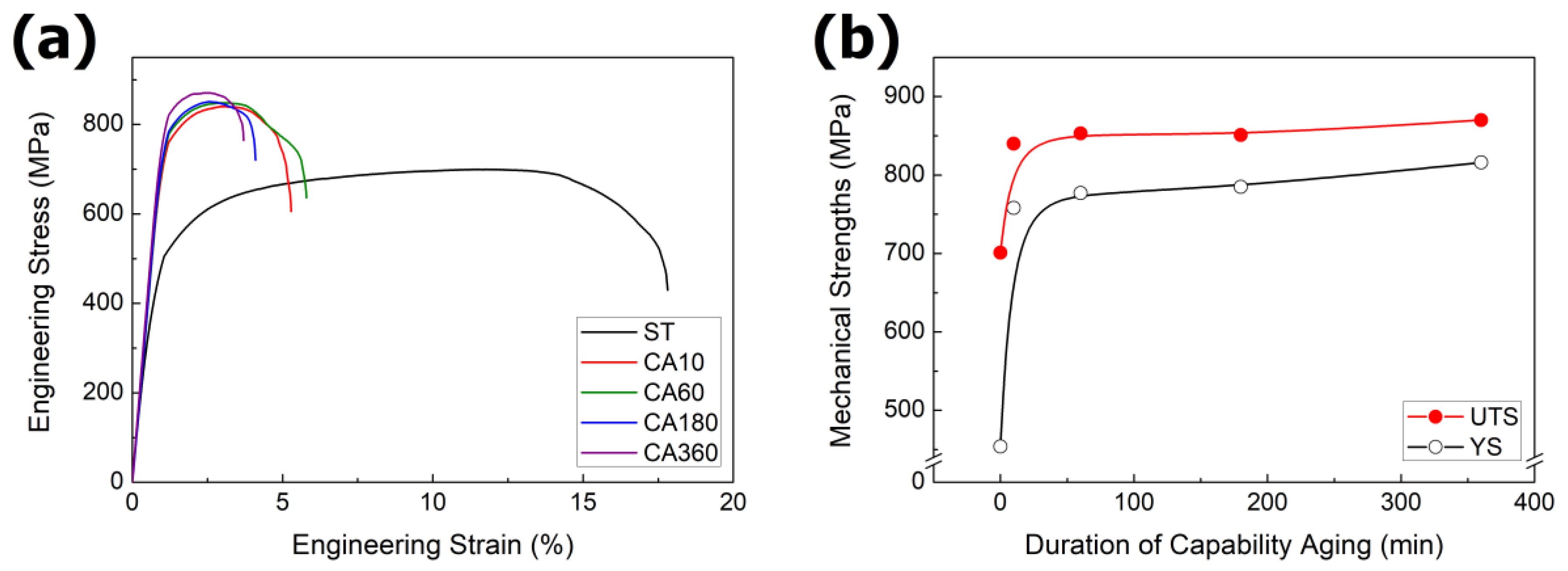

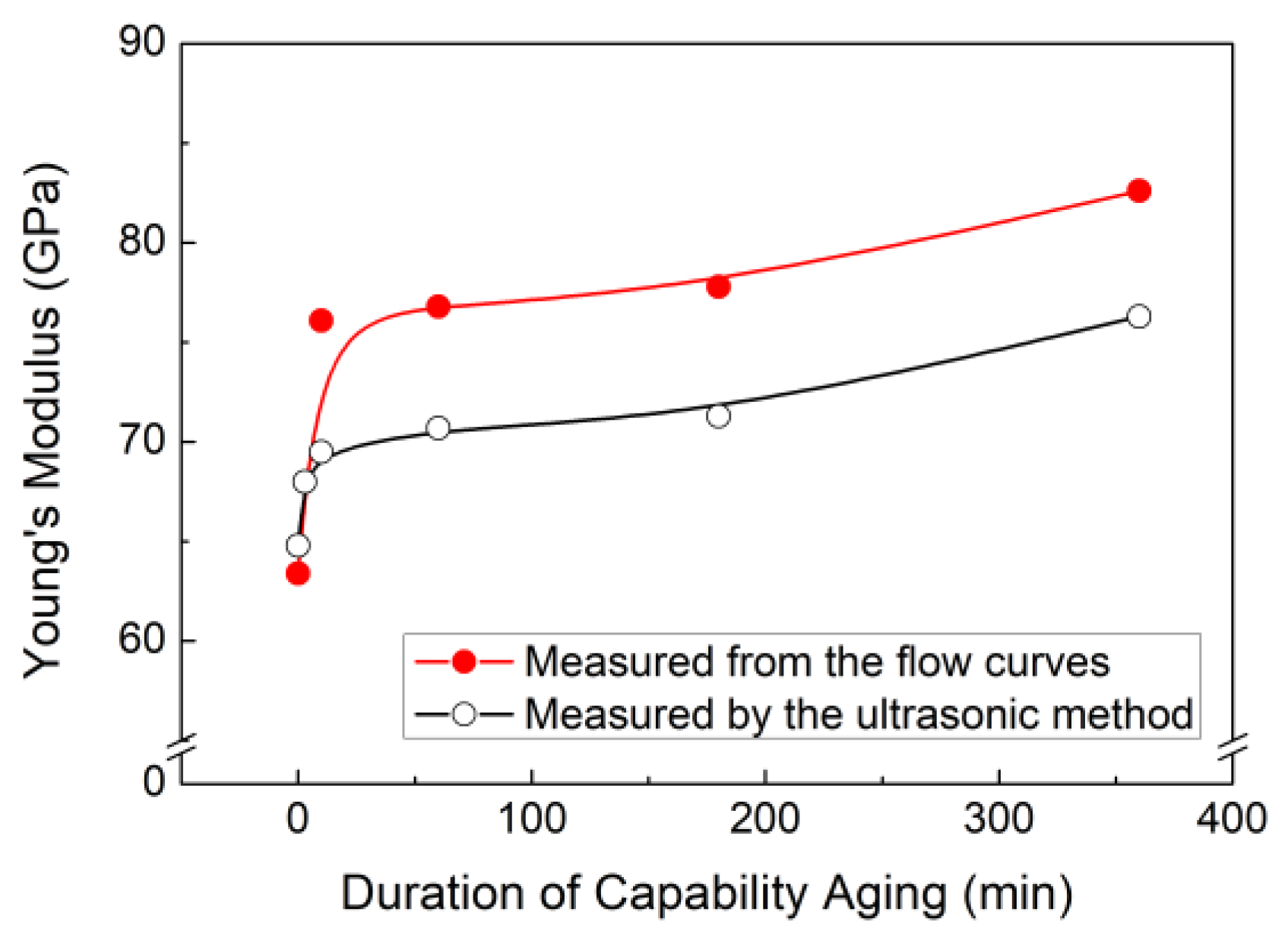

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Michalska, J.; Sowa, M.; Piotrowska, M.; Widziołek, M.; Tylko, G.; Dercz, G.; Socha, R.P.; Osyczka, A.M.; Simka, W. Incorporation of Ca ions into anodic oxide coatings on the Ti-13Nb-13Zr alloy by plasma electrolytic oxidation. Mater. Sci. Eng. C 2019, 104, 109957. [Google Scholar] [CrossRef] [PubMed]

- Kolli, R.; Devaraj, A. A Review of Metastable Beta Titanium Alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- ASTM F1713-08(2013). Standard Specification for Wrought Titanium-13Niobium-13Zirconium Alloy for Surgical Implant Applications (UNS R58130); ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Niinomi, M. Mechanical biocompatibilities of titanium alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2008, 1, 30–42. [Google Scholar] [CrossRef] [PubMed]

- Niinomi, M.; Kuroda, D.; Fukunaga, K.I.; Morinaga, M.; Kato, Y.; Yashiro, T.; Suzuki, A. Corrosion wear fracture of new β type biomedical titanium alloys. Mater. Sci. Eng. A 1999, 263, 193–199. [Google Scholar] [CrossRef]

- Lee, T.; Lee, S.; Kim, I.-S.; Moon, Y.H.; Kim, H.S.; Park, C.H. Breaking the limit of Young’s modulus in low-cost Ti-Nb-Zr alloy for biomedical implant applications. J. Alloys Compd. 2020, 828, 154401. [Google Scholar] [CrossRef]

- Park, C.H.; Park, J.-W.W.; Yeom, J.-T.T.; Chun, Y.S.; Lee, C.S. Enhanced mechanical compatibility of submicrocrystalline Ti-13Nb-13Zr alloy. Mater. Sci. Eng. A 2010, 527, 4914–4919. [Google Scholar] [CrossRef]

- Geetha, M.; Singh, A.K.; Muraleedharan, K.; Gogia, A.K.; Asokamani, R. Effect of thermomechanical processing on microstructure of a Ti-13Nb-13Zr alloy. J. Alloys Compd. 2001, 329, 264–271. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.B.; Chakraborty, M. The role of heat treatment on microstructure and mechanical properties of Ti-13Zr-13Nb alloy for biomedical load bearing applications. J. Mech. Behav. Biomed. Mater. 2011, 4, 1132–1144. [Google Scholar] [CrossRef]

- Geetha, M.; Kamachi Mudali, U.; Gogia, A.K.; Asokamani, R.; Raj, B. Influence of microstructure and alloying elements on corrosion behavior of Ti-13Nb-13Zr alloy. Corros. Sci. 2004, 46, 877–892. [Google Scholar] [CrossRef]

- Majumdar, P.; Singh, S.B.; Chakraborty, M. Elastic modulus of biomedical titanium alloys by nano-indentation and ultrasonic techniques-A comparative study. Mater. Sci. Eng. A 2008, 489, 419–425. [Google Scholar] [CrossRef]

- Lee, T.; Heo, Y.-U.U.; Lee, C.S. Microstructure tailoring to enhance strength and ductility in Ti-13Nb-13Zr for biomedical applications. Scr. Mater. 2013, 69, 785–788. [Google Scholar] [CrossRef]

- Wang, J.N.; Yang, J.; Xia, Q.; Wang, Y. On the grain size refinement of TiAl alloys by cyclic heat treatment. Mater. Sci. Eng. A 2002, 329–331, 118–123. [Google Scholar] [CrossRef]

- Saji, V.S.; Choe, H.C. Electrochemical corrosion behaviour of nanotubular Ti-13Nb-13Zr alloy in Ringer’s solution. Corros. Sci. 2009, 51, 1658–1663. [Google Scholar] [CrossRef]

- Zhou, L.; Yuan, T.; Li, R.; Tang, J.; Wang, M.; Li, L.; Chen, C. Microstructure and mechanical performance tailoring of Ti-13Nb-13Zr alloy fabricated by selective laser melting after post heat treatment. J. Alloys Compd. 2019, 775, 1164–1176. [Google Scholar] [CrossRef]

- Lee, T.; Park, K.-T.T.; Lee, D.J.; Jeong, J.; Oh, S.H.; Kim, H.S.; Park, C.H.; Lee, C.S. Microstructural evolution and strain-hardening behavior of multi-pass caliber-rolled Ti-13Nb-13Zr. Mater. Sci. Eng. A 2015, 648, 359–366. [Google Scholar] [CrossRef]

- Kumar, P.; Mahobia, G.S.; Singh, V.; Chattopadhyay, K. Lowering of elastic modulus in the near-beta Ti-13Nb-13Zr alloy through heat treatment. Mater. Sci. Technol. 2020, 36, 717–725. [Google Scholar] [CrossRef]

- Davidson, J.A.; Mishra, A.K.; Kovacs, P.; Poggie, R.A. New surface-hardened, low-modulus, corrosion-resistant Ti13Nb13Zr alloy for total hip arthroplasty. Biomed. Mater. Eng. 1994, 4, 231–243. [Google Scholar]

- Kobayashi, S.; Nakagawa, S.; Nakai, K.; Ohmori, Y. Phase Decomposition in a Ti-13Nb-13Zr Alloy during Aging at 600 °C. Mater. Trans. 2002, 43, 2956–2963. [Google Scholar] [CrossRef]

- Moffat, D.L.; Larbalestier, D.C. The competition between martensite and omega in quenched Ti-Nb alloys. Metall. Mater. Trans. A 1988, 19, 1677–1686. [Google Scholar] [CrossRef]

- Hussein, M.A.; Azeem, M.; Kumar, A.M.; Al-Aqeeli, N.; Ankah, N.K.; Sorour, A.A. Influence of Thermal Treatment on the Microstructure, Mechanical Properties, and Corrosion Resistance of Newly Developed Ti20Nb13Zr Biomedical Alloy in a Simulated Body Environment. J. Mater. Eng. Perform. 2019, 28, 1337–1349. [Google Scholar] [CrossRef]

- Gil Mur, F.X.X.; Rodríguez, D.; Planell, J.A. Influence of tempering temperature and time on the α′-Ti-6Al-4V martensite. J. Alloys Compd. 1996, 234, 287–289. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, R.; Niinomi, M.; Kuroda, D.; Zhou, Y.; Fukunaga, K.; Suzuki, A. Young’s modulus and mechanical properties of Ti-29Nb-13Ta-4.6Zr in relation to α″ martensite. Metall. Mater. Trans. A 2002, 33, 3137–3144. [Google Scholar] [CrossRef]

- Zhou, Y.L.; Niinomi, M.; Akahori, T. Effects of Ta content on Young’s modulus and tensile properties of binary Ti-Ta alloys for biomedical applications. Mater. Sci. Eng. A 2004, 371, 283–290. [Google Scholar] [CrossRef]

- Matsumoto, H.; Watanabe, S.; Hanada, S. Microstructures and mechanical properties of metastable [beta] TiNbSn alloys cold rolled and heat treated. J. Alloys Compd. 2007, 439, 146–155. [Google Scholar] [CrossRef]

- Baptista, C.A.R.P.; Schneider, S.G.; Taddei, E.B.; da Silva, H.M. Fatigue behavior of arc melted Ti–13Nb–13Zr alloy. Int. J. Fatigue 2004, 26, 967–973. [Google Scholar] [CrossRef]

- Zhentao, Y.; Lian, Z. Influence of martensitic transformation on mechanical compatibility of biomedical β type titanium alloy TLM. Mater. Sci. Eng. A 2006, 438–440, 391–394. [Google Scholar] [CrossRef]

| Sample | YS (MPa) | UTS (MPa) | E (GPa) * | E (GPa) † | EL (%) |

|---|---|---|---|---|---|

| ST | 454 | 701 | 63.4 | 64.8 | 17.8 |

| CA10 | 758 | 840 | 76.1 | 69.5 | 5.3 |

| CA60 | 777 | 853 | 76.8 | 70.7 | 5.8 |

| CA180 | 785 | 851 | 77.8 | 71.3 | 4.1 |

| CA360 | 816 | 870 | 82.6 | 76.3 | 3.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, M.; Kim, I.-S.; Moon, Y.H.; Yoon, H.S.; Park, C.H.; Lee, T. Kinetics of Capability Aging in Ti-13Nb-13Zr Alloy. Crystals 2020, 10, 693. https://doi.org/10.3390/cryst10080693

Lee M, Kim I-S, Moon YH, Yoon HS, Park CH, Lee T. Kinetics of Capability Aging in Ti-13Nb-13Zr Alloy. Crystals. 2020; 10(8):693. https://doi.org/10.3390/cryst10080693

Chicago/Turabian StyleLee, Myoungjae, In-Su Kim, Young Hoon Moon, Hyun Sik Yoon, Chan Hee Park, and Taekyung Lee. 2020. "Kinetics of Capability Aging in Ti-13Nb-13Zr Alloy" Crystals 10, no. 8: 693. https://doi.org/10.3390/cryst10080693

APA StyleLee, M., Kim, I.-S., Moon, Y. H., Yoon, H. S., Park, C. H., & Lee, T. (2020). Kinetics of Capability Aging in Ti-13Nb-13Zr Alloy. Crystals, 10(8), 693. https://doi.org/10.3390/cryst10080693