1. Introduction

Rolling technology is widely used in manufacturing metals and alloys. In general, deformation texture forms during rolling, and the resultant texture will affect the following processes and determine properties of final products [

1,

2]. Understanding the formation and evolution of deformation texture can provide theoretical insight for texture control, thus improving material properties [

3]. Other than experimental observation, the evolution of texture and crystallographic orientation can be evaluated based on simulation, which requires a reasonable and suitable model dedicated to polycrystalline plastic deformation.

Multiple models for polycrystalline plastic deformation have been developed from the original Sachs model and Taylor model. In recent years, grain interaction (GIA) model, viscoplastic self-consistent (VPSC) model, advanced lamel (ALAMEL) models and others have been proposed. With development of these models, the simulated deformation textures have been continuously improved and nicely match experimental observation [

4,

5,

6,

7,

8,

9,

10]. Regarding the stress and strain consistency during simulation, it is actualized inside grain groups by GIA and ALAMEL models, in which 8 grains and 2 grains are set as a group respectively, and different relaxation is implemented inside the groups [

4,

5,

6,

7,

11]. The VPSC model considers the stress and strain continuity between every deformed grain and its surrounding matrix statistically [

9,

10,

11].

Compared to the models developed based on the Taylor principle, the reaction stress (RS) model evaluates the deformation process based on the stress condition. At the beginning, only external stress is considered, and the slip system with the highest Schmid factor is activated. As soon as the active slip induces plastic strain, reaction stress by neighboring grains is taken into consideration. The reaction stress is calculated based on statistical matrix. These external and intergranular reaction stresses are combined to determine the following processes [

12,

13]. In simulation, the intergranular continuity of strain and stress is achieved in a natural way, and the calculation method does not have a complicated hypothesis [

12,

13,

14,

15]. RS model has been increasingly applied to metals and alloys with different crystal structures, including BCC, FCC and HCP structures. For BCC structured metals and alloys, this model has been applied to tungsten, which is elastically isotropic [

12,

13,

14,

15].

Ferritic steel with BCC structure has been widely applied in industry. For example, interstitial-free (IF) steel, low carbon steel and silicon steel are being used in automatic, architectural, and electronic fields. In general, the rolling deformation texture of BCC steel is characterized as α-fiber (rolling direction (RD) of the rolled plate//<110>) and γ-fiber (normal direction (ND) of the rolled plate//<111>). The deformation textures directly affect recrystallization behaviors and anisotropic properties of the final products [

1,

16,

17,

18]. Therefore, it is important to understand the evolution of deformation texture. Meanwhile, the evolution of specific deformation orientation of typical texture components needs to be studied as well. Moreover, BCC structured steel has demonstrated an elastic anisotropy, in which Young’s modulus in <111> crystal direction is 6 times of that in <100> direction [

19]. The elastic anisotropy and its effect on the deformation process have to be taken into consideration for simulation. Therefore, as a further theoretical study based on RS model, this study helps the development of simulation work by RS model, making it more systematically and comprehensively understood.

In this paper, a RS model is used to investigate the rolling deformation behaviors of a BCC structured steel and the simulated results are compared to the experimental results and results reported in the literature. The effects of reaction stress values and ranges in different directions, strain values, the ratio of critical resolved shear stress (CRSS) of {110}<111> slip system to CRSS of {112}<111> slip system are discussed, and the influence of elastic anisotropy is also considered. The study could help to clarify the deformation process of BCC structured steel.

2. Simulation and Experimental Methods

This study focuses on the rolling deformation behavior of BCC structured steel via both theoretical simulation and experimental characterization. RS model is used to mimic the texture evolution and orientation change of typical texture components. The RS model states that, the stress of a deformed grain undergoing in a polycrystal can be depicted as Equation (1) [

12,

13,

14,

15]:

is the yield strength. The index

i and

j = 1, 2, 3, and 1, 2, 3 represents rolling direction (RD), transverse direction (TD) and normal direction (ND), respectively.

represents the reaction stress, and it can be calculated based on intergranular stress and strain balance:

G(

g) and

G(

m) correspond to the shear modulus of the deformed grain and matrix, respectively, which are dependent on the orientations of the deformed grain and matrix.

is the shear strain of an active slip in the deformed grain.

can be illustrated by Frank-Read theory:

G is

G(g),

b and

μ are the burgers vector and the Schmid factor corresponding to the active slip system,

d is the effective dislocation distance, which decreases with the increasing strain [

15]. The connection between

and the parameters, including

b,

,

d,

as well as crystal orientation, can be obtained, and more details can be found in the literature [

12,

13,

14,

15].

What needs to be considered is that reaction stress varies in a certain range. Therefore, the accumulation coefficient

αij for reaction stress is introduced to impose the upper-limit for reaction stress

σij’, as shown in Equation (4).

αijs varies in the range of 0–1, and the value imposes significant effect on the texture evolution [

12,

15]:

As the initial orientations in this study, 1000 random orientations are chosen. The calculation step is Δ

ε33 = −0.0005. The calculated results at different strains are compared to experimental results and results reported in the literature. The effects of reaction stress accumulation coefficient

αij, the activation ability of {110}<111> and {112}<111> slip systems as well as strain values ε

33 on the deformation texture are discussed systematically. In particular, the value of

αij has been proven to have significant effect on the texture evolution in BCC structured tungsten [

15], and thus its effect on the calculated texture is evaluated in detail. Based on the analysis, simulation parameters are optimized and are used to discuss the orientation evolution of typical texture components in BCC steel. Surface shear stress has limited effect on texture evolution. One of the reasons is that rolling is usually performed at room temperature and thus there is no considerable shear stress by surface friction. Our earlier study on tungsten shows that small surface shear stress may lead to slight a deviation of the texture component or a decrease of texture intensity, while the major texture distribution is not affected [

15]. Therefore, this study does not discuss the effect of surface shear stress.

Two types of experiments were carried out in the study. First, a forged Fe-3 wt%.Si steel was annealed at 800 °C for 2 h to obtain a microstructure with an average grain size of ~200 μm, and then a 10 mm × 10 mm × 10 mm sample was cut from it. After being polished at the lateral plane, the sample was compressed to 5% reduction. Afterwards, the initially polished lateral plane was measured with a Zeiss GeminiSEM500 field emission scanning electron microscope (SEM) (Zeiss, Braunschweig, Germany.) to observe the slip traces, by which the strain distribution could be evaluated. The goal is to prove that the strain consistency is due to both penetrating plastic strain and local plastic strain. This hypothesis is proposed when studying the deformation behavior of BCC structured tungsten but is not verified experimentally because of difficulty to obtain experimental data. With reliable experimental results, the distribution of penetrating and local strain is discussed. Second, a Fe-0.46 wt%Si steel was cold rolled to different reductions. Its textures before and after rolling were measured by X-ray diffraction (XRD) (Bruker, Billerica, MA, USA) using Bruker D8 advance X-ray diffractometer. The texture evolution was compared to the simulation results so that the RS model dedicated to steels with BCC structure can be comprehensively studied and its validity will be eventually confirmed.

3. Results and Discussion

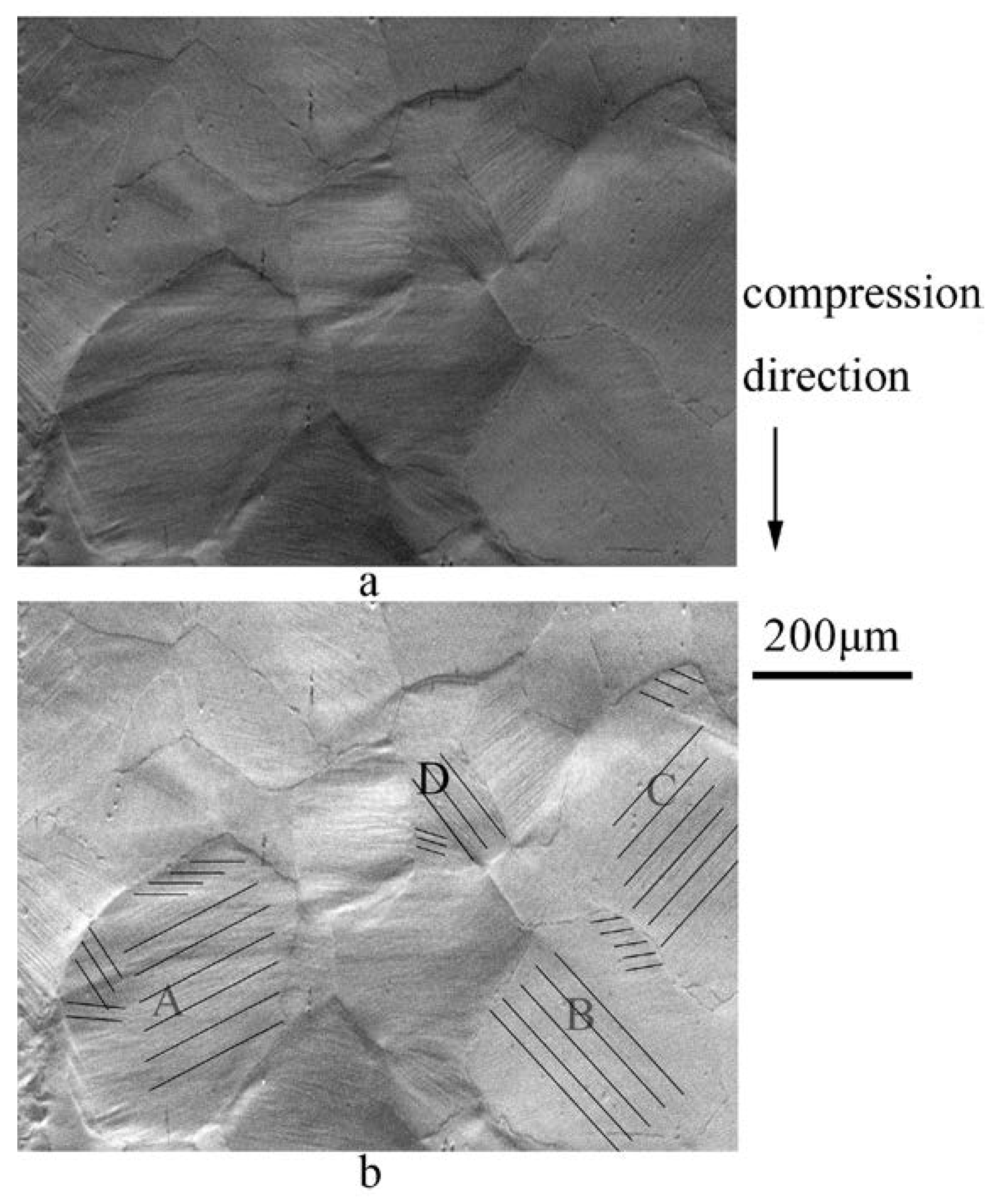

The microstructure of 5% compressed silicon steel sample and the compression direction are shown in

Figure 1a. Examples of typical slip traces inside grains are given in

Figure 1b, and multiple slip traces along different directions in deformed grains are highlighted and deformed grains are labeled as A, B, C and D. Each slip trace corresponds to activation of a specific slip system. At the early stage of rolling deformation, both penetrating slip and local slip can be observed in many grains. Various local slips can be generated simultaneously in a single deformed grain, such as in grain A. The same phenomenon has been reported in [

15]. The penetrating plastic strains in adjacent grains do not always coordinate with each other during the deformation, and the strain continuity is achieved via the coordination of penetrating plastic slip and local plastic slip. Elastic strain is not shown in the figure, however, its role in reducing strain inconsistency cannot be ignored, and moreover its corresponding elastic reaction stress contributes to stress continuity.

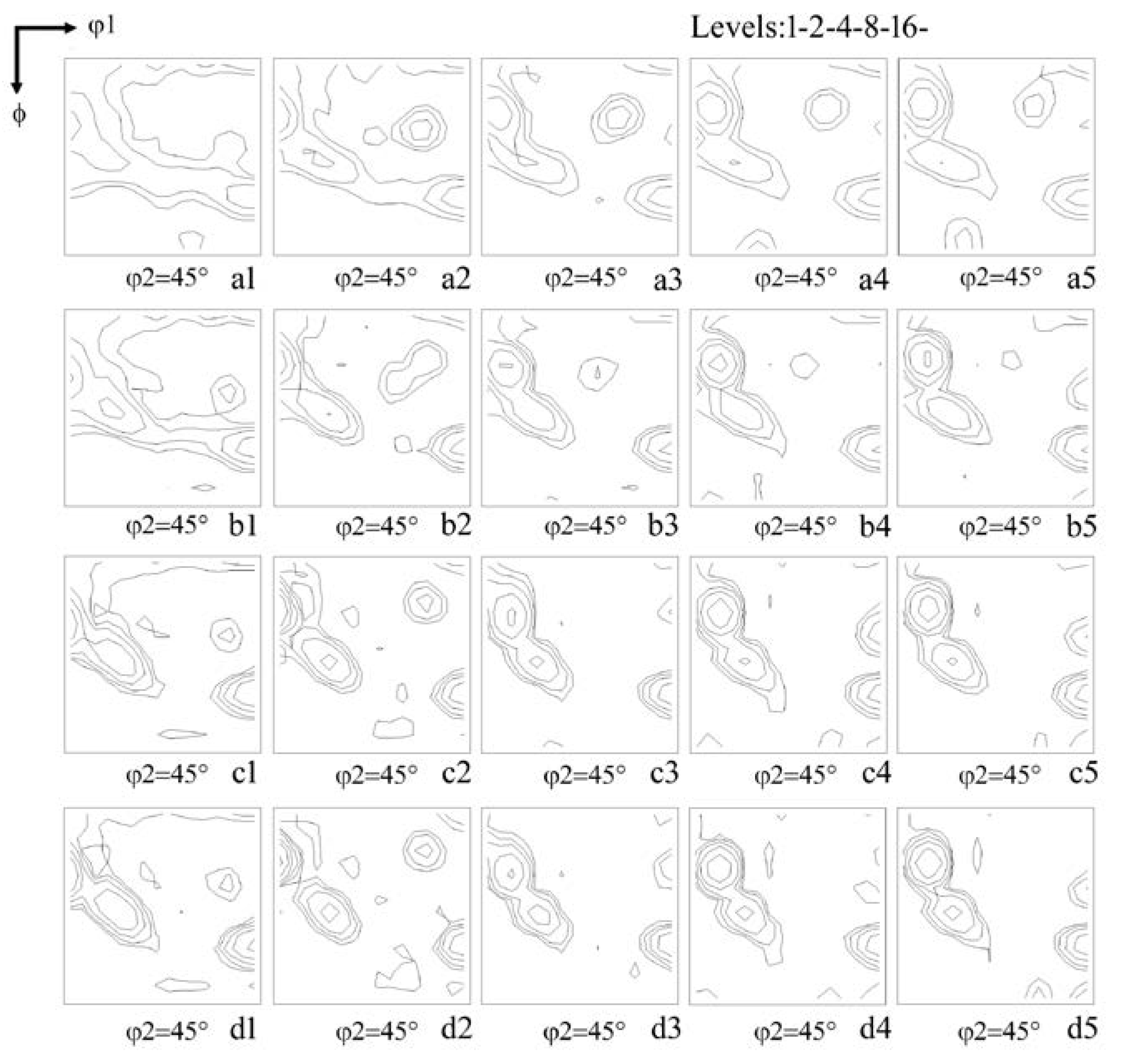

The texture evolution at different strains was calculated using various reaction stress accumulation coefficient

αij, and the results when only considering {110}<111> slip are shown in

Figure 2(a1–d5). The effect of elastic anisotropy is not considered here. Taylor texture is obtained at low strain when

αijs are set to be 0.2 in

Figure 2(a1,b1), and the values of reaction stress do not exceed 0.1

σy. Under this condition, some texture components near γ-fiber, especially near {111}<110> component, are weakened gradually with strain, while at the same time Taylor texture is further strengthened. When

ε33 reaches −1.1, Taylor texture becomes a major texture component and α-fiber texture starts to appear in

Figure 2(c1). When the

αij value increases, the calculated texture starts to deviate from α-fiber and the intensity of Taylor texture decreases. To sum up, the calculation results are similar to that of tungsten, and strong Taylor texture—which is a typical simulated rolling texture in BCC polycrystals under Taylor principle—is achieved with {110}<111> slip [

15].

The elastic anisotropy of Fe should be taken into consideration in the simulation because of its effect on multiple parameters, including reaction stress, slip system, orientation change and texture evolution. The textures at

ε33 = −1.1 are calculated with consideration of elastic anisotropy. The results are shown in

Figure 3. By comparing

Figure 3(a1–a5) and

Figure 2(c1–c5), it is obvious that the effect of elastic anisotropy is weak when other parameters remain unchanged. The orientation dependent

Gij affects the value of

σ’

ij, while it could not accumulate with no limits owing to the existence of reaction stress accumulation upper-limits. Therefore, the influence of elastic anisotropy on the calculated texture is restricted under current conditions. However, it may affect grains with certain orientations, and thus it should still be included in the simulation presented in the following sections.

The activation abilities of {110}<111> and {112}<111> slip systems are known to greatly influence the calculated texture. With different critical resolved shear stress ratios of {110}<111> vs {112}<111> slip systems (CRSS

{110}<111>/CRSS

{112}<111>), the change of calculated texture with varied

αisj is also illustrated in

Figure 3. Compared to the result under {110}<111> slip, {112}<111> slip promotes the formation of α-fiber texture in

Figure 3(b1–b5). When

αijs is low, {112}<111> slip results in higher percentage of {001}<110> texture. Stronger {001}<110> texture has been reported in silicon steel with higher Si content, and it is suggested that solute Si in the steel makes the activation of {112}<111> slip systems easier, resulting in the formation of {001}<110> texture [

20]. This assumption can also be applied to the calculated result shown in

Figure 3. Besides {001}<110> texture, α-fiber component between {112}<110> and {111}<110> is also present. When CRSS

{110}<111>/CRSS

{112}<111> = 1.05, the calculated texture is similar to that when only {112}<111> slip considered, as shown in

Figure 3(e1–e5). The slight decrease of {001}<110> texture in

Figure 3 proves the enhanced effect of {112}<111> slip on {001}<110> texture. The results in

Figure 3(c1–c5,d1–d5) are due to both {110}<111> and {112}<111> slips. In other words, when CRSS

{110}<111>/CRSS

{112}<111> values are either 0.95 or 1, alternative {110}<111> and {112}<111> slips are activated during rolling deformation. When the activation of {110}<111> slip systems becomes easier, as shown in

Figure 3(c1), the distribution of near γ-fiber texture is relatively more continuous.

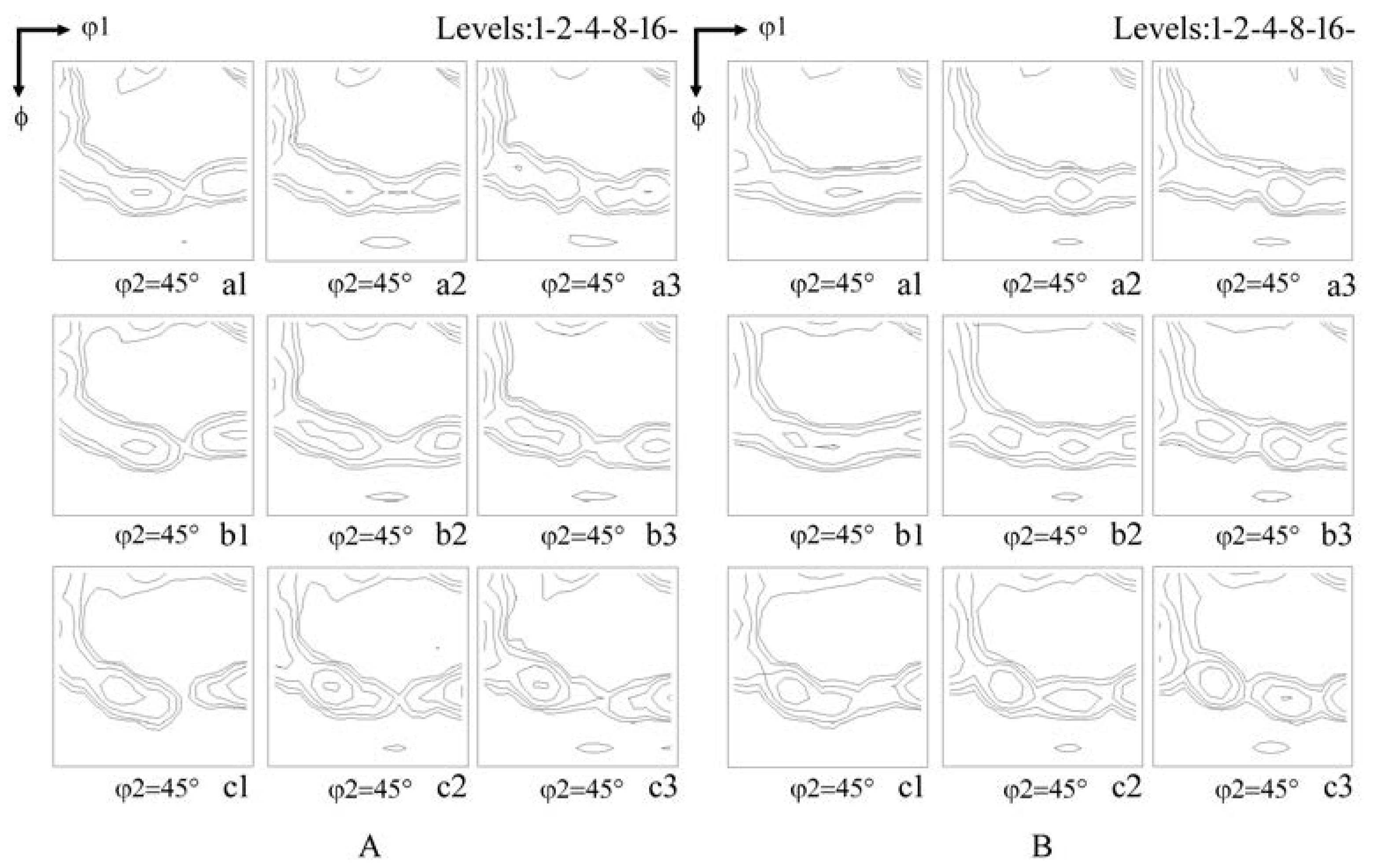

According to the results in

Figure 2 and

Figure 3, a set of low

αijs contribute to formation of typical α-fiber and γ-fiber textures in BCC steel but also cause the γ-fiber texture to deviate to Taylor component. Taylor texture is obtained due to reaction stress, and thus it is assumed that lower

αijs may lead to more exact γ-fiber texture. The effect of

α13 and

α23 on the deformation texture is shown in

Figure 4 when

α12 and

α22 are set as 0.2 and as 0 or 0.1, respectively.

αijs are selected based on the methods reported in our previous works [

12,

131415]. In general, compared to

ε12,

ε13 and

ε23 tend to occur easier and show distinct characteristic under rolling deformation [

12,

21]. The value of CRSS

{110}<111>/CRSS

{112}<111> is chosen to be 0.95, suggesting that {110}<111> slip is presumed to be more likely to be activated [

20]. As shown in

Figure 4, when

α13 and

α23 vary between 0 and 0.08, the calculated texture is a mixture of α-fiber and γ-fiber textures [

2,

22,

23,

24]. Therefore, it can be deduced that for BCC steel, the maximum accumulation of

σ’

12 is about 0.1

σy, and the existence of

σ’

12 is critical for obtaining γ-fiber texture. In comparison, the accumulation of

σ’

13 and

σ’

23 is restricted in a smaller range. Comparing

Figure 4A(a1–c3) to

Figure 4B(a1–c3), the {111}<110> texture is attributed to

σ’

22, while the value of

α22 still needs to remain small to prevent forming uneven γ-fiber. When

α13 and

α23 are discussed in a small range, respectively, their effects on texture evolution interacts with each other and shows a relationship with

α22. In detail, at the same

α23, higher

α13 increases α-fiber texture, while different α-fiber texture components occur due to varied

α22, and {111}<110> texture is achieved when

α22 is 0.1. At the same

α13, higher

α23 promotes {111}<112> texture, however, the {111}<112> texture deviates towards Taylor texture when

α13 increases to 0.08. It concludes that the calculation process is similar to that when tungsten is used, whereas the specific

αij values corresponding to the reasonable simulated textures are different [

15].

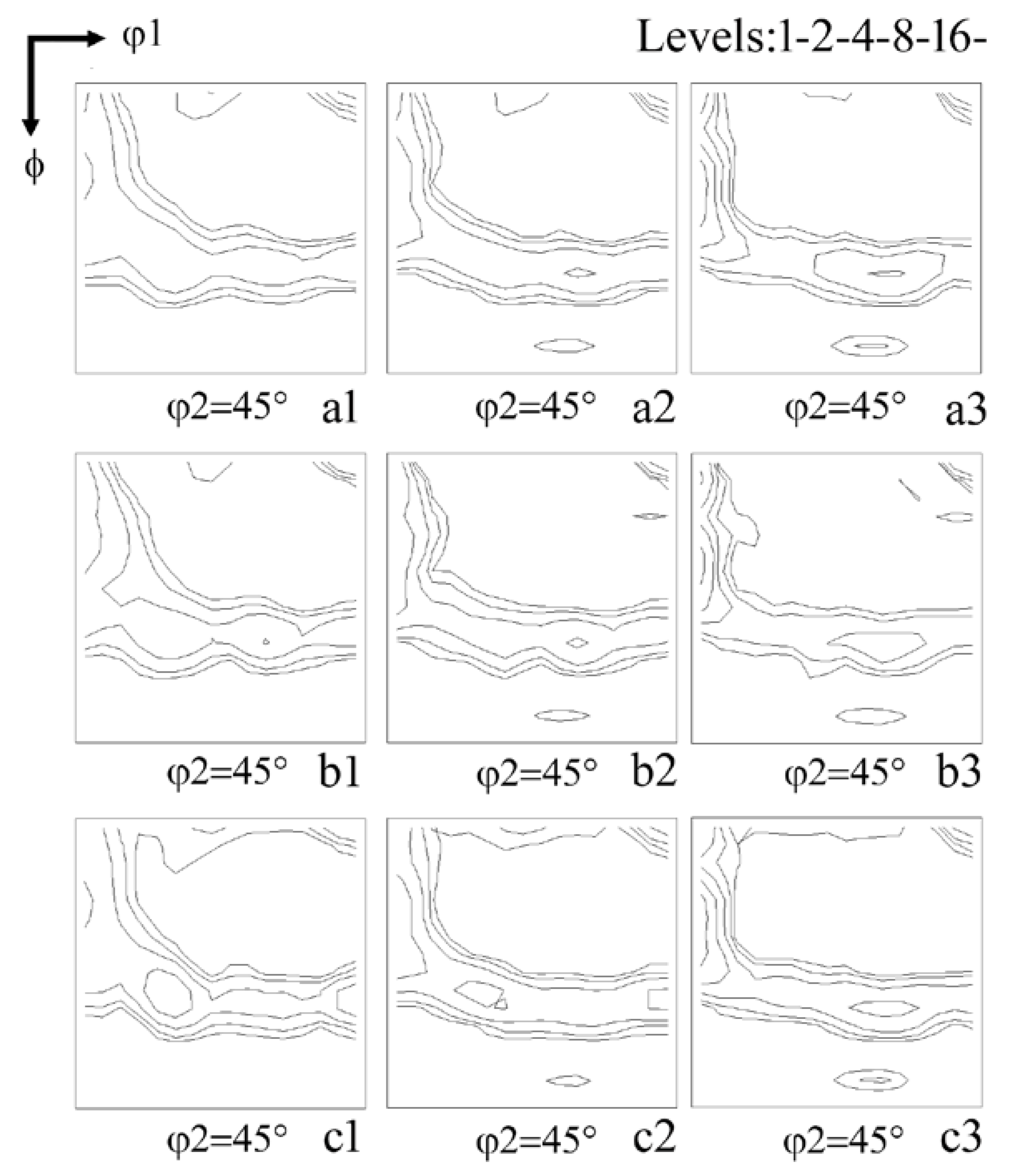

Based on previous results and discussion, the simulation process and selected parameters can be further optimized so that the calculated textures match more closely to the real deformation process [

2,

23,

24]. As shown in

Figure 5, typical α-fiber and γ-fiber textures are obtained at 50% reduction, and both textures are enhanced with increasing strain. {111}<110> texture as well as other α-fiber texture components becomes stronger while {111}<112> texture is weakened at higher strain. When the accumulation of

σ’

23 is permitted, compared to the situation of relaxing

σ’

23 in

Figure 5(a1–a3), stronger {111}<112> texture is shown in

Figure 5(c1–c3). When comparing

Figure 5(a1–a3) and

Figure 5(b1–b3), the preferred {110}<111> slip leads to stronger {112}<110> texture than {001}<110> texture. The stronger {111}<110> texture is also observed at higher strain.

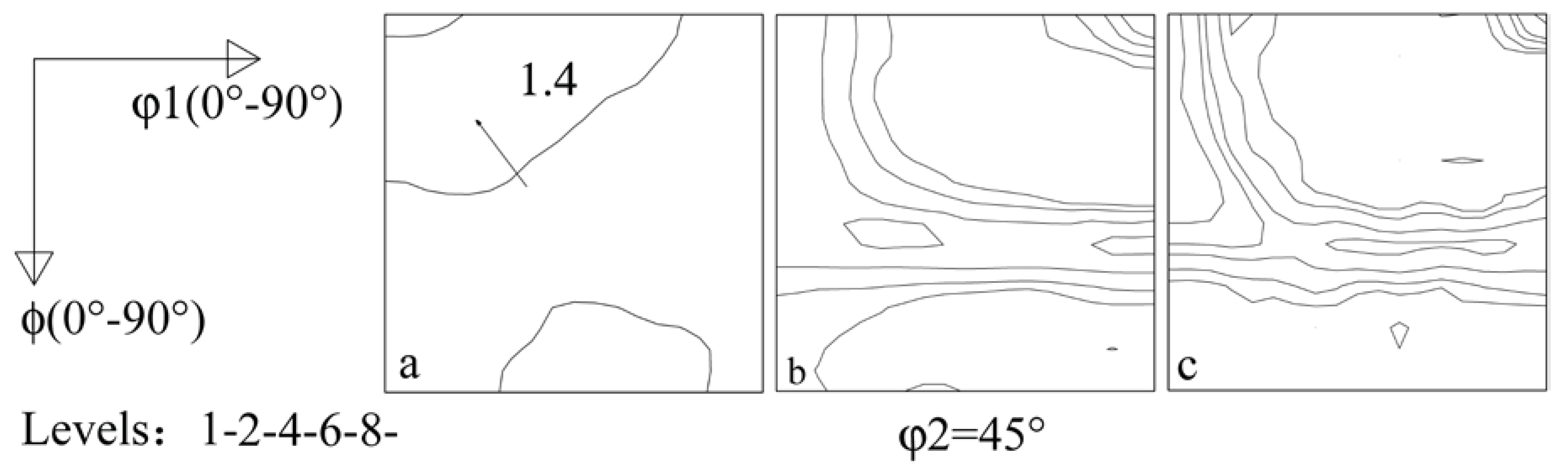

Since the simulated textures in

Figure 5 show characteristics of a typical rolling deformation texture of BCC structured steel, the selection of corresponding calculation parameters is proved to be reasonable. The experimental measurement shown in

Figure 6 illustrates the texture evolution of a cold rolled Fe-Si steel. A weak texture with an intensity less than 1.4 is displayed in the sample prior to rolling, which is similar to that used in the simulation. The cold-rolling process generated α-fiber and γ-fiber textures in 52% (ε

33 = −0.73) steel, as shown in

Figure 6b. When the rolling reduction increases to 80% (ε

33 = −1.6), the peak of γ-fiber changes from {111}<112> to {111}<110> in

Figure 6c. At the same time, α-fiber texture is also enhanced. The texture demonstrates a similar evolution process as the simulated results in

Figure 5. Therefore, RS model is considered to be applicable for texture simulation for BCC steel, and the parameters in

Figure 5 can be used for simulating this rolling process. Confirmed by both theoretical and experimental analysis, for this Si-Fe material, the {110}<111> slip system is easier to be activated to achieve a strong {112}<110> texture at high strain, and the accumulation of ε

23 should be permitted while in lower range than

Figure 5(c1–c3).

To sum up, when calculating the texture evolution in BCC steel, the applied assumptions include a moderate accumulation of

σ’

12 and much narrower range of the rest of

σ’

ijs. Similar to relaxed constraint (RC) model, the strain consistency of

ε13 and

ε23 is easy to be fulfilled or be compensated by local slip. Through this compensation strategy, the strain continuity in some directions is relaxed and the simulated result is more reasonable than that by Taylor model [

25,

26]. Although modification of simulation parameters will cause minor changes in the simulated results, major texture distribution and evolution trend remains stable.

It is worth noting that RS model considers the deformation process in a statistical view and the orientation change of major grains contributes to the statistical texture evolution. RS model can also be used to analyze the orientation evolution of many texture components. Based on previous discussions, the calculation parameters used in

Figure 5(a1–a3) are selected for theoretically analyzing the evolutions of {001}, {110}, α-fiber and γ-fiber orientations under rolling deformation. These orientations are commonly observed in BCC steels: {001} orientation corresponds to columnar grains; {110} orientations including Goss and brass components are usually obtained after hot rolling silicon steel; α-fiber and γ-fiber texture can be achieved after both hot and cold rolling.

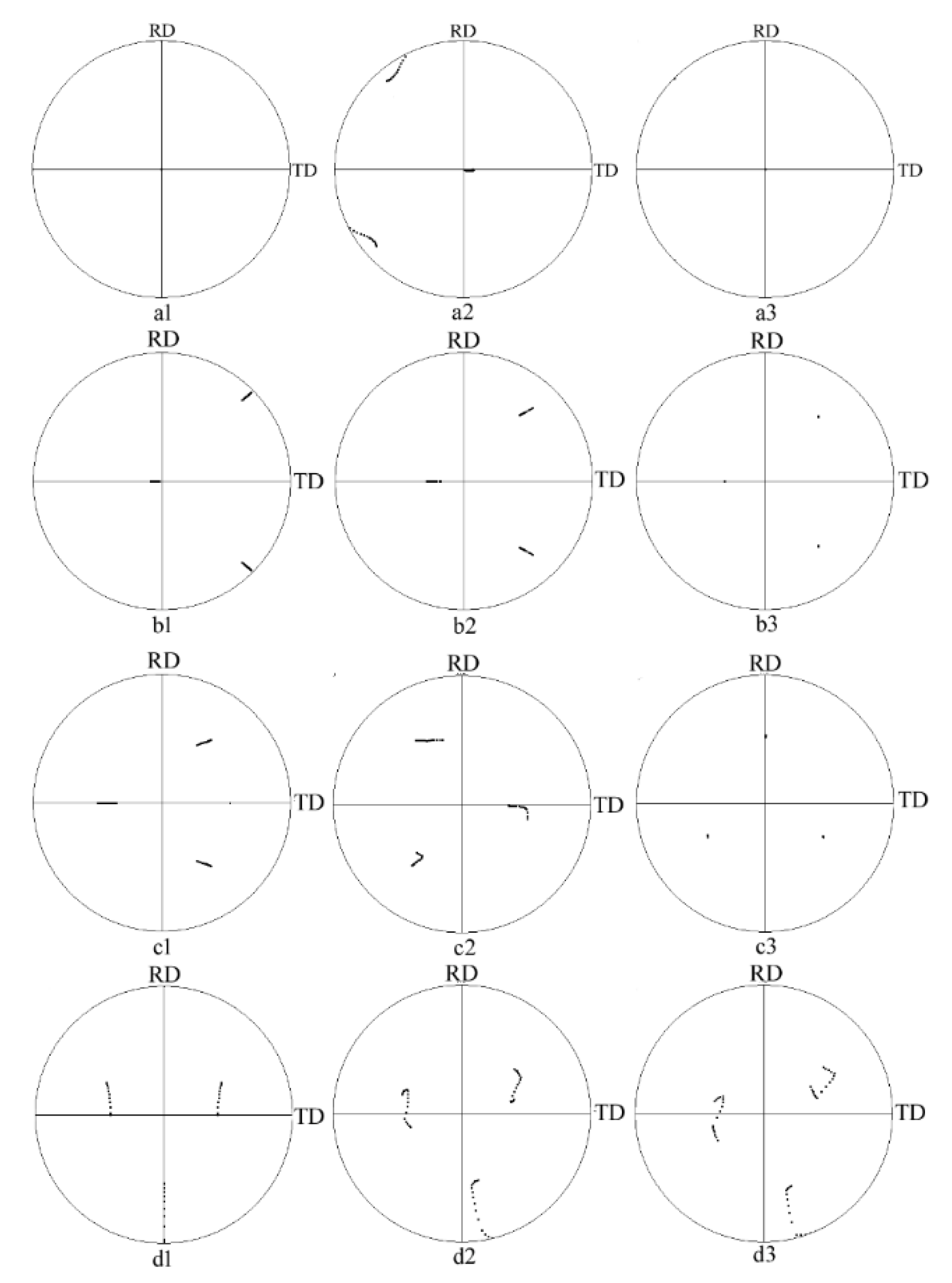

In

Figure 7(a1,a3), {001}<100>((45° 0° 45°)) and {001}<110>((0° 0° 45°)) orientations are stable under rolling deformation, and no changes in orientation are observed. Cube orientation shows meta-stability during rolling in silicon steel [

27], and stable end {001}<110> orientation is widely reported [

28,

29]. {001}<120>((20° 0° 45°)) orientation tends to rotate towards α-fiber and deviate from {001}-fiber simultaneously in

Figure 7(a2). A similar crystal rotation route is observed in other researchers’ work [

27,

30] as well as in our previous report when investigating the occurrence of {001}<112>-{113}<361> texture in silicon steel. Stability in {112}<110>((0° 35° 45°)) orientation is also confirmed, and the α-fiber components between it and {001}<110> components rotate to them alternatively in

Figure 7(b1–b3), depending on which component it is initially closer to. In consequence, {001}<110> and {112}<110> textures on α-fiber become stronger with strain, as shown in

Figure 5. As far as the γ-fiber components are concerned, as shown in

Figure 7(c1–c3), {111}<110>((0° 55° 45°)) orientation rotates towards {112}<110> orientation, whereas {111}<112>((30° 55° 45°)) orientations show strong stability and barely shift to other orientations. The (15° 55° 45°) orientation firstly rotates to {111}<110> orientation and then transits to {112}<110> orientation. Therefore, it can be deduced that strengthening {111}<110> texture with increasing strain may be not only due to its stability, but also affected by rotation from other orientations. For {110} shear texture components in

Figure 7(d1–d3), Goss((90° 90° 45°)) orientation is stable at the early stage but rotates to {111}<112> orientation at higher strain; {110}<229>((75° 90° 45°)) orientation rotates to γ-fiber closer to {111}<112> orientation in the beginning of rolling and then turns to near {111}<110> orientation; brass orientation((60° 90° 45°)) shows a transition route from γ-fiber towards α-fiber in the end. These transition routes for {110} orientations are consistent with the experimental data reported in our early work [

31]. Overall, for most of the typical orientations in

Figure 7(a1–d3), the rotation preferentially revolving towards α-fiber or γ-fiber is predicted.

4. Discussion

The influence of the reaction stress accumulation coefficients αijs on the stress tensor is evident by restricting the changing range of reaction stress. When the value of reaction stress σ’ij exceeds the upper-limit, it is set to be equal to the upper-limit value. According to the calculation results and discussion in this paper, the reaction stress should not be accumulated to a high level, however, moderate or even minor upper-limits are allowed. During the calculation, small reaction stress in the whole stress tensor may cause occurrence of a new slip, thus the accumulation of pre-existing reaction stress can be eliminated. Meanwhile, change in reaction stress value also affects the stress condition of neighboring grains, and the plastic slip of neighboring grains can also terminate accumulation of reaction stress. Under the combined effect of external and reaction stress with reasonable upper-limits, multiple slips are generated, and the simulated evolution tends to closely match the real situation when the calculation step is sufficiently refined.

On the other hand, moderate or even smaller

αij values are the intrinsic requirement of RS model. For doing so the strain that corresponds to the elastic reaction stress will remain as elastic strain during the process. As shown in

Figure 1, besides penetrating the plastic slip and elastic slip, the intergranular strain consistency requires the participation of a local plastic slip. In the case that reaction stress is restricted to the upper-limits, considering the low

αij values, the corresponding elastic strain may be much lower than the strain value used in Equation (2), thus the effect of local slip on strain consistency cannot be ignored.

During the deformation, an active slip usually causes crystal orientation to change, and the strain is accumulated if no other slip systems are activated. For polycrystals, the strain caused by active slip leads to discontinuity between a deformed grain and its environment, and this discontinuity shall be reduced by spontaneous reaction stress [

15]. In this study, some crystal symmetrical orientations show stability to a certain extent under rolling deformation.

Figure 7 illustrates that, {001}<100> and {110}<001> orientations are stable at the early rolling stage. For these symmetrical orientations, the Schmid factors of two or more slip systems are identical under external stress. For example, after a slip occurs in a grain, cube oriented single crystal shows one-directional crystal rotation around <001> axis [

28,

32], and then an opposite slip system with the highest Schmid factor will be activated by the accumulated reaction stress in polycrystals. The alternative activation of two slip systems leads to the orientation stability. Meanwhile the strains caused by alternative slips are compensated by each other, and so the total strain is reduced.