Partial and Total Substitution of Zn by Mg in the Cu2ZnSnS4 Structure

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Compositional Analysis

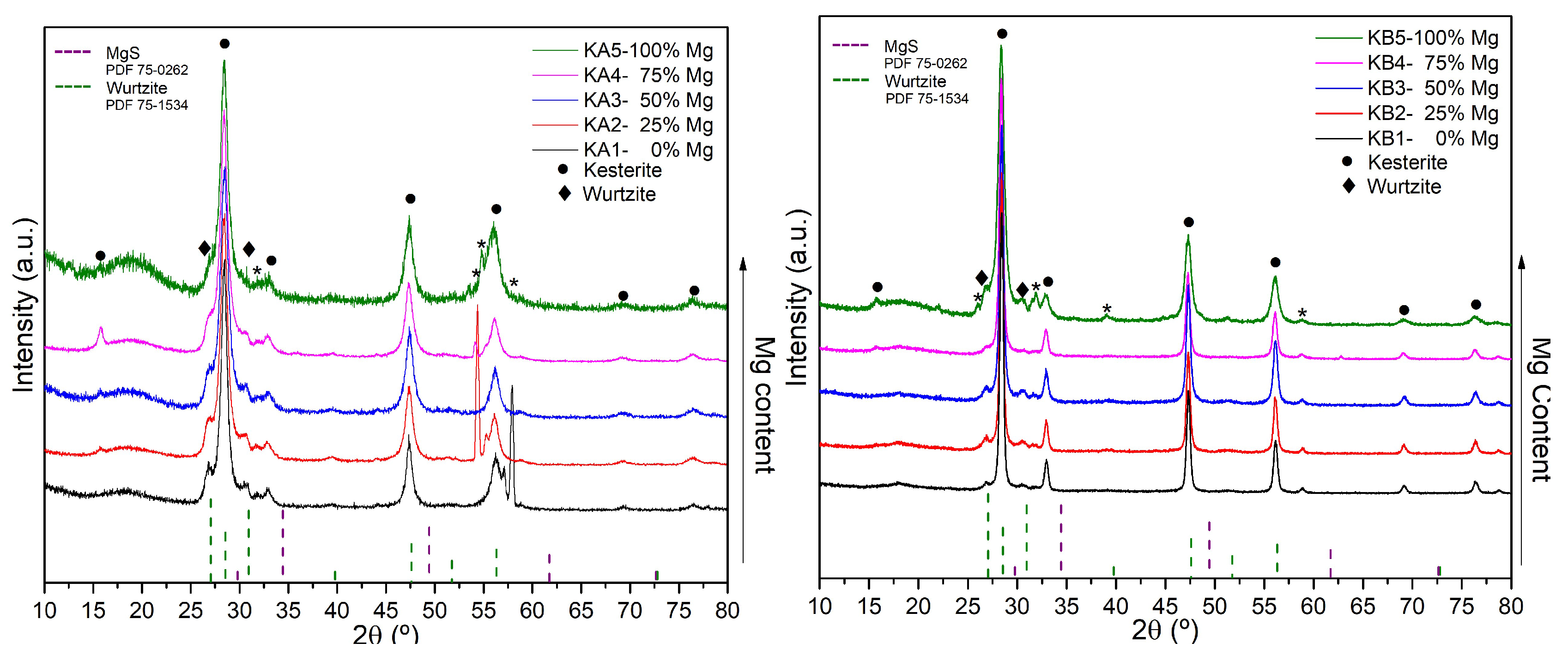

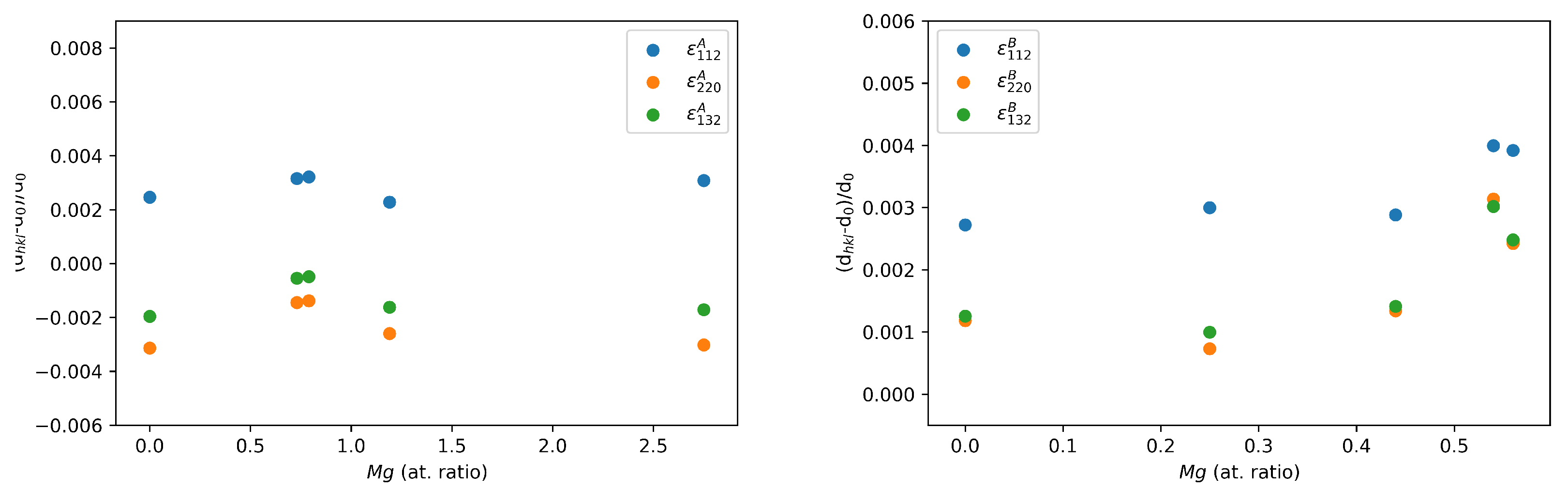

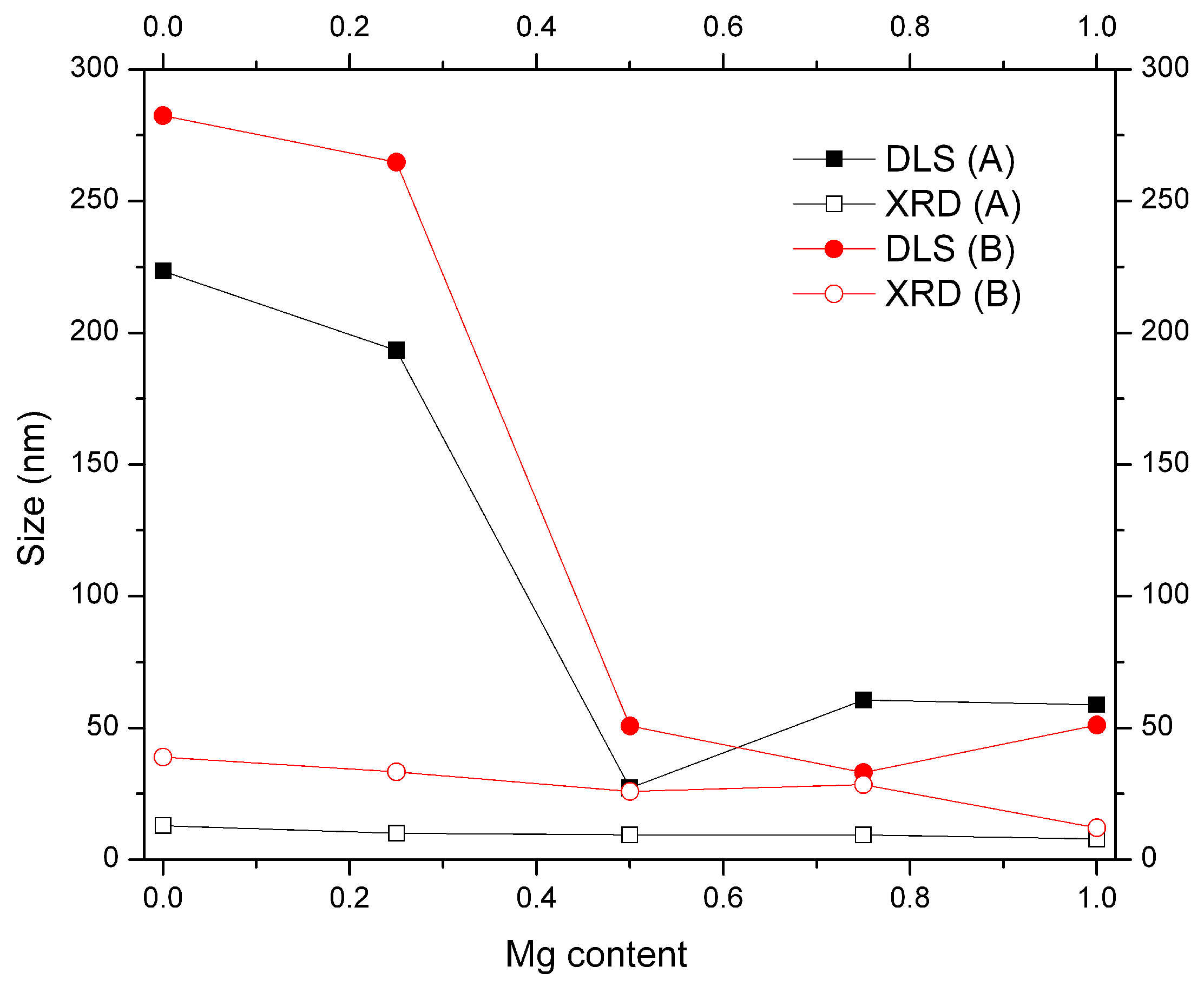

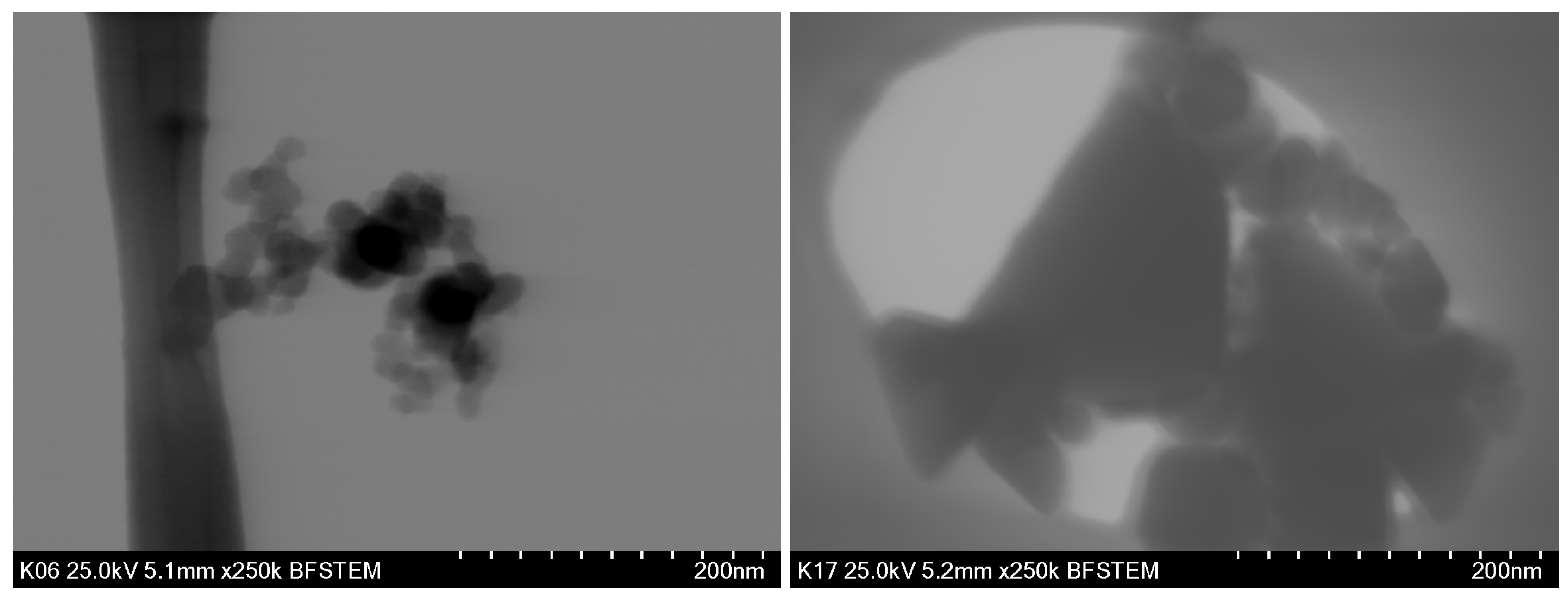

3.2. Size and Structure

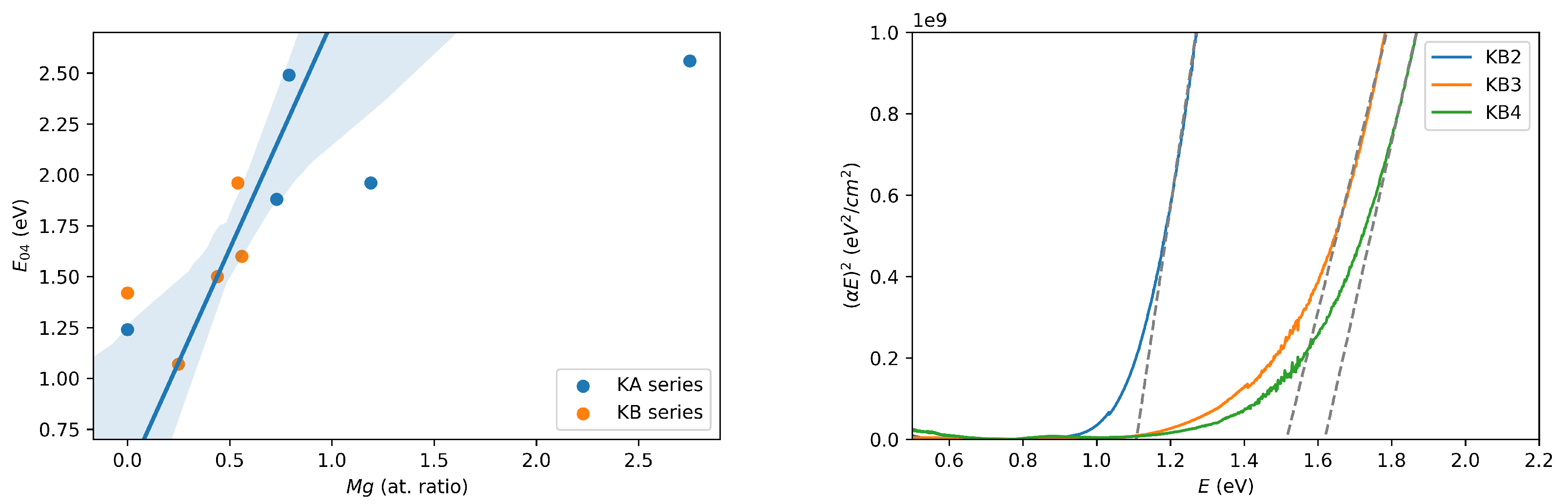

3.3. Optical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Akhavan, V.A.; Goodfellow, B.W.; Panthani, M.G.; Steinhagen, C.; Harvey, T.B.; Stolle, C.J.; Korgel, B.A. Colloidal CIGS and CZTS nanocrystals: A precursor route to printed photovoltaics. J. Solid State Chem. 2012, 189, 2–12. [Google Scholar] [CrossRef]

- Kumar, M.; Dubey, A.; Adhikari, N.; Venkatesan, S.; Qiao, Q. Strategic review of secondary phases, defects and defect-complexes in kesterite CZTS–Se solar cells. Energy Environ. Sci. 2015, 8, 3134–3159. [Google Scholar] [CrossRef]

- Kuo, D.H.; Wubet, W. Mg dopant in Cu2ZnSnSe4: An n-type former and a promoter of electrical mobility up to 120 cm2V−1s−1. J. Solid State Chem. 2014, 215, 122–127. [Google Scholar] [CrossRef]

- Green, M.A.; Emery, K.; Hishikawa, Y.; Warta, W.; Dunlop, E.D. Solar cell efficiency tables (version 47). Prog. Photovolt. Res. Appl. 2016, 24, 3–11. [Google Scholar] [CrossRef]

- Monsefi, M.; Kuo, D.H. Influence of Mg doping on electrical properties of Cu(In,Ga)Se2 bulk materials. J. Alloy. Compd. 2014, 582, 547–551. [Google Scholar] [CrossRef]

- Katagiri, H.; Jimbo, K.; Maw, W.S.; Oishi, K.; Yamazaki, M.; Araki, H.; Takeuchi, A. Development of CZTS-based thin film solar cells. Thin Solid Film. 2009, 517, 2455–2460. [Google Scholar] [CrossRef]

- Kim, S.Y.; Kim, J. Fabrication of CIGS thin films by using spray pyrolysis and post-selenization. J. Korean Phys. Soc. 2012, 60, 2018–2024. [Google Scholar] [CrossRef]

- Kamoun, N.; Bouzouita, H.; Rezig, B. Fabrication and characterization of Cu2ZnSnS4 thin films deposited by spray pyrolysis technique. Thin Solid Film. 2007, 515, 5949–5952. [Google Scholar] [CrossRef]

- Matur, U.C.; Akyol, S.; Baydoğan, N.; Cimenoglu, H. The Optical Properties of CIGS Thin Films Derived by Sol-gel Dip Coating Process at Different Withdrawal Speed. Procedia Soc. Behav. Sci. 2015, 195, 1762–1767. [Google Scholar] [CrossRef]

- Yeh, M.Y.; Lee, C.C.; Wuu, D.S. Influences of synthesizing temperatures on the properties of Cu2ZnSnS4 prepared by sol–gel spin-coated deposition. J. Sol-Gel Sci. Technol. 2009, 52, 65–68. [Google Scholar] [CrossRef]

- Caballero, R.; Haass, S.G.; Andres, C.; Arques, L.; Oliva, F.; Izquierdo-Roca, V.; Romanyuk, Y.E. Effect of Magnesium Incorporation on Solution-Processed Kesterite Solar Cells. Front. Chem. 2018, 6, 5. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Chen, S.; Yang, J.H.; Lang, L.; Xiang, H.J.; Gong, X.G.; Walsh, A.; Wei, S.H. Design of I2-II-IV-VI4 Semiconductors through Element Substitution: The Thermodynamic Stability Limit and Chemical Trend. Chem. Mater. 2014, 26, 3411–3417. [Google Scholar] [CrossRef]

- Guo, Y.; Cheng, W.; Jiang, J.; Zuo, S.; Shi, F.; Chu, J. The structural, morphological and optical–electrical characteristic of Cu2XSnS4 (X:Cu,Mg) thin films fabricated by novel ultrasonic co-spray pyrolysis. Mater. Lett. 2016, 172, 68–71. [Google Scholar] [CrossRef]

- Zhong, G.; Tse, K.; Zhang, Y.; Li, X.; Huang, L.; Yang, C.; Zhu, J.; Zeng, Z.; Zhang, Z.; Xiao, X. Induced effects by the substitution of Zn in Cu2ZnSnX4 (X = S and Se). Thin Solid Film. 2016, 603, 224–229. [Google Scholar] [CrossRef]

- Chen, S.; Yang, J.H.; Gong, X.G.; Walsh, A.; Wei, S.H. Intrinsic point defects and complexes in the quaternary kesterite semiconductor Cu2ZnSnS4. Phys. Rev. B 2010, 81, 245204. [Google Scholar] [CrossRef]

- Siebentritt, S.; Schorr, S. Kesterites-a challenging material for solar cells. Prog. Photovolt. Res. Appl. 2012, 20, 512–519. [Google Scholar] [CrossRef]

- Ananthoju, B.; Mohapatra, J.; Jangid, M.K.; Bahadur, D.; Medhekar, N.V.; Aslam, M. Cation/Anion Substitution in Cu2ZnSnS4 for Improved Photovoltaic Performance. Sci. Rep. 2016, 6, 35369. [Google Scholar] [CrossRef]

- Fontané, X.; Calvo-Barrio, L.; Izquierdo-Roca, V.; Saucedo, E.; Pérez-Rodríguez, A.; Morante, J.R.; Berg, D.M.; Dale, P.J.; Siebentritt, S. In-depth resolved Raman scattering analysis for the identification of secondary phases: Characterization of Cu2ZnSnS4 layers for solar cell applications. Appl. Phys. Lett. 2011, 98, 181905. [Google Scholar] [CrossRef]

- Rudisch, K.; Davydova, A.; Platzer-Björkman, C.; Scragg, J. The effect of stoichiometry on Cu-Zn ordering kinetics in Cu2ZnSnS4 thin films. J. Appl. Phys. 2018, 123, 161558. [Google Scholar] [CrossRef]

- Bekki, B.; Amara, K.; Keurti, M.E. First-principles study of the new potential photovoltaic absorber: Cu2MgSnS4 compound. Chin. Phys. B 2017, 26, 076201. [Google Scholar] [CrossRef]

- Wei, M.; Du, Q.; Wang, R.; Jiang, G.; Liu, W.; Zhu, C. Synthesis of New Earth-abundant Kesterite Cu2MgSnS4 Nanoparticles by Hot-injection Method. Chem. Lett. 2014, 43, 1149–1151. [Google Scholar] [CrossRef]

- Huang, C.; Chan, Y.; Liu, F.; Tang, D.; Yang, J.; Lai, Y.; Li, J.; Liu, Y. Synthesis and characterization of multicomponent Cu2(FexZn1−x)SnS4 nanocrystals with tunable band gap and structure. J. Mater. Chem. A 2013, 1, 5402–5407. [Google Scholar] [CrossRef]

- Oueslati, H.; Rabeh, M.B.; Martin, J.; Kanzari, M. Structural, morphological and optical properties of Cu2ZnxFe1−xSnS4 thin films grown by thermal evaporation. Thin Solid Film. 2019, 669, 633–640. [Google Scholar] [CrossRef]

- Agawane, G.; Vanalakar, S.; Kamble, A.; Moholkar, A.; Kim, J. Fabrication of Cu2(ZnxMg1−x)SnS4 thin films by pulsed laser deposition technique for solar cell applications. Mater. Sci. Semicond. Process. 2018, 76, 50–54. [Google Scholar] [CrossRef]

- Azanza Ricardo, C.L.; Girardi, F.; Cappelletto, E.; D’Angelo, R.; Ciancio, R.; Carlino, E.; Ricci, P.C.; Malerba, C.; Mittiga, A.; Di Maggio, R.; et al. Chloride-based route for monodisperse Cu2ZnSnS4 nanoparticles preparation. J. Renew. Sustain. Energy 2015, 7, 043150. [Google Scholar] [CrossRef]

- Xu, Y.; Xiao, X. Accelerated microwave synthesis of magnesium sulfide with the pro-heating medium of graphite. J. Mater. Res. 1995, 10, 334–338. [Google Scholar] [CrossRef]

- Li, M.; Zhou, W.H.; Guo, J.; Zhou, Y.L.; Hou, Z.L.; Jiao, J.; Zhou, Z.J.; Du, Z.L.; Wu, S.X. Synthesis of Pure Metastable Wurtzite CZTS Nanocrystals by Facile One-Pot Method. J. Phys. Chem. C 2012, 116, 26507–26516. [Google Scholar] [CrossRef]

- Khadka, D.B.; Kim, J. Structural Transition and Band Gap Tuning of Cu2(Zn,Fe)SnS4 Chalcogenide for Photovoltaic Application. J. Phys. Chem. C 2014, 118, 14227–14237. [Google Scholar] [CrossRef]

- Khadka, D.B.; Kim, J. Band Gap Engineering of Alloyed Cu2ZnGexSn1−xQ4 (Q = S,Se) Films for Solar Cell. J. Phys. Chem. C 2015, 119, 1706–1713. [Google Scholar] [CrossRef]

- Malerba, C.; Biccari, F.; Azanza Ricardo, C.; Valentini, M.; Chierchia, R.; Müller, M.; Santoni, A.; Esposito, E.; Mangiapane, P.; Scardi, P.; et al. CZTS stoichiometry effects on the band gap energy. J. Alloy. Compd. 2014, 582, 528–534. [Google Scholar] [CrossRef]

- Singh, O.P.; Vijayan, N.; Sood, K.; Singh, B.; Singh, V. Controlled substitution of S by Se in reactively sputtered CZTSSe thin films for solar cells. J. Alloy. Compd. 2015, 648, 595–600. [Google Scholar] [CrossRef]

| EDX (At%) | Expected Ratios | EDX/Cu = 2 | Cation Ratios | |||||||||||||||

| ID | Cu | Zn | Mg | Sn | S | Total | Zn | Mg | Zn | Zn | Mg | Mg | Sn | Sn | S | S | ||

| KA1 | 25.14 | 9.22 | 0 | 15.24 | 50.40 | 100 | 1 | 0 | 0.73 | 0.16 | 0 | 0 | 1.21 | 0.20 | 4.01 | 0.74 | 1.03 | 0.61 |

| KA2 | 20.95 | 9.03 | 7.67 | 12.14 | 50.20 | 100 | 0.75 | 0.5 | 0.86 | 0.10 | 0.73 | 0.18 | 1.16 | 0.14 | 4.79 | 0.68 | 0.73 | 1.38 |

| KA3 | 18.62 | 6.03 | 11.09 | 12.20 | 52.06 | 100 | 0.50 | 1 | 0.65 | 0.08 | 1.19 | 0.27 | 1.31 | 0.16 | 5.59 | 0.44 | 0.64 | 1.40 |

| KA4 | 25.77 | 3.74 | 10.23 | 13.92 | 46.35 | 100 | 0.25 | 1.5 | 0.29 | 0.04 | 0.79 | 0.18 | 1.08 | 0.13 | 3.60 | 0.50 | 0.92 | 1.00 |

| KA5 | 20.82 | 0 | 28.62 | 11.61 | 38.95 | 100 | 0 | 2 | 0 | 0 | 2.75 | 0.58 | 1.12 | 0.14 | 3.74 | 0.55 | 0.52 | 2.47 |

| EDX (At%) | Expected Ratios | EDX/Cu = 2 | Cation Ratios | |||||||||||||||

| ID | Cu | Zn | Mg | Sn | S | Total | Zn | Mg | Zn | Zn | Mg | Mg | Sn | Sn | S | S | ||

| KB1 | 29.47 | 6.76 | 0 | 14.81 | 48.96 | 100 | 1 | 0 | 0.46 | 0.02 | 0 | 0 | 1.00 | 0.04 | 3.32 | 0.16 | 1.37 | 0.46 |

| KB2 | 25.91 | 5.59 | 3.24 | 13.95 | 51.30 | 100 | 0.75 | 0.25 | 0.43 | 0.02 | 0.25 | 0.03 | 1.08 | 0.05 | 3.96 | 0.19 | 1.14 | 0.63 |

| KB3 | 26.86 | 5.97 | 5.91 | 14.27 | 47.00 | 100 | 0.50 | 0.5 | 0.44 | 0.02 | 0.44 | 0.04 | 1.06 | 0.05 | 3.50 | 0.17 | 1.03 | 0.83 |

| KB4 | 25.98 | 1.50 | 7.26 | 15.04 | 50.21 | 100 | 0.25 | 0.75 | 0.12 | 0.01 | 0.56 | 0.05 | 1.16 | 0.05 | 3.87 | 0.19 | 1.09 | 0.58 |

| KB5 | 28.94 | 0 | 7.80 | 15.22 | 48.04 | 100 | 0 | 1 | 0 | 0 | 0.54 | 0.04 | 1.05 | 0.05 | 3.32 | 0.16 | 1.26 | 0.51 |

| KA Series Size (nm) | KB Series Size (nm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | DLS | DLS | XRD | XRD | ID | DLS | DLS | XRD | XRD |

| KA1 | 223.4 | - | 12.9 | 0.2 | KB1 | 272.5 | - | 38.9 | 0.4 |

| KA2 | 193.3 | - | 10.0 | 0.1 | KB2 | 264.8 | - | 33.2 | 0.3 |

| KA3 | 27.1 | 208.6 | 9.4 | 0.1 | KB3 | 50.7 | 198.2 | 25.9 | 0.2 |

| KA4 | 60.5 | 161.2 | 9.4 | 0.1 | KB4 | 33.0 | 334.9 | 28.4 | 0.2 |

| KA5 | 58.7 | 187.6 | 5.6 | 0.1 | KB5 | 51.0 | 123.9 | 12.1 | 0.1 |

| Sample | (eV) | Sample | (eV) |

|---|---|---|---|

| KA1 | 1.24 | KB1 | 1.42 |

| KA2 | 1.88 | KB2 | 1.07 |

| KA3 | 1.96 | KB3 | 1.50 |

| KA4 | 2.49 | KB4 | 1.60 |

| KA5 | 2.56 | KB5 | 1.96 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mena Romero, D.M.; Victoria Valenzuela, D.; Azanza Ricardo, C.L. Partial and Total Substitution of Zn by Mg in the Cu2ZnSnS4 Structure. Crystals 2020, 10, 578. https://doi.org/10.3390/cryst10070578

Mena Romero DM, Victoria Valenzuela D, Azanza Ricardo CL. Partial and Total Substitution of Zn by Mg in the Cu2ZnSnS4 Structure. Crystals. 2020; 10(7):578. https://doi.org/10.3390/cryst10070578

Chicago/Turabian StyleMena Romero, Diana M., David Victoria Valenzuela, and Cristy L. Azanza Ricardo. 2020. "Partial and Total Substitution of Zn by Mg in the Cu2ZnSnS4 Structure" Crystals 10, no. 7: 578. https://doi.org/10.3390/cryst10070578

APA StyleMena Romero, D. M., Victoria Valenzuela, D., & Azanza Ricardo, C. L. (2020). Partial and Total Substitution of Zn by Mg in the Cu2ZnSnS4 Structure. Crystals, 10(7), 578. https://doi.org/10.3390/cryst10070578