Polarization Volume Gratings for Near-Eye Displays and Novel Photonic Devices

Abstract

1. Introduction

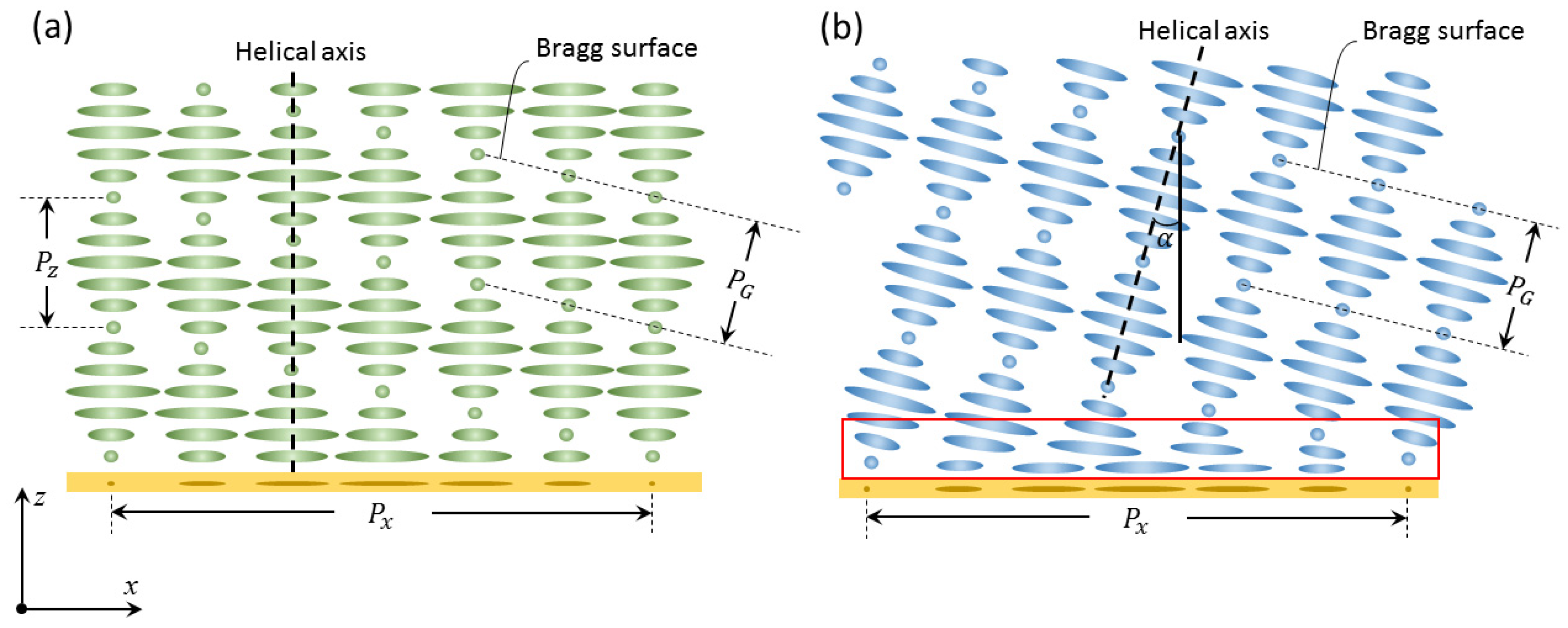

2. Operation Principles

3. Optical Properties

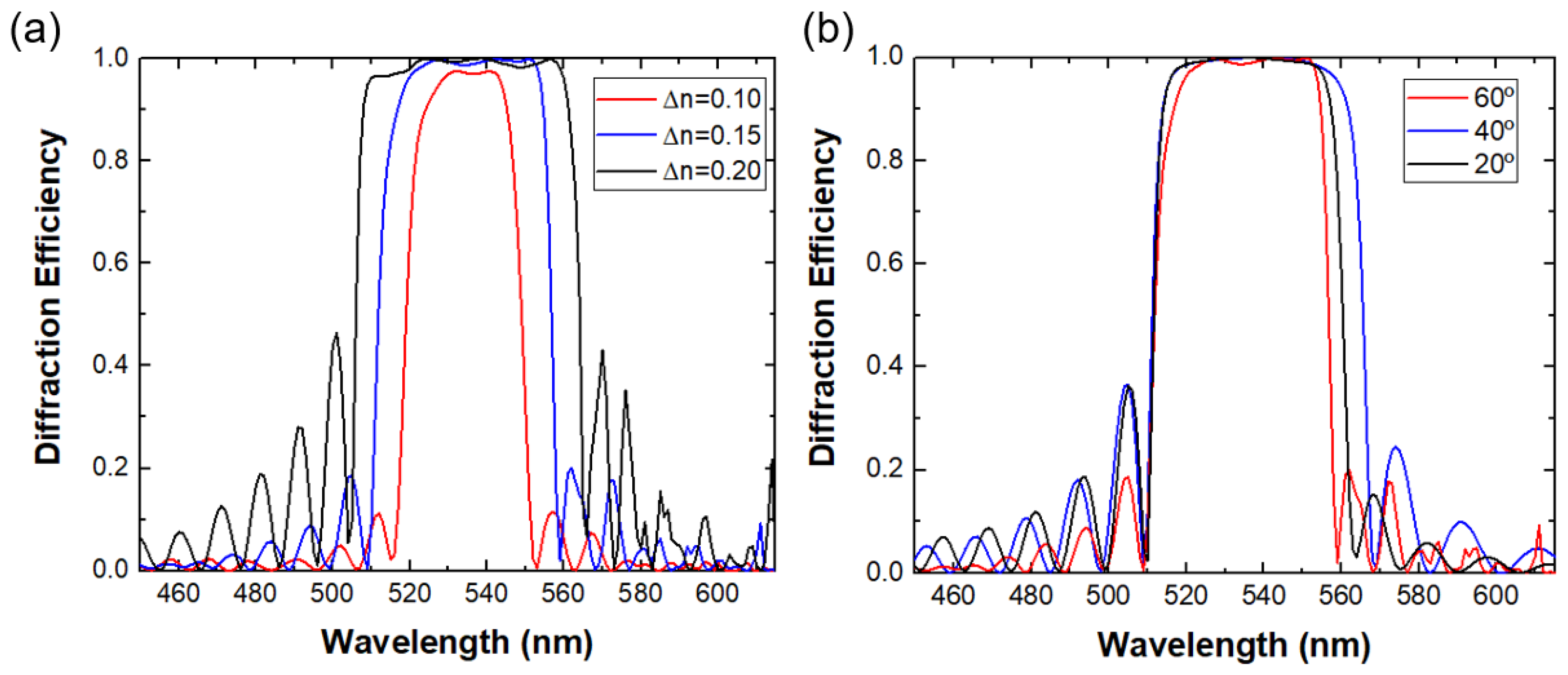

3.1. Wavelength Response

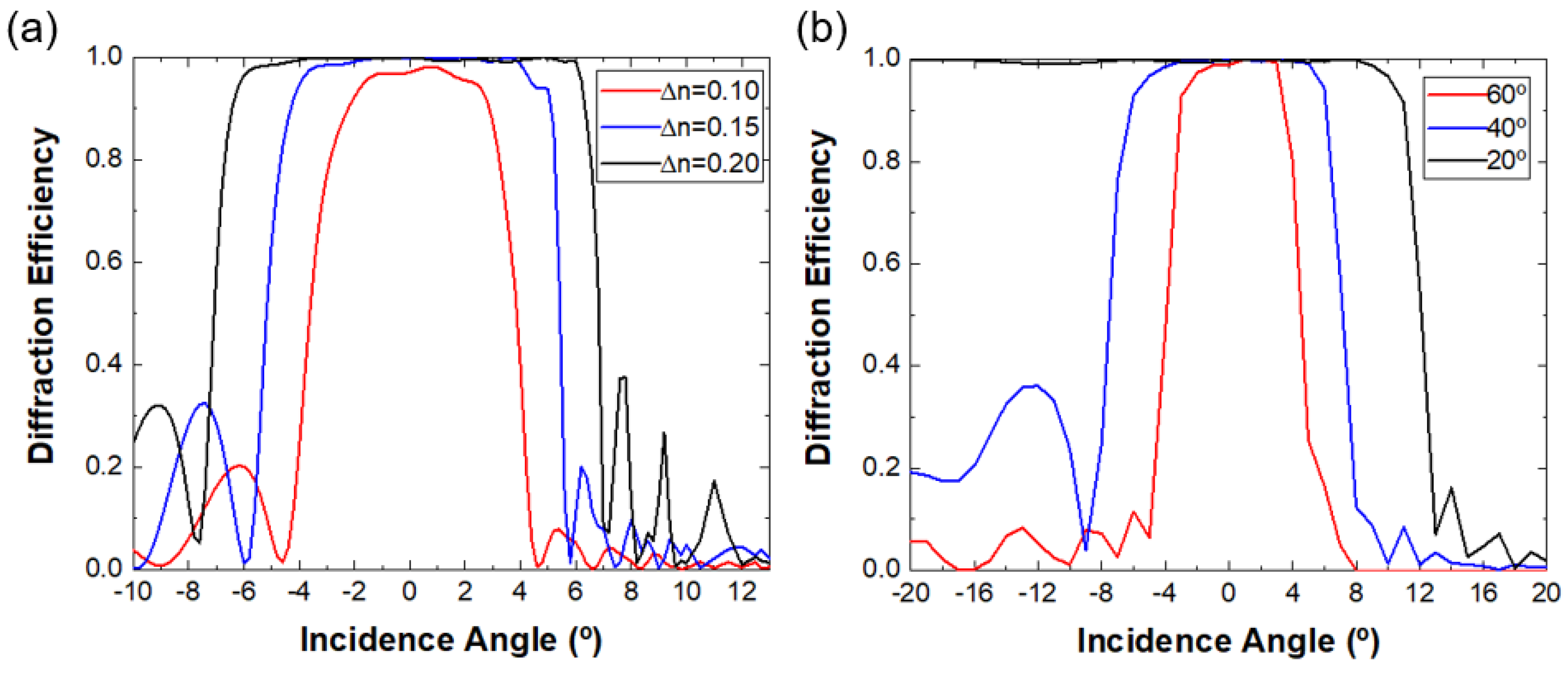

3.2. Angular Response

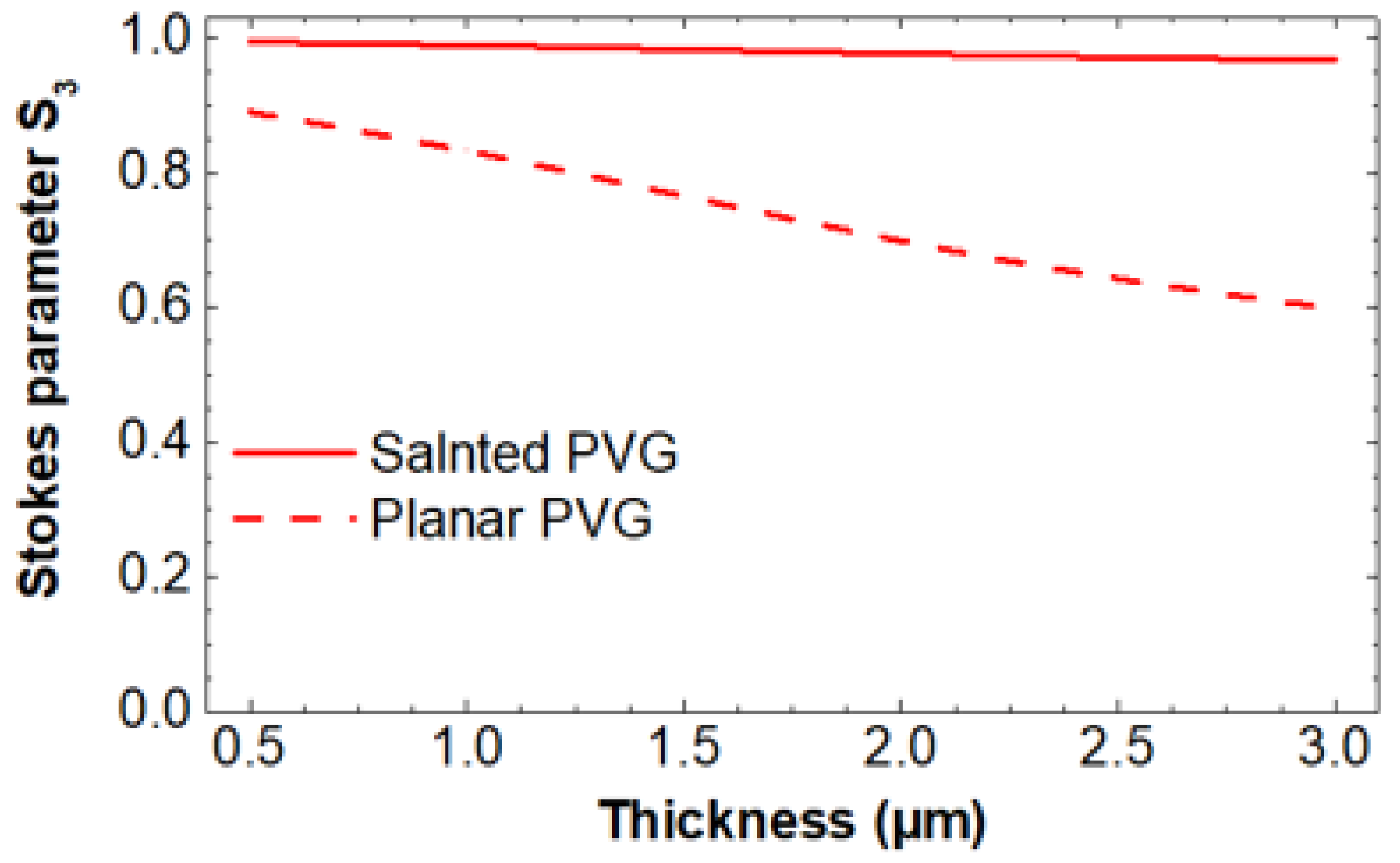

3.3. Polarization Response

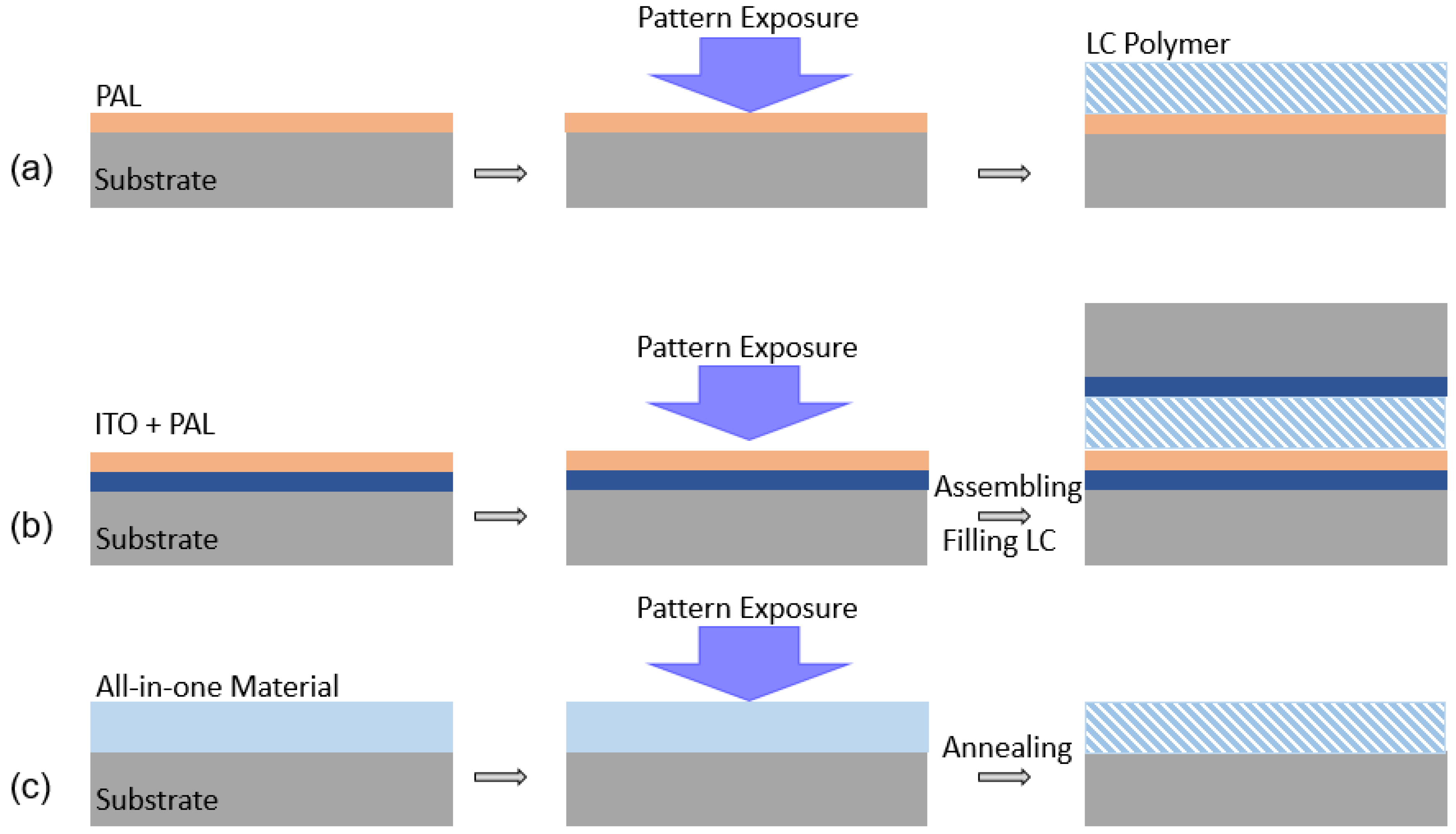

4. Fabrication Process

4.1. Liquid Crystal Alignment

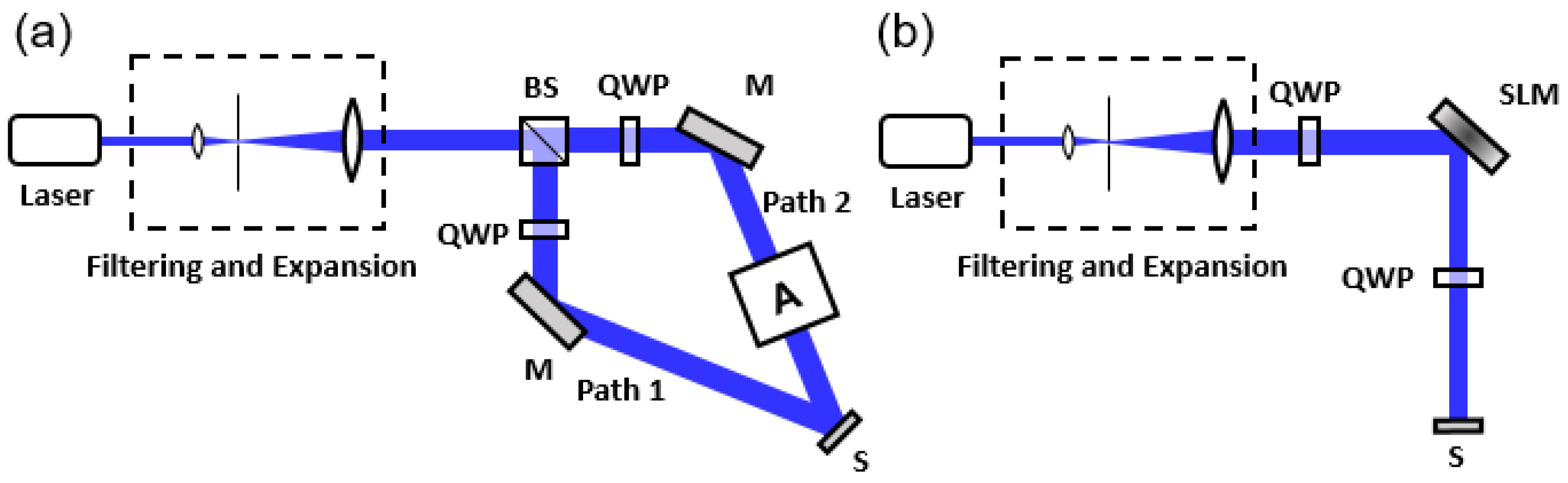

4.2. Exposure System

5. Emerging Applications

5.1. Novel Optical Devices

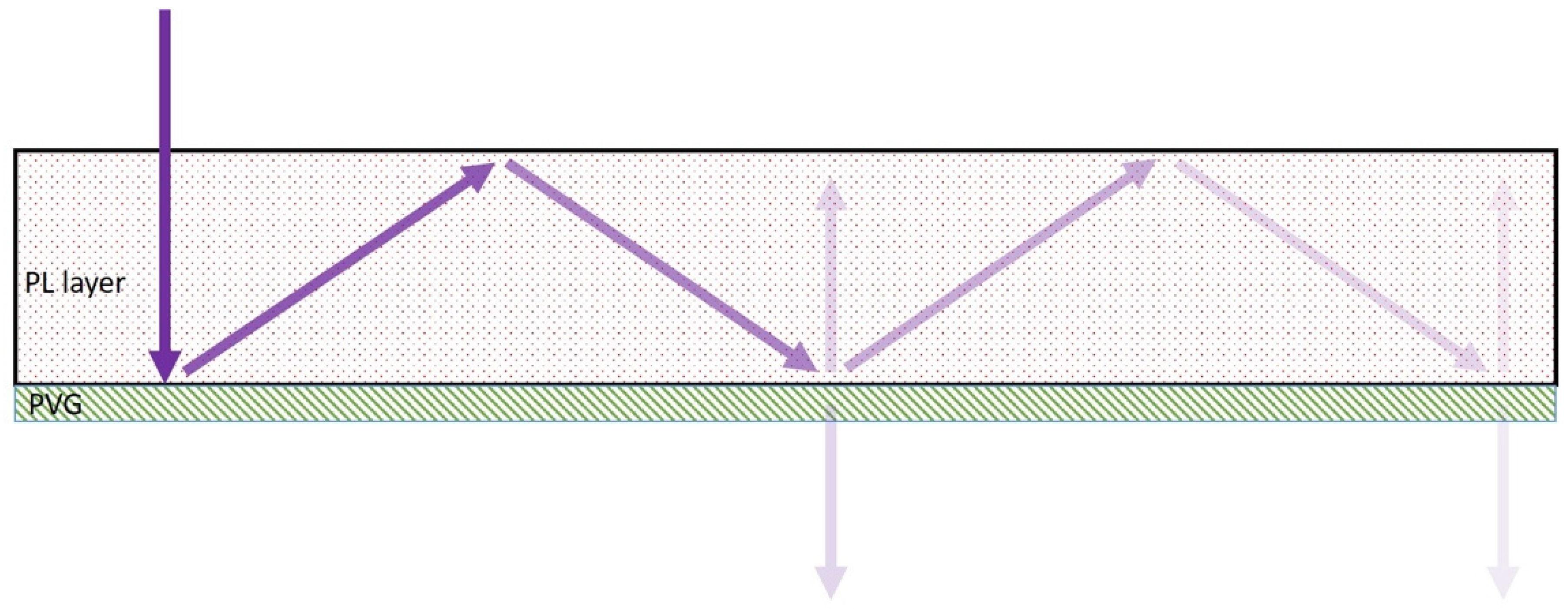

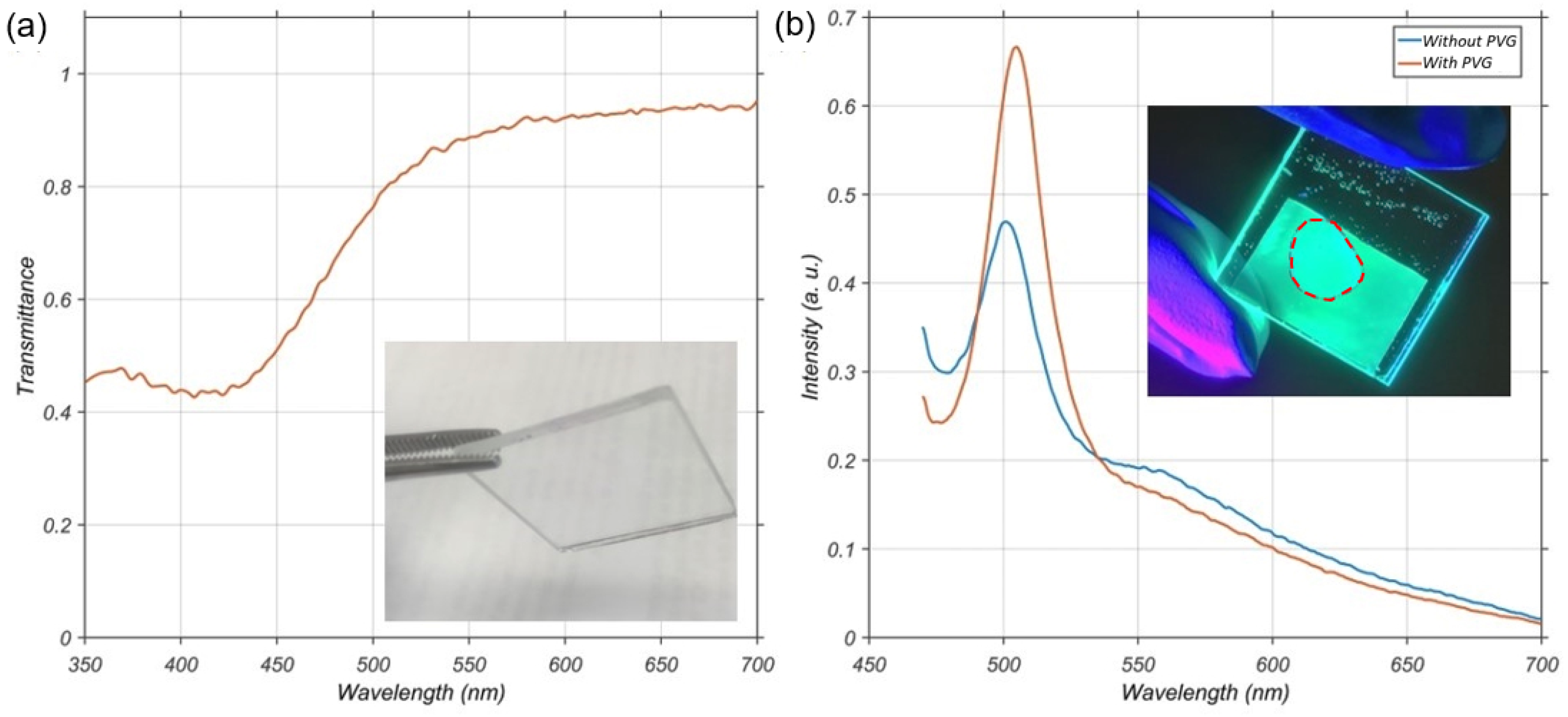

5.1.1. Photoluminescent Enhancement Film

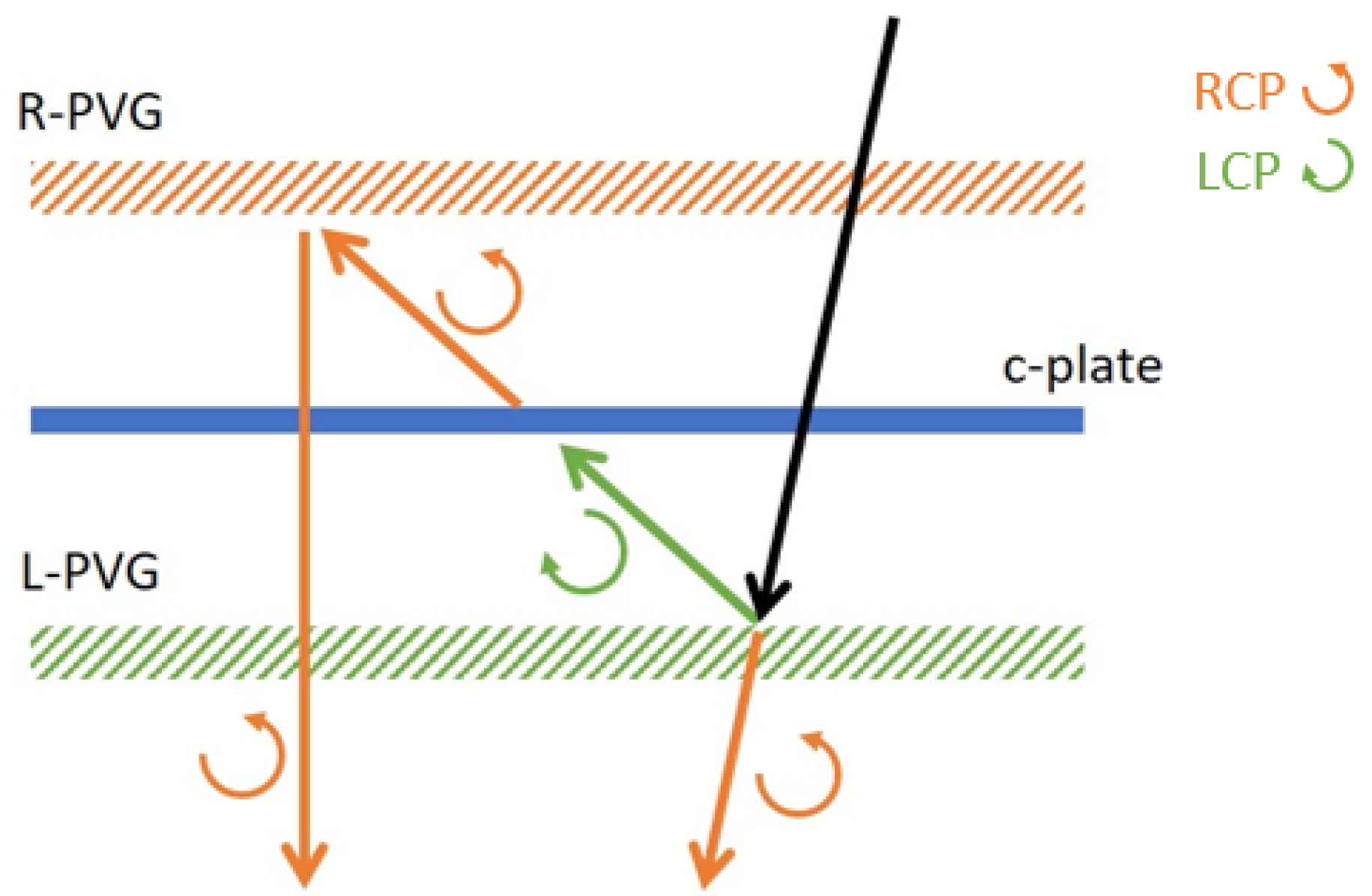

5.1.2. Polarization Converter

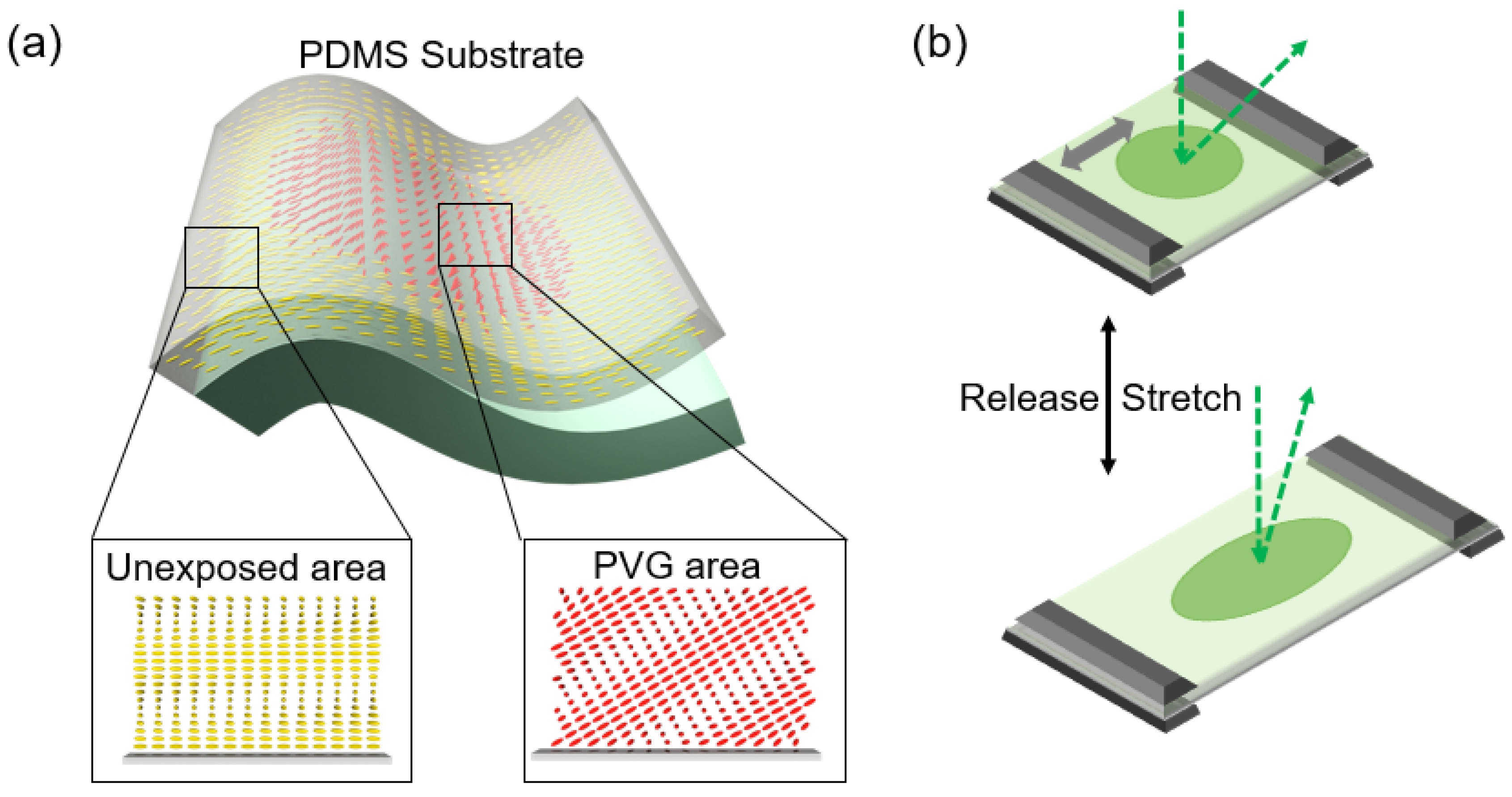

5.1.3. Beam Steering

5.2. Near-Eye Displays

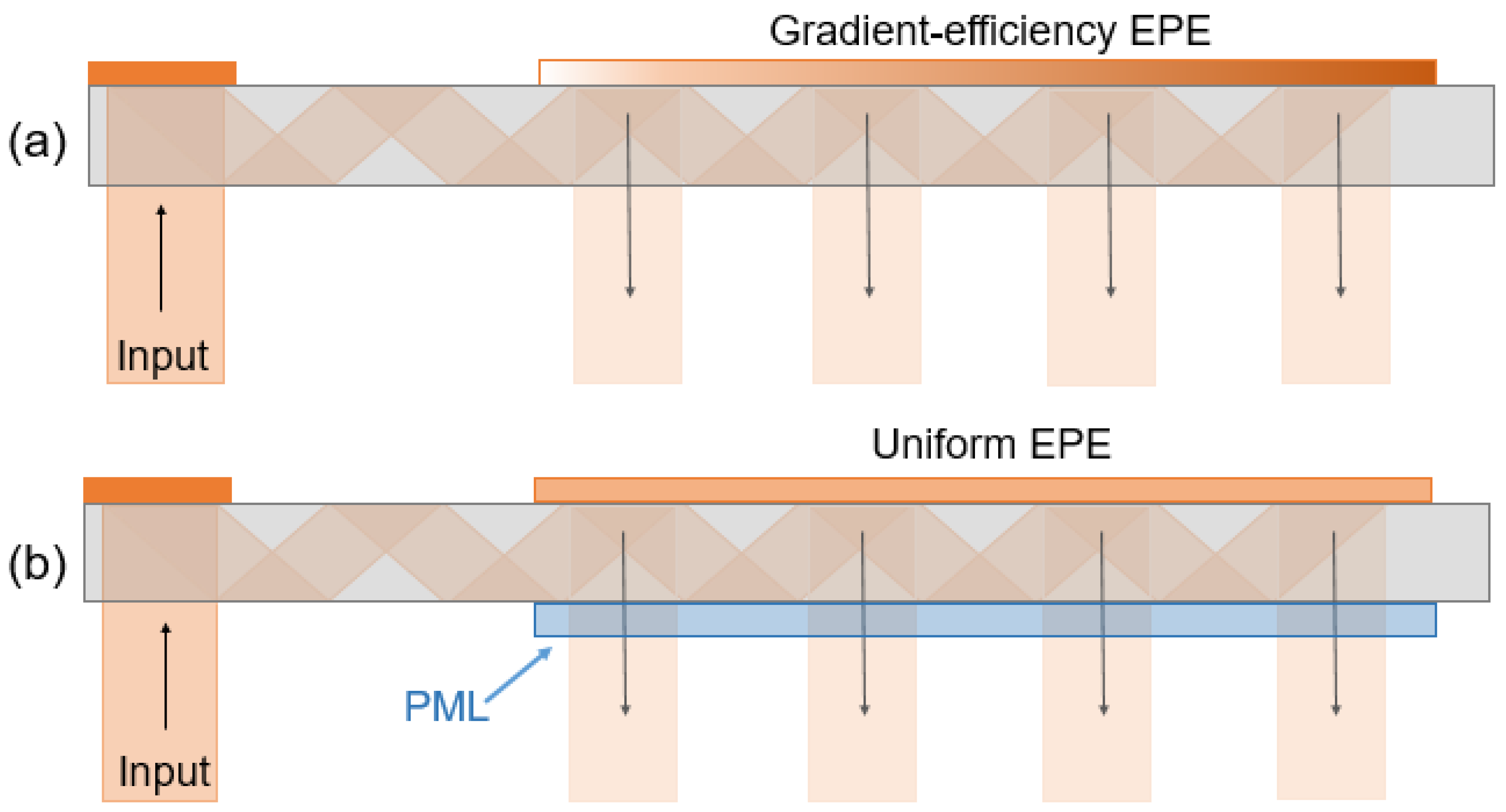

5.2.1. Waveguide-Based AR Display Coupler

5.2.2. Wide Field of View

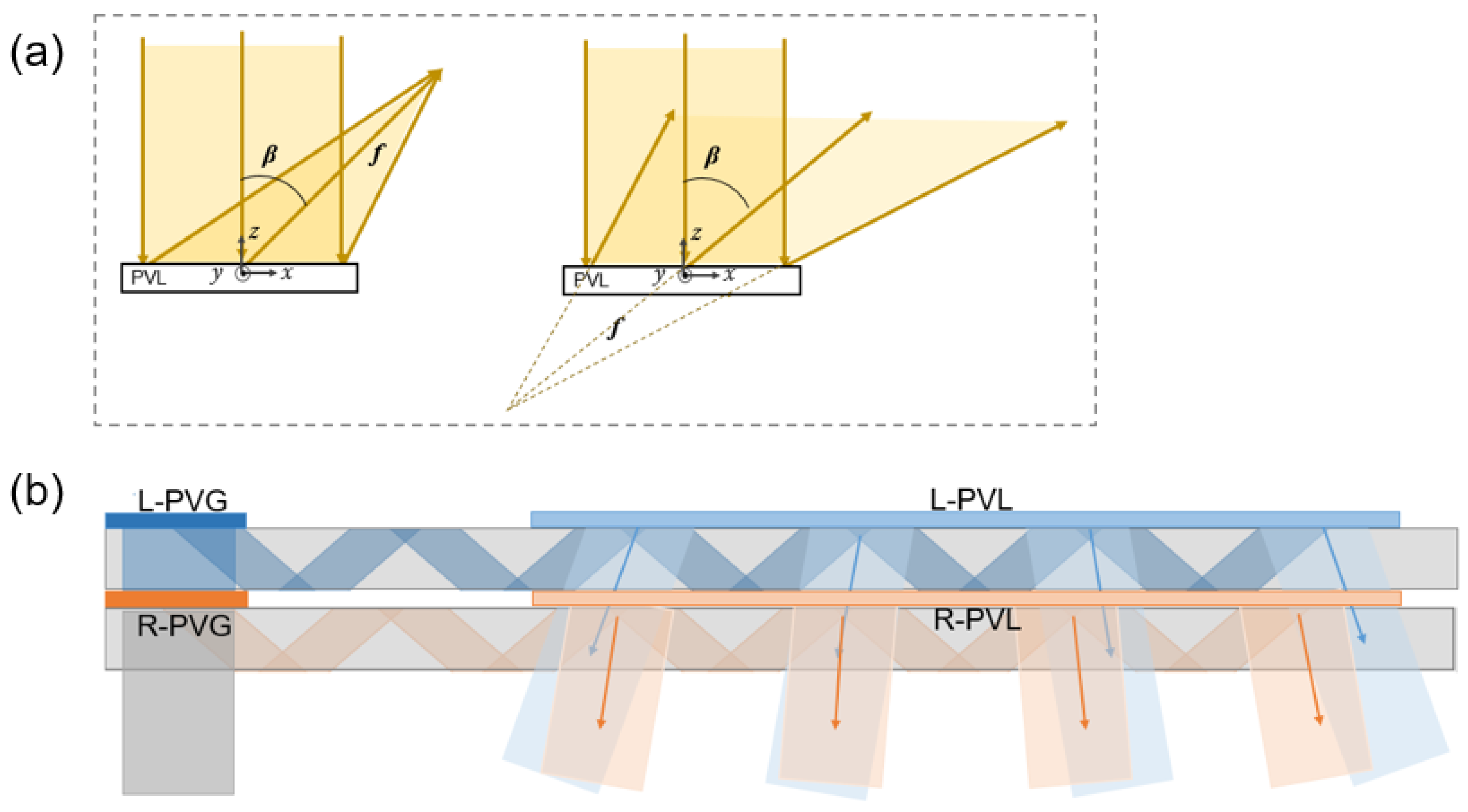

5.2.3. Polarization Volume Lens (PVL)

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Barboza, R.; Bortolozzo, U.; Clerc, M.G.; Residori, S. Berry phase of light under bragg reflection by chiral liquid-crystal media. Phys. Rev. Lett. 2016, 117, 053903. [Google Scholar] [CrossRef]

- Kobashi, J.; Yoshida, H.; Ozaki, M. Planar optics with patterned chiral liquid crystals. Nat. Photonics 2016, 10, 389. [Google Scholar] [CrossRef]

- Kobashi, J.; Mohri, Y.; Yoshida, H.; Ozaki, M. Circularly-polarized, large-angle reflective deflectors based on periodically patterned cholesteric liquid crystals. Opt. Data Process. Storage 2017, 3, 61–66. [Google Scholar] [CrossRef]

- Lee, Y.H.; Zhan, T.; Wu, S.T. Prospects and challenges in augmented reality displays. Virtual Real. Intell. Hardw. 2019, 1, 10–20. [Google Scholar] [CrossRef]

- Zhan, T.; Lee, Y.H.; Tan, G.; Xiong, J.; Yin, K.; Gou, F.; Zou, J.; Zhang, N.; Zhao, D.; Yang, J.; et al. Pancharatnam-Berry optical elements for head-up and near-eye displays. J. Opt. Soc. Am. B 2019, 36, D52–D65. [Google Scholar] [CrossRef]

- Gaylord, T.K.; Moharam, M.G. Thin and thick gratings: Terminology clarification. Appl. Opt. 1981, 20, 3271–3273. [Google Scholar] [CrossRef] [PubMed]

- Weng, Y.; Xu, D.; Zhang, Y.; Li, X.; Wu, S.T. Polarization volume grating with high efficiency and large diffraction angle. Opt. Express 2016, 24, 17746–17759. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.H.; Yin, K.; Wu, S.T. Reflective polarization volume gratings for high efficiency waveguide-coupling augmented reality displays. Opt. Express 2017, 25, 27008–27014. [Google Scholar] [CrossRef]

- Rasmussen, T. Overview of high-efficiency transmission gratings for molecular spectroscopy. Spectroscopy 2014, 29, 32–39. [Google Scholar]

- Moharam, M.G.; Grann, E.B.; Pommet, D.A.; Gaylord, T.K. Formulation for stable and efficient implementation of the rigorous coupled-wave analysis of binary gratings. J. Opt. Soc. Am. A 1995, 12, 1068–1076. [Google Scholar] [CrossRef]

- Yin, K.; Lee, Y.H.; He, Z.; Wu, S.T. Stretchable, flexible, and adherable polarization volume grating film for waveguide-based augmented reality displays. J. Soc. Inf. Disp. 2019, 27, 232–237. [Google Scholar] [CrossRef]

- Yin, K.; Lee, Y.H.; He, Z.; Wu, S.T. Stretchable, flexible, rollable, and adherable polarization volume grating film. Opt. Express 2019, 27, 5814–5823. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.; Lee, Y.H.; Zhan, T.; Yin, K.; An, Z.; Wu, S.T. Multistimuli-responsive self-organized liquid crystal Bragg gratings. Adv. Opt. Mater. 2019, 7, 1900101. [Google Scholar] [CrossRef]

- McDonald, L.T.; Finlayson, E.D.; Wilts, B.D.; Vukusic, P. Circularly polarized reflection from the scarab beetle Chalcothea smaragdina: Light scattering by a dual photonic structure. Interface Focus 2017, 7, 20160129. [Google Scholar] [CrossRef]

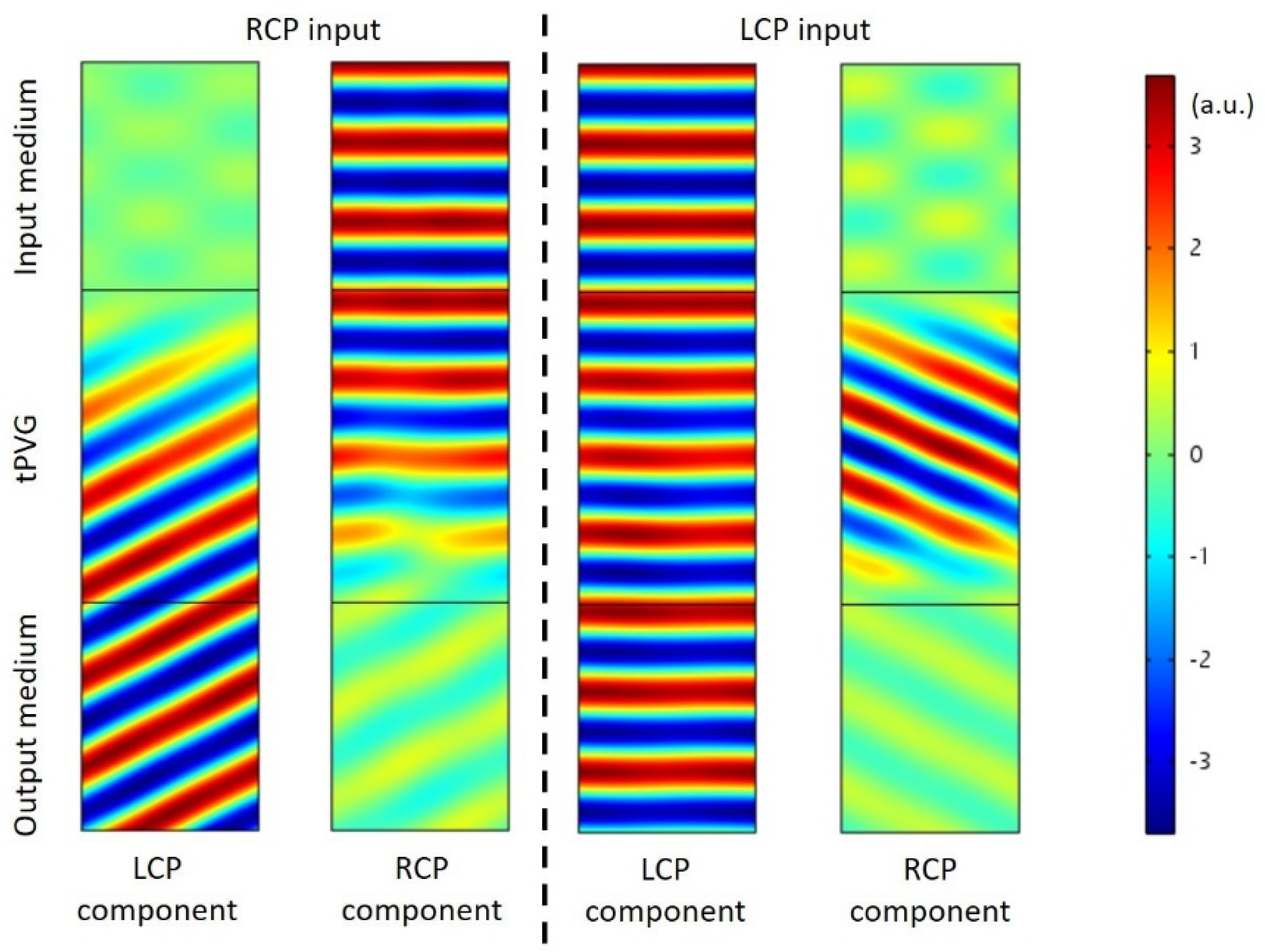

- Xiong, J.; Chen, R.; Wu, S.T. Device simulation of liquid crystal polarization gratings. Opt. Express 2019, 27, 18102–18112. [Google Scholar] [CrossRef]

- Zhan, T.; Lee, Y.H.; Xiong, J.; Tan, G.; Yin, K.; Yang, J.; Liu, S.; Wu, S.T. High-efficiency switchable optical elements for advanced head-up displays. J. Soc. Inf. Disp. 2019, 27, 223–231. [Google Scholar] [CrossRef]

- He, Z.; Gou, F.; Chen, R.; Yin, K.; Zhan, T.; Wu, S.T. Liquid Crystal Beam Steering Devices: Principles, Recent Advances, and Future Developments. Crystals 2019, 9, 292. [Google Scholar] [CrossRef]

- Yin, K.; Lin, H.Y.; Wu, S.T. Chirped polarization volume grating for wide FOV and high efficiency waveguide-based AR displays. J. Soc. Inf. Disp. 2020, 28, 368–374. [Google Scholar] [CrossRef]

- Lee, Y.H.; Tan, G.; Yin, K.; Zhan, T.; Wu, S.T. Compact see-through near-eye display with depth adaption. J. Soc. Inf. Disp. 2018, 26, 64–70. [Google Scholar] [CrossRef]

- Tabiryan, N.V.; Serak, S.V.; Roberts, D.E.; Steeves, D.M.; Kimball, B.R. Thin waveplate lenses of switchable focal length-new generation in optics. Opt. Express 2015, 23, 25783–25794. [Google Scholar] [CrossRef]

- McManamon, P.F.; Bos, P.J.; Escuti, M.J.; Heikenfeld, J.; Serati, S.; Xie, H.; Watson, E.A. A review of phased array steering for narrow-band electrooptical systems. Proc. IEEE 2009, 97, 1078–1096. [Google Scholar] [CrossRef]

- Lee, Y.H.; Tan, G.; Zhan, T.; Weng, Y.; Liu, G.; Gou, F.; Peng, F.; Tabiryan, N.V.; Gauza, S.; Wu, S.T. Recent progress in Pancharatnam-Berry phase optical elements and the applications for virtual/augmented realities. Opt. Data Process. Storage 2017, 3, 79–88. [Google Scholar] [CrossRef]

- Sarkissian, H.; Park, B.; Tabirian, N.; Zeldovich, B. Periodically aligned liquid crystal: potential application for projection displays. Mol. Cryst. Liq. Cryst. 2006, 451, 1–19. [Google Scholar] [CrossRef]

- Lee, Y.H.; He, Z.; Wu, S.T. Optical properties of reflective liquid crystal polarization volume gratings. J. Opt. Soc. Am. B 2019, 36, D9–D12. [Google Scholar] [CrossRef]

- Xiang, X.; Kim, J.; Komanduri, R.; Escuti, M.J. Nanoscale liquid crystal polymer Bragg polarization gratings. Opt. Express 2017, 25, 19298–19308. [Google Scholar] [CrossRef]

- Xiang, X.; Escuti, M.J. Numerical analysis of Bragg polarization gratings. J. Opt. Soc. Am. B 2019, 36, D1–D8. [Google Scholar] [CrossRef]

- Berreman, D.W. Solid surface shape and the alignment of an adjacent nematic liquid crystal. Phys. Rev. Lett. 1972, 28, 1683–1686. [Google Scholar] [CrossRef]

- Gibbons, W.M.; Shannon, P.J.; Sun, S.T.; Swetlin, B.J. Surface-mediated alignment of nematic liquid crystals with polarized laser light. Nature 1991, 351, 49–50. [Google Scholar] [CrossRef]

- Schadt, M.; Schmitt, K.; Kozinkov, V.; Chigrinov, V. Surface-Induced Parallel Alignment of Liquid Crystals by Linearly Polymerized Photopolymers. Jpn. J. Appl. Phys. 1992, 31, 2155–2164. [Google Scholar] [CrossRef]

- Ichimura, K. Photoalignment of liquid-crystal systems. Chem. Rev. 2000, 100, 1847–1874. [Google Scholar] [CrossRef]

- Chigrinov, V.; Muravski, A.; Kwok, H.S.; Takada, H.; Akiyama, H.; Takatsu, H. Anchoring properties of photoaligned azo-dye materials. Phys. Rev. E 2003, 68, 061702. [Google Scholar] [CrossRef]

- Tseng, M.C.; Yaroshchuk, O.; Bidna, T.; Srivastava, A.K.; Chigrinov, V.; Kwok, H.S. Strengthening of liquid crystal photoalignment on azo dye films: Passivation by reactive mesogens. RSC Adv. 2016, 6, 48181–48188. [Google Scholar] [CrossRef]

- Wang, J.; McGinty, C.; Reich, R.; Finnemeyer, V.; Clark, H.; Berry, S.; Bos, P. Process for a reactive monomer alignment layer for liquid crystals formed on an azodye sublayer. Materials 2018, 11, 1195. [Google Scholar] [CrossRef]

- Wang, J.; McGinty, C.; West, J.; Bryant, D.; Finnemeyer, V.; Reich, R.; Berry, S.; Clark, H.; Yaroshchuk, O.; Bos, P. Effects of humidity and surface on photoalignment of brilliant yellow. Liq. Cryst. 2017, 44, 863–872. [Google Scholar] [CrossRef]

- Ouskova, E.; Vergara, R.; Hwang, J.; Roberts, D.; Steeves, D.M.; Kimball, B.R.; Tabiryan, N. Dual-function reversible/irreversible photoalignment material. J. Mol. Liq. 2018, 267, 205–211. [Google Scholar] [CrossRef]

- Decker, C.; Moussa, K. Real-time kinetic study of laser-induced polymerization. Macromolecules 1989, 22, 4455–4462. [Google Scholar] [CrossRef]

- Bryant, S.J.; Nuttelman, C.R.; Anseth, K.S. Cytocompatibility of UV and visible light photoinitiating systems on cultured NIH/3T3 fibroblasts in vitro. J. Biomater. Sci. Polym. Ed. 2000, 11, 439–457. [Google Scholar] [CrossRef]

- Yang, D.K.; Wu, S.T. Fundamentals of Liquid Crystal Devices, 2nd ed.; John Wiley & Sons: Chichester, UK, 2014. [Google Scholar]

- Sakhno, O.; Gritsai, Y.; Sahm, H.; Stumpe, J. Fabrication and performance of efficient thin circular polarization gratings with Bragg properties using bulk photo-alignment of a liquid crystalline polymer. Appl. Phys. B 2018, 124, 52. [Google Scholar] [CrossRef]

- Emoto, A.; Matsumoto, T.; Yamashita, A.; Shioda, T.; Ono, H.; Kawatsuki, N. Large birefringence and polarization holographic gratings formed in photocross-linkable polymer liquid crystals comprising bistolane mesogenic side groups. J. Appl. Phys. 2009, 106, 073505. [Google Scholar] [CrossRef]

- Ono, H.; Emoto, A.; Takahashi, F.; Kawatsuki, N.; Hasegawa, T. Highly stable polarization gratings in photocrosslinkable polymer liquid crystals. J. Appl. Phys. 2003, 94, 1298–1303. [Google Scholar] [CrossRef]

- Gao, K.; McGinty, C.; Payson, H.; Berry, S.; Vornehm, J.; Finnemeyer, V.; Roberts, B.; Bos, P. High-efficiency large-angle Pancharatnam phase deflector based on dual-twist design. Opt. Express 2017, 25, 6283–6293. [Google Scholar] [CrossRef]

- Kakichashvili, S.D. Method for phase polarization recording of holograms. Sov. J. Quantum Electron. 1974, 4, 795–798. [Google Scholar] [CrossRef]

- Crawford, G.P.; Eakin, J.N.; Radcliffe, M.D.; Callan-Jones, A.; Pelcovits, R.A. Liquid-crystal diffraction gratings using polarization holography alignment techniques. J. Appl. Phys. 2005, 98, 123102. [Google Scholar] [CrossRef]

- Chen, P.; Wei, B.Y.; Hu, W.; Lu, Y.Q. Liquid-Crystal-Mediated Geometric Phase: From Transmissive to Broadband Reflective Planar Optics. Adv. Mater. 2019, 31, 1903665. [Google Scholar] [CrossRef]

- De Sio, L.; Roberts, D.E.; Liao, Z.; Nersisyan, S.; Uskova, O.; Wickboldt, L.; Tabiryan, N.; Steeves, D.M.; Kimball, B.R. Digital polarization holography advancing geometrical phase optics. Opt. Express 2016, 24, 18297–18306. [Google Scholar] [CrossRef]

- Wu, H.; Hu, W.; Hu, H.C.; Lin, X.W.; Zhu, G.; Choi, J.W.; Chigrinov, V.; Lu, Y.Q. Arbitrary photo-patterning in liquid crystal alignments using DMD based lithography system. Opt. Express 2012, 20, 16684–16689. [Google Scholar] [CrossRef]

- He, J.; He, Z.; Towers, A.; Zhan, T.; Chen, H.; Zhou, L.; Zhang, C.; Chen, R.; Sun, T.; Gesquiere, A.J.; et al. Ligand assisted swelling–deswelling microencapsulation (LASDM) for stable, color tunable perovskite–polymer composites. Nanoscale Adv. 2020, 2, 2034–2043. [Google Scholar] [CrossRef]

- Cheng, B.; Sun, L.; Yu, G.; Sun, T.X. A novel emissive projection display (EPD) on transparent phosphor screen. Proc. SPIE 2017, 10117. [Google Scholar] [CrossRef]

- Kim, J.; Komanduri, R.K.; Lawler, K.F.; Kekas, D.J.; Escuti, M.J. Efficient and monolithic polarization conversion system based on a polarization grating. Appl. Opt. 2020, 51, 4852–4857. [Google Scholar] [CrossRef]

- Du, T.; Fan, F.; Tam, A.M.W.; Sun, J.; Chigrinov, V.G.; Kwok, H.S. Complex nanoscale-ordered liquid crystal polymer film for high transmittance holographic polarizer. Adv. Mater. 2015, 27, 7191–7195. [Google Scholar] [CrossRef]

- Zhan, T.; Zou, J.; Lu, M.; Chen, E.; Wu, S.T. Wavelength-multiplexed multi-focal-plane seethrough near-eye displays. Opt. Express 2019, 27, 27507–27513. [Google Scholar] [CrossRef] [PubMed]

- Sutherland, R.L.; Natarajan, L.V.; Tondiglia, V.P.; Bunning, T.J. Bragg gratings in an acrylate polymer consisting of periodic polymer-dispersed liquid-crystal planes. Chem. Mater. 1993, 5, 1533–1538. [Google Scholar] [CrossRef]

- Liu, Y.J.; Sun, X.W. Holographic polymer-dispersed liquid crystals materials, formation, and applications. Adv. Optoelectron. 2008, 2008, 684349. [Google Scholar] [CrossRef]

- Cakmakci, O.; Rolland, J. Head-worn displays: A review. J. Disp. Tech. 2006, 2, 199–216. [Google Scholar] [CrossRef]

- Wang, J.; Liang, Y.; Xu, M. Design of a see-through head-mounted display with a freeform surface. JOSK 2015, 19, 614–618. [Google Scholar] [CrossRef][Green Version]

- Saarikko, P. Diffractive exit-pupil expander with a large field of view. Proc. SPIE 2008, 7001. [Google Scholar] [CrossRef]

- Äyräs, P.; Saarikko, P.; Levola, T. Exit pupil expander with a large field of view based on diffractive optics. J. Soc. Inf. Disp. 2009, 17, 659–664. [Google Scholar] [CrossRef]

- Xiang, X.; Kim, J.; Escuti, M.J. Bragg polarization gratings for wide angular bandwidth and high efficiency at steep deflection angles. Sci. Rep. 2018, 8, 7202. [Google Scholar] [CrossRef]

- Broer, D.J.; Lub, J.; Mol, G.N. Wide-band reflective polarizers from cholesteric polymer networks with a pitch gradient. Nature 1995, 378, 467–469. [Google Scholar] [CrossRef]

- Yin, K.; Lin, H.Y.; Wu, S.T. Chirped polarization volume grating with ultra-wide angular bandwidth and high efficiency for see-through near-eye displays. Opt. Express 2019, 27, 35895–35902. [Google Scholar] [CrossRef]

- Yin, K.; He, Z.; Wu, S.T. Reflective polarization volume lens with small f-number and large diffraction angle. Adv. Opt. Mater. 2020, 8, 2000170. [Google Scholar] [CrossRef]

- Hoffman, D.M.; Girshick, A.R.; Akeley, K.; Banks, M.S. Vergence-accommodation conflicts hinder visual performance and cause visual fatigue. J. Vis. 2008, 8, 33. [Google Scholar] [CrossRef] [PubMed]

- Hua, H. Enabling focus cues in head-mounted displays. Proc. IEEE 2017, 105, 805–824. [Google Scholar] [CrossRef]

- He, Z.; Yin, K.; Wu, S.T. Passive polymer-dispersed liquid crystal enabled multi-focal plane displays. Opt. Express 2020, 28, 15294–15299. [Google Scholar] [CrossRef]

- Arimoto, H.; Javidi, B. Integral 3D imaging with digital reconstruction. Opt. Lett. 2001, 26, 157–159. [Google Scholar] [CrossRef] [PubMed]

- Huang, F.C.; Chen, K.; Wetzstein, G. The light field stereoscope: Immersive computer graphics via factored near-eye light field displays with focus cues. ACM Trans. Graph. 2015, 34, 60. [Google Scholar] [CrossRef]

- Wakunami, K.; Hsieh, P.Y.; Oi, R.; Senoh, T.; Sasaki, H.; Ichihashi, Y.; Okui, M.; Huang, Y.P.; Yamamoto, K. Projection-type see-through holographic three-dimensional display. Nat. Commun. 2016, 7, 12954. [Google Scholar] [CrossRef]

- Li, G.; Lee, D.; Jeong, Y.; Cho, J.; Lee, B. Holographic display for see-through augmented reality using mirror-lens holographic optical element. Opt. Lett. 2016, 41, 2486–2489. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, K.; Zhan, T.; Xiong, J.; He, Z.; Wu, S.-T. Polarization Volume Gratings for Near-Eye Displays and Novel Photonic Devices. Crystals 2020, 10, 561. https://doi.org/10.3390/cryst10070561

Yin K, Zhan T, Xiong J, He Z, Wu S-T. Polarization Volume Gratings for Near-Eye Displays and Novel Photonic Devices. Crystals. 2020; 10(7):561. https://doi.org/10.3390/cryst10070561

Chicago/Turabian StyleYin, Kun, Tao Zhan, Jianghao Xiong, Ziqian He, and Shin-Tson Wu. 2020. "Polarization Volume Gratings for Near-Eye Displays and Novel Photonic Devices" Crystals 10, no. 7: 561. https://doi.org/10.3390/cryst10070561

APA StyleYin, K., Zhan, T., Xiong, J., He, Z., & Wu, S.-T. (2020). Polarization Volume Gratings for Near-Eye Displays and Novel Photonic Devices. Crystals, 10(7), 561. https://doi.org/10.3390/cryst10070561