Reactively Synthesized Porous Ti3SiC2 Compound and Its Mechanical Properties with Different Apertures

Abstract

1. Introduction

2. Experimental Procedure

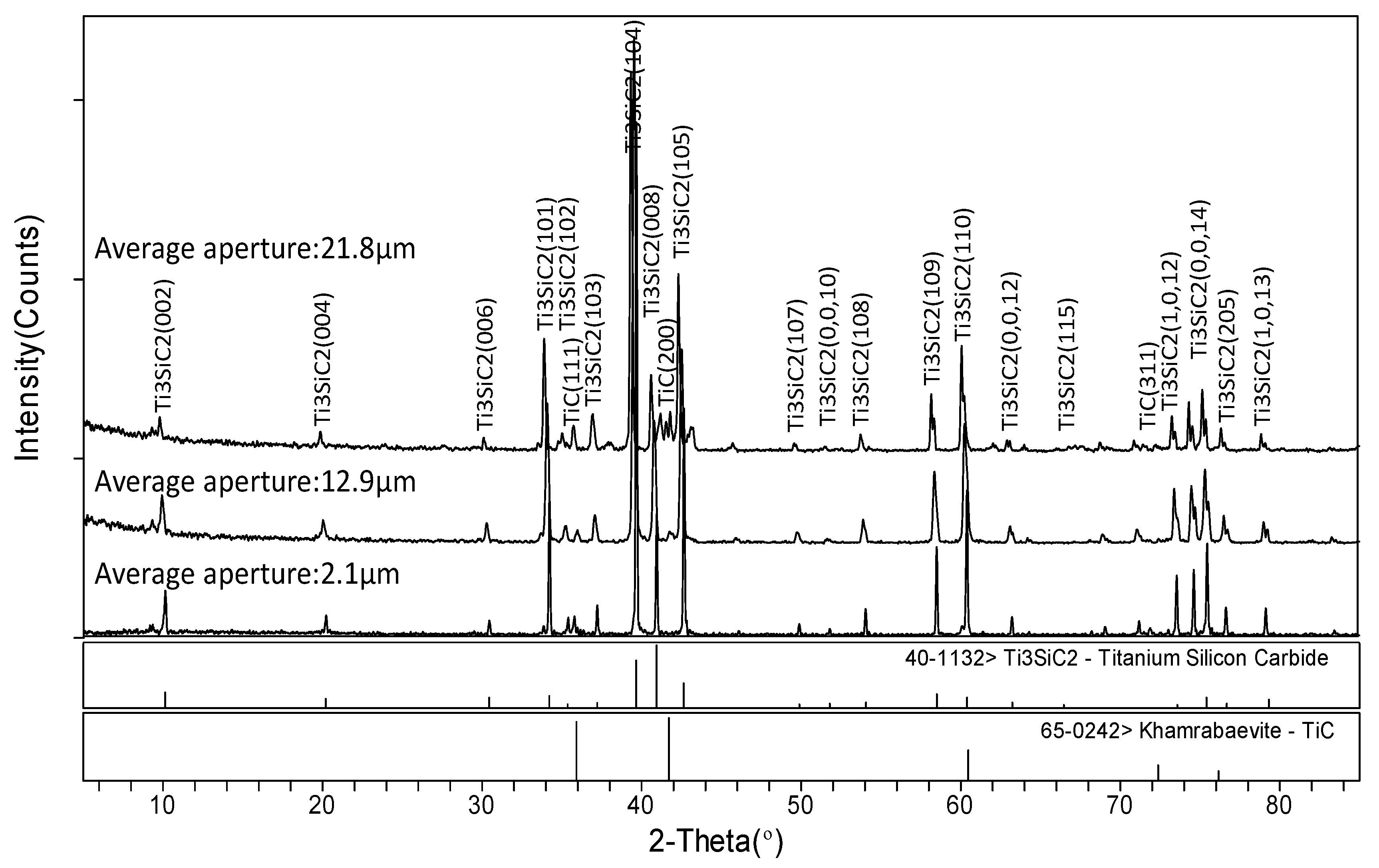

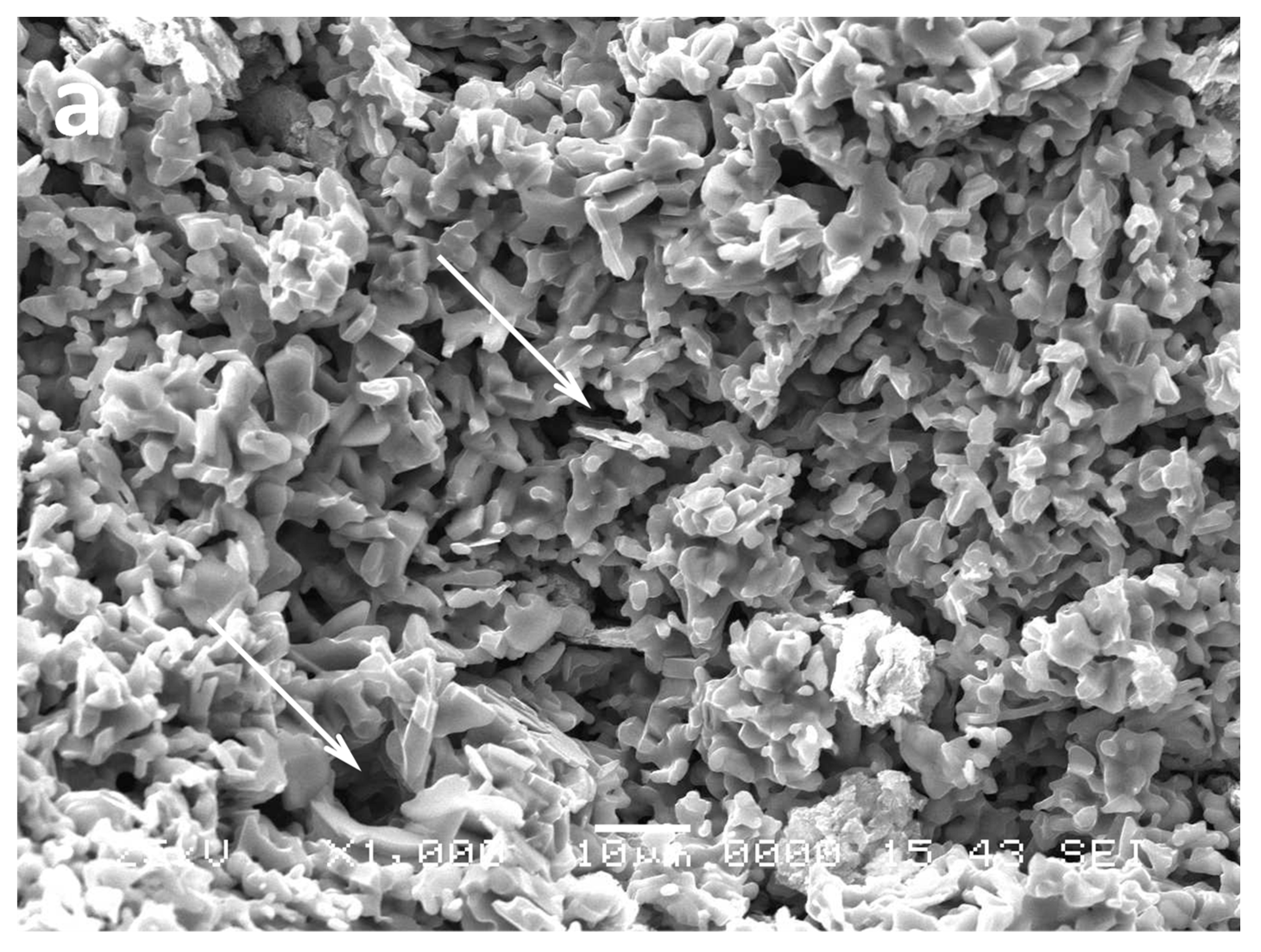

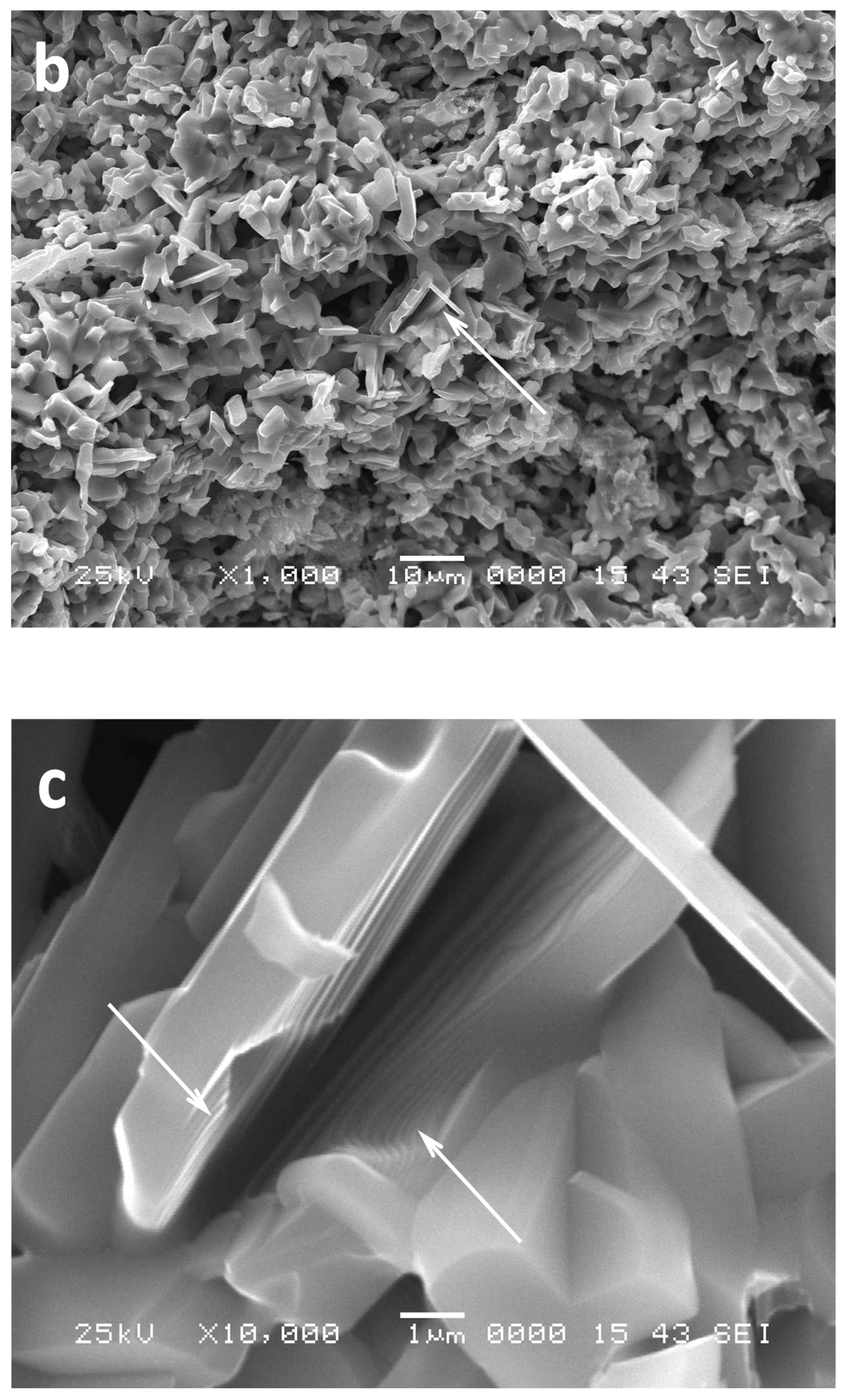

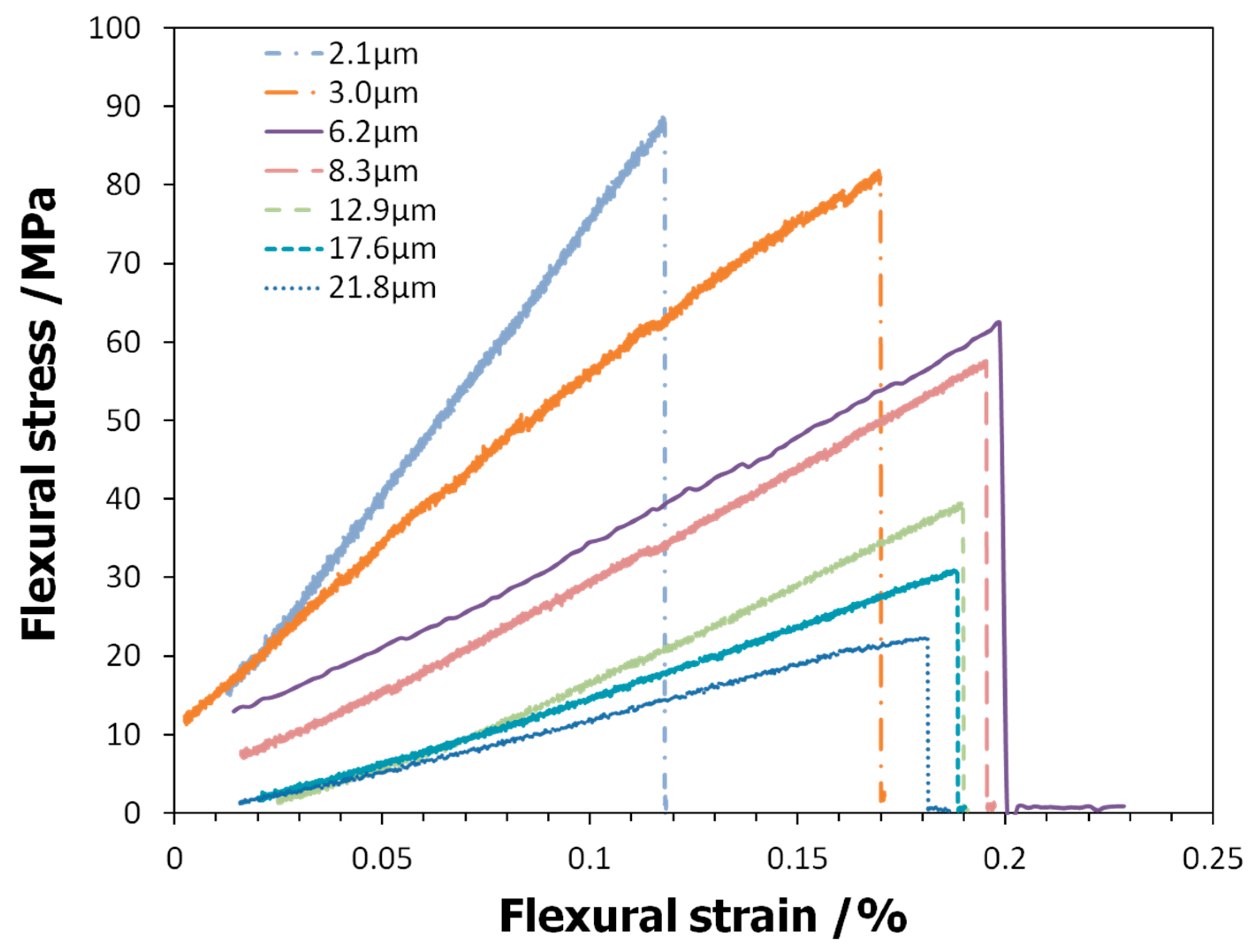

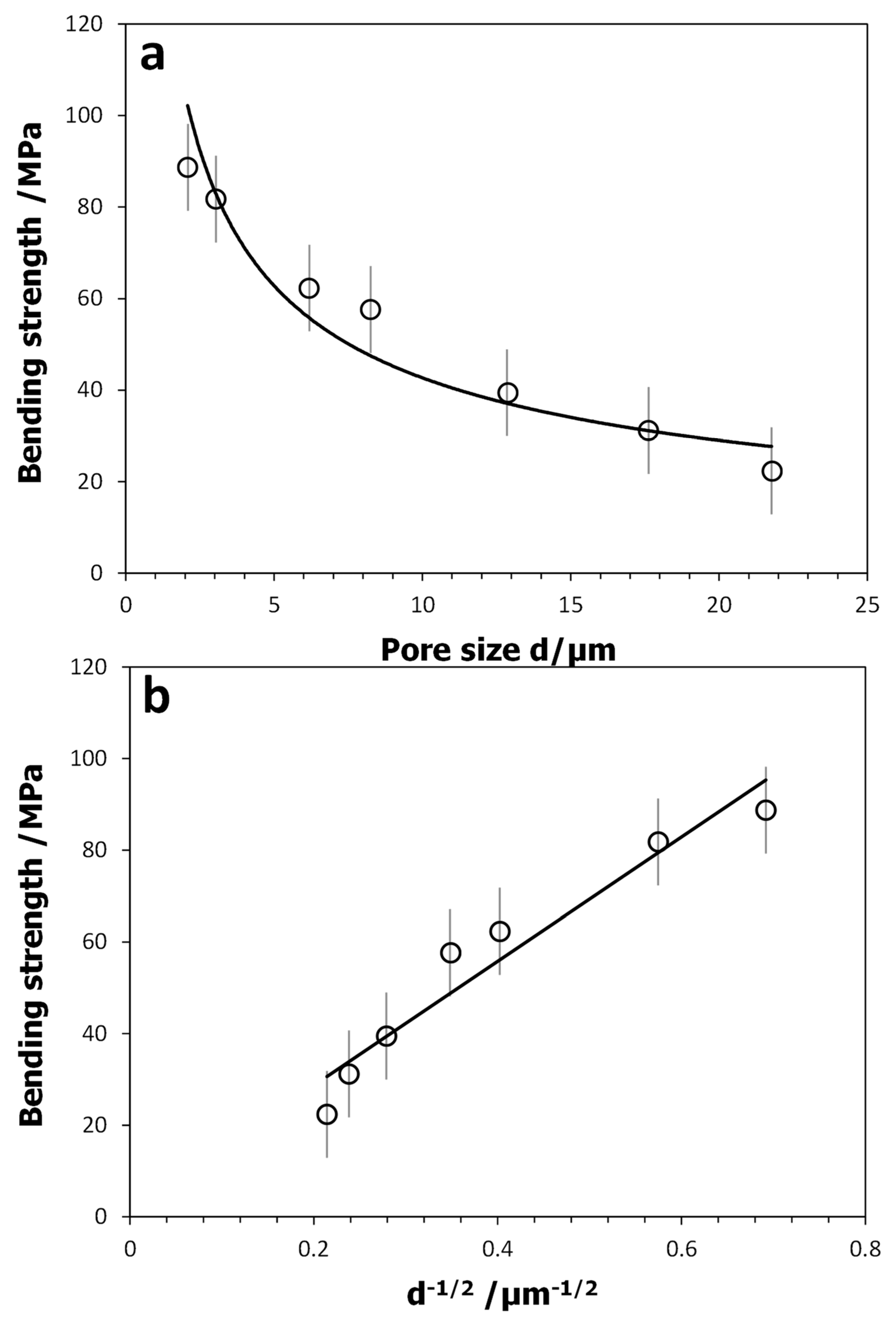

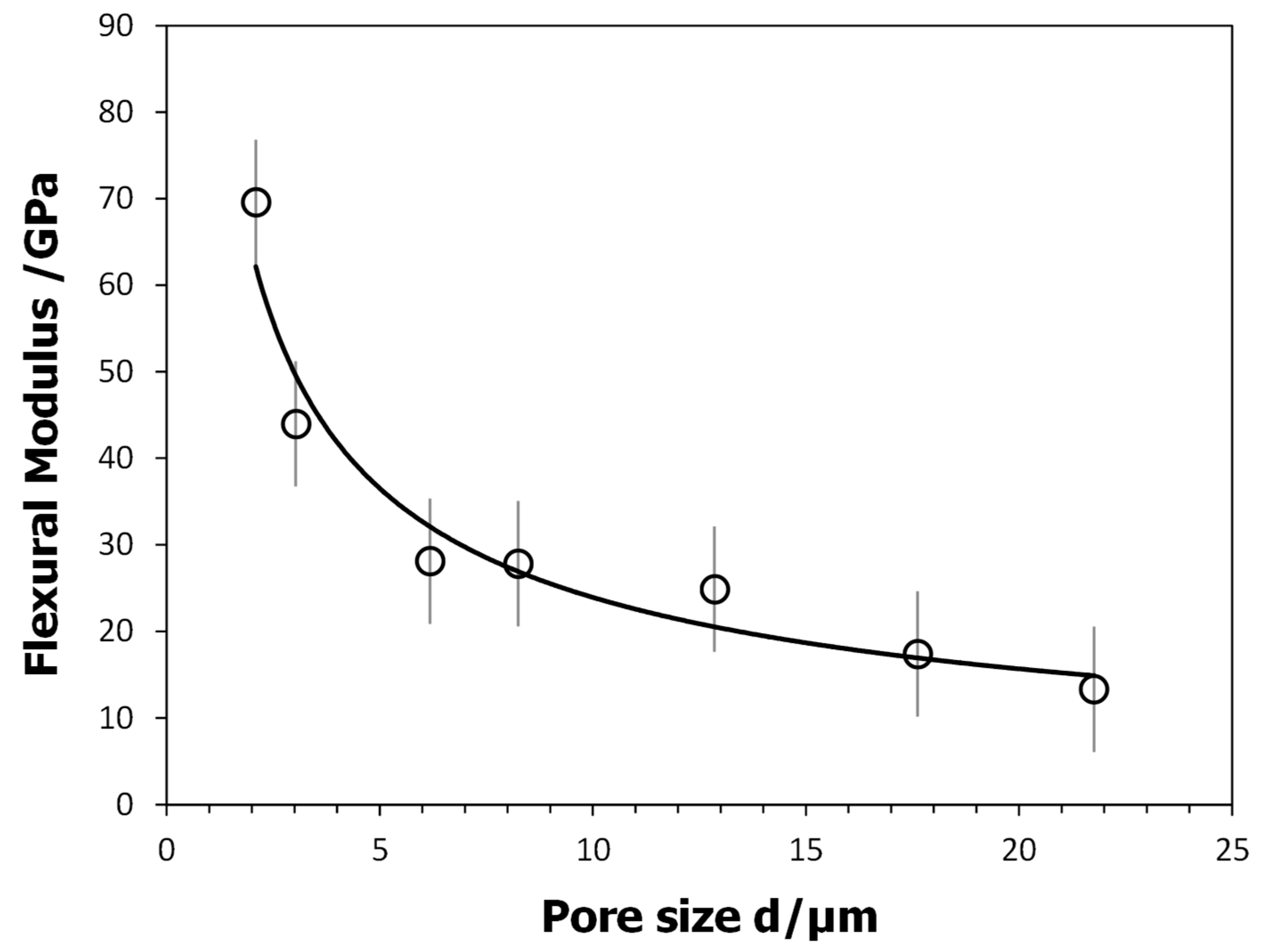

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Zhang, H.; Jiang, Y.; He, Y. Characterization and application of porous Ti3SiC2 ceramic prepared through reactive synthesis. Mater. Des. 2015, 79, 94–98. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, Y.; He, Y. Oxidation behavior of reactively synthesized porous Ti3(Si,Al)C2 compound at 800 °C in ambient air. Ceram. Int. 2019, 45, 15482–15487. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, Y.; Zhang, H.; Yu, L.; Kang, J.; He, Y. Porous Ti3SiC2 fabricated by mixed elemental powders reactive synthesis. J. Eur. Ceram. Soc. 2015, 35, 1349–1353. [Google Scholar] [CrossRef]

- Velasco, B.; Tsipas, S.A.; Ferrari, B.; Gordo, E. MAX phase foams produced via powder metallurgy process using water soluble space holder. Powder Metall. 2015, 58, 95–99. [Google Scholar] [CrossRef]

- Velasco, B.; Gordo, E.; Tsipas, S.A. MAX phase Ti2AlC foams using a leachable space-holder material. J. Alloys Compd. 2015, 646, 1036–1042. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, H.; Jiang, Y.; He, Y. Factors affecting the property of porous Ti3SiC2 metal ceramic fabricated through pressureless sintering. J. Porous Mater. 2015, 22, 1285–1290. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, H.; Liu, X.; Jiang, Y.; Gao, H.; He, Y. Reactive synthesis of porous nanolaminate Ti3(Si,Al)C2 intermetallic compound. Mater. Chem. Phys. 2018, 208, 85–90. [Google Scholar] [CrossRef]

- Sun, Z.M.; Murugaiah, A.; Zhen, T.; Zhou, A.; Barsoum, M.W. Microstructure and mechanical properties of porous Ti3SiC2. Acta Mater. 2005, 53, 4359–4366. [Google Scholar] [CrossRef]

- Zhao, B.; Gain, A.K.; Ding, W.; Zhang, L.; Li, X.; Fu, Y. A review on metallic porous materials: Pore formation, mechanical properties, and their applications. Int. J. Adv. Manuf. Technol. 2018, 95, 2641–2659. [Google Scholar] [CrossRef]

- Xiong, X.; Wang, Z.; Wang, X.; Liu, H.; Ma, Y. Enhancing the mechanical strength and air permeability of corundum porous materials using shape-modified coarse aggregates. Ceram. Int. 2019, 45, 11027–11031. [Google Scholar] [CrossRef]

- Zhang, B.; Huang, H.; Lu, X. Fabrication and properties of C/SiC porous ceramics by grinding-mould pressing-sintering process. J. Eur. Ceram. Soc. 2019, 39, 1775–1780. [Google Scholar] [CrossRef]

- Zhou, A.G.; Fraczkiewicz, M.; Barsoum, M.W. Mechanical damping in porous Ti3SiC2. Acta Mater. 2006, 54, 5261–5270. [Google Scholar]

- Velasco, B.; Gordo, E.; Hu, L.; Radovic, M.; Tsipas, S.A. Influence of porosity on elastic properties of Ti2AlC and Ti3SiC2 MAX phase foams. J. Alloys Compd. 2018, 764, 24–35. [Google Scholar] [CrossRef]

- Finkel, P.; Zhou, A.G.; Basu, S.; Yeheskel, O.; Barsoum, M.W. Direct observation of nonlinear acoustoelastic hysteresis in kinking nonlinear elastic solids. Appl. Phys. Lett. 2009, 94, 241904. [Google Scholar] [CrossRef]

- Zhou, A.G.; Basu, S.; Friedman, G.; Finkel, P.; Yeheskel, O.; Barsoum, M.W. Hysteresis in kinking nonlinear elastic solids and the Preisach-Mayergoyz model. Phys. Rev. B 2010, 82, 094105. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Q.; Zhang, H.; Jiang, Y.; He, Y. Development and characterization of microporous Ti3SiC2 ceramic membranes for filtration of microorganisms. J. Mater. Sci. 2016, 51, 2594–2597. [Google Scholar] [CrossRef]

- Gao, H.Y.; He, Y.H.; Zou, J.; Shen, P.Z.; Jiang, Y.; Liu, C.T. Mechanical properties of porous Fe-Al intermetallics. Powder Metall. 2015, 58, 197–201. [Google Scholar] [CrossRef]

- Liu, G.; Lu, D.H.; Liu, X.W.; Liu, F.C.; Yang, Q.; Du, H.; Hu, Q.; Fan, Z.T. Solute segregation effect on grain boundary migration and Hall–Petch relationship in CrMnFeCoNi high-entropy alloy. Mater. Sci. Technol. 2019, 35, 500–508. [Google Scholar] [CrossRef]

- Ryou, H.; Drazin, J.W.; Wahl, K.J.; Qadri, S.B.; Gorzkowski, E.P.; Feigelson, B.N.; Wollmershauser, J.A. Below the hall–petch limit in nanocrystalline ceramics. ACS Nano 2018, 12, 3083–3094. [Google Scholar] [CrossRef]

- Wollmershauser, J.A.; Feigelson, B.N.; Gorzkowski, E.P.; Ellis, C.T.; Goswami, R.; Qadri, S.B.; Tischler, J.G.; Kub, F.J.; Everett, R.K. An extended hardness limit in bulk nanoceramics. Acta Mater. 2014, 69, 9–16. [Google Scholar] [CrossRef]

- Wang, C.; Jiang, C.; Cai, F.; Zhao, Y.; Zhu, K.; Chai, Z. Effect of shot peening on the residual stresses and microstructure of tungsten cemented carbide. Mater. Des. 2016, 95, 159–164. [Google Scholar] [CrossRef]

- Roa, J.J.; Jiménez-Piqué, E.; Tarragó, J.M.; Sandoval, D.A.; Mateo, A.; Fair, J.; Llanes, L. Hall–Petch strengthening of the constrained metallic binder in WC–Co cemented carbides: Experimental assessment by means of massive nanoindentation and statistical analysis. Mater. Sci. Eng. A 2016, 676, 487–491. [Google Scholar] [CrossRef]

- Li, C.L.; Mei, Q.S.; Li, J.Y.; Chen, F.; Ma, Y.; Mei, X.M. Hall–Petch relations and strengthening of Al-ZnO composites in view of grain size relative to interparticle spacing. Scr. Mater. 2018, 153, 27–30. [Google Scholar] [CrossRef]

- He, W.; Weng, Q.G.; He, Y.H.; Jiang, Y. Preparation of ultrafine Ti powder by inhibitor coated/HDH combined method. Powder Metall. 2013, 56, 239–244. [Google Scholar] [CrossRef]

- Zhang, Z.F.; Sun, Z.M.; Hashimoto, H. Rapid synthesis of ternary carbide Ti3SiC2 through pulse-discharge sintering technique from Ti/Si/TiC powders. Metall. Mater. Trans. A 2002, 33, 3321–3328. [Google Scholar] [CrossRef]

- Ashizuka, M.; Ishida, E.; Matsushita, T.; Hisanaga, M. Elastic modulus, strength and fracture toughness of alumina ceramics containing pores. J. Ceram. Soc. Jpn. 2002, 110, 554–559. [Google Scholar] [CrossRef][Green Version]

- Xu, Z.; Wen, W.; Zhai, T. Effects of pore position in depth on stress/strain concentration and fatigue crack initiation. Metall. Mater. Trans. A 2012, 43, 2763–2770. [Google Scholar] [CrossRef]

- Li, Z.; Yang, L.; Li, Y.; Yang, Y.; Zhou, C.; Ding, Y.; Zhao, J.; Li, Y. Effects of pore size on the mechanical properties of three-dimensionally ordered macroporous nickel. Mater. Des. 2013, 45, 52–55. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Liu, X.; Gao, H.; He, Y. Reactively Synthesized Porous Ti3SiC2 Compound and Its Mechanical Properties with Different Apertures. Crystals 2020, 10, 82. https://doi.org/10.3390/cryst10020082

Jiang Y, Liu X, Gao H, He Y. Reactively Synthesized Porous Ti3SiC2 Compound and Its Mechanical Properties with Different Apertures. Crystals. 2020; 10(2):82. https://doi.org/10.3390/cryst10020082

Chicago/Turabian StyleJiang, Yao, Xinli Liu, Haiyan Gao, and Yuehui He. 2020. "Reactively Synthesized Porous Ti3SiC2 Compound and Its Mechanical Properties with Different Apertures" Crystals 10, no. 2: 82. https://doi.org/10.3390/cryst10020082

APA StyleJiang, Y., Liu, X., Gao, H., & He, Y. (2020). Reactively Synthesized Porous Ti3SiC2 Compound and Its Mechanical Properties with Different Apertures. Crystals, 10(2), 82. https://doi.org/10.3390/cryst10020082