How Nanoscale Dislocation Reactions Govern Low- Temperature and High-Stress Creep of Ni-Base Single Crystal Superalloys

Abstract

1. Introduction

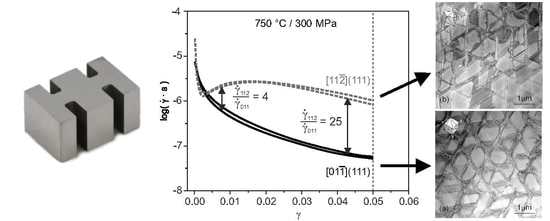

2. Materials and Methods

2.1. Material and Shear Creep Testing

2.2. Scanning Transmission Electron Microscopy (STEM)

2.3. Calculation of Peach Köhler Glide and Climb Forces (PKFg and PKFc)

3. Results

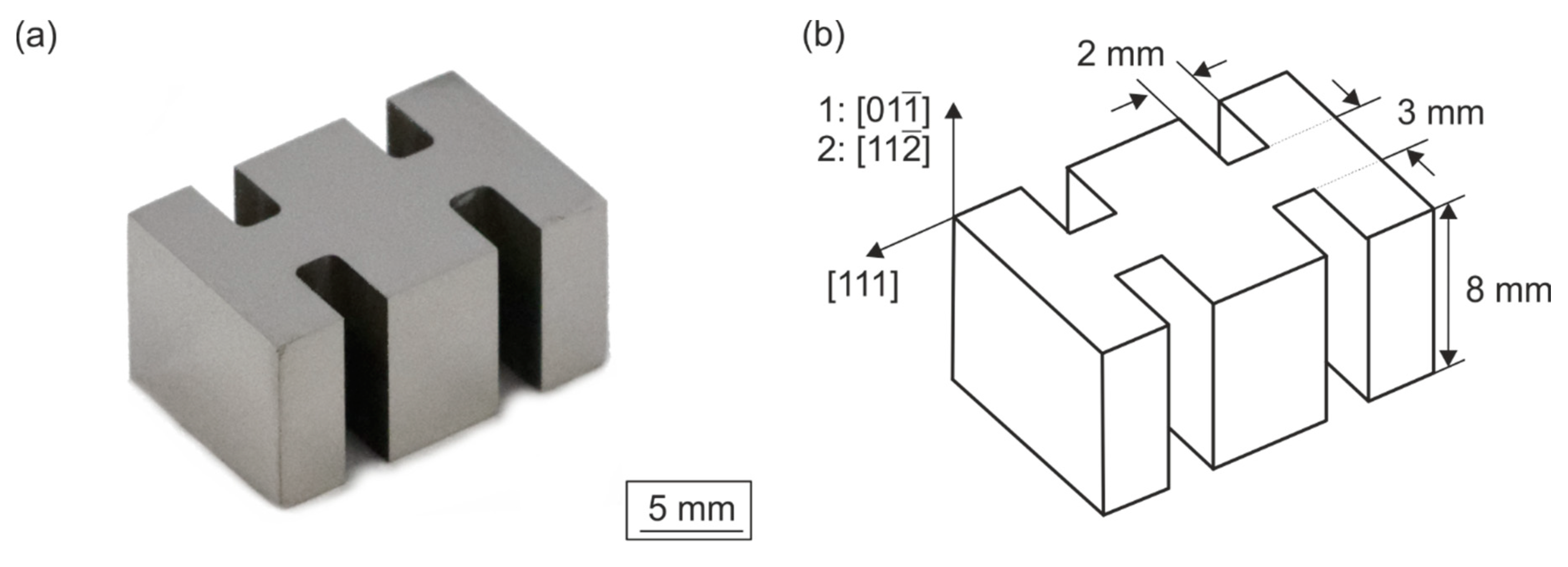

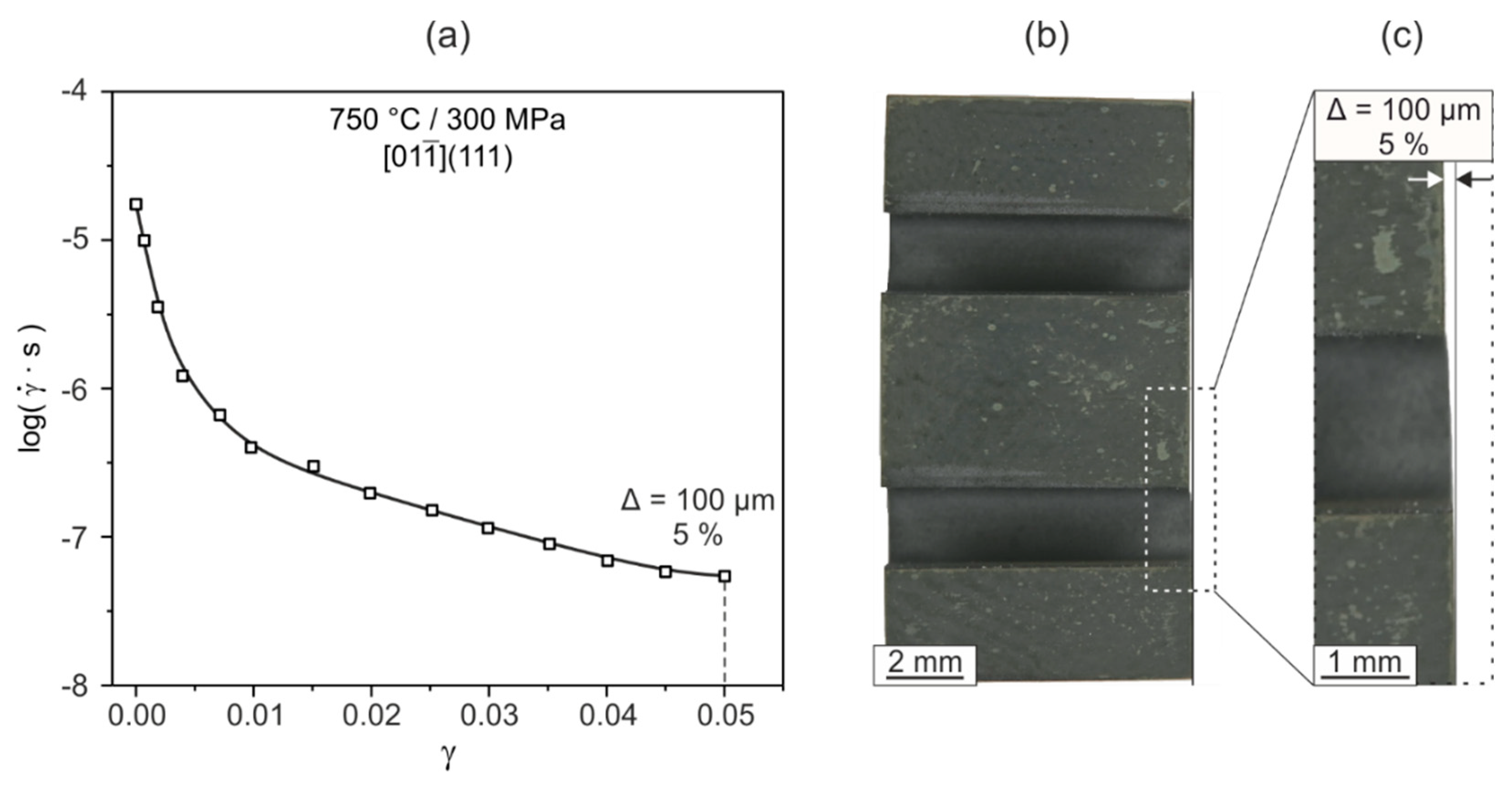

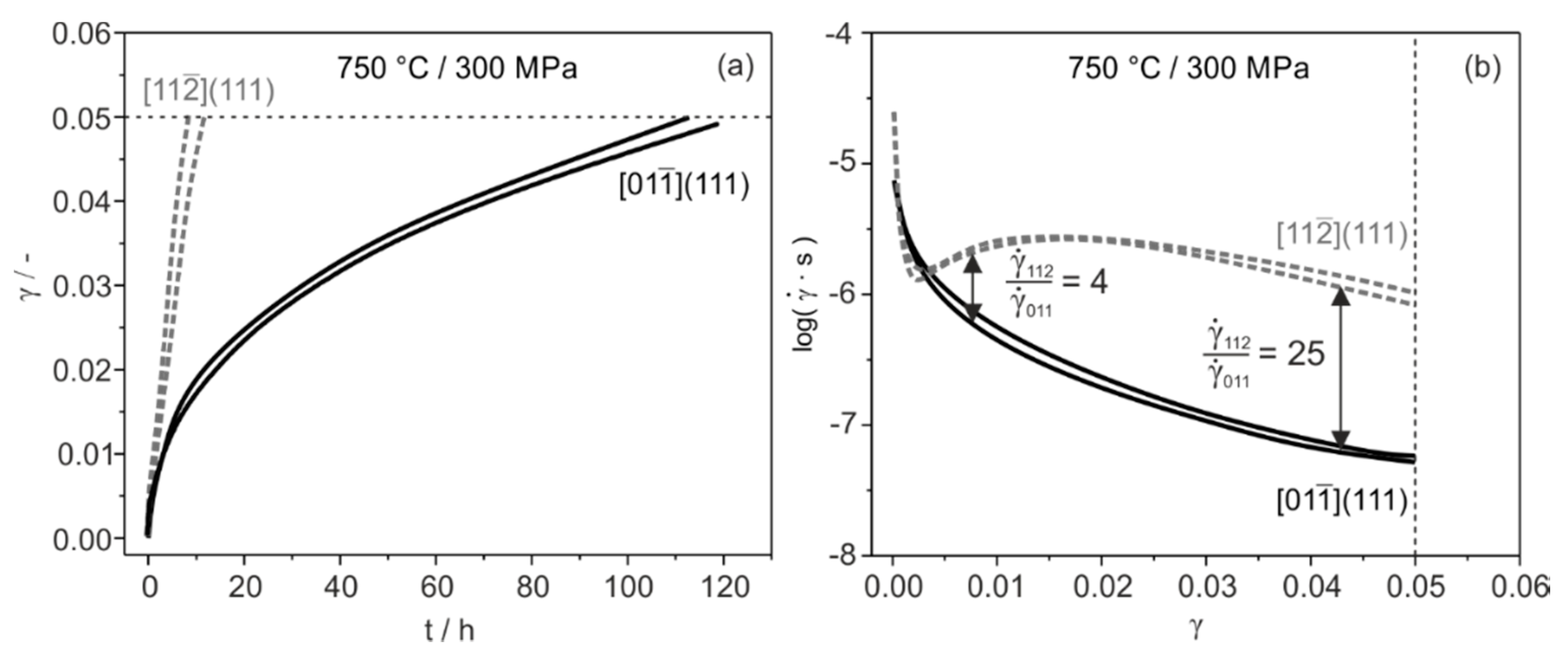

3.1. Creep in the Two MCSSs

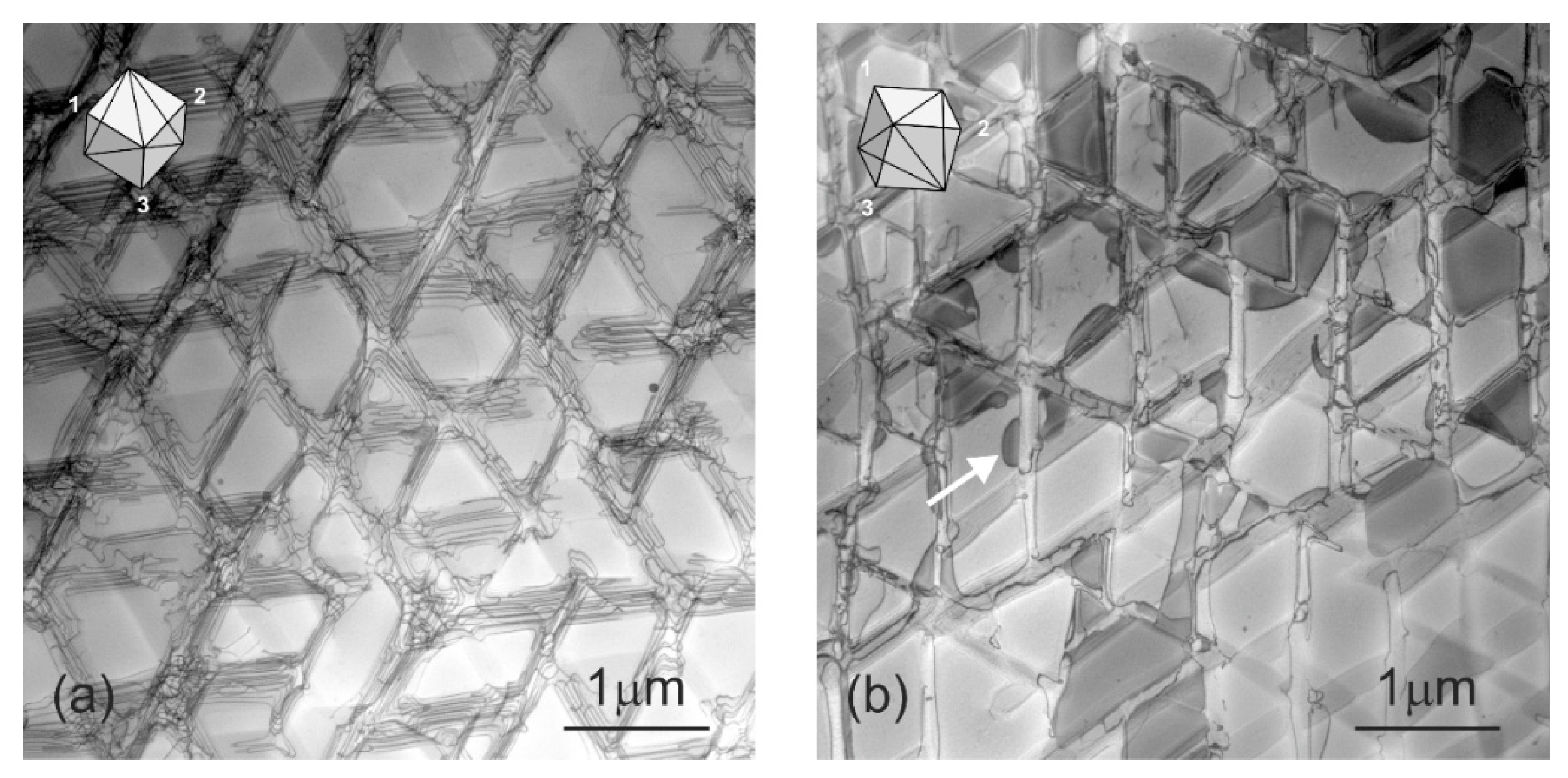

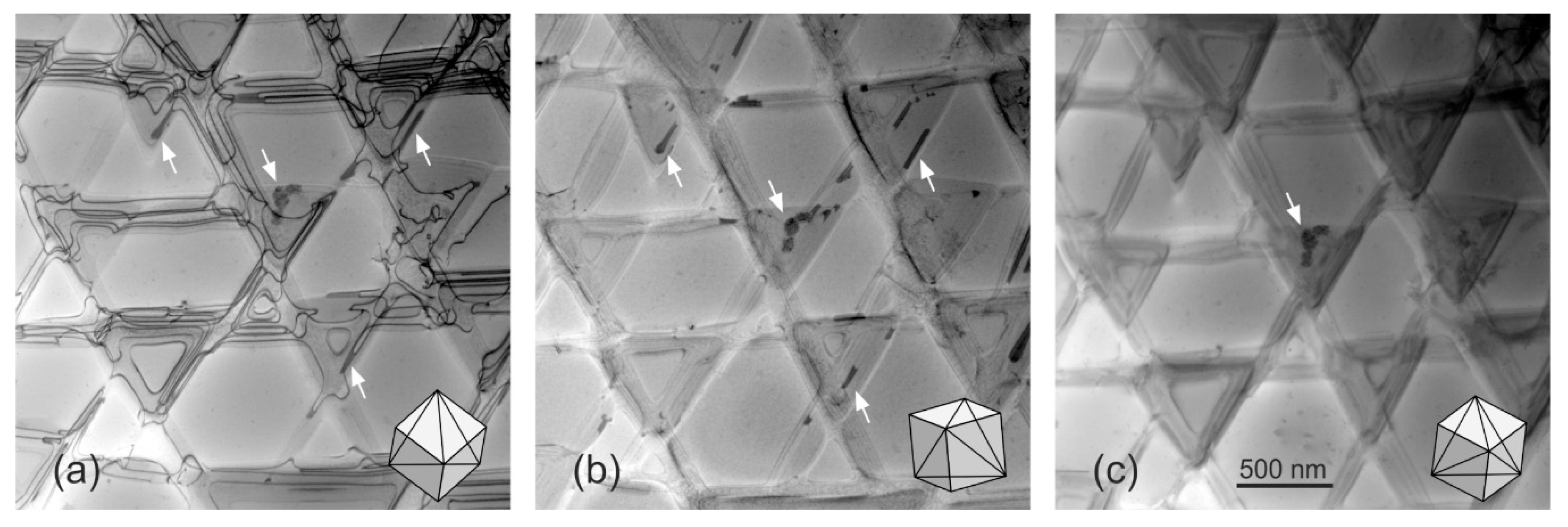

3.2. Dislocations and Planar Faults

4. Discussion

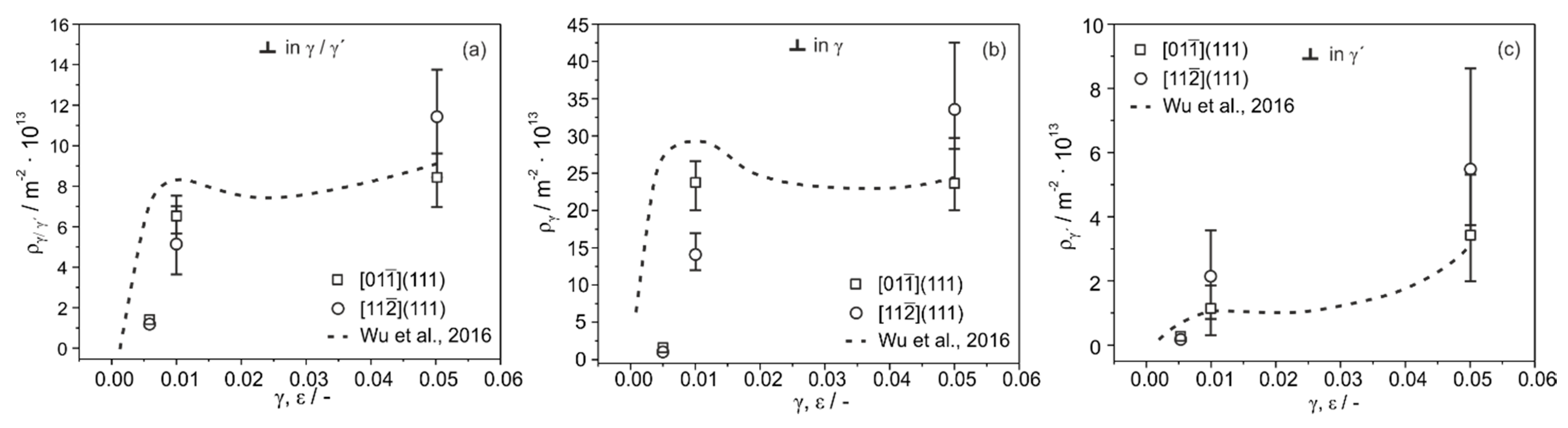

4.1. Mechanical and Micro Mechanical Analysis

4.2. Analysis of STEM Overview Micrographs

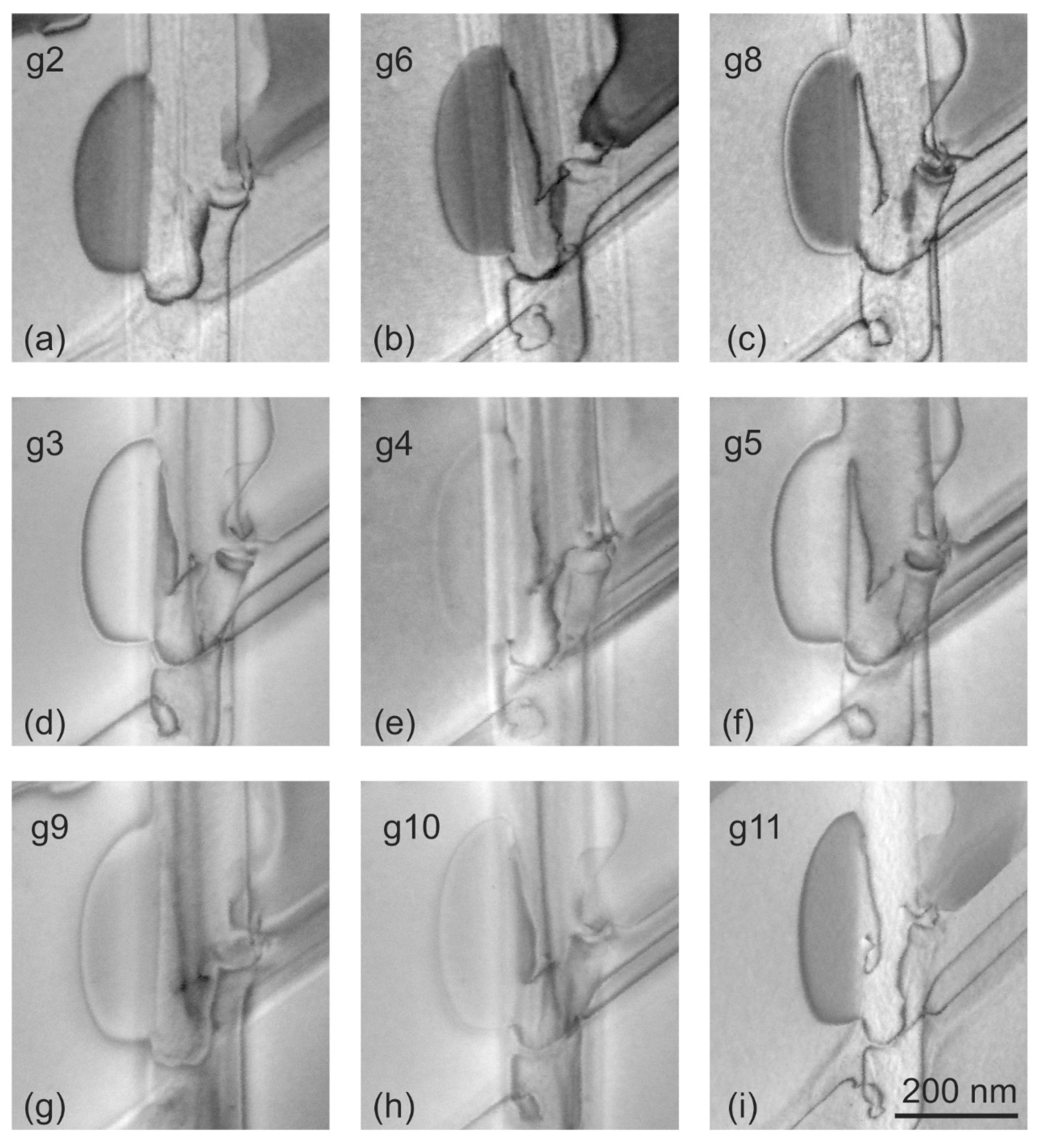

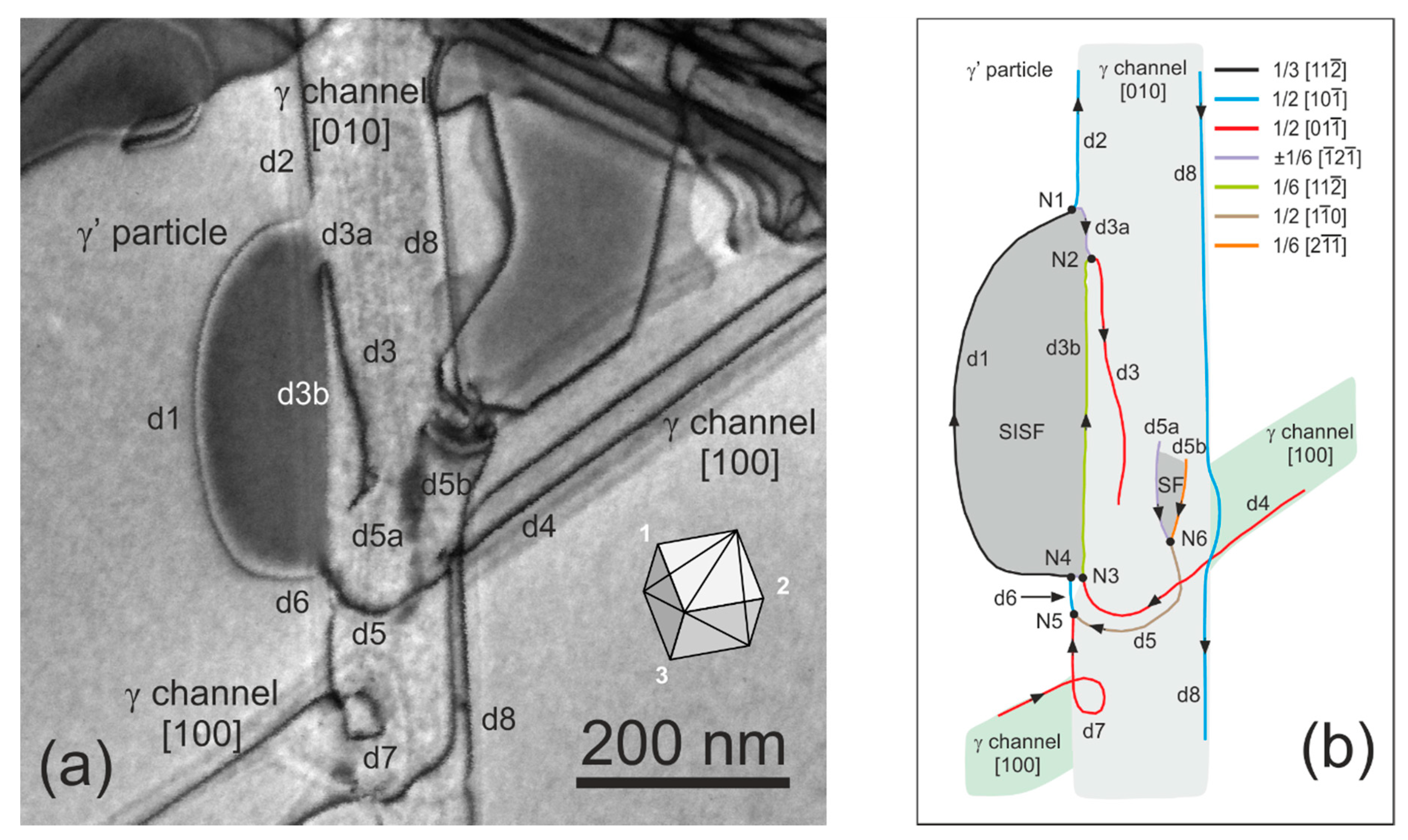

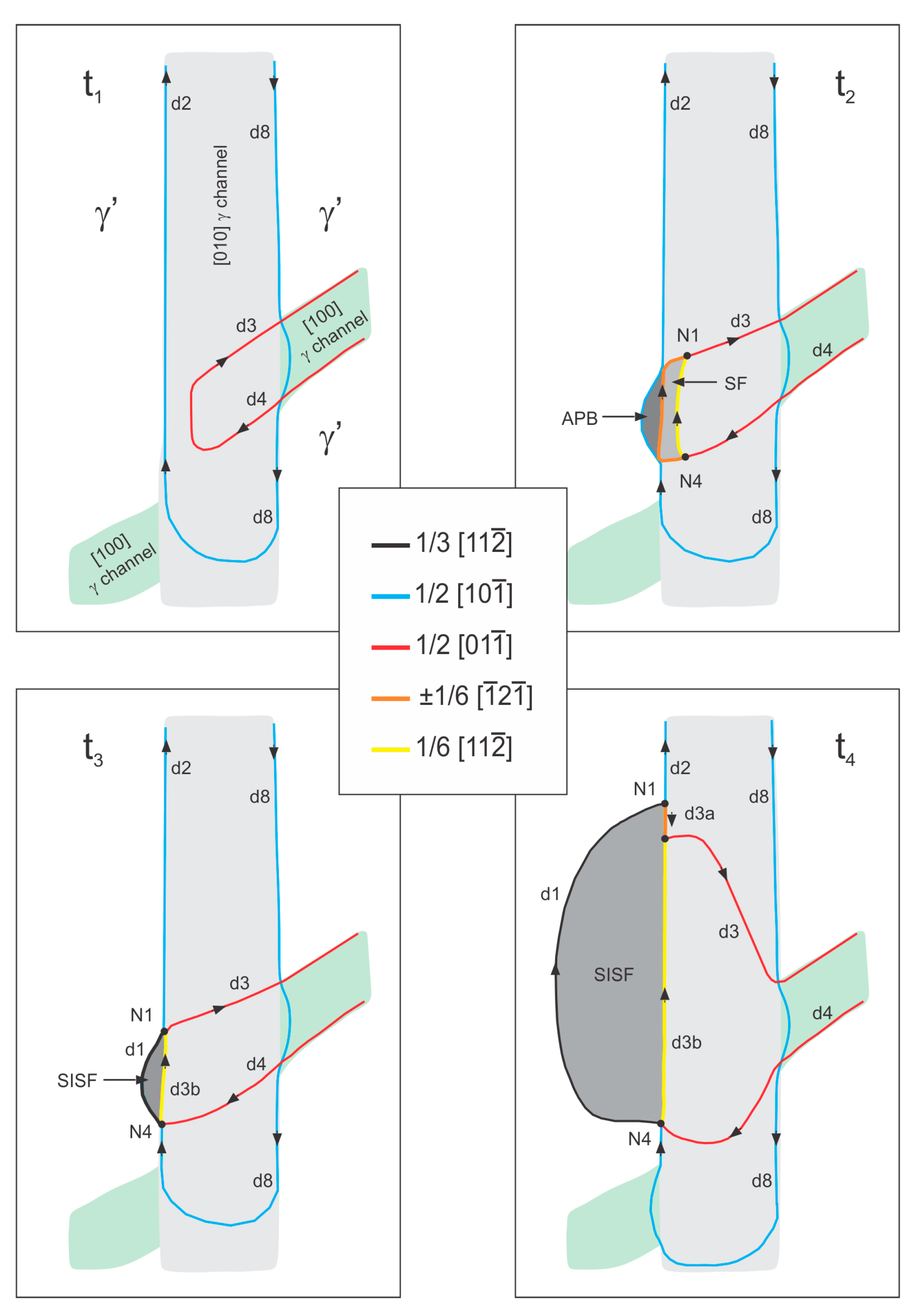

4.3. Analysis of a Local Dislocation Reaction

4.4. Relation to Previous Work

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Durand-Charre, M. The Microstructure of Superalloys; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Kear, B.H.; Leverant, G.R.; Oblak, J.M. An analysis of creep-induced intrinsic/extrinsic fault pairs in a precipitation hardened Nickel-base alloy. Trans. ASM 1969, 62, 639–650. [Google Scholar]

- Kear, B.H.; Oblak, J.M.; Giamei, A.F. Stacking faults in gamma prime (Ni3(Al,Ti) precipitation hardened Nickel-base alloys. Metall. Trans. 1970, 1, 2477–2486. [Google Scholar]

- Matan, N.; Cox, D.C.; Rist, M.A.; Rae, C.M.F.; Reed, R.C. Creep of CMSX-4 single crystals: Effect of misorientation and temperature. Acta Mater. 1999, 47, 1549–1563. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Matan, N.; Reed, R.C. The role of stacking fault shear in the primary creep of [001]-oriented single crystal superalloys at 750 °C and 750 MPa. Mater. Sci. Eng. 2001, 300, 125–134. [Google Scholar] [CrossRef]

- Drew, G.L.; Reed, R.C.; Kakehi, K.; Rae, C.M.F. Single crystal superalloys: The transition from primary to secondary creep. In Superalloys 2004; Green, K.A., Ed.; TMS: Warrendale, PA, USA, 2004; pp. 127–136. [Google Scholar]

- Rae, C.M.F.; Reed, R.C. Primary creep in single crystal superalloys: Origins, mechanisms and effects. Acta Mater. 2007, 55, 1067–1081. [Google Scholar] [CrossRef]

- Rae, C.M.F.; Zhang, L. Primary creep in single crystal superalloys: Some comments on effects of composition and microstructure. Mater. Sci. Technol. 2009, 25, 228–235. [Google Scholar] [CrossRef]

- Wu, X.; Wollgramm, P.; Somsen, C.; Dlouhy, A.; Kostka, A.; Eggeler, G. Double minimum creep of single crystal Ni-base superalloys. Acta Mater. 2016, 112, 242–260. [Google Scholar] [CrossRef]

- Wu, X.; Dlouhy, A.; Eggeler, Y.M.; Spiecker, E.; Kostka, A.; Somsen, C.; Eggeler, G. On the nucleation of planar faults during low temperature and high stress creep of single crystal Ni-base superalloys. Acta Mater. 2018, 144, 624–655. [Google Scholar] [CrossRef]

- Eggeler, G.; Wieczorek, N.; Fox, F.; Berglund, S.; Bürger, D.; Dlouhy, A.; Wollgramm, P.; Neuking, K.; Schreuer, J.; Agudo Jácome, L.; et al. On shear testing of single crystal Ni-base superalloys. Metall. Mater. Trans. 2018, 49, 3951–3962. [Google Scholar] [CrossRef]

- Parsa, A.P.; Wollgramm, P.; Buck, H.; Somsen, C.; Kostka, A.; Povstugar, I.; Choi, P.P.; Raabe, D.; Dlouhy, A.; Müller, J.; et al. Advanced scale bridging microstructure analysis of single crystal Ni-base superalloys. Adv. Eng. Mater. 2015, 17, 216–230. [Google Scholar] [CrossRef]

- Yardley, V.; Povstugar, I.; Choi, P.P.; Raabe, D.; Parsa, A.B.; Kostka, A.; Somsen, C.; Dlouhy, A.; Neuking, K.; George, E.; et al. On phase equilibria and the appearance of nanoparticles in the microstructure of single crystal Ni-base superalloys. Adv. Eng. Mater. 2016, 18, 1556–1567. [Google Scholar] [CrossRef]

- Wollgramm, P.; Bürger, D.; Parsa, A.B.; Neuking, K.; Eggeler, G. The effect of stress, temperature and loading direction on creep behavior of Ni-base single crystal superalloy miniature tensile creep specimens. Mater. High Temp. 2016, 33, 346–360. [Google Scholar] [CrossRef]

- Agudo Jácome, L.; Göbenli, G.; Eggeler, G. Transmission electron microscopy study of the microstructural evolution during high-temperature and low stress shear creep deformation of the superalloy single crystal CMSX 4. J. Mater. Res. 2017, 32, 4492–4502. [Google Scholar] [CrossRef]

- Jácome, L.A.; Nörtershäuser, P.; Heyer, J.K.; Lahni, A.; Frenzel, J.; Dlouhy, A.; Somsen, C.; Eggeler, G. High-temperature and low-stress creep anisotropy of single-crystal superalloys. Acta Mater. 2013, 61, 2926–2943. [Google Scholar] [CrossRef]

- Jácome, L.A.; Nörtershäuser, P.; Somsen, C.; Dlouhy, A.; Eggeler, G. On the nature of γ′ phase cutting and its effect on high temperature and low stress creep anisotropy of Ni-base single crystal superalloys. Acta Mater. 2014, 69, 246–264. [Google Scholar] [CrossRef]

- Jácome, L.A.; Eggeler, G.; Dlouhy, A. Advanced scanning transmission stereo electron microscopy of structural and functional engineering materials. Ultramicroscopy 2012, 122, 48–59. [Google Scholar] [CrossRef]

- Ham, R.K. The determination of dislocation densities in thin films. Philos. Mag. 1961, 6, 1183–1184. [Google Scholar] [CrossRef]

- Dlouhy, A.; Pesicka, J. Estimate of foil thickness by stereo TEM microscopy. Chech. J. Phys. 1990, 40, 539–584. [Google Scholar]

- Eggeler, G.; Dlouhy, A. On the formation of <010> dislocations in the gamma prime phase of superalloy single crystals during high temperature and low stress creep. Acta Mater. 1997, 45, 4251–4262. [Google Scholar] [CrossRef]

- Probst Hein, M.; Dlouhy, A.; Eggeler, G. Interface dislocation in superalloy single crystals. Acta Mater. 1999, 47, 2497–2510. [Google Scholar] [CrossRef]

- Schmid, E.; Boas, W. Kristallplastizität; Springer Verlag: Berlin, Germany, 1935. [Google Scholar]

- Williams, R.O. Origin of strengthening of precipitation: Ordered particles. Acta Metall. 1957, 5, 241–244. [Google Scholar] [CrossRef]

- Gleiter, H.; Hornbogen, E. Aushärtung durch kohärente geordnete Teilchen. Acta Metall. 1965, 13, 576–578. [Google Scholar] [CrossRef]

- Gleiter, H.; Hornbogen, E. Theorie der Wechselwirkung von Versetzungen mit kohärenten geordneten Zonen I. Phys. Stat. Sol. 1965, 12, 235–250. [Google Scholar] [CrossRef]

- Gleiter, H.; Hornbogen, E. Theorie der Wechselwirkung von Versetzungen mit kohärenten geordneten Zonen II. Phys. Stat. Sol. 1965, 12, 251–264. [Google Scholar] [CrossRef]

- Tituts, M.; Moturra, A.; Viswanathan, G.B.; Suzuki, A.; Mills, M.J.; Pollock, T.M. High resolution energy dispersive mapping of planar defects in L12-containing Co-based superalloy. Acta Mater. 2015, 82, 423–437. [Google Scholar] [CrossRef]

- Titus, M.; Eggeler, Y.M.; Suzuki, M.; Pollock, T.M. Creep-induced planar defects in L12-containing Co- and CoNi-based superalloys. Acta Mater. 2015, 82, 530–539. [Google Scholar] [CrossRef]

- Pollock, T.M.; Field, R.D. Dislocations and high-temperature plastic deformation of superalloy single crystals. In Dislocations in Solids; Nabarro, F.R.N., Duesbery, M.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2002; pp. 547–618. [Google Scholar]

- Feller-Kniepmeier, M.; Kuttner, T. [011] creep in a single crystal Ni-base superalloy at 1037 K. Acta Metall. Mater. 1994, 42, 3167–3174. [Google Scholar] [CrossRef]

- Sass, V.; Glatzel, U.; Feller-Kniepmeier, M. Anisotropic creep properties of the Ni-base superalloy CMSX-4. Acta Mater. 1996, 44, 1967–1977. [Google Scholar] [CrossRef]

- Sass, V.; Feller-Kniepmeier, M. Orientation dependence of dislocation structures and deformation mechanisms in creep deformed CMSX-4 single crystals. Mater. Sci. Eng. 1998, 245, 19–28. [Google Scholar] [CrossRef]

- Svoboda, J.; Lukas, P. Model of creep in <001>-oriented superalloy single crystals. Acta Mater. 1998, 46, 3421–3431. [Google Scholar] [CrossRef]

- Haghighat, S.M.H.; Eggeler, G.; Raabe, D. Effect of climb on dislocation mechanisms and creep rates in gamma prime strengthened superalloy single crystals: A discrete dislocation dynamics study. Acta Mater. 2013, 61, 3709–3723. [Google Scholar] [CrossRef]

- Li, Y.; Wang, L.; Zhang, G.; Zhang, J.; Lou, L. Creep anisotropy of a 3rd generation Ni-base single crystal super alloy at 850 °C. Mater. Sci. Eng. A 2019, 760, 26–36. [Google Scholar] [CrossRef]

| Element | Al | Co | Cr | Hf | Mo | Re | Ta | Ti | W | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| weight-% | 5.5 | 9.7 | 6.4 | 0.1 | 0.6 | 2.9 | 6.5 | 1.0 | 6.4 | Bal. |

| g-vector | g1 | g2 | g3 | g4 | g5 | g6 | g7 | g8 | g9 | g10 | g11 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | |||||||||||

| Fig. no. | 4b | 5b,6a | 6d | 6e | 6f | 6b | 4a, 5a | 6c, 7a | 5c, 6g | 6h | 6i |

| Dislocation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| d1 | + | 2/3 | + | −2 | res | 0 | + | −2 | + | 2/3 |

| d2 | + | 1 | + | −1 | + | −1 | + | −2 | − | 0 |

| d3 | − | 0 | + | −2 | + | 1 | + | −1 | + | 1 |

| d3a | − | −1/3 | + | −1 | + | 1 | - | 0 | + | 2/3 |

| d3b | − | −1/3 | w | −1 | − | 0 | + | −1 | − | 1/3 |

| d4 | − | 0 | + | −2 | + | 1 | + | −1 | + | 1 |

| d5 | + | 1 | + | 1 | + | −2 | + | −1 | + | −1 |

| d5a | − | 1/3 | + | 1 | + | −1 | - | 0 | + | −2/3 |

| d5b | + | 2/3 | − | 0 | w | −1 | + | −1 | − | −1/3 |

| d6 | + | 1 | + | −1 | ? | −1 | + | −2 | − | 0 |

| d7 | − | 0 | + | −2 | + | 1 | + | −1 | + | 1 |

| d8 | + | 1 | + | −1 | w | −1 | + | −2 | − | 0 |

| Dislocation | b/a | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| d1 | + | −4/3 | + | 4/3 | + | −4/3 | + | −2/3 | 1/3 |

| d2 | + | −1 | + | 2 | − | 0 | − | 0 | 1/2 |

| d3 | + | −1 | res | 0 | + | −2 | + | −1 | 1/2 |

| d3a | − | −1/3 | − | −2/3 | + | −4/3 | + | −2/3 | 1/6 |

| d3b | w | −2/3 | + | 2/3 | − | −2/3 | − | −1/3 | 1/6 |

| d4 | + | −1 | res | 0 | + | −2 | + | −1 | 1/2 |

| d5 | − | 0 | + | 2 | ? | 2 | + | 1 | 1/2 |

| d5a | − | 1/3 | ? | 2/3 | ? | 4/3 | + | 2/3 | 1/6 |

| d5b | − | −1/3 | + | 4/3 | ? | 2/3 | − | −1/3 | 1/6 |

| d6 | + | −1 | + | 2 | − | 0 | − | 0 | 1/2 |

| d7 | + | −1 | res | 0 | + | −2 | + | −1 | 1/2 |

| d8 | + | −1 | + | 2 | − | 0 | − | 0 | 1/2 |

| System | Plane | Direction | T: [001] | ||

|---|---|---|---|---|---|

| 1 | 0 | 0.5 | 0 | ||

| 2 | −0.41 | 0.5 | 0.87 | ||

| 3 | −0.41 | 1 | 0.87 | ||

| 4 | 0 | 0.17 | −0.19 | ||

| 5 | −0.41 | 0.17 | 0.48 | ||

| 6 | −0.41 | 0.33 | 0.29 | ||

| 7 | 0 | 0.50 | 0.19 | ||

| 8 | −0.41 | 0.17 | 0.29 | ||

| 9 | −0.41 | 0.67 | 0.48 | ||

| 10 | 0 | 0.17 | 0 | ||

| 11 | −0.41 | 0.50 | 0.67 | ||

| 12 | −0.41 | 0.67 | 0.67 |

| Channel | Line Direction | Dislocation Type | PKFg | PKFc |

|---|---|---|---|---|

| [100] | 60° | 0.190 | 0.217 | |

| [010] | screw | 0.612 | 0.0 | |

| [001] | 60° | 1.035 | −0.217 |

| Channel | Line Direction | Dislocation Type | PKFg | PKFc |

|---|---|---|---|---|

| [100] | screw | 0.612 | 0 | |

| [010] | 60° | 0.190 | 0.217 | |

| [001] | 60° | 1.035 | −0.217 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bürger, D.; Dlouhý, A.; Yoshimi, K.; Eggeler, G. How Nanoscale Dislocation Reactions Govern Low- Temperature and High-Stress Creep of Ni-Base Single Crystal Superalloys. Crystals 2020, 10, 134. https://doi.org/10.3390/cryst10020134

Bürger D, Dlouhý A, Yoshimi K, Eggeler G. How Nanoscale Dislocation Reactions Govern Low- Temperature and High-Stress Creep of Ni-Base Single Crystal Superalloys. Crystals. 2020; 10(2):134. https://doi.org/10.3390/cryst10020134

Chicago/Turabian StyleBürger, David, Antonin Dlouhý, Kyosuke Yoshimi, and Gunther Eggeler. 2020. "How Nanoscale Dislocation Reactions Govern Low- Temperature and High-Stress Creep of Ni-Base Single Crystal Superalloys" Crystals 10, no. 2: 134. https://doi.org/10.3390/cryst10020134

APA StyleBürger, D., Dlouhý, A., Yoshimi, K., & Eggeler, G. (2020). How Nanoscale Dislocation Reactions Govern Low- Temperature and High-Stress Creep of Ni-Base Single Crystal Superalloys. Crystals, 10(2), 134. https://doi.org/10.3390/cryst10020134