3.1. GaN Seeds Preparation

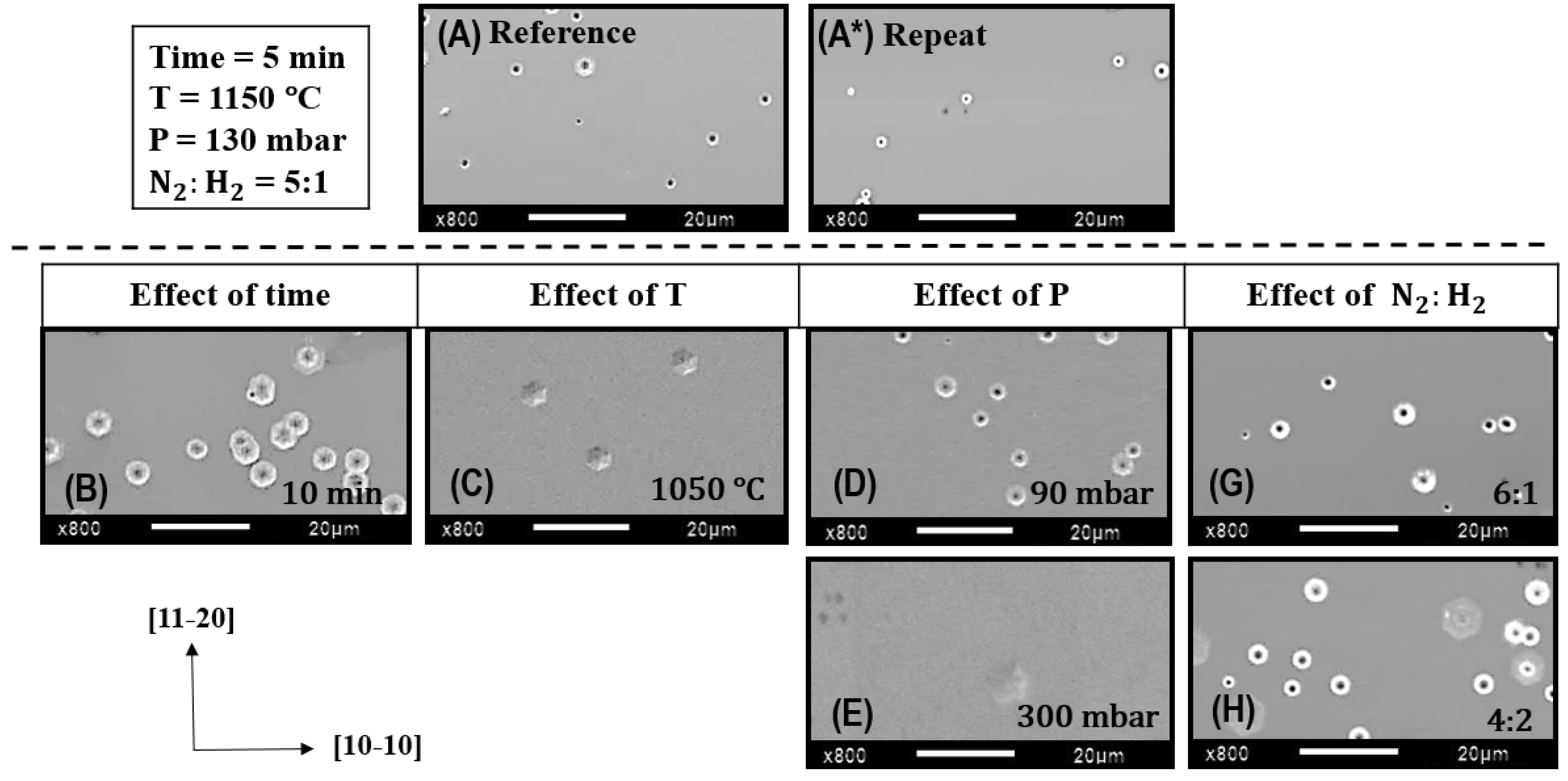

The SEM cross-sections and plan views of eight in-situ etched samples under different etching conditions are shown in

Figure 2 and

Figure 3, respectively. As it can be seen in all samples, the GaN surface remains quite smooth after the in-situ etching treatment. The smoothness of the GaN surface refers to the relative stability of the Ga-face against

etching, as was explained previously. Additionally, etch pits are visible on the samples, which are never present in untreated-GaN layers without an additional etching step. The density and the geometry of the pits depend on the etching parameters, as will be explained in the following sections.

In sample A, the depth of the etch pits is about, i.e., the tip of the pits is close to the interface between the GaN layer and the sapphire substrate. The etching procedure is considered reproducible as the density, geometry and relative depth of the pits are almost the same in sample A*, which was etched under the same conditions as sample A. However, a statistical variation in the observation of the exact physical depth should be considered, as the probability of being able to cut the sample exactly in the middle of a pit is low and therefore the depth of the etch pits are generally underestimated. It is worth noting that, since the pits have very steep inclined sidewalls, measuring the depth of them by means of confocal laser microscopy, atomic force microscopy or similar methods was not successful. Hence, the statistics from the SEM cross-section images must be considered as the only reliable method to obtain etch pit depth information.

Since the target was to etch the GaN seed layer in such a way that the etch pits become as close as possible to the GaN/sapphire interface in order to weaken the interface, we have increased the etching time to 10 min for sample B, in order to allow the

to further diffuse through the dislocations and eventually along the GaN/sapphire interface. It was found that the aspect ratio (diameter/depth) of the pits was increased with etching time, but no increase in the depth of the pits was observed. We conclude that either the GaN layer was etched up to some depth and then

continued etching the sidewalls of the formed pits laterally (see

Figure 2, sample H) so that only the diameter grew bigger. The other possibility would be that the pits are etched up to the interface and with increasing time etched sideward. However, as mentioned, the depth of the pits measured from the cross-sections could be underestimated. In order to prove which one of the above assumptions is valid, we undertook further experiments.

By lowering the temperature, the etching rate decreased notably, achieving a maximum pit depth of about

only (see sample C in

Figure 2 and

Figure 3). This indicates that the etching rate along the c-direction is higher at elevated temperatures. This can be attributed to the higher desorption flux of Ga atoms at higher temperatures, which more likely occurs at less stable crystal facets. Therefore, a higher temperature is suitable for more intense etching along the pits. However, this could only be proven up to the high-end-point temperature of our reactor heater, which was 1300 °C (surface temperature of 1150 °C).

In contrast, if instead the etching pressure was reduced from 130 mbar (sample A) to 90 mbar (sample D), the diameter of the etch pits did not change significantly, but the depth and pit density increased. This result was promising, considering that more volume of GaN is being etched and the pits become comparably closer to the GaN/sapphire interface. By increasing the reactor pressure to 300 mbar (sample E), the etching rate drops dramatically and the picture became inhomogeneous. In some areas of the sample, almost no etching appeared whereas a non-uniform distribution of the pits was observed in other regions of the sample. Obviously, the etching process under such conditions is less anisotropic compared to etching at a relatively low pressure. This can be explained by the smaller mean free path of the atoms and molecules in the gas phase, which is inversely proportional to the pressure at constant temperature. Therefore, low reactor pressure should be more suitable for vertical etching.

In order to further enhance the vertical etching towards the interface, the amount of flow was increased by changing the ratio to 4:2 (sample H). As a result, the etch pit density as well as the pit size increased significantly. On the other hand, it is obvious from the plan-view and cross-section SEM images of sample H that the size and depth of the etch pits were not homogenous anymore. Reducing the amount offlow by increasing the ratio offrom 5:1 (sample A) and to 6:1 (sample G) does not change the etch pit depth, but reduces the density of the pits, because the etchant gas is diluted by more, which results in less etching.

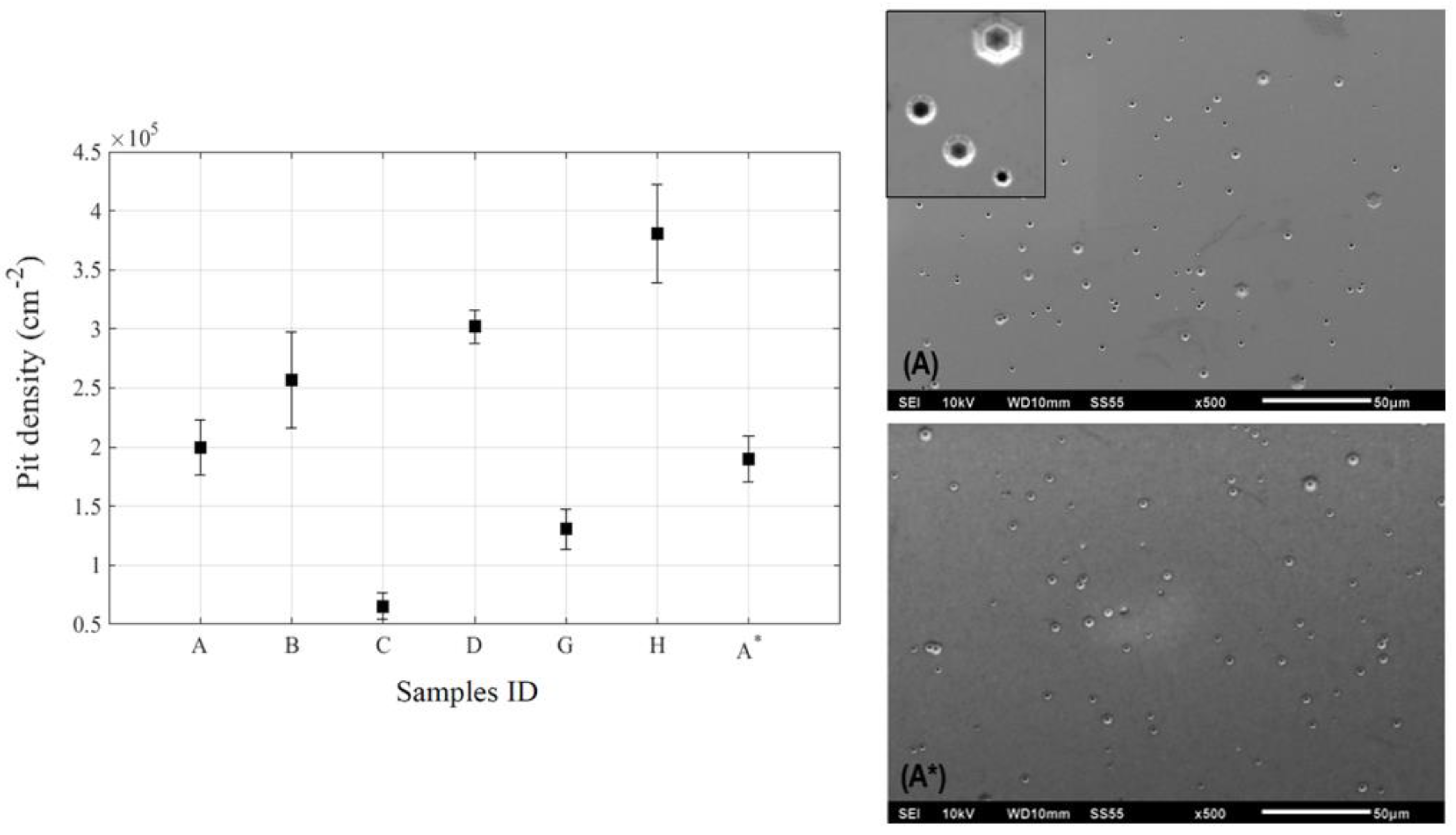

We assume that for a uniform separation of a larger diameter crystal, a uniform size and distribution of pits over the whole sample are required. Therefore, based on the results from the plan-view images, we have statistically analyzed the size and density of the pits on the GaN surfaces etched under different conditions. For this purpose, SEM images with an area of about 250 × 170 µm

2 from three positions radially from the center to the edge of the samples were analyzed. Two representative SEM images from samples A and A* in a large scale for comparison of the etch pit density and distribution along with a plot of summarized results are shown in

Figure 4. On all samples, the density of the pits is in the same order of magnitude, i.e., in the range of

, and the diameter of the pits varies from 1 to 10 µm. It is worth mentioning that the density of the pits formed at the surface is some orders of magnitude less than the typically expected dislocation density of a MOVPE GaN layer, which is usually

in our samples, meaning that not all present dislocations were etched to form pits. However, this topic will not be discussed further in this paper.

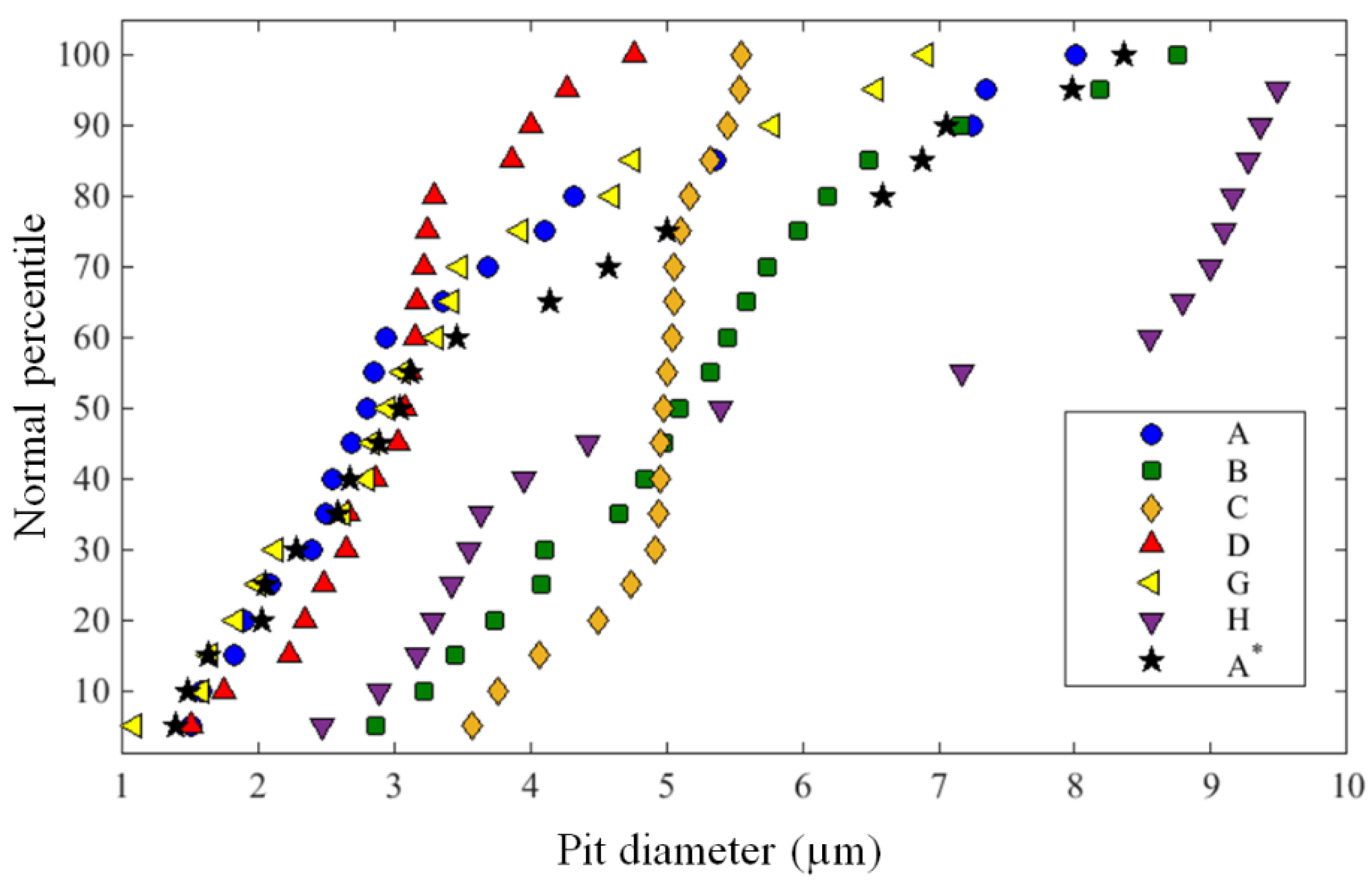

The diameters of the pits, which were measured out of the SEM images, are plotted in

Figure 5 for a better comparison of the average size and homogeneity of the etch pits. In principle, a narrow distribution of the etch pit diameter over the full wafer is required. In

Figure 5, one can see the largest inhomogeneity of the size distribution of the etch pits for sample H, with etch pits with diameters from about 2 to 10 µm. As mentioned before, such an inhomogeneity could cause a non-uniformity of the overgrown crystal and consequently influence the separation process. The large etch pits can easily be filled during overgrowth in the HVPE reactor. Therefore, this sample is not well suited for a subsequent overgrowth process. The best samples regarding uniform etch pit diameter are samples C and D with etch pits in the size of 3.5–5.5 µm and 1.5–4.5 µm, respectively. However, the density of the etch pits in sample C is lower than in sample D (see

Figure 4). This means that, in case of sample C, less voids would exist at the GaN/sapphire interface in comparison to sample D, helping the self-lift-off process.

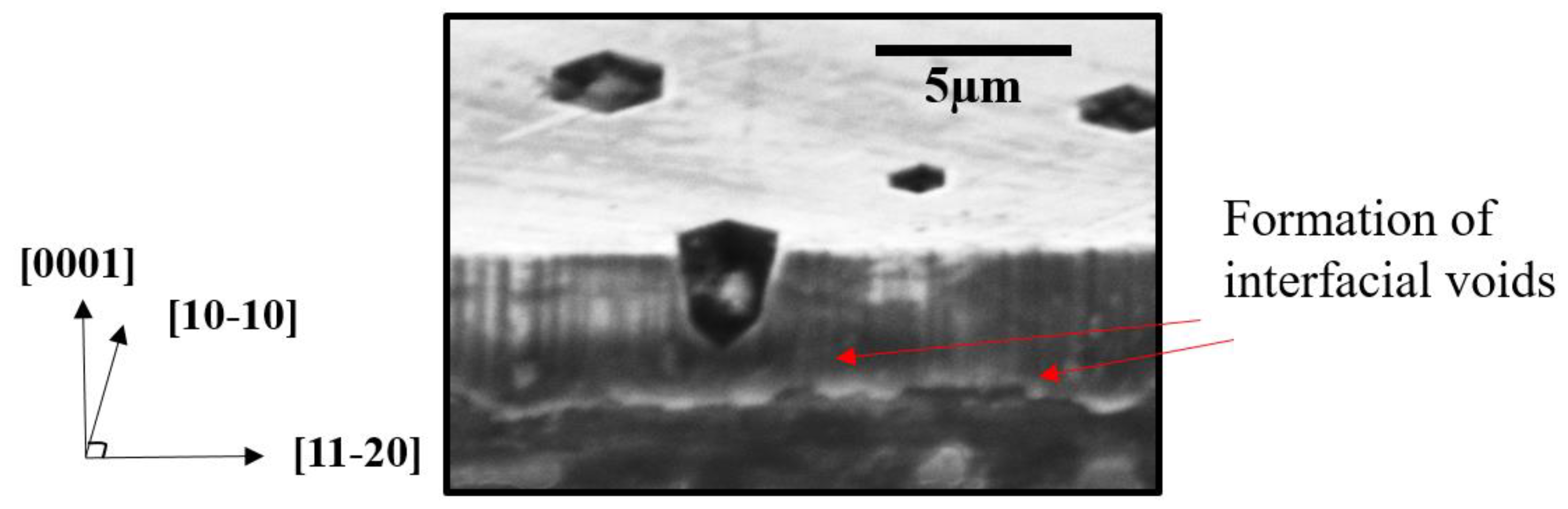

Summarizing the results shown above, we defined a set of criteria for the selection of an appropriate seed: the GaN layer should have relatively deep pits (as close as possible to the interface) with an extension of voids along the GaN/sapphire interface, uniformly distributed over the whole sample, in high density with moderate diameters (smaller than about 5 µm). In the ideal case, they would not be completely filled up during the HVPE overgrowth in order to remain as voids supporting the separation. However, whether they are being filled or not during the first growth stage in the HVPE process would not only depend on the etching procedure, but also on the parameters of the HVPE process itself. If a pit were too wide, it could mean that it will possibly not close during overgrowth and the result would be growth disturbances and an uneven growth front with macro defects. Alternatively, for wider pits, the probability is higher that the pit would be filled completely during the HVPE process and no voids remain—facilitating the separation process. However, irrespective of whether the pits would be filled or not, the lateral voids along the interface would act as a separation support feature. Taken all the above discussed issues into account, we conclude that the etching conditions for sample D are best-suited to prepare a seed for overgrowth in the HVPE process: the density of the pits is relatively high (3 × 10

5 cm

−2), the pits have an average depth of 4.6 µm and a narrow diameter range of 1.5–4.5 µm, and they are uniformly distributed over the whole sample. This is also underlined by further SEM investigations on sample D, in which one could clearly observe the formation of the interfacial voids, as shown in

Figure 6. These interfacial voids are very thin; therefore, they are not easily resolvable in standard SEM cross-section images. Thus, they cannot be seen in

Figure 2.

3.2. HVPE Overgrowth Process and Results

An in-situ etched seed prepared by the etching conditions of sample D was overgrown, applying a standard HVPE process suited for the growth of thicker layers of several 100 µm thickness or even bulk crystals. The 3 inch GaN crystal separated itself very smoothly from the substrate during the HVPE process at a thickness of about. It is worth noting that GaN crystals grown on untreated seeds usually remain attached to the sapphire substrate at such thickness values. The separated GaN crystal had some cracks close to the edge of the crystal. This could be the case because up to 1 mm away from the edge of sapphire substrate, a polycrystalline GaN growth occurred. This rim area also behaved differently during the seed preparation step by in-situ etching in the MOVPE reactor. Therefore, this area could affect the separation process. However, there are several options to overcome this problem, (i) optimize the etching process and ensure that the seed would be etched until the outer edges or (ii) optimize the HVPE GaN growth with regard to thickness homogeneity and better adapt the nucleation regime during HVPE to the new seed type.

Comparing the backside of the separated GaN crystal (about 400 µm) with an in-situ etched seed underneath to a GaN crystal that was separated from sapphire at a thickness of about 1.5 mm by stress-induced spontaneous self-lift-off shows a big difference. The difference can be seen in the microscopical images in

Figure 7 taken with a stereomicroscope.

On the backside of the latter crystals, we always observed huge grooves with depths from hundreds of micrometers up to some millimeters, as seen in

Figure 7b, while the separation from in-situ etched seeds occurs very gently, leaving a smooth crystal backside, as shown in

Figure 7a. The grooves are formed because the mechanical forces to tear the crystal off the seed are very high. Moreover, such a strong thermomechanical action may additionally cause the formation of micro cracks in the crystal.

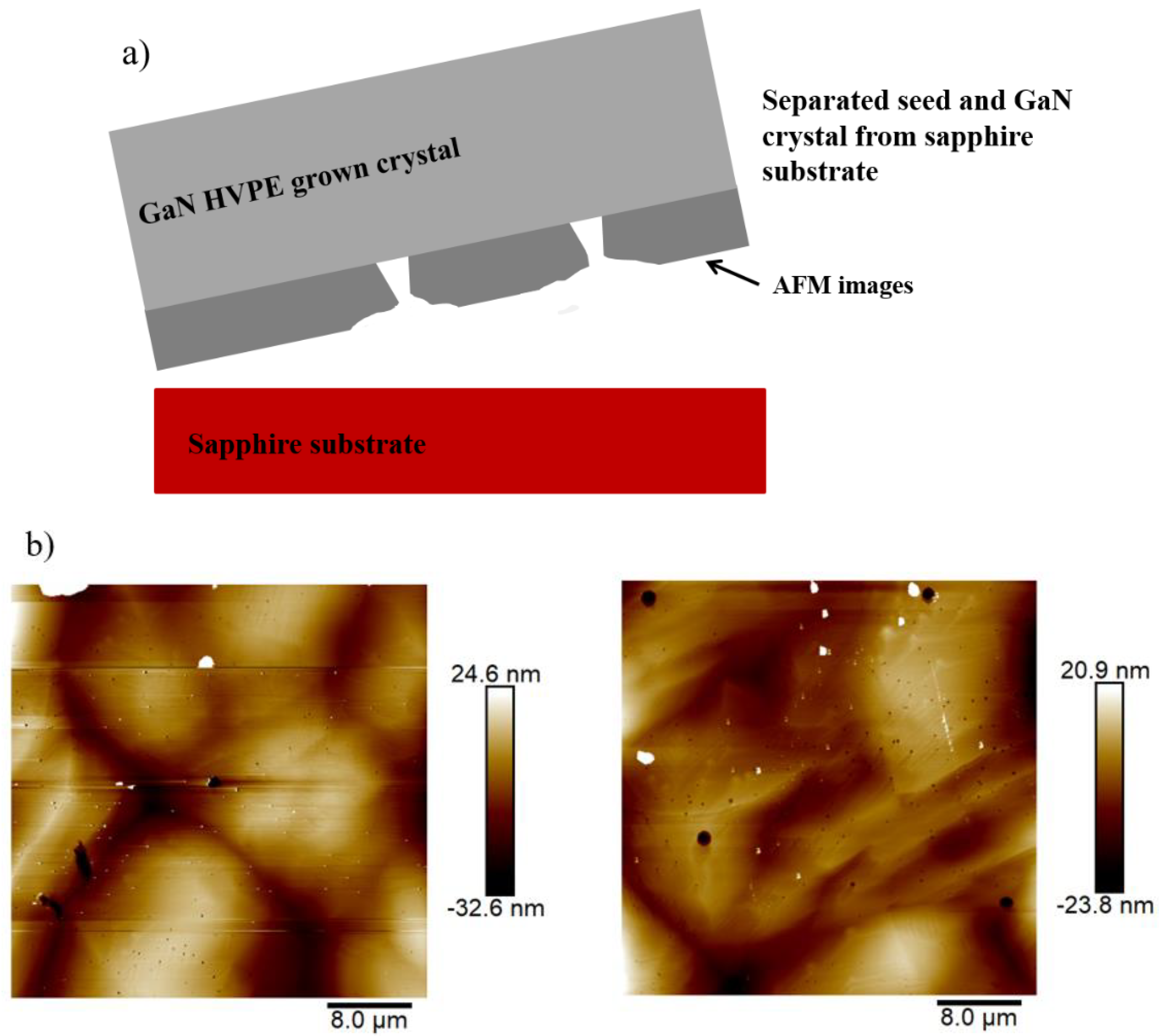

AFM images from the backside (separated interface) of the GaN crystal are shown in

Figure 8, along with a schematic indicating where the measurements were carried out. In the AFM images from the separated interface, one can clearly see the interfacial voids, which were initially generated by the in-situ etching of the seed. These voids have therefore likely caused the smooth separation of the crystal from the sapphire substrate. The depth of the depressions or voids is about 50 nm. This observation is very promising and proves that the GaN/sapphire interface was etched very nicely and weakened in a very thin layer.

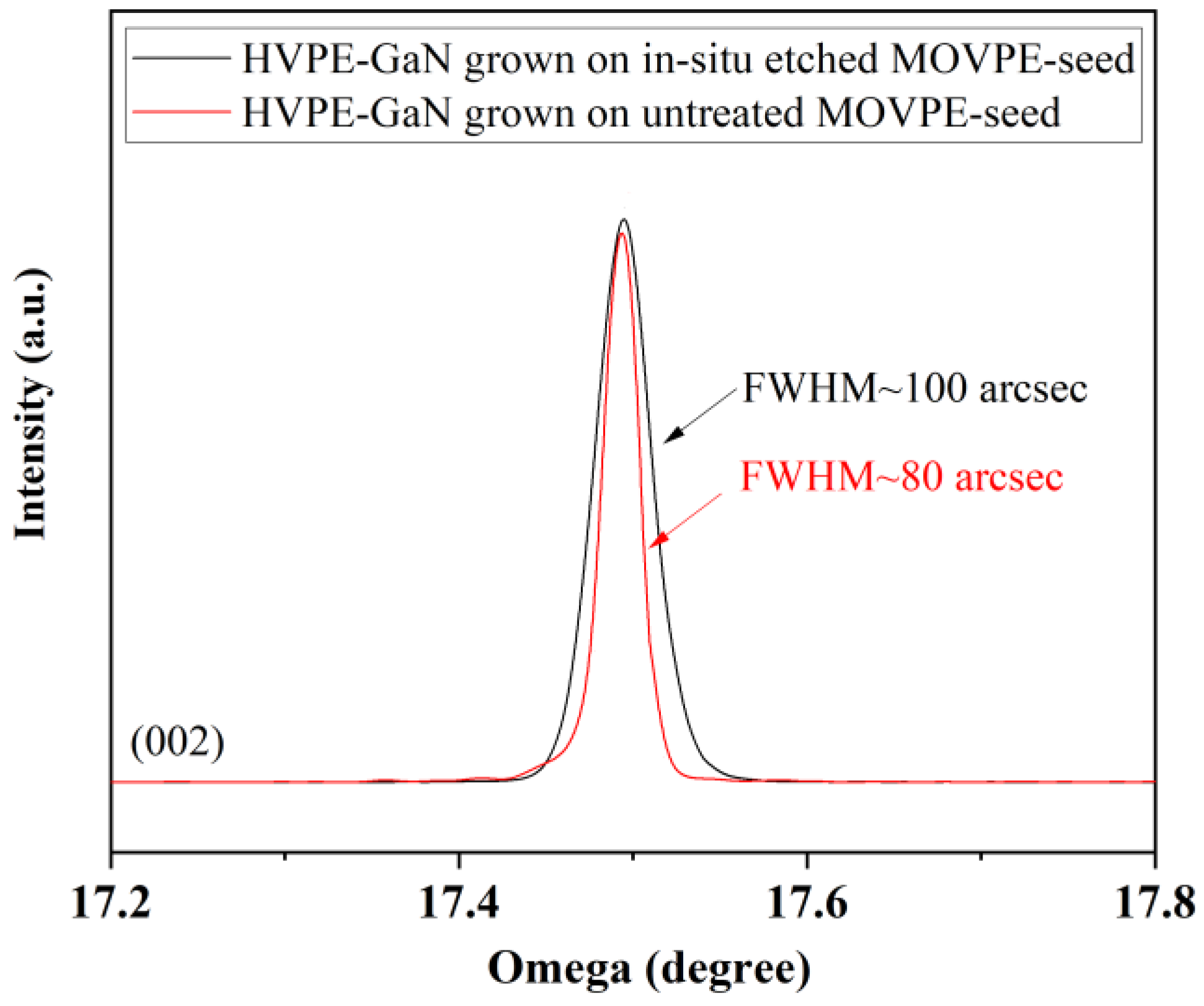

We investigated the crystal quality of the HVPE GaN crystal grown on the

etched seed and compared the results to that grown on an untreated seed. For this purpose, we performed XRD FWHM-rocking curves measurements in (002) reflection. The measurement was carried out in the center of the crystals with the spot size of about 2 × 8 mm

2. The full-width at half-maximum ω-scan values show similar values for the HVPE GaN crystals prepared on both a regular non-etched MOVPE seed and an in-situ etched GaN seed, as depicted in

Figure 9.

The XRD measurements were confirmed by DSE experiments. The dislocation density of the HVPE crystals measured by DSE is very similar, as shown in

Figure 10a,b. The etch pit density is about 6

for the GaN grown on the

etched seed and 4.7

for the GaN crystal grown on the untreated seed. Not important, but worth pointing out; the size of the etch pits are slightly different in

Figure 10a,b because the DSE experiments were carried out in two different ovens; therefore, the actual temperature could be slightly different.

It is worth noting that the crystal quality can be further improved by either increasing the thickness of the HVPE GaN crystal, due to defect annihilation [

13], or further optimizing the HVPE process and adapting the nucleation regime, which were not focused on in this work. According to our experience, a dislocation density of about 2 to 4

should be achievable.

This value is a quite acceptable standard for HVPE grown crystals and we conclude that the new seed preparation process does not have any drawbacks for the crystal quality of the HVPE material grown on top of it.