The Effect of Strain Rate on the Deformation Processes of NC Gold with Small Grain Size

Abstract

:1. Introduction

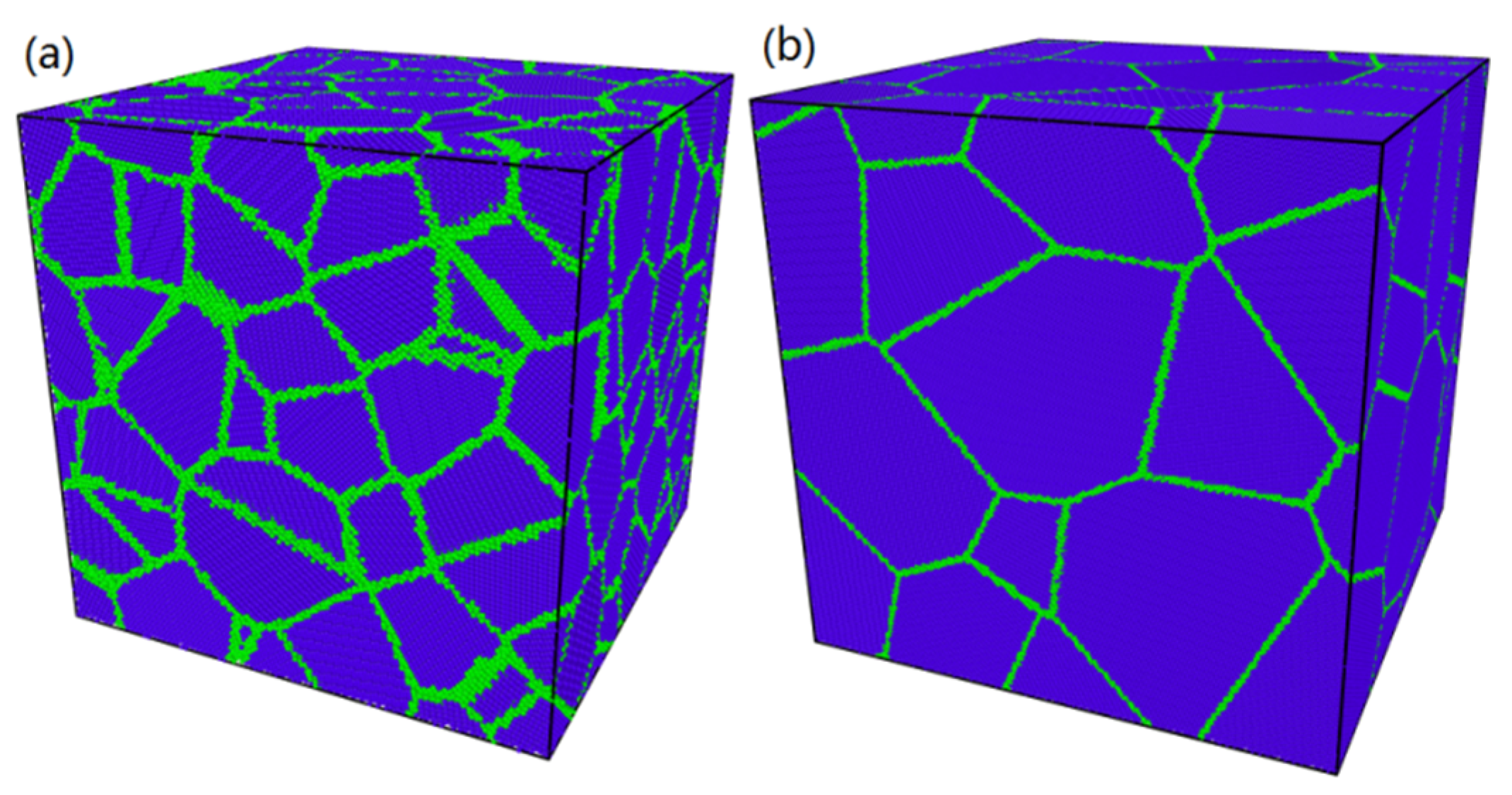

2. Computational Approach and Models

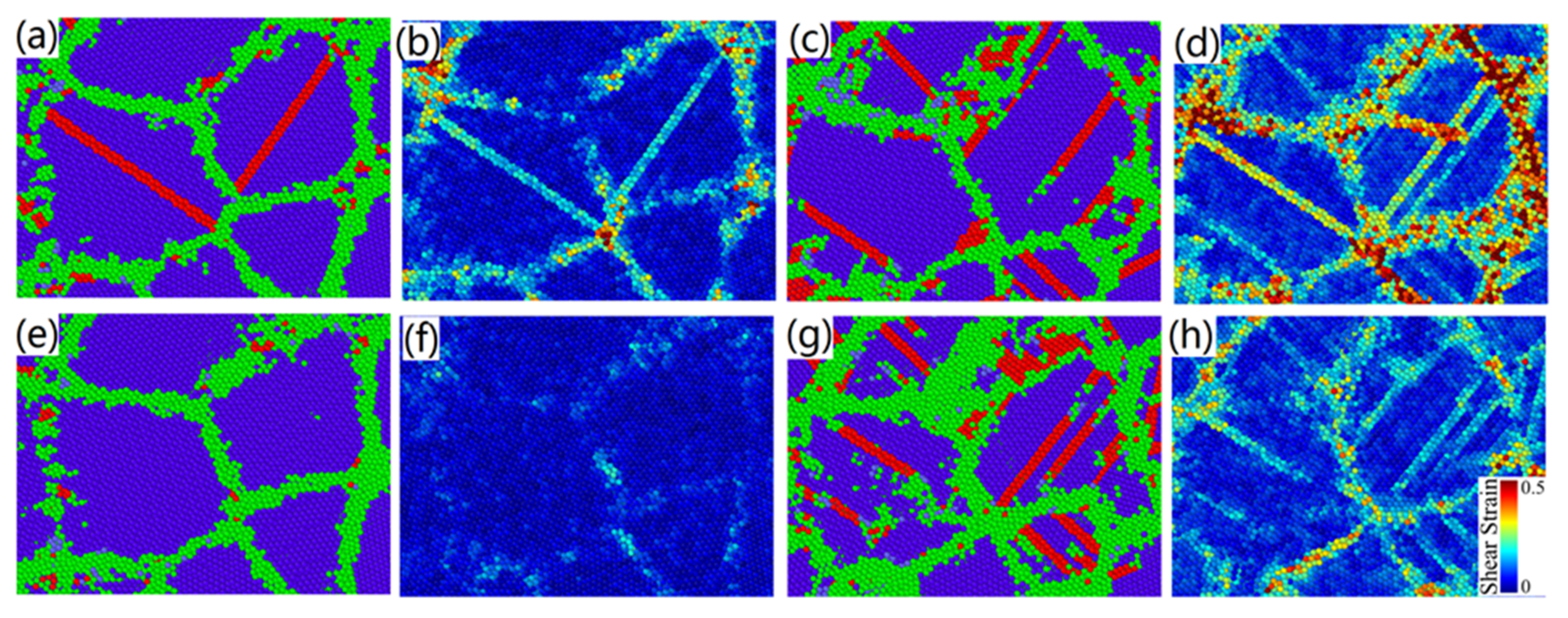

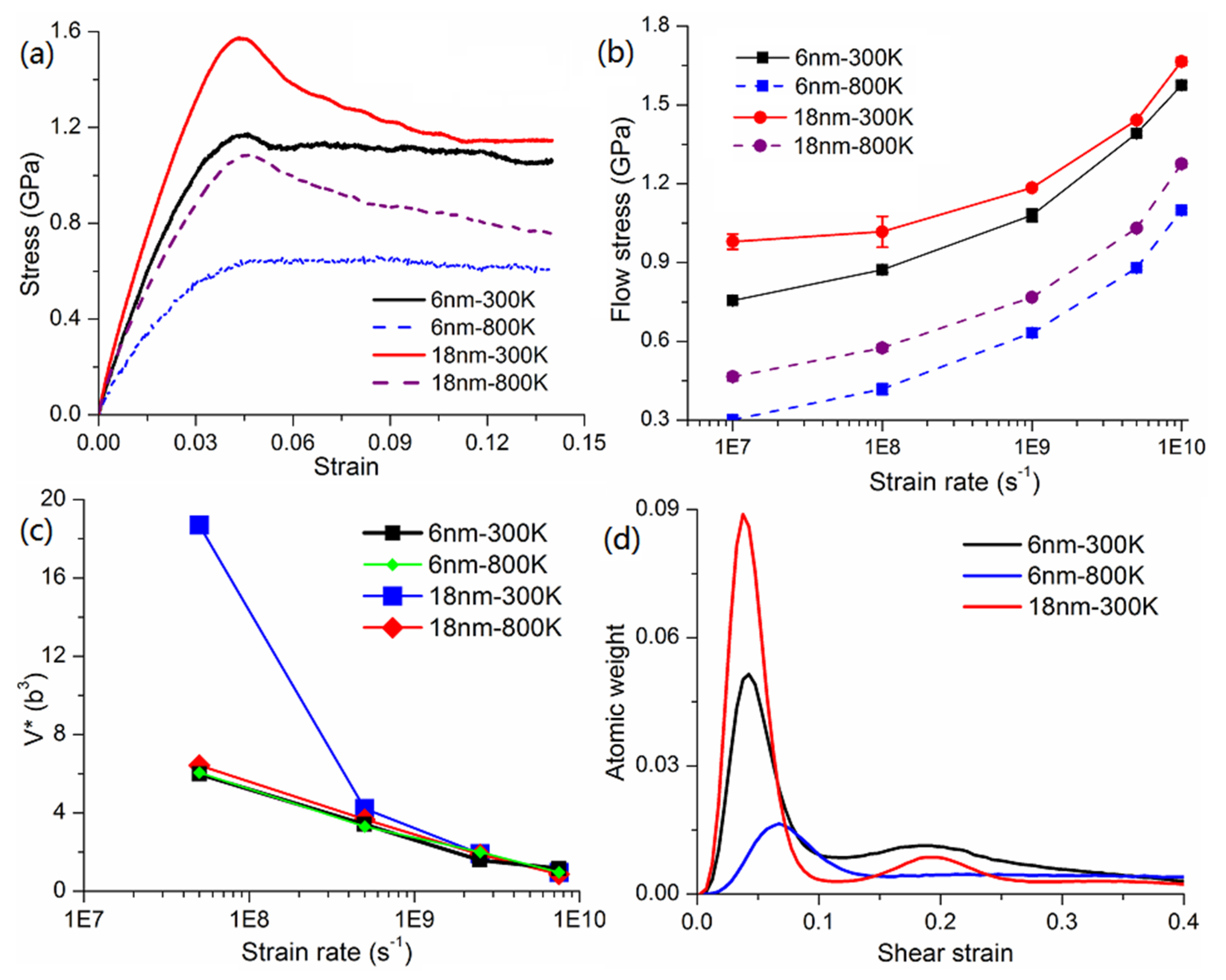

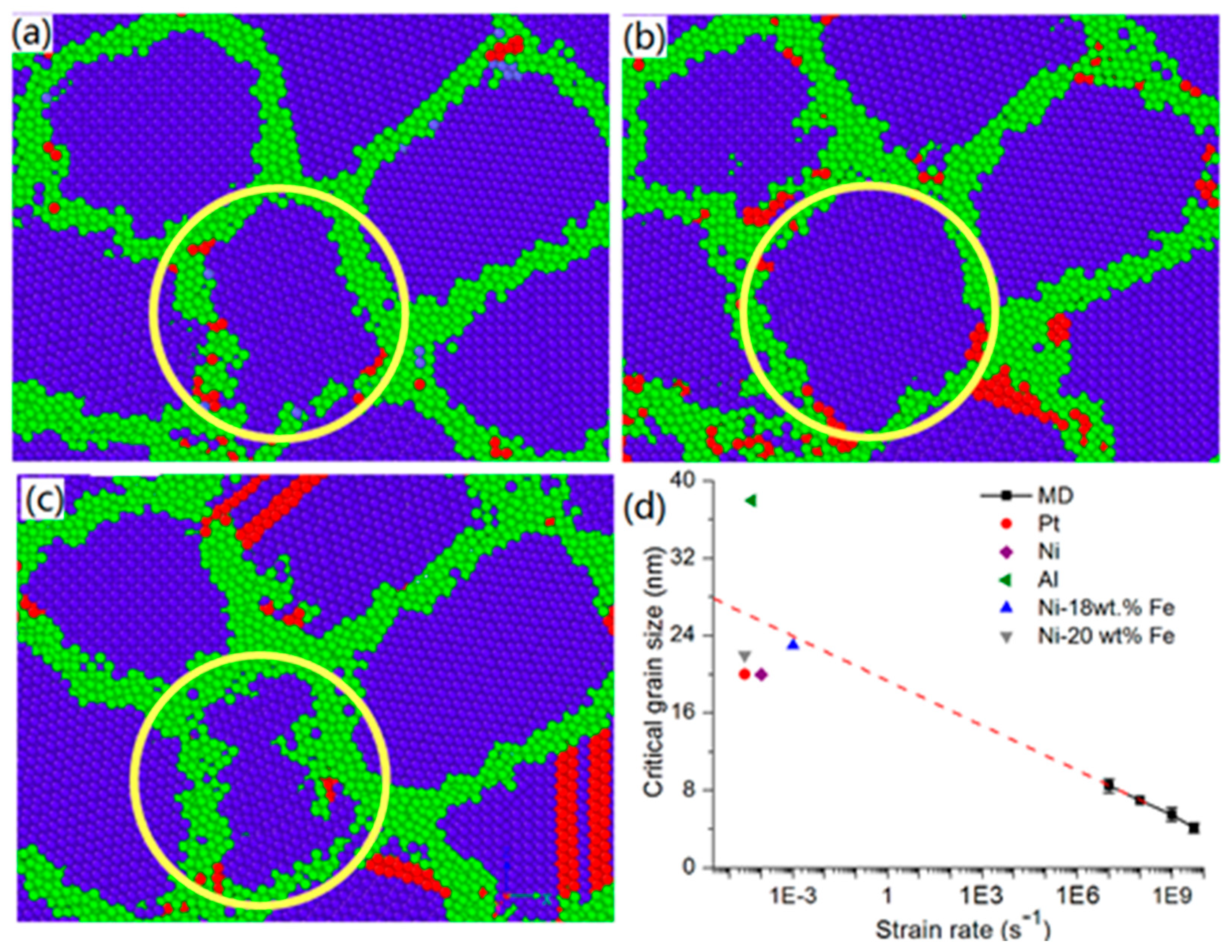

3. Results and Discussion

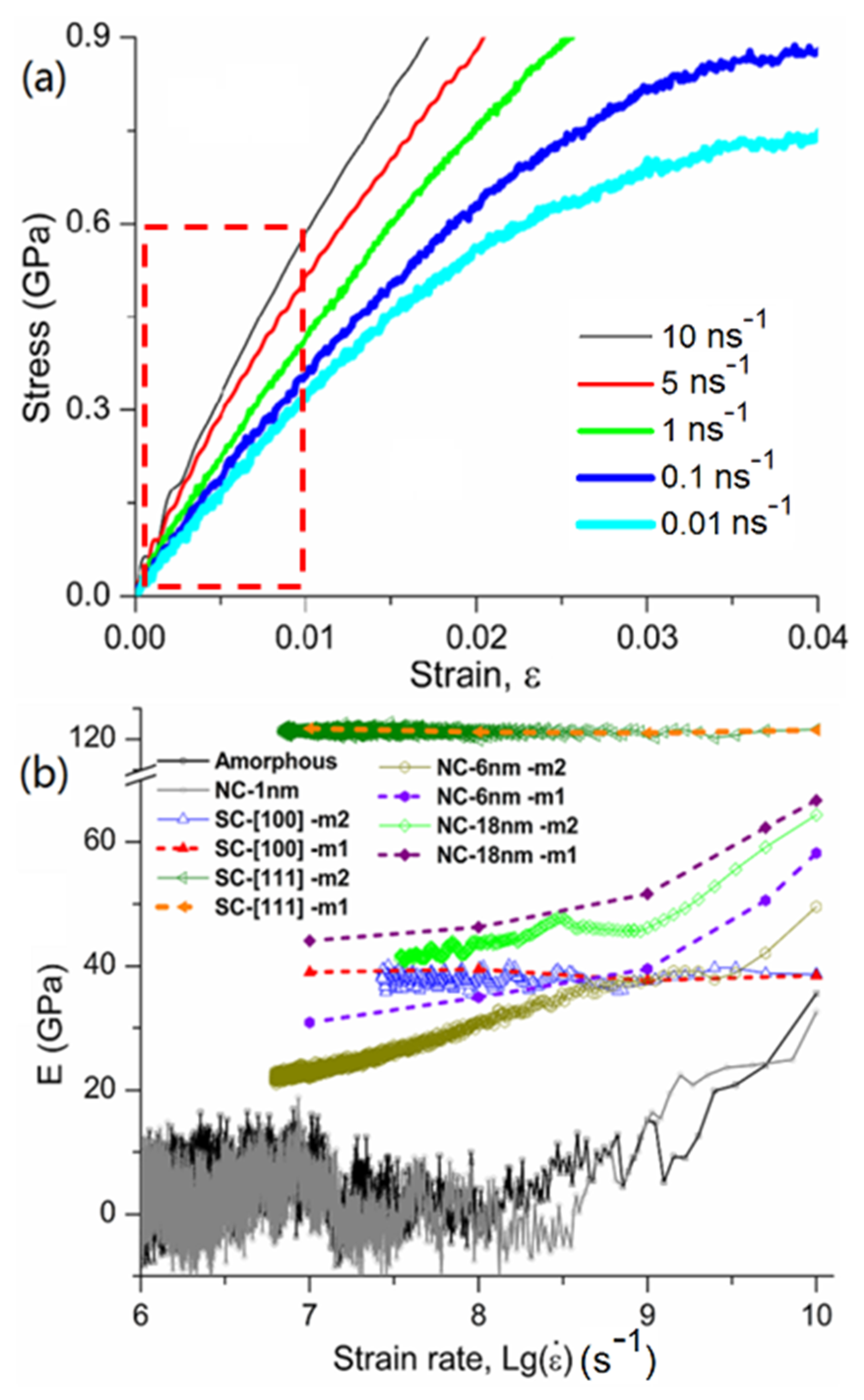

3.1. The Effect of Strain Rate on the Young’s Modulus

3.2. The Effect of Strain Rate on Flow Stress

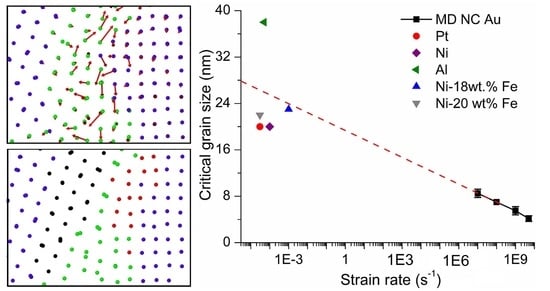

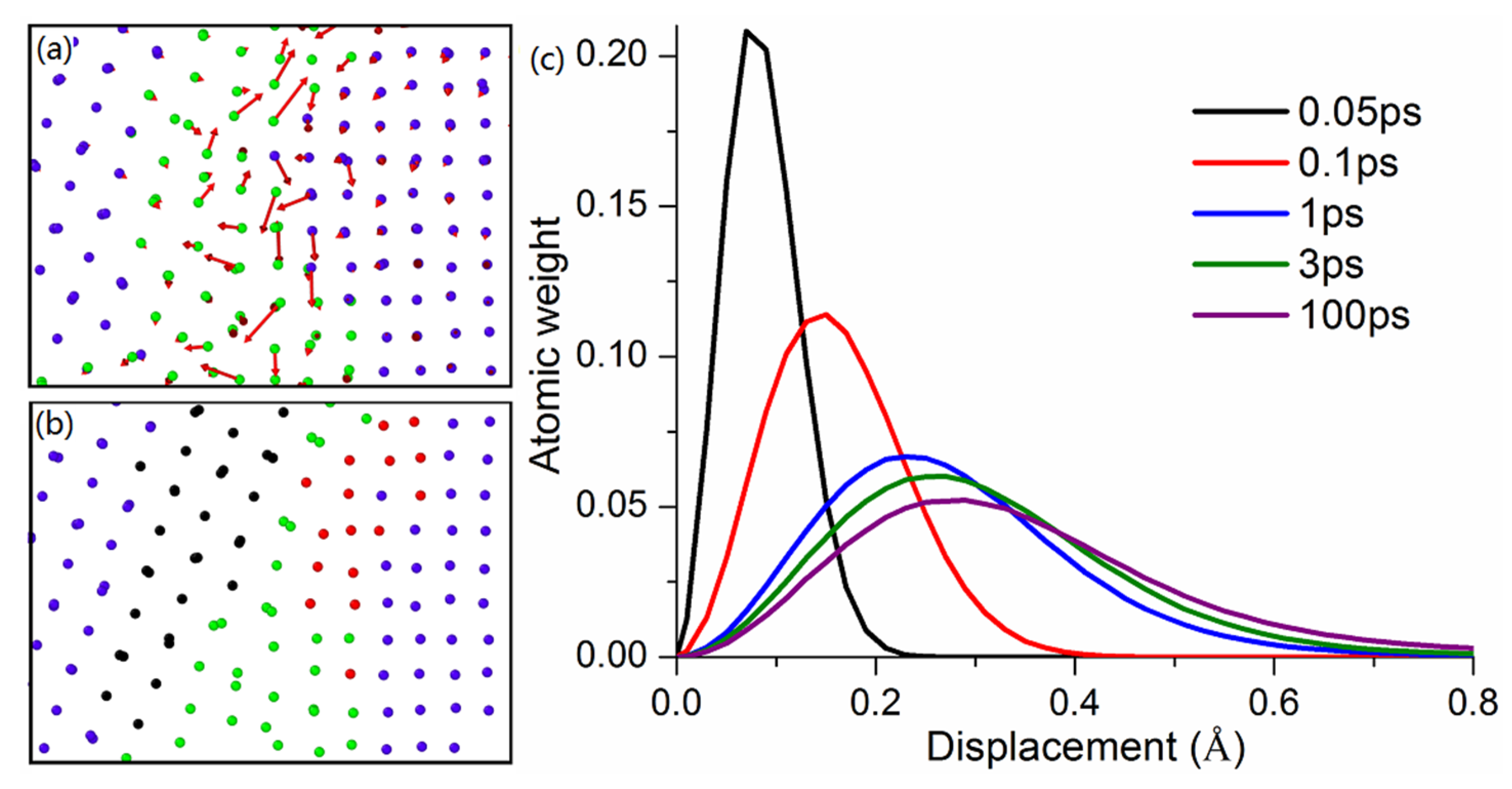

3.3. The Effect of Strain Rate on Grain Growth

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Youssef, K.M.; Scattergood, R.O.; Murty, K.L. Ultrahigh strength and high ductility of bulk nanocrystalline copper. Appl. Phys. Lett. 2005, 87, 091904. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, B.; Chu, J.; Nieh, T.G. Hardness enhancement in nanocrystalline tantalum thin films. Scr. Mater. 2006, 54, 1227–1230. [Google Scholar] [CrossRef]

- Schuh, C.A.; Nieh, T.G.; Yamasaki, T. Hall–Petch breakdown manifested in abrasive wear resistance of nanocrystalline nickel. Scr. Mater. 2002, 46, 735–740. [Google Scholar] [CrossRef]

- Pande, C.S.; Cooper, K.P. Nanomechanics of Hall–Petch relationship in nanocrystalline materials. Prog. Mater Sci. 2009, 54, 689–706. [Google Scholar] [CrossRef]

- Armstrong, R.W. 60 years of Hall-Petch: Past to present nano-scale connections. Mater. Trans. 2014, 55, 2–12. [Google Scholar] [CrossRef] [Green Version]

- Dao, M.; Lu, L.; Asaro, R.J.; Hosson, J.T.M.D.; Ma, E. Toward a quantitative understanding of mechanical behavior of nanocrystalline metals. Acta Mater. 2007, 55, 4041–4065. [Google Scholar] [CrossRef] [Green Version]

- Yamakov, V.; Wolf, D.; Phillpot, S.R.; Mukherjee, A.K.; Gleiter, H. Deformation-mechanism map for nanocrystalline metals by molecular-dynamics simulation. Nat. Mater. 2004, 3, 43–47. [Google Scholar] [CrossRef]

- Li, H.; Choo, H.; Ren, Y.; Saleh, T.A.; Lienert, U.; Liaw, P.K.; Ebrahimi, F. Strain-dependent deformation behavior in nanocrystalline metals. Phys. Rev. Lett. 2008, 101, 015502. [Google Scholar] [CrossRef] [PubMed]

- Schiøtz, J.; Jacobsen, K.W. A maximum in the strength of nanocrystalline copper. Science 2003, 301, 1357–1359. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.M.; Hamza, A.V.; Ma, E. Temperature-dependent strain rate sensitivity and activation volume of nanocrystalline Ni. Acta Mater. 2006, 54, 2715–2726. [Google Scholar] [CrossRef]

- Renk, O.; Maier-Kiener, V.; Issa, I.; Li, J.H.; Kiener, D.; Pippan, R. Anneal hardening and elevated temperature strain rate sensitivity of nanostructured metals: Their relation to intergranular dislocation accommodation. Acta Mater. 2019, 165, 409–419. [Google Scholar] [CrossRef]

- Huang, P.; Wang, F.; Xu, M.; Xu, K.W.; Lu, T.J. Dependence of strain rate sensitivity upon deformed microstructures in nanocrystalline Cu. Acta Mater. 2010, 58, 5196–5205. [Google Scholar] [CrossRef]

- Carlton, C.E.; Ferreira, P.J. What is behind the inverse Hall–Petch effect in nanocrystalline materials? Acta Mater. 2007, 55, 3749–3756. [Google Scholar] [CrossRef]

- Chen, J.; Lu, L.; Lu, K. Hardness and strain rate sensitivity of nanocrystalline Cu. Scr. Mater. 2006, 54, 1913–1918. [Google Scholar] [CrossRef]

- Schiøtz, J.; Vegge, T.; Tolla, F.D.D.; Jacobsen, K.W. Atomic-scale simulations of the mechanical deformation of nanocrystalline metals. Phys. Rev. B 1999, 60, 11971. [Google Scholar] [CrossRef] [Green Version]

- Wei, Q.; Cheng, S.; Ramesh, K.T.; Ma, E. Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: Fcc versus bcc metals. Mater. Sci. Eng. A 2004, 381, 71–79. [Google Scholar] [CrossRef]

- Asaro, R.J.; Suresh, S. Mechanistic models for the activation volume and rate sensitivity in metals with nanocrystalline grains and nano-scale twins. Acta Mater. 2005, 53, 3369–3382. [Google Scholar] [CrossRef]

- Kanel, G.I.; Zaretsky, E.B.; Razorenov, S.V.; Ashitkov, S.I.; Fortov, V.E. Unusual plasticity and strength of metals at ultra-short load durations. Phys. Uspekhi 2017, 60, 490. [Google Scholar] [CrossRef] [Green Version]

- Chen, A.Y.; Ruan, H.H.; Wang, J.; Chan, H.L.; Wang, Q.; Li, Q.; Lu, J. The influence of strain rate on the microstructure transition of 304 stainless steel. Acta Mater. 2011, 59, 3697–3709. [Google Scholar] [CrossRef]

- Jonnalagadda, K.N.; Chasiotis, I.; Yagnamurthy, S.; Lambros, J.; Pulskamp, J.; Polcawich, R.; Dubey, M. Experimental investigation of strain rate dependence of nanocrystalline Pt films. Exp. Mech. 2010, 50, 25–35. [Google Scholar] [CrossRef]

- Karanjgaokar, N.J.; Oh, C.-S.; Lambros, J.; Chasiotis, I. Inelastic deformation of nanocrystalline Au thin films as a function of temperature and strain rate. Acta Mater. 2012, 60, 5352–5361. [Google Scholar] [CrossRef]

- Lu, L.; Li, S.X.; Lu, K. An abnormal strain rate effect on tensile behavior in nanocrystalline copper. Scr. Mater. 2001, 45, 1163–1169. [Google Scholar] [CrossRef]

- Schwaiger, R.; Moser, B.; Dao, M.; Chollacoop, N.; Suresh, S. Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater. 2003, 51, 5159–5172. [Google Scholar]

- Lu, L.; Schwaiger, R.; Shan, Z.W.; Dao, M.; Lu, K.; Suresh, S. Nano-sized twins induce high rate sensitivity of flow stress in pure copper. Acta Mater. 2005, 53, 2169–2179. [Google Scholar]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rida, A.; Micoulaut, M.; Rouhaud, E.; Makke, A. Understanding the strain rate sensitivity of nanocrystalline copper using molecular dynamics simulations. Comp. Mater. Sci. 2020, 172, 109294. [Google Scholar]

- Jonnalagadda, K.; Karanjgaokar, N.; Chasiotis, I.; Chee, J.; Peroulis, D. Strain rate sensitivity of nanocrystalline Au films at room temperature. Acta Mater. 2010, 58, 4674–4684. [Google Scholar]

- Zhang, T.; Zhou, K.; Chen, Z.Q. Strain rate effect on plastic deformation of nanocrystalline copper investigated by molecular dynamics. Mater. Sci. Eng. A 2015, 648, 23–30. [Google Scholar]

- Yaghoobi, M.; Voyiadjis, G.Z. The effects of temperature and strain rate in fcc and bcc metals during extreme deformation rates. Acta Mater. 2018, 151, 1–10. [Google Scholar] [CrossRef]

- Rupert, T. Strain localization in a nanocrystalline metal: Atomic mechanisms and the effect of testing conditions. J. Appl. Phys. 2013, 114, 033527. [Google Scholar]

- Zhou, K.; Liu, B.; Yao, Y.; Zhong, K. Grain coarsening in nanocrystalline copper with very small grain size during tensile deformation. Mater. Sci. Eng. A 2014, 595, 118–123. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Foiles, S.M.; Baskes, M.I.; Daw, M.S. Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys. Rev. B 1986, 33, 7983. [Google Scholar] [CrossRef] [PubMed]

- Hirel, P. Atomsk: A tool for manipulating and converting atomic data files. Comput. Phys. Commun. 2015, 197, 212–219. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—The Open Visualization Tool. Model. Simul. Mater. Sci. Eng. 2009, 18, 015012. [Google Scholar] [CrossRef]

- Stukowski, A.; Bulato, V.V.; Arsenlis, A. Automated identification and indexing of dislocations in crystal interfaces. Model. Simul. Mater. Sci. Eng. 2012, 20, 085007. [Google Scholar] [CrossRef]

- Stukowski, A. Computational analysis methods in atomistic modeling of crystals. JOM 2014, 66, 399–407. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Zheng, W.; Singh, D.J.; Shi, Y. Nanocrystalline gold with small size: Inverse Hall–Petch between mixed regime and super-soft regime. Philos. Mag. 2020, 100, 2335–2351. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Shi, Y.; Singh, D.J.; Zheng, W. Nanopores in nanocrystalline gold. Materialia 2019, 5, 100195. [Google Scholar] [CrossRef]

- Fougere, G.E.; Riester, L.; Ferber, M.; Weertman, J.R.; Siegel, R.W. Young’s modulus of nanocrystalline Fe measured by nanoindentation. Mater. Sci. Eng. A 1995, 204, 1–6. [Google Scholar] [CrossRef]

- Sanders, P.G.; Eastman, J.A.; Weertman, J.R. Elastic and tensile behavior of nanocrystalline copper and palladium. Acta Mater. 1997, 45, 4019–4025. [Google Scholar] [CrossRef]

- Sharma, P.; Ganti, S. On the grain-size-dependent elastic modulus of nanocrystalline materials with and without grain-boundary sliding. J. Mater. Res. 2003, 18, 1823–1826. [Google Scholar] [CrossRef]

- Wang, Y.M.; Ma, E. Strain hardening, strain rate sensitivity, and ductility of nanostructured metals. Mater. Sci. Eng. A 2004, 375, 46–52. [Google Scholar] [CrossRef]

- Petegem, S.V.; Brandstetter, S.; Schmitt, B.; Swygenhoven, H.V. Creep in nanocrystalline Ni during X-ray diffraction. Scr. Mater. 2009, 60, 297–300. [Google Scholar]

- Kottada, R.S.; Chokshi, A.H. Low temperature compressive creep in electrodeposited nanocrystalline nickel. Scr. Mater. 2005, 53, 887–892. [Google Scholar] [CrossRef] [Green Version]

- Chokshi, A.H. Unusual stress and grain size dependence for creep in nanocrystalline materials. Scr. Mater. 2009, 61, 96–99. [Google Scholar] [CrossRef]

- Ma, E. Watching the nanograins roll. Science 2004, 305, 623–624. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Fan, X.; Shi, Y.; Singh, D.J.; Zheng, W. Melting of nanocrystalline gold. J. Phys. Chem. C 2018, 123, 907–914. [Google Scholar] [CrossRef]

- Rösner, H.; Markmann, J.; Weissmüller, J. Deformation twinning in nanocrystalline Pd. Philos. Mag. Lett. 2004, 84, 321–334. [Google Scholar] [CrossRef]

- Haslam, A.J.; Moldovan, D.; Yamakov, V.; Wolf, D.; Phillpot, S.R.; Gleiter, H. Stress-enhanced grain growth in a nanocrystalline material by molecular-dynamics simulation. Acta Mater. 2003, 51, 2097–2112. [Google Scholar] [CrossRef]

- Fan, G.J.; Fu, L.F.; Choo, H.; Liaw, P.K.; Browning, N.D. Uniaxial tensile plastic deformation and grain growth of bulk nanocrystalline alloys. Acta Mater. 2006, 54, 4781–4792. [Google Scholar]

- Sharon, J.A.; Su, P.-C.; Prinz, F.B.; Hemker, K.J. Stress-driven grain growth in nanocrystalline Pt thin films. Scr. Mater. 2011, 64, 25–28. [Google Scholar]

- Gianola, D.S.; Petegem, S.V.; Legros, M.; Brandstetter, S.; Swygenhoven, H.V.; Hemker, K.J. Stress-assisted discontinuous grain growth and its effect on the deformation behavior of nanocrystalline aluminum thin films. Acta Mater. 2006, 54, 2253–2263. [Google Scholar]

- Wang, Y.B.; Li, B.Q.; Sui, M.L. Deformation-induced grain rotation and growth in nanocrystalline Ni. Appl. Phys. Lett. 2008, 92, 011903. [Google Scholar]

- Wang, Y.B.; Ho, J.C.; Liao, X.Z.; Li, H.Q.; Ringer, S.P.; Zhu, Y.T. Mechanism of grain growth during severe plastic deformation of a nanocrystalline Ni–Fe alloy. Appl. Phys. Lett. 2009, 94, 011908. [Google Scholar]

- Sansoz, F.; Dupont, V. Grain growth behavior at absolute zero during nanocrystalline metal indentation. Appl. Phys. Lett. 2006, 89, 111901. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Fan, X.; Shi, Y.; Singh, D.J.; Zheng, W. The Effect of Strain Rate on the Deformation Processes of NC Gold with Small Grain Size. Crystals 2020, 10, 858. https://doi.org/10.3390/cryst10100858

Liu J, Fan X, Shi Y, Singh DJ, Zheng W. The Effect of Strain Rate on the Deformation Processes of NC Gold with Small Grain Size. Crystals. 2020; 10(10):858. https://doi.org/10.3390/cryst10100858

Chicago/Turabian StyleLiu, Jialin, Xiaofeng Fan, Yunfeng Shi, David J. Singh, and Weitao Zheng. 2020. "The Effect of Strain Rate on the Deformation Processes of NC Gold with Small Grain Size" Crystals 10, no. 10: 858. https://doi.org/10.3390/cryst10100858

APA StyleLiu, J., Fan, X., Shi, Y., Singh, D. J., & Zheng, W. (2020). The Effect of Strain Rate on the Deformation Processes of NC Gold with Small Grain Size. Crystals, 10(10), 858. https://doi.org/10.3390/cryst10100858