Evaluation of a Pilot-Scale Water Treatment System with Passive Aerated, Membraneless Microbial Fuel Cell

Abstract

1. Introduction

2. Results and Discussion

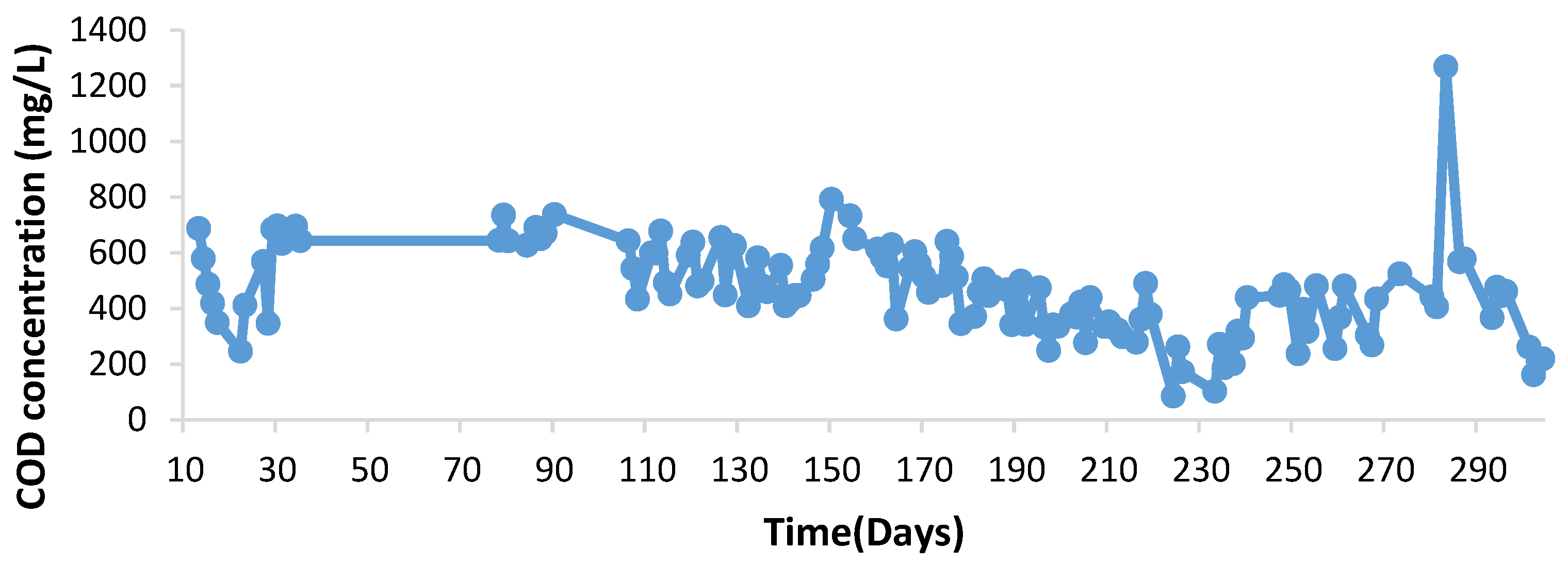

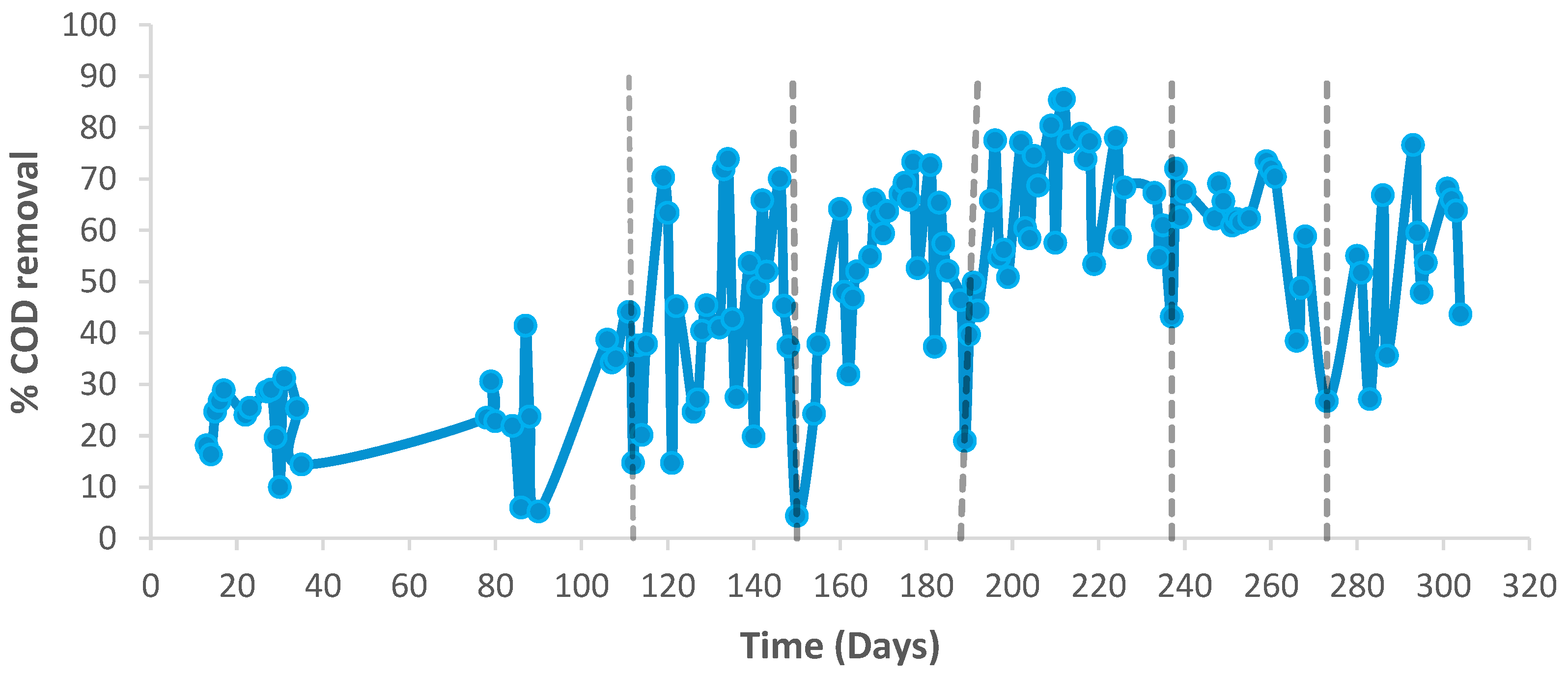

2.1. COD Removal of MFC System

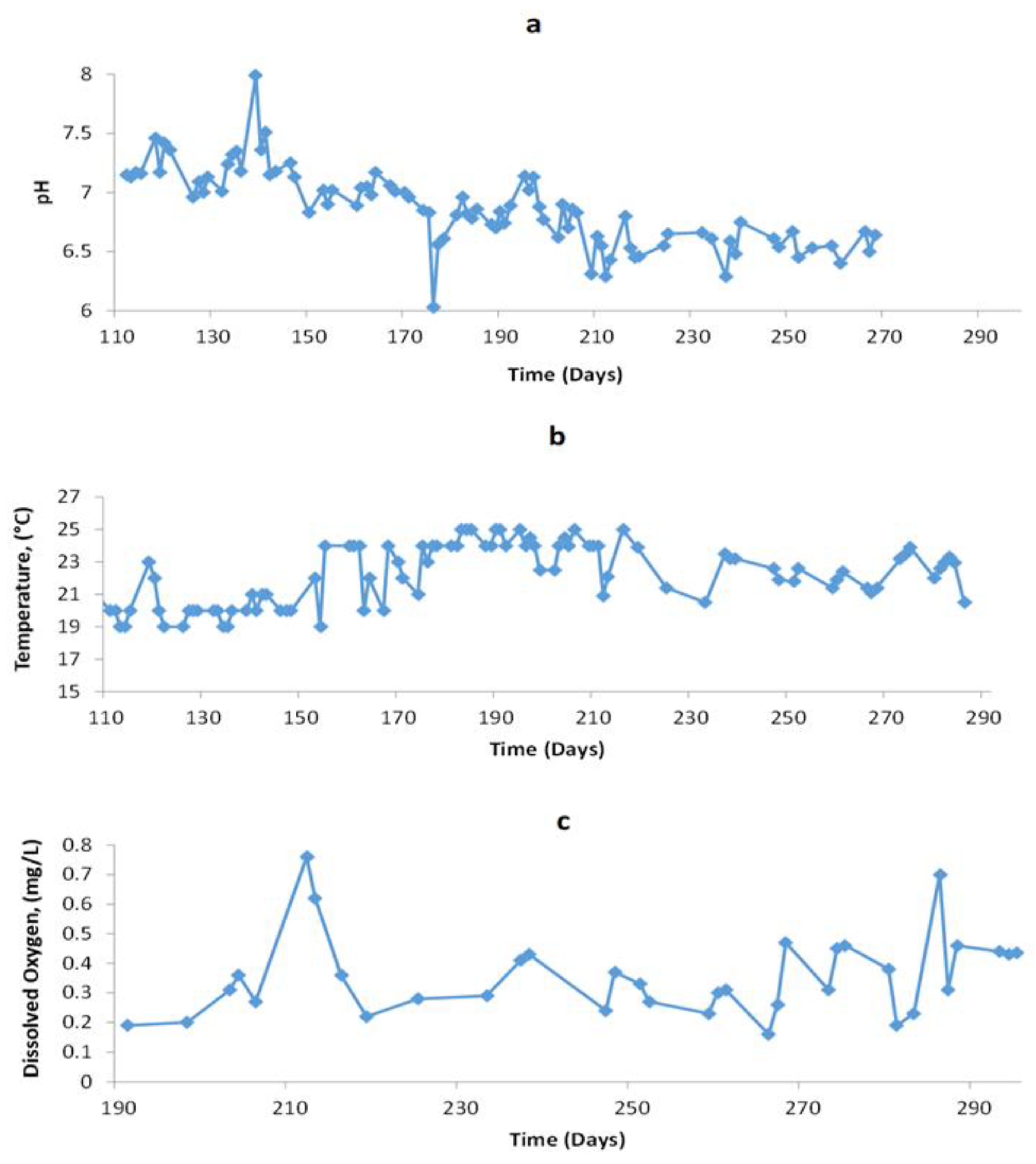

2.2. Physicochemical Parameters of the MFC System

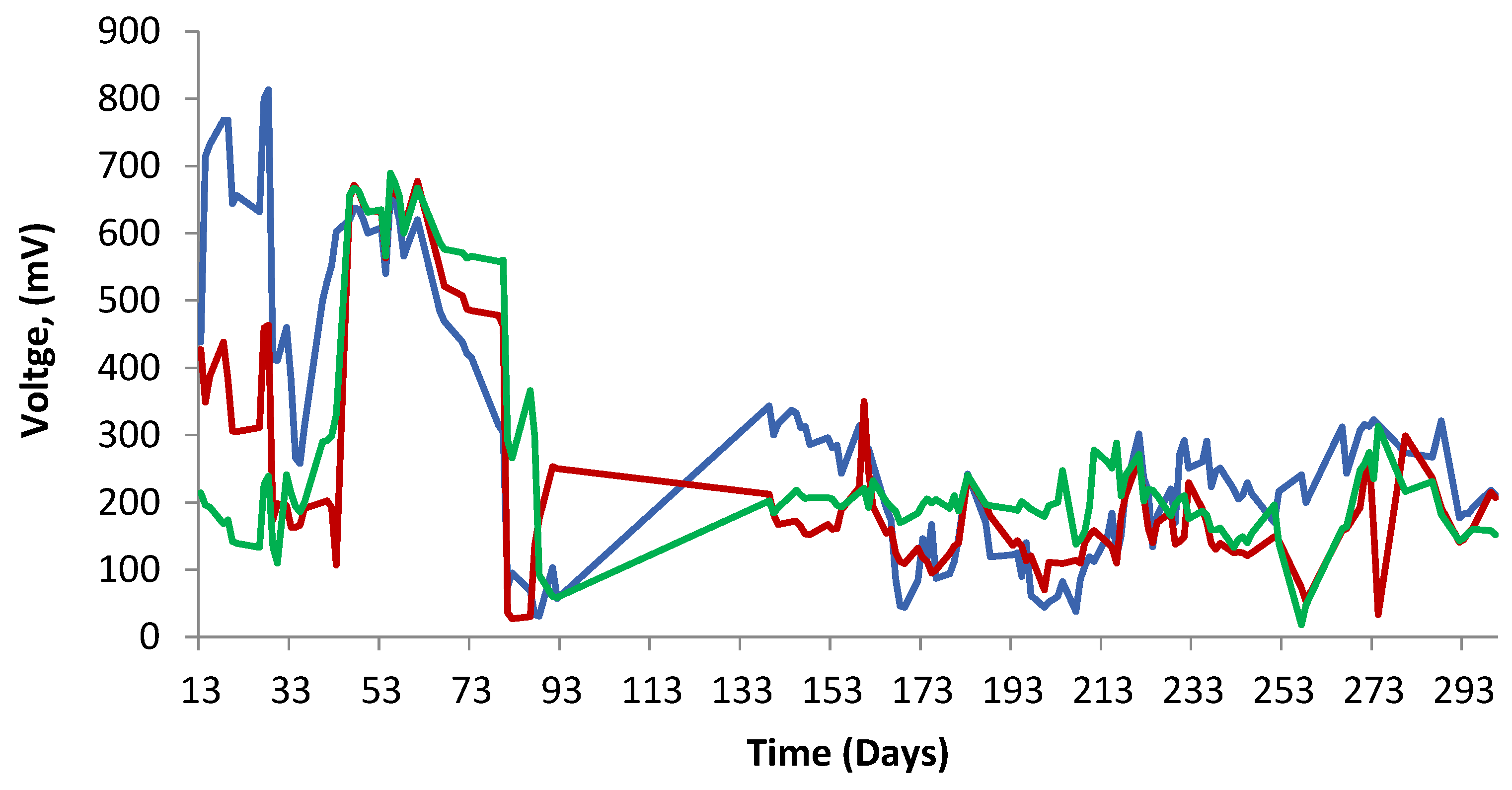

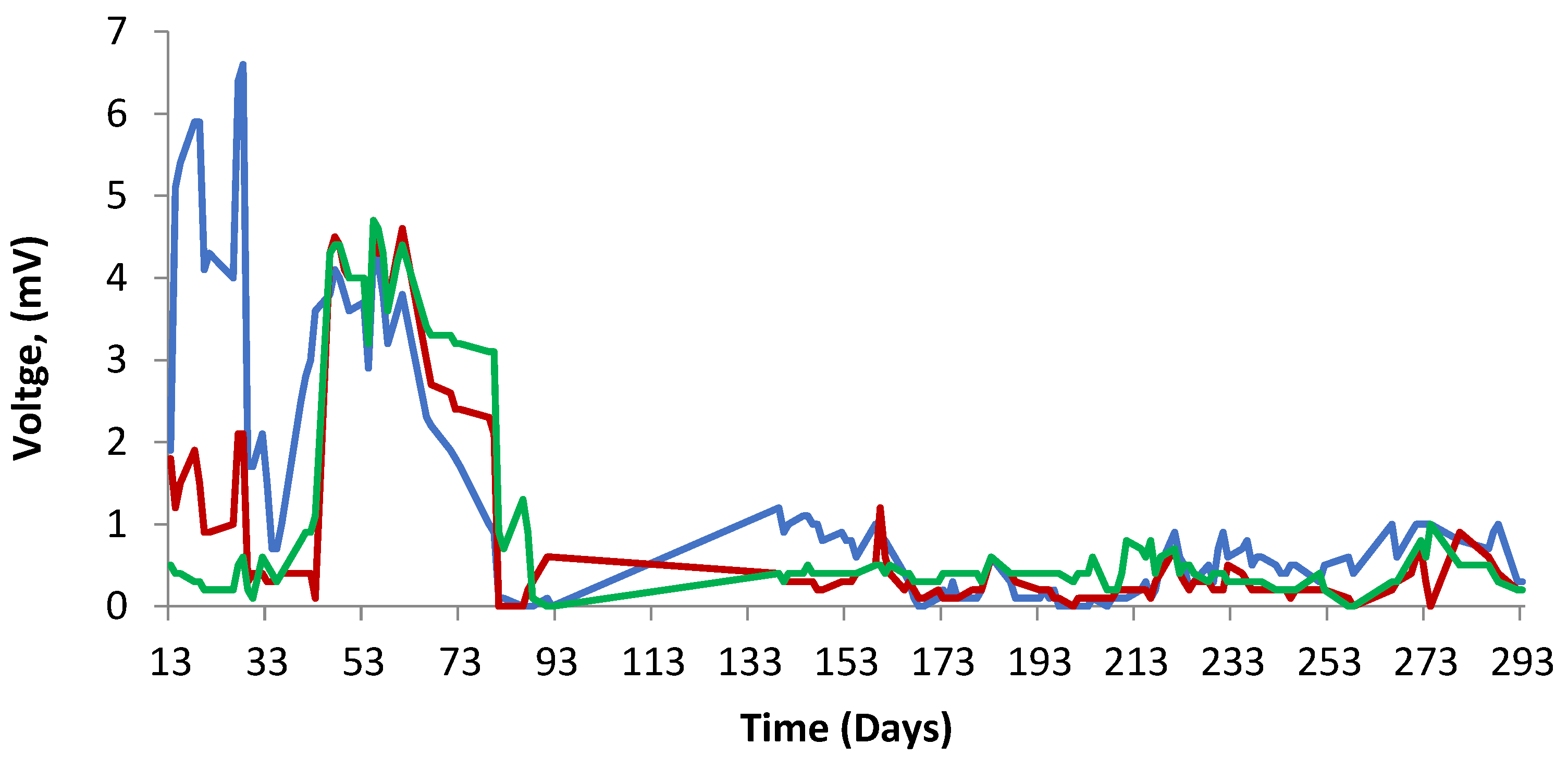

2.3. Electrical Parameters of the PAML-MFC System

3. Materials and Methods

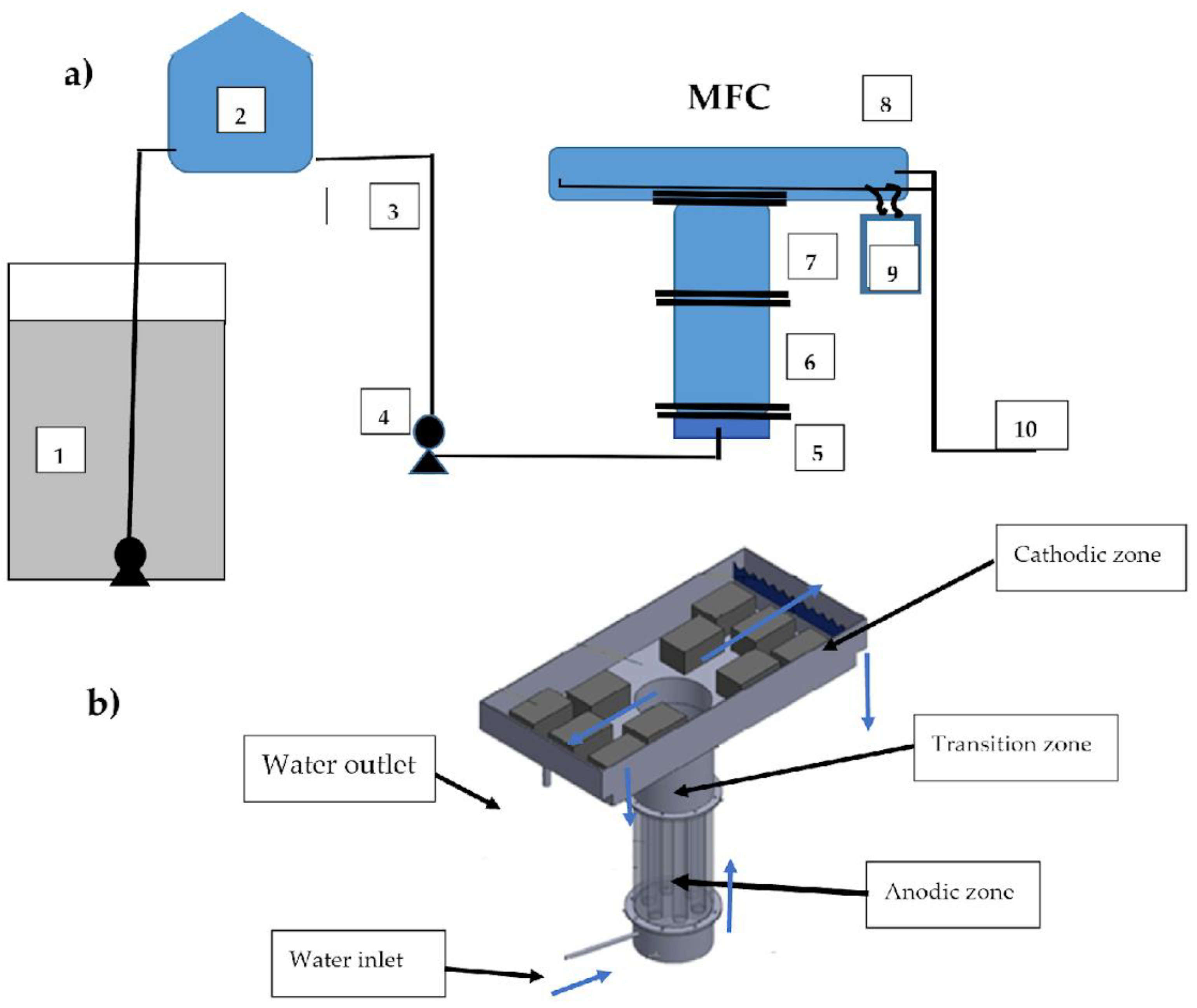

3.1. PAML-MFC

3.2. Inoculation

3.3. Analytical Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sonune, A.; Ghate, R. Developments in wastewater treatment methods. Desalination 2004, 167, 55–63. [Google Scholar] [CrossRef]

- Yoshizawa, T.; Miyahara, M.; Kouzuma, A.; Watanabe, K. Conversion of activated-sludge reactors to microbial fuel cells for wastewater treatment coupled to electricity generation. J. Biosci. Bioeng. 2014, 118, 533–539. [Google Scholar] [CrossRef]

- Gude, V.G. Wastewater treatment in microbial fuel cells—An overview. J. Clean. Prod. 2016, 122, 287–307. [Google Scholar] [CrossRef]

- Asai, Y.; Miyahara, M.; Kouzuma, A.; Watanabe, K. Comparative evaluation of wastewater-treatment microbial fuel cells in terms of organics removal, waste-sludge production, and electricity generation. Bioresour. Bioprocess. 2017, 4, 1–8. [Google Scholar] [CrossRef]

- Sarranyadhevi, D.; Shanmugasundaram, T.; Thirumalairaj, J.; Balagurunathan, R. Microbial fuel cells: An Actinobacterial Mediated Novel Approach For Power Generation. J. Appl. Microbiol. 2014, 3, 45–53. [Google Scholar]

- Du, Z.; Li, H.; Gu, T. A state of the art review on microbial fuel cells: A promising technology for wastewater treatment and bio-energy. Biotechnol. Adv. 2007, 25, 464–482. [Google Scholar] [CrossRef] [PubMed]

- Choudhury, P.; Uday, U.S.P.; Mahata, N.; Tiwari, O.N.; Ray, R.N.; Bandyopadhyay, T.K.; Bhunia, B. Performance improvement of microbial fuel cells for wastewater treatment along with value addition: A review on past achievements and recent perspectives. Renew. Sustain. Energy Rev. 2017, 79, 372–389. [Google Scholar] [CrossRef]

- Gajda, I.; Greenman, J.; Ieropoulos, I. Recent advancements in real-world microbial fuel cell applications. Curr. Opin. Electrochem. 2018, 11, 78–83. [Google Scholar] [CrossRef] [PubMed]

- Rodrigo, M.A.; Cañizares, P.; Lobato, J.; Paz, R.; Sáez, C.; Linares, J.J. Production of electricity from the treatment of urban waste water using microbial fuel cell. J. Power Sources 2007, 169, 198–204. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, J.; Shinde, S.; Wang, X.; Li, Y.; Dai, Y.; Ren, J.; Zhang, P.; Liu, X. Simultaneous wastewater treatment and energy harvesting in microbial fuel cells: An update on the biocatalyst. RSC Adv. 2020, 10, 25874–25887. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Adhami, A.; Darvari, S.; Zirepour, A.; Oh, S. Microbial fuel cell as new technology for bioelectricity generation: A review. Alexandria. Eng. J. 2015, 54, 745–756. [Google Scholar] [CrossRef]

- Sirinutsomboon, B. Modeling of a membraneless single-chamber microbial fuel cell with molasses as an energy source. Int. J. Energy Environ. Eng. 2014, 5, 1–9. [Google Scholar] [CrossRef]

- Thung, W.; Ong, S.; Ho, L.; Wong, Y.; Oon, Y.L.; Oon, Y.S.; Lehl, H. Simultaneous Wastewater Treatment and Power Generation with Innovative Design of an Upflow Membrane-Less Microbial Fuel Cell. Water Air Soil Pollut. 2015, 226, 1–7. [Google Scholar] [CrossRef]

- Jiménez, M.L.; Hernández, C.; Juárez, Z.; Zamudio, E.; Ramírez, V.; Robles, I.; Godínez, L.A.; Rodríguez-Valadez, F. Study of the Effect of Activated Carbon Cathode Configuration on the Performance of a Membrane-Less Microbial Fuel Cell. Catalysts 2020, 10, 619. [Google Scholar] [CrossRef]

- Hiegemann, H.; Herzer, D.; Nettmann, E.; Lübken, M.; Schulte, P.; Schmelz, K.G.; Gredigk-Hoffmann, S.; Wichern, M. An integrated 45 L pilot microbial fuel cell system at a full-scale wastewater treatment plant. Bioresour. Technol. 2016, 218, 115–122. [Google Scholar] [CrossRef] [PubMed]

- Valladares, R.; Domínguez-Maldonado, J.; Rodríguez-Leal, E.; Patrón, G.; Castillo-Hernández, A.; Miranda, A.; Díaz, D.; Moreno-Cervera, R.; Camara-Chale, G.; Borroto, C.; et al. Scale up of Microbial Fuel Cell Stack System for Residential Wastewater Treatment in Continuous Mode Operation. Water 2019, 11, 217. [Google Scholar] [CrossRef]

- Nakhate, P.; Patil, H.G.; Shah, V.; Salvi, T.; Marathe, K. Process validation of integrated bioelectrochemical and membrane reactor for synchronous bioenergy extraction and sustainable wastewater treatment at a semi-pilot scale. Biochem. Eng. J. 2019, 151, 107309. [Google Scholar] [CrossRef]

- Srivastava, P.; Abbassib, R.; Garaniya, V.; Lewis, T.; Yadav, A.K. Performance of pilot-scale horizontal subsurface flow constructed wetland coupled with a microbial fuel cell for treating wastewater. J. Water Process Eng. 2020, 33, 100994. [Google Scholar] [CrossRef]

- Tang, C.; Zhao, Y.; Kang, C.; Yang, Y.; Morgan, D.; Xu, L. Towards concurrent pollutants removal and high energy harvesting in a pilot-scale CW-MFC: Insight into the cathode conditions and electrodes connection. Chem. Eng. J. 2019, 373, 150–160. [Google Scholar] [CrossRef]

- Tota-Maharaj, K.; Parneet, P. Performance of pilot-scale microbial fuel cells treating wastewater with associated bioenergy production in the Caribbean context. Int. J. Energy Environ. Eng. 2015, 6, 213–220. [Google Scholar] [CrossRef]

- Vilajeliu-Pons, A.; Puig, S.; Salcedo-Dávila, I.; Balaguer, M.D.; Colprim, J. Long-term assessment of six-stacked scaled-up MFCs treating swine manure with different electrode materials. Environ. Sci. Water Res. Technol. 2017, 3, 947–959. [Google Scholar] [CrossRef]

- Wu, S.; Li, H.; Zhou, X.; Liang, P.; Zhang, X.; Jiang, Y.; Huang, X. A novel pilot-scale stacked microbial fuel cell for efficient electricity generation and wastewater treatment. Water Res. 2016, 98, 396–403. [Google Scholar] [CrossRef]

- Li, B.; Scheible, K.; Curtis, M. Electricity Generation from Anaerobic Wastewater Treatment in Microbial Fuel Cells; Water Environment Research Foundation: Alexandria, VA, USA; New York State Energy Research and Development Authority: Albany, NY, USA, 2011. [Google Scholar]

- Hsu, L.; Arias-Thodea, M.; Salvacion, M.; Benavidez, Z.; Mirhosseini, A.; Babanova, S.; Chen, S.; Bretschger, O. Demonstration of an Energy-Neutral, Off-Grid Microbial Fuel Cell System for Decentralized Wastewater Treatment. ECS Trans. 2017, 75, 19–29. [Google Scholar] [CrossRef]

- Dong, Y.; Qu, Y.; He, W.; Du, Y.; Liu, J.; Han, X. A 90-liter stackable baffled microbial fuel cell for brewery wastewater treatment based on energy self-sufficient mode. Bioresour. Technol. 2015, 195, 66–72. [Google Scholar] [CrossRef]

- Feng, Y.; He, W.; Liu, J.; Wang, X.; Qu, Y.; Ren, N. A horizontal plug flow and stackable pilot microbial fuel cell for municipal wastewater treatment. Bioresour Technol. 2014, 156, 132–138. [Google Scholar] [CrossRef]

- Liang, P.; Duan, R.; Jiang, Y.; Zhang, X.; Qiu, Y.; Huang, X. One-year operation of 1000-L modularized microbial fuel cell for municipal wastewater treatment. Water Res. 2018, 141, 1–8. [Google Scholar] [CrossRef]

- Du, F.; Li, Z.; Yang, S.; Xie, B.; Liu, H. Electricity generation directly using human feces wastewater for life support system. Acta Astronaut. 2011, 68, 1537–1547. [Google Scholar] [CrossRef]

- Rossi, R.; Hur, A.; Page, M.; O’Brien, A.; Butkiewicz, J.; Jones, D.; Baek, G.; Saikaly, P.; Cropek, D.; Logan, B. Pilot scale microbial fuel cells using air cathodes for producing electricity while treating wastewater. Water Res. 2022, 215, 118208. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, R.; Li, H.; Sun, J.; Li, M.; Qiu, Y. Enhancing microbial fuel cell performance with free-standing three-dimensional N-doped porous carbon anodes. Chem. Eng. J. 2024, 500, 156807. [Google Scholar] [CrossRef]

- Puig, S.; Serra, M.; Coma, M.; Cabré, M.; Dolors, M.; Colprim, J. Effect of pH on nutrient dynamics and electricity production using microbial fuel cells. Bioresour. Technol. 2010, 101, 9594–9599. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Dong, Y.; Li, C.; Han, X.; Liu, G.; Liu, J.; Feng, Y. Field tests of cubic-meter scale microbial electrochemical system in a municipal wastewater treatment plant. Water Res. 2019, 155, 372–380. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Chen, J.; Huang, H.; Liu, W.; Ye, Y.; Cheng, S. The effect of biofilm thickness of Geobacter sulfurreducens. Int. J. Hydrogen Energy. 2016, 41, 16523–16528. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Y.; Han, X.; Shan, Y.; Li, F.; Shi, L. Biofilm biology and engineering of Geobacter and Shewanella spp. for energy applications. Front. Bioeng. Biotechnol. 2021, 9, 786416. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Juarez, Z.A.; Ramírez, V.; Hernández-Benítez, C.; Godínez, L.A.; Gutierrez, I.R.; Rodríguez-Valadez, F.J. Evaluation of a Pilot-Scale Water Treatment System with Passive Aerated, Membraneless Microbial Fuel Cell. Catalysts 2025, 15, 765. https://doi.org/10.3390/catal15080765

Juarez ZA, Ramírez V, Hernández-Benítez C, Godínez LA, Gutierrez IR, Rodríguez-Valadez FJ. Evaluation of a Pilot-Scale Water Treatment System with Passive Aerated, Membraneless Microbial Fuel Cell. Catalysts. 2025; 15(8):765. https://doi.org/10.3390/catal15080765

Chicago/Turabian StyleJuarez, Zabdiel A., Víctor Ramírez, Carlos Hernández-Benítez, Luis A. Godínez, Irma Robles Gutierrez, and Francisco J. Rodríguez-Valadez. 2025. "Evaluation of a Pilot-Scale Water Treatment System with Passive Aerated, Membraneless Microbial Fuel Cell" Catalysts 15, no. 8: 765. https://doi.org/10.3390/catal15080765

APA StyleJuarez, Z. A., Ramírez, V., Hernández-Benítez, C., Godínez, L. A., Gutierrez, I. R., & Rodríguez-Valadez, F. J. (2025). Evaluation of a Pilot-Scale Water Treatment System with Passive Aerated, Membraneless Microbial Fuel Cell. Catalysts, 15(8), 765. https://doi.org/10.3390/catal15080765