Mechanism and Kinetic Study on Synthesis of Methacrolein Catalyzed by Amine/Acid

Abstract

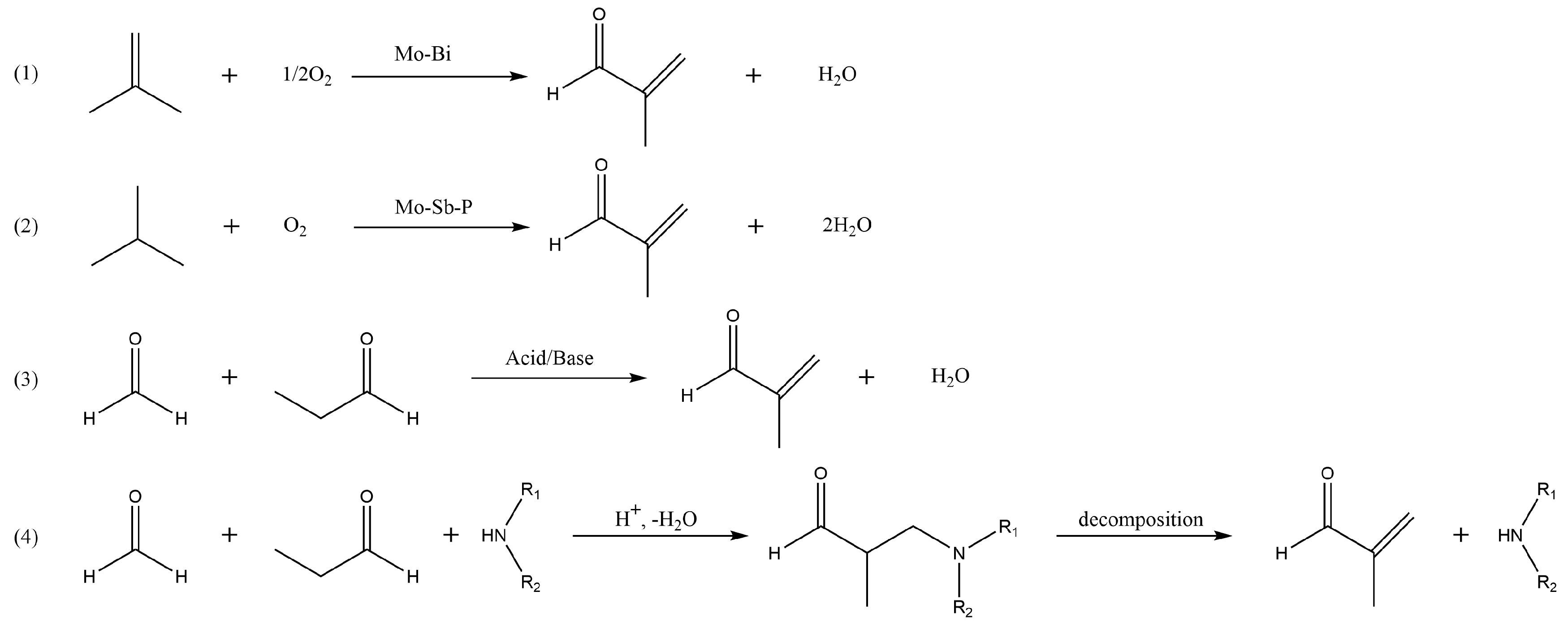

1. Introduction

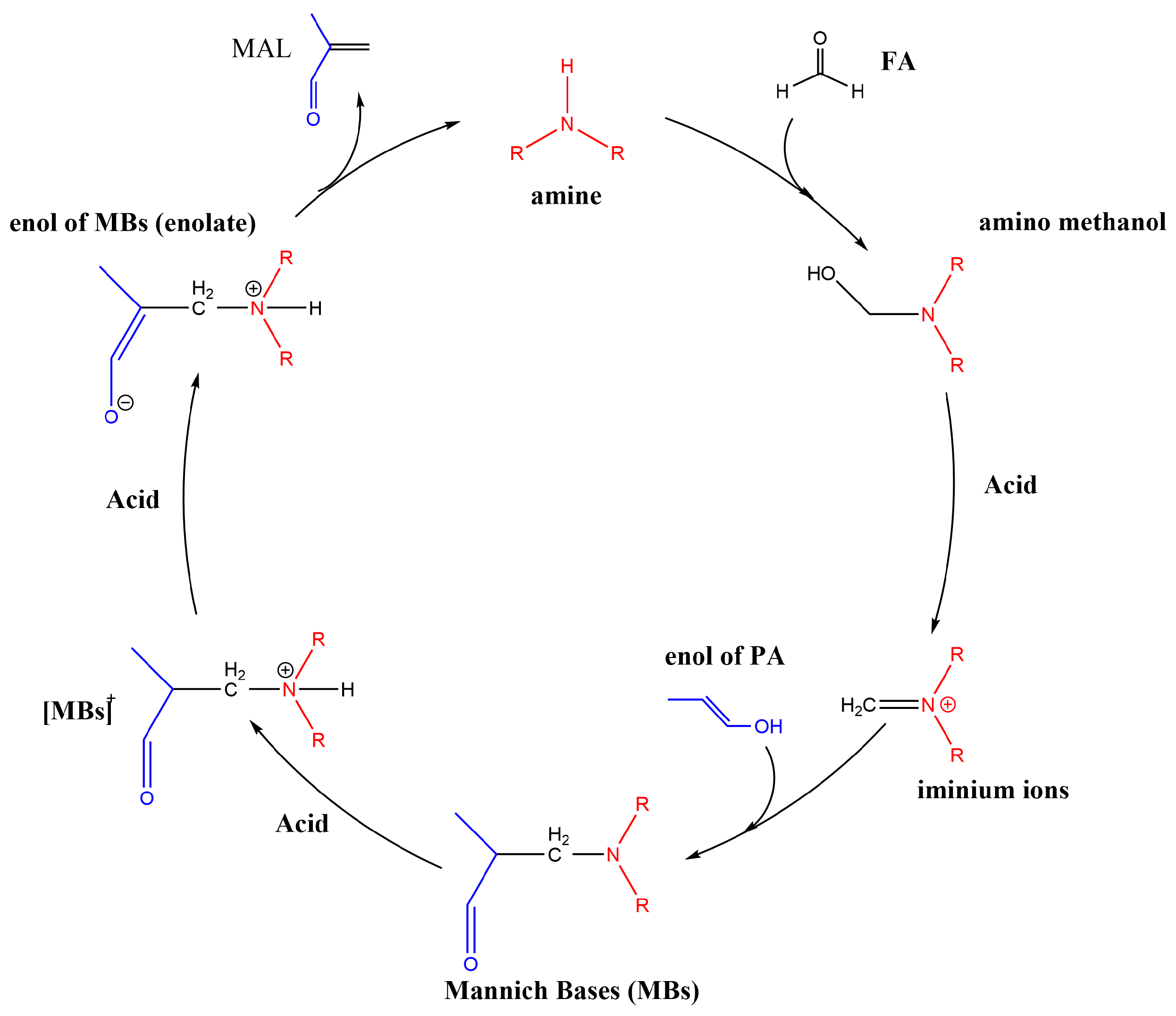

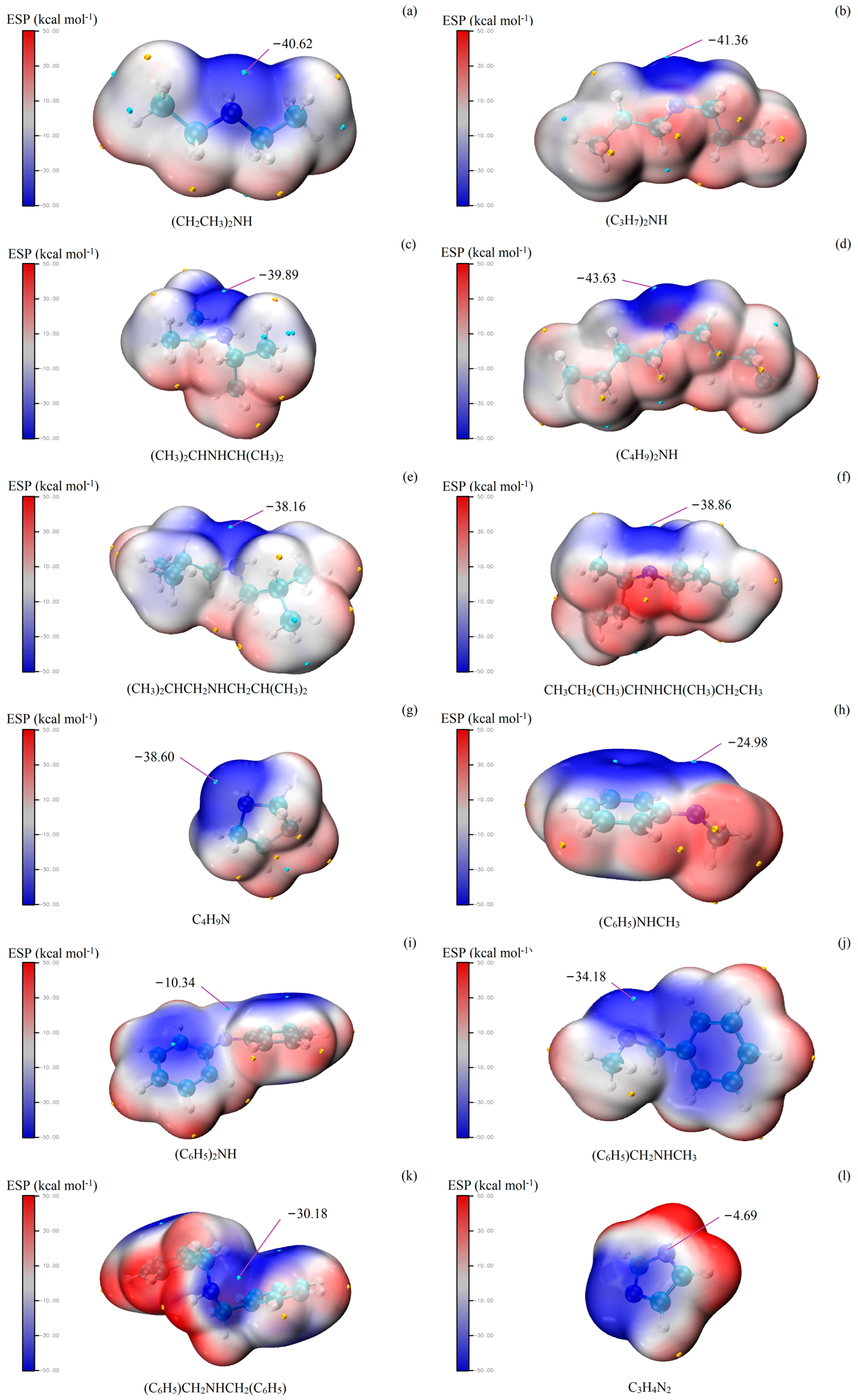

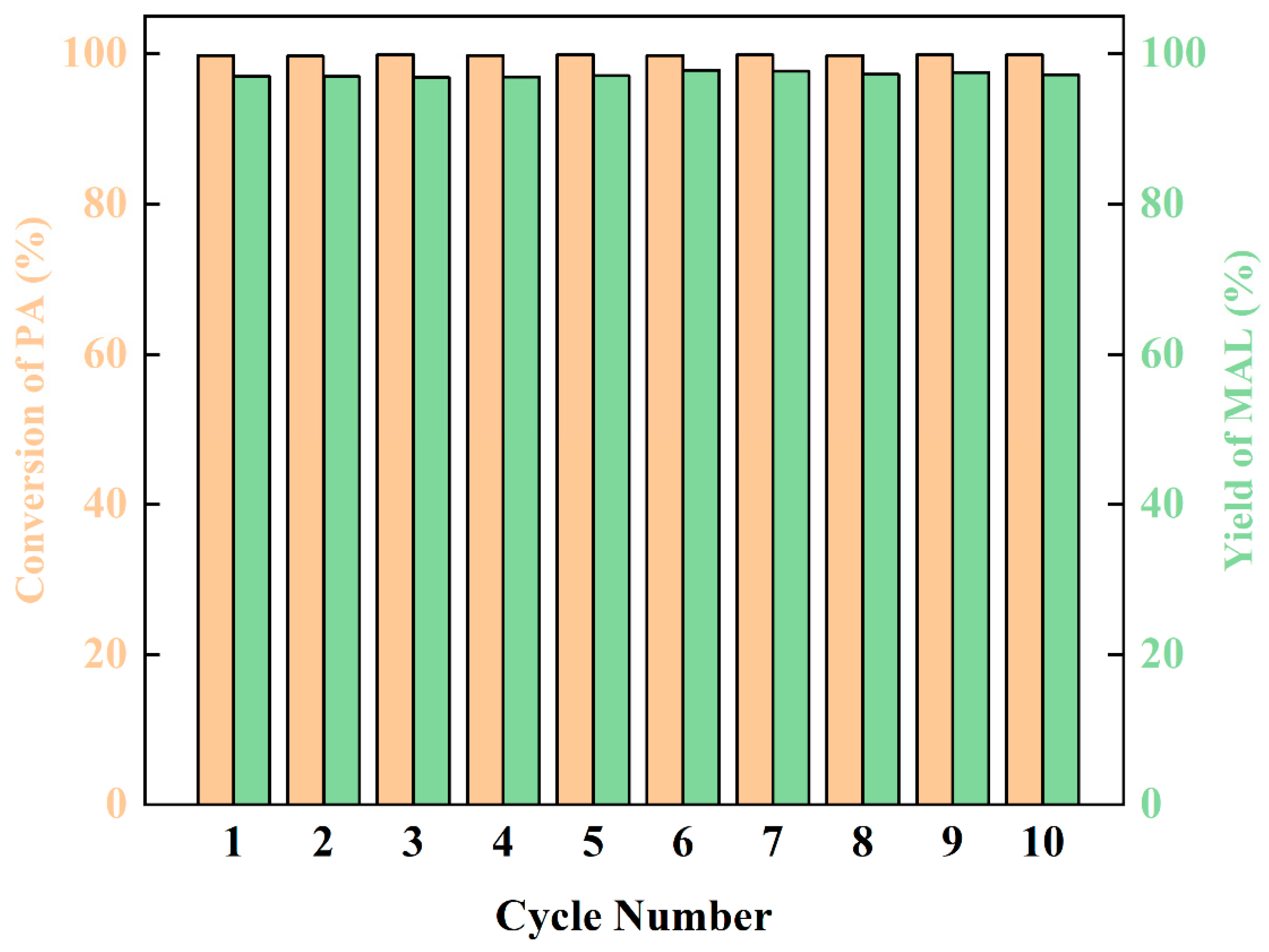

2. Results and Discussion

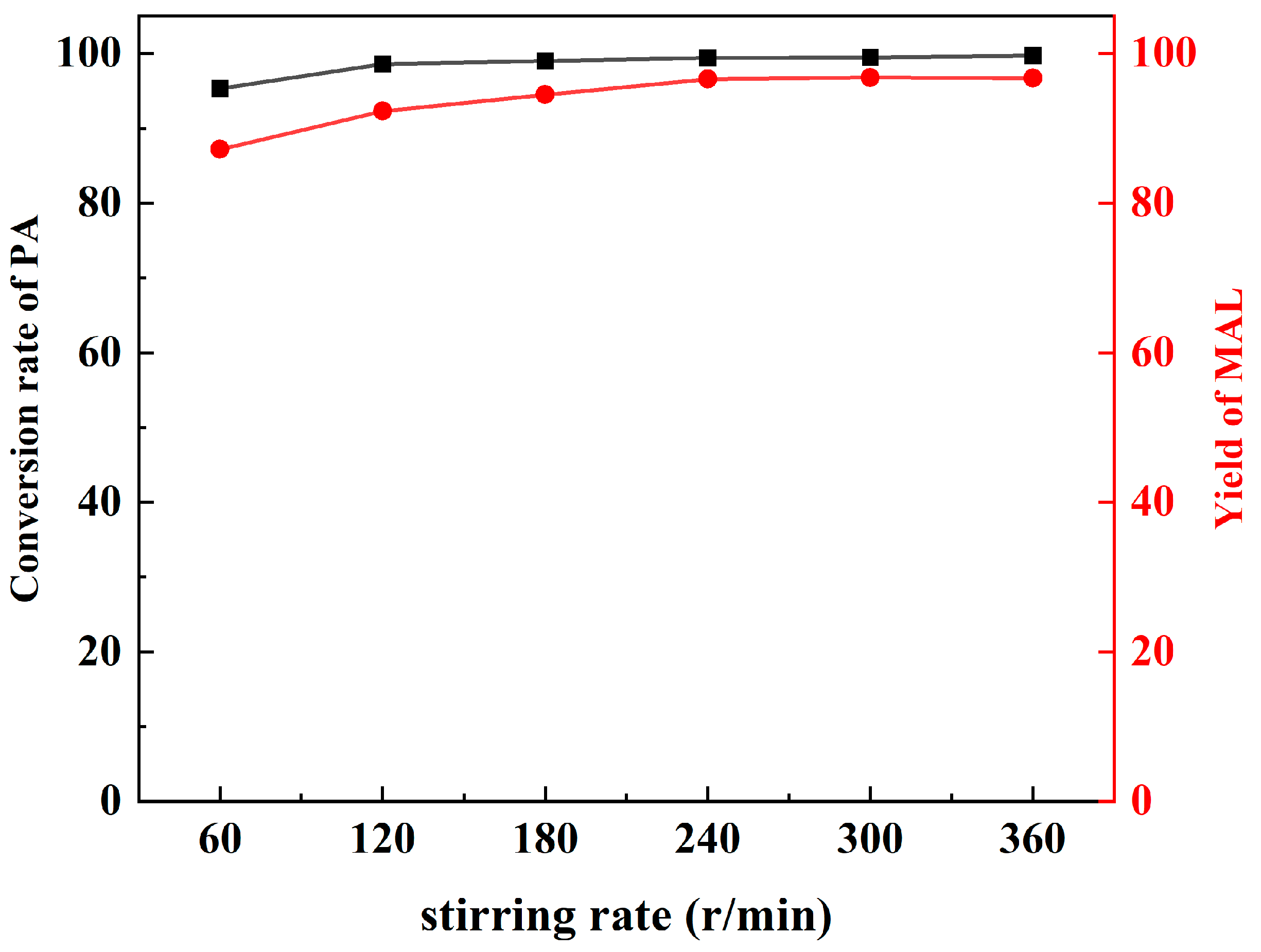

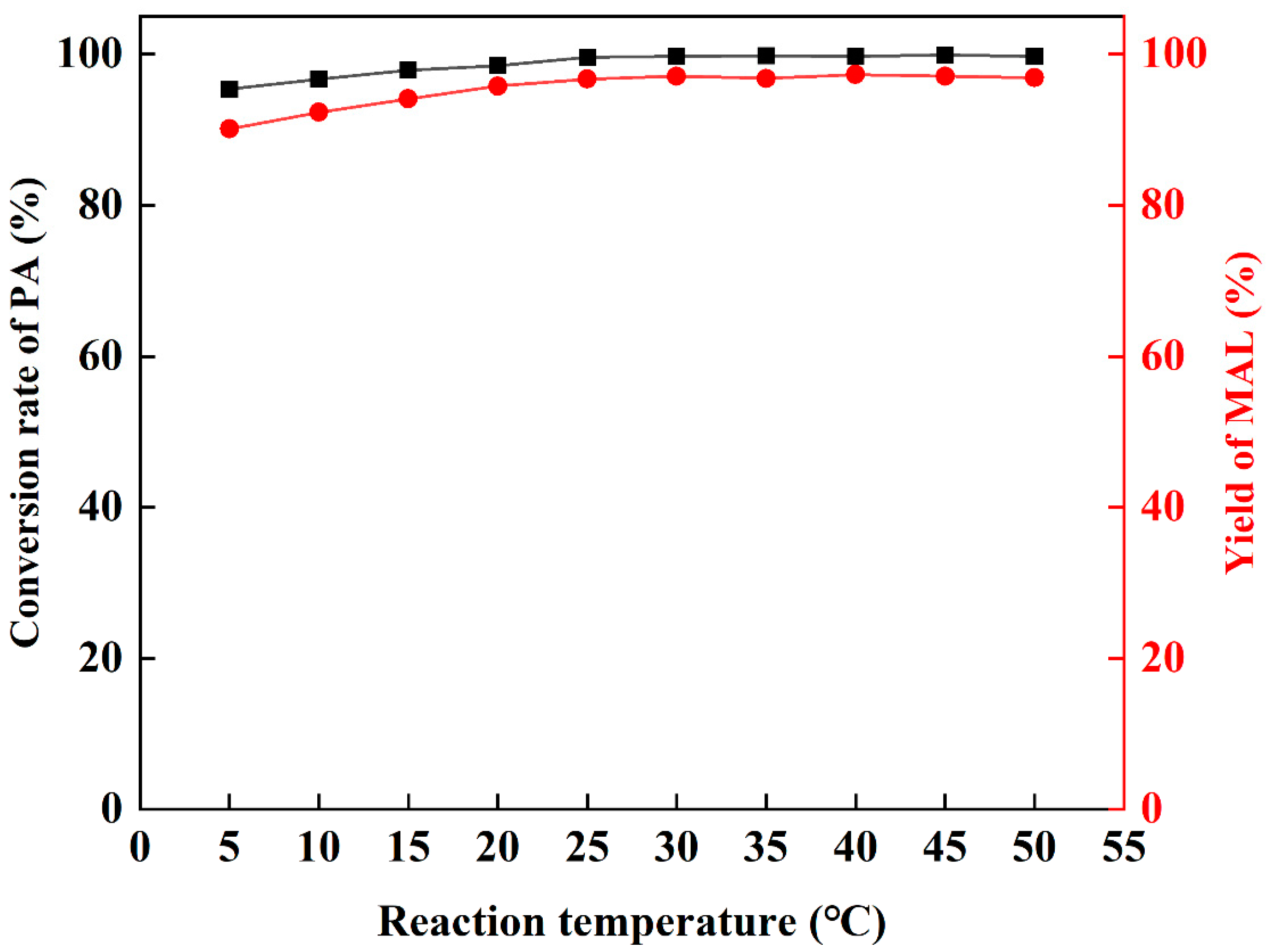

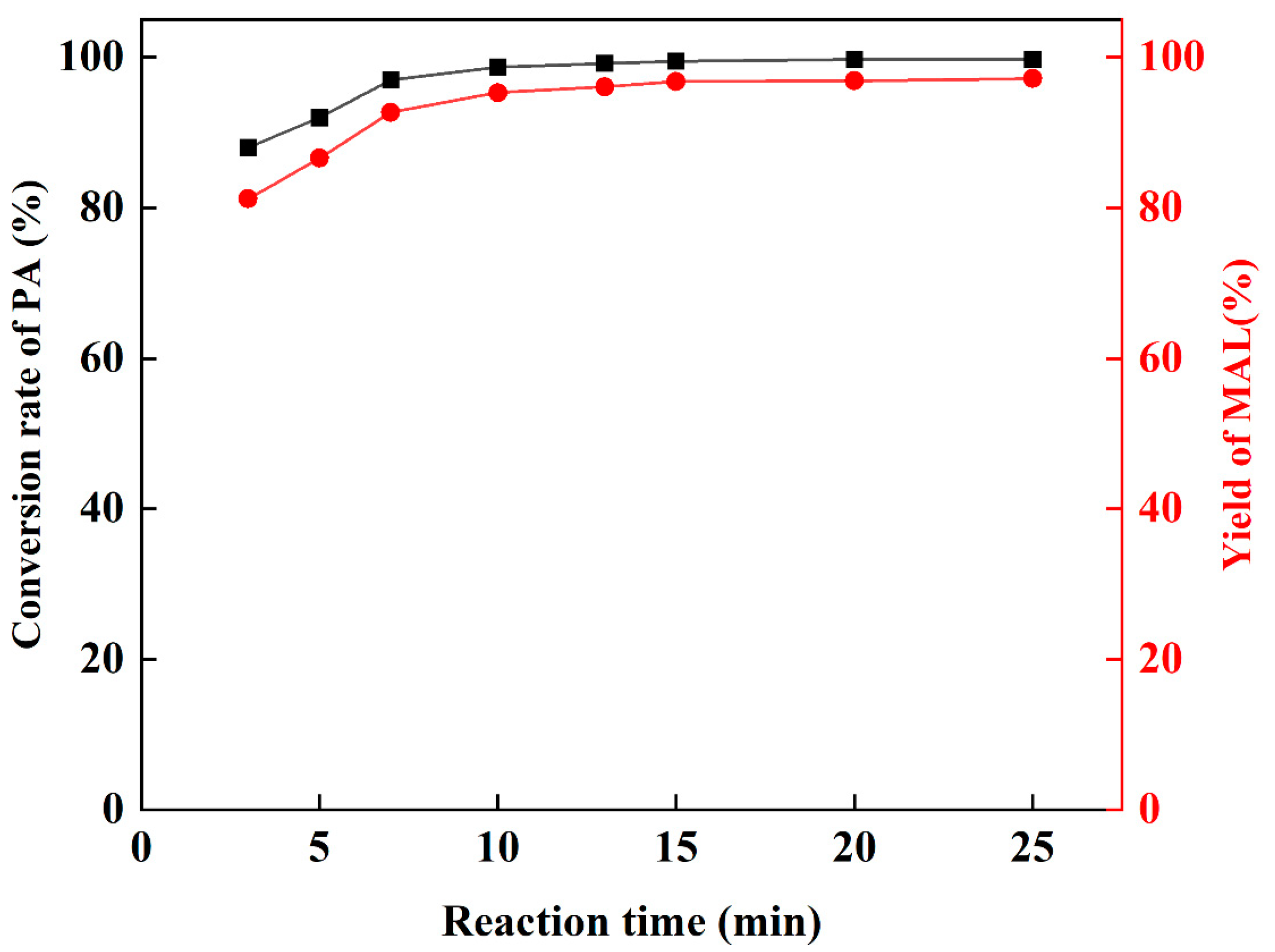

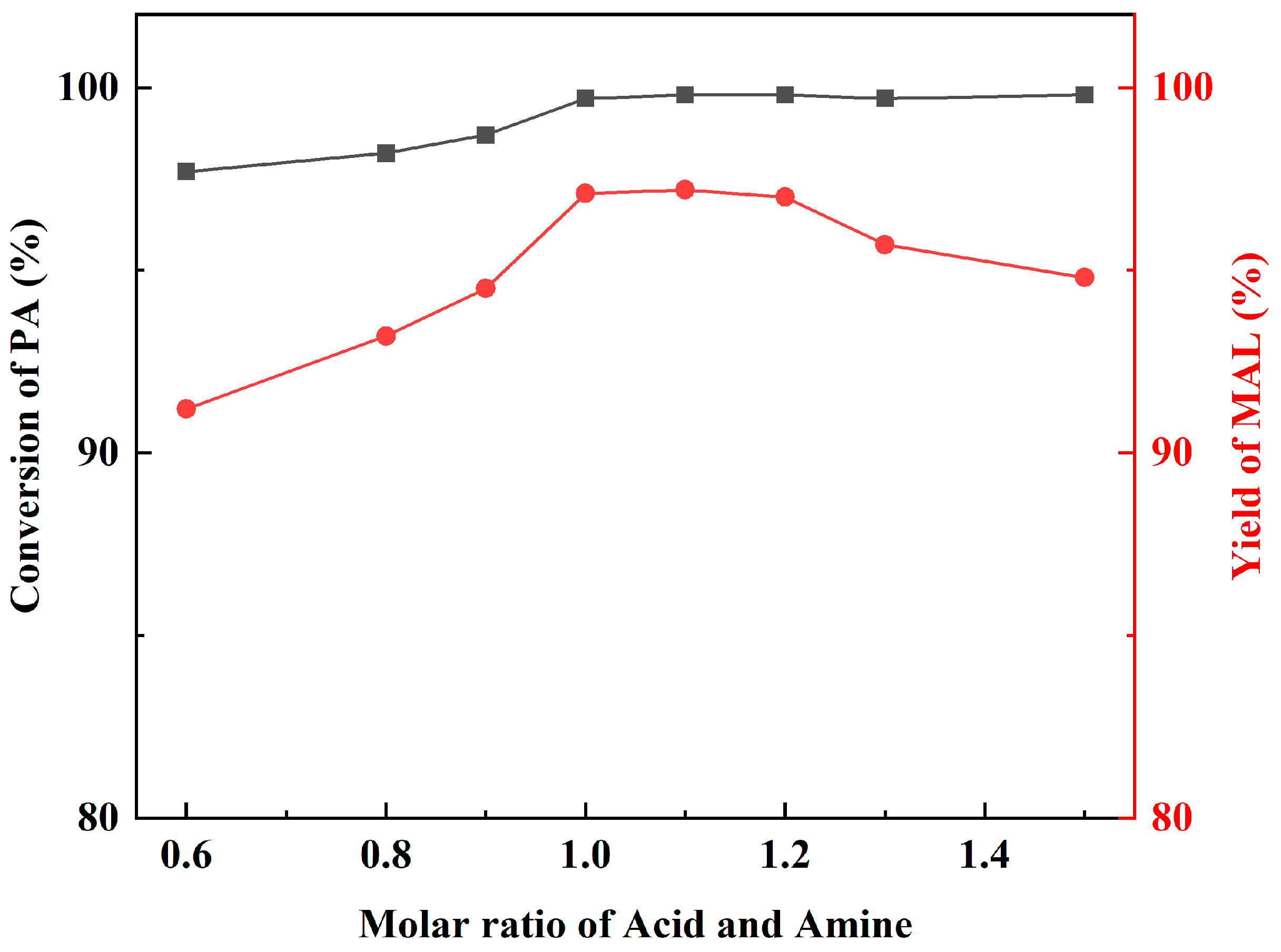

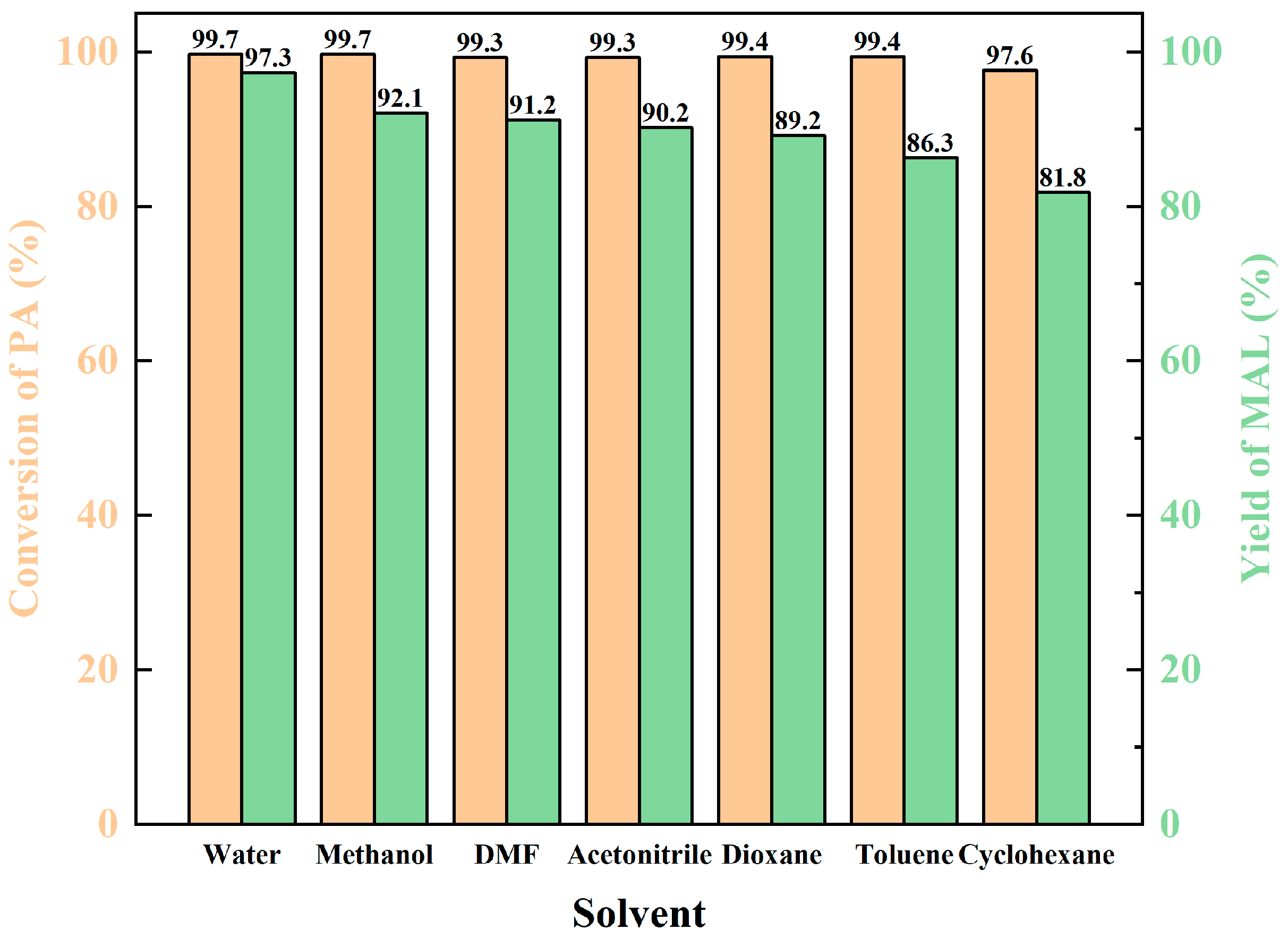

2.1. Optimization of MAL Synthesis

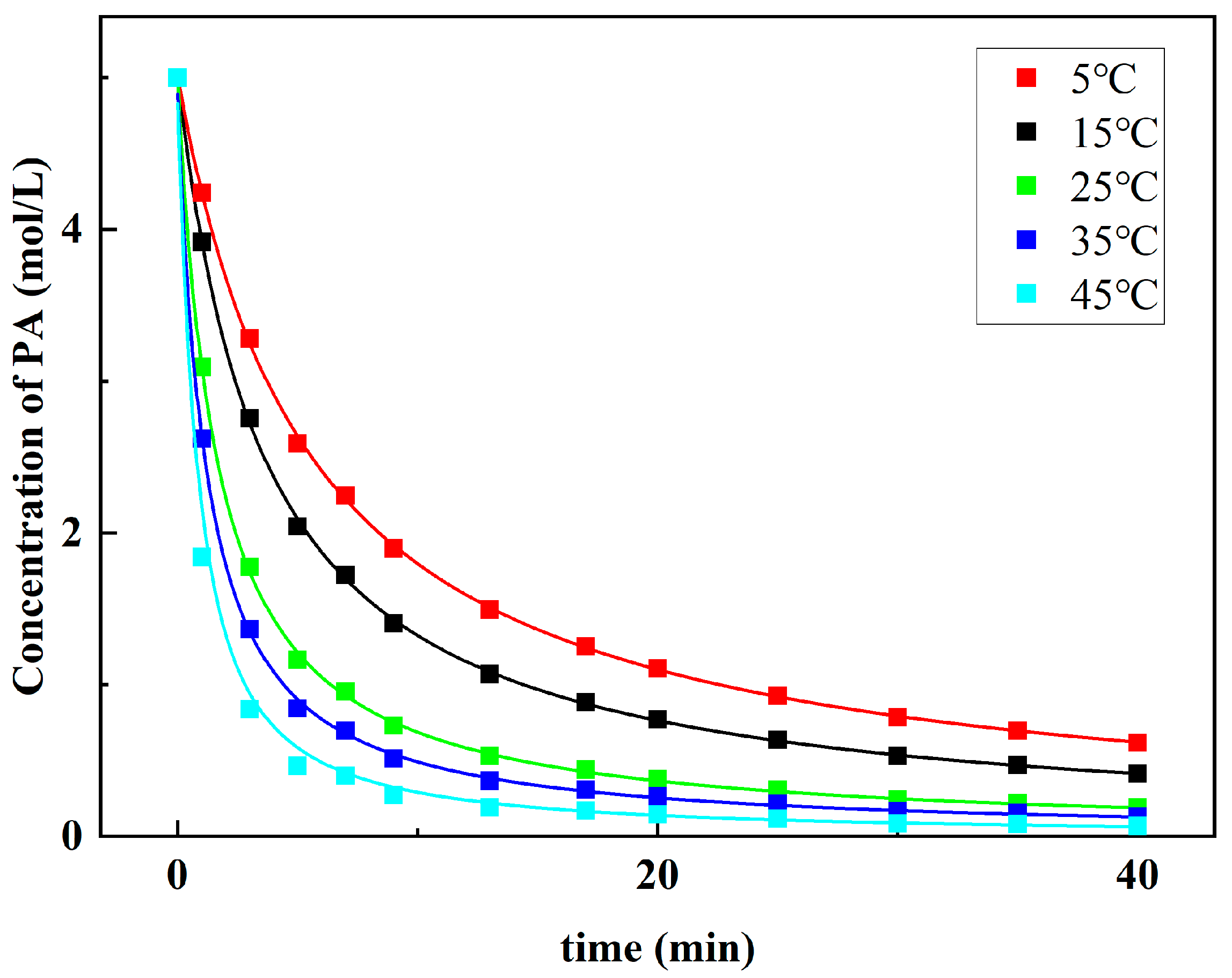

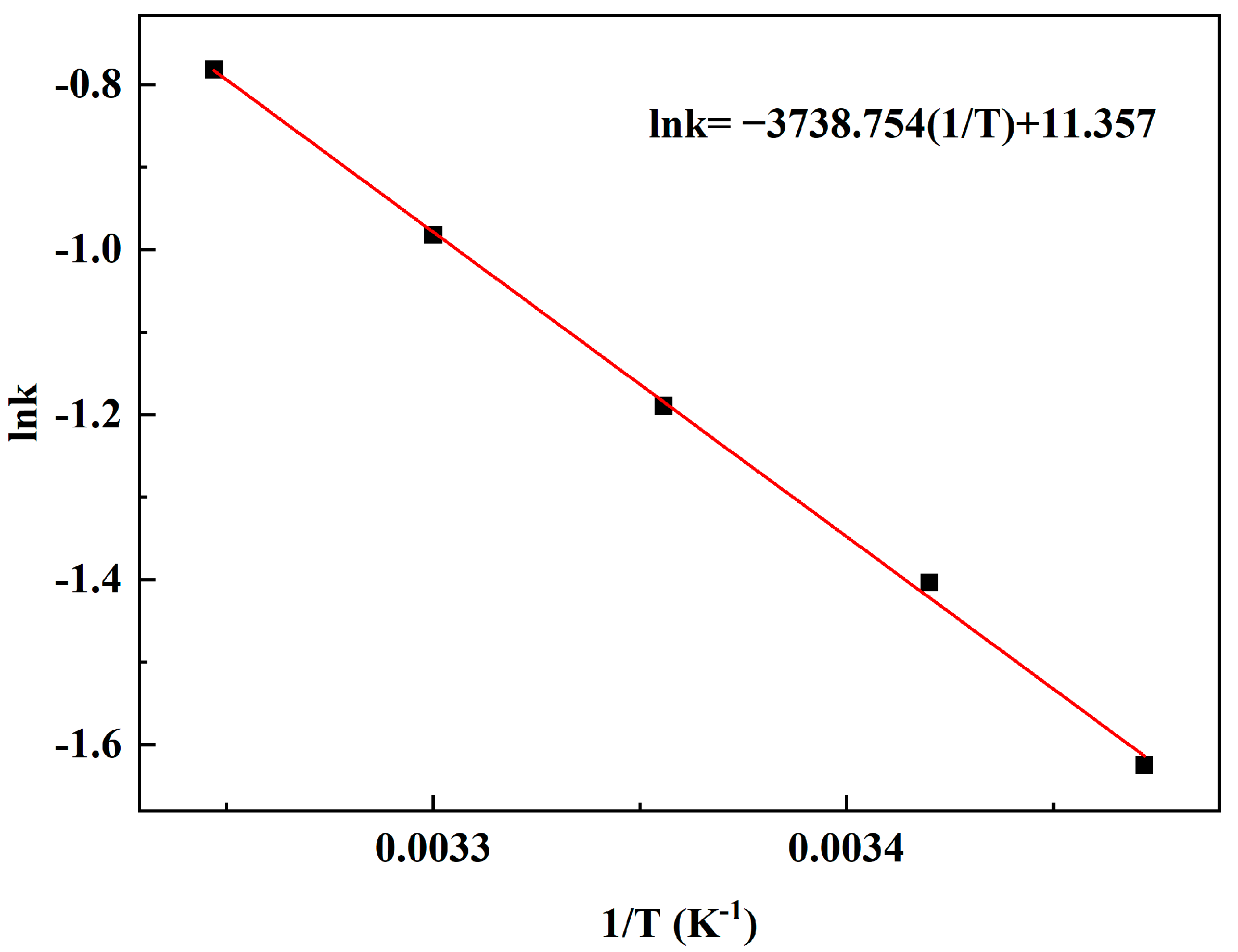

2.2. Kinetics of Synthesis of MAL from FA and PA

3. Experimental Section

3.1. Preparation of Catalyst

3.2. Synthesis of MAL

3.3. Recovery of Catalyst

3.4. Computational Details

3.5. Analysis Methods

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Smith, W.E.; Ham, G.E.; Anspon, H.D.; Gebura, S.E.; Alwani, D.W. Polylactones Derived from Polymethacrolein and StyreneMethacrolein Copolymerizations. J. Polym. Sci. Part A Polym. Chem. 1968, 6, 2001–2012. [Google Scholar] [CrossRef]

- Andreeva, I.V.; Koton, M.M.; Getmanchuk, Y.P.; Madorsikaya, L.Y.; Pokrovskii, E.I.; Koltsov, A.I. Polymerization of α-methacrolein and the structure of the polymers. J. Polym. Sci. Part C Polym. Symp. 2007, 16, 1409–1421. [Google Scholar] [CrossRef]

- Kumar, P.; Hegde, V.R.; Kumar, T.P. An Efficient Synthesis of Diacetates from Aldehydes Using Beta Zeolite. Tetrahedron Lett. 1995, 36, 601–602. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, H.; Jing, X.; Zhu, J. Solvent free catalytic synthesis of 2-methylallylidene diacetate using cation-exchange resin. Catal. Commun. 2010, 11, 753–757. [Google Scholar] [CrossRef]

- Diao, Y.; Yang, P.; Yan, R.; Jiang, L.; Wang, L.; Zhang, H.; Li, C.; Li, Z.; Zhang, S. Deactivation and regeneration of the supported bimetallic Pd–Pb catalyst in direct oxidative esterification of methacrolein with methanol. Appl. Catal. B Environ. 2013, 142–143, 329–336. [Google Scholar] [CrossRef]

- Yan, R.; Li, Z.; Diao, Y.; Fu, C.; Wang, H.; Li, C.; Chen, Q.; Zhang, X.; Zhang, S. Green process for methacrolein separation with ionic liquids in the production of methyl methacrylate. AlChE J. 2011, 57, 2388–2396. [Google Scholar] [CrossRef]

- Muller, A.H.E.; Roos, S.G.; Maryjaszewski, K. Copolymerization of N-butyl acrylate with methyl methacrylate and PMMA macromonomers: Comparison of reactivity ratios in conventional and atom transfer radical copolymerization. Polym. Prepr. 1999, 40, 352–353. [Google Scholar]

- Qi, M.; Wu, X.; Wang, L.; Song, Y.; Diao, Y. The effect of the bimetallic Pd-Pb structures on direct oxidative esterification of methacrolein with methanol. Mol. Catal. 2021, 510, 111714. [Google Scholar] [CrossRef]

- Gao, J.; Fan, G.; Yang, L.; Cao, X.; Zhang, P.; Li, F. Oxidative Esterification of Methacrolein to Methyl Methacrylate over Gold Nanoparticles on Hydroxyapatite. ChemCatChem 2017, 9, 1230–1241. [Google Scholar] [CrossRef]

- Wang, B.; Li, H.; Zhu, J.; Sun, W.; Chen, S. Preparation and characterization of mono-/multi-metallic hydrophobic catalysts for the oxidative esterification of methacrolein to methyl methacrylate. J. Mol. Catal. A Chem. 2013, 379, 322–326. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, Y.; Wang, L.; Fu, Z. Oxidative Esterification of Methacrolein to Methyl Methacrylate over Supported Gold Catalysts Prepared by Colloid Deposition. ChemCatChem 2017, 9, 1960–1968. [Google Scholar] [CrossRef]

- Song, N.; Rhodes, C.; Bartley, J.; Taylor, S.; Chadwick, D.; Hutchings, G. Oxidation of isobutene to methacrolein using bismuth molybdate catalysts: Comparison of operation in periodic and continuous feed mode. J. Catal. 2005, 236, 282–291. [Google Scholar] [CrossRef]

- Mascarenhas, C.M.; Miller, S.P.; White, P.S.; Morken, J.P. First Catalytic Asymmetric Aldol-Tishchenko Reaction-Insight into the Catalyst Structure and Reaction Mechanism. Angew. Chem. Int. Ed. 2001, 40, 601–603. [Google Scholar] [CrossRef]

- Saito, S.; Yamamoto, H. Reaction kinetics for preparation of methacrolein by condensation of formaldehyde with propionaldehyde. Acc. Chem. Res. 2004, 37, 570–579. [Google Scholar] [CrossRef]

- Mironov, G.S.; Farberov, M.I. Commercial methods of synthesis of α, β-unsaturated aldehydes and ketones. Russ. Chem. Rev. 1964, 33, 649–663. [Google Scholar] [CrossRef]

- Dashko, L.V.; Dmitriev, D.V.; Pestov, S.M.; Flid, V.R. Cross aldol condensation of acetaldehyde and formaldehyde in the presence of bifunctional systems. Russ. J. Org. Chem. 2015, 50, 1732–1737. [Google Scholar] [CrossRef]

- Wang, G.; Li, Z.; Fan, L.; Li, C.; Zhang, S. Sec-amine grafted D301 resin catalyzed fixed-bed process for continuous preparation of methacrolein via mannich reaction. Chem. Eng. J. 2019, 370, 625–636. [Google Scholar] [CrossRef]

- Pyo, S.-H.; Hedström, M.; Lundmark, S.; Rehnberg, N.; Hatti-Kaul, R. Self- and Cross-Aldol Condensation of Propanal Catalyzed by Anion-Exchange Resins in Aqueous Media. Org. Process Res. Dev. 2011, 15, 631–637. [Google Scholar] [CrossRef]

- Erkkilä, A.; Pihko, P.M. Rapid Organocatalytic Aldehyde-Aldehyde Condensation Reactions. Eur. J. Org. Chem. 2007, 2007, 4205–4216. [Google Scholar] [CrossRef]

- Erkkilä, A.; Pihko, P.M. Mild Organocatalytic r-Methylenation of Aldehydes. J. Org. Chem. 2006, 71, 2538–2541. [Google Scholar] [CrossRef]

- Li, Y.C.; Yan, R.Y.; Wang, L.; Liu, L.; Liu, D.; Zhang, H.; Diao, Y.Y.; Li, Z.X.; Zhang, S.J. Synthesis of Methacrolein by Condensation of Propionaldehyde with Formaldehyde. Adv. Mater. Res. 2011, 396–398, 1094–1097. [Google Scholar]

- He, J.; Xue, Y.; Han, B.; Zhang, C.; Wang, Y.; Zhu, S. Nickel-Catalyzed Asymmetric Reductive 1,2-Carboamination of Unactivated Alkenes. Angew. Chem. Int. Ed. Engl. 2020, 59, 2328–2332. [Google Scholar] [CrossRef] [PubMed]

- Sabatini, M.T.; Boulton, L.T.; Sneddon, H.F.; Sheppard, T.D. A green chemistry perspective on catalytic amide bond formation. Nat. Catal. 2019, 2, 10–17. [Google Scholar] [CrossRef]

- Sun, B.; Pluta, R.; Kumagai, N.; Shibasaki, M. Direct Catalytic Asymmetric mannich-Type Reaction en Route to alpha-Hydroxy-beta-amino Acid Derivatives. Org. Lett. 2018, 20, 526–529. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Xu, Y.; Zhang, S.; Li, Z.; Li, C. An ionic liquid catalyzed probase method for one-pot synthesis of α,β-unsaturated esters from esters and aldehydes under mild conditions. Green Chem. 2017, 19, 4838–4848. [Google Scholar] [CrossRef]

- Chang, Q.; Zhou, J.; Gan, L.-H. Theoretical study on the mechanisms of Proline-catalyzed mannich reaction between acetaldehyde and N-Boc imines. J. Phys. Org. Chem. 2012, 25, 667–673. [Google Scholar] [CrossRef]

- Li, Y.M.; Xiao, H.M. Studies on the Mechanism of mannich Reaction Involving Iminium Salt as Potential mannich Reagent. 111. Furan as Pseudo Acid Component. Int. J. Quantum Chem. 1995, 54, 293–297. [Google Scholar] [CrossRef]

- Pierce, M.D.; Johnston, R.C.; Mahapatra, S.; Yang, H.; Carter, R.G.; Ha-Yeon Cheong, P. Mechanism and stereoselectivity of a dual amino-catalyzed robinson annulation: Rare duumvirate stereocontrol. J. Am. Chem. Soc. 2012, 134, 13624–13631. [Google Scholar] [CrossRef]

- Yamashita, Y.; Suzuki, H.; Kobayashi, S. Development of strong Bronsted base catalysis: Catalytic direct-type mannich reactions of non-activated esters via a product-base mechanism. Org. Biomol. Chem. 2012, 10, 5750–5752. [Google Scholar] [CrossRef]

- Zhang, S.; Ran, Q.; Gu, Y. Polymerization mechanism of 1,3-benzoxazine catalyzed by PCl5 and rearrangement of chemical structures. Eur. Polym. J. 2021, 142, 110133. [Google Scholar] [CrossRef]

- Tanaka, F. Amines as Catalysts: Dynamic Features and Kinetic Control of Catalytic Asymmetric Chemical Transformations to Form C-C Bonds and Complex Molecules. Chem. Rec. 2022. [Google Scholar] [CrossRef] [PubMed]

- Petrovic, V.P.; Simijonovic, D.; Milovanovic, V.M.; Petrovic, Z.D. Acetophenone mannich bases: Study of ionic liquid catalysed synthesis and antioxidative potential of products. R. Soc. Open Sci. 2018, 5, 181232. [Google Scholar] [CrossRef] [PubMed]

- Zuvev, V.V.; Shibayev, L.; Stepanov, N.G.; Solovskaya, N.A.; Buryko, A.V. Electron cause of the evenness effect and its manifestation in the thermostability of a series of poly-4-n-alkylstyrenes. Polym. Sci. U.S.S.R. 1990, 32, 1780–1784. [Google Scholar] [CrossRef]

- Yan, H.; Huo, F.; Li, P.; Li, C. Mild Catalytic Mechanism of the mannich Reaction for Synthesizing Methylacrolein by sec-Amine Short-Chain Aliphatic Acid Ionic Liquid Catalysts. ACS Sustain. Chem. Eng. 2022, 10, 6687–6698. [Google Scholar] [CrossRef]

- Niu, H.; Lu, L.; Shi, R.; Chiang, C.W.; Lei, A. Catalyst-free N-methylation of amines using CO2. Chem. Commun. 2017, 53, 1148–1151. [Google Scholar] [CrossRef]

- Zou, Q.; Long, G.; Zhao, T.; Hu, X. Catalyst-free selective N-formylation and N-methylation of amines using CO2 as a sustainable C1 source. Green Chem. 2020, 22, 1134–1138. [Google Scholar] [CrossRef]

- Majerz, I.; Dziembowska, T. Geometric Aspects of Aromaticity: Interrelations between Intramolecular Hydrogen Bonds, Steric Effects and π-Electron Delocalisation in Nitroanilines. Eur. J. Org. Chem. 2011, 2011, 280–286. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, H.; Liu, F.; Huo, F.; He, Y.; Chen, Z.; Liu, X.; Bo, S.; Qiu, L.; Zhen, Z. Synthesis of novel nonlinear optical chromophores: Achieving enhanced electro-optic activity and thermal stability by introducing rigid steric hindrance groups into the julolidine donor. J. Mater. Chem. C 2017, 5, 1675–1684. [Google Scholar] [CrossRef]

- Ohashi, K.; Inokuchi, Y.; Izutsu, H.; Hino, K.; Yamamoto, N.; Nishi, N. Electronic and vibrational spectra of aniline–benzene hetero-dimer and aniline homo-dimer ions. Chem. Phys. Lett. 2000, 323, 43–48. [Google Scholar] [CrossRef]

- Arasi, A.Y.; Jeyakumari, J.J.; Sundaresan, B.; Dhanalakshmi, V.; Anbarasan, R. The structural properties of poly(aniline)—Analysis via FTIR spectroscopy. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2009, 74, 1229–1234. [Google Scholar] [CrossRef]

- Honkawa, Y.; Inokuchi, Y.; Ohashi, K.; Nishi, N.; Sekiya, H. Infrared spectra and structures of aniline+–furan and aniline+–phenol. Preference between π-type and σ-type hydrogen-bonded structures. Chem. Phys. Lett. 2003, 376, 244–250. [Google Scholar] [CrossRef]

- Seliger, J.; Zaga, V. 14 N NQR Study of Diphenylamine. Verl. Der Z. Für Nat. A 2008, 63, 88–92. [Google Scholar]

- Hao, W.J.; Jiang, B.; Tu, S.J.; Cao, X.D.; Wu, S.S.; Yan, S.; Zhang, X.H.; Han, Z.G.; Shi, F. A new mild base-catalyzed mannich reaction of hetero-arylamines in water: Highly efficient stereoselective synthesis of beta-aminoketones under microwave heating. Org. Biomol. Chem. 2009, 7, 1410–1414. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.; Meng, X.; Luo, Y.; Cao, S.; Zhao, G. A novel quaternary ammonium salts derived from α-amino acids with large steric hindrance group and its application in asymmetric mannich reaction. Tetrahedron 2020, 76, 131484. [Google Scholar] [CrossRef]

- Rogalski, M.; Domannska, U.; Czyrny, D.; Dyczko, D. Surface and conductivity properties of imidazoles solutions. Chem. Phys. 2002, 285, 355–370. [Google Scholar] [CrossRef]

- Thomason, M.J.; Seabourne, C.R.; Sattelle, B.M.; Hembury, G.A.; Stevens, J.S.; Scott, A.J.; Aziz, E.F.; Schroeder, S.L. Self-association of organic solutes in solution: A NEXAFS study of aqueous imidazole. Faraday Discuss. 2015, 179, 269–289. [Google Scholar] [CrossRef] [PubMed]

- Cope, A.; Burrows, W. Clarke—Eschweiler Cyclization. Scope and Mechanism. J. Org. Chem. 1966, 31, 3099–3103. [Google Scholar] [CrossRef]

- Yu, J.; Jensen, A.D.; Wang, L.; Li, C.; Zhang, S. Catalytic synthesis of methacrolein via the condensation of formaldehyde and propionaldehyde with l-proline. Green Chem. 2020, 22, 4222–4230. [Google Scholar] [CrossRef]

- Frisch, M.J.; Trucks, G.W.; Schlegel, J.; Scuseria, G.E.; Robb, M.; Cheeseman, J.R.; Scalmani, G.; Barone, V.; Mennucci, B.; Petersson, G.A.; et al. Gaussian 09, Rev C.; Gaussian Inc.: Wallingford, CT, USA, 2009. [Google Scholar]

- Johnson, B.G.; Gill, P.M.; Weoplee, J.A. The performance of a family of density functional methods. J. Chem. Phys. 1993, 98, 5612–5626. [Google Scholar] [CrossRef]

- Raghavachari, K.; Trucks, G.W. Highly correlated systems. Excitation energies of first row transition metals Sc−Cu. J. Chem. Phys. 1989, 91, 1062–1065. [Google Scholar] [CrossRef]

- Zhao, Y.; Truhlar, D.G. The M06 suite of density functionals for main group thermochemistry, thermochemical kinetics, non-covalent interactions, excited states, and transition elements: Two new functionals and systematic testing of four M06-class functionals and 12 other functionals. Theor. Chem. Acc. 2007, 120, 215–241. [Google Scholar]

- Weigend, F.; Ahlrichs, R. Balanced basis sets of split valence, triple zeta valence and quadruple zeta valence quality for H to Rn: Design and assessment of accuracy. Phys. Chem. Chem. Phys. 2005, 7, 3297–3305. [Google Scholar] [CrossRef] [PubMed]

- Weigend, F. Accurate Coulomb-fitting basis sets for H to Rn. Phys. Chem. Chem. Phys. 2006, 8, 1057–1065. [Google Scholar] [CrossRef] [PubMed]

- Lu, T.; Chen, F. Multiwfn: A Multifunctional Wavefunction Analyzer. J. Comput. Chem. 2012, 33, 580–592. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Lu, T. Efficient Evaluation of Electrostatic Potential with Computerized Optimized Code. Phys. Chem. Chem. Phys. 2021, 23, 20323. [Google Scholar] [CrossRef]

- Lu, T.; Chen, Q. van der Waals Potential: An Important Complement to Molecular Electrostatic Potential in Studying Intermolecular Interactions. J. Mol. Model. 2020, 26, 315. [Google Scholar] [CrossRef]

- Humphrey, W.; Dalke, A.; Schulten, K. VMD: Visual molecular dynamics. J. Mol. Graph. 1996, 14, 33–38. [Google Scholar] [CrossRef]

| Entry | Amine | Conversion (%) | Yield (%) |

|---|---|---|---|

| 1 | diethylamine | 87.8 | 83.0 |

| 2 | di-n-propylamine | 97.2 | 87.1 |

| 3 | diisopropylamine | 13.7 | 11.3 |

| 4 | dibutylamine | 99.8 | 96.3 |

| 5 | diisobutylamine | 86.3 | 70.6 |

| 6 | di-sec-butylamine | 65.4 | 49.7 |

| 7 | pyrrolidine | 99.6 | 90.1 |

| 8 | n-methylaniline | 57.6 | 0 |

| 9 | diphenylamine | 27.7 | 0 |

| 10 | n-benzylmethylamine | 67.0 | 34.8 |

| 11 | dibenzylamine | 54.1 | 4.75 |

| 12 | imidazole | 3.0 | 0 |

| Entry | Acid a | Conversion (%) | Yield (%) |

|---|---|---|---|

| 1 | Hydrochloric acid | 49.3 | 1.7 |

| 2 | Sulfuric acid | 47.2 | 1.3 |

| 3 | Acetic acid | 99.8 | 96.3 |

| 4 | Propanoic acid | 99.2 | 94.2 |

| 5 | Butyric acid | 99.5 | 93.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Li, J.; Yan, H.; Zhang, G.; Li, S. Mechanism and Kinetic Study on Synthesis of Methacrolein Catalyzed by Amine/Acid. Catalysts 2023, 13, 799. https://doi.org/10.3390/catal13050799

Wang T, Li J, Yan H, Zhang G, Li S. Mechanism and Kinetic Study on Synthesis of Methacrolein Catalyzed by Amine/Acid. Catalysts. 2023; 13(5):799. https://doi.org/10.3390/catal13050799

Chicago/Turabian StyleWang, Tao, Jie Li, Hanwen Yan, Guoliang Zhang, and Shifeng Li. 2023. "Mechanism and Kinetic Study on Synthesis of Methacrolein Catalyzed by Amine/Acid" Catalysts 13, no. 5: 799. https://doi.org/10.3390/catal13050799

APA StyleWang, T., Li, J., Yan, H., Zhang, G., & Li, S. (2023). Mechanism and Kinetic Study on Synthesis of Methacrolein Catalyzed by Amine/Acid. Catalysts, 13(5), 799. https://doi.org/10.3390/catal13050799