A Comparative Review of Binder-Containing Extrusion and Alternative Shaping Techniques for Structuring of Zeolites into Different Geometrical Bodies

Abstract

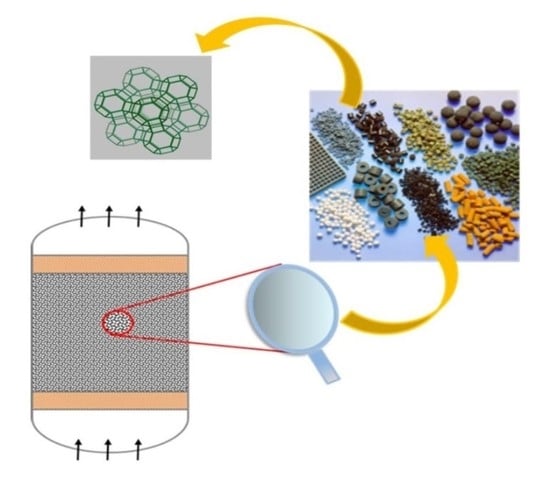

1. Introduction

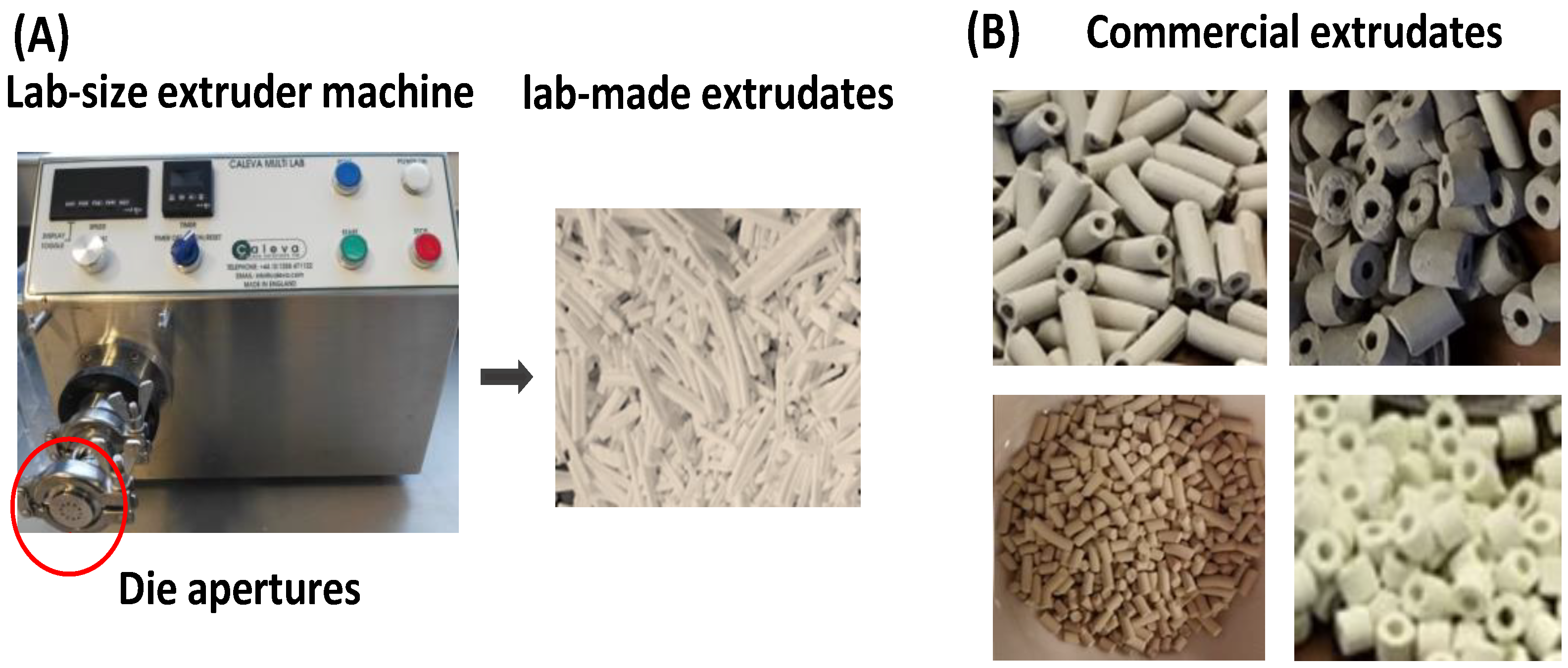

2. Zeolites Shaping Using Extrusion Technique and by Means of Inorganic and/or Organic Binders

| Entry | Zeolite Type | Organic Binder | Inorganic Binder | Ref. |

|---|---|---|---|---|

| 1 | 3A | Copolymer (ethylene/butyle acrylate, 17 wt% and 30 wt% copolymer) | - | [31] |

| 2 | 3A | Polyethylene | - | [31] |

| 3 | Y | Cellulose fibers | - | [32] |

| 4 | TiO2 monolith | Polyethylene and methyl-hydroxyl- cellulose | Bentonite, glass fiber | [42] |

| 5 | ZSM-5 | Aluminum phosphate γ-Al2O3 | [28] | |

| 6 | X, Y, ZSM-12, Mordenite, zeolite A, P, ZSM-5, MCM-41 | - | Portland cement, High Al cement Sulphoaluminate cements, phosphate, bonded cements, blast furnace slag cements, Ca3SiO5, (Ca2SiO4), alumino-ferrite, tricalcium aluminate, calcium aluminates such as monocalcium aluminate (Ca3Al2O6), and calcium hexoaluminate (CaAl2O4), used alone or as a mixture | [29] |

| 7 | ZSM-5 | - | α-Alumina monohydrate | [30] |

| 8 | ZSM-5 | Cellulose | Catapal D (Boehmite alumina) | [34] |

| 9 | 5A | carboxymethycellulose | Kaolin | [43] |

| 10 | ZSM-5 | - | Silica/Alumina | [36] |

| 11 | ZSM-5, 11, 23, 35, 38, 48, Beta, X, Y, L | - | Silica | [44] |

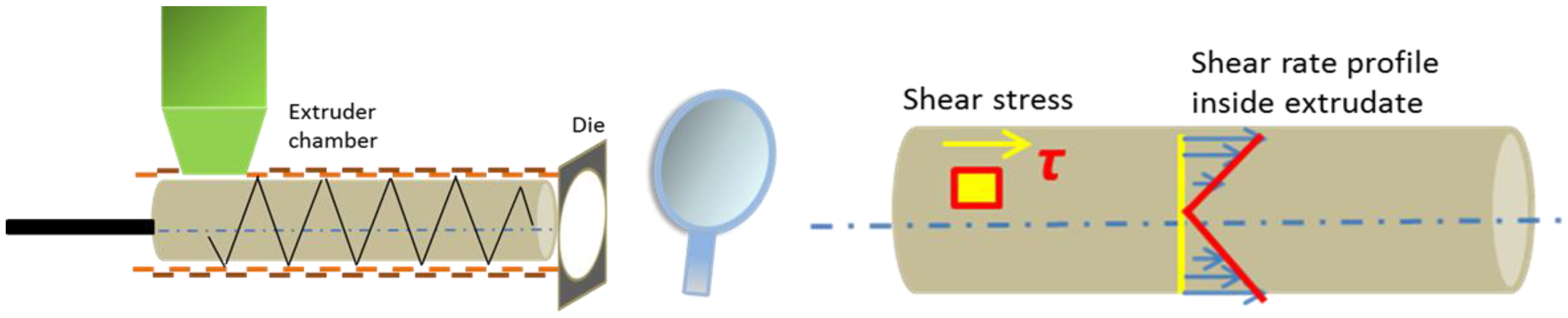

2.1. The Important Parameters in Rheological Behavior of Extrudates

2.2. Binder Effects on Zeolite Physicochemical Properties

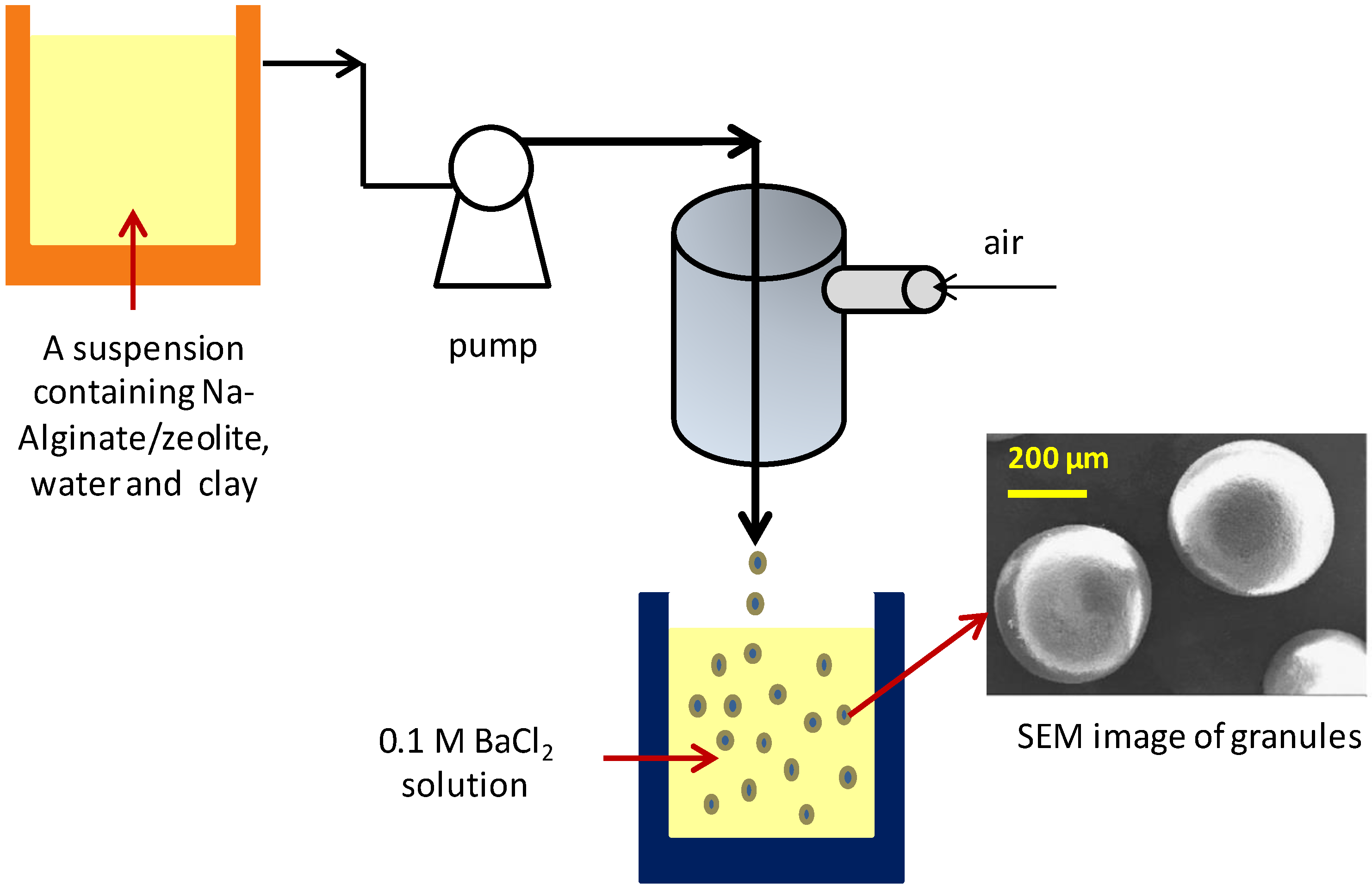

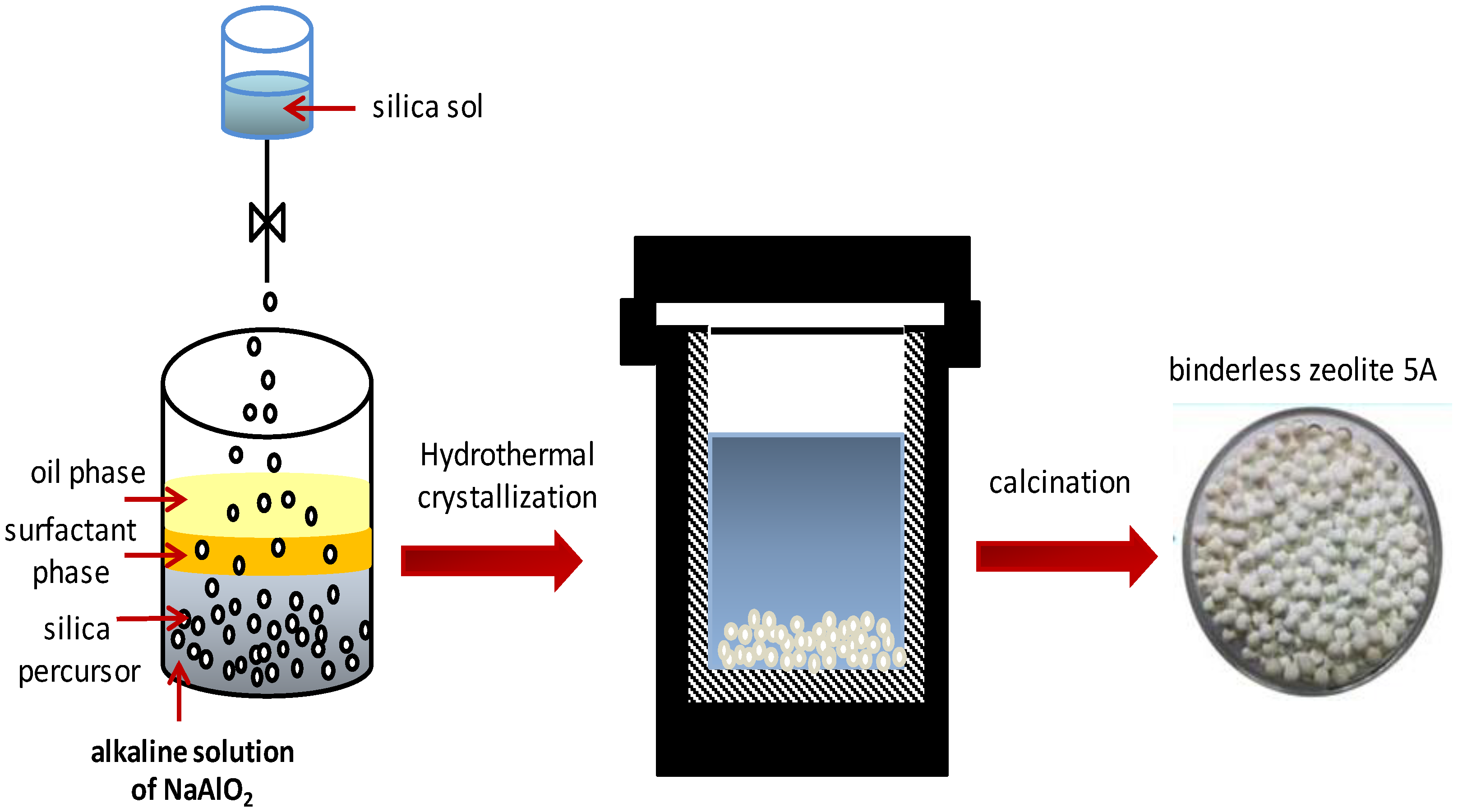

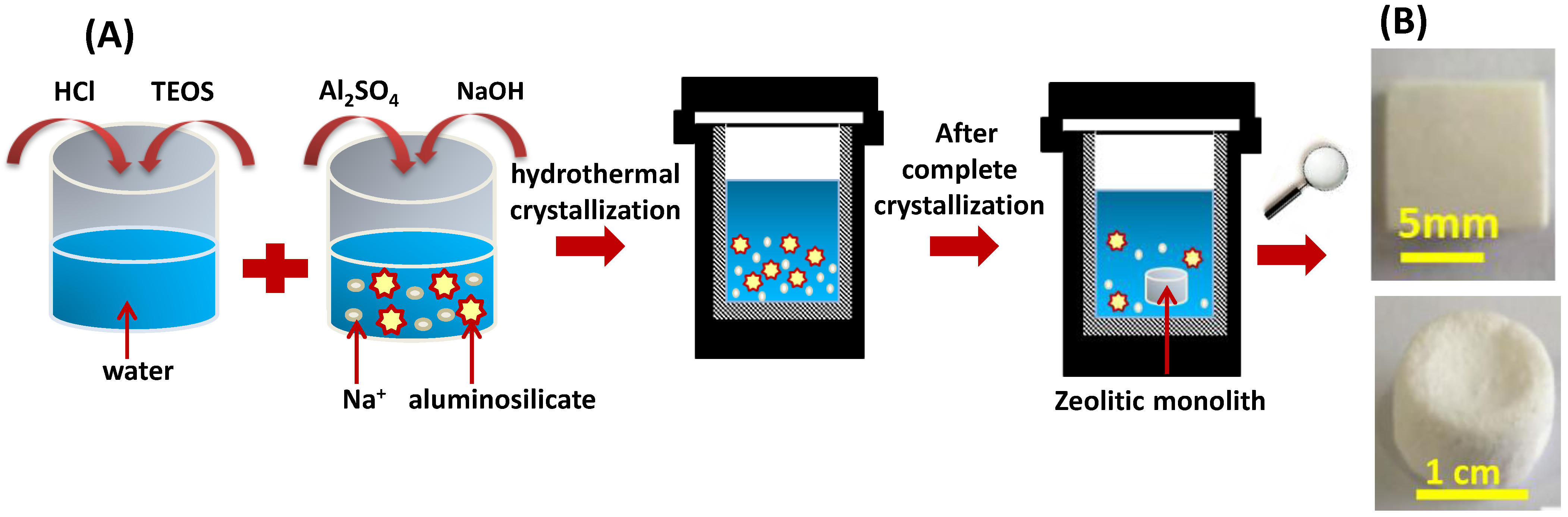

3. Zeolites Shaping Using Alternative Binder-Free Techniques

3.1. Macroscopic Hard Templating Casting

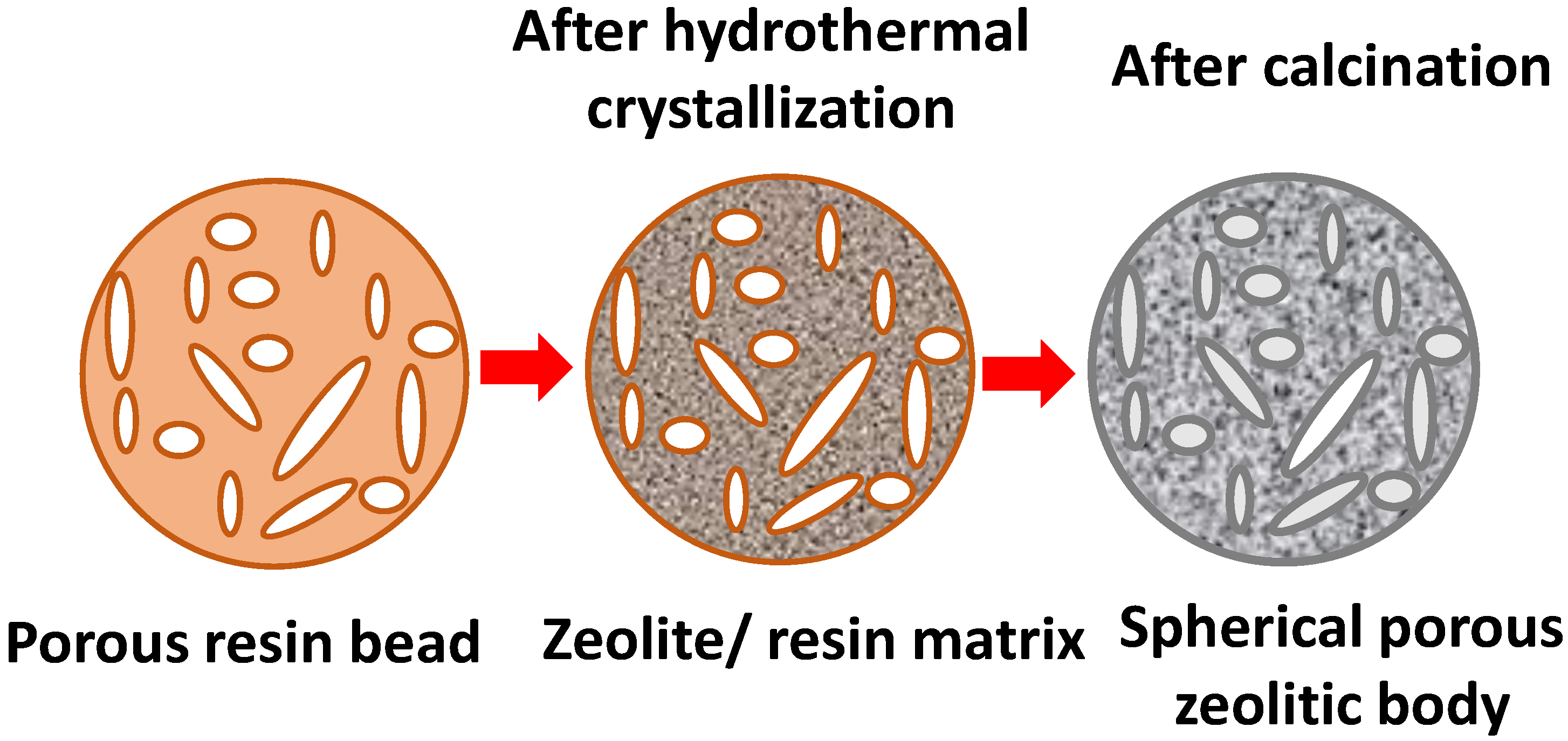

3.2. Hydrothermal Transformation

4. Conclusions, Recommendations and Future Perspectives

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ergun, S. Fluid flow through packed columns. Chem. Eng. Prog. 1952, 48, 89–94. [Google Scholar]

- Foumeny, E.A.; Kulkarni, A.; Roshani, S. Elucidation of pressure drop in packed-bed systems. J. Appl. Therm. Eng. 1996, 16, 195–202. [Google Scholar] [CrossRef]

- Devyatkov, S.; Kuzichkin, N.V.; Murzin, D.Y. On Comprehensive Understanding of Catalyst Shaping by Extrusion. Chim. Oggi-Chem. Today 2015, 33, 57–64. [Google Scholar]

- De Wind, M.; Plantenga, F.L.; Heinerman, J.J.L.; Free, H.W.H. Upflow versus Downflow Testing of Hydrotreating Catalysts. Appl. Catal. 1988, 43, 239–252. [Google Scholar] [CrossRef]

- Corma, A.; Martinez, A. Zeolites and Zeotypes as Catalysts. Adv. Mater. 1995, 7, 137–144. [Google Scholar] [CrossRef]

- Asgar Pour, Z.; Sebakhy, K.O. A Review on the Effects of Organic Structure-Directing Agents on the Hydrothermal Synthesis and Physicochemical Properties of Zeolites. Chemistry 2022, 4, 431–446. [Google Scholar] [CrossRef]

- Rabo, J.A.; Schoonover, M.W. Early Discoveries in Zeolite Chemistry and Catalysis at Union Carbide, and Follow-up in Industrial Catalysis. Appl. Catal. A Gen. 2001, 222, 261–275. [Google Scholar] [CrossRef]

- Tanabe, K.; Hölderich, W.F. Industrial Application of Solid Acid–Base Catalysts. Appl. Catal. A Gen. 1999, 181, 399–434. [Google Scholar] [CrossRef]

- Dapsens, P.Y.; Mondelli, C.; Pérez-Ramírez, J. Design of Lewis-Acid Centres in Zeolitic Matrices for the Conversion of Renewables. Chem. Soc. Rev. 2015, 44, 7025–7043. [Google Scholar] [CrossRef]

- Ch Deka, R. Acidity in Zeolites and Their Characterization by Different Spectroscopic Methods, 5th ed.; Indian Journal of Technology: New Delhi, India, 1998. [Google Scholar]

- Moshoeshoe, M.N.; Nadiye-Tabbiruka, M.S.; Obuseng, V.C. A Review of the Chemistry, Structure, Properties and Applications of Zeolites. Am. J. Mater. Sci. 2017, 7, 196–221. [Google Scholar]

- Primo, A.; Garcia, H. Zeolites as Catalysts in Oil Refining. Chem. Soc. Rev. 2014, 43, 7548–7561. [Google Scholar] [CrossRef]

- Davis, M.E. Ordered Porous Materials for Emerging Applications. Nature 2002, 417, 813–821. [Google Scholar] [CrossRef]

- Corma, A. From Microporous to Mesoporous Molecular Sieve Materials and Their Use in Catalysis. Chem. Rev. 1997, 97, 2373–2420. [Google Scholar] [CrossRef]

- Mintova, S.; Gilson, J.-P.; Valtchev, V. Advances in Nanosized Zeolites. Nanoscale 2013, 5, 6693–6703. [Google Scholar] [CrossRef]

- Lakiss, L.; Gilson, J.P.; Valtchev, V.; Mintova, S.; Vicente, A.; Vimont, A.; Bedard, R.; Abdo, S.; Bricker, J. Zeolites in a good shape: Catalyst forming by extrusion modifies their performances. Microporous Mesoporous Mater. 2020, 299, 110114. [Google Scholar] [CrossRef]

- Wang, Y.; Chang, Y.; Liu, M.; Zhang, A.; Guo, X. A facile strategy to prepare shaped ZSM-5 catalysts with enhanced para-xylene selectivity and stability for toluene methylation: The effect of in situ modification by attapulgite. Molecules 2019, 24, 3462. [Google Scholar] [CrossRef]

- Perego, C.; Villa, P. Catalyst Preparation Methods. Catal. Today 1997, 34, 281–305. [Google Scholar] [CrossRef]

- Pérez-Ramírez, J.; Mitchell, S.; Verboekend, D.; Milina, M.; Michels, N.-L.; Krumeich, F.; Marti, N.; Erdmann, M. Expanding the Horizons of Hierarchical Zeolites: Beyond Laboratory Curiosity towards Industrial Realization. ChemCatChem 2011, 3, 1731–1734. [Google Scholar] [CrossRef]

- Verboekend, D.; Mitchell, S.; Pérez-Ramírez, J. Hierarchical Zeolites Overcome All Obstacles: Next Stop Industrial Implementation. Chimia 2013, 67, 327. [Google Scholar] [CrossRef]

- Michels, N.-L.; Mitchell, S.; Milina, M.; Kunze, K.; Krumeich, F.; Marone, F.; Erdmann, M.; Marti, N.; Pérez-Ramírez, J. Hierarchically Structured Zeolite Bodies: Assembling Micro-, Meso-, and Macroporosity Levels in Complex Materials with Enhanced Properties. Adv. Funct. Mater. 2012, 22, 2509–2518. [Google Scholar] [CrossRef]

- Beeckman, J.W.L.; Fassbender, N.A.; Datz, T.E. Length to diameter ratio of extrudates in catalysis technology I. Bending Strength versus impulsive forces. AICHE J. 2016, 62, 2658–2669. [Google Scholar] [CrossRef]

- Gustafson, W.R.; Conn, T. Shaped Catalyst Particle. US Patent 3,966,644, 29 June 1967. [Google Scholar]

- Hagen, J. Catalyst Shapes and Production of Heterogeneous Catalysts. Ind. Catal. 2015, 211–238. [Google Scholar] [CrossRef]

- Michels, N.-L.; Mitchell, S.; Pérez-Ramírez, J. Effects of Binders on the Performance of Shaped Hierarchical MFI Zeolites in Methanol-to-Hydrocarbons. ACS Catal. 2014, 4, 2409–2417. [Google Scholar] [CrossRef]

- Jasra, R.V.; Tyagi, B.; Badheka, Y.M.; Choudary, V.N.; Bhat, T.S.G. Effect of Clay Binder on Sorption and Catalytic Properties of Zeolite Pellets. Ind. Eng. Chem. Res. 2003, 42, 3263–3272. [Google Scholar] [CrossRef]

- Tischer, R.E. Preparation of Bimodal Aluminas and Molybdena/Alumina Extrudates. J. Catal. 1981, 72, 255–265. [Google Scholar] [CrossRef]

- Freiding, J.; Patcas, F.-C.; Kraushaar-Czarnetzki, B. Extrusion of Zeolites: Properties of Catalysts with a Novel Aluminium Phosphate Sintermatrix. Appl. Catal. A General. 2007, 328, 210–218. [Google Scholar] [CrossRef]

- Bazer-Bachi, D.; Harbuzaru, B.; Lecolier, E. Zeolite Formed by Extrsion and Pelleting with a Hydraulic Binder Having Improved Mechanical Properties and Process and Preparing Same. U.S. Patent 20,160,288,109A1, 6 October 2016. [Google Scholar]

- Shihabi, D.S.; Garwood, W.E.; Chu, P.; Miale, J.N.; Lago, R.M.; Chu, C.T.-W.; Chang, C.D. Aluminum Insertion into High-Silica Zeolite Frameworks: II. Binder Activation of High-Silica ZSM-5. J. Catal. 1985, 93, 471–474. [Google Scholar] [CrossRef]

- Bouvier, L.; Nicolas, S.; Medevielle, A.; Alex, P. Zeolite Adsorbent Having an Organic Binder. U.S. Patent 8,932,386B2, 13 January 2015. [Google Scholar]

- Akhtar, F.; Andersson, L.; Ogunwumi, S.; Hedin, N.; Bergström, L. Structuring Adsorbents and Catalysts by Processing of Porous Powders. J. Eur. Ceram. Soc. 2014, 34, 1643–1666. [Google Scholar] [CrossRef]

- Lynn, M. Method of Making a High Strength Catalys, Catalyst Support or Adsorber. U.S. Patent 5,633,217, 27 May 1997. [Google Scholar]

- Whiting, G.T.; Chung, S.-H.; Stosic, D.; Chowdhury, A.D.; van der Wal, L.I.; Fu, D.; Zecevic, J.; Travert, A.; Houben, K.; Baldus, M.; et al. Multiscale Mechanistic Insights of Shaped Catalyst Body Formulations and Their Impact on Catalytic Properties. ACS Catal. 2019, 9, 4792–4803. [Google Scholar] [CrossRef]

- Baldovino-Medrano, V.G.; Le, M.T.; Van Driessche, I.; Bruneel, E.; Alcázar, C.; Colomer, M.T.; Moreno, R.; Florencie, A.; Farin, B.; Gaigneaux, E.M. Role of Shaping in the Preparation of Heterogeneous Catalysts: Tableting and Slip-Casting of Oxidation Catalysts. Catal. Today 2015, 246, 81–91. [Google Scholar] [CrossRef]

- Devyatkov, S.Y.; Al Zinnurova, A.; Aho, A.; Kronlund, D.; Peltonen, J.; Kuzichkin, N.V.; Lisitsyn, N.V.; Murzin, D.Y. Shaping of Sulfated Zirconia Catalysts by Extrusion: Understanding the Role of Binders. Ind. Eng. Chem. Res. 2016, 55, 6595–6606. [Google Scholar] [CrossRef]

- Absi-Halabi, M.; Stanislaus, A.; Al-Zaid, H. Effect of Acidic and Basic Vapors on Pore Size Distribution of Alumina under Hydrothermal Conditions. Appl. Catal. A Gen. 1993, 101, 117–128. [Google Scholar] [CrossRef]

- Mitchell, S.; Michels, N.L.; Pérez-Ramírez, J. From Powder to Technical Body: The Undervalued Science of Catalyst Scale Up. Chem. Soc. Rev. 2013, 42, 6094–6112. [Google Scholar] [CrossRef]

- Li, Y.; Wu, D.; Zhang, J.; Chang, L.; Wu, D.; Fang, Z.; Shi, Y. Measurement and Statistics of Single Pellet Mechanical Strength of Differently Shaped Catalysts. Powder Technol. 2000, 113, 176–184. [Google Scholar] [CrossRef]

- ASTM Committee D-32; 1985 Annual Book of ASTM Standards, vol. 5.03. American Society for Testing and Materials: New York, NY, USA, 1984.

- Rhee, Y.W.; Guin, J.A. Preparation of Alumina Catalyst Supports and NiMo/Al2O3 Catalysts. Korean J. Chem. Eng. 1993, 10, 112–123. [Google Scholar] [CrossRef]

- Forzatti, P.; Orsenigo, C.; Ballardini, D.; Berti, F. On the Relations Between the Rheology of Tio2-Based Ceramic Pastes and the Morphological and Mechanical Properties of the Extruded Catalysts. In Studies in Surface Science and Catalysis; Delmon, B., Jacobs, P.A., Maggi, R., Martens, J.A., Grange, P., Poncelet, G., Eds.; Elsevier: Amsterdam, The Netherlands, 1998; Volume 118, pp. 787–796. ISBN 0167-2991. [Google Scholar]

- Shams, K.; Mirmohammadi, S.J. Preparation of 5A Zeolite Monolith Granular Extrudates Using Kaolin: Investigation of the Effect of Binder on Sieving/Adsorption Properties Using a Mixture of Linear and Branched Paraffin Hydrocarbons. Microporous Mesoporous Mater. 2007, 106, 268–277. [Google Scholar] [CrossRef]

- Bowes, E.; Amwell, E. Extrusion of Silica-Rich Solids. U.S. Patent 4,582,815, 15 April 1986. [Google Scholar]

- Gleichmann, K.; Unger, B.; Brandt, A. Industrial Zeolite Molecular Sieves. Zeolites Useful. Miner. 2016, 5, 89–108. [Google Scholar] [CrossRef]

- Mitchell, S.; Michels, N.L.; Kunze, K.; Pérez-Ramírez, J. Visualization of Hierarchically Structured Zeolite Bodies from Macro to Nano Length Scales. Nat. Chem. 2012, 4, 825–831. [Google Scholar] [CrossRef]

- Koutsoukos, P.K.; Klepetsanis, P.G.; Spanos, N.; Somasundaran, P. Calculation of Zeta-Potentials from Electrokinetic Data, Encyclopedia of Surface and Colloid Science; CRC Press: New York, NY, USA, 2006. [Google Scholar]

- Foundas, M.; Britcher, L.G.; Fornasiero, D.; Morris, G.E. Boehmite Suspension Behaviour upon Adsorption of Methacrylate–Phosphonate Copolymers. Powder Technol. 2015, 269, 385–391. [Google Scholar] [CrossRef]

- Catalyst Fundamentals. In Catalytic Air Pollution Control; Wiley: Hoboken, NJ, USA, 2009; pp. 1–23. ISBN 978-1-118-39774-9.

- Sun, H.; Shen, B.; Liu, J. N-Paraffins Adsorption with 5A Zeolites: The Effect of Binder on Adsorption Equilibria. Sep. Purif. Technol. 2008, 64, 135–139. [Google Scholar] [CrossRef]

- Luna-Murillo, B.; Pala, M.; Paioni, A.L.; Baldus, M.; Ronsse, F.; Prins, W.; Bruijnincx, P.C.A.; Weckhuysen, B.M. Catalytic fast pyrolysis of biomass: Catalyst characterization reveals the feed-dependent deactivation of a technical ZSM-5-based catalyst. ACS Sustain. Chem. Eng. 2020, 9, 291–304. [Google Scholar] [CrossRef]

- Devadas, P.; Kinage, A.K.; Choudhary, V.R. Effect of Silica Binder on Acidity, Catalytic Activity and Deactivation Due to Coking in Propane Aromatization over H-Gallosilicate (MFI). In Studies in Surface Science and Catalysis; Rao, T.S.R.P., Dhar, G.M., Eds.; Elsevier: Amsterdam, The Netherlands, 1998; Volume 113, pp. 425–432. ISBN 0167-2991. [Google Scholar]

- Whiting, G.T.; Meirer, F.; Mertens, M.M.; Bons, A.-J.; Weiss, B.M.; Stevens, P.A.; de Smit, E.; Weckhuysen, B.M. Binder Effects in SiO2− and Al2O3-Bound Zeolite ZSM-5-Based Extrudates as Studied by Microspectroscopy. ChemCatChem 2015, 7, 1312–1321. [Google Scholar] [CrossRef] [PubMed]

- Mitra, B.; Kunzru, D. Washcoating of Different Zeolites on Cordierite Monoliths. J. Am. Ceram. Soc. 2008, 91, 64–70. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, J.H.; Park, D.-W.; Cho, S.J. Effect of Base Binder, Flash Calcined Hydrotalcite, in MFI Zeolite Granule: Catalytic Activity over 1-Butene Isomerization and MTO Reaction. Appl. Catal. A Gen. 2015, 502, 42–47. [Google Scholar] [CrossRef]

- Du, X.; Kong, X.; Chen, L. Influence of Binder on Catalytic Performance of Ni/HZSM-5 for Hydrodeoxygenation of Cyclohexanone. Catal. Commun. 2014, 45, 109–113. [Google Scholar] [CrossRef]

- Kasture, M.W.; Niphadkar, P.S.; Bokade, V.V.; Joshi, P.N. On the Catalytic Performance in Isopropylation of Benzene over H/β Zeolite Catalysts: Influence of Binder. Catal. Commun. 2007, 8, 1003–1008. [Google Scholar] [CrossRef]

- Mehlhorn, D.; Valiullin, R.; Kärger, J.; Schumann, K.; Brandt, A.; Unger, B. Transport Enhancement in Binderless Zeolite X- and A-Type Molecular Sieves Revealed by PFG NMR Diffusometry. Microporous Mesoporous Mater. 2014, 188, 126–132. [Google Scholar] [CrossRef]

- Kong, X.; Liu, J. Influence of Alumina Binder Content on Catalytic Performance of Ni/HZSM-5 for Hydrodeoxygenation of Cyclohexanone. PLoS ONE 2014, 9, e101744. [Google Scholar] [CrossRef]

- Sánchez, P.; Dorado, F.; Fúnez, A.; Jiménez, V.; Ramos, M.J.; Valverde, J.L. Effect of the Binder Content on the Catalytic Performance of Beta-Based Catalysts. J. Mol. Catal. A Chem. 2007, 273, 109–113. [Google Scholar] [CrossRef]

- Uguina, M.A.; Sotelo, J.L.; Serrano, D.P. Toluene Disproportionation over ZSM-5 Zeolite: Effects of Crystal Size, Silicon-to-Aluminum Ratio, Activation Method and Pelletization. Appl. Catal. 1991, 76, 183–198. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, D.; Zou, M.; Yu, L.; Huang, S. The Known and Overlooked Sides of Zeolite-Extrudate Catalysts. ChemCatChem 2021, 13, 1414–1423. [Google Scholar] [CrossRef]

- Dorado, F.; Romero, R.; Cañizares, P. Hydroisomerization of N-Butane over Pd/HZSM-5 and Pd/Hβ with and without Binder. Appl. Catal. A Gen. 2002, 236, 235–243. [Google Scholar] [CrossRef]

- de Lucas, A.; Valverde, J.L.; Sánchez, P.; Dorado, F.; Ramos, M.J. Influence of the Binder on the N-Octane Hydroisomerization over Palladium-Containing Zeolite Catalysts. Ind. Eng. Chem. Res. 2004, 43, 8217–8225. [Google Scholar] [CrossRef]

- Michaiko, E. Method for Producing Molecular Sieves Zeolite Particles. U.S. Patent 3,348,911A, 24 December 1967. [Google Scholar]

- Michaiko, E. Preparation of Crystalline Zeolite Particles. U.S. Patent 3,359,068A, 19 December 1967. [Google Scholar]

- Vasiliev, P.; Akhtar, F.; Grins, J.; Mouzon, J.; Andersson, C.; Hedlund, J.; Bergstrom, L. Strong hierarchically porous monoliths by pulsed current processing of zeolite powder assemblies. ACS Appl. Mater. Interfaces 2010, 2, 732–737. [Google Scholar] [CrossRef]

- Lu, S.; Han, R.; Wang, H.; Song, C.; Ji, N.; Lu, X.; Ma, D.; Liu, Q. Three birds with one stone: Designing a novel binder-free monolithic zeolite pellet for wet VOC gas adsorption. Chem. Eng. J. 2022, 448, 137629. [Google Scholar] [CrossRef]

- Holland, B.T.; Abrams, L.; Stein, A. Dual Templating of Macroporous Silicates with Zeolitic Microporous Frameworks. J. Am. Chem. Soc. 1999, 121, 4308–4309. [Google Scholar] [CrossRef]

- Dong, A.; Wang, Y.; Tang, Y.; Zhang, Y.; Ren, N.; Gao, Z. Mechanically Stable Zeolite Monoliths with Three-Dimensional Ordered Macropores by the Transformation of Mesoporous Silica Spheres. Adv. Mater. 2002, 14, 1506–1510. [Google Scholar] [CrossRef]

- García-Martínez, J.; Cazorla-Amorós, D.; Linares-Solano, A.; Lin, Y.S. Synthesis and Characterisation of MFI-Type Zeolites Supported on Carbon Materials. Microporous Mesoporous Mater. 2001, 42, 255–268. [Google Scholar] [CrossRef]

- Tosheva, L.; Valtchev, V.; Sterte, J. Silicalite-1 Containing Microspheres Prepared Using Shape-Directing Macro-Templates. Microporous Mesoporous Mater. 2000, 35–36, 621–629. [Google Scholar] [CrossRef]

- Tosheva, L.; Mihailova, B.; Valtchev, V.; Sterte, J. Zeolite Beta Spheres. Microporous Mesoporous Mater. 2001, 48, 31–37. [Google Scholar] [CrossRef]

- Tosheva, L.; Sterte, J. ZSM-5 Spheres Prepared by Resin Templating. In Studies in Surface Science and Catalysis; Aiello, R., Giordano, G., Testa, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2002; Volume 142, pp. 183–190. ISBN 0167-2991. [Google Scholar]

- Naydenov, V.; Tosheva, L.; Sterte, J. Chromium Containing Zeolite Beta Macrostructures. In Studies in Surface Science and Catalysis; Aiello, R., Giordano, G., Testa, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2002; Volume 142, pp. 1449–1455. ISBN 0167-2991. [Google Scholar]

- Naydenov, V.; Tosheva, L.; Sterte, J. Palladium-Containing Zeolite Beta Macrostructures Prepared by Resin Macrotemplating. Chem. Mater. 2002, 14, 4881–4885. [Google Scholar] [CrossRef]

- Lee, Y.-J.; Lee, J.S.; Park, Y.S.; Yoon, K.B. Synthesis of Large Monolithic Zeolite Foams with Variable Macropore Architectures. Adv. Mater. 2001, 13, 1259–1263. [Google Scholar] [CrossRef]

- Li, W.-C.; Lu, A.-H.; Palkovits, R.; Schmidt, W.; Spliethoff, B.; Schüth, F. Hierarchically Structured Monolithic Silicalite-1 Consisting of Crystallized Nanoparticles and Its Performance in the Beckmann Rearrangement of Cyclohexanone Oxime. J. Am. Chem. Soc. 2005, 127, 12595–12600. [Google Scholar] [CrossRef] [PubMed]

- Tong, Y.; Zhao, T.; Li, F.; Wang, Y. Synthesis of Monolithic Zeolite Beta with Hierarchical Porosity Using Carbon as a Transitional Template. Chem. Mater. 2006, 18, 4218–4220. [Google Scholar] [CrossRef]

- Flank, W.H.; Fethke, W.P.; Marte, J. Process for Preparing Molecular Sieve Bodies. U.S. Patent 4,818,508A, 4 April 1989. [Google Scholar]

- Verduijn, J.P. Process for Producing Substantially Binder-Free Zeolites. U.S. Patent 5,460,796A, 24 October 1995. [Google Scholar]

- Pavlov, M.L.; Basimova, R.A. Improvement of Synthesis Methods of Powdery Mordenite Type Zeolite. J. Oil Gas. Bus. 2012, 2, 459–469. [Google Scholar]

- Akolekar, D.; Chaffee, A.; Howe, R.F. The Transformation of Kaolin to Low-Silica X Zeolite. Zeolites 1997, 19, 359–365. [Google Scholar] [CrossRef]

- Rauscher, M.; Selvam, T.; Schwieger, W.; Freude, D. Hydrothermal Transformation of Porous Glass Granules into ZSM-5 Granules. Microporous Mesoporous Mater. 2004, 75, 195–202. [Google Scholar] [CrossRef]

- Scheffler, F.; Schwieger, W.; Freude, D.; Liu, H.; Heyer, W.; Janowski, F. Transformation of Porous Glass Beads into MFI-Type Containing Beads. Microporous Mesoporous Mater. 2002, 55, 181–191. [Google Scholar] [CrossRef]

- Özcan, A.; Kalıpçılar, H. Preparation of Zeolite A Tubes from Amorphous Aluminosilicate Extrudates. Ind. Eng. Chem. Res. 2006, 45, 4977–4984. [Google Scholar] [CrossRef]

- Shimizu, S.; Kiyozumi, Y.; Maeda, K.; Mizukami, F.; Pál-Borbély, G.; Mihályi, R.M.; Beyer, H.K. Transformation of Intercalated Layered Silicates to Zeolites in the Solid State. Adv. Mater. 1996, 8, 759–762. [Google Scholar] [CrossRef]

- Shimizu, S.; Hamada, H. Direct Conversion of Bulk Materials into MFI Zeolites by a Bulk-Material Dissolution Technique. Adv. Mater. 2000, 12, 1332–1335. [Google Scholar] [CrossRef]

- De Luca, P.; Crea, F.; Fonseca, A.; Nagy, J.B. Direct Formation of Self-Bonded Pellets during the Synthesis of Mordenite and ZSM-11 Zeolites from Low Water Content Systems. Microporous Mesoporous Mater. 2001, 42, 37–48. [Google Scholar] [CrossRef]

- Madhusoodana, C.D.; Kameshima, Y.; Yasumori, A.; Okada, K. Preparation of Fiber-Reinforced Binderless Zeolite Disks in Solid State. J. Mater. Sci. Lett. 2003, 22, 553–556. [Google Scholar] [CrossRef]

- Charkhi, A.; Kazemeini, M.; Ahmadi, S.J.; Kazemian, H. Fabrication of Granulated NaY Zeolite Nanoparticles Using a New Method and Study the Adsorption Properties. Powder Technol. 2012, 231, 1–6. [Google Scholar] [CrossRef]

- Mańko, M.; Vittenet, J.; Rodriguez, J.; Cot, D.; Mendret, J.; Brosillon, S.; Makowski, W.; Galarneau, A. Synthesis of Binderless Zeolite Aggregates (SOD, LTA, FAU) Beads of 10, 70μm and 1mm by Direct Pseudomorphic Transformation. Microporous Mesoporous Mater. 2013, 176, 145–154. [Google Scholar] [CrossRef]

- Lei, Q.; Zhao, T.; Li, F.; Wang, Y.F.; Hou, L. Zeolite Beta Monoliths with Hierarchical Porosity by the Transformation of Bimodal Pore Silica Gel. J. Porous Mater. 2008, 15, 643–646. [Google Scholar] [CrossRef]

- Sun, H.; Sun, Z.; Shen, B.; Liu, J.; Li, G.; Wu, D.; Zhang, Y. One-Pot Synthesis of Binderless Zeolite A Spheres via in Situ Hydrothermal Conversion of Silica Gel Precursors. AIChE J. 2018, 64, 4027–4038. [Google Scholar] [CrossRef]

- Zhang, J.; Mao, Y.; Li, J.; Wang, X.; Xie, J.; Zhou, Y.; Wang, J. Ultrahigh Mechanically Stable Hierarchical Mordenite Zeolite Monolith: Direct Binder-/Template-Free Hydrothermal Synthesis. Chem. Eng. Sci. 2015, 138, 473–481. [Google Scholar] [CrossRef]

- Sebakhy, K.O.; Vitale, G.; Pereira-Almao, P. Production of Highly Dispersed Ni within Nickel Silicate Materials with the MFI Structure for the Selective Hydrogenation of Olefins. Ind. Eng. Chem. Res. 2019, 58, 8597–8611. [Google Scholar] [CrossRef]

- Sebakhy, K.O.; Vitale, G.; Pereira-Almao, P. Dispersed Ni-doped Aegirine Nanocatalysts for the Selective Hydrogenation of Olefinic Molecules. ACS. Appl. Nano Mater. 2018, 1, 6269–6280. [Google Scholar] [CrossRef]

- Asgar Pour, Z.; Koelewijn, R.; El Hariri El Nokab, M.; van der Wel, P.C.A.; Sebakhy, K.O.; Pescarmona, P.P. Binder-free Zeolite Beta Beads with Hierarchical Porosity: Synthesis and Application as Heterogeneous Catalysts for Anisole Acylation. ChemCatChem 2022, 14, e202200518. [Google Scholar] [CrossRef]

| Entry | Type of Zeolite Framework | Commercial Name of Resin | Si/Al Ratio | Surface Area (m2/g) | Application | Ref. |

|---|---|---|---|---|---|---|

| 1 | Silicalite-1/MFI | MSA-1 | ∞ | 930 | Catalysis/Molecular Sieve | [72] |

| 2 | Silicalite-1/MFI | WBA | ∞ | 559 | Catalysis/Molecular Sieve | [72] |

| 3 | Beta/BEA | MSA-1 | 50 | 640 | Catalysis | [73] |

| 4 | ZSM-5/MFI | MSA-1 | 50 | 300–850 | Catalysis | [74] |

| 5 | Cr-Beta/BEA | MSA-1 | 50 | 651 | Catalysis | [75] |

| 6 | Pd-Beta/BEA | MSA-1 | 50 | 144 | Catalysis | [76] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asgar Pour, Z.; Abduljawad, M.M.; Alassmy, Y.A.; Cardon, L.; Van Steenberge, P.H.M.; Sebakhy, K.O. A Comparative Review of Binder-Containing Extrusion and Alternative Shaping Techniques for Structuring of Zeolites into Different Geometrical Bodies. Catalysts 2023, 13, 656. https://doi.org/10.3390/catal13040656

Asgar Pour Z, Abduljawad MM, Alassmy YA, Cardon L, Van Steenberge PHM, Sebakhy KO. A Comparative Review of Binder-Containing Extrusion and Alternative Shaping Techniques for Structuring of Zeolites into Different Geometrical Bodies. Catalysts. 2023; 13(4):656. https://doi.org/10.3390/catal13040656

Chicago/Turabian StyleAsgar Pour, Zahra, Marwan M. Abduljawad, Yasser A. Alassmy, Ludwig Cardon, Paul H. M. Van Steenberge, and Khaled O. Sebakhy. 2023. "A Comparative Review of Binder-Containing Extrusion and Alternative Shaping Techniques for Structuring of Zeolites into Different Geometrical Bodies" Catalysts 13, no. 4: 656. https://doi.org/10.3390/catal13040656

APA StyleAsgar Pour, Z., Abduljawad, M. M., Alassmy, Y. A., Cardon, L., Van Steenberge, P. H. M., & Sebakhy, K. O. (2023). A Comparative Review of Binder-Containing Extrusion and Alternative Shaping Techniques for Structuring of Zeolites into Different Geometrical Bodies. Catalysts, 13(4), 656. https://doi.org/10.3390/catal13040656