Waste-Extracted Zn and Ag Co-Doped Spent Catalyst-Extracted V2O5 for Photocatalytic Degradation of Congo Red Dye: Effect of Metal-Nonmetal Co-Doping

Abstract

1. Introduction

2. Results

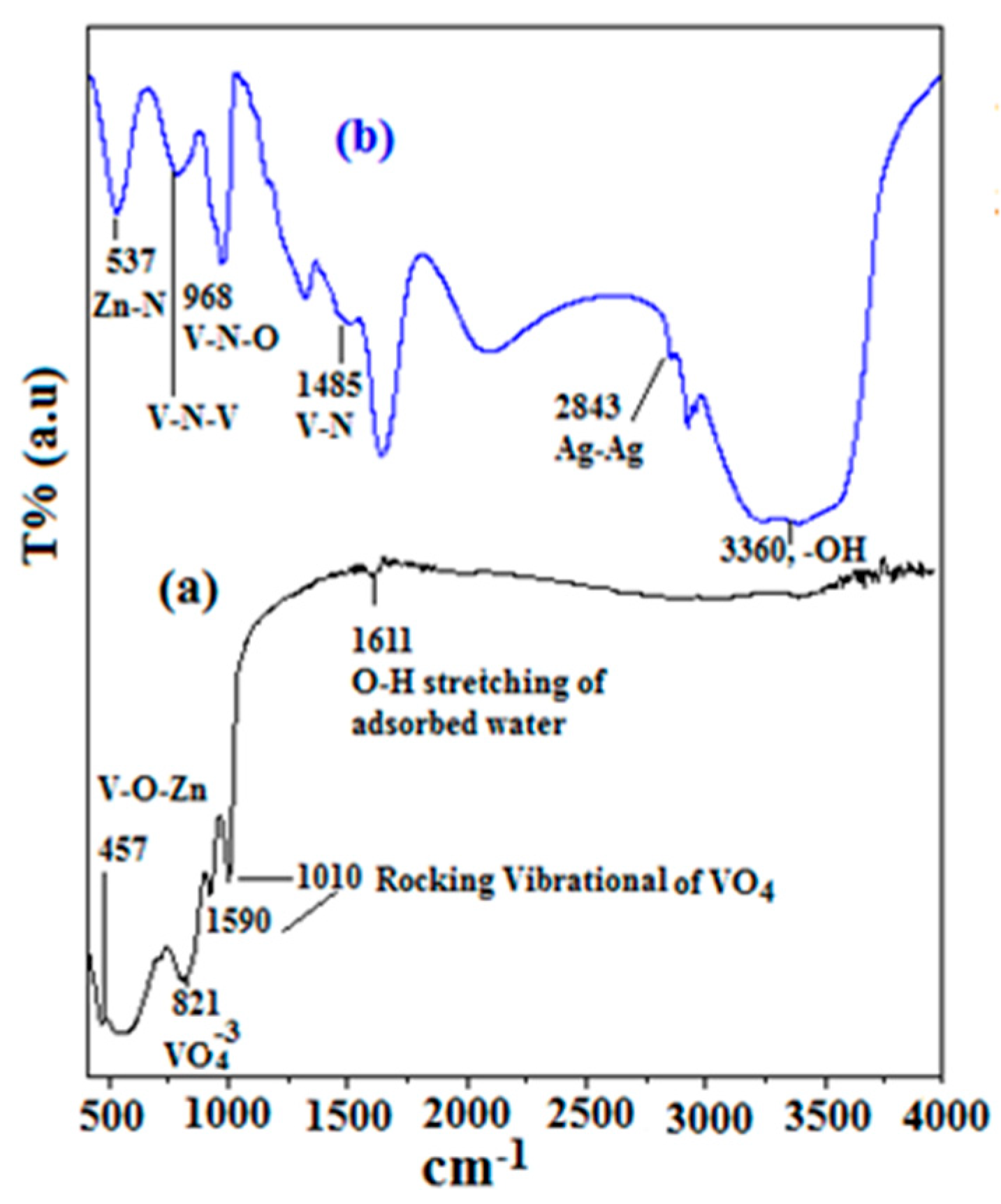

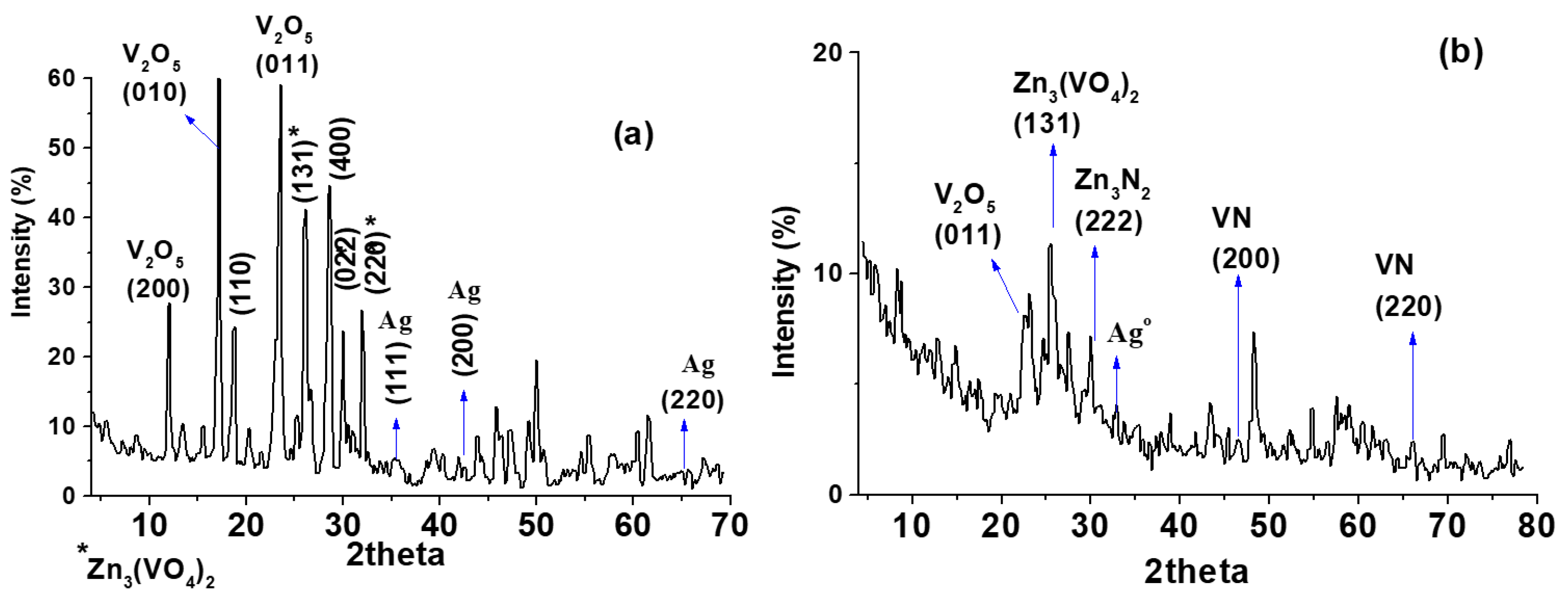

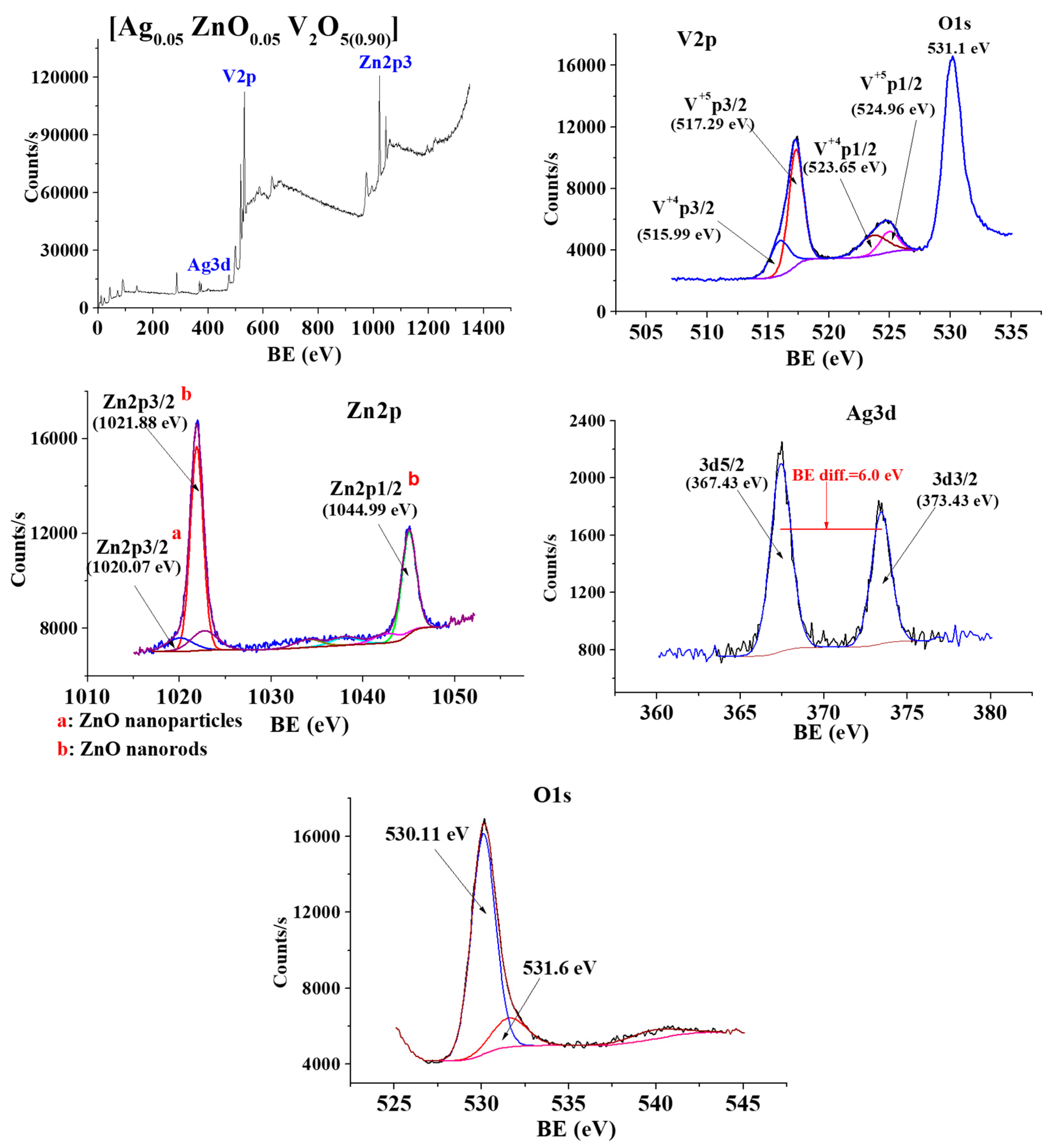

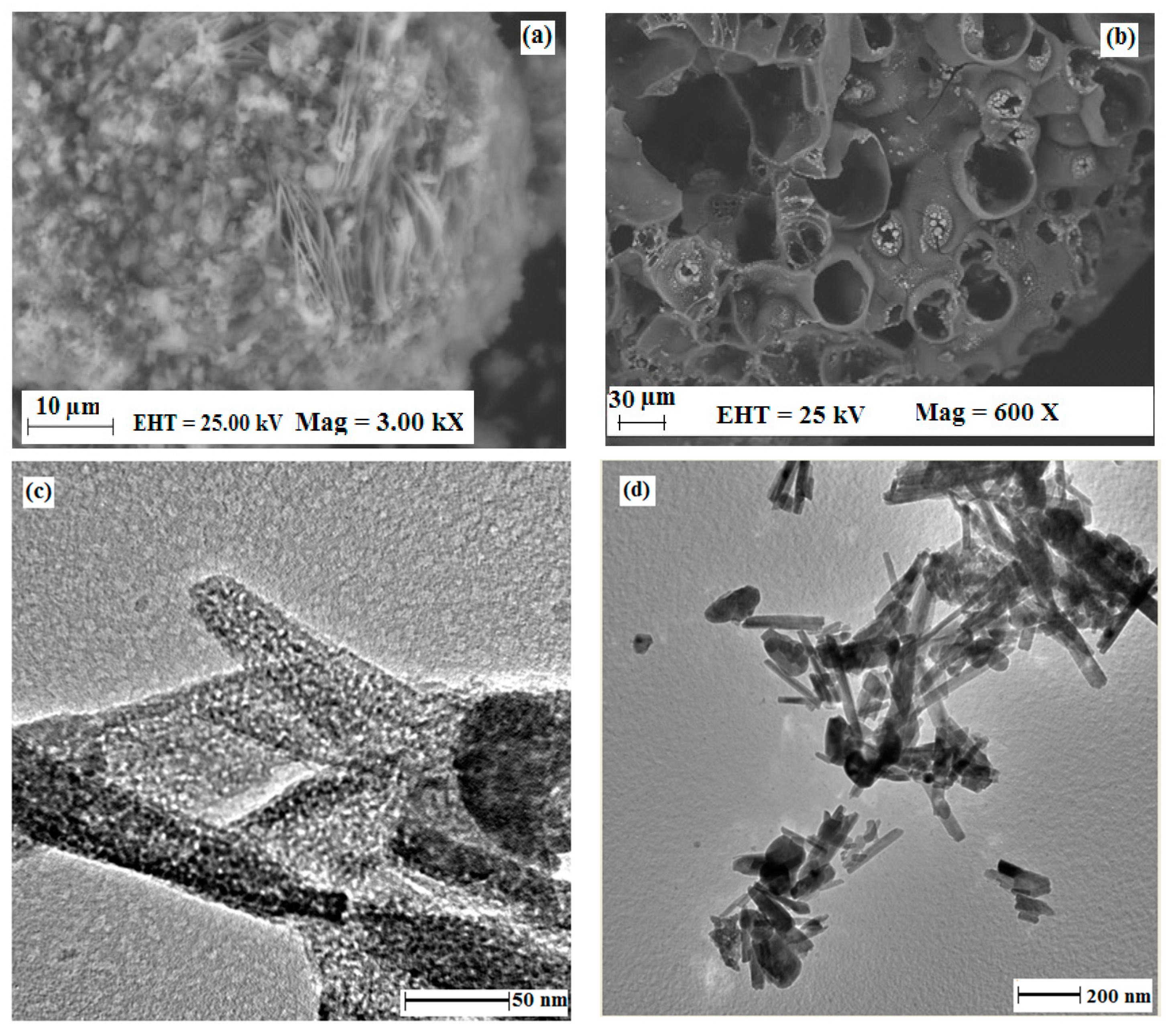

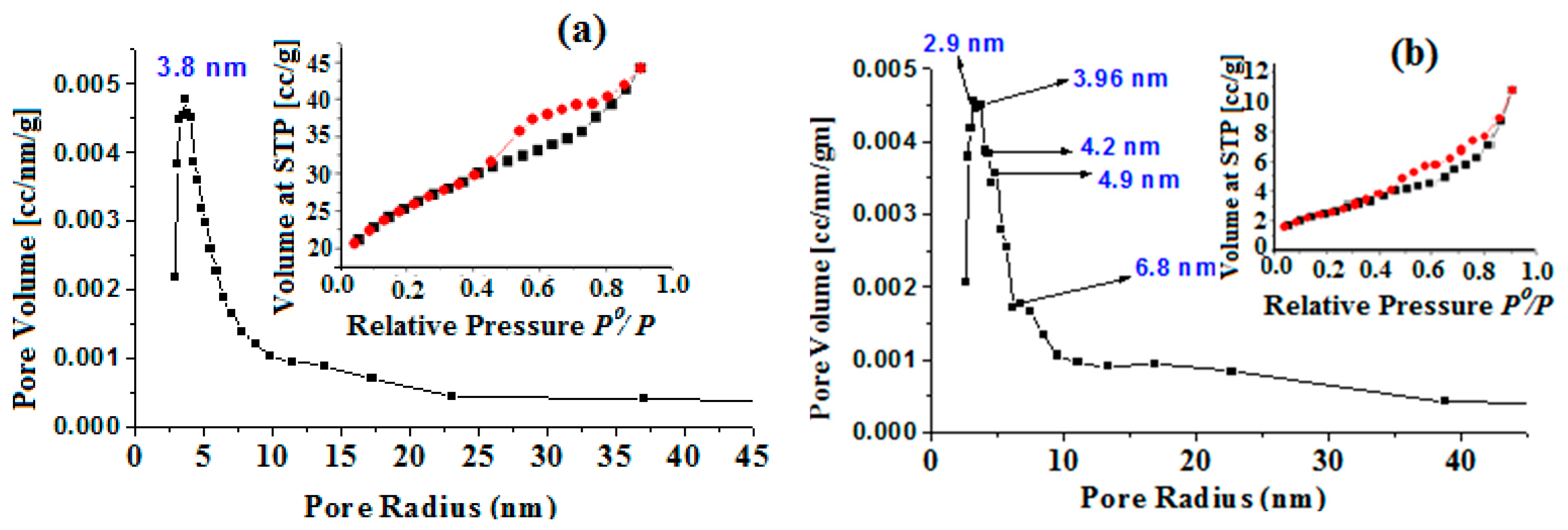

2.1. Description of Structure

2.2. Optical Properties

2.3. Catalytic Performance

2.4. The Effect of pH

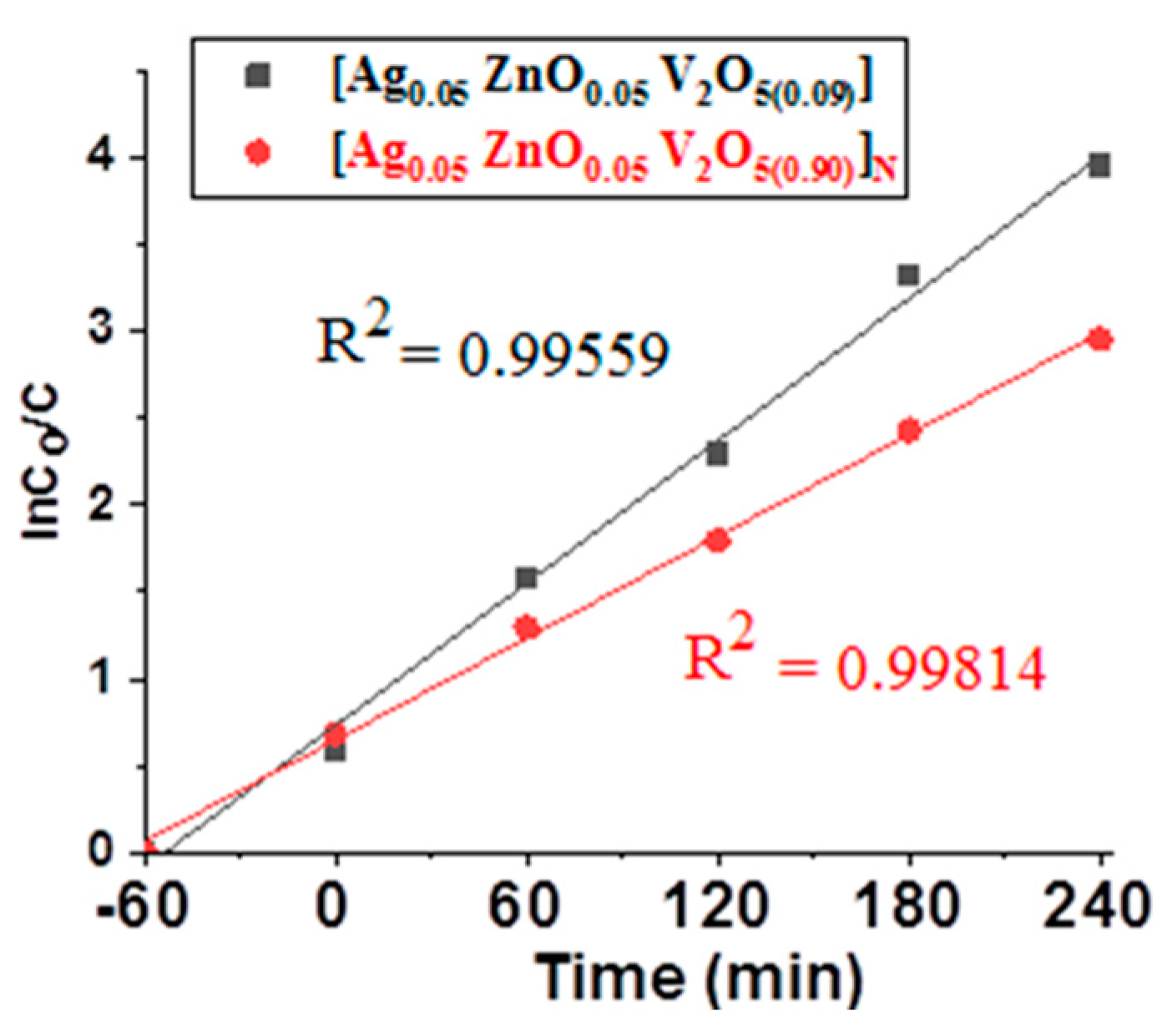

2.5. Kinetics

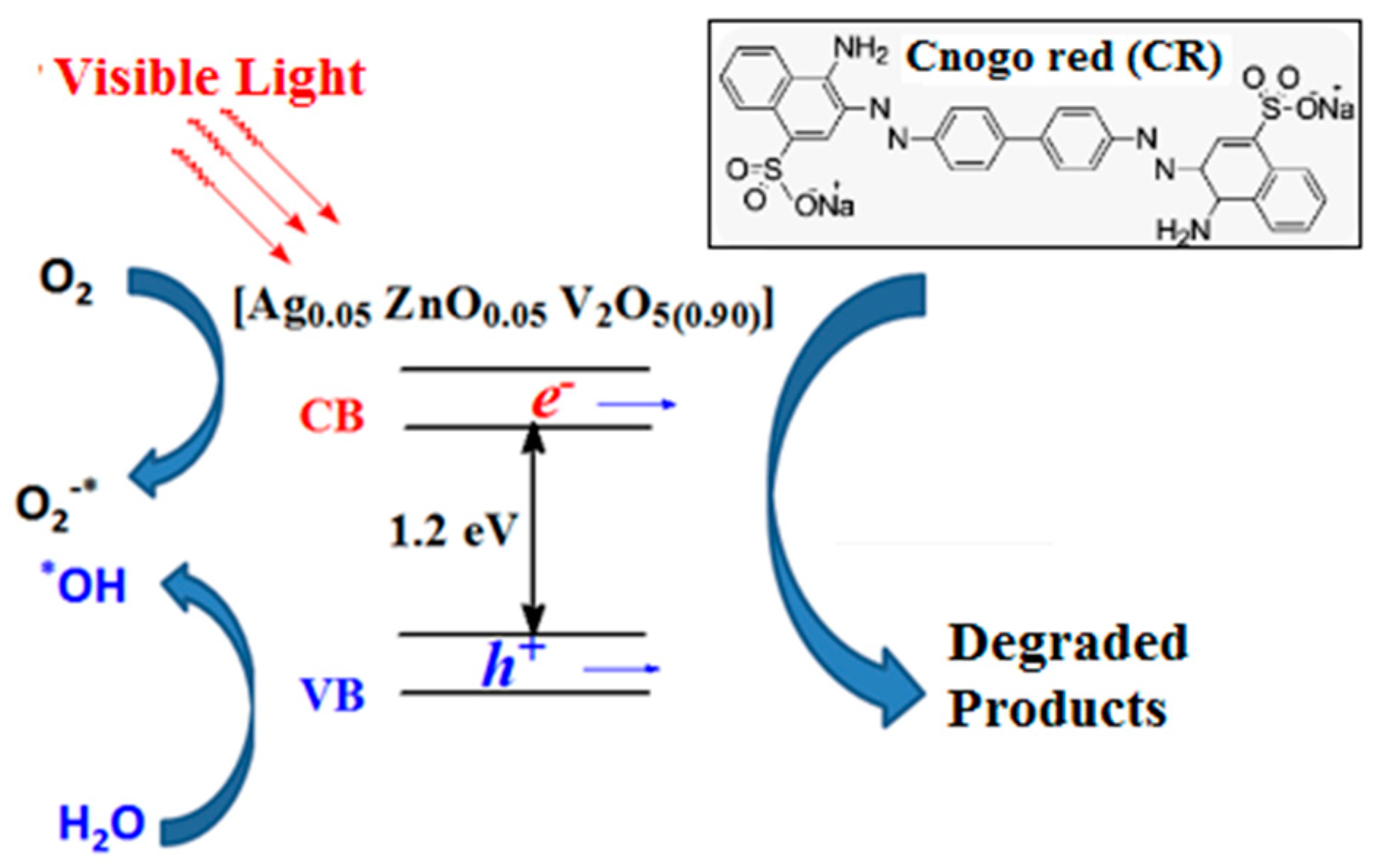

2.6. Photo-Degradation Mechanism

2.7. Periodicity Test

2.8. Catalyst Comparability

3. Materials and Methods

3.1. Materials

3.2. Extraction of Metallic Species

3.2.1. Zn

3.2.2. Ag

3.2.3. Extraction of V2O

3.3. Preparation of Composite Photocatalysts

3.3.1. Ag and ZnO Co-Doped V2O5

3.3.2. Nitrogen Doped [Ag0.05 ZnO0.05 V2O5(0.90)]

3.4. Photocatalytic Performance

3.5. Testing Procedures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, C.; Ma, W.; Zhao, J. Semiconductor-mediated photodegradation of pollutants under visible-light irradiation. Chem. Soc. Rev. 2010, 39, 4206–4219. [Google Scholar] [CrossRef]

- Zamani, A.; Sadjadi, M.S.; Mahjoub, A.; Yousefi, M.; Farhadyar, N. Synthesis, characterization and investigation of photocatalytic activity of ZnMnO3/Fe3O4 nanocomposite for degradation of dye Congo red under visible light irradiation. Int. J. Ind. Chem. 2020, 11, 205–216. [Google Scholar] [CrossRef]

- Thomas, M.; Naikoo, G.A.; Sheikh, M.U.-D.; Bano, M.; Khan, F. Effective photocatalytic degradation of Congo red dye using alginate/carboxymethyl cellulose/TiO2 nanocomposite hydrogel under direct sunlight irradiation. J. Photochem. Photobiol. A 2016, 327, 33–43. [Google Scholar] [CrossRef]

- Saeed, M.; Muneer, M.; Mumtaz, N.; Siddique, M.; Akram, N.; Hamayun, M. Ag-Co3O4: Synthesis, characterization and evaluation of its photocatalytic activity towards degradation of rhodamine B dye in aqueous medium. Chin. J. Chem. Eng. 2018, 26, 1264–1269. [Google Scholar] [CrossRef]

- Lachheb, H.; Puzenat, E.; Houas, A.; Ksibi, M.; Elaloui, E.; Guillard, C.; Herrmann, J.-M. Photocatalytic degradation of various types of dyes (Alizarin S, Crocein Orange G, Methyl Red, Congo Red, Methylene Blue) in water by UV-irradiated titania. Appl. Catal. B 2002, 39, 75–90. [Google Scholar] [CrossRef]

- Srivind, J.; Nagarethinam, V.S.; Suganya, M.; Balamurugan, S.; Prabha, D.; Balu, A.R. Visible light irradiated photocatalytic performance of SnS2-CdO nanocomposite against the degradation of rhodamine B (cationic) and congo red (anionic) dyes. Mater. Sci. Eng. B 2020, 255, 114530. [Google Scholar] [CrossRef]

- Sathiyavimal, S.; Vasantharaj, S.; Shanmugavel, M.E.; Manikandan, E.; Nguyen-Trie, P.; Brindhadevi, K.; Pugazhendhi, A. Facile synthesis and characterization of hydroxyapatite from fish bones: Photocatalytic degradation of industrial dyes (crystal violet and Congo red). Prog. Org. Coat. 2020, 148, 10589. [Google Scholar] [CrossRef]

- Saeed, M.; Siddique, M.; Usman, M.; ul Haq, A.; Khan, S.G.; Abdur Raoof, H. Synthesis and Characterization of Zinc Oxide and Evaluation of its Catalytic Activities for Oxidative Degradation of Rhodamine B Dye in Aqueous Medium. Z. Phys. Chem. 2017, 231, 1559–1572. [Google Scholar] [CrossRef]

- Chin, Y.-H.; Sin, J.-C.; Lam, S.-M.; Zeng, H.; Lin, H.; Li, H.; Huang, L.; Mohamed, A.R. 3-D/3-Z-Scheme Heterojunction Composite Formed by Marimo-like Bi2WO6 an Mammillaria-like ZnO for Expeditious Sunligh Photodegradation of Dimethyl Phthalate. Catalysts 2022, 12, 1427. [Google Scholar] [CrossRef]

- Byrne, C.; Subramanian, G.; Pillai, S.C. Recent advances in photocatalysis for environmental applications. J. Environ. Chem. Eng. 2018, 6, 3531–3555. [Google Scholar] [CrossRef]

- Jamshaid, M.; Nazir, M.A.; Najam, T.; Shah, S.S.A.; Khan, H.M.; Rehman, A. Facile synthesis of Yb3+-Zn2+ substituted M type hexaferrites: Structural, electric and photocatalytic properties under visible light for methylene blue removal. Chem. Phys. Lett. 2022, 805, 139939. [Google Scholar] [CrossRef]

- Lam, S.-M.; Jaffari, Z.H.; Sin, J.-C.; Zeng, H.; Lin, H.; Li, H.; Mohamed, A.R.; Ng, D.-Q. Surface decorated coral-like magnetic BiFeO3 with Au nanoparticles for effective sunlight photodegradation of 2,4-D and E. coli inactivation. J. Mol. Liq. 2021, 326, 115372. [Google Scholar] [CrossRef]

- Shahzad, K.; Hussain, S.; Nazir, M.A.; Jamshaid, M.; Rehman, A.; Alkorbi, A.S.; Alsaiari, R.; Alhemiary, N.A. Versatile Ag2O and ZnO nanomaterials fabricated via annealed Ag-PMOS and ZnO-PMOS: An efficient photocatalysis tool for azo dyes. J. Mol. Liq. 2022, 356, 119036. [Google Scholar] [CrossRef]

- Nazir, M.A.; Najam, T.; Jabeen, S.; Wattoo, M.A.; Bashir, M.S.; Shah, S.S.A.; Rehman, A. Facile synthesis of Tri-metallic layered double hydroxides (NiZnAl-LDHs): Adsorption of Rhodamine-B and methyl orange from water. Inorg. Chem. Commun. 2022, 145, 11000. [Google Scholar] [CrossRef]

- Venkatesham, N.; Reddy, K.R.; Rajanna, K.C.; Veerasomaiah, P. Vanadium Pentoxide as a Catalyst for Regioselective Nitration of Organic Compounds under Conventional and Nonconventional Conditions. Synth. React. Inorg. Met.-Org. Nano-Met. Chem. 2014, 44, 921–926. [Google Scholar] [CrossRef]

- Kumawat, A.K.; Nathawat, R.; Rathore, S.; Mukhopadhyay, A.K. Band gap tuning possibilities in vanadium oxide. Mater. Today Proc. 2021, 43, 2939–2943. [Google Scholar] [CrossRef]

- Varma, R.S.; Thorat, N.; Fernandes, R.; Kothari, D.C.; Patel, N.; Miotello, A. Dependence of photocatalysis on charge carrier separation in Ag-doped and decorated TiO2 nanocomposites. Catal. Sci. Technol. 2016, 6, 8428–8440. [Google Scholar] [CrossRef]

- Aziz, S.B.; Hussein, G.; Brza, M.A.; Mohammed, S.J.; Abdulwahid, R.T.; Saeed, S.R.; Hassanzadeh, A. Fabrication of Interconnected Plasmonic Spherical Silver Nanoparticles with Enhanced Localized Surface Plasmon Resonance (LSPR) Peaks Using Quince Leaf Extract Solution. Nanomaterials 2019, 9, 1557. [Google Scholar] [CrossRef]

- AlShibane, I.; Hargreaves, J.S.J.; Hector, A.L.; Levasonb, W.; McFarlanea, A. Synthesis and methane cracking activity of a silicon nitride supported vanadium nitride nanoparticle composite. Dalton Trans. 2017, 46, 8782–8787. [Google Scholar] [CrossRef]

- Jayarambabu, N.; Kumari, B.S.; Rao, K.V.; Prabhu, Y.T. Germination and Growth Characteristics of Mungbean Seeds (Vigna radiata L.) affected by Synthesized Zinc Oxide Nanoparticles. Int. J. Curr. Eng. Technol. 2014, 4, 3411–3416. [Google Scholar]

- Rupa, A.V.; Manikandan, D.; Divakar, D.; Sivakumar, T. Effect of deposition of Ag on TiO2 nanoparticles on the photodegradation of Reactive Yellow-17. J. Hazard. Mater. 2007, 147, 906–913. [Google Scholar] [CrossRef] [PubMed]

- Behnajady, M.A.; Modirshahla, N.; Shokri, M.; Rad, B. Enhancement of photocatalytic activity of TiO2 nanoparticles by silver doping: Photodeposition versus liquid impregnation methods. Glob. Nest. J. 2008, 10, 1–7. [Google Scholar] [CrossRef]

- Silversmit, G.; Depla, D.; Poelman, H.; Marin, G.B.; De Gryse, R. Determination of the V2p XPS binding energies for different vanadium oxidation states (V5+ to V0+). J. Electron Spectrosc. Relat. Phenom. 2004, 135, 167–175. [Google Scholar] [CrossRef]

- Yu, Z.-T.; Xu, J.-J.; Jiang, Y.-S.; Shi, Z.; Guo, Y.; Wang, D.J.; Chen, J.-S. Photoluminescent and photovoltaic properties observed in a zinc borate Zn2(OH)BO3. J. Mater. Chem. 2003, 13, 2227–2233. [Google Scholar] [CrossRef]

- Gao, X.-Y.; Wang, S.-Y.; Li, J.; Zheng, Y.-X.; Zhang, R.-J.; Zhou, P.; Yang, Y.M.; Chen, L.-Y. Study of structure and optical properties of silver oxide films by ellipsometry, XRD and XPS methods. Thin Solid Films 2004, 455, 438–442. [Google Scholar] [CrossRef]

- Masetti, E.; Bulir, J.; Gagliardi, S.; Janicki, V.; Krasilnikova, A.; Di Santo, G.; Coluzza, C. Ellipsometric and XPS analysis of the interface between silver and SiO2, TiO2 and SiNx thin films. Thin Solid Films 2004, 455, 468–472. [Google Scholar] [CrossRef]

- Shalaby, N.H.; Sayed, M.A. Stover ash—Extracted mixed oxides surface-doped with Ni for photo-degradation of water organic pollutants. Int. J. Environ. Anal. Chem. 2021. [Google Scholar] [CrossRef]

- Zhuk, S.; Siol, S. Chemical state analysis of reactively sputtered zinc vanadium nitride: The Auger parameter as a tool in materials design. Appl. Surf. Sci. 2022, 601, 154172. [Google Scholar] [CrossRef]

- Wua, Q.-H.; Thissena, A.; Jaegermanna, W.; Liu, M. Photoelectron spectroscopy study of oxygen vacancy on vanadium oxides surface. Appl. Surf. Sci. 2004, 236, 473–478. [Google Scholar] [CrossRef]

- Hu, Q.H.; Qiao, S.Z.; Haghseresht, F.; Wilson, M.A.; Lu, G.Q. Adsorption Study for Removal of Basic Red Dye Using Bentonite. Ind. Eng. Chem. Res. 2006, 45, 733–738. [Google Scholar] [CrossRef]

- Srilakshmi, P.; Maheswari, A.U.; Sajeev, V.; Sivakumar, M. Tuning the optical bandgap of V2O5 nanoparticles by doping transition metal ions. Mater. Today Proc. 2019, 18, 1375–1379. [Google Scholar] [CrossRef]

- Nah, Y.-C.; Paramasivam, I.; Schmuki, P. Doped TiO2 and TiO2 Nanotubes: Synthesis and Applications. Chem. Phys. Chem. 2010, 11, 2698–2713. [Google Scholar] [CrossRef]

- Zaleska, A. Doped-TiO2: A Review. Recent Pat. Eng. 2008, 2, 157–164. [Google Scholar] [CrossRef]

- Maeda, M.; Yamada, T. Photocatalytic activity of metal-doped titanium oxide films prepared by sol-gel process. J. Phys. Conf. Ser. 2007, 61, 755–759. [Google Scholar] [CrossRef]

- Makwana, V.D.; Son, Y.-C.; Howell, A.R.; Suib, S.L. The Role of Lattice Oxygen in Selective Benzyl Alcohol Oxidation Using OMS-2 Catalyst: A Kinetic and Isotope-Labeling Study. J. Catal. 2002, 210, 46–52. [Google Scholar] [CrossRef]

- Shalaby, N.H. Photocatalytic Performance of Organically Templated Cr-Doped Co3O4 in Remediation of Industrial Wastewater: Effect of Order–Disorde in the Lattice. Arab. J. Sci. Eng. 2022. [Google Scholar] [CrossRef]

- Hansheng, L.; Jungang, W.; Congbiao, C.; Litao, J.; Bo, H.; Debao, L. Effects of macropores on reducing internal diffusion limitations in Fischer–Tropsch synthesis using a hierarchical cobalt catalyst Catalyst. RSC Adv. 2017, 7, 9436–9445. [Google Scholar] [CrossRef]

- Emam, E.A.; Aboul-Gheit, N.A.K. Photocatalytic degradation of oil-emulsion in water/seawater using titanium dioxide. Energy Sources A Recov. Util. Environ. Eff. 2014, 36, 1123–1133. [Google Scholar] [CrossRef]

- Sowmya, S.R.; Madhu, G.M.; Hashir, M. Studies on Nano-Engineered TiO2 Photo Catalyst for Effective Degradation of Dye. Mater. Sci. Eng. 2018, 310, 012026. [Google Scholar] [CrossRef]

- Huancong, S.; Min, H.; Yuandong, H.; Lifeng, C.; Linna, Z.; Mingqi, C.; Linhua, J.; Hussameldin, I.; Paitoon, T. Eley–Rideal model of heterogeneous catalytic carbamate formation based on CO2-MEA absorptions with CaCO. R. Soc. Open Sci. 2019, 6, 1903. [Google Scholar] [CrossRef]

- Palominos, R.; Freer, J.; Mondaca, M.A.; Mansilla, H.D. Evidence for hole participation during the photocatalytic oxidation of the antibiotic flumequine. J. Photochem. Photobiol. A 2008, 193, 139–145. [Google Scholar] [CrossRef]

- Erdemoğlu, S.; Aksu, S.K.; Sayılkan, F.; İzgi, B.; Asiltürk, M.; Sayılkan, H.; Frimmel, F.; Güçer, S. Photocatalytic degradation of Congo Red by hydrothermally synthesized nanocrystalline TiO2 and identification of degradation products by LC–MS. J. Hazard. Mater. 2008, 155, 469–476. [Google Scholar] [CrossRef]

- Sin, J.-C.; Lam, S.-M.; Zeng, H.; Lin, H.; Li, H.; Huang, L.; Tham, K.-O.; Mohamed, A.R.; Lim, J.-W. Enhanced synchronous photocatalytic 4 chlorophenol degradation and Cr(VI) reduction by novel magnetic separable visible-light-driven Z-scheme CoFe2O4/P-doped BiOBr heterojunction nanocomposites. Environ. Res. 2022, 212, 113394. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Jiang, R.; Xiao, L.; Chang, Y.; Guan, Y.; Li, X.; Zeng, G. Photocatalytic decolorization and degradation of Congo Red on innovative crosslinked chitosan/nano-CdS composite catalyst under visible light irradiation. J. Hazard. Mater. 2009, 169, 933–940. [Google Scholar] [CrossRef] [PubMed]

- Natarajan, T.S.; Natarajan, K.; Bajaj, H.C.; Tayade, R.J. Energy Efficient UV-LED Source and TiO2 Nanotube Array-Based Reactor for Photocatalytic Application. Ind. Eng. Chem. Res. 2011, 50, 7753–7762. [Google Scholar] [CrossRef]

- Jiang, R.; Yao, J.; Zhu, H.; Fu, Y.; Guan, Y.; Xiao, L.; Zeng, G. Effective decolorization of congo red in aqueous solution by adsorption and photocatalysis using novel magnetic alginate/γ-Fe2O3/CdS nanocomposite. Desalin. Water Treat. 2014, 52, 238–247. [Google Scholar] [CrossRef]

- Jafry, H.R.; Liga, M.V.; Barron, A.R. Single walled carbon nanotubes (SWNTs) as templates for the growth of TiO2: The effect of silicon in coverage and the positive and negative synergies for the photocatalytic degradation of Congo red dye. New J. Chem. 2011, 35, 400–406. [Google Scholar] [CrossRef]

- Guo, H.; Lin, K.; Zheng, Z.; Xiao, F.; Li, S. Sulfanilic Acid-Modified P25 TiO2 Nanoparticles with Improved Photocatalytic Degradation on Congo Red under Visible Light. Dyes Pigm. 2012, 92, 1278–1284. [Google Scholar] [CrossRef]

- Ma, A.; Zhang, L.; Peng, J.; Zheng, X.; Li, S.; Yang, K.; Chen, W. Extraction of zinc from blast furnace dust in ammonia leaching system. Green Process. Synth. 2016, 5, 23–30. [Google Scholar] [CrossRef]

- Ganesan, R.; Narasimhalu, P.; Joseph, A.I.J.; Pugazhendhi, A. Synthesis of silver nanoparticle from X-ray film and its application in production of biofuel from jatropha oil. Int. J. Energy Res. 2020, 45, 17378–17388. [Google Scholar] [CrossRef]

- Holloway, P.; Merriam, K.; Etsell, T. Nitric acid leaching of silver sulphide precipitates. Hydrometallurgy 2004, 74, 213–220. [Google Scholar] [CrossRef]

- Mohanty, J.; Rath, P.C.; Bhattacharya, I.N.; Paramguru, R.K. The recovery of vanadium from spent catalyst: A case study. Trans. Inst. Min. Metall. C 2011, 120, 56–60. [Google Scholar] [CrossRef]

- Pan, Y.X.; Sun, Y.; Qi, M.; Qin, R.; Che, X.; Zhang, Y. A clean and efficient method for separation of vanadium and molybdenum by aqueous two-phase systems. J. Mol. Liq. 2020, 313, 113540. [Google Scholar] [CrossRef]

- Rengifo-Herrera, J.A.; Pulgarin, C. Photocatalytic activity of N, S co-doped and N-doped commercial anatase TiO2 powders towards phenol oxidation and E. coli inactivation under simulated solar light irradiation. J. Sol. Energy 2010, 84, 37–43. [Google Scholar] [CrossRef]

| Item | [Ag0.05 ZnO0.05 V2O5(0.90)] | [Ag0.05 ZnO0.05 V2O5(0.90)]N |

|---|---|---|

| DPCP (nm) | 7.22 | 6.71 |

| VP0.95 (cm3 g−1) | 3.1 | 2.58 |

| SBET (m2 g−1) | 88.6 | 95.7 |

| Catalyst | Light Source | Time (min) | %Degradation | References |

|---|---|---|---|---|

| Chitosan/nano-CdS | Xenon lamp (300 W) | 180 | 85.9 | [44] |

| TNA-450 | UV-LED- 400 nm (0.6 W) | 300 | 100 | [45] |

| m-alginate/Fe2O3/CdS composite | xenon lamp (300 W) | 300 | 91.6 | [46] |

| TiO2-SWNT-P-21 | UV-A 350 nm (8 W) | 80 | 82 | [47] |

| Sulfanilic acid-modified P25 TiO2 | halogen-tungsten lamp 400 nm (300 W) | 210 | 90 | [48] |

| [Ag0.05 ZnO0.05 V2O5(0.90)] | 300 W high-pressure mercury lamp | 120 | 89.9 | This work |

| Element | O | Zn | C | Fe | Si | Ca | Al | Mg | Pb | S |

|---|---|---|---|---|---|---|---|---|---|---|

| wt.(%) | 35.1 | 5.13 | 28.9 | 25.2 | 1.72 | 1.33 | 1.28 | 0.32 | 0.50 | 0.44 |

| Item | V2O5 | Fe2O3 | SiO2 | S | Na2O | K2O | Al2O |

|---|---|---|---|---|---|---|---|

| wt.(%) | 5.2 | 0.82 | 44.6 | 38.2 | 2.24 | 7.6 | 1.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shalaby, N.H.; Al-Mhyawi, S.R.; Ragab, A.H.; Elmawgoud, H.A.; Al-Swat, E.A.; Al-Thubaiti, N.M. Waste-Extracted Zn and Ag Co-Doped Spent Catalyst-Extracted V2O5 for Photocatalytic Degradation of Congo Red Dye: Effect of Metal-Nonmetal Co-Doping. Catalysts 2023, 13, 584. https://doi.org/10.3390/catal13030584

Shalaby NH, Al-Mhyawi SR, Ragab AH, Elmawgoud HA, Al-Swat EA, Al-Thubaiti NM. Waste-Extracted Zn and Ag Co-Doped Spent Catalyst-Extracted V2O5 for Photocatalytic Degradation of Congo Red Dye: Effect of Metal-Nonmetal Co-Doping. Catalysts. 2023; 13(3):584. https://doi.org/10.3390/catal13030584

Chicago/Turabian StyleShalaby, Nasser H., Saedah R. Al-Mhyawi, Ahmed H. Ragab, H. A. Elmawgoud, Eman A. Al-Swat, and Noha M. Al-Thubaiti. 2023. "Waste-Extracted Zn and Ag Co-Doped Spent Catalyst-Extracted V2O5 for Photocatalytic Degradation of Congo Red Dye: Effect of Metal-Nonmetal Co-Doping" Catalysts 13, no. 3: 584. https://doi.org/10.3390/catal13030584

APA StyleShalaby, N. H., Al-Mhyawi, S. R., Ragab, A. H., Elmawgoud, H. A., Al-Swat, E. A., & Al-Thubaiti, N. M. (2023). Waste-Extracted Zn and Ag Co-Doped Spent Catalyst-Extracted V2O5 for Photocatalytic Degradation of Congo Red Dye: Effect of Metal-Nonmetal Co-Doping. Catalysts, 13(3), 584. https://doi.org/10.3390/catal13030584