Pyrite Cinder as an Effective Fenton-like Catalyst for the Degradation of Reactive Azo Dye: Effects of Process Parameters and Complete Effluent Characterization

Abstract

1. Introduction

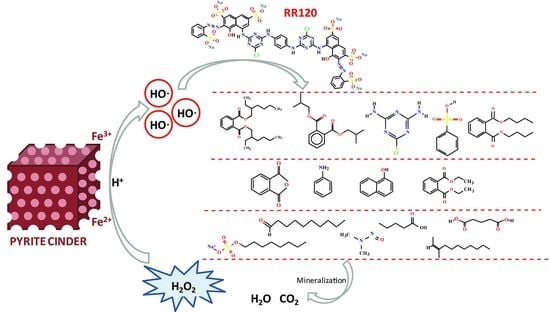

| ▓Fe2+ + H2O2 + H+ → ▓Fe3+ + HO• + H2O | (1) |

| ▓Fe2+ + H2O2 → ▓Fe3+ + HO− + HO• | (2) |

| ▓Fe3+ + H2O2 → ▓Fe3+(H2O2) | (3) |

| ▓Fe3+(H2O2) → (▓Fe2+•O2H) + H+ | (4) |

| (▓Fe2+•O2H) → ▓Fe2+ + HO2•/O2•− | (5) |

| ▓Fe3+ + O2•- → ▓Fe2+ + O2 | (6) |

| ▓Fe2+ + HO2•/O2•− → ▓Fe3+ + HO2− | (7) |

| ▓Fe + RR120 ↔ ▓Fe(RR120)s | (8) |

| ▓Fe(RR120)s + HO• → ▓Fe + (RR120 by-products)solution → CO2 + H2O | (9) |

| HO• + RR120solution → (RR120 by-products)solution→ CO2 + H2O | (10) |

2. Results and Discussion

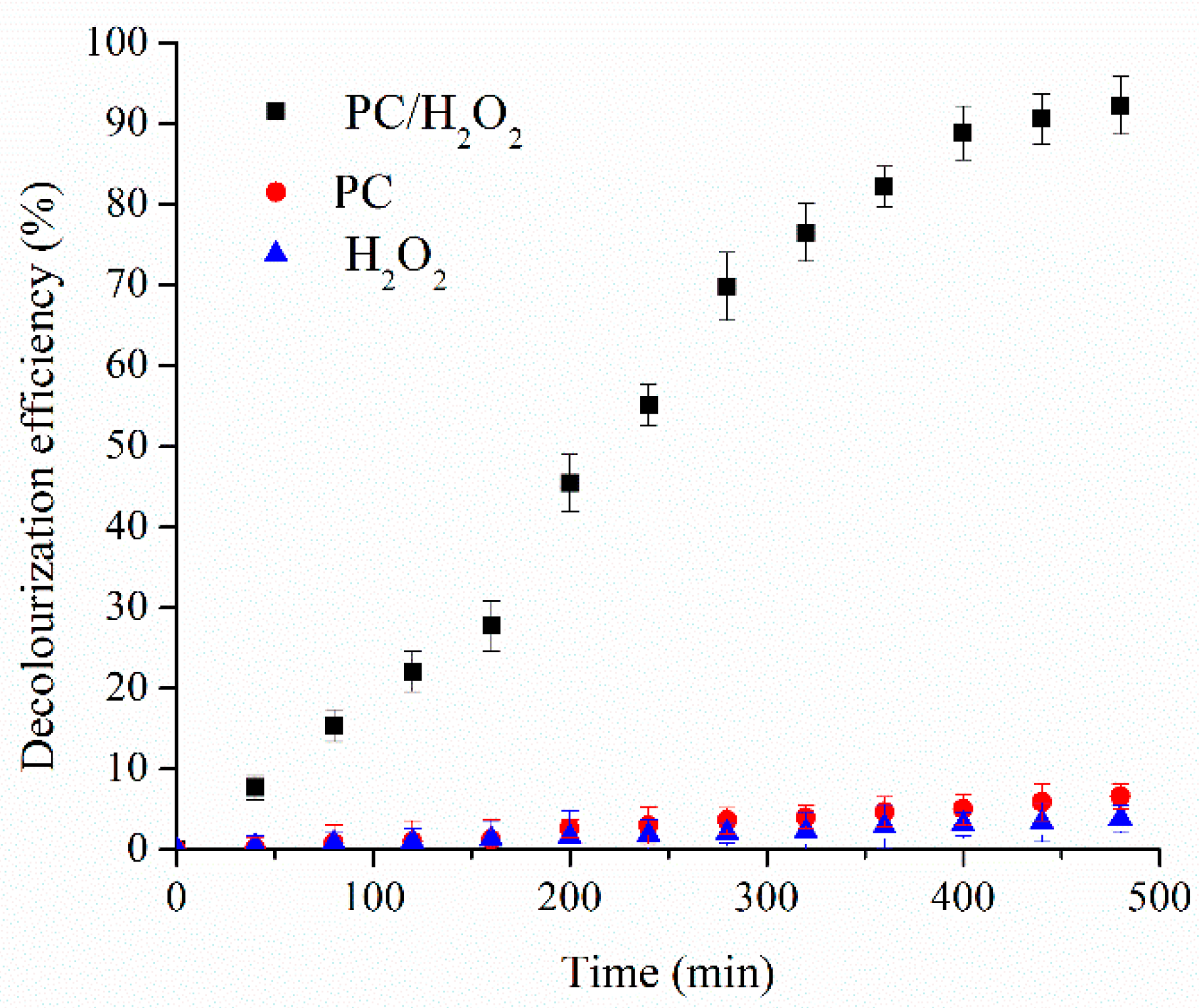

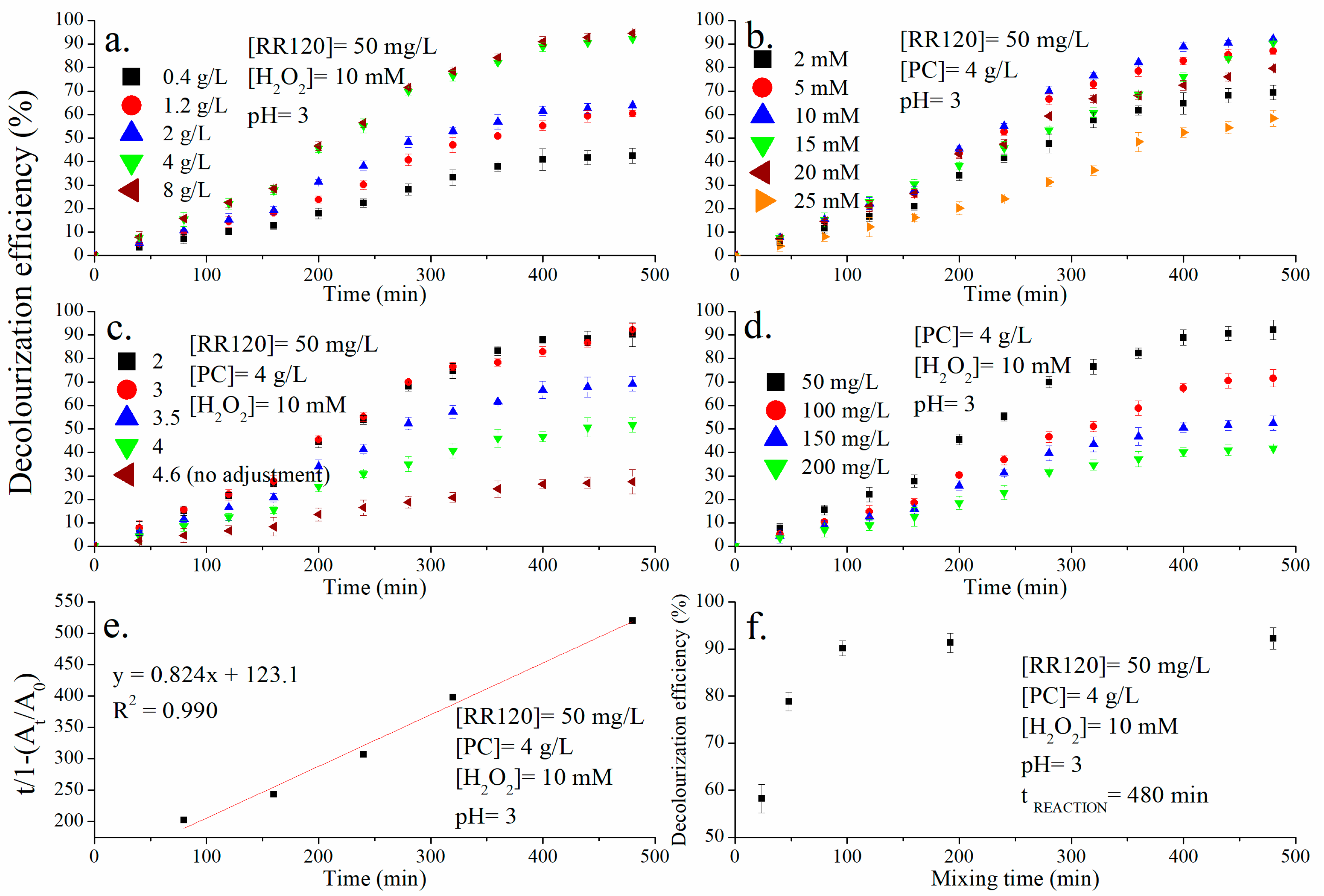

2.1. Optimization of Operating Conditions for Dye solution Decolourization

2.2. Effluent Characterization

3. Materials and Methods

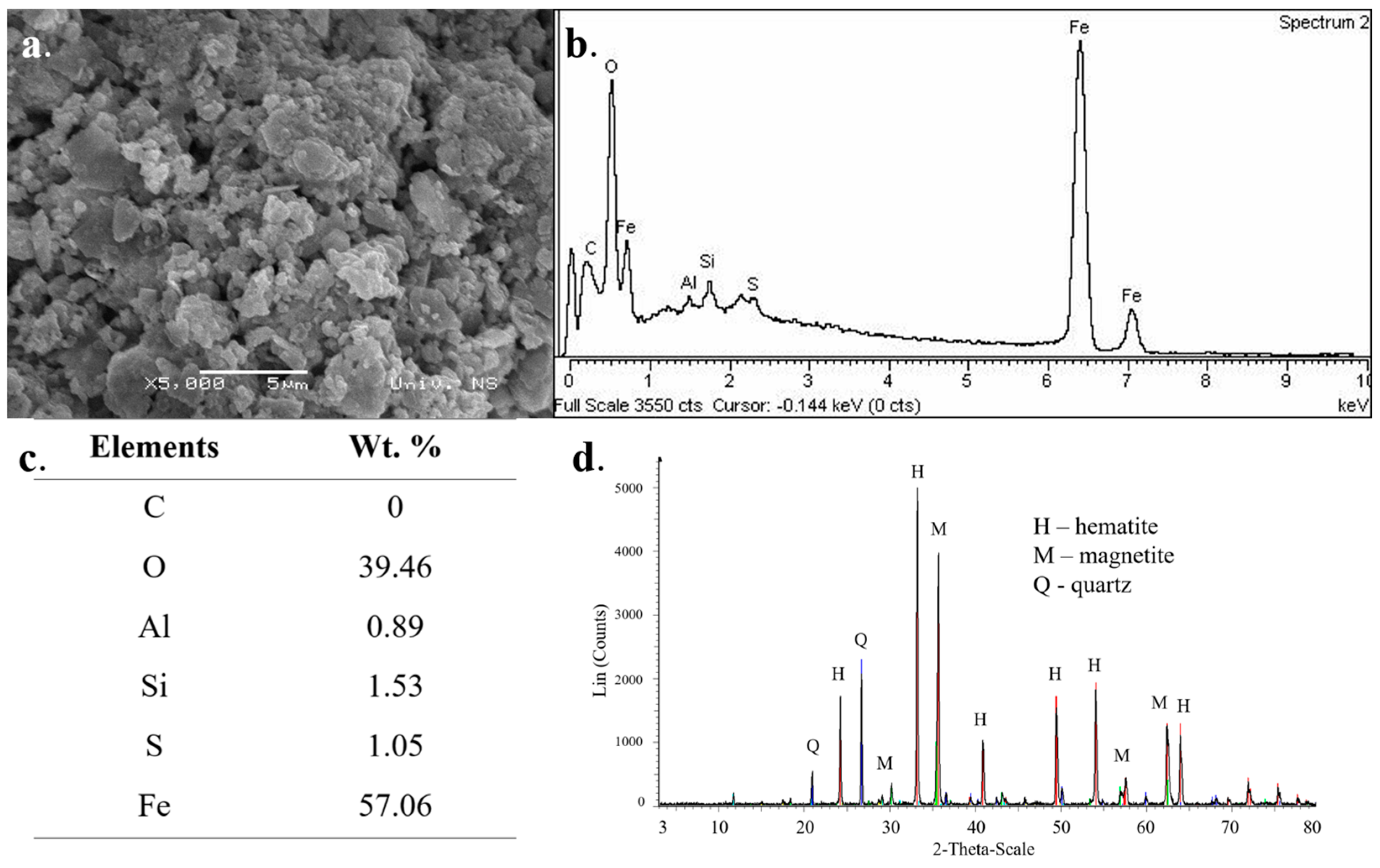

3.1. PC Characterization

3.2. Optimization of Operating Conditions for Dye Solution Decolorization

3.3. Effluent Characterization

4. Conclusions

- i.

- The PC characterization, in terms of structure, composition, and iron oxides content, indicated that this material can be considered as a promising catalyst in Fenton-like systems.

- ii.

- PC demonstrated superior catalyst features for the decolorization of azo dye RR120 in a modified Fenton process. Under the optimal conditions (RR120 = 50 mg/L, PC = 4 g/L, H2O2 = 10 mM, and pH = 3) decolorization of 92% was achieved.

- iii.

- The metal content in the resulting effluent suggested the necessity for an additional treatment step (the addition of lime) in order to remove the leached metals and As.

- iv.

- A notable degree of mineralization was achieved under the applied condition (85% and 62% of COD and TOC removal, respectively).

- v.

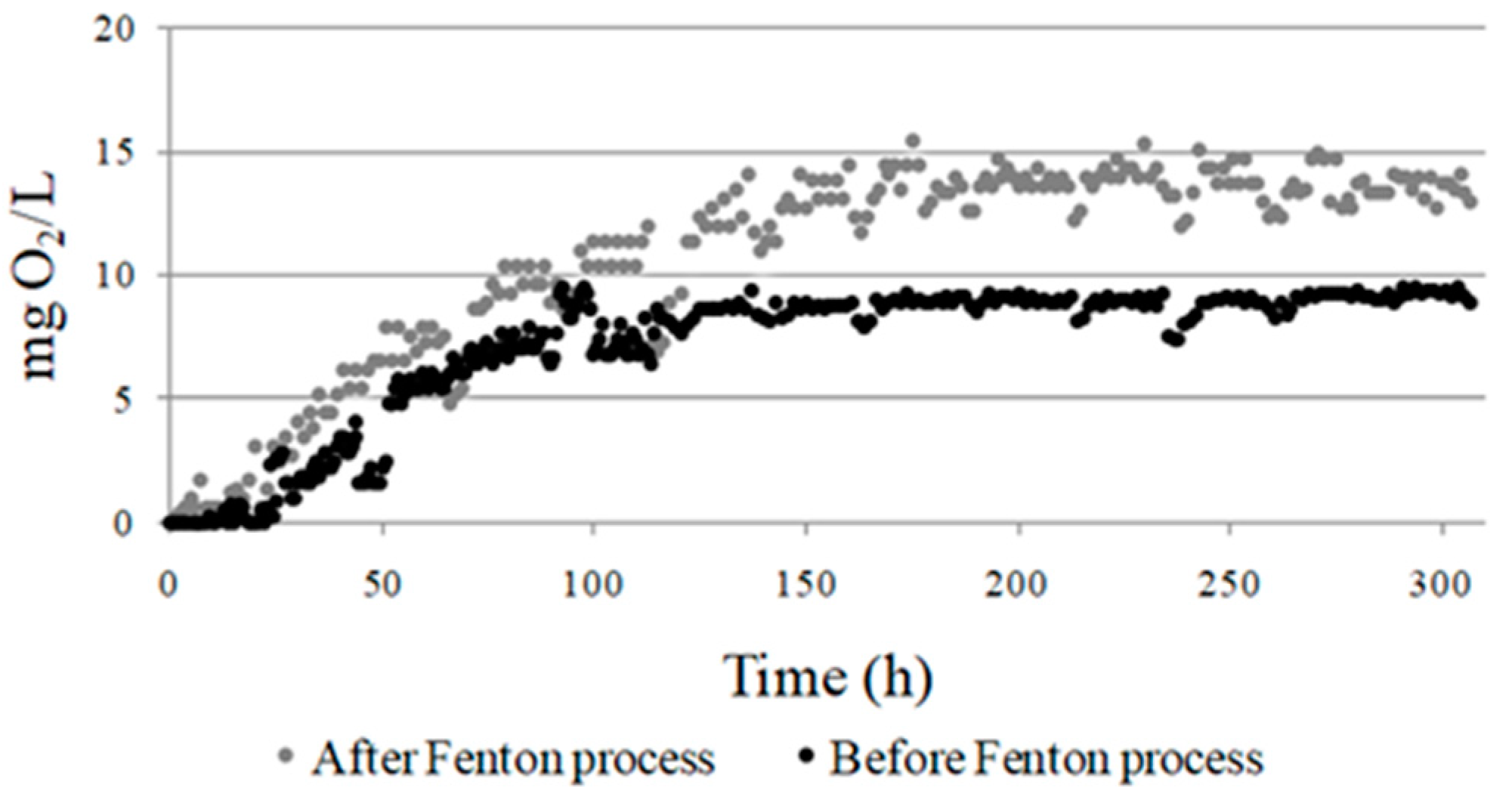

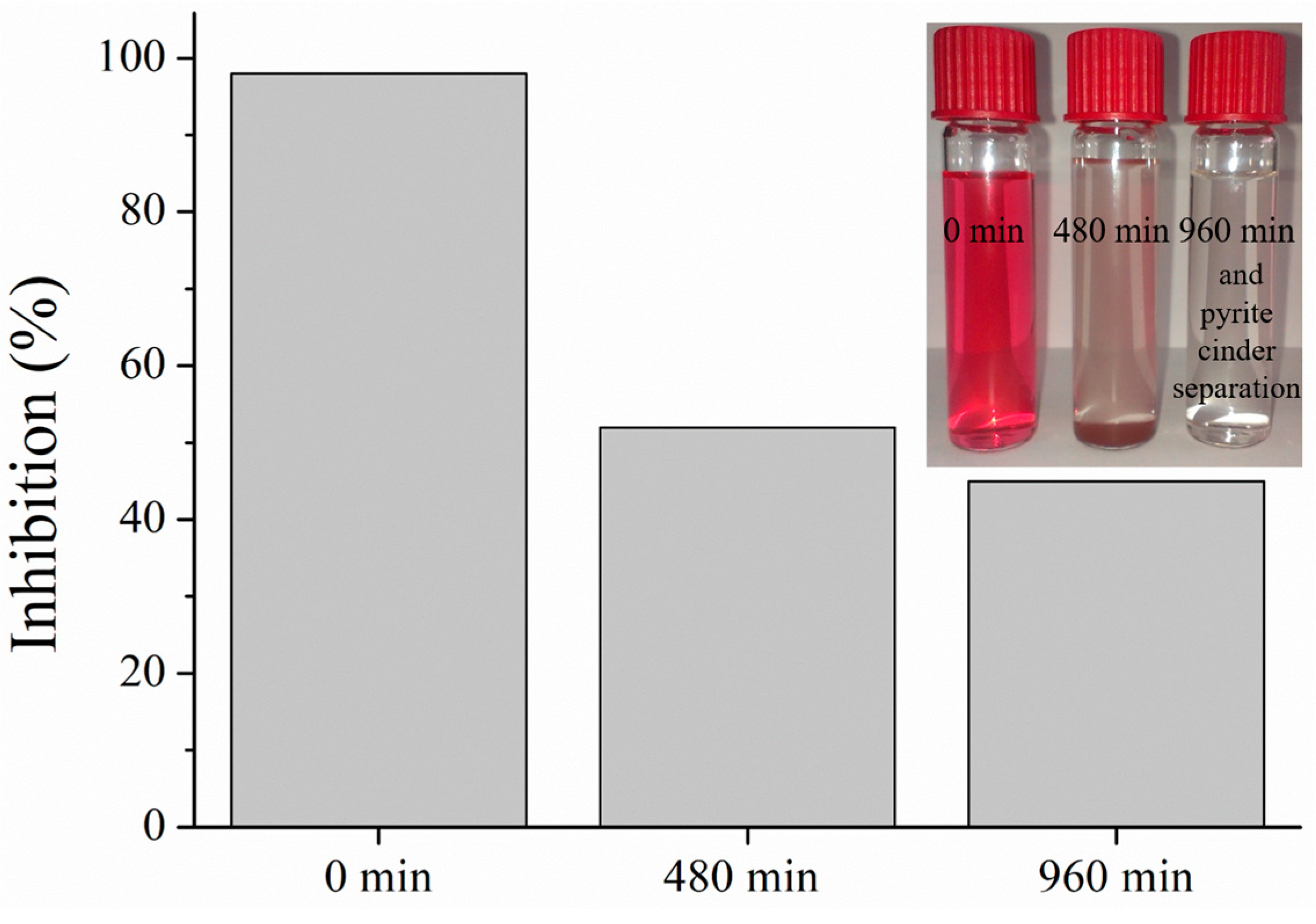

- The respirometry measurements showed increased oxygen consumption, indicating the higher biodegradability of the compounds in the treated effluent and the absence of the toxic effects of resulting oxidation intermediates towards the microorganisms that carry out biodegradation. The bioluminescence test showed that as the Fenton-like reactions proceeded, inhibition was reduced to 45% (originating from the simpler dye molecule intermediates).

- vi.

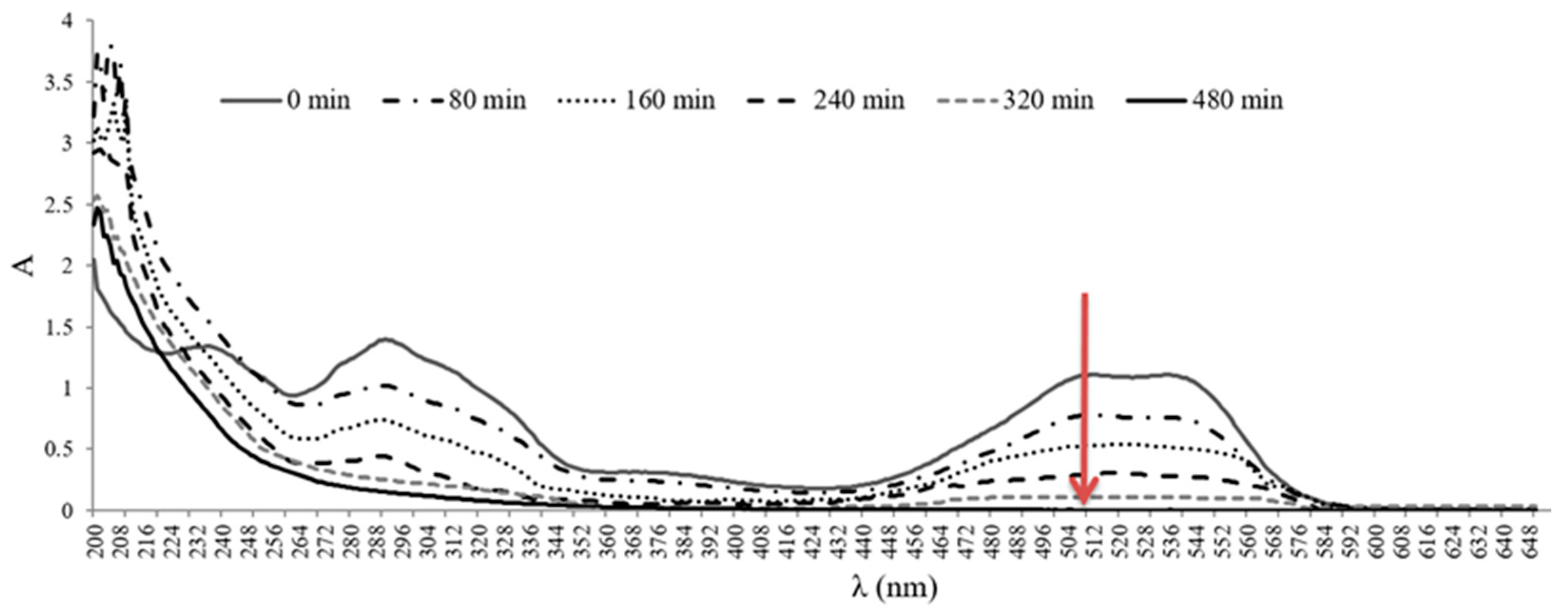

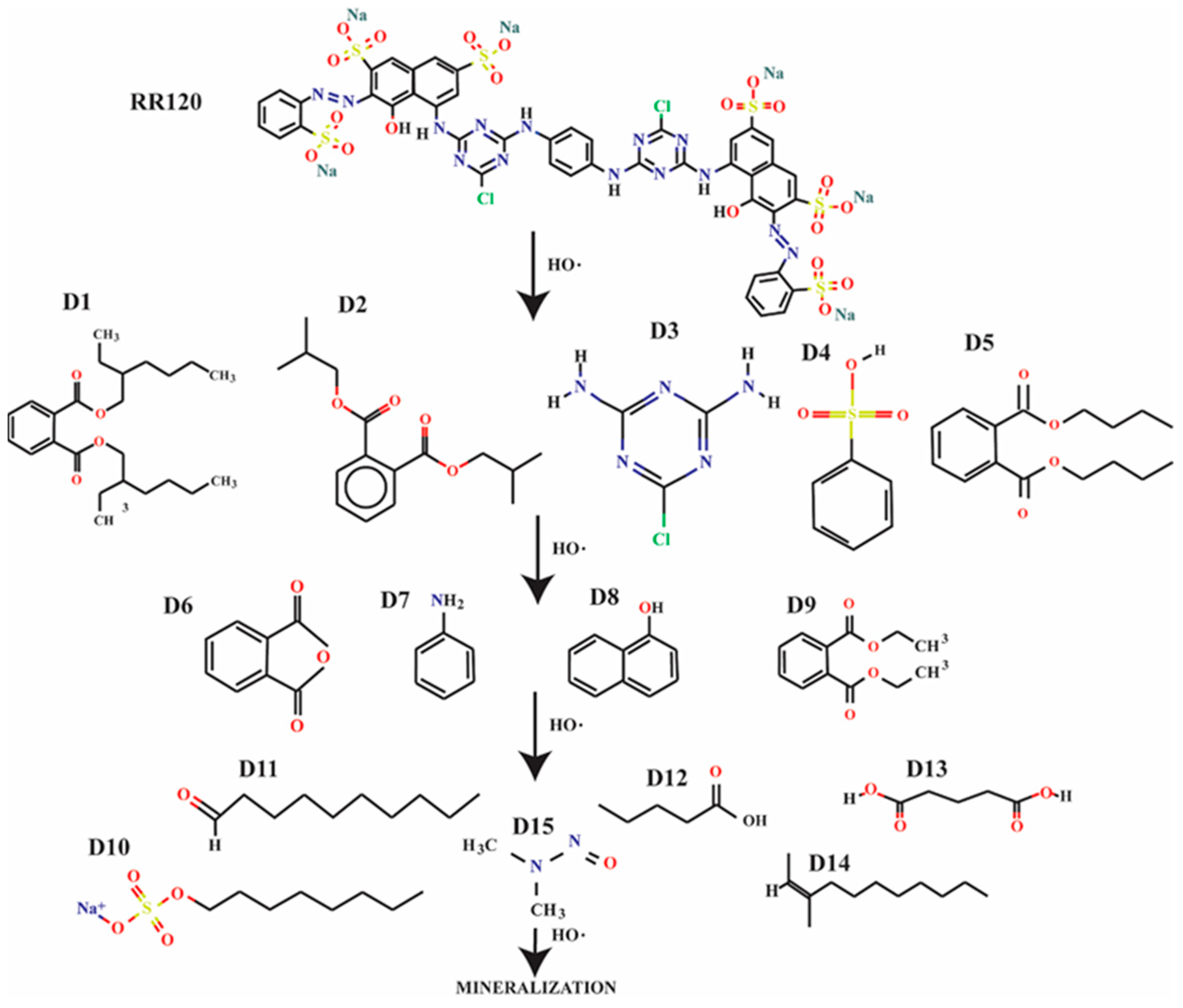

- The UV-VIS and GC/MS analysis confirmed that the azo link was broken down, and the later decomposition of the dye molecules proceeded in the direction of creating simpler aromatic and aliphatic intermediates.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Santos, O.D.S.H.; de Freitas Carvalho, C.; da Silva, G.A.; Dos Santos, C.G. Manganese ore tailing: Optimization of acid leaching conditions and recovery of soluble manganese. J. Environ. Manag. 2015, 147, 314–320. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Gao, Z.; He, H.; Yang, S.; Sun, C. Efficient degradation of Acid Orange 7 in aqueous solution by iron ore tailing Fenton-like process. Chemosphere 2016, 150, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Ajmal, A.; Majeed, I.; Malik, R.N.; Idriss, H.; Nadeem, M.A. Principles and mechanisms of photocatalytic dye degradation on TiO2 based photocatalysts: A comparative overview. RSC Adv. 2014, 4, 37003–37026. [Google Scholar] [CrossRef]

- Bae, S.; Kim, D.; Lee, W. Degradation of diclofenac by pyrite catalyzed Fenton oxidation. Appl. Catal. B Environ. 2013, 134–135, 93–102. [Google Scholar] [CrossRef]

- Becelic-Tomin, M.; Dalmacija, B.; Rajic, L.; Tomasevic, D.; Kerkez, D.; Watson, M.; Prica, M. Degradation of anthraquinone dye Reactive Blue 4 in pyrite ash catalyzed Fenton reaction. Sci. World J. 2014, 2014, 234654. [Google Scholar] [CrossRef] [PubMed]

- Tiberg, C.; Bendz, D.; Theorin, G.; Kleja, D.B. Evaluating solubility of Zn, Pb, Cu and Cd in pyrite cinder using leaching tests and geochemical modelling. Appl. Geochem. 2017, 85, 106–117. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Xiao, T.; Chen, Y.; Long, J.; Zhang, G.; Zhang, P.; Li, C.; Zhuang, L.; Li, K. Efficient removal of thallium(I) from wastewater using flower-like manganese dioxide coated magnetic pyrite cinder. Chem. Eng. J. 2018, 353, 867–877. [Google Scholar] [CrossRef]

- Tomin, M.B.; Kulic, A.; Kerkez, D.; Prica, M.; Rapajic, S.; Pilipovic, D.T.; Pesic, V. Reactive dye degradation using Fe-loaded bentonite as a Fenton-like catalyst: From process optimization to effluent acute toxicity. Fresen. Environ. Bull. 2017, 26, 569–583. [Google Scholar]

- Donadelli, J.A.; Carlos, L.; Arques, A.; Einschlag, F.S.G. Kinetic and mechanistic analysis of azo dyes decolorization by ZVI-assisted Fenton systems: pH dependent shift in the contributions of reductive and oxidative transformation pathways. Appl. Catal. B Environ. 2018, 231, 51–61. [Google Scholar] [CrossRef]

- Oladipo, A.A.; Ifebajo, A.O.; Gazi, M. Magnetic LDH-based CoO–NiFe2O4 catalyst with enhanced performance and recyclability for efficient decolorization of Azo dye via Fenton-like reactions. Appl. Catal. B Environ. 2019, 243, 243–252. [Google Scholar] [CrossRef]

- Li, F.; Xia, Q.; Gao, Y.; Cheng, Q.; Ding, L.; Yang, B.; Tian, Q.; Ma, C.; Sand, W.; Liu, Y. Anaerobic biodegradation and decolorization of a refractory acid dye by a forward osmosis membrane bioreactor. Environ. Sci. Water Res. Technol. 2018, 4, 272–280. [Google Scholar] [CrossRef]

- Gioia, L.; Ovsejevi, K.; Manta, C.; Míguez, D.; Menéndez, P. Biodegradation of acid dyes by an immobilized laccase: An ecotoxicological approach. Environ. Sci. Water Res. Technol. 2018, 4, 2125–2135. [Google Scholar] [CrossRef]

- Govindan, K.; Raja, M.; Maheshwari, S.U.; Noel, M. Analysis and understanding of amido black 10B dye degradation in aqueous solution by electrocoagulation with the conventional oxidants peroxomonosulfate, peroxodisulfate and hydrogen peroxide. Environ. Sci. Water Res. Technol. 2015, 1, 108–119. [Google Scholar] [CrossRef]

- Kerkez, D.V.; Tomašević, D.D.; Kozma, G.; Bečelić-Tomin, M.R.; Prica, M.D.; Rončević, S.D.; Kukovecz, A.; Dalmacija, B.D.; Kónya, Z. Three different clay-supported nanoscale zero-valentiron materials for industrial azo dye degradation: A comparative study. J. Taiwan Inst. Chem. Eng. 2014, 45, 2451–2461. [Google Scholar] [CrossRef]

- Dou, J.; Yin, S.; Chong, J.Y.; Zhang, B.; Han, J.; Huang, Y.; Xu, R. Carbon spheres anchored Co3O4 nanoclusters as an efficient catalyst for dye degradation. Appl. Catal. A Gen. 2016, 513, 106–115. [Google Scholar] [CrossRef]

- Milidrag, G.P.; Prica, M.; Kerkez, D.; Dalmacija, B.; Kulic, A.; Pilipovic, D.T.; Tomin, M.B. A comparative study of the decolorization capacity of the solar-assisted Fenton process using ferrioxalate and Al, Fe bentonite catalysts in a parabolic trough reactor. J. Taiwan Inst. Chem. Eng. 2018, 93, 436–449. [Google Scholar] [CrossRef]

- Arslan-Alaton, I.; Gursoy, B.H.; Schmidt, J.-E. Advanced oxidation of acid and reactive dyes: Effect of Fenton treatment on aerobic, anoxic and anaerobic processes. Dye. Pigment. 2008, 78, 117–130. [Google Scholar] [CrossRef]

- Babuponnusami, B.; Muthukumar, K. A review on Fenton and improvements to the Fenton process for wastewater treatment. J. Environ. Chem. Eng. 2014, 2, 557–572. [Google Scholar] [CrossRef]

- Shoaebargh, S.; Karimi, A.; Dehghan, G. Performance study of open channel reactor on AO7 decolorization using glucose oxidase/TiO2/polyurethane under UV-VIS LED. J. Taiwan Inst. Chem. Eng. 2014, 45, 1677–1684. [Google Scholar] [CrossRef]

- Rache, M.L.; García, A.R.; Zea, H.R.; Silva, A.M.; Madeira, L.M.; Ramírez, J.H. Azo-dye orange II degradation by the heterogeneous Fenton-like process using a zeolite Y-Fe catalyst—Kinetics with a model based on the Fermi’s equation. Appl. Catal. B Environ. 2014, 146, 192–200. [Google Scholar] [CrossRef]

- Gozmen, B.; Kayan, B.; Gizir, A.M.; Hesenov, A. Oxidative degradations of reactive blue 4 dye by different advanced oxidation methods. J. Hazard. Mater. 2009, 168, 129–136. [Google Scholar] [CrossRef] [PubMed]

- Chang, M.-W.; Chern, J.-M. Decolorization of peach red azo dye, HF6 by Fenton reaction: Initial rate analysis. J. Taiwan Inst. Chem. E 2010, 41, 221–228. [Google Scholar] [CrossRef]

- Ilinoiu, E.C.; Pode, R.; Manea, F.; Colar, L.A.; Jakab, A.; Orha, C.; Ratiu, C.; Lazau, C.; Sfarloaga, P. Photocatalytic activity of a nitrogen-doped TiO2 modified zeolite in the degradation of Reactive Yellow 125 azo dye. J. Taiwan Inst. Chem. E 2013, 44, 270–278. [Google Scholar] [CrossRef]

- Saravanan, R.; Gupta, V.K.; Narayanan, V.; Stephen, A. Visible light degradation of textile effluent using novel catalyst ZnO/Mn2O3. J. Taiwan Inst. Chem. E 2014, 45, 1910–1917. [Google Scholar] [CrossRef]

- Labiadh, L.; Oturan, M.A.; Panizza, M.; Ben Hamadi, N.; Ammar, S. Complete removal of AHPS synthetic dye from water using new electro-Fenton oxidation catalyzed by natural pyrite as heterogeneous catalyst. J. Hazard. Mater. 2015, 297, 34–41. [Google Scholar] [CrossRef] [PubMed]

- Saravanan, A.; Deivayanai, V.; Kumar, P.S.; Rangasamy, G.; Hemavathy, R.; Harshana, T.; Gayathri, N.; Alagumalai, K. A detailed review on advanced oxidation process in treatment of wastewater: Mechanism, challenges and future outlook. Chemosphere 2022, 308, 136524. [Google Scholar] [CrossRef]

- Hu, Q.; Xu, L.; Fu, K.; Zhu, F.; Yang, T.; Yang, T.; Luo, J.; Wu, M.; Yu, D. Ultrastable MOF-based foams for versatile applications. Nano Res. 2022, 15, 2961–2970. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, M.; Xu, L.; Wang, S.; Yang, T.; Wu, M.; Lu, W.; Li, Y.; Yu, D. Unraveling timescale-dependent Fe-MOFs crystal evolution for catalytic ozonation reactivity modulation. J. Hazard. Mater. 2022, 431, 128575. [Google Scholar] [CrossRef]

- Guo, D.; Liu, Y.; Ji, H.; Wang, C.-C.; Chen, B.; Shen, C.; Li, F.; Wang, Y.; Lu, P.; Liu, W. Silicate-Enhanced Heterogeneous Flow-Through Electro-Fenton System Using Iron Oxides under Nanoconfinement. Environ. Sci. Technol. 2021, 55, 4045–4053. [Google Scholar] [CrossRef]

- Loeb, S.K.; Alvarez, P.J.J.; Brame, J.A.; Cates, E.L.; Choi, W.; Crittenden, J.; Dionysiou, D.D.; Li, Q.; Li-Puma, G.; Quan, X.; et al. The Technology Horizon for Photocatalytic Water Treatment: Sunrise or Sunset? Environ. Sci. Technol. 2019, 53, 2937–2947. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, C.; Xu, B.; Qi, F.; Chu, W. Degradation of benzotriazole by a novel Fenton-like reaction with mesoporous Cu/MnO2: Combination of adsorption and catalysis oxidation. Appl. Catal. B Environ. 2016, 199, 447–457. [Google Scholar] [CrossRef]

- Nidheesh, P.V. Heterogeneous Fenton catalysts for the abatement of organic pollutants from aqueous solution: A review. RSC Adv. 2015, 5, 40552–40577. [Google Scholar] [CrossRef]

- Zhang, B.; Li, X.; Akiyama, K.; Bingham, P.A.; Kubuki, S. Elucidating the Mechanistic Origin of a Spin State-Dependent FeNx−C Catalyst toward Organic Contaminant Oxidation via Peroxymonosulfate Activation. Environ. Sci. Technol. 2022, 56, 1321–1330. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Yu, D.; Wang, D.; Yang, T.; Li, Z.; Wu, M.; Petru, M.; Crittenden, J. Accelerating Fe(III)/Fe(II) cycle via Fe(II) substitution for enhancing Fenton-like performance of Fe-MOFs. Appl. Catal. B Environ. 2021, 286, 119859. [Google Scholar] [CrossRef]

- Qi, C.; Wen, Y.; Zhao, Y.; Dai, Y.; Li, Y.; Xu, C.; Yang, S.; He, H. Enhanced degradation of organic contaminants by Fe(III)/peroxymonosulfate process with L-cysteine. Chin. Chem. Lett. 2022, 33, 2125–2128. [Google Scholar] [CrossRef]

- Dai, Y.; Qi, C.; Cao, H.; Wen, Y.; Zhao, Y.; Xu, C.; Yang, S.; He, H. Enhanced degradation of sulfamethoxazole by microwave-activated peracetic acid under alkaline condition: Influencing factors and mechanism. Sep. Purif. Technol. 2022, 288, 120716. [Google Scholar] [CrossRef]

- Peng, J.; Wang, Z.; Wang, S.; Liu, J.; Zhang, Y.; Wang, B.; Gong, Z.; Wang, M.; Dong, H.; Shi, J.; et al. Enhanced removal of methylparaben mediated by cobalt/carbon nanotubes (Co/CNTs) activated peroxymonosulfate in chloride-containing water: Reaction kinetics, mechanisms and pathways. Chem. Eng. J. 2021, 409, 128176. [Google Scholar] [CrossRef]

- Dai, Y.; Cao, H.; Qi, C.; Zhao, Y.; Wen, Y.; Xu, C.; Zhong, Q.; Sun, D.; Zhou, S.; Yang, B.; et al. L-cysteine boosted Fe(III)-activated peracetic acid system for sulfamethoxazole degradation: Role of L-cysteine and mechanism. Chem. Eng. J. 2023, 451, 138588. [Google Scholar] [CrossRef]

- Xue, X.; Hanna, K.; Abdelmoula, M.; Deng, N. Adsorption and oxidation of PCP on the surface of magnetite: Kinetic experiments and spectroscopic investigations. Appl. Catal. B Environ. 2009, 89, 432–444. [Google Scholar] [CrossRef]

- Duan, H.; Liu, Y.; Yin, X.; Bai, J.; Qi, J. Degradation of nitrobenzene by Fenton-like reaction in a H2O2/schwertmannite system. Chem. Eng. J. 2016, 283, 873–879. [Google Scholar] [CrossRef]

- Du, J.; Bao, J.; Fu, X.; Lu, C.; Kim, S.H. Mesoporous sulfur-modified iron oxide as an effective Fenton-like catalyst for degradation of bisphenol A. Appl. Catal. B Environ. 2016, 184, 132–141. [Google Scholar] [CrossRef]

- Gao, Y.; Guo, Y.; Zhang, H. Enhanced adsorption performance for organic pollutant and its regeneration by heterogeneous visible light photo-Fenton process at circumneutral pH. J. Hazard. Mater. 2016, 302, 105–113. [Google Scholar] [CrossRef] [PubMed]

- Khataee, A.; Gholami, P.; Sheydaei, M. Heterogeneous Fenton process by natural pyrite for removal of a textile dye from water: Effect of parameters and intermediate identification. J. Taiwan. Inst. Chem. E 2016, 58, 366–373. [Google Scholar] [CrossRef]

- Oliveira, M.L.; Ward, C.R.; Izquierdo, M.; Sampaio, C.H.; de Brum, I.A.; Kautzmann, R.M.; Sabedot, S.; Querol, X.; Silva, L.F. Chemical composition and minerals in pyrite ash of an abandoned sulphuric acid production plant. Sci. Total Environ. 2012, 430, 34–47. [Google Scholar] [CrossRef] [PubMed]

- Garrido-Ramírez, E.G.; Marco, J.F.; Escalona, N.; Ureta-Zañartu, M.S. Preparation and characterization of bimetallic Fe-Cuallophanenanoclays and their activity in the phenol oxidation by heterogeneous electro-Fenton reaction. Microporous Mesoporous Mater. 2016, 225, 303–311. [Google Scholar] [CrossRef]

- Che, H.; Bae, S.; Lee, W. Degradation of trichloroethylene by Fenton reaction in pyrite suspension. J. Hazard. Mater. 2011, 185, 1355–1361. [Google Scholar] [CrossRef]

- Daud, N.; Hameed, B.H. Decolorization of Acid Red 1 by Fenton-like process using rice husk ash-based catalyst. J. Hazard. Mater. 2010, 176, 938–944. [Google Scholar] [CrossRef]

- Wu, D.; Feng, Y.; Ma, L. Oxidation of azo dyes by H2O2 in presence of natural pyrite. Water Air Soil Poll. 2013, 224, 1407. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, Z.; Tian, P.; Sheng, Y.; Xu, J.; Han, Y.-F. Oxidative degradation of nitrobenzene by a Fenton-like reaction with Fe-Cu bimetallic catalysts. Appl. Catal. B Environ. 2019, 244, 1–10. [Google Scholar] [CrossRef]

- Hassan, H.; Hameed, B. Fe-clay as effective heterogeneous Fenton catalyst for the decolorization of Reactive Blue 4. Chem. Eng. J. 2011, 171, 912–918. [Google Scholar] [CrossRef]

- Pichat, P. Photocatalytic Degradation of Pollutants in Water and Air: Basic Concepts and Application; Tarr, M.A., Ed.; Marcel Dekker, Inc.: New York, NY, USA, 2003; pp. 165–200. [Google Scholar]

- Zhao, Y.; Hu, J. Photo-Fenton degradation of 17β-estradiol in presence of α-FeOOHR and H2O2. Appl. Catal. B Environ. 2008, 78, 250–258. [Google Scholar]

- Arslan-Alaton, I.; Teksoy, S. Acid dyebath effluent pretreatment using Fenton’s reagent: Process optimization, reaction kinetics and effects on acute toxicity. Dye. Pigment. 2007, 73, 31–39. [Google Scholar] [CrossRef]

- Chen, A.; Ma, X.; Sun, H. Decolorization of KN-R catalyzed by Fe-containing Y and ZSM-5 zeolites. J. Hazard. Mater. 2008, 156, 568–575. [Google Scholar] [CrossRef] [PubMed]

- Garcia, J.C.; Oliveira, J.L.; Silva, A.E.C.; Oliveira, C.C.; Nozaki, J.; de Souza, N.E. Comparative study of the degradation of real textile effluents by photocatalytic reactions involving UV/TiO2/H2O2 and UV/Fe2+/H2O2 systems. J. Hazard. Mater. 2007, 147, 105–110. [Google Scholar] [CrossRef]

- Galeano, L.A.; Vicente, M.; Gil, A. Treatment of municipal leachate of landfill by Fenton-like heterogeneous catalytic wet peroxide oxidation using an Al/Fe-pillared montmorillonite as active catalyst. Chem. Eng. J. 2011, 178, 146–153. [Google Scholar] [CrossRef]

- Strlič, M.; Kolar, J.; Šelih, V.S.; Kočar, D.; Pihlar, B. A comparative study of several transition metals in Fenton-like reaction systems at circum-neutral pH. Acta Chim. Slov. 2003, 50, 619–632. [Google Scholar]

- Ministry of Energy, Development and Environmental Protection of Republic of Serbia. Regulation on limit values of pollutants in water and deadlines for their achievement. Off. Gaz. 2011, 67, 13–41. [Google Scholar]

- Levasseur, B.; Blais, J.-F.; Mercier, G. Study of the metal precipitation from decontamination leachates of municipal wastes fly ash incinerators. Environ. Technol. 2005, 26, 421–431. [Google Scholar] [CrossRef]

- SMirbagheri, S.; Hosseini, S. Pilot plant investigation on petrochemical wastewater treatmentfor the removal of copper and chromium with the objective of reuse. Desalination 2005, 171, 85–93. [Google Scholar] [CrossRef]

- Kusvuran, E.; Gulnaz, O.; Irmak, S.; Atanur, O.M.; Yavuz, H.I.; Erbatur, O. Comparison of several advanced oxidation processes for the decolorization of Reactive Red 120 azo dye in aqueous solution. J. Hazard. Mater. 2004, 109, 85–93. [Google Scholar] [CrossRef]

- Paul, J.; Rawat, K.; Sarma, K.; Sabharwal, S. Decoloration and degradation of Reactive Red-120 dye by electron beam irradiation in aqueous solution. Appl. Radiat. Isot. 2011, 69, 982–987. [Google Scholar] [CrossRef] [PubMed]

- Mainardis, M.; Buttazzoni, M.; Cottes, M.; Moretti, A.; Goi, D. Respirometry tests in wastewater treatment: Why and how? A critical review. Sci. Total Environ. 2021, 793, 148607. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.; Chen, Y.; Zou, L.; Deng, S.; Li, G.; Zhang, D. Monitoring the Activated Sludge Activities Affected by Industrial Toxins via an Early-Warning System Based on the Relative Oxygen Uptake Rate (ROUR) Index. Appl. Sci. 2019, 9, 154. [Google Scholar] [CrossRef]

- Foladori, P.; Bruni, L.; Tamburini, S. Toxicant inhibition in activated sludge: Fractionation of the physiological status of bacteria. J. Hazard. Mater. 2014, 280, 758–766. [Google Scholar] [CrossRef] [PubMed]

- Santos-Juanes, L.; Amat, A.; Arques, A.; Bernabeu, A.; Silvestre, M.; Vicente, R.; Añó, E. Activated sludge respirometry to assess solar detoxification of a metal finishing effluent. J. Hazard. Mater. 2008, 153, 905–910. [Google Scholar] [CrossRef]

- Dalzell, D.J.B.; Alte, S.; Aspichueta, E.; de la Sota, A.; Etxebarria, J.; Gutierrez, M.; Hoffmann, C.; Sales, D.; Obst, U.; Christofi, N. A comparison of five rapid direct toxicity assessment methods to determine toxicity of pollutants to activated sludge. Chemosphere 2002, 47, 535–545. [Google Scholar] [CrossRef]

- Tekin, H.; Bilkay, O.; Ataberk, S.S.; Balta, T.H.; Ceribasi, I.H.; Sanin, F.D.; Dilek, F.B.; Yetis, U. Use of Fenton oxidation to improve the biodegradability of a pharmaceutical wastewater. J. Hazard. Mater. 2006, 136, 258–265. [Google Scholar] [CrossRef]

- Farre, M.J.; Franch, M.I.; Ayllon, J.A.; Peral, J.; Domènech, X. Biodegradability of treated aqueous solutions of biorecalcitrant pesticides by means of photocatalytic ozonation. Desalination 2007, 211, 22–33. [Google Scholar] [CrossRef]

- Zhang, F.; Yediler, A.; Liang, X. Decomposition pathways and reaction intermediate formation of the purified, hydrolyzed azo reactive dye C.I. Reactive Red 120 during ozonation. Chemosphere 2007, 67, 712–717. [Google Scholar] [CrossRef]

- Dias, F.F.; Oliveira, A.A.; Arcanjo, A.P.; Moura, F.C.; Pacheco, J.G. Residue-based iron catalyst for the degradation of textile dye via heterogeneous photo-Fenton. Appl. Catal. B Environ. 2016, 186, 136–142. [Google Scholar] [CrossRef]

- Xu, L.; Zhao, H.; Shi, S.; Zhang, G.; Ni, J. Electrolytic treatment of C.I. Acid Orange 7 in aqueous solution using a three-dimensional electrode reactor. Dye. Pigment. 2008, 77, 158–164. [Google Scholar] [CrossRef]

- Kecić, V.; Kerkez, Đ.; Prica, M.; Lužanin, O.; Bečelić-Tomin, M.; Tomašević Pilipović, D.; Dalmacija, B. Optimization of azo printing dye removal with oak leaves-nZVI/H2O2 system using statistically designed experiment. J. Clean. Prod. 2018, 202, 65–80. [Google Scholar] [CrossRef]

- Behnajady, M.; Modirshahla, N.; Ghanbary, F. A kinetic model for the decolorization of C.I. Acid Yellow 23 by Fenton process. J. Hazard. Mater. 2007, 148, 98–102. [Google Scholar] [CrossRef] [PubMed]

- USEPA Method 7000B. Flame Atomic Absorption Spectrophotometry; Revision 2 (February 2007), Part of Test Methods for Evaluating Solid Waste, Physical/Chemical, Hazardous Waste Test Methods/SW-846; United States Environmental Protection Agency: Washington, DC, USA, 2007.

- USEPA Method 7010. Graphite Furnace Absorption Spectrophotometry; Revision 0; United States Environmental Protection Agency: Washington, DC, USA, 2007.

- SRPS ISO 6060: 1994; Chemical Oxigen Demand Determination. Institute for Standardization of Serbia: Beograd, Serbia, 1994.

- System OxiTop® Control, OxiTop® OC110-OxiTop®-C; BA31116de03; Wissenschaftlich-TechnischeWerkstätten GmbH: Weilheim, Germany, 2006.

- ISO 11348-1: 2008; Water Quality—Determination of the Inhibitory Effect of Water Samples on the Light Emission of Vibrio fischeri (Luminiscent Bacteria Test). British Standards Institution: London, UK, 2008.

- Jóźwiak, W.K.; Mitros, M.; Kalużna-Czaplińska, J.; Tosik, R. Oxidative decomposition of Acid Brown 159 dye in aqueous solution by H2O2/Fe2+ and ozone with GC/MS analysis. Dye. Pigment. 2007, 74, 9–16. [Google Scholar] [CrossRef]

- Pachhade, K.; Sandhya, S.; Swaminathan, K. Ozonation of reactive dye, Procion red MX-5B catalyzed by metal ions. J. Hazard. Mater. 2009, 167, 313–318. [Google Scholar] [CrossRef] [PubMed]

| Compound | Stoichiometric Forms | Content (%) |

|---|---|---|

| Hematite | Fe2O3 | 74.6 |

| Quartz | SiO2 | 11.9 |

| Magnetite | Fe3O4 | 4.69 |

| Mullite | 3Al2O3 2SiO2 or 2Al2O3 SiO2 | 2.30 |

| Alite | Tricalcium silicate (Ca3SiO5) | 2.21 |

| Plagioclase | Respective compositions of NaAlSi3O8 and CaAl2Si2O8 | 2.018 |

| Rutil | Most common natural form of TiO2 | 0.885 |

| Calcite | CaCO3 | 0.624 |

| Gehlenite | Sorosilicate(Ca2Al(AlSiO7)) | 0.478 |

| Cristobalite | High-temperature polymorph of silica (SiO2) | 0.121 |

| Periclase | Cubic form of magnesium oxide (MgO) | 0.087 |

| Thenardite | Anhydrous sodium sulphate mineral (Na2SO4) | 0.025 |

| Flyash-amorph | / | 0.009 |

| K-Feldspar | a group of rock-forming tectosilicate minerals (KAlSi3O8- NaAlSi3O8-CaAl2Si2O8) | 0.005 |

| Effluent | Metals | pH | |||||||

|---|---|---|---|---|---|---|---|---|---|

| As | Cd | Cr | Cu | Fe | Ni | Pb | Zn | ||

| mg/L | |||||||||

| After the Fenton process | 0.052 | 0.018 | 0.482 | 1.521 | 20.15 | 0.258 | 2.228 | 1.231 | 2.47 |

| After the pH adjustment | <DL | <DL | 0.043 | 0.052 | 1.203 | 0.008 | 0.012 | 0.085 | 8 |

| A | - | - | 0.5 | 0.5 | - | 0.5 | - | 2 | - |

| B | - | 0.1 | 0.5 | 0.5 | - | 0.5 | 0.5 | 2 | 6.5–9.0 |

| RR120 | COD mg O2/L | TOC mg C/L |

|---|---|---|

| Before Fenton process | 104 | 16.1 |

| After Fenton process | 15.9 | 6.11 |

| Removal (%) | 84.7 | 62.1 |

| CAS Number | Compounds | RR120 Synthetic Solution after Treatment | PC + H2O2 + dH2O | |

|---|---|---|---|---|

| 85-44-9 | Phthalic anhydride | D6 | ♦ | |

| 96-76-4 | Phenol and 2,4-bis(1,1-dimethylethyl)- | ♦ | ♦ | |

| 112-42-5 | 1-Undecanol | ♦ | ♦ | |

| 1921-70-6 | Pentadecane and 2,6,10,14-tetramethyl- | ♦ | ♦ | |

| 112-39-0 | Hexadecanoic acid and methyl ester | ♦ | ♦ | |

| 84-74-2 | Dibutyl phthalate | D5 | ♦ | |

| 117-81-7 | Bis(2-ethylhexyl) phthalate | D1 | ♦ | |

| 104-76-7 | 1-Hexanol and 2-ethyl- | ♦ | ||

| 84-66-2 | Diethyl phthalate | D9 | ♦ | |

| 544-63-8 | Tetradecanoic acid | ♦ | ||

| 62-75-9 | N-Nitrosodimethylamine | D15 | ♦ | |

| 62-53-3 | Amino benzene | D7 | ♦ | |

| 287476-17-9 | 6-chloro-n-ethyl-n’-(propan-2-yl)-1,3,5-triazine-2,4-diamine hydrochloride | D3 | ♦ | |

| 98-11-3 | Benzene sulphonic acid | D4 | ♦ | |

| 90-15-3 | Naphtalen-1-ol | D8 | ♦ | |

| 84-69-5 | 1,2-Benzenedicarboxylic acid and bis (2-methylpropyl) ester | D2 | ♦ | |

| 142-31-4 | Sodium octyl sulfate | D10 | ♦ | |

| 112-31-2 | Decanal | D11 | ♦ | |

| 109-52-4 | Pentanoic acid | D12 | ♦ | |

| 110-94-1 | Pentanedioic acid | D13 | ♦ | |

| 56851-34-4 | 2-Undecene and 5-methyl- | D14 | ♦ |

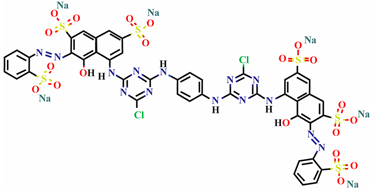

| Chemical structure |  |

| Chemical name | Reactive Red 120 |

| Abbreviation | RR120 |

| Chemical formula | C44H24Cl2N14O20S6Na6 |

| CAS | 61951-82-4 |

| Molar mass (g/mol) | 1469.98 |

| λmax (nm) | 512 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kerkez, D.; Bečelić-Tomin, M.; Gvoić, V.; Mandić, A.K.; Leovac Maćerak, A.; Tomašević Pilipović, D.; Pešić, V. Pyrite Cinder as an Effective Fenton-like Catalyst for the Degradation of Reactive Azo Dye: Effects of Process Parameters and Complete Effluent Characterization. Catalysts 2023, 13, 424. https://doi.org/10.3390/catal13020424

Kerkez D, Bečelić-Tomin M, Gvoić V, Mandić AK, Leovac Maćerak A, Tomašević Pilipović D, Pešić V. Pyrite Cinder as an Effective Fenton-like Catalyst for the Degradation of Reactive Azo Dye: Effects of Process Parameters and Complete Effluent Characterization. Catalysts. 2023; 13(2):424. https://doi.org/10.3390/catal13020424

Chicago/Turabian StyleKerkez, Djurdja, Milena Bečelić-Tomin, Vesna Gvoić, Aleksandra Kulić Mandić, Anita Leovac Maćerak, Dragana Tomašević Pilipović, and Vesna Pešić. 2023. "Pyrite Cinder as an Effective Fenton-like Catalyst for the Degradation of Reactive Azo Dye: Effects of Process Parameters and Complete Effluent Characterization" Catalysts 13, no. 2: 424. https://doi.org/10.3390/catal13020424

APA StyleKerkez, D., Bečelić-Tomin, M., Gvoić, V., Mandić, A. K., Leovac Maćerak, A., Tomašević Pilipović, D., & Pešić, V. (2023). Pyrite Cinder as an Effective Fenton-like Catalyst for the Degradation of Reactive Azo Dye: Effects of Process Parameters and Complete Effluent Characterization. Catalysts, 13(2), 424. https://doi.org/10.3390/catal13020424