Abstract

A series of Ce1−XSnXO2 (X = 0, 0.2, 0.3, 0.4, 0.5, 0.9, 1) catalysts were synthesized via the combustion method. The physical and chemical structures of the prepared catalysts were systematically characterized by XRD, BET, SEM, TEM, XPS, and TPR. The Ce1−XSnXO2 catalysts have higher catalytic activities than the mono-oxide catalysts, as there are synergistic effects between CeO2 and SnO2. The catalytic activities of the Ce1−XSnXO2 catalysts are dependent on the X for the catalytic combustion of ethyl acetate (EA). The Ce1−XSnXO2 (X < 0.5) catalysts show high catalytic performances. Meanwhile, the Ce0.8Sn0.2O2 and Ce0.7Sn0.3O2 catalysts display the highest catalytic performance, with T50 = 190 °C and T90 = 210 °C. More importantly, the Ce0.8Sn0.2O2 catalyst exhibits superior thermal and catalytic activity stability. It is found that the Ce1−XSnXO2 catalysts form solid solutions, as the X is <0.5. The reduction of Sn4+ species to Sn2+ is significantly promoted by the CeO2, which is an important factor attributed to the high catalytic activities of the solid solution Ce1−XSnXO2 catalysts. The catalytic activities of the Ce1−XSnXO2 catalysts exhibit a strong correlation to the surface atomic areas of Ce3+ and Oα (VO). In other words, the higher surface atomic areas of Ce3+ and Oα (VO) are, the higher the catalytic activities will have.

1. Introduction

As one of the volatile organic compounds (VOCs), ethyl acetate (EA) is a precursor to tropospheric ozone and photochemical smog [1,2,3,4]. It mainly originates from industrial production, which poses a significant threat to human health and the environment [5]. Hence, the control and reduction of EA emissions have become increasingly imperative in recent years [3,6,7]. The implementation of end-of-pipe emission reduction technology has thus become prevalent to attain this objective. As the demand for sustainable production and environmental protection continues to grow, the adoption of these technologies is expected to increase in the future [5,7]. Due to its ability to efficiently eliminate harmful VOCs and minimize energy consumption, catalytic oxidation/combustion is widely regarded as an excellent treatment technology among various methods [8,9]. While VOC combustion catalysts play a pivotal role in catalytic combustion technology, their current performances fall short of the desired standards [2,3,4]. Therefore, the development of highly active catalysts is indispensable for enhancing the efficiency of catalytic combustion technology.

Significant progress has been achieved over the past decades in the development of catalysts for the catalytic combustion of VOCs. It has been shown that inexpensive non-noble metal oxides are viable alternatives to noble metal catalysts for the catalytic combustion of VOCs [10,11,12,13,14]. These oxides can always achieve high catalytic activities via improving their surface areas and redox activities, tuning surface chemistry properties [15,16]. Importantly, they possess better thermal stabilities and higher poisoning resistances, which are crucial characteristics for long-term industrial applications. Notably, the CeO2-based catalysts have been proven to be promising catalysts for oxidation reactions because of their excellent redox properties, which can even rival the performance of supported noble metal catalysts [17,18]. Due to the importance of the redox property to a highly active CeO2-based catalyst, many attempts have been made to boost the ratio of Ce3+/Ce4+, enhancing the redox property of the catalyst and increasing the amount of oxygen vacancies (VO) [17,19,20,21,22,23]. Usually, heteroatoms such as Zr [24,25,26], Ti [27,28], Mn [29,30,31] and Sn [32,33,34,35,36,37] were doped into CeO2 lattice-forming solid solutions to increase their redox properties. Among them, the materials incorporating Sn into CeO2 have been applied in various fields, including sensors [37], solid-state films [38], electrode materials [39,40], biological applications [40,41] and catalysts [33,36,42,43]. And the most interesting applications of CeO2–SnO2 were used for the environmental catalysts directly and catalyst supports [34,35,36,44,45,46,47]. Foletto et al. revealed that the CeO2–SnO2 nanocomposite with an optimum CeO2 loading of 7 wt.% acted as an effective photocatalyst in the degradation of DB38 dye under sunlight [42]. Wang et al. demonstrated that Ce1−XSnXO2 composite oxide with a molar ratio of Sn: Ce = 4:6 exhibited the best catalytic performance for the soot oxidation reaction in the presence of water [36]. Jayachandran et al. found that the CeO2-SnO2/Al2O3 mixed oxides coated on the SS filter plates demonstrated a good catalytic performance in the exhaust emission test, which is a great challenge [48]. Zhou et al. reported that the CeSnOx catalysts for the selective catalytic oxidation of NH3 showed excellent N2 selectivity at high temperatures compared to CeO2 [44]. The Liu group reported that CeO2-SnO2 catalysts displayed high NH3-SCR activity and with highly resisted the poisons of H2O and SO2 [45]. The addition of dopants of Sn4+ in the CeO2 lattice increased the specific surface area and provided more VO sites to enhance the adsorption of surface oxygen species, and then the catalytic performance and the thermal stability of SnO2-CeO2 were enhanced [33,34,35,36,45,48]. Although significant achievements have been made in the CeO2-SnO2 catalysts for varieties of catalytic reactions, Ce1−xSnxO2 catalysts for the catalytic combustion of VOCs has yet not to be fully explored.

In the present work, a series of Ce1−XSnXO2 composite oxide materials for the catalytic oxidation of EA were synthesized via a combustion approach. The catalysts were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscopy (TEM), H2 temperature-programmed reduction (H2-TPR), specific surface area determinations and X-ray photoelectron spectroscopy (XPS) to elucidate the structure–activity relationship.

2. Results and Discussion

2.1. XRD

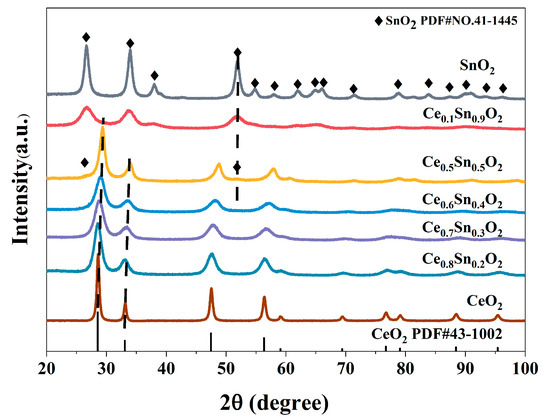

The XRD patterns of the Ce1−XSnXO2 catalysts are displayed in Figure 1. It can be seen that the mono-oxides of SnO2 and CeO2 show a tetragonal crystalline phase (PDF No. 41-1445) and cubic fluorite phase (PDF No. 43-1002) [20,49,50]. The composite oxides of Ce1−XSnXO2 (X > 0.5) exhibit single SnO2 phases of tetragonal crystalline. But the diffraction peak intensities of SnO2 on the Ce0.1Sn0.9O2 sample are weakened compared to those of the pure SnO2. The crystalline size of SnO2 is from 7.7 to 3.6 nm as the X decreases from 1.0 to 0.9, as shown in Table 1. Weak peaks at 26.788 and 51.730 two theta degrees attributed to the SnO2 phase are about to disappear over the Ce0.5Sn0.5O2 catalyst. The diffraction peaks of the SnO2 phase disappear totally as the X is < 0.5, and the single phase of CeO2 is observed. Furthermore, the positions of the diffraction peaks of CeO2 shift to lower angles, from 29.282 to 28.622 two theta degree, accompanying the increase in the lattice parameters of CeO2 from 5.2851 to 5.3806 Å (shown in Table 1) as the X decreases from 0.5 to 0.2. The above results indicate that the Sn4+ ions, with their radius diameters of 0.81 Å, which is smaller the radius diameters of of Ce4+ (0.97 Å) [20,51], enter the CeO2 lattice and replace part of the Ce4+ ions to form a solid solution [52,53]. As a result of the solid solution formations, the CeO2 crystalline sizes in the Ce1−XSnXO2 (0 < X ≤ 0.5) are smaller than those of the pristine CeO2 (16.4 nm) shown in Table 1.

Figure 1.

XRD patterns of the samples prepared by combustion methods.

Table 1.

Crystalline sizes and lattice constants of the Ce1−XSnXO2 samples.

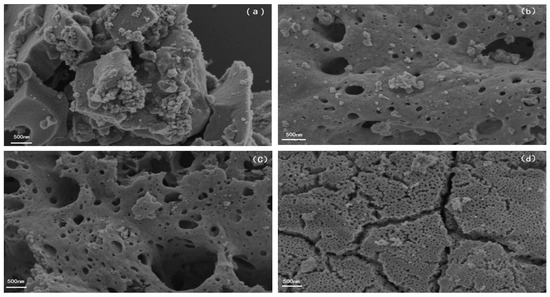

2.2. SEM and BET Results

The SEM is one of the most popular tools used to characterize and analyze the morphology and surface of solid samples. Figure 2 displays the SEM images of the Ce1−XSnXO2 (X = 0, 0.2, 0.4, 1) catalysts. The SnO2 catalyst presents a compact surface structure with no primary macrospores. However, porous structures are clearly observed on the Ce1−XSnXO2 (x = 0.2, 0.4) catalysts shown in Figure 2b,c. And the CeO2 morphology, with a notable reduction of macropores, lies between SnO2 and Ce1−xSnxO2 (Figure 2d). The results show that the morphologies of Ce1−XSnXO2 show significant difference from the morphology of the pristine CeO2 and SnO2. Accordingly, the BET surface areas of Ce1−XSnXO2 listed in Table 2 are higher than those of the pure CeO2. Among them, the Ce0.8Sn0.2O2 and Ce0.1Sn0.9O2 samples have the highest surface area (around 51 m2/g).

Figure 2.

SEM images of Ce1−XSnXO2 catalysts: (a) SnO2, (b) Ce0.6Sn0.4O2, (c) Ce0.8Sn0.9O2 and (d) CeO2.

Table 2.

BET surface areas, SAAs, and atomic proportions on the Ce1−XSnXO2 catalysts.

SAAs can be calculated by the following equations:

where , , and are the atomic concentrations of Ce4+, Ce3+, O2− and Sn4+, respectively. And , ,, and are 0.97, 1.02, 1.40 and 0.81 Å, respectively [51,53,54].

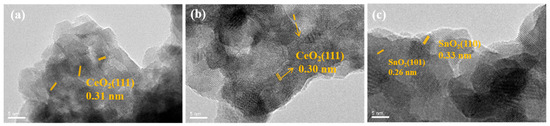

2.3. TEM Results

TEM is applied to deeply reveal information about the microstructure of a catalyst. The TEM image of CeO2 in Figure 3a displays an interplanar spacing of 0.31 nm assigned to CeO2 (111) lattice fringes [47,55,56]. As shown in Figure 3b, no SnO2 crystal facets are observed over the Ce0.8Sn0.2O2 catalyst, and it is also proved by the XRD results that it has a single-phase fluorite structure. Nevertheless, crystal facets with d-spacing of 0.30 nm assigned to CeO2 (111) lattice fringes are found [20,22]. The d-spacing value of CeO2 over the Ce0.8Sn0.2O2 catalyst is slightly smaller than that of the pristine CeO2, indicating that the Sn atom is incorporated into the CeO2 lattice to form a solid solution, as the radius of Sn (0.81 Å) is smaller than that of the Ce (0.97 Å). The prepared SnO2 sample was also characterized by TEM, as shown in Figure 3c. The (111) and (101) planes of SnO2 are recognized to have d-spacing values of 0.33 nm and 0.26 nm [22,50,57].

Figure 3.

TEM images of Ce1−xSnxO2 catalysts: (a) CeO2, (b) Ce0.8Sn0.9O2 and (c) SnO2.

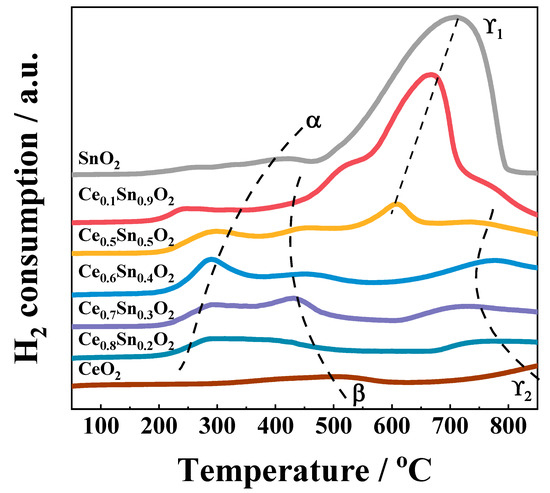

2.4. H2-TPR Results

H2-TPR is a useful method to characterize the reduced property of a sample. The H2-TPR profiles of Ce1−XSnXO2 catalysts are presented in Figure 4. For the CeO2 sample, it is well known that the peaks at ~500 (β) and >800 °C (γ2) can be attributed to the reduction of the surface Ce4+ and bulk Ce4+ [58,59]. And the H2-TPR profile of SnO2 shows two groups of reduction peaks with >450 (α) and ~670 °C (γ1), which can be assigned to the reduction of surface of Sn4+ to Sn2+ and the reduction of bulk Sn4+, along with the surface Sn2+ to metallic Sn [53]. However, the α peaks shift to a lower temperature, i.e., <350 °C, over the Ce1−XSnXO2 (X= 0.2–0.9), and this shift can be attributed to the reduction of the surface of Sn4+ to Sn2+ and the surface of Ce4+ to Ce3+ [51]. And the bulk CeO2 peaks of γ2 shift to lower temperatures at <800 °C as a result of the doping with Sn. Furthermore, the peak of γ1 that emerged over the Ce0.5Sn0.5O2 can be assigned to the reduction of SnO2 crystallites, as proved by the XRD result that weak diffraction peaks of SnO2 appear on the Ce0.5Sn0.5O2. The reduction temperatures of the β peak increase from ~400 to 500 °C as the X increases from 0.2 to 0.9, and these increases are tentatively ascribed to the reduction of Ce4+ and Sn4+ in the structures of Ce-O-Sn. The above results indicate that the reduction abilities of Ce1−XSnXO2 catalysts are promoted due to the promoted electron transfer between Ce and Sn species over the Ce1−XSnXO2 [22,45,60].

Figure 4.

H2-TPR profiles of the Ce1−XSnXO2 catalysts.

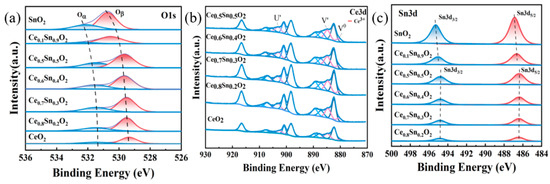

2.5. XPS Results

XPS was used to investigate the interactions among the metal oxides and the chemical states of oxygen, cerium and tin in the catalysts. As can be seen from Figure 5a, the O 1s bands can be deconvoluted into lattice oxygen (Oβ) at 529.5–530.5 eV and adsorbed oxygen (Oα) at 531.5–532.5 eV [61,62]. Markedly, the binding energy of Oα shifts to a higher value, from 531.5 to 532.5 eV, when the X increases from 0 to 1 over the Ce1−XSnXO2 catalysts, indicating that the chemical state of Oα is changed as the CeO2 is doped with the SnO2. The spectra of Ce 3d on the Ce1−XSnXO2 catalysts are shown in Figure 5b. According to the literature [60,62], the bands labeled with v0 (~880.5 eV), v′ (~884.7 eV) and u′ (~903.2 eV) correspond to the Ce3+, while the other bands are related to Ce4+ [24,32]. The spectrum of Sn 3d orbital shows two peaks at 495~494.7 and 486.3~486.6 eV, which are allocated to the Sn 3d3/2 and the Sn 3d5/2, respectively [14,61]. Meanwhile, the Sn 3d5/2 and Sn 3d3/2 peaks of the Ce1−XSnXO2 (X = 0.2–0.9) shown in Figure 5c shift to low binding energy compared with that of SnO2, indicating that there are interactions between Ce and Sn in the Ce1−XSnXO2 catalysts. The results are consistent with the results of H2-TPR.

Figure 5.

XPS spectra of the Ce1−xSnxO2 samples in the region of (a) O 1s, (b) Ce 3d and (c) Sn 3d.

And the atomic concentrations of Ce3+, Ce4+, Oα, Oβ and Sn over the samples calculated from the XPS results are listed in Table 2. It is widely accepted that the catalytic oxidation activity is tightly correlated to the species of Ce3+ or Oα, which are derived from VO [32,60,63]. Generally, the higher the concentrations of Ce3+ or Oα are, the higher the concentrations of the VO present [10,54,64,65]. It is well known that the amount of VO over a catalyst plays a crucial role in a catalytic oxidation reaction. The concentration of Ce3+ or Oα is used to characterize the amount of VO on a catalyst, as it is difficult to accurately measure the concentration of VO. However, it is not always satisfied to clarify the differences of catalytic activities over different catalysts through comparison with the surface atomic ratios of Ce3+/(Ce3+ + Ce4+) and Oα/(Oα + Oβ) calculated by XPS results, because different catalysts always have different surface areas and Ce (Ce3+ and Ce4+) concentrations. The surface atomic areas (SAAs) that are needed to achieve the authentic distribution of the Ce3+ or Oα species over the prepared catalysts are listed in Table 2, and they were calculated approximately based on the BET surface areas, their ionic radiuses and their surface atomic concentrations. It can be clearly seen that the SAAs of Ce3+ on the Ce1−xSnxO2 catalysts are higher than those of pure CeO2 oxide. The SAAs of Ce3+ and Oα on the pure CeO2 oxide are as low as 0.2 and 2.4. Moreover, the SAA of Oα on the pure SnO2 oxide is 2.7. Nevertheless, the Ce0.8Sn0.2O2 and Ce0.7Sn0.3O2 catalysts possess high SAAs of Ce3+ (≥0.8 m2/g) and Oα (≥11.3 m2/g). It was revealed by the aforementioned XRD results that Ce1−XSnXO2 solid solutions are formed when the X is <0.5, indicating that the replacement of Ce4+ by Sn4+ in the CeO2 lattice leads to the formation of a higher number of Ce3+ sites and a higher concentration of Oα, i.e., higher concentration of VO [10,54,60,64].

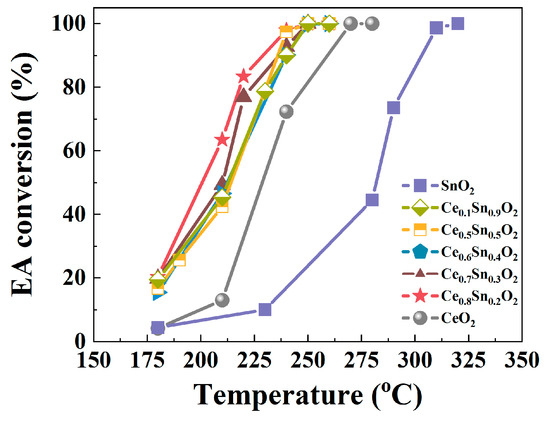

2.6. Catalytic Activity

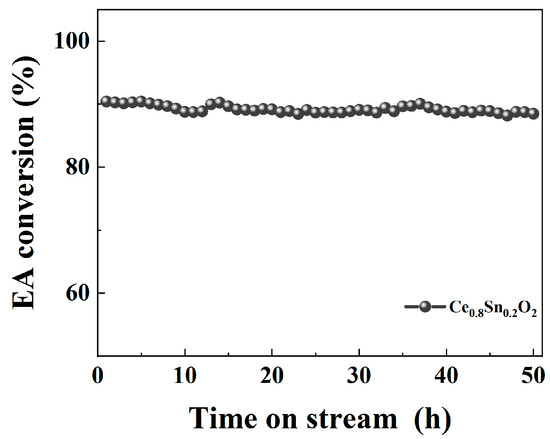

The effects of Sn on the Ce1−xSnxO2 catalysts’ catalytic activities are shown in Figure 6. Evidently, the catalytic activities of Ce1−XSnXO2 are heavily dependent on the X. The T50 and T90 over the SnO2 catalyst are 280 °C and 300 °C. And the T50 and T90 over the CeO2 catalyst are 225 °C and 250 °C. The activities of the pure mono-oxides of CeO2 and SnO2 are lower than those of the Ce1−XSnXO2 (X = 0, 0.2, 0.3, 0.4, 0.5, 0.9) in the whole range of reaction temperatures (150–350 °C). The Ce0.8Sn0.2O2 and Ce0.7Sn0.3O2 catalysts show the highest catalytic activities with T50 = 200 °C and T90 = 230 °C. The catalytic activities are slightly decreased as the X increases to 0.4 and 0.5 on the Ce1−XSnXO2 catalysts. Nevertheless, the catalytic performance is decreased significantly when the X is >0.5 on the Ce1−XSnXO2. The stability of the Ce0.8Sn0.2O2 catalyst was also tested at 210 °C, as shown in Figure 7. It is clearly shown that the Ce0.8Sn0.2O2 catalyst remains quite stable, maintaining an ~90% EA conversion during a 50 h time-on-stream reaction.

Figure 6.

Catalytic activities of Ce1−XSnXO2 catalysts.

Figure 7.

Stability of the Ce0.8Sn0.2O2 catalyst at 210 °C.

The catalytic performance results clearly indicate that there is a synergistic effect between SnO2 and CeO2 to promote the catalytic activities of Ce1−XSnXO2 catalysts. The H2-TPR results show that the reduction abilities of both Ce4+ and Sn4+ are promoted synergistically over the Ce1−XSnXO2 catalysts. Especially, the reduction ability is significantly enhanced as the formation of the SnO2-CeO2 solid solution, which means that it is easier to create the Ce3+ sites (VO) from the Ce4+ by 2Ce4+ + Sn2+ ↔ 2Ce3+ + Sn4+ [36,45,53]. The high reduction abilities of the Ce1−XSnXO2 solid solution catalysts may be responsible for their high activities. It is also found that the catalytic activities of the Ce1−xSnxO2 catalysts can strongly correlate to the SAA of Ce3+ and Oα (VO) presented in Table 2. The solid solutions of Ce1−XSnXO2 (X = 0.2, 0.3) catalysts with the highest SAA of Ce3+ and Oα (VO) have the best catalytic performances. And the pure mono-oxides of SnO2 and CeO2 with the lowest SAA of Ce3+ and Oα possess the poorest catalytic activities.

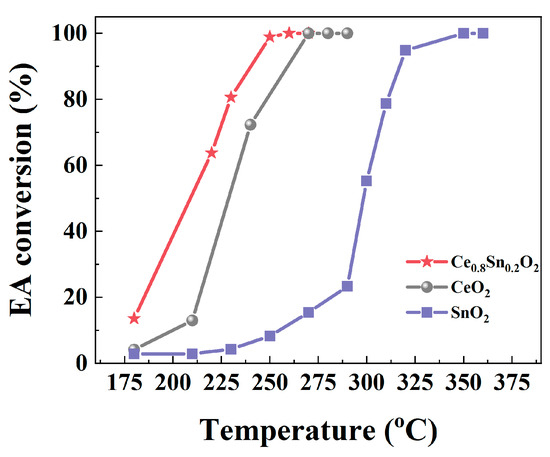

Thermal stability is one of the foremost concerns for industrial application of a VOC combustion catalyst. Therefore, the catalysts were subjected to calcination at 800 °C for 4 h to test their thermal stabilities by measuring their catalytic performances. The T50 and T90 over the Ce0.8Sn0.2O2 annealed at 800 °C is 210 and 240 °C, as shown in Figure 8, which is slightly higher than those on the Ce0.8Sn0.2O2 calcined at 500 °C. However, the catalytic activities of the mono-oxides of CeO2 and SnO2 are decayed significantly after calcination at 800 °C. The XRD results shown in Supplementary Figure S2 reveal that the crystalline size of CeO2 on the Ce0.8Sn0.2O2 catalyst calcined at 800 °C was slightly increased from 5.4 to 8.3 nm. Nevertheless, the crystalline sizes of the mono-oxides of CeO2 and SnO2 calcined at 800 °C are sharply increased to 37.8 and 25.3 nm, which is the main reason for the decreases in their catalytic performances. The results indicate that the CeO2 doping with SnO2 to form a solid solution demonstrates superior thermal stability.

Figure 8.

Catalytic activities of the catalysts calcined at 800 °C.

3. Experimental

3.1. Catalyst Preparation

The Ce1−XSnXO2 (x = 0, 0.2, 0.3, 0.4, 0.5, 0.9, 1) catalysts were prepared by the combustion method [51,54]. The Ce0.6Sn0.4O2 catalyst was used as an example to clarify the preparation procedure. All the chemicals used in this study were analytic reagents from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China) and used without further purification. Ceric ammonium nitrate hexahydrate (4.9894 g), stannous oxalate (1.2557 g) and glycine (2.3326 g) were used as precursors of CeO2, SnO2 and fuel, respectively. The above mixture was dissolved in 10 mL of D.I. water and 5 mL HNO3 to form a clarified solution. Then, the solution was heated at 250 °C, with a stirring rate of 450 r/min, to ignite a violent combustion reaction obtaining a fluffy solid. Finally, the powder was ground and calcined in a tube furnace at 500 °C for 6 h, with a heat rate of 10 °C/min. The catalyst images of different stages are presented in Supplementary Figure S1.

3.2. Catalyst Characterization

XRD experiments were carried out on an instrument of Rigaku Miniflex 600 (Rigaku, Tokyo, Japan) equipped with a Cu target K-ray (40 KV, 15 mA) X-ray source. The diffraction angle (2θ) range was scanned from 20 to 100°, with a step size of 0.02°. The CeO2 and SnO2 crystalline sizes were calculated using the Scherrer equation.

SEM characterizations were operated on a ZEISS Sigma 300(Oberkochen, Germany). TEM images were taken on a FEI Tecnai G2 F20 (Hillsboro, OR, USA). The samples were dispersed in ethanol and sonicated for 30 min before TEM measurements. Subsequently, the dispersed solutions were dropped on the copper grids and dried in air at room temperature for TEM characterizations.

H2-TPR experiments were conducted on a VDSorb-91i-BMFC automated chemisorption apparatus (Vodo, QuZhou, China) equipped with a TCD. A total of 50 mg of the catalyst was loaded into a U-shape quartz tube (I.D. = 6 mm). Then, a mixed gas (5% H2/N2) with a flow rate of 10 mL/min was introduced to the reactor heating from room temperature to 900 °C, with a heating ramp of 10 °C/min. The H2 consumption was monitored by a TCD detector after the water and contaminants in the effluent were removed by dried silica.

Specific surface area determinations were conducted on an instrument of Quantachrome NOVA 2200e (Boynton Beach, FL, USA). Prior to testing, the samples were degassed at 200 °C for 6 h. And the adsorption/desorption data of 46 points were acquired at 77 K with a pressure range from 0.05 to 0.25. The specific surface areas were calculated by the Brunner–Emmett–Teller (BET) method.

XPS spectra were obtained on a Thermo Scientific K-Alpha XPS instrument (Hillsboro, OR, USA) with voltage of 12 kW and a filament current of 6 mA. The charge effect was calibrated using a binding energy standard of C 1s (284.8 eV).

3.3. Catalytic Reaction

The catalytic activities of the prepared samples were measured by the reaction of the EA combustion reaction in a fixed-bed reactor produced by Vodo in China. Then, 100 mg of the catalyst was put in the middle of a quartz reactor (D.I.: 6 mm) and fixed by quartz wool between the top and bottom of the reaction tube. A K-type thermocouple inserted into the quartz wool was used to detect the reactant temperature of the inlet, which was controlled by a temperature controller. A total flow rate of 100 mL/min containing 1000 ppm EA and synthetic air (21%O2/N2) was adopted with a gas hourly space velocity (GHSV) of 60,000 mL·h−1·g−1. The EA concentration was controlled by the flow rate of synthetic air through the vapor generator of EA at 0 °C. The flow rates of the synthetic air were monitored by mass flow controllers. The organic products were analyzed by a GC equipped with an FID and a column of SE-30. The temperatures for the 50% and 90% conversion of EA that were used to evaluate the catalytic performance of a catalyst were designated as T50 and T90.

4. Conclusions

In this article, the Ce1−XSnXO2 composite catalysts for the catalytic combustion of EA were prepared via the combustion method. The catalytic performances and structures of the Ce1−XSnXO2 are heavily dependent on the X. As the X is within the range of 0 and 0.5, Ce1−XSnXO2 solid solutions are formed and display very good catalytic activities for the EA combustion. And the Ce1−XSnXO2 catalysts with X = 0.2 and 0.3 exhibit the highest catalytic activities with the lowest T50 (190 °C) and T90 (210 °C). Furthermore, the catalytic performance of the Ce0.8Sn0.2O2 catalyst calcined at high temperature of 800 °C decreases modestly only, showing that the solid solution catalyst has superior thermal stability compared with the pure mono-oxides of CeO2 and SnO2. Evidently, there is a synergistic effect between CeO2 and SnO2 on the Ce1−XSnXO2 catalysts. The H2-TPR results show that the reduction abilities of the Ce1−xSnxO2 catalysts are promoted by the incorporation of Sn4+ into the CeO2 lattice, attributing to their high catalytic activities. The catalytic activities of Ce1−XSnXO2 catalysts are well correlated to the surface atomic areas of Ce3+ and Oα (VO). The higher the surface atomic areas of Ce3+ and Oα (VO) are, the higher the catalytic activities will be. In conclusion, the Ce1−XSnXO2 solid solution catalysts present excellent catalytic performances and thermal stabilities for the catalytic combustion of EA, which may be potentially used for practical industrial applications for catalytic elimination of VOCs.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/catal13111400/s1, Figure S1: Figure S1-A: Images of all uncalcined samples after combustion (a: SnO2, b: Ce0.1Sn0.9O2, c: Ce0.5Sn0.5O2, d: Ce0.6Sn0.4O2, e: Ce0.7Sn0.3O2, f: Ce0.8Sn0.2O2, g: CeO2). Figure S1-B: Image of all catalysts calcined at 500 °C for 6 h (a: SnO2, b: Ce0.1Sn0.9O2, c: Ce0.5Sn0.5O2, d: Ce0.6Sn0.4O2, e: Ce0.7Sn0.3O2, f: Ce0.8Sn0.2O2, g: CeO2). Figure S1-C: Image of all catalysts calcined at 800 °C for 4 h (a: SnO2, b: Ce0.8Sn0.2O2, c: CeO2). Figure S2: XRD patterns of the catalysts calcined at 800 °C.

Author Contributions

Data curation, Y.J. (Yue Jiang) and Q.W. (Qing Wang); Investigation, L.M. and L.C.; Methodology, S.Z., J.X., L.W. and L.C.; Supervision, L.M.; Writing—review & editing, Y.J. and L.M. All authors have read and agreed to the published version of the manuscript.

Funding

Zhejiang province public welfare technology application research project (LGG21E010004, China) for financial support.

Data Availability Statement

Data sharing is not applicable to this article.

Acknowledgments

The authors thank Hui Wang from Hangzhou Dianzi University for his beneficial discussions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- He, C.; Cheng, J.; Zhang, X.; Douthwaite, M.; Pattisson, S.; Hao, Z. Recent Advances in the Catalytic Oxidation of Volatile Organic Compounds: A Review Based on Pollutant Sorts and Sources. Chem. Rev. 2019, 119, 4471–4568. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Miao, G.; Pi, Y.; Xia, Q.; Wu, J.; Li, Z.; Xiao, J. Abatement of various types of VOCs by adsorption/catalytic oxidation: A review. Chem. Eng. J. 2019, 370, 1128–1153. [Google Scholar] [CrossRef]

- Konsolakis, M.; Carabineiro, S.a.C.; Marnellos, G.E.; Asad, M.F.; Soares, O.S.G.P.; Pereira, M.F.R.; Órfão, J.J.M.; Figueiredo, J.L. Volatile organic compounds abatement over copper-based catalysts: Effect of support. Inorg. Chim. Acta 2017, 455, 473–482. [Google Scholar] [CrossRef]

- Guo, Y.; Wen, M.; Li, G.; An, T. Recent advances in VOC elimination by catalytic oxidation technology onto various nanoparticles catalysts: A critical review. Appl. Catal. B. 2021, 281, 119447. [Google Scholar] [CrossRef]

- Li, X.; Niu, Y.; Su, H.; Qi, Y. Simple Thermocatalytic Oxidation Degradation of VOCs. Catal. Lett. 2022, 152, 1801–1818. [Google Scholar] [CrossRef]

- Carabineiro, S.A.; Konsolakis, M.; Marnellos, G.E.; Asad, M.F.; Soares, O.S.; Tavares, P.B.; Pereira, M.F.; Órfão, J.J.; Figueiredo, J.L. Ethyl Acetate Abatement on Copper Catalysts Supported on Ceria Doped with Rare Earth Oxides. Molecules 2016, 21, 644. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xue, Z.; Li, H.; Yan, L.; Yang, Y.; Wang, Y.; Duan, J.; Li, L.; Chai, F.; Cheng, M.; et al. Ambient volatile organic compounds pollution in China. J. Environ. Sci. 2017, 55, 69–75. [Google Scholar] [CrossRef]

- Kamal, M.S.; Razzak, S.A.; Hossain, M.M. Catalytic oxidation of volatile organic compounds (VOCs)—A review. Atmos. Environ. 2016, 140, 117–134. [Google Scholar] [CrossRef]

- Zang, M.; Zhao, C.; Wang, Y.; Chen, S. A review of recent advances in catalytic combustion of VOCs on perovskite-type catalysts. J. Saudi Chem. Soc. 2019, 23, 645–654. [Google Scholar] [CrossRef]

- Ye, Y.; Gao, L.; Xu, J.; Wang, L.; Mo, L.; Zhang, X. Effect of CuO species and oxygen vacancies over CuO/CeO2 catalysts on low-temperature oxidation of ethyl acetate. J. Rare Earths 2023, 41, 862–869. [Google Scholar] [CrossRef]

- Deng, L.; Ding, Y.; Duan, B.; Chen, Y.; Li, P.; Zhu, S.; Shen, S. Catalytic deep combustion characteristics of benzene over cobalt doped Mn-Ce solid solution catalysts at lower temperatures. Mol. Catal. 2018, 446, 72–80. [Google Scholar] [CrossRef]

- Li, W.B.; Wang, J.X.; Gong, H. Catalytic combustion of VOCs on non-noble metal catalysts. Catal. Today 2009, 148, 81–87. [Google Scholar] [CrossRef]

- Li, Z.; Yi, J. Enhanced ethanol sensing of Ni-doped SnO2 hollow spheres synthesized by a one-pot hydrothermal method. Sens. Actuators B Chem. 2017, 243, 96–103. [Google Scholar] [CrossRef]

- Sun, Q.; Xu, X.; Peng, H.; Fang, X.; Liu, W.; Ying, J.; Yu, F.; Wang, X. SnO2-based solid solutions for CH4 deep oxidation: Quantifying the lattice capacity of SnO2 using an X-ray diffraction extrapolation method. Chin. J. Catal. 2016, 37, 1293–1302. [Google Scholar] [CrossRef]

- Pan, H.; Jian, Y.; Chen, C.; He, C.; Hao, Z.; Shen, Z.; Liu, H. Sphere-shaped Mn3O4 Catalyst with Remarkable Low-temperature Activity for Methyl–ethyl–ketone Combustion. Environ. Sci. Technol. 2017, 51, 6288. [Google Scholar] [CrossRef]

- Delimaris, D.; Ioannides, T. VOC oxidation over MnOx–CeO2 catalysts prepared by a combustion method. Appl. Catal. B. 2008, 84, 303–312. [Google Scholar] [CrossRef]

- Kuntaiah, K.; Sudarsanam, P.; Reddy, B.M.; Vinu, A. Nanocrystalline Ce1−xSmxO2−δ (x = 0.4) solid solutions: Structural characterization versus CO oxidation. RSC Adv. 2013, 3, 7953–7962. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, X.; Sun, K. Catalytic combustion of ethyl acetate on supported copper oxide catalysts. J. Hazard. Mater. 2007, 139, 140–145. [Google Scholar] [CrossRef]

- Lin, Y.; Wu, Z.; Wen, J.; Ding, K.; Yang, X.; Poeppelmeier, K.R.; Marks, L.D. Adhesion and Atomic Structures of Gold on Ceria Nanostructures: The Role of Surface Structure and Oxidation State of Ceria Supports. Nano Lett. 2015, 15, 5375–5381. [Google Scholar] [CrossRef]

- Liu, C.; Xian, H.; Jiang, Z.; Wang, L.; Zhang, J.; Zheng, L.; Tan, Y.; Li, X. Insight into the improvement effect of the Ce doping into the SnO2 catalyst for the catalytic combustion of methane. Appl. Catal. B 2015, 176–177, 542–552. [Google Scholar] [CrossRef]

- Kumar, K.B.S.; Deshpande, P.A. On Identification of Labile Oxygen in Ceria-Based Solid Solutions: Which Oxygen Leaves the Lattice? J. Phys. Chem. C 2015, 119, 8692–8702. [Google Scholar] [CrossRef]

- El Desouky, F.G.; Saadeldin, M.M.; El Zawawi, I.K. Synthesis and tuning the structure, morphological, optical, and photoluminescence properties of heterostructure cerium oxide and tin oxide nanocomposites. J. Lumin. 2022, 241, 118450. [Google Scholar] [CrossRef]

- Sk, M.A.; Kozlov, S.M.; Lim, K.H.; Migani, A.; Neyman, K.M. Oxygen vacancies in self-assemblies of ceria nanoparticles. J. Mater. Chem. A 2014, 2, 18329–18338. [Google Scholar] [CrossRef]

- Xu, S.; Cao, Y.; Liu, Z. Dimethyl carbonate synthesis from CO2 and methanol over CeO2-ZrO2 catalyst. Catal. Commun. 2022, 162, 106397. [Google Scholar] [CrossRef]

- Mishra, U.K.; Chandel, V.S.; Singh, O.P.; Alam, N. Synthesis of CeO2 and Zr-Doped CeO2 (Ce1−xZrxO2) Catalyst by Green Synthesis for Soot Oxidation Activity. Arab. J. Sci. Eng. 2023, 48, 771–777. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, Z.; Guo, Y.; Guo, Y.; Wang, L.; Zhan, W. A novel method for the synthesis of CexZr1−XO2 solid solution with high purity of κappa phase and excellent reactive activity. Catal. Today 2019, 327, 262–270. [Google Scholar] [CrossRef]

- Xue, Y.-J.; Liu, H.-B.; Lan, M.-M.; Li, J.-S.; Li, H. Effect of different electrodeposition methods on oxidation resistance of Ni–CeO2 nanocomposite coating. Surf. Coat. Technol. 2010, 204, 3539–3545. [Google Scholar] [CrossRef]

- Zhang, P.; Hou, Q. SnO2 modified Ce–Ti–Ox catalyst for the selective catalytic reduction of NOx with NH3. React. Kinet. Mech. Catal. 2016, 117, 119–128. [Google Scholar] [CrossRef]

- Du, J.; Qu, Z.; Dong, C.; Song, L.; Qin, Y.; Huang, N. Low-temperature abatement of toluene over Mn-Ce oxides catalysts synthesized by a modified hydrothermal approach. Appl. Surf. Sci. 2018, 433, 1025–1035. [Google Scholar] [CrossRef]

- Hu, F.; Chen, J.; Zhao, S.; Li, K.; Si, W.; Song, H.; Li, J. Toluene catalytic combustion over copper modified Mn0.5Ce0.5 Ox solid solution sponge-like structures. Appl. Catal. A-Gen. 2017, 540, 57–67. [Google Scholar] [CrossRef]

- Wang, J.; Yang, S.; Sun, H.; Qiu, J.; Men, Y. Highly improved soot combustion performance over synergetic MnxCe1−xO2 solid solutions within mesoporous nanosheets. J. Colloid Interface Sci. 2020, 577, 355–367. [Google Scholar] [CrossRef] [PubMed]

- Yao, X.; Xiong, Y.; Zou, W.; Zhang, L.; Wu, S.; Dong, X.; Gao, F.; Deng, Y.; Tang, C.; Chen, Z.; et al. Correlation between the physicochemical properties and catalytic performances of CexSn1–xO2 mixed oxides for NO reduction by CO. Appl. Catal. B 2014, 144, 152–165. [Google Scholar] [CrossRef]

- Li, X.; Li, Y.; Deng, S.A.; Rong, T. A Ce–Sn–Ox catalyst for the selective catalytic reduction of NOx with NH3. Catal. Commun. 2013, 40, 47–50. [Google Scholar] [CrossRef]

- Huang, J.; Lin, J.; Chen, X.; Zheng, Y.; Xiao, Y.; Zheng, Y. Optimizing the Microstructure of SnO2–CeO2 Binary Oxide Supported Palladium Catalysts for Efficient and Stable Methane Combustion. ACS Appl. Mater. Interfaces 2022, 14, 16233–16244. [Google Scholar] [CrossRef] [PubMed]

- Shen, K.; Lin, J.-P.; Xia, Q.; Dai, L.; Zhou, G.-J.; Guo, Y.-L.; Lu, G.-Z.; Zhan, W.-C. Tuning performance of Pd/Sn0.9Ce0.1O2 catalyst for methane combustion by optimizing calcination temperature of support. Rare Met. 2019, 38, 107–114. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, C.; Xie, Y.; Pan, Z.; Xue, X.; Zhang, R. A study on the catalytic oxidation of soot by Sn–Ce composite oxides: Adsorbed oxygen and defect sites synergistically enhance catalytic activity. New J. Chem. 2019, 43, 17423–17432. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, M.; Dong, Z.; Natan, A.; Chen, S.; Yang, Y.; Huang, X.; Yang, Y. Enhanced acetone detection performance using facile CeO2–SnO2 nanosheets. Appl. Phys. A 2019, 126, 33. [Google Scholar] [CrossRef]

- Berton, M.; Avellaneda, C. Electrochemical and optical properties of CeO2-SnO2 and CeO2-SnO2:X (X = Li, C, Si) films. Mater. Res. 2001, 4, 241–244. [Google Scholar] [CrossRef]

- Sukanya, R.; Ramki, S.; Chen, S.-M.; Karthik, R. Ultrasound treated cerium oxide/tin oxide (CeO2/SnO2) nanocatalyst: A feasible approach and enhanced electrode material for sensing of anti-inflammatory drug 5-aminosalicylic acid in biological samples. Anal. Chim. Acta 2020, 1096, 76–88. [Google Scholar] [CrossRef]

- Li, C.; Zhou, Q. Synergistic effect between Ce-doped SnO2 and bio-carbon for electrocatalytic degradation of tetracycline: Experiment, CFD, and DFT. Chemosphere 2023, 332, 138705. [Google Scholar] [CrossRef]

- Naidi, S.N.; Khan, F.; Tan, A.L.; Harunsani, M.H.; Kim, Y.-M.; Khan, M.M. Green synthesis of CeO2 and Zr/Sn-dual doped CeO2 nanoparticles with photoantioxidant and antibiofilm activities. Biomater. Sci. 2021, 9, 4854–4869. [Google Scholar] [CrossRef] [PubMed]

- Foletto, E.L.; Battiston, S.; Collazzo, G.C.; Bassaco, M.M.; Mazutti, M.A. Degradation of Leather Dye Using CeO2–SnO2 Nanocomposite as Photocatalyst Under Sunlight. Water Air Soil Pollut. 2012, 223, 5773–5779. [Google Scholar] [CrossRef]

- Borker, P.; Salker, A.V. Photocatalytic degradation of textile azo dye over Ce1−xSnxO2 series. Mater. Sci. Eng. B 2006, 133, 55–60. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, M.; Liu, C.; Wang, H.; Zhang, Y.; Zang, Y.; Zhang, Z.; Han, R.; Ji, N.; Song, C.; et al. Synergistic Effect over CeSnO x Catalyst for the Selective Catalytic Oxidation of NH3. ACS Appl. Energy Mater. 2022, 5, 14211–14221. [Google Scholar] [CrossRef]

- Liu, Z.; Feng, X.; Zhou, Z.; Feng, Y.; Li, J. Ce-Sn binary oxide catalyst for the selective catalytic reduction of NOx by NH3. Appl. Surf. Sci. 2018, 428, 526–533. [Google Scholar] [CrossRef]

- Wang, M.; Zhang, Y.; Shan, W.; Yu, Y.; Liu, J.; He, H. Developing a thermally stable Co/Ce-Sn catalyst via adding Sn for soot and CO oxidation. iScience 2022, 25, 104103. [Google Scholar] [CrossRef] [PubMed]

- Long, Y.; Meng, Q.; Chen, M.; Luo, X.; Dai, Q.; Lu, H.; Wu, Z.; Weng, X. Selective Ru Adsorption on SnO2/CeO2 Mixed Oxides for Efficient Destruction of Multicomponent Volatile Organic Compounds: From Laboratory to Practical Possibility. Environ. Sci. Technol. 2022, 56, 9762–9772. [Google Scholar] [CrossRef]

- Jayachandran, V.; Dhandapani, V.; Muniappan, E.; Park, D.; Kim, B.; Arun, A.; Ayyappan, P. Assessment of the Synergetic Performance of Nanostructured CeO2-SnO2/Al2O3 Mixed Oxides on Automobile Exhaust Control. Materials 2022, 15, 8460. [Google Scholar] [CrossRef]

- Leangtanom, P.C.N.; Phanichphant, S.; Kruefu, V. Facile Synthesis of CeO2/SnO2 N-N Heterostructure. AMM 2019, 891, 200–205. [Google Scholar] [CrossRef]

- Wan, W.; Li, Y.; Ren, X.; Zhao, Y.; Gao, F.; Zhao, H. 2D SnO2 Nanosheets: Synthesis, Characterization, Structures, and Excellent Sensing Performance to Ethylene Glycol. Nanomaterials 2018, 8, 112. [Google Scholar] [CrossRef]

- Gupta, A.; Hegde, M.S.; Priolkar, K.R.; Waghmare, U.V.; Sarode, P.R.; Emura, S. Structural Investigation of Activated Lattice Oxygen in Ce1−xSnxO2 and Ce1−x−ySnxPdyO2−δ by EXAFS and DFT calculation. Chem. Mater. 2009, 21, 5836–5847. [Google Scholar] [CrossRef]

- Ayastuy, J.L.; Iglesias-González, A.; Gutiérrez-Ortiz, M.A. Synthesis and characterization of low amount tin-doped ceria (CeXSn1−XO2−δ) for catalytic CO oxidation. Chem. Eng. J. 2014, 244, 372–381. [Google Scholar] [CrossRef]

- Baidya, T.; Gupta, A.; Deshpandey, P.A.; Madras, G.; Hegde, M.S. High Oxygen Storage Capacity and High Rates of CO Oxidation and NO Reduction Catalytic Properties of Ce1−xSnxO2 and Ce0.78Sn0.2Pd0.02O2-δ. J. Phys. Chem. C 2009, 113, 4059–4068. [Google Scholar] [CrossRef]

- Baidya, T.; Bera, P.; Kröcher, O.; Safonova, O.; Abdala, P.M.; Gerke, B.; Pöttgen, R.; Priolkar, K.R.; Mandal, T.K. Understanding the anomalous behavior of Vegard’s law in Ce1−xMxO2 (M = Sn and Ti; 0 < x ≤ 0.5) solid solutions. Phys. Chem. Chem. Phys. 2016, 18, 13974–13983. [Google Scholar] [CrossRef]

- Motaung, D.E.; Mhlongo, G.H.; Makgwane, P.R.; Dhonge, B.P.; Cummings, F.R.; Swart, H.C.; Ray, S.S. Ultra-high sensitive and selective H2 gas sensor manifested by interface of n–n heterostructure of CeO2-SnO2 nanoparticles. Sens. Actuators B Chem. 2018, 254, 984–995. [Google Scholar] [CrossRef]

- López, J.M.; Gilbank, A.L.; García, T.; Solsona, B.; Agouram, S.; Torrente-Murciano, L. The Prevalence of Surface Oxygen Vacancies over the Mobility of Bulk Oxygen in Nanostructured Ceria for the Total Toluene Oxidation. Appl. Catal. B Environ. 2015, 174–175, 403. [Google Scholar] [CrossRef]

- Motsoeneng, R.G.; Kortidis, I.; Ray, S.S.; Motaung, D.E. Designing SnO2 Nanostructure-Based Sensors with Tailored Selectivity toward Propanol and Ethanol Vapors. ACS Omega 2019, 4, 13696–13709. [Google Scholar] [CrossRef]

- Gao, X.; Zhu, S.; Dong, M.; Wang, J.; Fan, W. Ru/CeO2 catalyst with optimized CeO2 morphology and surface facet for efficient hydrogenation of ethyl levulinate to γ-valerolactone. J Catal. 2020, 389, 60–70. [Google Scholar] [CrossRef]

- Sheng, Y.; Zhou, Y.; Lu, H.; Zhang, Z.; Chen, Y. Soot combustion performance and H2-TPR study on ceria-based mixed oxides. Chin. J. Catal. 2013, 34, 567–577. [Google Scholar] [CrossRef]

- Liu, C.; Han, J.; Bi, Y.; Wang, J.; Guo, M.; Liu, Q. A novel Cerium-Tin composite oxide catalyst with high SO2 tolerance for selective catalytic reduction of NOx with NH3. Catal. Today 2021, 376, 65–72. [Google Scholar] [CrossRef]

- Sellick, D.R.; Aranda, A.; García, T.; López, J.M.; Solsona, B.; Mastral, A.M.; Morgan, D.J.; Carley, A.F.; Taylor, S.H. Influence of the preparation method on the activity of ceria zirconia mixed oxides for naphthalene total oxidation. Appl. Catal. B 2013, 132–133, 98–106. [Google Scholar] [CrossRef]

- Yan, L.; Liu, Y.; Zha, K.; Li, H.; Shi, L.; Zhang, D. Deep insight into the structure–activity relationship of Nb modified SnO2–CeO2 catalysts for low-temperature selective catalytic reduction of NO by NH3. Catal. Sci. Technol. 2017, 7, 502–514. [Google Scholar] [CrossRef]

- Nolan, M.; Fearon, J.E.; Watson, G.W. Oxygen vacancy formation and migration in ceria. Solid State Ion. 2006, 177, 3069–3074. [Google Scholar] [CrossRef]

- Mi, R.; Li, D.; Hu, Z.; Yang, R.T. Morphology Effects of CeO2 Nanomaterials on the Catalytic Combustion of Toluene: A Combined Kinetics and Diffuse Reflectance Infrared Fourier Transform Spectroscopy Study. ACS Catalysis 2021, 11, 7876–7889. [Google Scholar] [CrossRef]

- Campbell, C.T.; Peden, C.H.F. Oxygen Vacancies and Catalysis on Ceria Surfaces. Science 2005, 309, 713–714. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).