Steam Reforming of Bioethanol Using Metallic Catalysts on Zeolitic Supports: An Overview

Abstract

:1. Introduction

2. Ethanol Steam Reforming

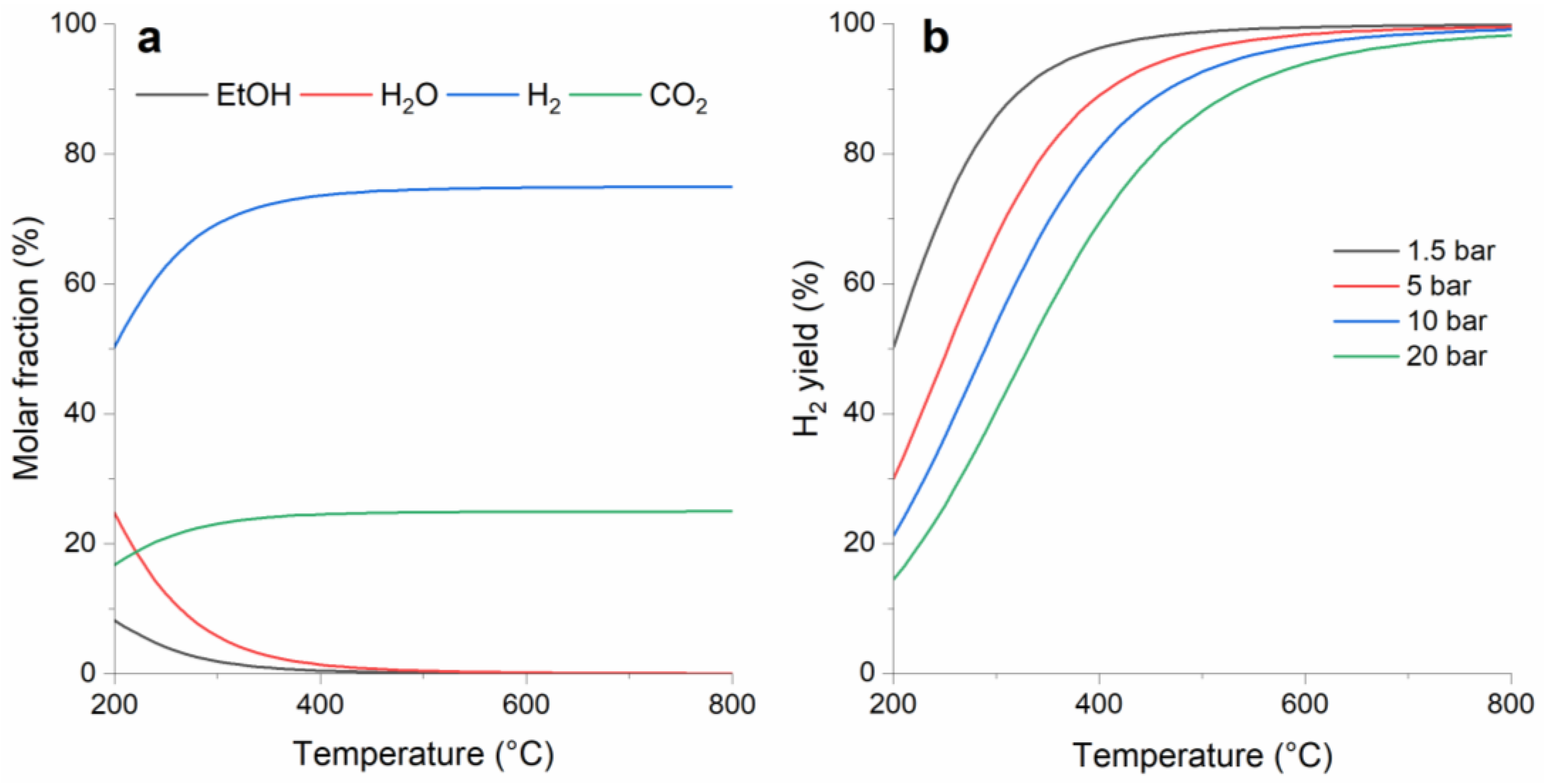

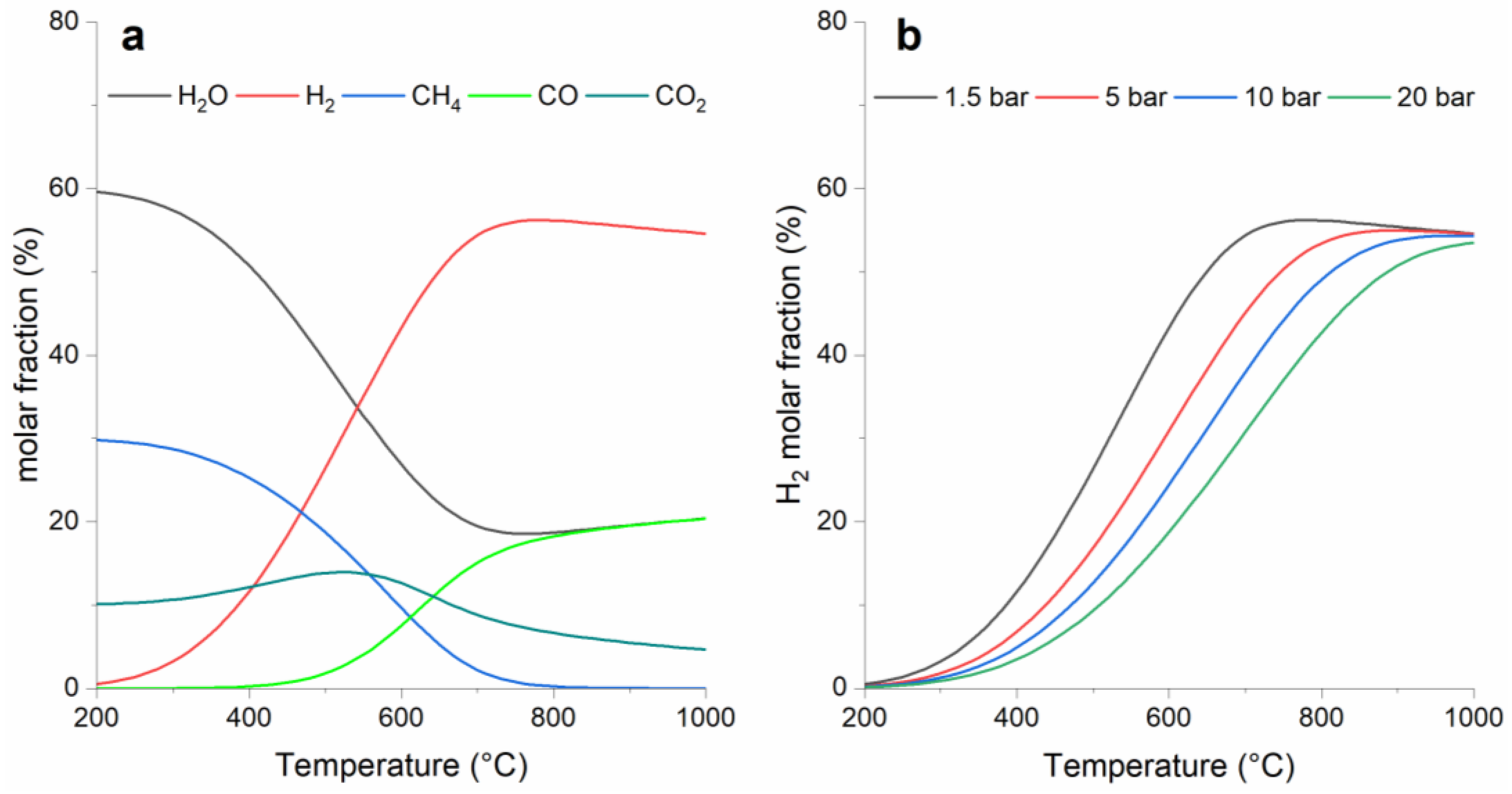

2.1. Thermodynamics of Ethanol Steam Reforming

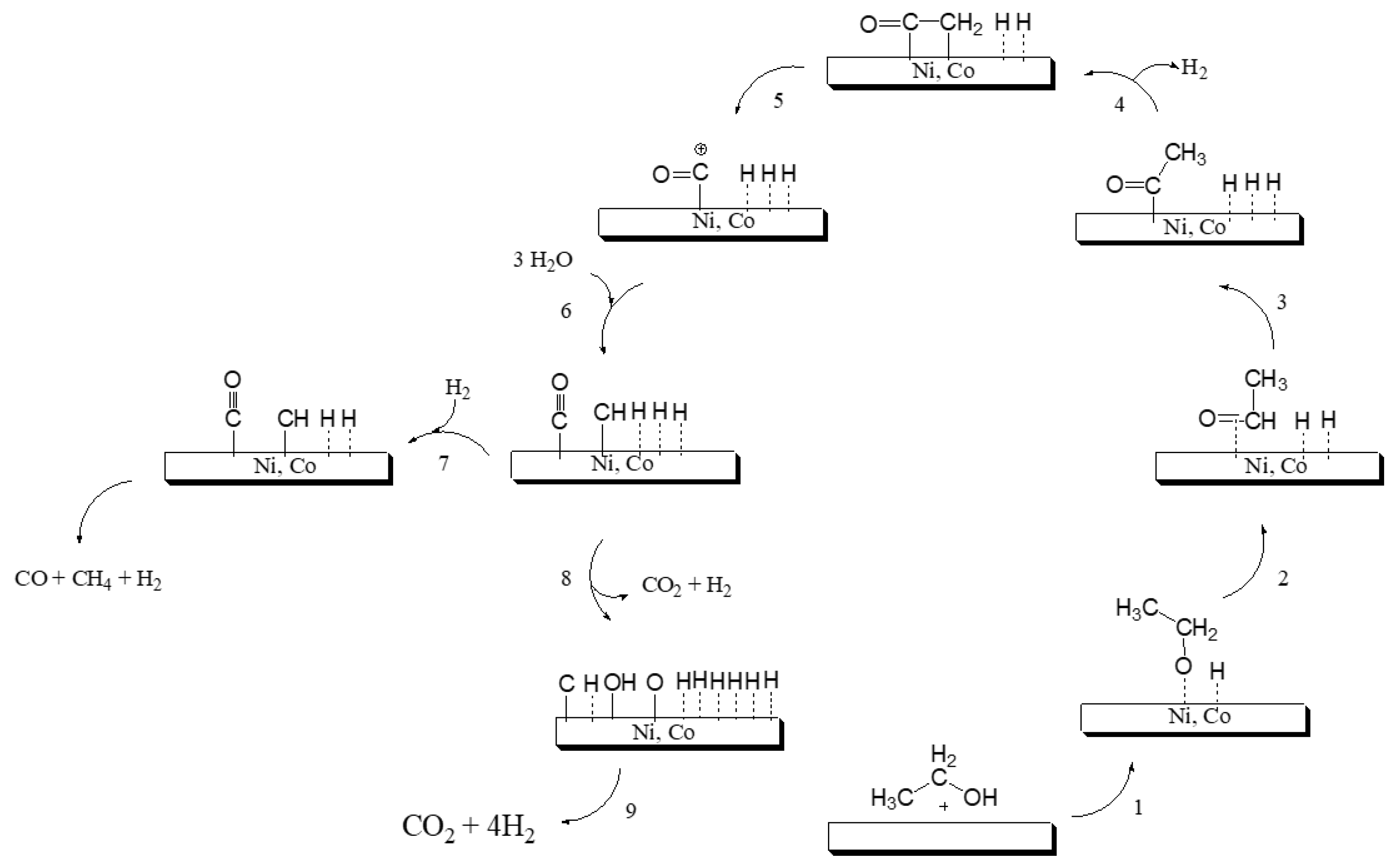

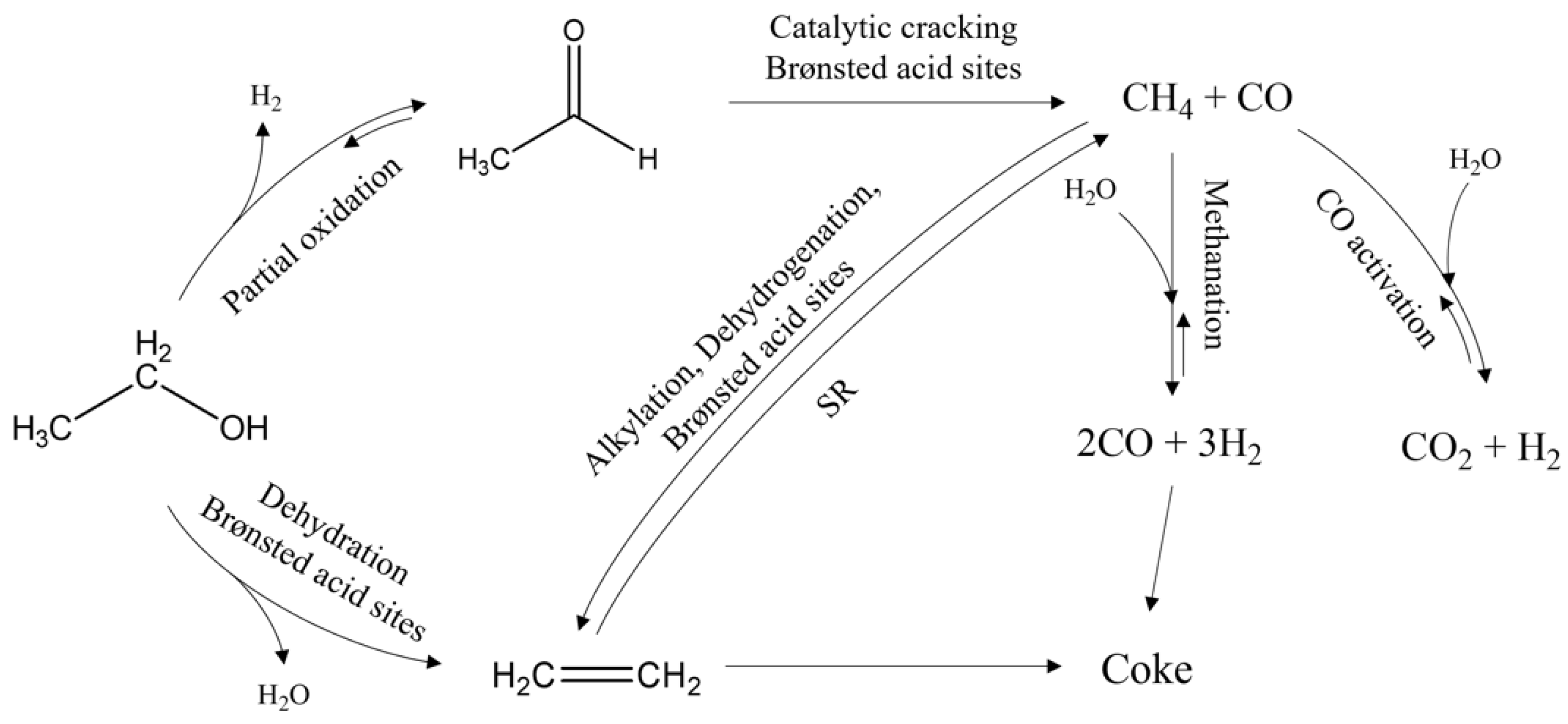

2.2. Reaction Mechanism

3. Metals for ESR

4. Zeolitic Support for ESR

4.1. ZSM-5 Zeolites

4.2. BETA Zeolites

4.3. Y Zeolite

4.4. ITQ Zeolites

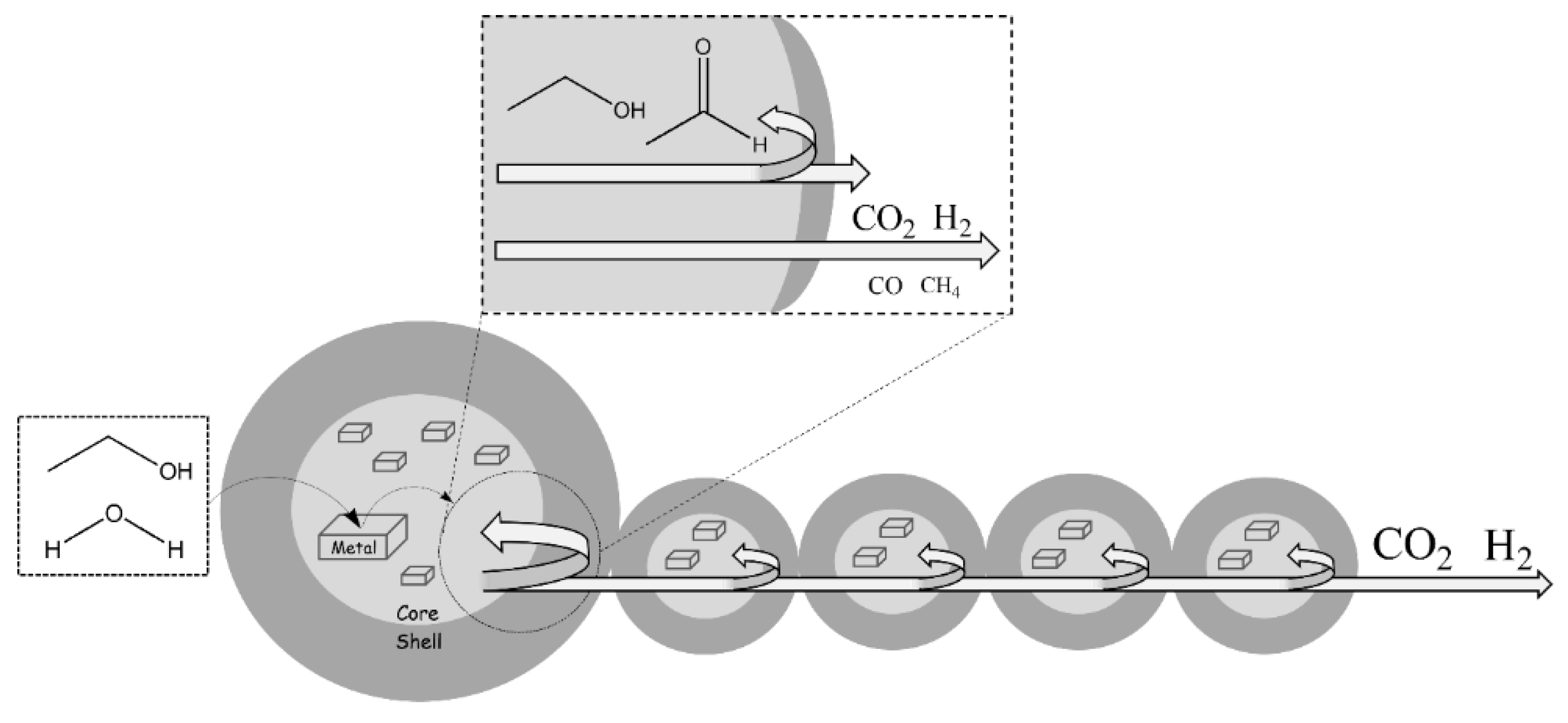

4.5. Core Shell Zeolites

5. Comparison and Future Trend

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

List of Abbreviations

| ASR | acetaldehyde steam reforming |

| EDH | ethanol dehydrogenation |

| EDHy | ethanol dehydration |

| ESR | ethanol steam reforming |

| EtOH | ethanol |

| GHSV | gas hourly space velocity |

| MSR | methane steam reforming |

| mole flow (mol s−1) | |

| PEM | polymer electrolyte membrane |

| S | selectivity of a reaction product |

| SBET | specific surface area (m2 g−1) |

| T | temperature (°C) |

| TOS | time on stream (h) |

| Vmicro | volume of micropores (cm3 g−1) |

| WGS | water gas shift reaction |

| WHSV | weight hourly space velocity |

| X | conversion of the limiting reactant |

| Y | product yield |

| ΔHr°298K | reaction enthalpy at standard condition (kJ mol−1) |

| product yield |

References

- Sayed, E.T.; Wilberforce, T.; Elsaid, K.; Rabaia, M.K.H.; Abdelkareem, M.A.; Chae, K.; Olabi, A.G. A Critical Review on Environmental Impacts of Renewable Energy Systems and Mitigation Strategies: Wind, Hydro, Biomass and Geothermal. Sci. Total Environ. 2021, 766, 144505. [Google Scholar] [CrossRef]

- Wasif, M.; Shahbaz, M.; Sinha, A.; Sengupta, T.; Qin, Q. How Renewable Energy Consumption Contribute to Environmental Quality? The Role of Education in OECD Countries. J. Clean. Prod. 2020, 268, 122149. [Google Scholar] [CrossRef]

- Dalena, F.; Senatore, A.; Iulianelli, A.; Di Paola, L.; Basile, M.; Basile, A. Ethanol from Biomass: Future and Perspectives. In Ethanol: Science and Engineering; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 25–59. [Google Scholar]

- Rajeswari, S.; Baskaran, D.; Saravanan, P.; Rajasimman, M.; Rajamohan, N.; Vasseghian, Y. Production of Ethanol from Biomass–Recent Research, Scientometric Review and Future Perspectives. Fuel 2022, 317, 123448. [Google Scholar] [CrossRef]

- Molino, A.; Migliori, M.; Macrì, D.; Valerio, V.; Villone, A.; Nanna, F.; Iovane, P.; Marino, T. Glucose Gasification in Super-Critical Water Conditions for Both Syngas Production and Green Chemicals with a Continuous Process. Renew. Energy 2016, 91, 451–455. [Google Scholar] [CrossRef]

- Dalena, F.; Senatore, A.; Basile, M.; Marino, D.; Basile, A. From Sugars to Ethanol—From Agricultural Wastes to Algal Sources: An Overview. In Second and Third Generation of Feedstocks: The Evolution of Biofuels; Elsevier Inc.: Amsterdam, The Netherlands, 2019; pp. 3–34. ISBN 9780128151624. [Google Scholar]

- Yu, Y.; Wu, J.; Ren, X.; Lau, A.; Rezaei, H.; Takada, M.; Bi, X.; Sokhansanj, S. Steam Explosion of Lignocellulosic Biomass for Multiple Advanced Bioenergy Processes: A Review. Renew. Sustain. Energy Rev. 2022, 154, 111871. [Google Scholar] [CrossRef]

- Kumar, D.; Singh, B.; Korstad, J. Utilization of Lignocellulosic Biomass by Oleaginous Yeast and Bacteria for Production of Biodiesel and Renewable Diesel. Renew. Sustain. Energy Rev. 2017, 73, 654–671. [Google Scholar] [CrossRef]

- Papanikolaou, G.; Lanzafame, P.; Giorgianni, G.; Abate, S.; Perathoner, S.; Centi, G. Highly Selective Bifunctional Ni Zeo-Type Catalysts for Hydroprocessing of Methyl Palmitate to Green Diesel. Catal. Today 2020, 345, 14–21. [Google Scholar] [CrossRef]

- Hoang, A.T.; Sirohi, R.; Pandey, A.; Nižetić, S.; Lam, S.S.; Chen, W.-H.; Luque, R.; Thomas, S.; Arıcı, M.; Pham, V.V. Biofuel Production from Microalgae: Challenges and Chances. Phytochem. Rev. 2022, 0123456789. [Google Scholar] [CrossRef]

- Dalena, F.; Senatore, A.; Iulianelli, A.; Di Paola, L.; Basile, M.; Basile, A. Ethanol From Biomass. In Ethanol; Elsevier: Amsterdam, The Netherlands, 2019; pp. 25–59. ISBN 9780128114582. [Google Scholar]

- Sanchez, N.; Ruiz, R.; Hacker, V.; Cobo, M. Impact of Bioethanol Impurities on Steam Reforming for Hydrogen Production: A Review. Int. J. Hydrogen Energy 2020, 45, 11923–11942. [Google Scholar] [CrossRef]

- Giorgianni, G.; Abate, S.; Centi, G.; Perathoner, S.; van Beuzekom, S.; Soo-Tang, S.-H.; Van der Waal, J.C. Effect of the Solvent in Enhancing the Selectivity to Furan Derivatives in the Catalytic Hydrogenation of Furfural. ACS Sustain. Chem. Eng. 2018, 6, 16235–16247. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, D.; Rodríguez-Padrón, D.; Len, C. Recent Advances in Catalytic Hydrogenation of Furfural. Catalysts 2019, 9, 796. [Google Scholar] [CrossRef] [Green Version]

- Pizzi, R.; van Putten, R.-J.; Brust, H.; Perathoner, S.; Centi, G.; van der Waal, J. High-Throughput Screening of Heterogeneous Catalysts for the Conversion of Furfural to Bio-Based Fuel Components. Catalysts 2015, 5, 2244–2257. [Google Scholar] [CrossRef] [Green Version]

- Rodríguez-Machín, L.; Piloto-Rodríguez, R.; Rubio-González, A.; Iturria-Quintero, P.J.; Ronsse, F. Pretreatment of Sugarcane Residues for Combustion in Biomass Power Stations: A Review. Sugar Tech 2022, 24, 732–745. [Google Scholar] [CrossRef]

- Borgogna, A.; Centi, G.; Iaquaniello, G.; Perathoner, S.; Papanikolaou, G.; Salladini, A. Assessment of Hydrogen Production from Municipal Solid Wastes as Competitive Route to Produce Low-Carbon H2. Sci. Total Environ. 2022, 827, 154393. [Google Scholar] [CrossRef]

- Catizzone, E.; Migliori, M.; Purita, A.; Giordano, G. Ferrierite vs. Γ-Al2O3: The Superiority of Zeolites in Terms of Water-Resistance in Vapour-Phase Dehydration of Methanol to Dimethyl Ether. J. Energy Chem. 2019, 30, 162–169. [Google Scholar] [CrossRef] [Green Version]

- Migliori, M.; Aloise, A.; Catizzone, E.; Giordano, G. Kinetic Analysis of Methanol to Dimethyl Ether Reaction over H-MFI Catalyst. Ind. Eng. Chem. Res. 2014, 53, 14885–14891. [Google Scholar] [CrossRef]

- Semelsberger, T.A.; Borup, R.L.; Greene, H.L. Dimethyl Ether (DME) as an Alternative Fuel. J. Power Source 2006, 156, 497–511. [Google Scholar] [CrossRef]

- Catizzone, E.; Aloise, A.; Migliori, M.; Giordano, G. Dimethyl Ether Synthesis via Methanol Dehydration: Effect of Zeolite Structure. Appl. Catal. A Gen. 2015, 502, 215–220. [Google Scholar] [CrossRef]

- Migliori, M.; Catizzone, E.; Aloise, A.; Bonura, G.; Gómez-Hortigüela, L.; Frusteri, L.; Cannilla, C.; Frusteri, F.; Giordano, G. New Insights about Coke Deposition in Methanol-to-DME Reaction over MOR-, MFI- and FER-Type Zeolites. J. Ind. Eng. Chem. 2018, 68, 196–208. [Google Scholar] [CrossRef]

- Migliori, M.; Condello, A.; Dalena, F.; Catizzone, E.; Giordano, G. CuZnZr-Zeolite Hybrid Grains for DME Synthesis: New Evidence on the Role of Metal-Acidic Features on the Methanol Conversion Step. Catalysts 2020, 10, 671. [Google Scholar] [CrossRef]

- Catizzone, E.; Giglio, E.; Migliori, M.; Cozzucoli, P.C.; Giordano, G. The Effect of Zeolite Features on the Dehydration Reaction of Methanol to Dimethyl Ether: Catalytic Behaviour and Kinetics. Materials 2020, 13, 5577. [Google Scholar] [CrossRef]

- Jhang, S.; Lin, Y.-C.; Chen, K.; Lin, S.; Batterman, S. Evaluation of Fuel Consumption, Pollutant Emissions and Well-to-Wheel GHGs Assessment from a Vehicle Operation Fueled with Bioethanol, Gasoline and Hydrogen. Energy 2020, 209, 118436. [Google Scholar] [CrossRef]

- Zabed, H.; Sahu, J.N.; Suely, A.; Boyce, A.N.; Faruq, G. Bioethanol Production from Renewable Sources: Current Perspectives and Technological Progress. Renew. Sustain. Energy Rev. 2017, 71, 475–501. [Google Scholar] [CrossRef]

- Kadam, S.A.; Shamzhy, M.V. IR Operando Study of Ethanol Dehydration over MFI Zeolite. Catal. Today 2018, 304, 51–57. [Google Scholar] [CrossRef]

- Tarach, K.A.; Tekla, J.; Filek, U.; Szymocha, A.; Tarach, I.; Góra-Marek, K. Alkaline-Acid Treated Zeolite L as Catalyst in Ethanol Dehydration Process. Microporous Mesoporous Mater. 2017, 241, 132–144. [Google Scholar] [CrossRef]

- Phung, T.K.; Proietti Hernández, L.; Lagazzo, A.; Busca, G. Dehydration of Ethanol over Zeolites, Silica Alumina and Alumina: Lewis Acidity, Brønsted Acidity and Confinement Effects. Appl. Catal. A Gen. 2015, 493, 77–89. [Google Scholar] [CrossRef]

- Zoppi, G.; Pipitone, G.; Pirone, R.; Bensaid, S. Aqueous Phase Reforming Process for the Valorization of Wastewater Streams: Application to Different Industrial Scenarios. Catal. Today 2022, 387, 224–236. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Kumar, A.; Prasad, R.; Upadhyay, S.N. Ethanol Steam Reforming for Hydrogen Production: Latest and Effective Catalyst Modification Strategies to Minimize Carbonaceous Deactivation. Renew. Sustain. Energy Rev. 2017, 74, 89–103. [Google Scholar] [CrossRef]

- Ni, M.; Leung, D.Y.C.; Leung, M.K.H. A Review on Reforming Bio-Ethanol for Hydrogen Production. Int. J. Hydrogen Energy 2007, 32, 3238–3247. [Google Scholar] [CrossRef]

- Ogo, S.; Sekine, Y. Recent Progress in Ethanol Steam Reforming Using Non-Noble Transition Metal Catalysts: A Review. Fuel Process. Technol. 2020, 199, 106238. [Google Scholar] [CrossRef]

- Frusteri, F.; Freni, S.; Spadaro, L.; Chiodo, V.; Bonura, G.; Donato, S.; Cavallaro, S. H2 Production for MC Fuel Cell by Steam Reforming of Ethanol over MgO Supported Pd, Rh, Ni and Co Catalysts. Catal. Commun. 2004, 5, 611–615. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Rezazadeh, A. Hydrogen Fuel and Electricity Generation from a New Hybrid Energy System Based on Wind and Solar Energies and Alkaline Fuel Cell. Energy Rep. 2021, 7, 2594–2604. [Google Scholar] [CrossRef]

- Khan, U.; Yamamoto, T.; Sato, H. An Insight into Potential Early Adopters of Hydrogen Fuel-Cell Vehicles in Japan. Int. J. Hydrogen Energy 2021, 46, 10589–10607. [Google Scholar] [CrossRef]

- Eba, H.; Masuzoe, Y.; Sugihara, T.; Yagi, H.; Liu, T. Ammonia Production Using Iron Nitride and Water as Hydrogen Source under Mild Temperature and Pressure. Int. J. Hydrogen Energy 2021, 46, 10642–10652. [Google Scholar] [CrossRef]

- Giglio, E.; Vitale, G.; Lanzini, A.; Santarelli, M. Integration between Biomass Gasification and High-Temperature Electrolysis for Synthetic Methane Production. Biomass Bioenergy 2021, 148, 106017. [Google Scholar] [CrossRef]

- Giglio, E.; Pirone, R.; Bensaid, S. Dynamic Modelling of Methanation Reactors during Start-up and Regulation in Intermittent Power-to-Gas Applications. Renew. Energy 2021, 170, 1040–1051. [Google Scholar] [CrossRef]

- Guzmán, H.; Salomone, F.; Bensaid, S.; Castellino, M.; Russo, N.; Hernández, S. CO2 Conversion to Alcohols over Cu/ZnO Catalysts: Prospective Synergies between Electrocatalytic and Thermocatalytic Routes. ACS Appl. Mater. Interfaces 2022, 14, 517–530. [Google Scholar] [CrossRef] [PubMed]

- Marchese, M.; Heikkinen, N.; Giglio, E.; Lanzini, A.; Lehtonen, J.; Reinikainen, M. Kinetic Study Based on the Carbide Mechanism of a Co-Pt/γ-Al2O3 Fischer–Tropsch Catalyst Tested in a Laboratory-Scale Tubular Reactor. Catalysts 2019, 9, 717. [Google Scholar] [CrossRef] [Green Version]

- Pein, M.; Neumann, N.C.; Venstrom, L.J.; Vieten, J.; Roeb, M.; Sattler, C. Two-Step Thermochemical Electrolysis: An Approach for Green Hydrogen Production. Int. J. Hydrogen Energy 2021, 46, 24909–24918. [Google Scholar] [CrossRef]

- Freire Ordóñez, D.; Shah, N.; Guillén-Gosálbez, G. Economic and Full Environmental Assessment of Electrofuels via Electrolysis and Co-Electrolysis Considering Externalities. Appl. Energy 2021, 286, 116488. [Google Scholar] [CrossRef]

- Martinelli, M.; Castro, J.D.; Alhraki, N.; Matamoros, M.E.; Kropf, A.J.; Cronauer, D.C.; Jacobs, G. Effect of Sodium Loading on Pt/ZrO2 during Ethanol Steam Reforming. Appl. Catal. A Gen. 2021, 610, 117947. [Google Scholar] [CrossRef]

- Chen, W.-H.; Li, S.; Lim, S.; Chen, Z.; Juan, J.C. Reaction and Hydrogen Production Phenomena of Ethanol Steam Reforming in a Catalytic Membrane Reactor. Energy 2021, 220, 119737. [Google Scholar] [CrossRef]

- Zhurka, M.D.; Lemonidou, A.A.; Anderson, J.A.; Kechagiopoulos, P.N. Kinetic Analysis of the Steam Reforming of Ethanol over Ni/SiO2 for the Elucidation of Metal-Dominated Reaction Pathways. React. Chem. Eng. 2018, 3, 883–897. [Google Scholar] [CrossRef] [Green Version]

- Grzybek, G.; Góra-Marek, K.; Patulski, P.; Greluk, M.; Rotko, M.; Słowik, G.; Kotarba, A. Optimization of the Potassium Promotion of the Co/α-Al2O3 Catalyst for the Effective Hydrogen Production via Ethanol Steam Reforming. Appl. Catal. A Gen. 2021, 614, 118051. [Google Scholar] [CrossRef]

- Ghasemzadeh, K.; Jalilnejad, E.; Sadati Tilebon, S.M. Hydrogen Production Technologies from Ethanol. In Ethanol; Elsevier: Amsterdam, The Netherlands, 2019; pp. 307–340. ISBN 9780128114582. [Google Scholar]

- Li, M.-R.; Wang, G.-C. The Mechanism of Ethanol Steam Reforming on the Co0 and Co2+ Sites: A DFT Study. J. Catal. 2018, 365, 391–404. [Google Scholar] [CrossRef]

- Kumar, A.; Prasad, R.; Sharma, Y.C. Ethanol Steam Reforming Study over ZSM-5 Supported Cobalt versus Nickel Catalyst for Renewable Hydrogen Generation. Chinese J. Chem. Eng. 2019, 27, 677–684. [Google Scholar] [CrossRef]

- Roychowdhury, S.; Mukthar Ali, M.; Dhua, S.; Sundararajan, T.; Ranga Rao, G. Thermochemical Hydrogen Production Using Rh/CeO2/γ-Al2O3 Catalyst by Steam Reforming of Ethanol and Water Splitting in a Packed Bed Reactor. Int. J. Hydrogen Energy 2021, 46, 19254–19269. [Google Scholar] [CrossRef]

- Martínez, A.H.; Lopez, E.; Cadús, L.E.; Agüero, F.N. Elucidation of the Role of Support in Rh/Perovskite Catalysts Used in Ethanol Steam Reforming Reaction. Catal. Today 2021, 372, 59–69. [Google Scholar] [CrossRef]

- Greluk, M.; Rotko, M.; Słowik, G.; Turczyniak-Surdacka, S. Hydrogen Production by Steam Reforming of Ethanol over Co/CeO2 Catalysts: Effect of Cobalt Content. J. Energy Inst. 2019, 92, 222–238. [Google Scholar] [CrossRef]

- Nejat, T.; Jalalinezhad, P.; Hormozi, F.; Bahrami, Z. Hydrogen Production from Steam Reforming of Ethanol over Ni-Co Bimetallic Catalysts and MCM-41 as Support. J. Taiwan Inst. Chem. Eng. 2019, 97, 216–226. [Google Scholar] [CrossRef]

- Ferencz, Z.; Varga, E.; Puskás, R.; Kónya, Z.; Baán, K.; Oszkó, A.; Erdőhelyi, A. Reforming of Ethanol on Co/Al2O3 Catalysts Reduced at Different Temperatures. J. Catal. 2018, 358, 118–130. [Google Scholar] [CrossRef]

- Lang, L.; Zhao, S.; Yin, X.; Yang, W.; Wu, C. Catalytic Activities of K-Modified Zeolite ZSM-5 Supported Rhodium Catalysts in Low-Temperature Steam Reforming of Bioethanol. Int. J. Hydrogen Energy 2015, 40, 9924–9934. [Google Scholar] [CrossRef]

- Vizcaino, A.; Carrero, A.; Calles, J. Hydrogen Production by Ethanol Steam Reforming over Cu–Ni Supported Catalysts. Int. J. Hydrogen Energy 2007, 32, 1450–1461. [Google Scholar] [CrossRef]

- Phung, T.K.; Busca, G. Diethyl Ether Cracking and Ethanol Dehydration: Acid Catalysis and Reaction Paths. Chem. Eng. J. 2015, 272, 92–101. [Google Scholar] [CrossRef]

- Rossetti, I.; Compagnoni, M.; Finocchio, E.; Ramis, G.; Di Michele, A.; Zucchini, A.; Dzwigaj, S. Syngas Production via Steam Reforming of Bioethanol over Ni–BEA Catalysts: A BTL Strategy. Int. J. Hydrogen Energy 2016, 41, 16878–16889. [Google Scholar] [CrossRef]

- Anggoro, D.D.; Oktavianty, H.; Sasongko, S.B.; Buchori, L. Effect of Dealumination on the Acidity of Zeolite Y and the Yield of Glycerol Mono Stearate (GMS). Chemosphere 2020, 257, 127012. [Google Scholar] [CrossRef] [PubMed]

- Dias, S.C.L.; Dias, J.A. Effects of the Dealumination Methodology on the FER Zeolite Acidity: A Study with Fractional Factorial Design. Mol. Catal. 2018, 458, 139–144. [Google Scholar] [CrossRef]

- Peron, D.V.; Zholobenko, V.L.; de Melo, J.H.S.; Capron, M.; Nuns, N.; de Souza, M.O.; Feris, L.A.; Marcilio, N.R.; Ordomsky, V.V.; Khodakov, A.Y. External Surface Phenomena in Dealumination and Desilication of Large Single Crystals of ZSM-5 Zeolite Synthesized from a Sustainable Source. Microporous Mesoporous Mater. 2019, 286, 57–64. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Gong, J. Catalytic Reforming of Oxygenates: State of the Art and Future Prospects. Chem. Rev. 2016, 116, 11529–11653. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Contreras, J.L.; Salmones, J.; Colín-Luna, J.A.; Nuño, L.; Quintana, B.; Córdova, I.; Zeifert, B.; Tapia, C.; Fuentes, G.A. Catalysts for H2 Production Using the Ethanol Steam Reforming (a Review). Int. J. Hydrogen Energy 2014, 39, 18835–18853. [Google Scholar] [CrossRef]

- Zanchet, D.; Santos, J.B.O.; Damyanova, S.; Gallo, J.M.R.; Bueno, J.M.C. Toward Understanding Metal-Catalyzed Ethanol Reforming. ACS Catal. 2015, 5, 3841–3863. [Google Scholar] [CrossRef]

- Choi, Y.; Liu, P. Understanding of Ethanol Decomposition on Rh(1 1 1) from Density Functional Theory and Kinetic Monte Carlo Simulations. Catal. Today 2011, 165, 64–70. [Google Scholar] [CrossRef]

- Sutton, J.E.; Vlachos, D.G. Ethanol Activation on Closed-Packed Surfaces. Ind. Eng. Chem. Res. 2015, 54, 4213–4225. [Google Scholar] [CrossRef]

- Jones, G.; Jakobsen, J.G.; Shim, S.S.; Kleis, J.; Andersson, M.P.; Rossmeisl, J.; Abild-Pedersen, F.; Bligaard, T.; Helveg, S.; Hinnemann, B.; et al. First Principles Calculations and Experimental Insight into Methane Steam Reforming over Transition Metal Catalysts. J. Catal. 2008, 259, 147–160. [Google Scholar] [CrossRef]

- Wang, S.; He, B.; Tian, R.; Sun, C.; Dai, R.; Li, X.; Wu, X.; An, X.; Xie, X. Ni-Hierarchical Beta Zeolite Catalysts Were Applied to Ethanol Steam Reforming: Effect of Sol Gel Method on Loading Ni and the Role of Hierarchical Structure. Mol. Catal. 2018, 453, 64–73. [Google Scholar] [CrossRef]

- Iulianelli, A.; Dalena, F.; Basile, A. Steam Reforming, Preferential Oxidation, and Autothermal Reforming of Ethanol for Hydrogen Production in Membrane Reactors. In Ethanol; Elsevier: Amsterdam, The Netherlands, 2019; pp. 193–213. ISBN 9780128114582. [Google Scholar]

- Phung, T.K.; Pham, T.L.M.; Nguyen, A.-N.T.; Vu, K.B.; Giang, H.N.; Nguyen, T.; Huynh, T.C.; Pham, H.D. Effect of Supports and Promoters on the Performance of Ni-Based Catalysts in Ethanol Steam Reforming. Chem. Eng. Technol. 2020, 43, 672–688. [Google Scholar] [CrossRef]

- Zheng, Z.; Sun, C.; Dai, R.; Wang, S.; Wu, X.; An, X.; Wu, Z.; Xie, X. Ethanol Steam Reforming on Ni-Based Catalysts: Effect of Cu and Fe Addition on the Catalytic Activity and Resistance to Deactivation. Energy Fuels 2017, 31, 3091–3100. [Google Scholar] [CrossRef]

- Vicente, J.; Ereña, J.; Montero, C.; Azkoiti, M.J.; Bilbao, J.; Gayubo, A.G. Reaction Pathway for Ethanol Steam Reforming on a Ni/SiO2 Catalyst Including Coke Formation. Int. J. Hydrogen Energy 2014, 39, 18820–18834. [Google Scholar] [CrossRef]

- Kwak, B.S.; Lee, G.; Park, S.M.; Kang, M. Effect of MnOx in the Catalytic Stabilization of Co2MnO4 Spinel during the Ethanol Steam Reforming Reaction. Appl. Catal. A Gen. 2015, 503, 165–175. [Google Scholar] [CrossRef]

- Greluk, M.; Gac, W.; Rotko, M.; Słowik, G.; Turczyniak-Surdacka, S. Co/CeO2 and Ni/CeO2 Catalysts for Ethanol Steam Reforming: Effect of the Cobalt/Nickel Dispersion on Catalysts Properties. J. Catal. 2021, 393, 159–178. [Google Scholar] [CrossRef]

- Zhang, H.; Fan, Y.F.; Huan, Y.H.; Yue, M.B. Dry-Gel Synthesis of Shaped Transition-Metal-Doped M-MFI (M = Ti, Fe, Cr, Ni) Zeolites by Using Metal-Occluded Zeolite Seed Sol as a Directing Agent. Microporous Mesoporous Mater. 2016, 231, 178–185. [Google Scholar] [CrossRef] [Green Version]

- Inokawa, H.; Maeda, M.; Nishimoto, S. Synthesis of Nickel Nanoparticles with Excellent Thermal Stability in Micropores of Zeolite. Int. J. Hydrogen Energy 2013, 38, 13579–13586. [Google Scholar] [CrossRef]

- Bozbag, S.E.; Zhang, L.C.; Aindow, M.; Erkey, C. Carbon Aerogel Supported Nickel Nanoparticles and Nanorods Using Supercritical Deposition. J. Supercrit. Fluids 2012, 66, 265–273. [Google Scholar] [CrossRef]

- Isarapakdeetham, S.; Kim-Lohsoontorn, P.; Wongsakulphasatch, S.; Kiatkittipong, W.; Laosiripojana, N.; Gong, J.; Assabumrungrat, S. Hydrogen Production via Chemical Looping Steam Reforming of Ethanol by Ni-Based Oxygen Carriers Supported on CeO2 and La2O3 Promoted Al2O3. Int. J. Hydrogen Energy 2020, 45, 1477–1491. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, J.; Li, W. Ethanol Steam Reforming over Ni-Cu/Al2O3-MyOz (M = Si, La, Mg, and Zn) Catalysts. J. Nat. Gas Chem. 2009, 18, 55–65. [Google Scholar] [CrossRef]

- Zhurka, M.D.; Lemonidou, A.A.; Kechagiopoulos, P.N. Elucidation of Metal and Support Effects during Ethanol Steam Reforming over Ni and Rh Based Catalysts Supported on (CeO2)-ZrO2-La2O3. Catal. Today 2021, 368, 161–172. [Google Scholar] [CrossRef]

- Garbarino, G.; Wang, C.; Valsamakis, I.; Chitsazan, S.; Riani, P.; Finocchio, E.; Flytzani-Stephanopoulos, M.; Busca, G. A Study of Ni/Al2O3 and Ni–La/Al2O3 Catalysts for the Steam Reforming of Ethanol and Phenol. Appl. Catal. B Environ. 2015, 174–175, 21–34. [Google Scholar] [CrossRef] [Green Version]

- Song, J.H.; Yoo, S.; Yoo, J.; Park, S.; Gim, M.Y.; Kim, T.H.; Song, I.K. Hydrogen Production by Steam Reforming of Ethanol over Ni/Al2O3-La2O3 Xerogel Catalysts. Mol. Catal. 2017, 434, 123–133. [Google Scholar] [CrossRef]

- Campos-Skrobot, F.C.; Rizzo-Domingues, R.C.P.; Fernandes-Machado, N.R.C.; Cantão, M.P. Novel Zeolite-Supported Rhodium Catalysts for Ethanol Steam Reforming. J. Power Source 2008, 183, 713–716. [Google Scholar] [CrossRef]

- Gac, W.; Greluk, M.; Słowik, G.; Millot, Y.; Valentin, L.; Dzwigaj, S. Effects of Dealumination on the Performance of Ni-Containing BEA Catalysts in Bioethanol Steam Reforming. Appl. Catal. B Environ. 2018, 237, 94–109. [Google Scholar] [CrossRef]

- Bizkarra, K.; Barrio, V.L.; Gartzia-Rivero, L.; Bañuelos, J.; López-Arbeloa, I.; Cambra, J.F. Hydrogen Production from a Model Bio-Oil/Bio-Glycerol Mixture through Steam Reforming Using Zeolite L Supported Catalysts. Int. J. Hydrogen Energy 2019, 44, 1492–1504. [Google Scholar] [CrossRef]

- Rodriguez-Gomez, A.; Caballero, A. Bimetallic Ni-Co/SBA-15 Catalysts for Reforming of Ethanol: How Cobalt Modifies the Nickel Metal Phase and Product Distribution. Mol. Catal. 2018, 449, 122–130. [Google Scholar] [CrossRef] [Green Version]

- Lindo, M.; Vizcaíno, A.J.; Calles, J.A.; Carrero, A. Ethanol Steam Reforming on Ni/Al-SBA-15 Catalysts: Effect of the Aluminium Content. Int. J. Hydrogen Energy 2010, 35, 5895–5901. [Google Scholar] [CrossRef]

- Bayram, B.; Soykal, I.I.; Von Deak, D.; Miller, J.T.; Ozkan, U.S. Ethanol Steam Reforming over Co-Based Catalysts: Investigation of Cobalt Coordination Environment under Reaction Conditions. J. Catal. 2011, 284, 77–89. [Google Scholar] [CrossRef]

- Garbarino, G.; Cavattoni, T.; Riani, P.; Brescia, R.; Canepa, F.; Busca, G. On the Role of Support in Metallic Heterogeneous Catalysis: A Study of Unsupported Nickel–Cobalt Alloy Nanoparticles in Ethanol Steam Reforming. Catal. Lett. 2019, 149, 929–941. [Google Scholar] [CrossRef]

- Pinton, N.; Vidal, M.V.; Signoretto, M.; Martínez-Arias, A.; Cortés Corberán, V. Ethanol Steam Reforming on Nanostructured Catalysts of Ni, Co and CeO2: Influence of Synthesis Method on Activity, Deactivation and Regenerability. Catal. Today 2017, 296, 135–143. [Google Scholar] [CrossRef]

- Rodriguez-Gomez, A.; Holgado, J.P.; Caballero, A. Cobalt Carbide Identified as Catalytic Site for the Dehydrogenation of Ethanol to Acetaldehyde. ACS Catal. 2017, 7, 5243–5247. [Google Scholar] [CrossRef]

- Gonçalves, A.A.S.; Faustino, P.B.; Assaf, J.M.; Jaroniec, M. One-Pot Synthesis of Mesoporous Ni-Ti-Al Ternary Oxides: Highly Active and Selective Catalysts for Steam Reforming of Ethanol. ACS Appl. Mater. Interfaces 2017, 9, 6079–6092. [Google Scholar] [CrossRef]

- Słowik, G.; Greluk, M.; Rotko, M.; Machocki, A. Evolution of the Structure of Unpromoted and Potassium-Promoted Ceria-Supported Nickel Catalysts in the Steam Reforming of Ethanol. Appl. Catal. B Environ. 2018, 221, 490–509. [Google Scholar] [CrossRef]

- Riani, P.; Garbarino, G.; Canepa, F.; Busca, G. Cobalt Nanoparticles Mechanically Deposited on α-Al2O3: A Competitive Catalyst for the Production of Hydrogen through Ethanol Steam Reforming. J. Chem. Technol. Biotechnol. 2019, 94, 538–546. [Google Scholar] [CrossRef]

- Chen, M.; Wang, C.; Wang, Y.; Tang, Z.; Yang, Z.; Zhang, H.; Wang, J. Hydrogen Production from Ethanol Steam Reforming: Effect of Ce Content on Catalytic Performance of Co/Sepiolite Catalyst. Fuel 2019, 247, 344–355. [Google Scholar] [CrossRef]

- Parlett, C.M.A.; Aydin, A.; Durndell, L.J.; Frattini, L.; Isaacs, M.A.; Lee, A.F.; Liu, X.; Olivi, L.; Trofimovaite, R.; Wilson, K.; et al. Tailored Mesoporous Silica Supports for Ni Catalysed Hydrogen Production from Ethanol Steam Reforming. Catal. Commun. 2017, 91, 76–79. [Google Scholar] [CrossRef] [Green Version]

- da Silva, A.L.M.; den Breejen, J.P.; Mattos, L.V.; Bitter, J.H.; de Jong, K.P.; Noronha, F.B. Cobalt Particle Size Effects on Catalytic Performance for Ethanol Steam Reforming – Smaller Is Better. J. Catal. 2014, 318, 67–74. [Google Scholar] [CrossRef]

- Kourtelesis, M.; Verykios, X. Stability of Pt/γ-Al2O3 Catalyst for the Low Temperature Steam Reforming of Ethanol & Acetaldehyde. Effect of Carrier Modification with Ca. Mater. Today Proc. 2018, 5, 27406–27415. [Google Scholar] [CrossRef]

- Wu, Y.; Chung, W.; Chang, M. Modification of Ni/γ-Al2O3 Catalyst with Plasma for Steam Reforming of Ethanol to Generate Hydrogen. Int. J. Hydrogen Energy 2015, 40, 8071–8080. [Google Scholar] [CrossRef]

- Lucredio, A.F.; Bellido, J.D.A.; Zawadzki, A.; Assaf, E.M. Co Catalysts Supported on SiO2 and γ-Al2O3 Applied to Ethanol Steam Reforming: Effect of the Solvent Used in the Catalyst Preparation Method. Fuel 2011, 90, 1424–1430. [Google Scholar] [CrossRef]

- Kim, D.; Sub, B.; Min, B.; Kang, M. Applied Surface Science Characterization of Ni and W Co-Loaded SBA-15 Catalyst and Its Hydrogen Production Catalytic Ability on Ethanol Steam Reforming Reaction. Appl. Surf. Sci. 2015, 332, 736–746. [Google Scholar] [CrossRef]

- He, S.; He, S.; Zhang, L.; Li, X.; Wang, J.; He, D.; Lu, J.; Luo, Y. Hydrogen Production by Ethanol Steam Reforming over Ni/SBA-15 Mesoporous Catalysts: Effect of Au Addition. Catal. Today 2015, 258, 162–168. [Google Scholar] [CrossRef]

- Bussi, J.; Musso, M.; Veiga, S.; Bespalko, N.; Faccio, R.; Roger, A. Ethanol Steam Reforming over NiLaZr and NiCuLaZr Mixed Metal Oxide Catalysts. Catal. Today 2013, 213, 42–49. [Google Scholar] [CrossRef]

- Coleman, L.J.I.; Epling, W.; Hudgins, R.R.; Croiset, E. Ni/Mg–Al Mixed Oxide Catalyst for the Steam Reforming of Ethanol. Appl. Catal. A Gen. 2009, 363, 52–63. [Google Scholar] [CrossRef]

- Marino, A.; Aloise, A.; Hernando, H.; Fermoso, J.; Cozza, D.; Giglio, E.; Migliori, M.; Pizarro, P.; Giordano, G.; Serrano, D.P. ZSM-5 Zeolites Performance Assessment in Catalytic Pyrolysis of PVC-Containing Real WEEE Plastic Wastes. Catal. Today 2022, 390–391, 210–220. [Google Scholar] [CrossRef]

- Cychosz, K.A.; Guillet-Nicolas, R.; García-Martínez, J.; Thommes, M. Recent Advances in the Textural Characterization of Hierarchically Structured Nanoporous Materials. Chem. Soc. Rev. 2017, 46, 389–414. [Google Scholar] [CrossRef] [PubMed]

- Centi, G.; Perathoner, S.; Pino, F.; Arrigo, R.; Giordano, G.; Katovic, A.; Pedulà, V. Performances of Fe-[Al, B]MFI Catalysts in Benzene Hydroxylation with N2O: The Role of Zeolite Defects as Host Sites for Highly Active Iron Species. Catal. Today 2005, 110, 211–220. [Google Scholar] [CrossRef]

- Katovic, A.; Giordano, G.; Bonelli, B.; Onida, B.; Garrone, E.; Lentz, P.; Nagy, J.B. Preparation and Characterization of Mesoporous Molecular Sieves Containing Al, Fe or Zn. Microporous Mesoporous Mater. 2001, 44–45, 275–281. [Google Scholar] [CrossRef]

- Sandoval-Díaz, L.-E.; González-Amaya, J.-A.; Trujillo, C.-A. General Aspects of Zeolite Acidity Characterization. Microporous Mesoporous Mater. 2015, 215, 229–243. [Google Scholar] [CrossRef]

- Weitkamp, J. Zeolites and Catalysis. Solid State Ionics 2000, 131, 175–188. [Google Scholar] [CrossRef]

- Maesen, T. The Zeolite Scene—An Overview. In Introduction to Zeolite Science and Practice; Čejka, J., van Bekkum, H., Corma, A., Schüth, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; Volume 168, pp. 1–12. ISBN 0444530630. [Google Scholar]

- Milliken, T.H.; Mills, G.A.; Oblad, A.G. The Chemical Characteristics and Structure of Cracking Catalysts. Discuss. Faraday Soc. 1950, 8, 279–290. [Google Scholar] [CrossRef]

- Busca, G. Acidity and Basicity of Zeolites: A Fundamental Approach. Microporous Mesoporous Mater. 2017, 254, 3–16. [Google Scholar] [CrossRef]

- Madeira, F.F.; Gnep, N.S.; Magnoux, P.; Maury, S.; Cadran, N. Ethanol Transformation over HFAU, HBEA and HMFI Zeolites Presenting Similar Brønsted Acidity. Appl. Catal. A Gen. 2009, 367, 39–46. [Google Scholar] [CrossRef]

- Santi, D.; Rabl, S.; Calemma, V.; Dyballa, M.; Hunger, M.; Weitkamp, J. Effect of Noble Metals on the Strength of Brønsted Acid Sites in Bifunctional Zeolites. ChemCatChem 2013, 5, 1524–1530. [Google Scholar] [CrossRef]

- Aloise, A.; Marino, A.; Dalena, F.; Giorgianni, G.; Migliori, M.; Frusteri, L.; Cannilla, C.; Bonura, G.; Frusteri, F.; Giordano, G. Desilicated ZSM-5 Zeolite: Catalytic Performances Assessment in Methanol to DME Dehydration. Microporous Mesoporous Mater. 2020, 302, 110198. [Google Scholar] [CrossRef]

- Dalena, F.; Giglio, E.; Giorgianni, G.; Cozza, D.; Marino, A.; Aloise, A. DME Production via Methanol Dehydration with H Form and Desilicated ZSM-5 Type Zeolitic Catalysts: Study on the Correlation between Acid Sites and Conversion. Chem. Eng. Trans. 2021, 84, 211–216. [Google Scholar] [CrossRef]

- Rossetti, I.; Lasso, J.; Nichele, V.; Signoretto, M.; Finocchio, E.; Ramis, G.; Di Michele, A. Silica and Zirconia Supported Catalysts for the Low-Temperature Ethanol Steam Reforming. Appl. Catal. B Environ. 2014, 150–151, 257–267. [Google Scholar] [CrossRef]

- Gołąbek, K.; Tarach, K.A.; Filek, U.; Góra-Marek, K. Ethylene Formation by Dehydration of Ethanol over Medium Pore Zeolites. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 192, 464–472. [Google Scholar] [CrossRef]

- Kuz’mina, R.I.; Frolov, M.P.; Liventsev, V.T.; Vetrova, T.K.; Kovnev, A. V Development of Zeolite-Containing Reforming Catalysts. Catal. Ind. 2010, 2, 329–333. [Google Scholar] [CrossRef]

- Čejka, J.; van Bekkum, H.; Corma, A.; Schüth, F. (Eds.) Introduction to Zeolite Science and Practice, 3rd ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Da Costa-Serra, J.F.; Navarro, M.T.; Rey, F.; Chica, A. Bioethanol Steam Reforming on Ni-Based Modified Mordenite. Effect of Mesoporosity, Acid Sites and Alkaline Metals. Int. J. Hydrogen Energy 2012, 37, 7101–7108. [Google Scholar] [CrossRef]

- Rokicińska, A.; Drozdek, M.; Dudek, B.; Gil, B.; Michorczyk, P.; Brouri, D.; Dzwigaj, S.; Kuśtrowski, P. Cobalt-Containing BEA Zeolite for Catalytic Combustion of Toluene. Appl. Catal. B Environ. 2017, 212, 59–67. [Google Scholar] [CrossRef] [Green Version]

- Newsam, J.M.; Treacy, M.M.J.; Koetsier, W.T.; De Gruyter, C.B. Structural Characterization of Zeolite Beta. Proc. R. Soc. Lond. A. Math. Phys. Sci. 1988, 420, 375–405. [Google Scholar] [CrossRef]

- International Zeolite Association (IZA)—Database of Zeolite Structures. Available online: http://www.iza-structure.org/databases/ (accessed on 28 April 2022).

- Pinheiro, A.N.; Valentini, A.; Sasaki, J.M.; Oliveira, A.C. Highly Stable Dealuminated Zeolite Support for the Production of Hydrogen by Dry Reforming of Methane. Appl. Catal. A Gen. 2009, 355, 156–168. [Google Scholar] [CrossRef]

- Che, Q.; Yang, M.; Wang, X.; Yang, Q.; Rose Williams, L.; Yang, H.; Zou, J.; Zeng, K.; Zhu, Y.; Chen, Y.; et al. Influence of Physicochemical Properties of Metal Modified ZSM-5 Catalyst on Benzene, Toluene and Xylene Production from Biomass Catalytic Pyrolysis. Bioresour. Technol. 2019, 278, 248–254. [Google Scholar] [CrossRef]

- Shi, W.; Yi, B.; Hou, M.; Shao, Z. The Effect of H2S and CO Mixtures on PEMFC Performance. Int. J. Hydrogen Energy 2007, 32, 4412–4417. [Google Scholar] [CrossRef]

- Baschuk, J.J.; Li, X. Carbon Monoxide Poisoning of Proton Exchange Membrane Fuel Cells. Int. J. Energy Res. 2001, 25, 695–713. [Google Scholar] [CrossRef]

- Tian, R.; Wang, S.; Lian, C.; Wu, X.; An, X.; Xie, X. Synthesis of the Hierarchical Fe-Substituted Porous HBeta Zeolite and the Exploration of Its Catalytic Performance. J. Fuel Chem. Technol. 2019, 47, 1476–1485. [Google Scholar] [CrossRef]

- Centi, G.; Perathoner, S.; Arrigo, R.; Giordano, G.; Katovic, A.; Pedulà, V. Characterization and Reactivity of Fe-[Al,B]MFI Catalysts for Benzene Hydroxylation with N2O. Appl. Catal. A Gen. 2006, 307, 30–41. [Google Scholar] [CrossRef]

- Centi, G.; Genovese, C.; Giordano, G.; Katovic, A.; Perathoner, S. Performance of Fe–BEA Catalysts for the Selective Hydroxylation of Benzene with N2O. Catal. Today 2004, 91–92, 17–26. [Google Scholar] [CrossRef]

- Zheng, Z.; Sun, C.; Dai, R.; Wang, S.; Wu, X.; An, X.; Xie, X. Organotemplate-Free Synthesis of Hollow Beta Zeolite Supported Pt-Based Catalysts for Low-Temperature Ethanol Steam Reforming. Catal. Sci. Technol. 2016, 6, 6472–6475. [Google Scholar] [CrossRef]

- Khaleque, A.; Alam, M.M.; Hoque, M.; Mondal, S.; Haider, J.B.; Xu, B.; Johir, M.A.H.; Karmakar, A.K.; Zhou, J.L.; Ahmed, M.B.; et al. Zeolite Synthesis from Low-Cost Materials and Environmental Applications: A Review. Environ. Adv. 2020, 2, 100019. [Google Scholar] [CrossRef]

- Lutz, W. Zeolite Y: Synthesis, Modification, and Properties—A Case Revisited. Adv. Mater. Sci. Eng. 2014, 2014, 1–20. [Google Scholar] [CrossRef] [Green Version]

- Sang, S.; Liu, Z.; Tian, P.; Liu, Z.; Qu, L.; Zhang, Y. Synthesis of Small Crystals Zeolite NaY. Mater. Lett. 2006, 60, 1131–1133. [Google Scholar] [CrossRef]

- Domoroshchina, E.N.; Chernyshev, V.V.; Kuz’micheva, G.M.; Dorokhov, A.V.; Pirutko, L.V.; Kravchenko, G.V.; Chumakov, R.B. Changing the Characteristics and Properties of Zeolite Y and Nano-Anatase in the Formation of a Nano-Anatase/Y Composite with Improved Photocatalytic and Adsorption Properties. Appl. Nanosci. 2018, 8, 19–31. [Google Scholar] [CrossRef] [Green Version]

- Inokawa, H.; Nishimoto, S.; Kameshima, Y.; Miyake, M. Difference in the Catalytic Activity of Transition Metals and Their Cations Loaded in Zeolite Y for Ethanol Steam Reforming. Int. J. Hydrogen Energy 2010, 35, 11719–11724. [Google Scholar] [CrossRef]

- Inokawa, H.; Nishimoto, S.; Kameshima, Y.; Miyake, M. Promotion of H2 Production from Ethanol Steam Reforming by Zeolite Basicity. Int. J. Hydrogen Energy 2011, 36, 15195–15202. [Google Scholar] [CrossRef]

- Sub, B.; Su, J.; Sung, J.; Choi, B.; Jung, M.; Kang, M. Hydrogen-Rich Gas Production from Ethanol Steam Reforming over Ni/Ga/Mg/Zeolite Y Catalysts at Mild Temperature. Appl. Energy 2011, 88, 4366–4375. [Google Scholar] [CrossRef]

- Chica, A.; Sayas, S. Effective and Stable Bioethanol Steam Reforming Catalyst Based on Ni and Co Supported on All-Silica Delaminated ITQ-2 Zeolite. Catal. Today 2009, 146, 37–43. [Google Scholar] [CrossRef]

- Da Costa-Serra, J.F.; Chica, A. Bioethanol Steam Reforming on Co/ITQ-18 Catalyst: Effect of the Crystalline Structure of the Delaminated Zeolite ITQ-18. Int. J. Hydrogen Energy 2011, 36, 3862–3869. [Google Scholar] [CrossRef]

- Giordano, G.; Migliori, M.; Ferrarelli, G.; Giorgianni, G.; Dalena, F.; Peng, P.; Debost, M.; Boullay, P.; Liu, Z.; Guo, H.; et al. Passivated Surface of High Aluminum Containing ZSM-5 by Silicalite-1: Synthesis and Application in Dehydration Reaction. ACS Sustain. Chem. Eng. 2022, 10, 4839–4848. [Google Scholar] [CrossRef]

- Ferrarelli, G.; Giordano, G.; Migliori, M. ZSM-5@Sil-1 Core Shell: Effect of Synthesis Method over Textural and Catalytic Properties. Catal. Today 2022, 390–391, 176–184. [Google Scholar] [CrossRef]

- Deng, Y.; Zhou, W.; Lv, H.; Zhang, Y.; Au, C.; Yin, S. Synthesis of HZSM-5@silicalite-1 Core–Shell Composite and Its Catalytic Application in the Generation of p-Xylene by Methylation of Toluene with Methyl Bromide. RSC Adv. 2014, 4, 37296–37301. [Google Scholar] [CrossRef]

- Li, N.; Zhang, Y.; Chen, L.; Au, C.; Yin, S. Synthesis and Application of HZSM-5@silicalite-1 Core–Shell Composites for the Generation of Light Olefins from CH3Br. Microporous Mesoporous Mater. 2016, 227, 76–80. [Google Scholar] [CrossRef]

- Li, X.; Zheng, Z.; Wang, S.; Sun, C.; Dai, R.; Wu, X.; An, X.; Xie, X. Preparation and Characterization of Core–Shell Composite Zeolite BEA@MFI and Their Catalytic Properties in ESR. Catal. Lett. 2019, 149, 766–777. [Google Scholar] [CrossRef]

- Bouizi, Y.; Diaz, I.; Rouleau, L.; Valtchev, V.P. Core-Shell Zeolite Microcomposites. Adv. Funct. Mater. 2005, 15, 1955–1960. [Google Scholar] [CrossRef]

- Kwak, B.S.; Kim, J.; Kang, M. Hydrogen Production from Ethanol Steam Reforming over Core–Shell Structured NixOy–, FexOy–, and CoxOy–Pd Catalysts. Int. J. Hydrogen Energy 2010, 35, 11829–11843. [Google Scholar] [CrossRef]

- Dai, R.; Zheng, Z.; Sun, C.; Li, X.; Wang, S.; Wu, X.; An, X.; Xie, X. Pt Nanoparticles Encapsulated in a Hollow Zeolite Microreactor as a Highly Active and Stable Catalyst for Low-Temperature Ethanol Steam Reforming. Fuel 2018, 214, 88–97. [Google Scholar] [CrossRef]

- Zheng, Z.; Yang, D.; Li, T.; Yin, X.; Wang, S.; Wu, X.; An, X.; Xie, X. A Novel BEA-Type Zeolite Core–Shell Multiple Catalyst for Hydrogen-Rich Gas Production from Ethanol Steam Reforming. Catal. Sci. Technol. 2016, 6, 5427–5439. [Google Scholar] [CrossRef]

- Wang, S.; He, B.; Tian, R.; Wu, X.; An, X.; Liu, Y.; Su, J.; Yu, Z.; Xie, X. Novel Core-Shell-like Ni-Supported Hierarchical Beta Zeolite Catalysts on Bioethanol Steam Reforming. Int. J. Hydrogen Energy 2020, 45, 16409–16420. [Google Scholar] [CrossRef]

- Sun, C.; Zheng, Z.; Wang, S.; Li, X.; Wu, X.; An, X.; Xie, X. Yolk-Shell Structured Pt-CeO2@Ni-SiO2 as an Efficient Catalyst for Enhanced Hydrogen Production from Ethanol Steam Reforming. Ceram. Int. 2018, 44, 1438–1442. [Google Scholar] [CrossRef]

- Pizzolitto, C.; Menegazzo, F.; Ghedini, E.; Innocenti, G.; Di Michele, A.; Cruciani, G.; Cavani, F.; Signoretto, M. Increase of Ceria Redox Ability by Lanthanum Addition on Ni Based Catalysts for Hydrogen Production. ACS Sustain. Chem. Eng. 2018, 6, 13867–13876. [Google Scholar] [CrossRef]

- Dai, R.; Zheng, Z.; Shi, K.; Wu, X.; An, X.; Xie, X. A Multifunctional Core–Shell Nanoreactor with Unique Features of Sintering Resistance for High-Performance Ethanol Steam Reforming Reaction. Fuel 2021, 287, 119514. [Google Scholar] [CrossRef]

| Catalyst | Steam-to-Carbon Ratio (S/C) | T (°C) | Space Velocity | Ethanol Conversion | H2 Yield | Ref. |

|---|---|---|---|---|---|---|

| Ni/SiO2 | 3 | 500 | W/FEtOH = 91.88 gcat s g EtOH−1 | ≈35% | ≈20% | [46] |

| Ni/Al2O3-La2O3 | 3 | 450 | 23,140 mL h−1 gcat−1 | 100% | 62% | [83] |

| 10 Ni/TiO2-Al2O3 | 1.5 | 500 | WHSV = 2773 h−1 | 93% | 75% | [93] |

| 10Ni/CeO2 | 6 | 420 | 60,000 mL gcat−1 h−1 | 100% | 68% | [94] |

| 10Ni/SBA-15 | 1.85 | 500 | 60,000 mL gcat−1 h−1 | 69% | 41% | [87] |

| 17Co/α-Al2O3 | 3 | 500 | GHSV= 51700 h−1 | 86% | 64% | [95] |

| 29Co/CeO2 | 6 | 500 | 60,000 mL gcat−1 h−1 | 100% | 94% | [53] |

| 29Co/CeO2 | 3 | 500 | 60,000 mL gcat−1 h−1 | ≈85% | ≈80% | [53] |

| 10Co-0.3Ce/SEP (Sepiolite) | 3 | 600 | WHSV = 21.5 h−1 | 91% | 69% | [96] |

| 10Co/SEP (Sepiolite) | 3 | 600 | WHSV = 21.5 h−1 | 54% | 34% | [96] |

| 10Co/SBA-15 | 1.85 | 500 | 60,000 mL gcat−1 h−1 | 89% | 49% | [92] |

| 10Co/Al2O3 | 1.5 | 550 | 72,000 mL gcat−1 h−1 | 99% | 86% | [55] |

| 9Ni-1Co/MCM-41 | 2.5 | 490 | 9000 mL gcat−1 h−1 | 90% | 80% | [54] |

| 5Ni-5Co/MCM-41 | 2.5 | 490 | 9000 mL gcat−1 h−1 | ≈80% | ≈65% | [54] |

| 1Ni-9Co/MCM-41 | 2.5 | 490 | 9000 mL gcat−1 h−1 | ≈75% | ≈60% | [54] |

| (Ni, Co) NPs (Nanoparticles) (Ni/Co = 0.26) | 3 | 500 | GHSV = 324,000 h−1 | 100% | 87% | [90] |

| 8Ni-2Co/SBA-15 | 1.85 | 500 | 60,000 mL gcat−1 h−1 | 86% | 53% | [87] |

| 5Ni-5Co/SBA-15 | 1.85 | 500 | 60,000 mL gcat−1 h−1 | 68% | 43% | [87] |

| 2Ni-8Co/SBA-15 | 1.85 | 500 | 60,000 mL gcat−1 h−1 | 59% | 42% | [87] |

| 20Ni-20Co/CeO2 | 3 | 500 | W/F => 0.12 gcat h molEtOH−1 | ≈85% | ≈55% | [91] |

| Metal | Support | Experimental Condition | ΧEtOH (%) | Selectivity (%) | Ref. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Si/Al | SBET (m2·g−1) | Vmicro (cm3·g−1) | T (°C) | Space Velocity | H2 | CO | CO2 | CH4 | C2H4 | |||

| Co (10 wt.-%) | ZSM-5 | 50 | 440 | 0.281 | 500 | WHSV = 35.4 ggas h−1 gcat−1 | ~97 | ~45 | ~1 | ~1 | ~8 | ~90 | [50] |

| 600 | ~100 | ~60 | ~40 | ~20 | ~6 | ~25 | |||||||

| Ni (10 wt.-%) | ZSM-5 | 50 | 345.5 | 0.190 | 500 | ~97 | ~47 | ~5 | ~16 | ~13 | ~43 | ||

| 600 | ~100 | ~72 | ~20 | ~24 | ~10 | ~0 | |||||||

| Rh (1 wt.-%) | ZSM-5 | 48.1 | 305 | 0.083 | 300 | n.a. | 79 | 28 | 29 | 18 | 48 | 2 | [56] |

| 400 | ~100 | 33 | 3 | 47 | 46 | 1 | |||||||

| Ni (19.9 wt.-%) | MOR | 10 | 360 | 0.18 | 400 | GHSV = 4700 h−1 | 84.3 | 24.1 | 1.6 | 5.8 | 2.8 | 64.2 | [123] |

| Ni (19.4 wt.-%) | MOR (treated) | 10 | 340 | 0.06 | 400 | GHSV = 4700 h−1 | 97.5 | 69.0 | 8.2 | 4.4 | 14.4 | 0.6 | |

| Metal | Support | Experimental Condition | ΧEtOH (%) | Selectivity (%) | Ref. | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Si/Al | SBET (m2 g−1) | Vmicro (cm3 g−1) | T (°C) | Space Velocity | H2 | CO | CO2 | CH4 | C2H4 | |||

| Ni (10 wt.-%) | BEA | 17 | 481.7 | 0.48 | 500 | WHSV ≈ 9.5 gEtOH h−1 gcat−1 | 100 | 60 | 3 | 30 | 1 | 70 | [85] |

| Ni (10 wt.-%) | BEA | 496.8 | 0.42 | 500 | 100 | 75 | 10 | 55 | 35 | 0 | |||

| Ni (10 wt.-%) | BEA | 100 | 570 | 0.19 | 300 | WHSV ≈ 7.35 gEtOH h−1 gcat−1 | ≈87 | ≈35 | ≈14 | ≈9 | ≈16 | n.a. | [72] |

| 400 | ≈97 | ≈57 | ≈7 | ≈17 | ≈11 | n.a. | |||||||

| 500 | 100 | ≈68 | ≈5 | ≈20 | ≈7 | n.a. | |||||||

| Fe (1.5 wt.-%) | BEA | 100 | 508 | 0.21 | 300 | WHSV ≈ 7.35 gEtOH h−1 gcat−1 | ≈90 | ≈52 | ≈7 | ≈15 | ≈14 | n.a. | |

| Cu (1.5 wt.-%) | 400 | ≈99 | ≈68 | ≈3 | ≈21 | ≈8 | n.a. | ||||||

| Ni (10 wt.-%) | 500 | 100 | ≈72 | ≈3 | ≈21 | ≈4 | n.a. | ||||||

| Metal | Support | Experimental Condition | Product/Ethanol Feed | Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Type | Si/Al | T (°C) | Space Velocity | H2 | CO | CO2 | CH4 | C2H4 | ||

| Ni (9 wt.-%) | Na_Y | 2.75 | 300 | 96.8 | 3.8 | 0.4 | 0.1 | 0.2 | 0.06 | [140] |

| K_Y | 2.75 | 300 | 96.8 | 4.7 | 0.5 | 0.2 | 0.4 | 0.01 | ||

| Cs_Y | 2.75 | 300 | 96.8 | 5.7 | 0.7 | 0.2 | 0.5 | 0.01 | ||

| Ni (4.5 wt.-%) | Y (Ni loaded via wet impregnation) | 2.75 | 300 | 8 | 7.0 | 0.9 | 0.5 | 0.5 | 0.2 | [139] |

| Ni (2.4 wt.-%) | Y (Ni loaded via ionic exchange) | 2.75 | 300 | 8 | 0.5 | 0.0 | 0.0 | 0.0 | 29.5 | |

| Catalyst | Support | Experimental Condition | ΧEtOH (%) | Selectivity (%) | Ref. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | SBET (m2·g−1) | Pore Volume (BJH) (cm3·g−1) | T (°C) | Space Velocity | H2 | CO | CO2 | CH4 | C2H4 | |||

| Co (19.9 wt.-%) | ITQ-18 | 293 | 0.17 | 500 °C | GHSV ≈ 4700 h−1 | 97.9 | 71.2 | 3.1 | 19.5 | 5.7 | 0.1 | [143] |

| Co (20.1 wt.-%) | ITQ-2 | 507 | 0.54 | 300 °C | GHSV ≈ 4700 h−1 | ≈70 | ≈55 | ≈12 | ≈8 | ~15 | ≈0 | [142] |

| 400 °C | ≈86 | ≈62 | ≈4 | ≈15 | ~16 | ≈0 | ||||||

| 500 °C | ≈97 | ≈69 | ≈1 | ≈21 | ~9 | ≈0 | ||||||

| Ni (19.5 wt.-%) | ITQ-2 | 517 | 0.53 | 300 °C | GHSV ≈ 4700 h−1 | ≈77 | ≈50 | ≈18 | ≈2 | ~19 | ≈0 | |

| 400 °C | ≈95 | ≈59 | ≈12 | ≈10 | ~18 | ≈0 | ||||||

| 500 °C | ≈100 | ≈66 | ≈2 | ≈21 | ~10 | ≈0 | ||||||

| Core | Shell | Support | Experimental Condition | XEtOH (%) | Selectivity (%) | Ref. | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Metal | Type | Metal | Type | SBET (m2·g−1) | VTOT (cm3·g−1) | T (°C) | WHSV (gEtOH h−1 gcat−1) | H2 | CO | CO2 | CH4 | ||

| Pt (1 wt.-%) (core + shell) | BEA | Pt (1 wt.-%) (core + shell) | SiO2 | 557 | 0.65 | 300 | 8.5 | ≈98 | ≈64 | ≈4 | ≈19 | ≈10 | [151] |

| 350 | ≈100 | ≈68 | ≈2 | ≈21 | ≈7 | ||||||||

| 400 | ≈100 | ≈72 | ≈1 | ≈22 | ≈2 | ||||||||

| Cu (2.5 wt.-%) Fe (2.5 wt.-%) | BEA | Ni (10 wt.-%) | Al-BEA | 428 | 0.24 | 300 | 7.3 | ≈97 | ≈57 | ≈4 | ≈21 | ≈18 | [152] |

| 350 | ≈100 | ≈69 | ≈0 | ≈24 | ≈7 | ||||||||

| 400 | ≈100 | ≈67 | ≈2 | ≈28 | ≈2 | ||||||||

| Ni (22 wt.-%) (core + shell) | BEA | Ni (22 wt.-%) (core + shell) | BEA | 295.5 | 1.19 | 350 | 29.4 | ≈85 | ≈76 | ≈7 | ≈16 | ≈1 | [153] |

| 400 | ≈89 | ≈73 | ≈6 | ≈18 | ≈3 | ||||||||

| 450 | ≈92 | ≈72 | ≈8 | ≈17 | ≈2 | ||||||||

| 500 | ≈95 | ≈71 | ≈8 | ≈17 | ≈2 | ||||||||

| Sample Name | Operating Conditions | ΧEtOH (%) | SH2 (%) | Ref. | |||

|---|---|---|---|---|---|---|---|

| Temperature (°C) | Space Velocity | EtOH/H2O | TOS (h) | ||||

| Pt-CeO2@Ni-SiO2 | 400 | WHSV = 8.9 h−1 | 1:6 | 28 | 100 | ~67 | [154] |

| Co-Ni/_La-Ce | 550 | WHSV = 2.26 h−1 | 1:6 | 60 | 90 (100% for the first 20 h) | ~69 | [155] |

| Co/CeO2_N-CA (Citric Acid) | 420 | GHSV = 60,000 mL g−1 h−1 | 1:12 | 21 | ~60 | ~76 | [75] |

| Pt-Cu@Ni-SiO2 | 450 | WHSV = 7.2 h−1 | 1:6 | 50 | 100 | ~71 | [156] |

| Ni(10)/Ga(30)/Mg(30)_Zeolite Y | 600 | WHSV = 6.7 h−1 | 1:3 | 59 | 100 | ~69 | [141] |

| Ni10SiBEA | 500 | WHSV = 9.5 gEtOH h−1gcat−1 | 1:12 | 22 | 100 | ~65 (~75 for t = 18 h) | [85] |

| 10.0 wt% CoxOy@Pd_ Zeolite Y | 600 | GHSV = 16,800 h−1 | 1:3 | 45 | 100 | 75–100 | [150] |

| 2.5Fe2.5CuSB@NB (Si-Beta core and Ni-Beta shell) | 500 | WHSV = 7.3 h−1 | 1:6 | 8 | 100 | 71 | [152] |

| NiNPs/OH-MBEA | 400 | WHSV = 29.4 h−1 | 1:5 | 100 | ~93 | ~77 | [153] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dalena, F.; Giglio, E.; Marino, A.; Aloise, A.; Giorgianni, G.; Migliori, M.; Giordano, G. Steam Reforming of Bioethanol Using Metallic Catalysts on Zeolitic Supports: An Overview. Catalysts 2022, 12, 617. https://doi.org/10.3390/catal12060617

Dalena F, Giglio E, Marino A, Aloise A, Giorgianni G, Migliori M, Giordano G. Steam Reforming of Bioethanol Using Metallic Catalysts on Zeolitic Supports: An Overview. Catalysts. 2022; 12(6):617. https://doi.org/10.3390/catal12060617

Chicago/Turabian StyleDalena, Francesco, Emanuele Giglio, Alessia Marino, Alfredo Aloise, Gianfranco Giorgianni, Massimo Migliori, and Girolamo Giordano. 2022. "Steam Reforming of Bioethanol Using Metallic Catalysts on Zeolitic Supports: An Overview" Catalysts 12, no. 6: 617. https://doi.org/10.3390/catal12060617

APA StyleDalena, F., Giglio, E., Marino, A., Aloise, A., Giorgianni, G., Migliori, M., & Giordano, G. (2022). Steam Reforming of Bioethanol Using Metallic Catalysts on Zeolitic Supports: An Overview. Catalysts, 12(6), 617. https://doi.org/10.3390/catal12060617