In Situ Removal of Benzene as a Biomass Tar Model Compound Employing Hematite Oxygen Carrier

Abstract

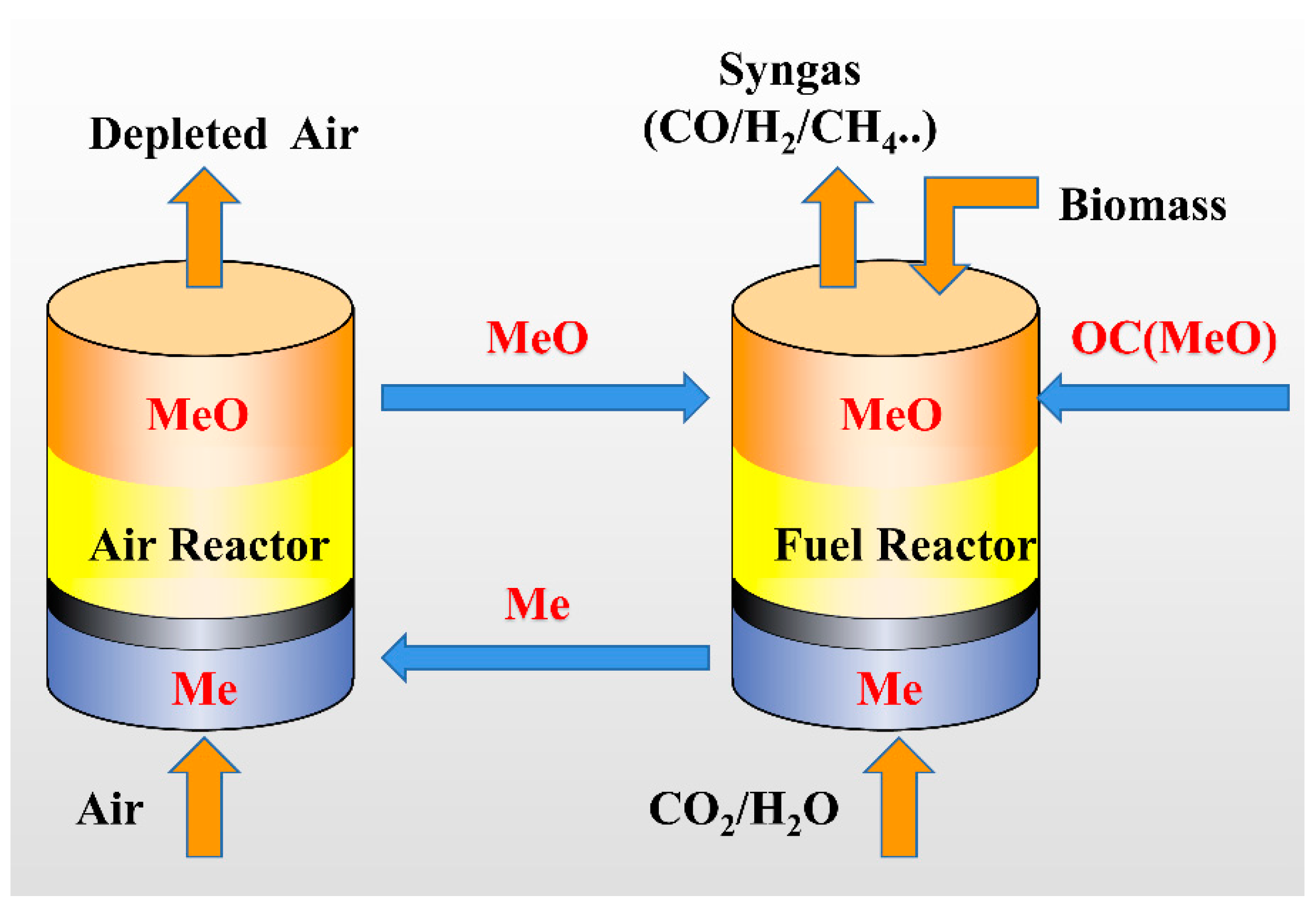

:1. Introduction

2. Results and Discussion

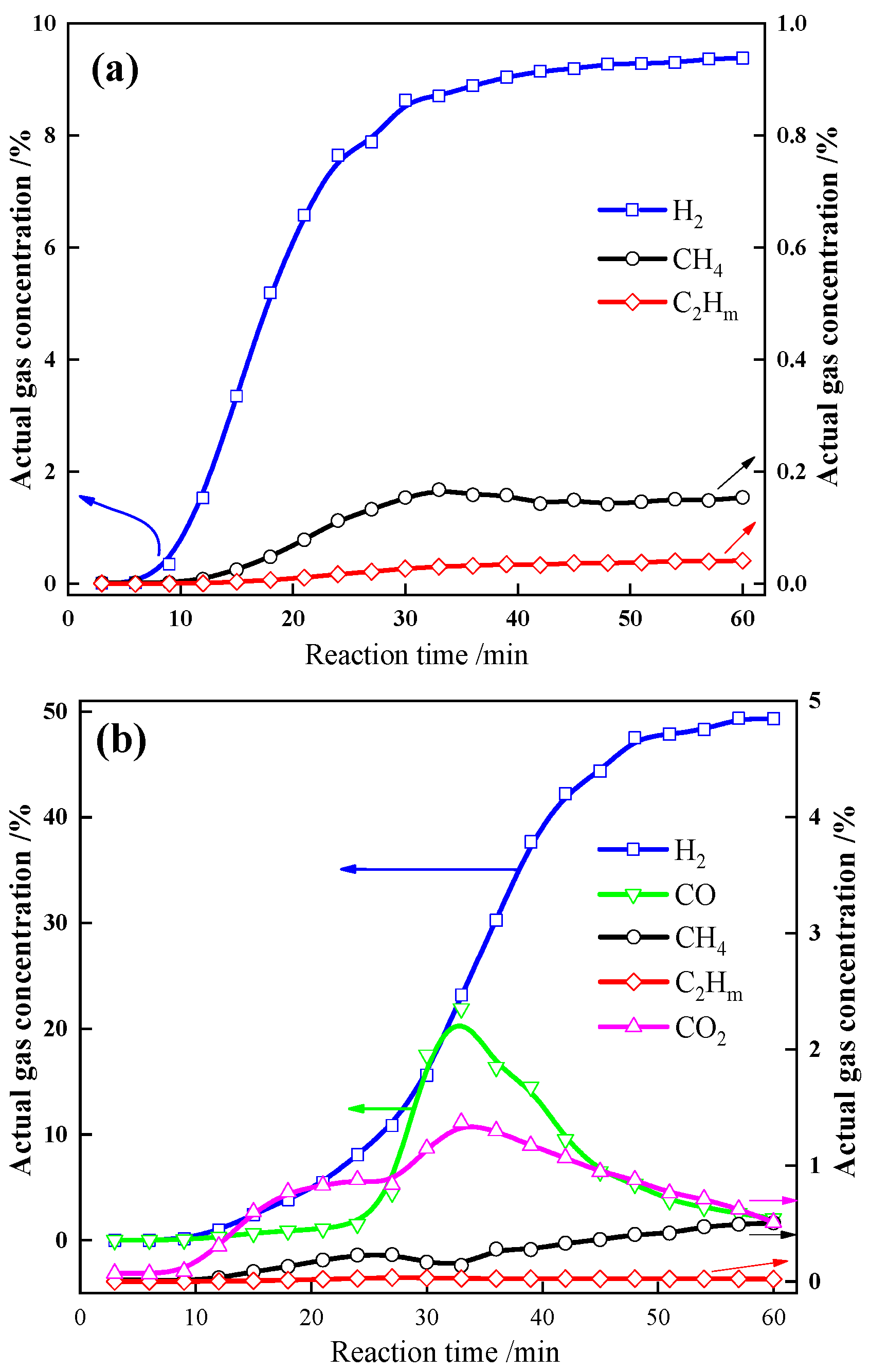

2.1. Benzene Conversion Characteristics Using Hematite

∆H > 0

∆H > 0

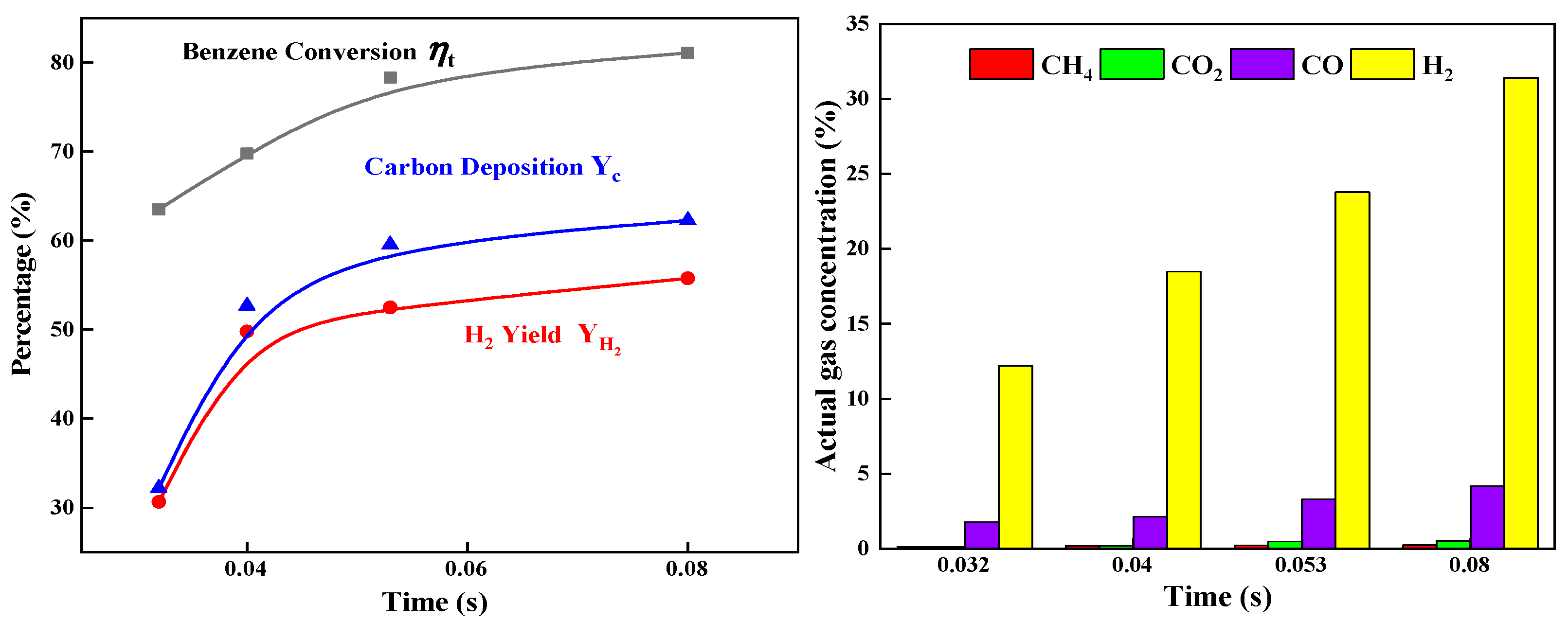

2.2. The Residence Time

2.3. H2O Steam Content

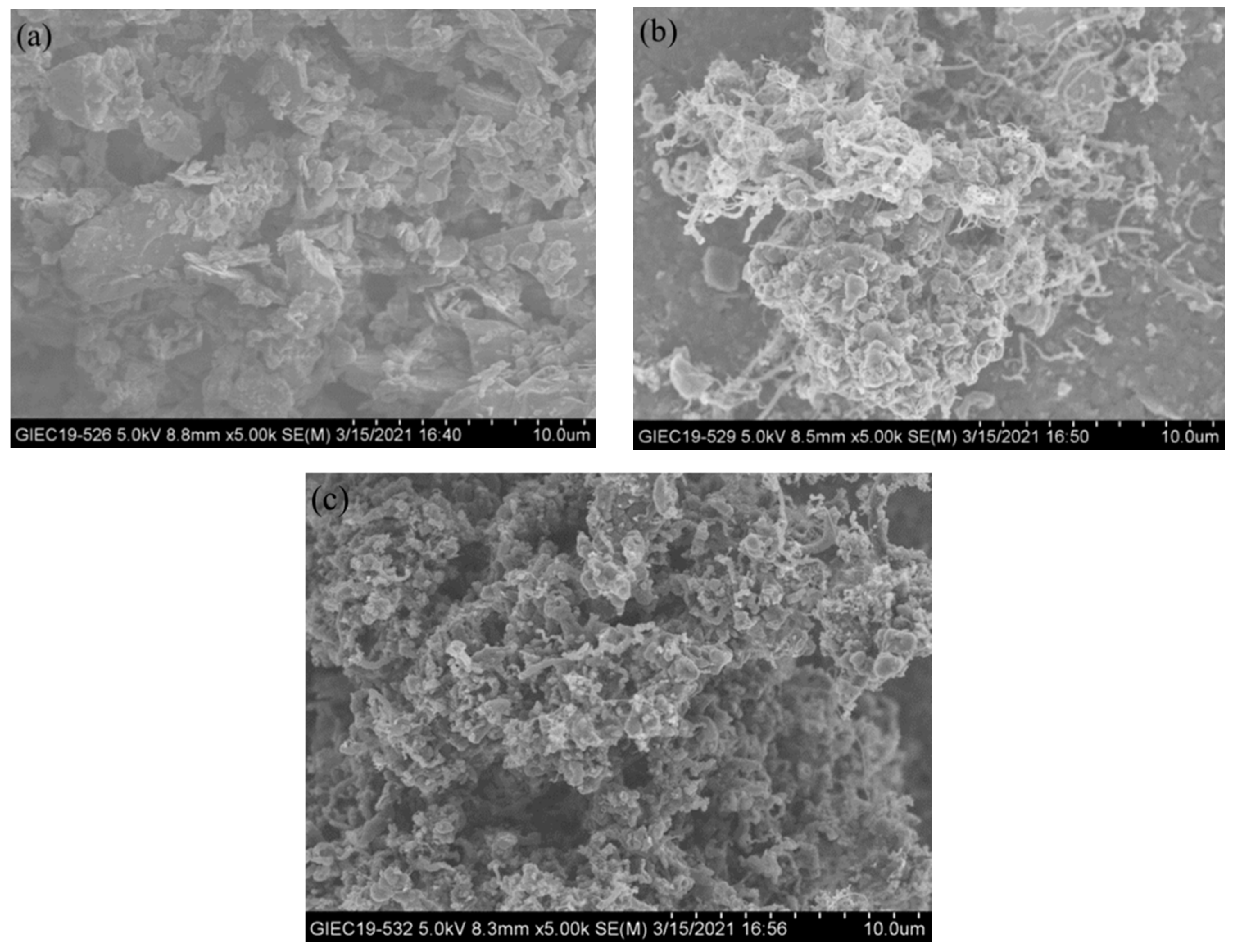

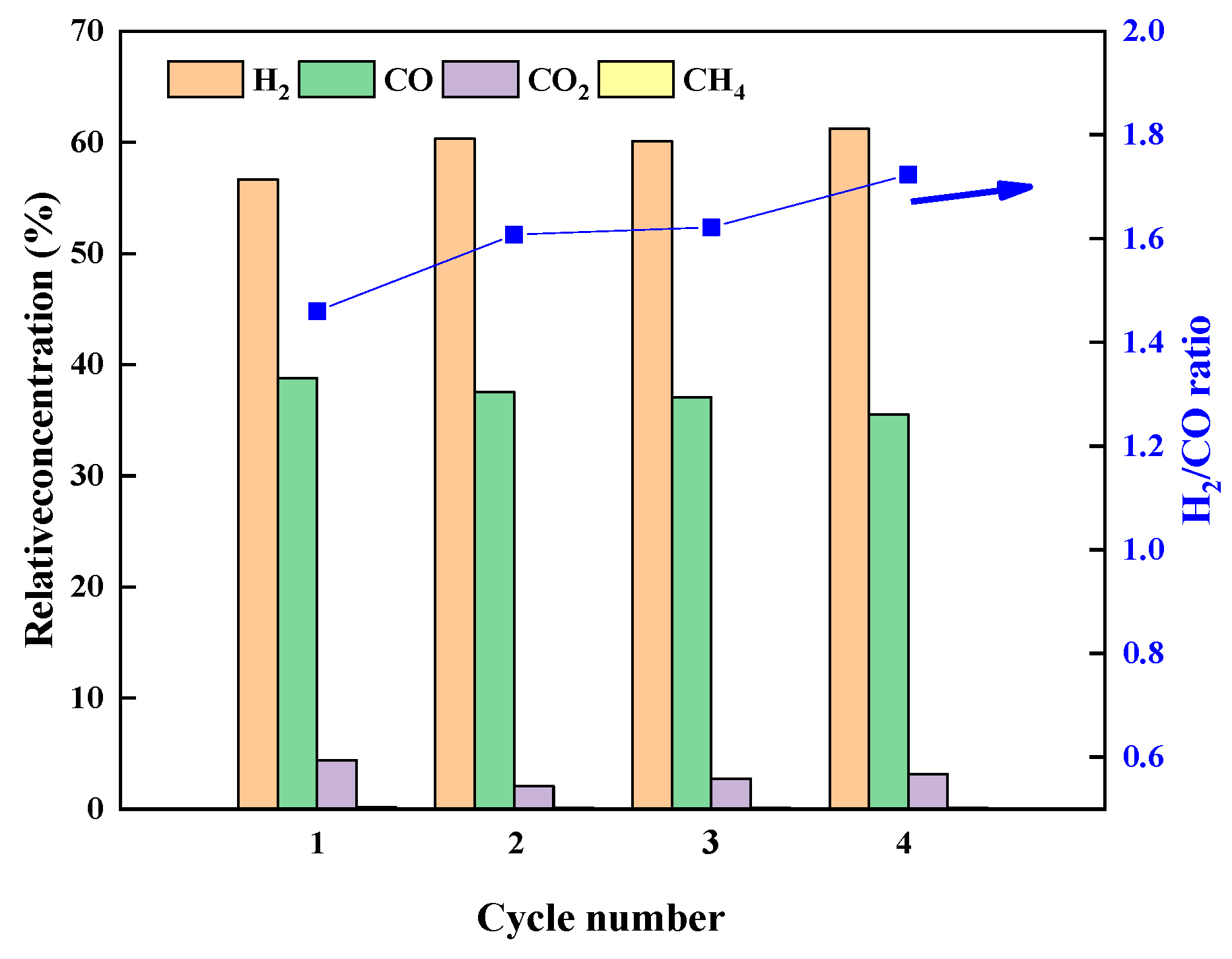

2.4. The Cycle Numbers

3. Materials and Methods

3.1. Hematite

3.2. Fixed Bed Experiment

3.3. Data Processing

4. Conclusions

- (1)

- During benzene conversion, hematite functioned as both an oxidative and a catalytic OC. Hematite also improved the benzene conversion degree by about 20%, going from 55.37% to 69.05%.

- (2)

- As the residence time increased from 0.032 s to 0.08 s, the benzene conversion increased from 63.5% to 81.1%. However, the positive influence of the increased residence time declined when the residence time was over 0.053 s.

- (3)

- The introduction of H2O steam was advantageous for the removal of carbon deposition. As the S/C ratio increased from 0.49 to 1.14, the carbon deposition decreased from 35.7% to 0.33%, and H2O inhibited the benzene conversion, resulting in a decrease in H2 yield.

- (4)

- A significant primary effect was observed in the multiple redox cycles. The benzene conversion increased in the 2nd cycle. The agglomeration of hematite deactivated a part of lattice oxygen vacancy, resulting in a decline in the oxidative performance of the hematite after the redox cycle. As the cycle number increased, the benzene conversion improved.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- C.R.E.D.S.R. Group. China Renewable Energy Development Strategy Research Series; China Electric Power Press: Beijing, China, 2008. [Google Scholar]

- Chen, H.; Lu, D.; An, J.; Qiao, S.; Dong, Y.; Jiang, X.; Xu, G.; Liu, T. Thermo-Economic analysis of a novel biomass Gasification-Based power system integrated with a supercritical CO2 cycle and a Coal-Fired power plant. Energy Convers. Manag. 2022, 266, 115860. [Google Scholar] [CrossRef]

- Chen, C.; Bi, Y.; Huang, Y.; Huang, H. Review on slagging evaluation methods of biomass fuel combustion. J. Anal. Appl. Pyrolysis 2021, 155, 105082. [Google Scholar] [CrossRef]

- Hanchate, N.; Ramani, S.; Mathpati, C.S.; Dalvi, V.H. Biomass gasification using dual fluidized bed gasification systems: A review. J. Clean. Prod. 2021, 280, 123148. [Google Scholar] [CrossRef]

- Liu, R.; Tsiava, R.; Xu, S.; Chen, D. Experimental study of char gasification characteristics with high temperature flue gas. J. Energy Inst. 2021, 97, 187–193. [Google Scholar] [CrossRef]

- Dos Santos, R.G.; Alencar, A.C. Biomass-derived syngas production via gasification process and its catalytic conversion into fuels by Fischer Tropsch synthesis: A review. Int. J. Hydrogen Energy 2020, 45, 18114–18132. [Google Scholar] [CrossRef]

- Cheng, K.; Zhang, L.; Kang, J.; Peng, X.; Zhang, Q.; Wang, Y. Selective Transformation of Syngas into Gasoline-Range Hydrocarbons over Mesoporous H-ZSM-5-Supported Cobalt Nanoparticles. Chem.—A Eur. J. 2015, 21, 1928–1937. [Google Scholar] [CrossRef]

- Wei, G. Chemical Looping Gasification of Biomass Coupled with CO2 Splitting with Fe-Based Mixed Oxygen Carriers. Ph.D. Thesis, Taiyuan University of Technology, Taiyuan, China, 2020. [Google Scholar] [CrossRef]

- Jiang, C.; Jin, X.; Xu, T.; Xiao, B.; Hu, Z.; Wang, X. Biomass chemical looping gasification for syngas production using modified hematite as oxygen carriers. J. Environ. Sci. 2023, 125, 171–184. [Google Scholar] [CrossRef]

- González, C.A.D.; Sandoval, L.P. Sustainability aspects of biomass gasification systems for small power generation. Renew. Sustain. Energy Rev. 2020, 134, 110180. [Google Scholar] [CrossRef]

- Yan, X.; Hu, J.; Zhang, Q.; Zhao, S.; Dang, J.; Wang, W. Chemical-looping gasification of corn straw with Fe-based oxygen carrier: Thermogravimetric analysis. Bioresour. Technol. 2020, 303, 122904. [Google Scholar] [CrossRef]

- Sepe, A.M.; Li, J.; Paul, M.C. Assessing biomass steam gasification technologies using a multi-purpose model. Energy Convers. Manag. 2016, 129, 216–226. [Google Scholar] [CrossRef]

- Pacioni, T.R.; Soares, D.; Domenico, M.D.; Rosa, M.F.; Moreira, R.D.F.P.M.; José, H.J. Bio-syngas production from agro-industrial biomass residues by steam gasification. Waste Manag. 2016, 58, 221–229. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Suzuki, K. Tar property, analysis, reforming mechanism and model for biomass gasification—An overview. Renew. Sustain. Energy Rev. 2009, 13, 594–604. [Google Scholar] [CrossRef]

- Yan, B.; Liu, Z.; Wang, J.; Ge, Y.; Tao, J.; Cheng, Z.; Chen, G. Mn-doped Ca2Fe2O5 oxygen carrier for chemical looping gasification of biogas residue: Effect of oxygen uncoupling. Chem. Eng. J. 2022, 446, 137086. [Google Scholar] [CrossRef]

- Wang, S.; Yin, X.; Jarolin, K.; Dymala, T.; Xu, J.; Yin, S.; Dosta, M.; Song, T.; Heinrich, S.; Shen, L. Mechanical strength evolution of biomass pellet during chemical looping gasification in fluidized bed. Fuel Process. Technol. 2021, 221, 106951. [Google Scholar] [CrossRef]

- Liu, Q.; Hu, C.; Peng, B.; Liu, C.; Li, Z.; Wu, K.; Zhang, H.; Xiao, R. High H2/CO ratio syngas production from chemical looping co-gasification of biomass and polyethylene with CaO/Fe2O3 oxygen carrier. Energy Convers. Manag. 2019, 199, 111951. [Google Scholar] [CrossRef]

- Wen, Y.-Y.; Li, Z.S.; Xu, L.; Cai, N.S. Experimental Study of Natural Cu Ore Particles as Oxygen Carriers in Chemical Looping with Oxygen Uncoupling (CLOU). Energy Fuels 2012, 26, 3919–3927. [Google Scholar] [CrossRef]

- Wang, L.; Lin, Y.; Huang, Z.; Zeng, K.; Huang, H. Conversion of carbon dioxide to carbon monoxide: Two-step chemical looping dry reforming using Ca2Fe2O5–Zr0.5Ce0.5O2 composite oxygen carriers. Fuel 2022, 322, 124182. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, H.; Huang, Z.; Liu, M.; Wei, G.; Zhao, Z.; Li, H.; Fang, Y. Chemical looping gasification coupled with steam reforming of biomass using NiFe2O4: Kinetic analysis of DAEM-TI, thermodynamic simulation of OC redox, and a loop test. Chem. Eng. J. 2020, 395, 125046. [Google Scholar] [CrossRef]

- Sun, R.; Shen, L.; Wang, S.; Bai, H. CO conversion over LaFeO3 perovskite during chemical looping processes: Influences of Ca-doping and oxygen species. Appl. Catal. B Environ. 2022, 316, 121598. [Google Scholar] [CrossRef]

- Tian, X.; Zheng, C.; Zhao, H. Ce-modified SrFeO3-δ for ethane oxidative dehydrogenation coupled with CO2 splitting via a chemical looping scheme. Appl. Catal. B Environ. 2022, 303, 120894. [Google Scholar] [CrossRef]

- Kang, Y.; Han, Y.; Tian, M.; Huang, C.; Wang, C.; Lin, J.; Hou, B.; Su, Y.; Li, L.; Wang, J.; et al. Promoted methane conversion to syngas over Fe-based garnets via chemical looping. Appl. Catal. B Environ. 2020, 278, 119305. [Google Scholar] [CrossRef]

- Zeng, D.; Qiu, Y.; Li, M.; Ma, L.; Cui, D.; Zhang, S.; Xiao, R. Spatially controlled oxygen storage materials improved the syngas selectivity on chemical looping methane conversion. Appl. Catal. B Environ. 2021, 281, 119472. [Google Scholar] [CrossRef]

- Liu, G.; Wang, H.; Deplazes, S.; Veksha, A.; Wirz-Töndury, C.; Giannis, A.; Lim, T.T.; Lisak, G. Ba–Al-decorated iron ore as bifunctional oxygen carrier and HCl sorbent for chemical looping combustion of syngas. Combust. Flame 2021, 223, 230–242. [Google Scholar] [CrossRef]

- Nam, H.; Wang, Z.; Shanmugam, S.R.; Adhikari, S.; Abdoulmoumine, N. Chemical looping dry reforming of benzene as a gasification tar model compound with Ni- and Fe-based oxygen carriers in a fluidized bed reactor. Int. J. Hydrogen Energy 2018, 43, 18790–18800. [Google Scholar] [CrossRef]

- Lin, Y.; Liao, Y.; Yu, Z.; Fang, S.; Ma, X. A study on co-pyrolysis of bagasse and sewage sludge using TG-FTIR and Py-GC/MS. Energy Convers. Manag. 2017, 151, 190–198. [Google Scholar] [CrossRef]

- Bangala, D.N.; Abatzoglou, N.; Martin, J.-P.; Chornet, E. Catalytic Gas Conditioning: Application to Biomass and Waste Gasification. Ind. Eng. Chem. Res. 1997, 36, 4184–4192. [Google Scholar] [CrossRef]

- Coll, R.; Salvadó, J.; Farriol, X.; Montané, D. Steam reforming model compounds of biomass gasification tars: Conversion at different operating conditions and tendency towards coke formation. Fuel Process. Technol. 2001, 74, 19–31. [Google Scholar] [CrossRef]

- Claude, V.; Courson, C.; Köhler, M.; Lambert, S.D. Overview and Essentials of Biomass Gasification Technologies and Their Catalytic Cleaning Methods. Energy Fuels 2016, 30, 8791–8814. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Zawawi, N.A.; Kasim, F.H.; Inayat, A.; Khasri, A. Assessing the gasification performance of biomass: A review on biomass gasification process conditions, optimization and economic evaluation. Renew. Sustain. Energy Rev. 2016, 53, 1333–1347. [Google Scholar] [CrossRef]

- Furusawa, T.; Miura, Y.; Kori, Y.; Sato, M.; Suzuki, N. The cycle usage test of Ni/MgO catalyst for the steam reforming of naphthalene/benzene as model tar compounds of biomass gasification. Catal. Commun. 2009, 10, 552–556. [Google Scholar] [CrossRef]

- Park, H.J.; Park, S.H.; Sohn, J.M.; Park, J.; Jeon, J.-K.; Kim, S.-S.; Park, Y.-K. Steam reforming of biomass gasification tar using benzene as a model compound over various Ni supported metal oxide catalysts. Bioresour. Technol. 2010, 101, S101–S103. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.; Dong, X.; Yan, B.; Li, J.; Yoshikawa, K.; Jiao, L. Photothermal steam reforming: A novel method for tar elimination in biomass gasification. Appl. Energy 2022, 305, 117917. [Google Scholar] [CrossRef]

- Chen, Y.-H.; Parvez, A.M.; Schmid, M.; Scheffknecht, G.; Chen, T.-L. 20 kW Pilot scale steam-oxygen gasification of solid recovered fuel with a focus on newly developed off-line and on-line tar measurement methods. Fuel Process. Technol. 2022, 227, 107096. [Google Scholar] [CrossRef]

- Schmid, M.; Hafner, S.; Biollaz, S.; Schneebeli, J.; Waizmann, G.; Scheffknecht, G. Steam-oxygen gasification of sewage sludge: Reduction of tar, H2S and COS with limestone as bed additive. Biomass Bioenergy 2021, 150, 106100. [Google Scholar] [CrossRef]

- Li, J.; Tao, J.; Yan, B.; Jiao, L.; Chen, G.; Hu, J. Review of microwave-based treatments of biomass gasification tar. Renew. Sustain. Energy Rev. 2021, 150, 111510. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, Z.; Das, S.; Kawi, S. Reforming of tar from biomass gasification in a hybrid catalysis-plasma system: A review. Appl. Catal. B Environ. 2019, 250, 250–272. [Google Scholar] [CrossRef]

- Delagrange, S.; Pinard, L.; Tatibouët, J.-M. Combination of a non-thermal plasma and a catalyst for toluene removal from air: Manganese based oxide catalysts. Appl. Catal. B Environ. 2006, 68, 92–98. [Google Scholar] [CrossRef]

- Caballero, M.A.; Corella, J.; Aznar, M.-P.; Gil, J. Biomass Gasification with Air in Fluidized Bed. Hot Gas Cleanup with Selected Commercial and Full-Size Nickel-Based Catalysts. Ind. Eng. Chem. Res. 2000, 39, 1143–1154. [Google Scholar] [CrossRef]

- Kaisalo, N.; Simell, P.; Lehtonen, J. Benzene steam reforming kinetics in biomass gasification gas cleaning. Fuel 2016, 182, 696–703. [Google Scholar] [CrossRef]

- He, L.; Hu, S.; Jiang, L.; Liao, G.; Zhang, L.; Han, H.; Chen, X.; Wang, Y.; Xu, K.; Su, S.; et al. Co-production of hydrogen and carbon nanotubes from the decomposition/reforming of biomass-derived organics over Ni/α-Al2O3 catalyst: Performance of different compounds. Fuel 2017, 210, 307–314. [Google Scholar] [CrossRef]

| Species | Benzene | Naphthalene | Toluene | Xylene | Indene | Phenols | 2~3 Rings Compounds |

|---|---|---|---|---|---|---|---|

| Composition (wt.%) | 28 | 15 | 14 | 7 | 7 | 7 | 21 |

| Carrier | Relative Gas Concentration (%) | ηt (%) | YH2 (%) | Yc (%) | ||||

|---|---|---|---|---|---|---|---|---|

| H2 | CO | CH4 | C2Hm | CO2 | ||||

| SiO2 | 95.40 | - | 3.91 | 0.69 | - | 55.37 | 7.22 | 1.98 |

| Hematite | 72.25 | 24.42 | 0.37 | 0.09 | 2.87 | 69.05 | 21.96 | 39.13 |

| Carrier | Mass of Liquid Products (g) | ||||

|---|---|---|---|---|---|

| Biphenyl C12H10 | Meta-Terphenyl C18H14 | Para-Terphenyl C18H14 | Benzanthracene C18H12 | Sum | |

| SiO2 | 0.91 | 0.15 | 0.14 | - | 1.20 |

| Hematite | 0.24 | 0.07 | 0.06 | 0.18 | 0.55 |

| Carrier | The Mass of Carbon (C) in the Products (g) | Carbon Balance (%) | ||||

|---|---|---|---|---|---|---|

| C-Gas | C-Liquid | C-Residual Benzene | C-Solid | C-Total | ||

| SiO2 | 0.01 | 1.13 | 1.09 | 0.06 | 2.29 | 93.85 |

| Hematite | 0.05 | 0.51 | 0.75 | 1.00 | 2.31 | 94.67 |

| Element | Fe | O | Si | Al | K | Ca | P | Ti | Mn |

|---|---|---|---|---|---|---|---|---|---|

| Composition (wt/%) | 61.9 | 32.4 | 3.3 | 1.7 | 0.3 | 0.1 | 0.1 | 0.1 | 0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Wang, Y.; Dong, N.; Song, D.; Lin, Y.; Deng, L.; Huang, H. In Situ Removal of Benzene as a Biomass Tar Model Compound Employing Hematite Oxygen Carrier. Catalysts 2022, 12, 1088. https://doi.org/10.3390/catal12101088

Huang Z, Wang Y, Dong N, Song D, Lin Y, Deng L, Huang H. In Situ Removal of Benzene as a Biomass Tar Model Compound Employing Hematite Oxygen Carrier. Catalysts. 2022; 12(10):1088. https://doi.org/10.3390/catal12101088

Chicago/Turabian StyleHuang, Zhen, Yonghao Wang, Nanhang Dong, Da Song, Yan Lin, Lisheng Deng, and Hongyu Huang. 2022. "In Situ Removal of Benzene as a Biomass Tar Model Compound Employing Hematite Oxygen Carrier" Catalysts 12, no. 10: 1088. https://doi.org/10.3390/catal12101088

APA StyleHuang, Z., Wang, Y., Dong, N., Song, D., Lin, Y., Deng, L., & Huang, H. (2022). In Situ Removal of Benzene as a Biomass Tar Model Compound Employing Hematite Oxygen Carrier. Catalysts, 12(10), 1088. https://doi.org/10.3390/catal12101088