CO2 Hydrogenation to Methane over Ni-Catalysts: The Effect of Support and Vanadia Promoting

Abstract

1. Introduction

2. Materials and Methods

2.1. Synthesis, Materials, and Reagents

2.2. Physicochemical Characterization

2.3. CO2 Hydrogenation Tests

3. Results and Discussion

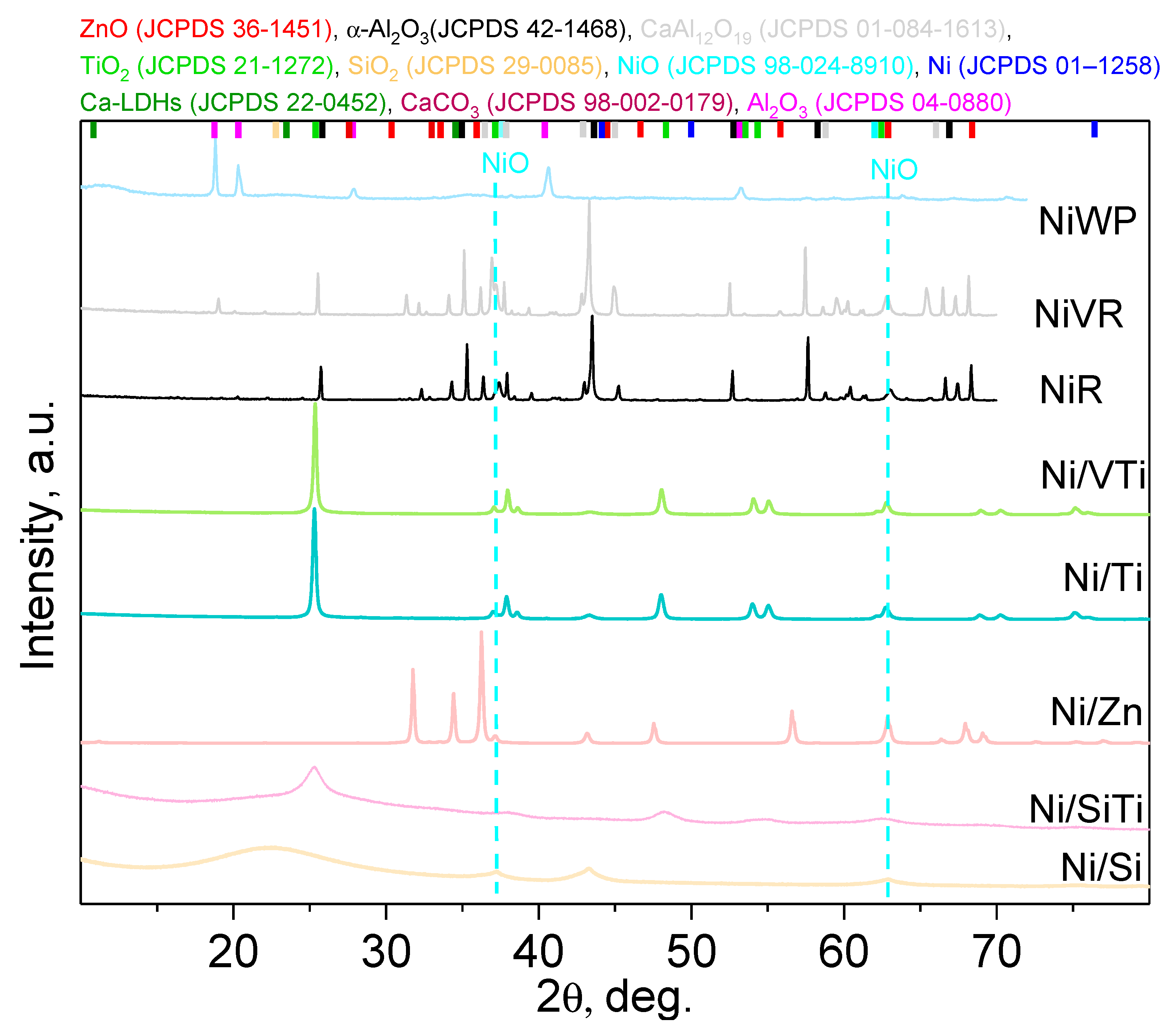

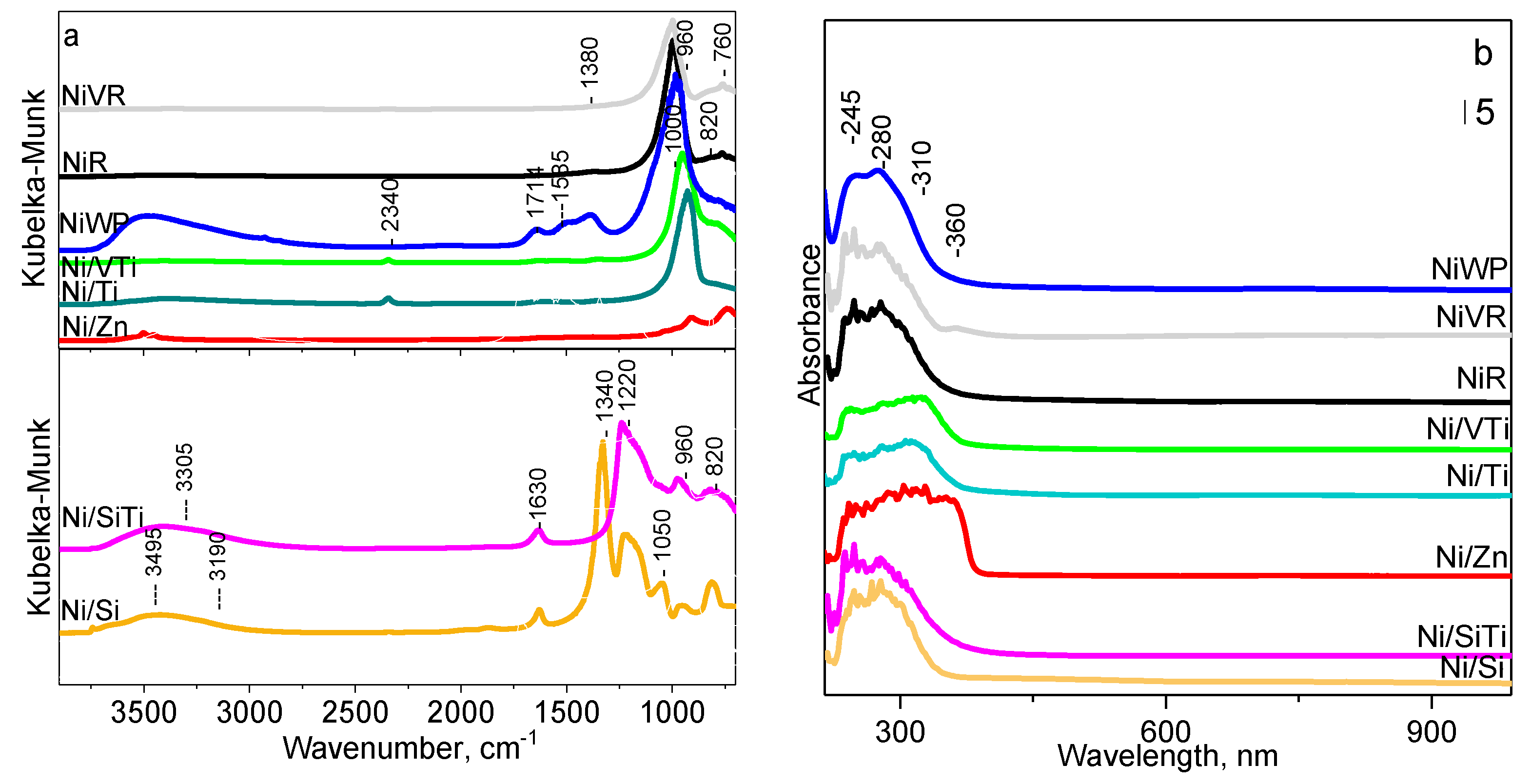

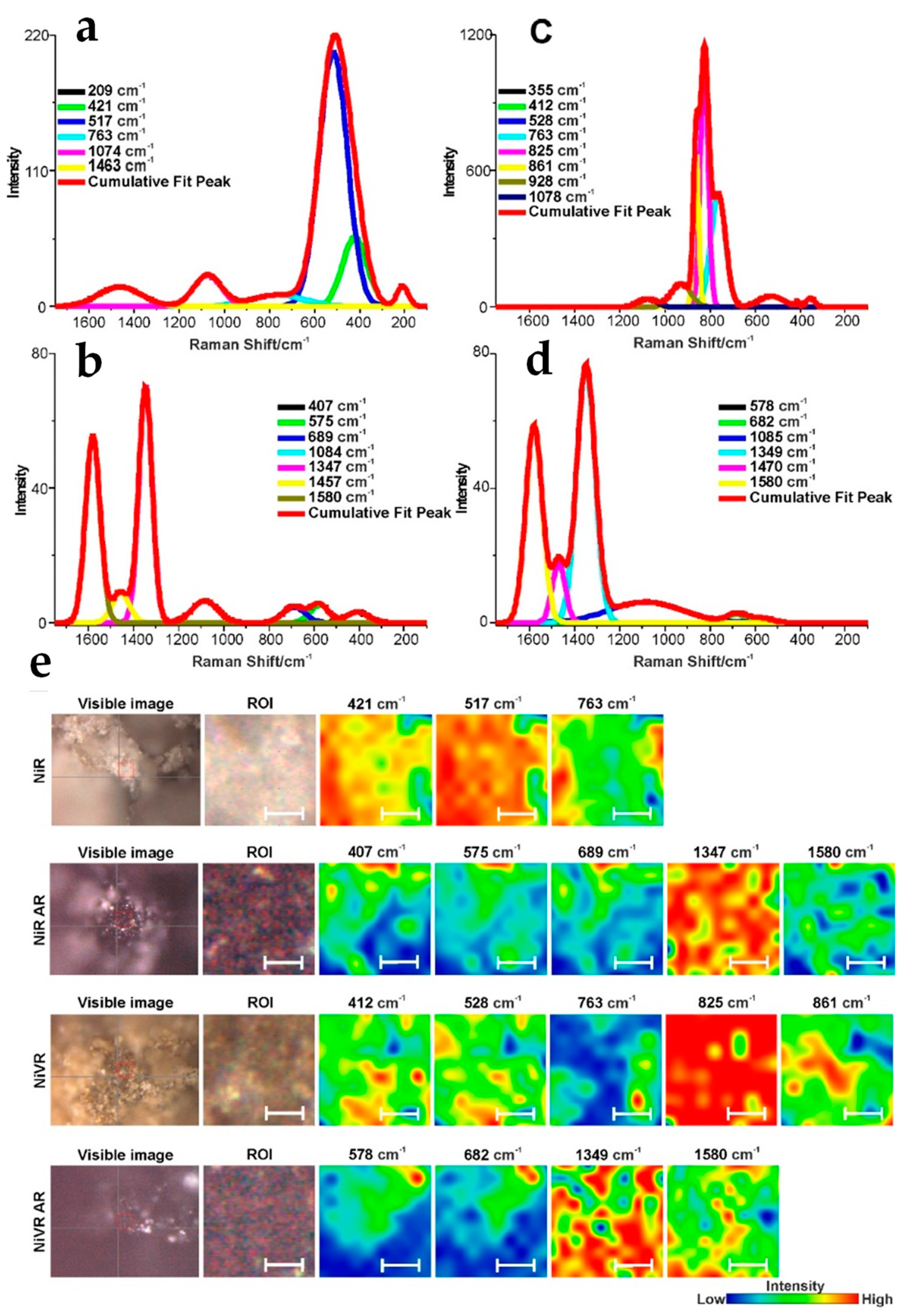

3.1. Physicochemical Characterization of Fresh and Spent Catalysts

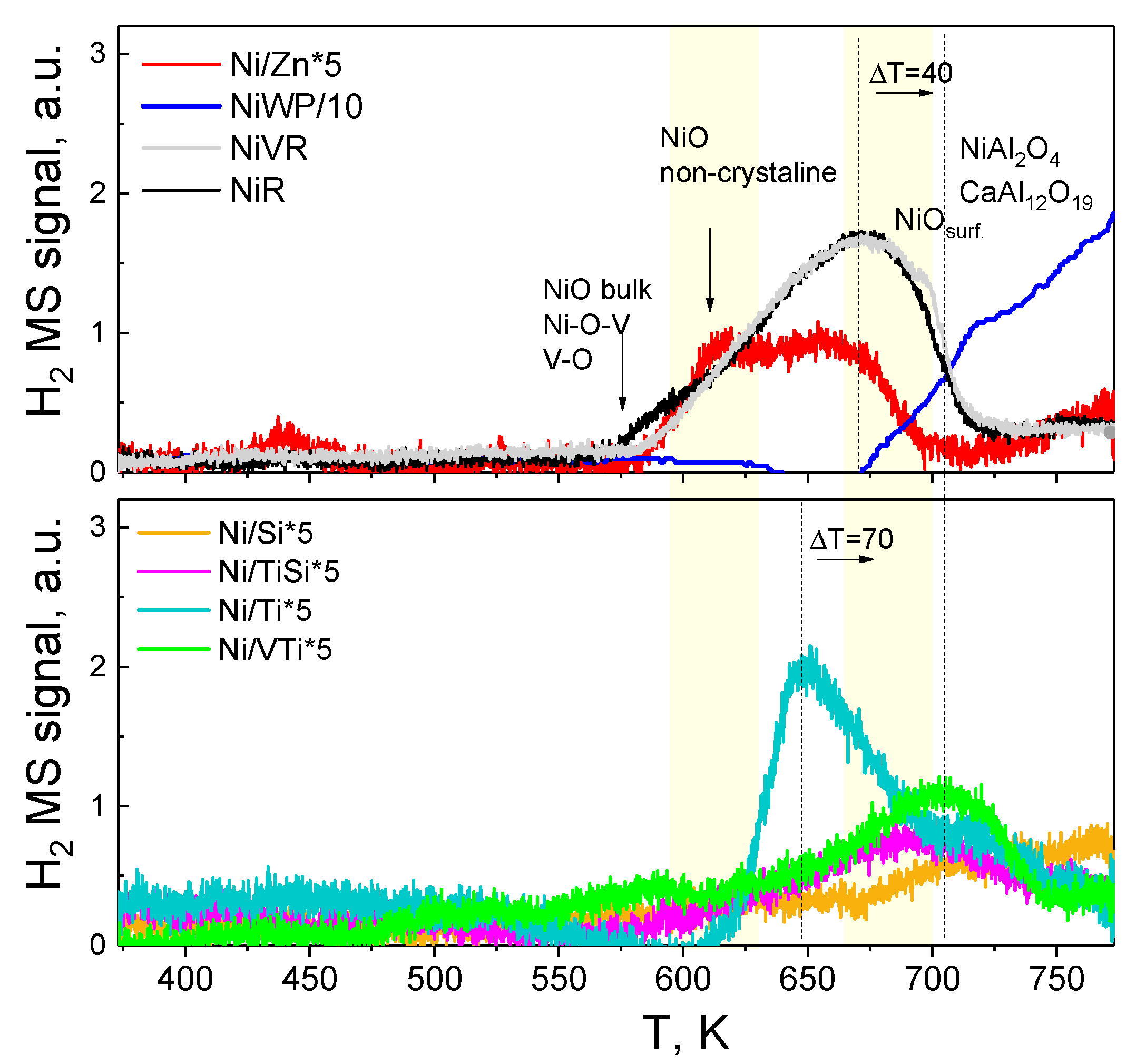

3.2. Catalyst Reducibility

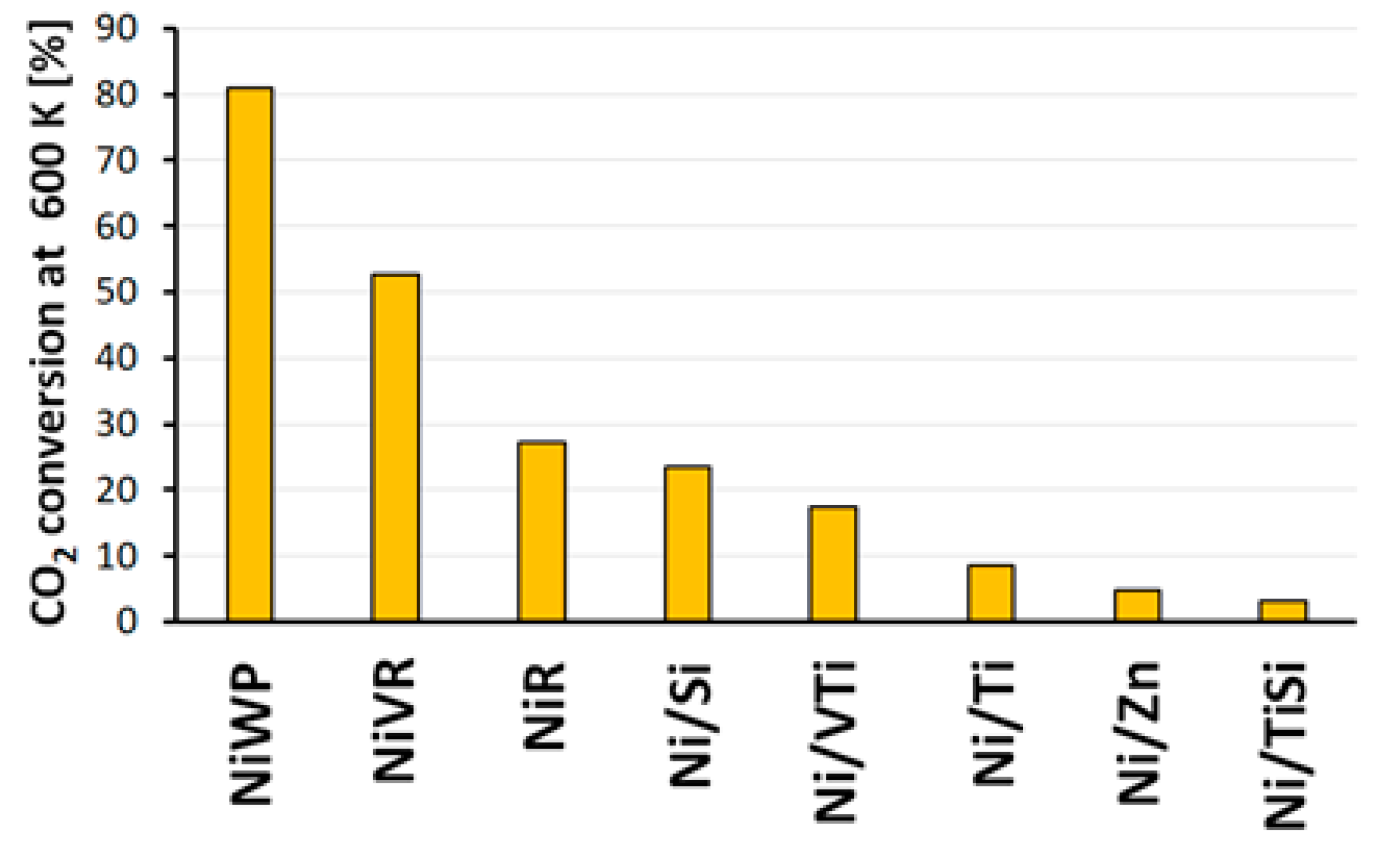

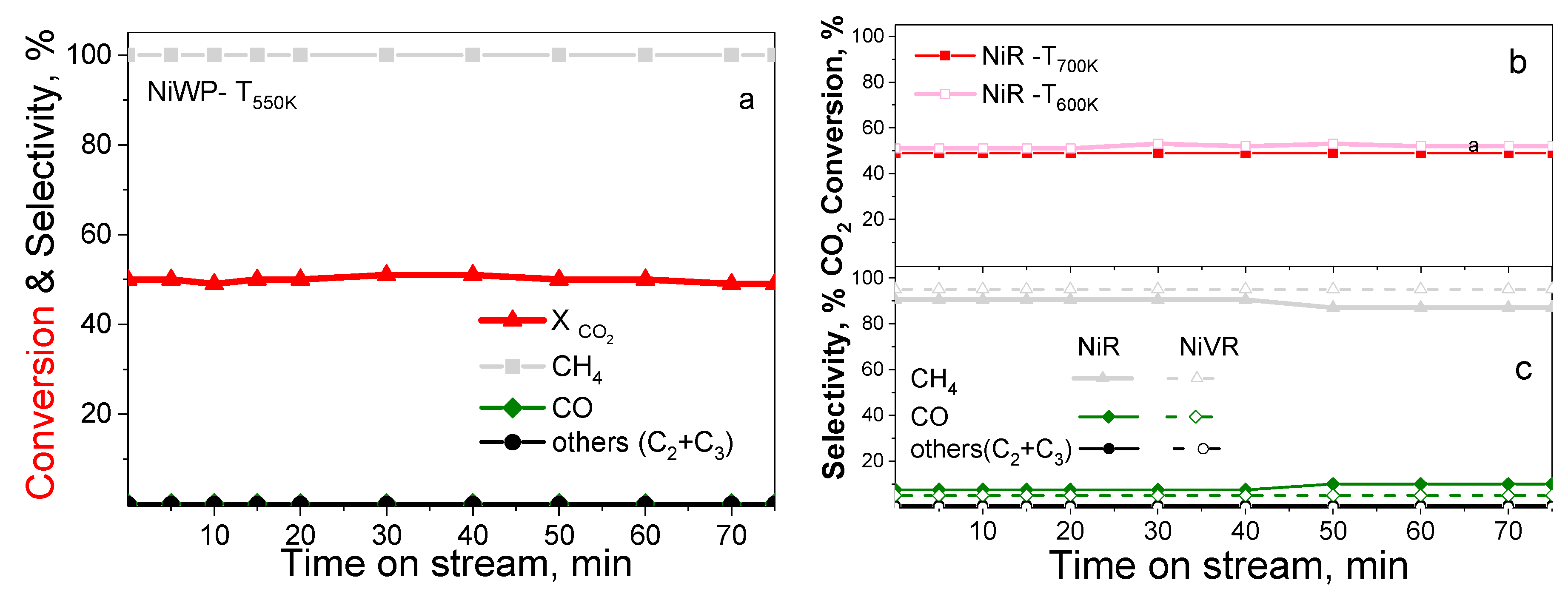

3.3. Catalyst Activity

3.4. Catalyst Stability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gac, W.; Zawadzki, W.; Rotko, M.; Greluk, M.; Słowik, G.; Kolb, G. Effects of support composition on the performance of nickel catalysts in CO2 methanation reaction. Catal. Today 2020, 357, 468–482. [Google Scholar] [CrossRef]

- Müller, K.; Fleige, M.; Rachow, F.; Schmeißer, D. Sabatier based CO2-methanation of flue gas emitted byconventional power plants. Energy Proc. 2013, 40, 240–248. [Google Scholar] [CrossRef]

- Frontera, P.P.; Macario, A.; Ferraro, M.; Antonucci, P.L. Supported Catalysts for CO2 Methanation: A Review. Catalysts 2017, 7, 59. [Google Scholar] [CrossRef]

- Wang, L.; Rao, M.; Diethelm, S.; Lin, T.-E.; Zhang, H.; Hagen, A.; Maréchal, F.; van Herle, J. Power-to-methane via co-electrolysis of H2O and CO2: The effects of pressurized operation and internal methanation. Appl. Energy 2019, 250, 1432–1445. [Google Scholar] [CrossRef]

- Guerra, L.; Rossi, S.; Rodrigues, J.; Gomes, J.; Puna, J.; Santos, M.T. Methane production by a combined Sabatier reaction/water electrolysis process. J. Environ. Chem. Eng. 2018, 6, 671–676. [Google Scholar] [CrossRef]

- He, Z.; Cui, M.; Qian, Q.; Zhang, J.; Liu, H.; Ha, B. Synthesis of liquid fuel via direct hydrogenation of CO2. Proc. Natl. Acad. Sci. USA 2019, 116, 12654–12659. [Google Scholar] [CrossRef]

- Ashok, J.; Pati, S.; Hongmanorom, P.; Tianxi, Z.; Junmei, C.; Kawi, S. A review of recent catalyst advances in CO2 methanation processes. Catal. Today 2020, 356, 471–489. [Google Scholar] [CrossRef]

- Zosen, H. Available online: https://www.hz-inova.com/cms/en/?p=4748 (accessed on 15 February 2021).

- HELMETH. Available online: https://www.kit.edu/kit/english/pi_2018_009_power-to-gas-with-high-efficiency.php# (accessed on 15 February 2021).

- Electrochaea. Available online: http://www.electrochaea.com/electrochaea-commissions-worlds-largest-power-to-gas-demonstration-project-based-on-biological-methanation/ (accessed on 15 February 2021).

- BioCat. Available online: https://www.bio-cat.com/bio-cat-patents-microbial-enzyme-blend-for-pancreatic-insufficiency-patients/ (accessed on 15 February 2021).

- Li, W.; Wang, H.; Jiang, X.; Zhu, J.; Liu, Z.; Guo, X.; Song, C. A short review of recent advances in CO2 hydrogenation to hydrocarbons over heterogeneous catalysts. RSC Adv. 2018, 8, 7651–7669. [Google Scholar] [CrossRef]

- Garbarino, G.; Riani, P.; Magistri, L.; Busca, G. A study of the methanation of carbon dioxide on Ni/Al2O3 catalysts at atmospheric pressure. Int. J. Hydrogen Energy 2014, 39, 11557–11565. [Google Scholar] [CrossRef]

- Liu, Q.; Gu, F.; Lu, X.; Liu, Y.; Li, H.; Zhong, Z.; Xu, G.; Su, F. Enhanced catalytic performances of Ni/Al2O3 catalyst via the addition of V2O3 for CO methanation. Appl. Catal. A 2014, 488, 37–47. [Google Scholar] [CrossRef]

- Muroyama, H.; Tsuda, Y.; Asakoshi, T.; Masitah, H.; Okanishi, T.; Matsui, T.; Eguchi, K. Carbon dioxide methanation over Ni catalysts supported on variousmetal oxides. J. Catal. 2016, 343, 178–184. [Google Scholar] [CrossRef]

- Yang, B.; He, J.; Zhang, G.; Guo, J. Vanadium; Elsevier: Amsterdam, The Netherlands, 2021; ISBN 978-0-12-818898-9. [Google Scholar]

- Valentini, A.; Carreño, N.L.V.; Probst, L.F.D.; Lisboa-Filho, P.N.; Schreiner, W.H.; Leite, E.R.; Longo, E. Role of vanadium in Ni:Al2O3 catalysts for carbon dioxide reforming of methane. Appl. Catal. 2003, 255, 211–220. [Google Scholar] [CrossRef]

- Kowalik, P.; Antoniak-Jurak, K.; Błesznowski, M.; Herrera, M.C.; Larrubia, M.A.; Alemany, L.J.; Pieta, I.S. Biofuel steam reforming catalyst for fuel cell application. Catal. Today 2015, 254, 129–134. [Google Scholar] [CrossRef]

- SBŁ-INS Commercial Catalysts, Brochure Available on Request. Available online: http://www.ins.pulawy.pl/index.php/en/products/catalysts-and-sorbents/hydrocarbon-steam-reforming (accessed on 17 March 2021).

- Pieta, I.S.; Pieta, P.; Nowakowski, R. Nickel-vanadium catalyst for the valorization of carbon dioxide, a method of obtaining a nickel-vanadium catalyst and the use of a nickel-vanadium catalyst in the processes of carbon dioxide hydrogenation and reforming. Polish Patent P-434122, 9 September 2020. [Google Scholar]

- Pieta, S.I. The Method and Installation for Continuous Multi-Parameter Analysis of Gaseous Fuel Conversion Including Reforming and Measurement of Post-Reaction Gas Pollutants Nitrogen, Carbon and Sulfur Oxides and Chlorine. UP RP nr Patent P-412277, 8 May 2015. [Google Scholar]

- Cavani, F.; Trifiro, F.; Vaccari, A. Hydrotalcite-type anionic clays: Preparation, properties and applications. Catal. Today 1991, 11, 173–301. [Google Scholar] [CrossRef]

- di Cosimo, J.I.; Díez, V.K.; Xu, M.; Iglesia, E.; Apesteguía, C.R. Structure and surface and catalytic properties of Mg-Al basic oxides. J. Catal. 1998, 178, 499–510. [Google Scholar] [CrossRef]

- Frost, R.L.; Palmer, S.J.; Theiss, F. Synthesis and Raman spectroscopic characterisation of hydrotalcites based on the formula Ca6Al2(CO3)(OH)16 4H2O. J. Raman Spectrosc. 2011, 42, 1163–1167. [Google Scholar] [CrossRef]

- Kong, X.; Zheng, R.; Zhu, Y.; Ding, G.; Zhu, Y.; Li, Y.W. Rational design of Ni-based catalysts derived from hydrotalcite for selective hydrogenation of 5-hydroxymethylfurfural. Green Chem. 2015, 17, 2504–2514. [Google Scholar] [CrossRef]

- Michalik, A.; Napruszewska, B.D.; Walczyk, A.; Krysciak-Czerwenka, J.; Duraczynska, D.; Serwicka, E.M. Synthesis of Nanocrystalline Mg-Al Hydrotalcites in the Presence of Starch-the Effect on Structure and Composition. Materials 2020, 13, 602. [Google Scholar] [CrossRef] [PubMed]

- Napruszewska, B.D.; Michalik-Zym, A.; Dula, R.; Duraczyńska, D.; Rojek, W.; Socha, W.; Lityńska-Dobrzyńska, L.; Bahranowski, K.; Serwicka, E.M. VOCs combustion catalysts based on composites of exfoliated organo-Laponite and multimetallic (Mn, Al, Zr, Ce) hydrotalcites prepared by inverse microemulsion. Catal. Today 2019, 333, 182–189. [Google Scholar] [CrossRef]

- Olszówka, J.E.; Karcz, R.; Michalik-Zym, A.; Napruszewska, B.D.; Bielańska, E.; Kryściak-Czerwenka, J.; Socha, R.P.; Nattich-Rak, M.; Krzan, M.; Klimek, A.; et al. Effect of grinding on the physico-chemical properties of Mg-Al hydrotalcite and its performance as a catalyst for Baeyer-Villiger oxidation of cyclohexanone. Catal. Today 2019, 333, 147–153. [Google Scholar] [CrossRef]

- Rives, V.; Kannan, S. Layered double hydroxides with the hydrotalcite-type structurecontaining Cu2z, Ni2z and Al3z. J. Mater. Chem. 2000, 10, 489–495. [Google Scholar] [CrossRef]

- Cheng, C.; Xu, G.; Zhang, H.; Luo, Y. Hydrothermal synthesis Ni-doped ZnO nanorods with room-temperature ferromagnetism. Mater. Lett. 2008, 62, 1617–1620. [Google Scholar] [CrossRef]

- Zhang, K.; Mukhriza, T.; Liu, X.; Greco, P.P.; Chiremba, E. A study on CO2 and CH4conversion to synthesis gas and higherhydrocarbons by the combination of catalysts and dielectric-barrierdischarges. Appl. Catal. A Gen. 2015, 502, 138–149. [Google Scholar] [CrossRef]

- Bantignies, J.L.; Deabate, S.; Righi, A.; Rols, S.; Hermet, P.; Sauvajol, J.L.; Henn, F. New Insight into the Vibrational Behavior of Nickel Hydroxide and Oxyhydroxide Using Inelastic Neutron Scattering, Far/Mid-Infrared and Raman Spectroscopies. J. Phys. Chem. C 2008, 112, 2193–2201. [Google Scholar] [CrossRef]

- Feret, F.; Roy, D.; Boulanger, C. Determination of alpha and beta alumina in ceramic alumina by X-ray diffraction. Spectrochim. Acta Part B 2000, 55, 1051–1061. [Google Scholar] [CrossRef]

- NIST. Available online: https://www.nist.gov/pml/productsservices/physical-reference-data (accessed on 15 February 2021).

- Galvita, V.; Siddiqi, G.; Sun, P.; Bell, A.T. Ethane dehydrogenation on Pt/Mg(Al)O and PtSn/Mg(Al)O catalysts. J. Catal. 2010, 271, 209–219. [Google Scholar] [CrossRef]

- Zhou, Q.; Chen, W.; Xu, L.; Peng, S. Hydrothermal Synthesis of Various Hierarchical ZnO Nanostructures and Their Methane Sensing Properties. Sensors 2013, 13, 6171–6182. [Google Scholar] [CrossRef] [PubMed]

- Hu, A.; Zhang, X.; Luong, D.; Oakes, K.D.; Servos, M.R.; Liang, R.; Kurdi, S.; Peng, P.; Zhou, Y. Adsorption and Photocatalytic Degradation Kineticsof Pharmaceuticals by TiO2Nanowires During Water Treatmen. Waste Biomass Valorization 2012, 3, 443–449. [Google Scholar] [CrossRef]

- Busca, G.; Lorenzelli, V. Infrared spectroscopic identification of species arising from reactive adsorption of carbon oxides on metal oxide surfaces. Mater. Chem. 1982, 7, 89–126. [Google Scholar] [CrossRef]

- Gonzalez-Gil, R.; Herrera, C.; Larrubia, M.A.; Kowalik, P.; Pieta, I.S.; Alemany, L.J. Hydrogen production by steam reforming of DME over Ni-based catalysts modified with vanadium. Int. J. Hydrogen Energy 2016, 41, 19781–19788. [Google Scholar] [CrossRef]

- Vedrine, J. Acid-base characterization of heterogeneous catalysts: An up-to-date overview. Res. Chem. Intermed. 2015, 41, 9387–9423. [Google Scholar] [CrossRef]

- Garcia-Dieguez, M.; Pieta, I.S.; Herrera, M.C.; Larrubia, M.A.; Alemany, L.J. Improved Pt-Ni nanocatalysts for dry reforming of methane. Appl. Catal. A Gen. 2010, 377, 191–199. [Google Scholar] [CrossRef]

- Mustapha, S.; Ndamitso, M.M.; Abdulkareem, A.S.; Tijani, J.O.; Shuaib, D.T.; Ajala, A.O.; Mohammed, A.K. Application of TiO2 and ZnO nanoparticles immobilized on clay in wastewater treatment: A review. Appl. Water Sci. 2020, 10, 49. [Google Scholar] [CrossRef]

- Kayani, Z.N.; Naz, F.; Riaz, S.; Naseem, S. Characteristics of Al-doped ZnO:Ni films grown on glass by sol-gel dip coating technique. J. Saudi Chem. Soc. 2017, 21, 425–433. [Google Scholar] [CrossRef]

- León, A.; Reuquen, P.; Garín, C.; Segura, R.; Vargas, P.; Zapata, P.; Orihuela, P.A. FTIR and Raman Characterization of TiO2 Nanoparticles Coated with Polyethylene Glycol as Carrier for 2-Methoxyestradiol. Appl. Sci. 2017, 7, 49. [Google Scholar] [CrossRef]

- Amin, M.H. Relationship Between the Pore Structure of Mesoporous Silica Supports and the Activity of Nickel Nanocatalysts in the CO2 Reforming of Methane. Catalysts 2020, 10, 51. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Niaei, A.; Salari, D. Production of γ-Al2O3 from Kaolin. Open J. Phys. Chem. 2011, 1, 23–27. [Google Scholar] [CrossRef]

- Noonuruk, R.; Techitdheera, W.; Pecharapa, W. Study of Structural Properties of NiZnO Thin Films under UV/Ozone Treatment by Atomic Force Microscopy and Fourier Transform Infrared Spectroscopy. J. Microsc. Soc. Thail. 2011, 4, 28–31. [Google Scholar]

- Pieta, I.S.; Garcia-Dieguez, M.; Herrera, C.; Larrubia, M.A.; Alemany, L.J. In situ DRIFT–TRM study of simultaneous NOx and soot removal over Pt–Ba and Pt–K NSR catalysts. J. Catal. 2010, 270, 256–267. [Google Scholar] [CrossRef]

- Solis, B.H.; Cui, Y.; Weng, X.; Seifert, J.; Schauermann, S.; Sauer, J.; Shaikhutdinov, S.; Freund, H.-J. Initial stages of CO2 adsorption on CaO: A combined experimental and computational study. Phys. Chem. Chem. Phys. 2017, 19, 423. [Google Scholar] [CrossRef]

- Chernyshova, I.V.; Ponnurangam, S.; Somasundaran, P. Linking interfacial chemistry of CO2 to surface structures of hydrated metal oxide nanoparticles: Hematite. Phys. Chem. Chem. Phys. 2013, 15, 6953. [Google Scholar] [CrossRef]

- Li, H.; Jiao, X.; Li, L.; Zhao, N.; Xiao, F.; Wei, W.; Sund, Y.; Zhang, B. Synthesis of glycerol carbonate by direct carbonylation of glycerol with CO2 over solid catalysts derived from Zn/Al/La and Zn/Al/La/M (M = Li, Mg and Zr) hydrotalcites. Catal. Sci. Technol. 2015, 5, 989–1005. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Zhou, Z.; Zu, X.; Deng, Y. Evolution of the zinc compound nanostructures in zinc acetate single-source solution. J. Nanopart. Res. 2011, 13, 5193–5202. [Google Scholar] [CrossRef]

- Bezrodna, T.; Puchkovska, G.; Shymanovska, V.; Baran, J.; Ratajczak, H. IR-analysis of H-bonded H2O on the pure TiO2 surface. J. Mol. Struct. 2004, 700, 175–181. [Google Scholar] [CrossRef]

- Aw, M.S.; Dražić, G.; Djinović, P.; Pintar, A. Transition metal pairs on ceria-promoted, ordered mesoporous alumina as catalysts for the CO2 reforming reaction of methane. Catal. Sci. Technol. 2016, 6, 3797–3805. [Google Scholar] [CrossRef]

- Yuan, X.; Zhu, Z.; Tang, K.; Cheng, Y.; Xu, Z.; Yang, W. Formation and Properties of 1-D Alumina Nanostructures Prepared via a Template-free Thermal Reaction. Procedia Eng. 2015, 102, 602–609. [Google Scholar] [CrossRef]

- Zhou, L.; Huang, J.; Yu, B.; You, T. A novel self-enhanced electrochemiluminescence immunosensor based on hollow Ru-SiO2@PEI nanoparticles for NSE analysis. Sci. Rep. 2016, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Damyanova, S.; Pawelec, B.; Palcheva, R.; Karakirova, Y.; Sanchez, M.C.C.; Tyuliev, G.; Gaigneaux, E.; Fierro, J.L.G. Structure and surface properties of ceria-modified Ni-based catalysts forhydrogen production. Appl. Catal. B Environ. 2018, 225, 340–353. [Google Scholar] [CrossRef]

- Dobrowolska, P.; Krajewska, A.; Gajda-Rączka, M.; Bartosewicz, B.; Nyga, P.; Jankiewicz, B.J. Application of Turkevich Method for Gold Nanoparticles Synthesis to Fabrication of SiO2@Au and TiO2@Au Core-Shell Nanostructures. Materials 2015, 8, 2849–2862. [Google Scholar] [CrossRef]

- Elhalil, A.; Elmoubarki, R.; Farnane, M.; Machrouhi, A.; Sadiq, M.; Mahjoubi, F.Z.; Qourzal, S.; Barka, N. Photocatalytic degradation of caffeine as a model pharmaceutical pollutanton Mg doped ZnO-Al2O3heterostructure. Environ. Nanotech. Monit. Manag. 2018, 10, 63–72. [Google Scholar]

- Li, W.; Liang, R.; Hu, A.; Huang, Z.; Zhou, Y.N. Generation of oxygen vacancies in visible lightactivated one-dimensional iodine TiO2photocatalysts. RSC Adv. 2014, 4, 36959. [Google Scholar] [CrossRef]

- Jayalakshmi, G.; Saravanan, K. Surface plasmons enhanced band-edge emission in Ni nanoparticles decorated ZnO nanorods arrays architecture. J. Lumin. 2020, 222, 117049. [Google Scholar] [CrossRef]

- Patil, S.S.; Patil, R.H.; Kale, S.B.; Tamboli, M.; Ambekar, J.D.; Gade, W.N.; Kolekar, S.S.; Kale, B.B. Nanostructured microspheres of silver @ zinc oxide:an excellent impeder of bacterial growth and biofilm. J. Nanopart. Res. 2014, 16, 2717. [Google Scholar] [CrossRef]

- Lundegaard, L.F.; Tiruvalam, R.R.; Tyrsted, C.; Carlsson, A.; Morales-Cano, F.; Ovesena, C.V. Migrating Al species hindering NiO reduction on Alcontaining catalyst carriers. Catal. Today 2016, 272, 25–31. [Google Scholar] [CrossRef]

- Scheffer, B.; Molhoek, P.; Moulijn, J.A. Temperature-programmed reduction of NiOsingle bondWO3/Al2O3 Hydrodesulphurization catalysts. Appl. Catal. 1989, 46, 11. [Google Scholar] [CrossRef]

- Li, G.; Hu, L.; Hill, J.M. Comparison of reducibility and stability of alumina-supported Ni catalysts prepared by impregnation and co-precipitation. Appl. Catal. A 2006, 301, 16. [Google Scholar] [CrossRef]

- Lemonidou, A.A.; Goula, M.A.; Vasalos, I.A. Carbon dioxide reforming of methane over 5 wt.% nickelcalcium aluminate catalysts ± effect of preparation method. Cat. Today 1998, 46, 175–183. [Google Scholar] [CrossRef]

- Rogers, J.L.; Mangarella, M.C.; D’Amico, A.D.; Gallagher, J.R.; Dutzer, M.R.; Stavitski, E.; Miller, J.T.; Sievers, C. Differences in the Nature of Active Sites for Methane Dry Reforming and Methane Steam Reforming over Nickel Aluminate Catalysts. ACS Catal. 2016, 6, 5873–5886. [Google Scholar] [CrossRef]

- Sahli, N.; Petit, C.; Roger, A.C.; Kiennemann, A.; Libs, S.; Bettahar, M.M. Ni catalysts from NiAl2O4 spinel for CO2 reforming of methane. Catal. Today 2006, 113, 187–193. [Google Scholar] [CrossRef]

- Richardson, J.T.; Turk, B.; Twing, M.V. Reduction of model steam reforming catalysts: Effect of oxide additives. Appl. Catal. A 1996, 148, 97. [Google Scholar] [CrossRef]

- Hamid, M.Y.S.; Jalil, A.A.; Rahman, A.F.A.; Abdullah, T.A.T. Enhanced reactive CO2 species formation via V2O5-promoted Ni/KCC-1 for low temperature activation of CO2 methanation. React. Chem. Eng. 2019, 4, 1126–1135. [Google Scholar] [CrossRef]

- Chary, K.V.R.; Kishan, G.; Bhaskar, T.; Sivaraj, C. Structure and Reactivity of Vanadium Oxide Catalysts Supported on Anatase TiO2. J. Phys. Chem. B 1998, 102, 6792–6798. [Google Scholar] [CrossRef]

- Ruitenbeek, M.; van Dillen, A.J.; deGroot, F.M.F.; Wachs, I.E.; Geus, J.W.; Koningsberger, D.C. The structure of vanadium oxide species on-alumina;anin situX-ray absorption study during catalytic oxidation. Top Catal. 2000, 10, 241–254. [Google Scholar] [CrossRef]

- Wang, F.; He, S.; Chen, H.; Wang, B.; Zheng, L.; Wei, M.; Evans, D.G.; Duan, X. Active Site Dependent Reaction Mechanism over Ru/CeO2 Catalyst toward CO2 Methanation. JACS 2016, 138, 6298–6305. [Google Scholar] [CrossRef] [PubMed]

- Younas, M.; Kong, L.L.; Bashir, M.J.K.; Nadeem, H.; Shehzad, A.; Sethupathi, S. Recent Advancements, Fundamental Challenges, and Opportunities in Catalytic Methanation of CO2. Energy Fuels 2016, 30, 8815–8831. [Google Scholar] [CrossRef]

- Pan, Q.; Peng, J.; Sun, T.; Wang, S.; Wang, S. Insight into the reaction route of CO2 methanation: Promotion effect of medium basic sites. Catal. Commun. 2014, 45, 74–78. [Google Scholar] [CrossRef]

- Pandey, D.; Deo, G. Effect of support on the catalytic activity of supported Ni−Fe catalysts for the CO2 methanation reaction. J. Ind. Eng. Chem. 2016, 33, 99–107. [Google Scholar] [CrossRef]

- Dorner, R.W.; Hardy, D.R.; Williams, F.W.; Willauer, H.D. Heterogeneous catalytic CO2 conversion to value-added hydrocarbons. Energy Environ. Sci. 2010, 3, 884–890. [Google Scholar] [CrossRef]

- Lu, X.; Gu, F.; Liu, Q.; Ga, J.; Liu, Y.; Li, H.; Jia, L.; Xu, G.; Zhong, Z.; Su, F. VOx promoted Ni catalysts supported on the modified bentonite for CO and CO2 methanation. Fuel Proc. Technol. 2015, 135, 34–46. [Google Scholar] [CrossRef]

- Garcia-Dieguez, M.; Pieta, I.S.; Herrera, M.C.; Larrubia, M.A.; Alemany, L.J. Nanostructured Pt- and Ni-based catalysts for CO2-reforming of methane. J. Catal. 2010, 270, 136–145. [Google Scholar] [CrossRef]

- Lavoie, J. Review on dry reforming of methane, a potentially more environmentally-friendly approach to the increasing natural gas exploitation. Front. Chem. 2014, 2, 81. [Google Scholar] [CrossRef]

- Peppley, B.; Amphlett, J.; Kearns, L.; Mann, R. Methanol-steamreforming on Cu/ZnO/Al2O3catalysts. Part2. A comprehensive kinetic model. Appl. Catal. A Gen. 1999, 179, 1–2. [Google Scholar] [CrossRef]

- Benrabbah, R.; Cavaniol, C.; Liu, H.; Ognier, S.; Cavadias, S.; Galvez, M.E.; da Costaa, P. Plasma DBD activated ceria-zirconia-promoted Ni-catalysts for plasma catalytic CO2 hydrogenation at low temperature. Catal. Comm. 2017, 89, 73–76. [Google Scholar] [CrossRef]

- Smith, J.F.; Carlson, O.N.; Nash, P.G. The Ni-V (Nickel-Vanadium) system. Bull. Alloy Phase Diagr. 1982, 3, 342–348. [Google Scholar] [CrossRef]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies; Wiley: Hoboken, NJ, USA, 2001; ISBN 978-0-470-09307-8. [Google Scholar]

- Tarte, P. Infrared spectra of inorganic alumi-nates and characteristic vibrational frequencies of AIO4 tetrahedra and A106 octahedra. Spectrochem. Acta 1967, 23A, 2127–2143. [Google Scholar] [CrossRef]

- Lázaro, M.J.; Echegoyen, Y.; Suelves, I.; Palacios, J.M.; Moliner, R. Decomposition of methane over Ni-SiO2 and Ni-Cu-SiO2 catalysts: Effect of catalyst preparation method. Appl. Catal. A Gen. 2007, 329, 22–29. [Google Scholar] [CrossRef]

- Xie, Y.; You, J.; Lu, L.; Wang, M.; Wang, J. Raman Spectroscopic Study of Coal Samplesduring Heating. Appl. Sci. 2019, 9, 4699. [Google Scholar] [CrossRef]

| No. | Reaction | Equation | ΔH298K0 (kJ mol−1) | |

|---|---|---|---|---|

| 1 | CO2 methanation | CO2+ 4H2 ⇄ CH4 + 2H2O | (1) | −165.0 |

| 2 | CO methanation | CO + 3H2 ⇄ CH4 + H2O | (2) | −206.1 |

| 3 | Water–gas shift (WGS) | CO + H2O ⇄ CO2 + H2 | (3) | −41.2 |

| 4 | Reverse water–gas shift (RWGS) | CO2 + H2 ⇄ CO + H2O | (4) | 41.2 |

| 5 | Methane cracking | CH4 ⇄ C + 2H2 | (5) | 74.8 |

| 6 | Boduouard reaction | 2CO ⇄ CO2 + C | (6) | −172 |

| Catalyst | Description | Ni Content, % | SBET, m2gcat−1 | H2 ConsumptionT, K | DNiO *, nm |

|---|---|---|---|---|---|

| Ni/α-Al2O3 | NiR | 13.4 | 2.0 | >750 | <197 |

| Ni-V a/α-Al2O3 | NiVR | 13.2 | 2.0 | 603, 673, | <187 |

| Ni/Al2O3 | NiWP | 7 | 223 | >750 | <6 |

| Ni/SiO2 | Ni/Si | 7 | 124 | >750 | <9 |

| Ni/TiO2 | Ni/Ti | 7 | 197 | 723, >750 | <30 |

| Ni/Vx aTiyO2 | Ni/VTi | 7 | 179 | 653, 723 | <50 |

| Ni/SixTiyO2 | Ni/SiTi | 7 | 137 | 523, 573, 723 | <8 |

| Ni/ZnO | Ni/Zn | 7 | 18 | 603, 673 | <36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pieta, I.S.; Lewalska-Graczyk, A.; Kowalik, P.; Antoniak-Jurak, K.; Krysa, M.; Sroka-Bartnicka, A.; Gajek, A.; Lisowski, W.; Mrdenovic, D.; Pieta, P.; et al. CO2 Hydrogenation to Methane over Ni-Catalysts: The Effect of Support and Vanadia Promoting. Catalysts 2021, 11, 433. https://doi.org/10.3390/catal11040433

Pieta IS, Lewalska-Graczyk A, Kowalik P, Antoniak-Jurak K, Krysa M, Sroka-Bartnicka A, Gajek A, Lisowski W, Mrdenovic D, Pieta P, et al. CO2 Hydrogenation to Methane over Ni-Catalysts: The Effect of Support and Vanadia Promoting. Catalysts. 2021; 11(4):433. https://doi.org/10.3390/catal11040433

Chicago/Turabian StylePieta, Izabela S., Agnieszka Lewalska-Graczyk, Pawel Kowalik, Katarzyna Antoniak-Jurak, Mikolaj Krysa, Anna Sroka-Bartnicka, Arkadiusz Gajek, Wojciech Lisowski, Dusan Mrdenovic, Piotr Pieta, and et al. 2021. "CO2 Hydrogenation to Methane over Ni-Catalysts: The Effect of Support and Vanadia Promoting" Catalysts 11, no. 4: 433. https://doi.org/10.3390/catal11040433

APA StylePieta, I. S., Lewalska-Graczyk, A., Kowalik, P., Antoniak-Jurak, K., Krysa, M., Sroka-Bartnicka, A., Gajek, A., Lisowski, W., Mrdenovic, D., Pieta, P., Nowakowski, R., Lew, A., & Serwicka, E. M. (2021). CO2 Hydrogenation to Methane over Ni-Catalysts: The Effect of Support and Vanadia Promoting. Catalysts, 11(4), 433. https://doi.org/10.3390/catal11040433