Conditions Optimization and Physiochemical Analysis of Oil Obtained by Catalytic Pyrolysis of Scrap Tube Rubber Using MgO as Catalyst

Abstract

1. Introduction

2. Results and Discussion

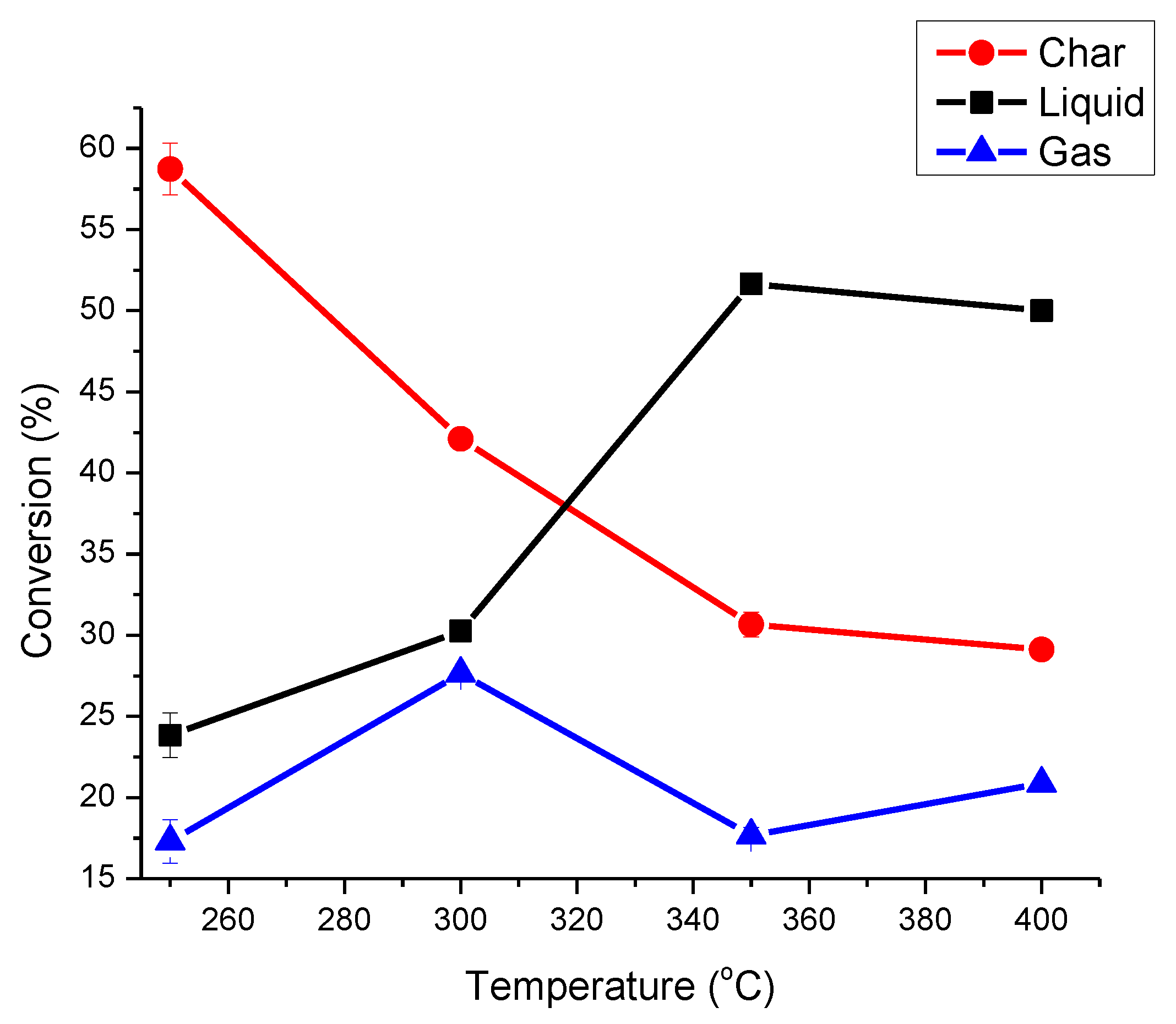

2.1. Temperature Optimization for Catalytic Cracking of Tube Rubber

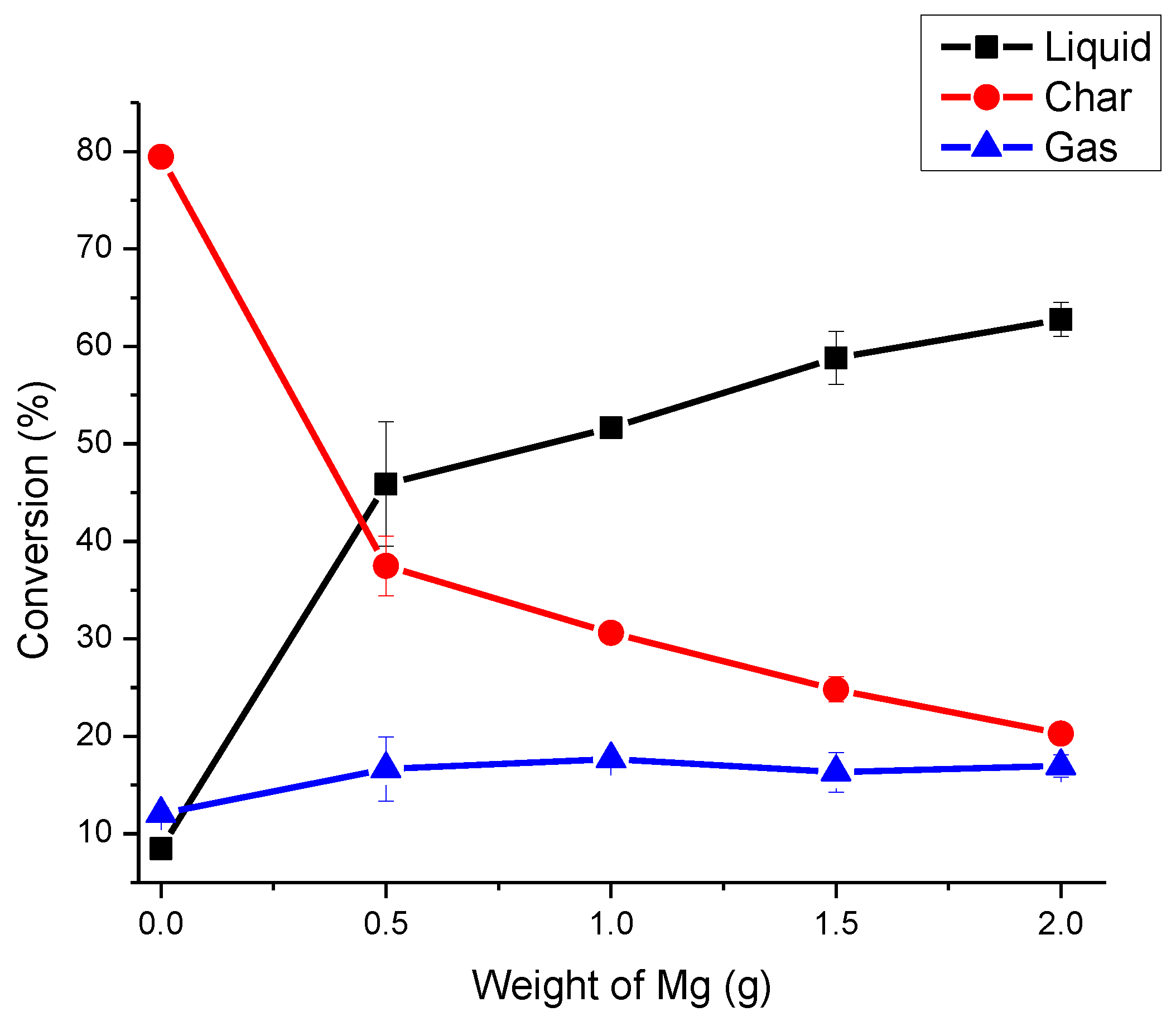

2.2. Weight of Catalyst Optimization for Catalytic Cracking of Tube Rubber

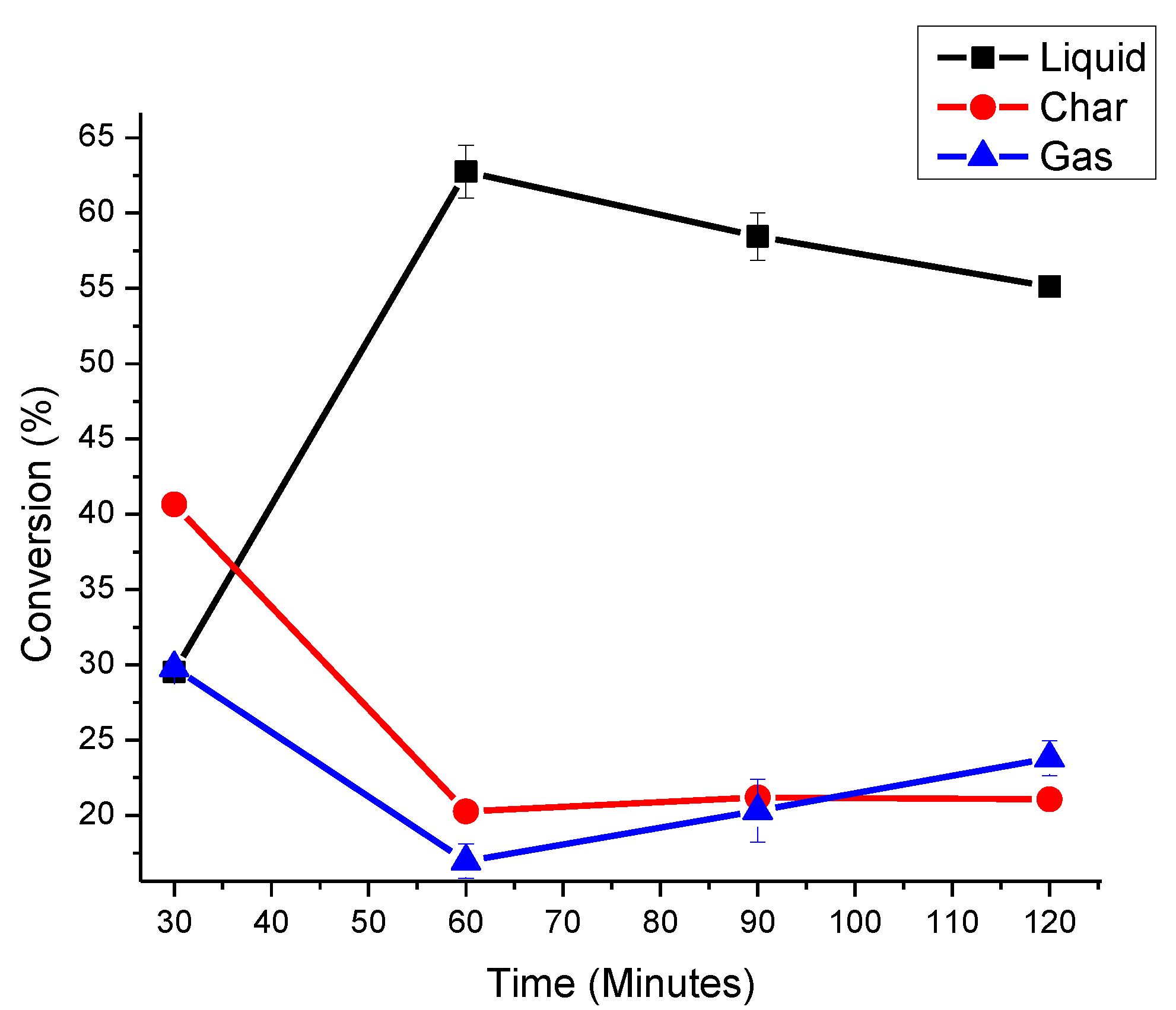

2.3. Heating Time and Rate Optimization for Catalytic Cracking of Tube Rubber

3. Material and Methodology

3.1. Material Used

3.2. Instruments Used

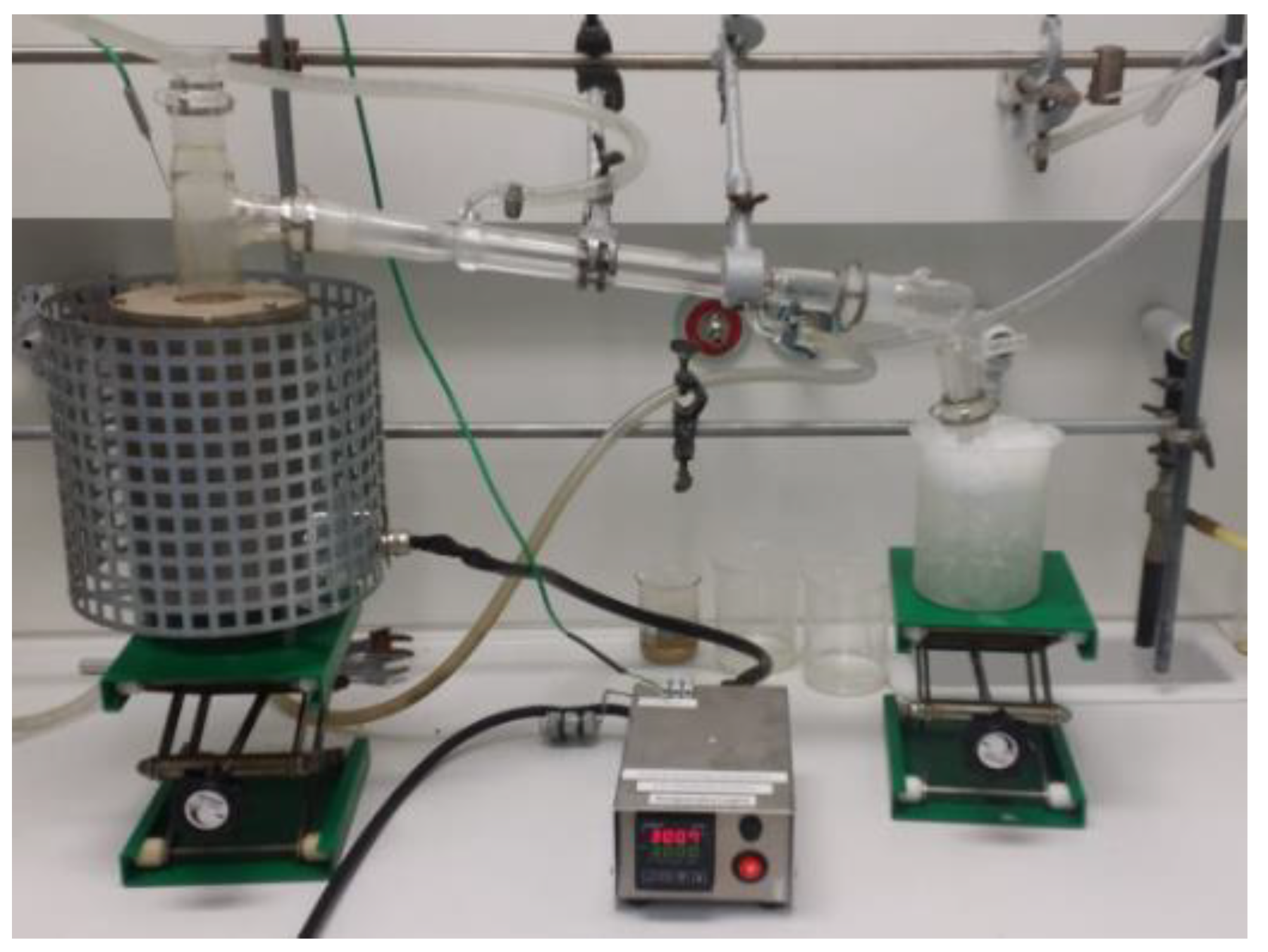

3.3. Pyrolysis Batch Reactor

3.4. Sample Treatment

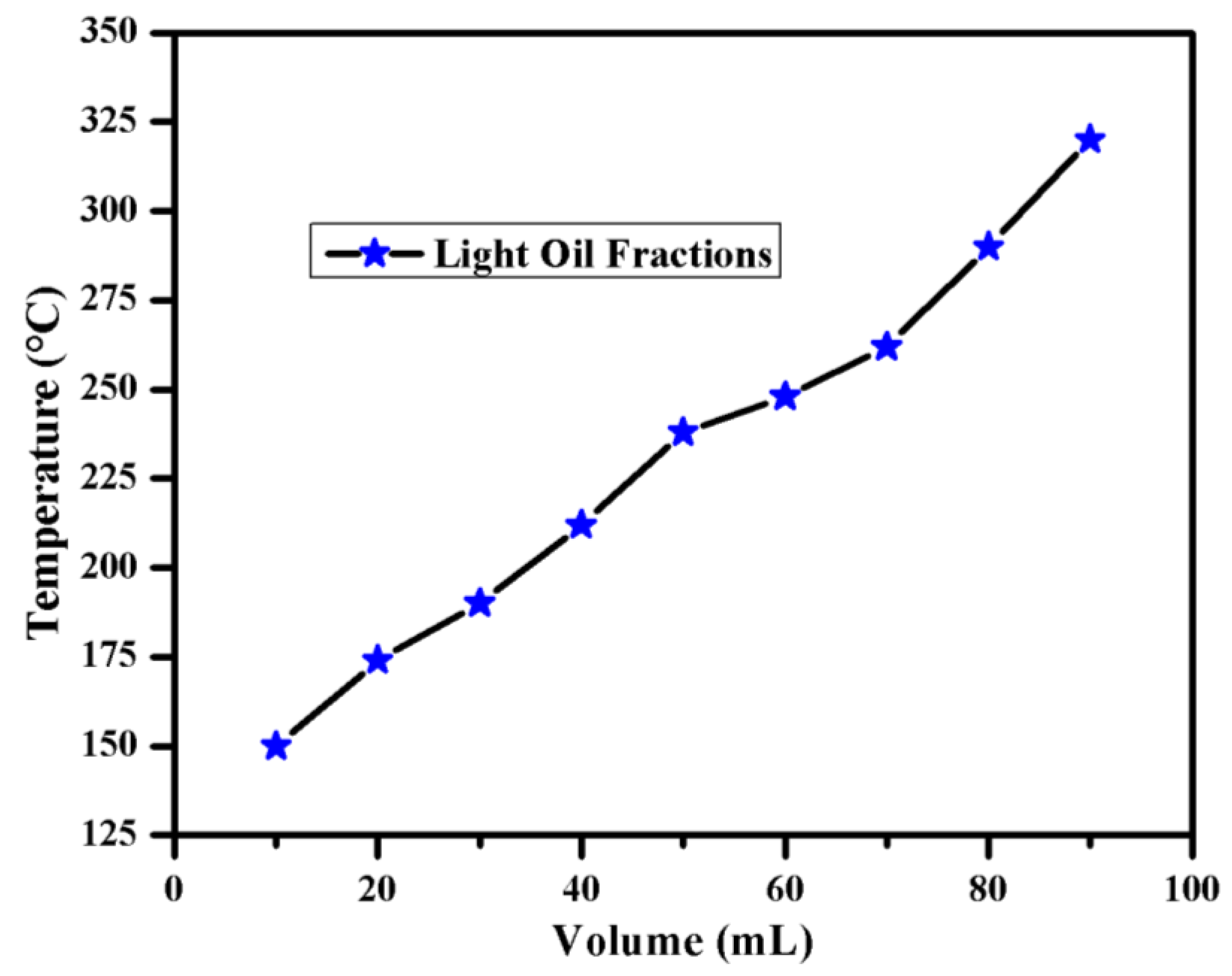

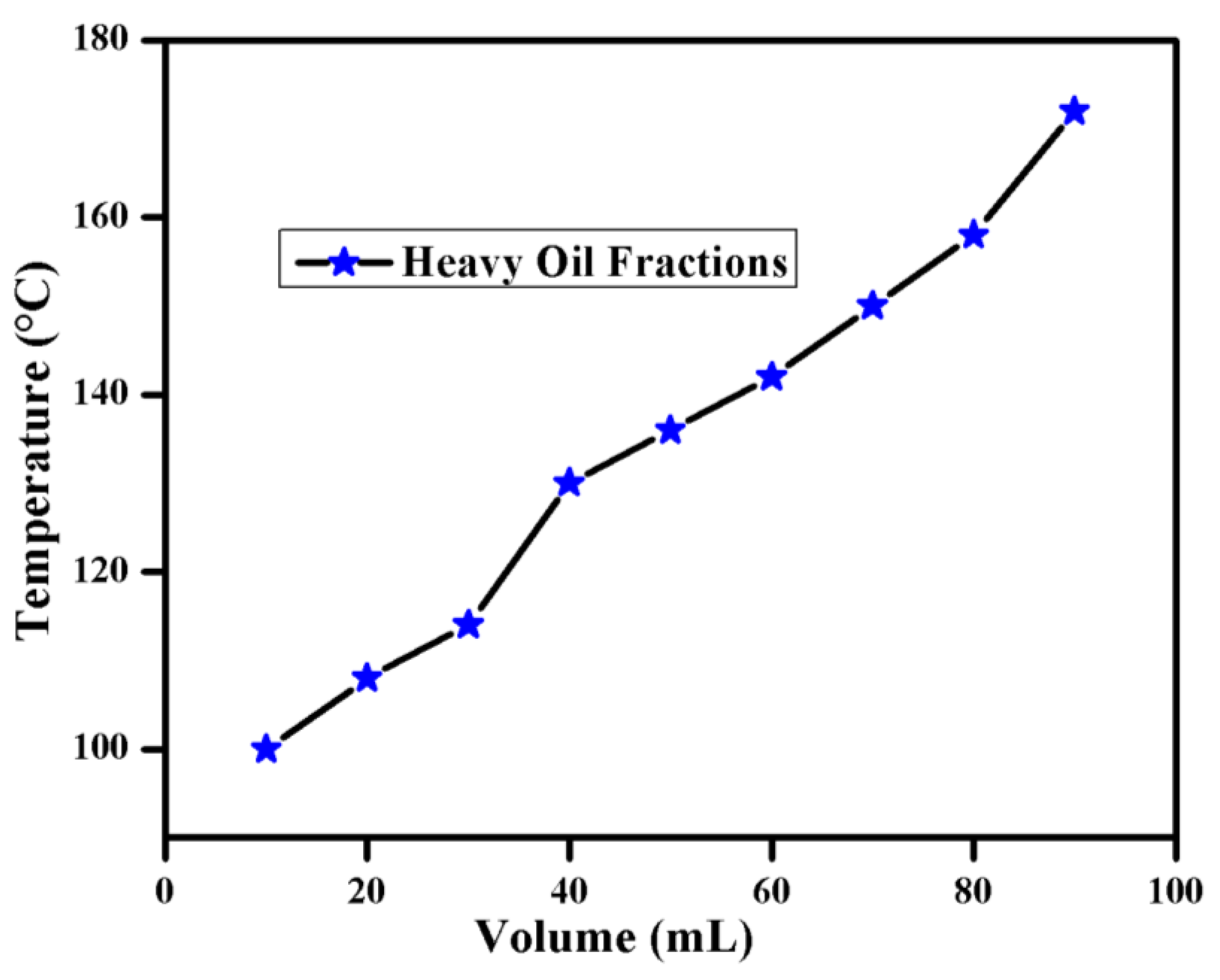

3.5. Distillation of Liquid from Catalytic Cracking of Tube Rubber

3.6. Physical Properties Analysis

3.6.1. Density

3.6.2. Specific Gravity

3.6.3. API-Gravity

3.6.4. Viscosity

3.6.5. Kinematic Viscosity

3.6.6. Aniline Point

3.6.7. Flash Point

3.7. Chemical Analysis

3.7.1. Qualitative Determination by Bromine Water Test

Potassium Permanganate Test:

3.7.2. Quantitative Determination by Phenol Test using Antipyrene Method

3.8. Determination of Bromine Number by Mercury Catalyzed Bromate –Bromide Titration

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, J.; Zou, H.; Ding, L.; Li, X.; Jiang, K.; Chen, T.; Zhang, X.; Zhang, L.; Ren, D. Continuous production of liquid reclaimed rubber from ground tire rubber and its application as reactive polymeric plasticizer. Polym. Degrad. Stab. 2014, 99, 166–175. [Google Scholar] [CrossRef]

- Torretta, V.; Rada, E.C.; Ragazzi, M.; Trulli, E.; Istrate, I.A.; Cioca, L.I. Treatment and disposal of Tires: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef] [PubMed]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Brandsma, S.H.; Brits, M.; Groenewoud, Q.R.; Van Velzen, M.J.M.; Leonards, P.E.G.; De Boer, J. Chlorinated Paraffins in Car Tires Recycled to Rubber Granulates and Playground Tiles. Environ. Sci. Technol. 2019, 53, 7595–7603. [Google Scholar] [CrossRef]

- Nagano, H. Exxon Butyl Rubber Compounding and Applications; Exxon Chemical: Yokohama, Japan, 2001. [Google Scholar]

- Sparks, W.J.; Thomas, R.M. Interpolymer of Isoolefine and Polyolefine. U.S. Patent 2418912A, 15 April 1947. [Google Scholar]

- Gomes, J.; Mota, H.; Bordado, J.; Cadete, M.; Sarmento, G.; Ribeiro, A.; Baiao, M.; Fernandes, J.; Pampulim, V.; Custódio, M.; et al. Toxicological assessment of coated versus uncoated rubber granulates obtained from used tires for use in sport facilities. J. Air Waste Manag. Assoc. 2010, 60, 741–746. [Google Scholar] [CrossRef] [PubMed]

- Feng, Z.G.; Rao, W.Y.; Chen, C.; Tian, B.; Li, X.J.; Li, P.L.; Guo, Q.L. Performance evaluation of bitumen modified with pyrolysis carbon black made from waste Tires. Constr. Build. Mat. 2016, 111, 495–501. [Google Scholar] [CrossRef]

- Ayanoğlua, A.; Yumrutaş, R. Rotary kiln and batch pyrolysis of waste tire to produce gasoline and diesel like fuels. Energy Convers. Manag. 2016, 111, 261–270. [Google Scholar] [CrossRef]

- Czajczyńska, D.; Krzyżyńska, R.; Jouhara, H.; Spencer, N. Use of pyrolytic gas from waste tire as a fuel: A review. Energy 2017, 134, 1121–1131. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, Z.; Ding, K.; Zhang, B.; Deng, A.; Min, M.; Chen, P.; Ruan, R. Co-pyrolysis of bamboo residual with waste tire over dual catalytic stage of CaO and co-modified HZSM-5. Energy 2017, 133, 90–98. [Google Scholar] [CrossRef]

- Lin, J.P.; Chang, C.Y.; Wu, C.H. Pyrolytic treatment of rubber waste: Pyrolysis kinetics of sTyrene—butadiene rubber. J. Chem. Technol. Biotech. 1996, 66, 7–14. [Google Scholar] [CrossRef]

- Miranda, M.; Pinto, F.; Gulyurtlu, I.; Cabrita, I. Pyrolysis of rubber Tire wastes: A. kinetic study. Fuel 2013, 103, 542–552. [Google Scholar] [CrossRef]

- Raj, R.E.; Kennedy, Z.R.; Pillai, B.C. Optimization of process parameters in flash pyrolysis of waste Tires to liquid and gaseous fuel in a fluidized bed reactor. Energy Convers. Manag. 2013, 67, 145–151. [Google Scholar]

- Telnov, A.; Zavyalov, N.; Khokhlov, Y.; Sitnikov, N.; Smetanin, M.; Tarantasov, V.; Shadrin, D.; Shorikov, I.; Liakumovich, A.; Miryasova, F. Radiation degradation of spent butyl rubbers. Radiat. Phys. Chem. 2002, 63, 245–248. [Google Scholar] [CrossRef]

- Sen, M.; Uzun, C.; Kantoǧlu, Ö.; Erdoǧan, S.; Deniz, V.; Güven, O. Effect of gamma irradiation conditions on the radiation-induced degradation of isobutylene–isoprene rubber. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2003, 208, 480–484. [Google Scholar] [CrossRef]

- Perera, R.; Albano, C.; Gonzalez, J.; Silva, P.; Ichazo, M. The effect of gamma radiation on the properties of poly-propylene blends with sTirene–butadiene–sTirene copolymers. Polym. Degrad. Stab. 2004, 85, 741–750. [Google Scholar] [CrossRef]

- Hassan, M.M.; Badway, N.A.; Elnaggar, M.Y.; Hegazy, E.-S.A. Thermo-mechanical properties of devulcanized rubber/high crystalline polypropylene blends modified by ionizing radiation. J. Ind. Eng. Chem. 2013, 19, 1241–1250. [Google Scholar] [CrossRef]

- Shah, J.; Jan, M.R.; Mabood, F. Catalytic conversion of waste Tires into valuable hydrocarbons. J. Polym. Environ. 2007, 15, 207–211. [Google Scholar] [CrossRef]

- Quek, A.; Balasubramanian, R. Liquefaction of waste tires by pyrolysis for oil and chemicals—A review. J. Anal. Appl. Pyrolysis 2013, 101, 1–16. [Google Scholar] [CrossRef]

- Choi, G.G.; Jung, S.H.; Oh, S.J.; Kim, J.S. Total utilization of waste tire rubber through pyrolysis to obtain oils and CO2 activation of pyrolysis char. Fuel Process. Technol. 2014, 123, 57–64. [Google Scholar] [CrossRef]

- Danmaliki, G.I.; Saleh, T.A. Influence of conversion parameters of waste tires to activated carbon on adsorption of dibenzothiophene from model fuels. J. Clean. Prod. 2016, 117, 50–55. [Google Scholar] [CrossRef]

- Yu, B.C.; Jung, J.W.; Park, K.; Goodenough, J.B. A new approach for recycling waste rubber products in Li–S batteries. Energy Environ. Sci. 2016, 10, 86–90. [Google Scholar] [CrossRef]

- Seljak, T.; Oprešnik, S.R.; Katrašnik, T. Combustion characteristics of tire pyrolysis oil in turbo charged compression ignition engine. Fuel 2015, 150, 226–235. [Google Scholar]

- Luo, S.; Feng, Y. The production of fuel oil and combustible gas by catalytic pyrolysis of waste tire using waste heat of blast-furnace slag. Energy Convers. Manag. 2017, 136, 27–35. [Google Scholar] [CrossRef]

- Ahoor, A.H.; Zandi-Atashbar, N. Fuel production based on catalytic pyrolysis of waste tires as an optimized model. Energy Convers. Manag. 2014, 87, 653–669. [Google Scholar] [CrossRef]

- Ilkılıç, C.; Aydın, H. Fuel production from waste vehicle tires by catalytic pyrolysis and its application in a diesel engine. Fuel Process. Technol. 2011, 92, 1129–1135. [Google Scholar] [CrossRef]

- Yazdani, E.; Hashemabadi, S.H.; Taghizadeh, A. Study of waste tire pyrolysis in a rotary kiln reactor in a wide range of pyrolysis temperature. Waste Manag. 2019, 85, 195–201. [Google Scholar] [CrossRef]

- Shah, J.; Jan, M.R.; Mabood, F.; Shahid, M. Conversion of waste Tires into carbon black and their utilization as ad-sorbent. J. Chin. Chem. Soc. 2006, 53, 1085–1089. [Google Scholar] [CrossRef]

- Mabood, F.; Jan, M.R.; Shah, J.; Jabeen, F.; Alam, S.; Sadiq, M.; Hussain, Z. Catalytic Conversion of Waste Inner tube Rubber (Isobutylene Isoprene) into Valuable Products. J. Chem. Soc. Pak. 2010, 32, 767–773. [Google Scholar]

- Shah, J.; Rasul Jan, M.; Mabood, F. Catalytic pyrolysis of waste Tire rubber into hydrocarbons via base catalysts. Iran. J. Chem. Chem. Eng. (IJCCE) 2008, 27, 103–109. [Google Scholar]

- Sui, H.; Wang, X.; Wu, Z.; Wang, S.; Chen, H. Influence of Temperature and Residence Time of Gas on Property of Waste Tire Pyrolysis. J. Biobased Mat. Bioenergy 2020, 14, 98–107. [Google Scholar] [CrossRef]

- Cunliffe, A.M.; Williams, P.T. Composition of oils derived from the batch pyrolysis of Tires. J. Anal. Appl. Pyrolysis 1998, 44, 131–152. [Google Scholar] [CrossRef]

- Murillo, R.; Aylón, E.; Navarro, M.V.; Callén, M.S.; Aranda, A.; Mastral, A.M. The application of thermal processes to valorise waste Tire. Fuel Process. Technol. 2006, 87, 143–147. [Google Scholar] [CrossRef]

- Qu, W.; Zhou, Q.; Wang, Y.Z.; Zhang, J.; Lan, W.W.; Wu, Y.H.; Yang, J.W.; Wang, D.Z. Pyrolysis of waste tire on ZSM-5 zeolite with enhanced catalytic activities. Polym. Degrad. Stab. 2006, 91, 2389–2395. [Google Scholar] [CrossRef]

- Murugan, S.; Ramaswamy, M.C.; Nagarajan, G. The use of Tire pyrolysis oil in diesel engines. Waste Manag. 2008, 28, 2743–2749. [Google Scholar] [CrossRef] [PubMed]

- Kar, Y. Catalytic pyrolysis of car tire waste using expanded perlite. Waste Manag. 2011, 31, 1772–1782. [Google Scholar] [CrossRef] [PubMed]

- Sathiskumar, C.; Karthikeyan, S. Recycling of waste tires and its energy storage application of by-products:A review. Sustain. Mater. Technol. 2019, 22, e00125. [Google Scholar] [CrossRef]

- Laresgoiti, M.F.; Caballero, B.M.; de Marco, I.; Torres, A.; Cabrero, M.A.; Chomón, M.J. Characterization of the liquid products obtained in Tire pyrolysis. J. Anal. Appl. Pyrolysis 2004, 71, 917–934. [Google Scholar] [CrossRef]

- Marco Rodriguez, I.; Laresgoiti, M.F.; Cabrero, M.A.; Torres, A.; Chomon, M.J.; Caballero, B. Pyrolysis of scrap Tires. Fuel Process. Technol. 2001, 72, 9–22. [Google Scholar] [CrossRef]

| S.No | Temp (°C) | % (L) ± S.D | % (S) ± S.D | % (G) ± S.D | T. Con ± S.D |

|---|---|---|---|---|---|

| 1 | 250 | 23.84 ± 1.38 | 58.73 ± 1.60 | 17.30 ± 1.34 | 99.88 ± 0.21 |

| 2 | 300 | 30.26 ± 0.14 | 42.10 ± 0.10 | 27.64 ± 0.04 | 100.0 ± 0.00 |

| 3 | 350 | 51.66 ± 0.56 | 30.66 ± 0.76 | 17.67 ± 0.50 | 99.60 ± 0.41 |

| S.No | W(g) | % (L) ± S.D | % (S) ± S.D | % (G) ± S.D | T.Con ± S.D |

|---|---|---|---|---|---|

| 1 | 0 | 8.46 ± 0.18 | 79.46 ± 0.42 | 12.06 ± 0.589 | 100 ± 0.00 |

| 2 | 0.5 | 45.89 ± 6.37 | 37.48 ± 3.07 | 16.64 ± 3.32 | 100 ± 0.00 |

| 3 | 1 | 51.66 ± 0.56 | 30.6 ± 0.76 | 17.67 ± 0.50 | 99.66 ± 0.41 |

| 4 | 1.5 | 58.82 ± 2.71 | 24.8 ± 1.29 | 16.31 ± 2.04 | 100 ± 0.000 |

| 5 | 2 | 62.77 ± 1.76 | 20.26 ± 0.64 | 16.96 ± 1.13 | 100 ± 0.000 |

| S.No | Time (min) | %(L) ± S.D | %(S) ± S.D | %(G) ± S.D | %T.Con ± S.D |

|---|---|---|---|---|---|

| 1 | 30 | 29.53 ± 0.44 | 40.66 ± 0.31 | 29.80 ± 0.14 | 100.0 ± 0.00 |

| 2 | 60 | 62.76 ± 1.75 | 20.26 ± 0.64 | 16.96 ± 1.13 | 99.99 ± 0.01 |

| 3 | 90 | 58.46 ± 1.58 | 21.20 ± 0.53 | 20.30 ± 2.09 | 99.99 ± 0.01 |

| 4 | 120 | 55.13 ± 0.69 | 21.06 ± 0.50 | 23.80 ± 1.17 | 100.0 ± 0.00 |

| Parameters | Light Oil Values | Heavy Oil Values |

|---|---|---|

| Density (g/mL) | 0.8432 | 0.9992 |

| Specific Gravity | 0.8432 | 0.9992 |

| Viscosity (centipoises) | 1.63 | 1.046 |

| API Gravity | 36.31 | 10.11 |

| Kinematic (mm2/sec) | 1.933 | 1.0468 |

| Aniline Point (°C) | 69 | 52 |

| Flash Point (°C) | 39 | 45 |

| Diesel Index | 56.71 | 12.69 |

| Kw Valve | 9.255 | 6.695 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhammad, R.; Ali, Y.; Messaddeq, Y.; ur Rashid, H.; Antonio Utrera Martines, M.; Naveed Umar, M.; Khan, S.W.; Riaz, A. Conditions Optimization and Physiochemical Analysis of Oil Obtained by Catalytic Pyrolysis of Scrap Tube Rubber Using MgO as Catalyst. Catalysts 2021, 11, 357. https://doi.org/10.3390/catal11030357

Muhammad R, Ali Y, Messaddeq Y, ur Rashid H, Antonio Utrera Martines M, Naveed Umar M, Khan SW, Riaz A. Conditions Optimization and Physiochemical Analysis of Oil Obtained by Catalytic Pyrolysis of Scrap Tube Rubber Using MgO as Catalyst. Catalysts. 2021; 11(3):357. https://doi.org/10.3390/catal11030357

Chicago/Turabian StyleMuhammad, Riaz, Yousaf Ali, Younes Messaddeq, Haroon ur Rashid, Marco Antonio Utrera Martines, Muhammad Naveed Umar, Sher Wali Khan, and Ali Riaz. 2021. "Conditions Optimization and Physiochemical Analysis of Oil Obtained by Catalytic Pyrolysis of Scrap Tube Rubber Using MgO as Catalyst" Catalysts 11, no. 3: 357. https://doi.org/10.3390/catal11030357

APA StyleMuhammad, R., Ali, Y., Messaddeq, Y., ur Rashid, H., Antonio Utrera Martines, M., Naveed Umar, M., Khan, S. W., & Riaz, A. (2021). Conditions Optimization and Physiochemical Analysis of Oil Obtained by Catalytic Pyrolysis of Scrap Tube Rubber Using MgO as Catalyst. Catalysts, 11(3), 357. https://doi.org/10.3390/catal11030357