Abstract

Chemical looping can be considered a technology platform, which refers to one common basic concept that can be used for various applications. Compared with a traditional catalytic process, the chemical looping concept allows fuels’ conversion and products’ separation without extra processes. In addition, the chemical looping technology has another major advantage: combinability, which enables the integration of different reactions into one process, leading to intensification. This review collects various important state-of-the-art examples, such as integration of chemical looping and catalytic processes. Hereby, we demonstrate that chemical looping can in principle be implemented for any catalytic reaction or at least assist in existing processes, provided that the targeted functional group is transferrable by means of suitable carriers.

1. Concept of Chemical Looping

Currently, there is significant effort to resign our dependence on fossil resources and to minimize the emission of carbon dioxide [1,2]. Clearly, this calls for new and improved catalytic processes and for catalytic technologies that focus on prevention rather than on remediation [3]. To be honest, at present, no efficient technologies exist that enable the use of CO2 as starting or raw material [4,5,6]. Such processes could however serve the dual purpose of producing value-added chemicals using CO2 as a C1 base chemical and reducing CO2 emissions. If this were to be carried out at a large scale, say megatons, it would definitely help with mitigating climate change effects by recycling part of the waste CO2, while creating new opportunities for the chemical industry. What to do? A possible solution can be provided by chemical looping [7,8,9,10,11,12,13,14,15,16], a promising technology of low emission, with applications in electricity or heat production, as well as in chemicals and fuels. This novel technology is rapidly evolving towards an established “clean combustion” due to the intrinsic, very efficient CO2 separation. However, the term chemical looping (CL) is not limited to combustion but can be used in a much broader sense to describe a specific type of reaction scheme. In chemical looping, a conventional catalytic reaction is split in sub-reactions, using intermediates that react and are regenerated in a cyclic way. Based on the type of intermediate, chemical looping processes can be classified in three groups:

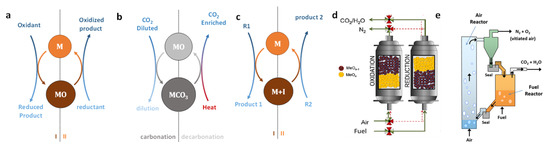

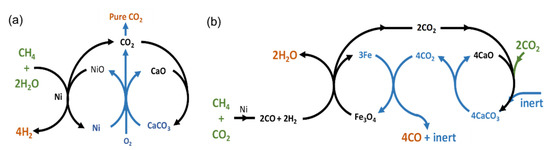

- Chemical looping of redox reactions [8,11,12,13,14,15]. Herein, a metal oxide (MO) acts as oxygen storage material (OSM) (M: reduced form), which takes up oxygen from the oxidant (e.g., H2O, O2 or CO2) and passes it on to the reductant (e.g., C, H2, CH4, plastic, etc.) (Figure 1a). By dividing the global reaction in two, the reduced and oxidized products can be separated by running the sub-reactions at two different times or places (temporal or spatial separation). Even solid fuels can be oxidized by appropriate chemical looping materials at a quite reasonable rate. However, the technology of chemical looping is not limited to oxidation only. On the contrary, combinations of oxygen carriers with other carrier materials can cover a very diverse field of reactions.

Figure 1. Scheme of some chemical looping processes for: (a) redox reactions and (b) carbon dioxide separation. In (a,b) reduction and decarbonation can equally be achieved by oxygen and carbon dioxide partial pressure decrease, e.g., through an inert gas feed. (c) Chemical looping transfer, where solid materials pass on surface reaction intermediates (carbon, -OH, S,) between separate reactions (R1 and R2). Chemical looping using (d) fixed-bed reactors and (e) two interconnected fluidized-bed reactors.

Figure 1. Scheme of some chemical looping processes for: (a) redox reactions and (b) carbon dioxide separation. In (a,b) reduction and decarbonation can equally be achieved by oxygen and carbon dioxide partial pressure decrease, e.g., through an inert gas feed. (c) Chemical looping transfer, where solid materials pass on surface reaction intermediates (carbon, -OH, S,) between separate reactions (R1 and R2). Chemical looping using (d) fixed-bed reactors and (e) two interconnected fluidized-bed reactors. - Chemical looping separation of carbon dioxide [8,15,16,17,18,19,20,21,22]. Chemical looping CO2 separation applies an (earth) alkali metal oxide (MO) as sorbent, to reversibly retain and set free CO2 (Figure 1b). The process of CO2 storing is called carbonation because it transforms MO into the corresponding carbonate MCO3. The opposite process takes place upon heating, thereby releasing the CO2 (decarbonation). By alternating MO carbonation and decarbonation, CO2 can be separated from exhaust gases or other dilute streams. The oxygen storage and CO2 sorbent materials of the processes 1 and 2 can easily be regenerated and hence reused in the next cycle [8,15,18].

- Transfer of surface reaction intermediates by chemical looping (carbon, -OH, S, etc.) between distinct reactions [23,24]. Materials in these chemical looping processes can carry reaction intermediates, which are different from oxygen or CO2 (Figure 1c). As intermediates form on the surface of the carrier in one step, they are subsequently used in the next. For example, Ni and Zn materials can be used to carry carbon and sulfur, respectively.

The installation of a chemical looping process either requires fixed-bed reactors (number of reactors ≥2) (Figure 1d) or alternatively, two interconnected fluidized-bed reactors (Figure 1e).

Considering that it can have various applications, starting from one common basic concept, chemical looping can be considered a true technology platform. Compared to a traditional catalytic process, the chemical looping concept allows to: (i) minimize exergy loss [8,25,26], (ii) intensify the targeted process by combining reaction and separation in a single step [27], (iii) apply H2O/CO2 as an oxidant (steam/dry reforming), which enables to produce pure H2 and CO without the need for downstream separation [8,28,29], (iv) feed lower grade or less pure feedstocks, (v) use cheap materials (CaO, FeOx) [13,30] and (vi) use fuel without the need for upstream desulfurization [23,31]. A quite notable feature is its ability to provide product separation in situ. Since separation is very energy-intensive, the product separation in chemical looping offers valuable prospects of energy savings and emission reductions.

Next to the above intrinsic qualities, chemical looping has another major advantage: combinability, which allows for integration of different reactions into one process, leading to intensification. Several of the above-mentioned processes are then combined into more advanced chemical looping schemes, such as, e.g., in chemical looping methane reforming enhanced by sorption, or in super-dry reforming, or they are coupled with catalytic reactions, such as, e.g., in catalyst-assisted chemical looping. This review collects various important state-of-the-art examples of such integrations of catalytic processes and chemical looping and the role of multifunctional materials therein.

2. Catalyst-Assisted Chemical Looping

The role that hydrogen plays nowadays in the chemical industry, in parallel to its contribution to energy supply, cannot be underestimated. Currently, hydrogen is mainly used for ammonia production (62%), refining industry (24%), methanol production (8%), metallurgy, in manufacture of high-quality electronic components and in many more applications. There is no doubt that the demand for hydrogen will further rise, both in existing industries and in new technologies like fuel cells [32,33]. A typical process to produce hydrogen comprises methane steam reforming, then water gas shift and a final pressure swing adsorption for purification [34,35]. One or two separate reactors are required for the water gas shift reaction: the high-temperature shift reactor with an iron/chrome catalyst, operating at 350–500 °C. Hereafter, a CO concentration of around 4 mol% on dry basis is present in the outlet stream. To reach a lower CO concentration, a second reactor working at lower temperature is needed. Finally, a preferential oxidation reactor (PROX) or pressure swing adsorption reduces the CO concentration down to the ppm level. The need for such a reactor train means, however, a significant decrease in full process efficiency.

To shorten this conventional production chain, one can consider a chemical looping concept for methane reforming. Such process generates high-purity hydrogen (with carbon oxides at the ppm level) starting from hydrocarbons. Although this is still a two-step process, only a single reactor is required without any post-processing, meaning significant economic profit. Central to this technology are cheap and abundant iron oxide materials, which are to be reduced/re-oxidized periodically, a process in which they transfer oxygen. In the first step, iron oxide gets reduced by methane (or renewable biogas), while the second stage brings the reduced iron back to an oxidized state by feeding steam as an oxidant. Together with the material re-oxidation, hydrogen is being produced.

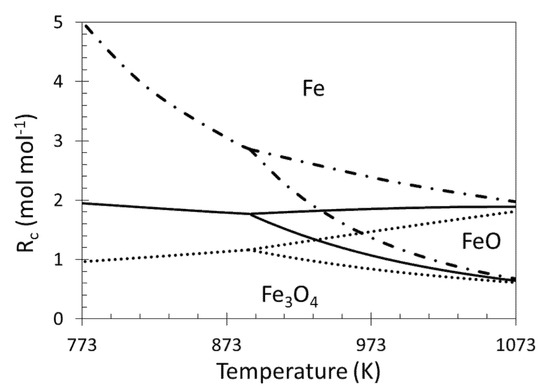

Obviously, the deeper the oxygen storage material can be reduced, the more hydrogen can be generated upon re-oxidation. In the above process description, reduction of iron oxide, in particular Fe3O4, by methane is slow, so that it limits the attainable degree of reduction [36]. If biogas, a mixture of carbon dioxide and methane, is used as a source of methane, iron oxide reduction is drastically decreased, because it is opposed by carbon dioxide acting as an oxidant [37,38], see Figure 2. Actually, this effect is induced by both feed and product CO2, counteracting the iron oxide reduction by methane. To circumvent this drawback, the oxygen storage material bed can be foreseen of a Ni-based catalyst in addition to the iron oxide, either in layers or as physical mixture [39]. The Ni-based catalyst will convert the CH4 and CO2 mixture to syngas, i.e., H2 + CO, by dry reforming. The latter gases ensure a deeper reduction of iron oxide than with CH4. The dry reforming of methane is recently gaining interest as it converts two greenhouse gases as a carbon source. Not only does it produce syngas, which compared to methane has a higher reduction potential, but it also consumes CO2 from the feed, allowing for deeper reduction of iron oxide, and as a result, for a larger amount of H2 to be produced in the second re-oxidation step. This is an example of synergy between catalysis over Ni and chemical looping using Fe3O4, in a so-called “catalyst-assisted chemical looping process”.

Figure 2.

Phase diagram for the equilibrium between iron and its oxides (Fe3O4, FeO and Fe) as a function of temperature and feed gas reduction capacity: −∙−H2/H2O; − H2/CO/H2O/CO2 (C and H2 equimolar amount, representing a feed of CH4 + CO2); ∙∙∙∙∙ CO/CO2 [38].

Chemical looping allows to easily switch between desired products. If in the re-oxidation step steam is replaced by CO2 as an oxidizing agent, the process turns into chemical looping dry reforming (CLDR). Compared to the conventional form of catalytic dry reforming (DR), CLDR solves some challenges and brings advantages:

- First, removal of deposited carbon: this important issue of DR is solved as carbon will react with CO2 in every regeneration step of the looping material.

- Second, the use of CO2 as an oxidant for material regeneration in the re-oxidation allows to convert more CO2 than in the conventional reaction, namely three times more in CLDR than in DR [40]. As such, the target of chemical looping dry reforming is no longer a high syngas yield as for DR, but rather optimal activation and utilization of CO2. A proof of principle for the CLDR process was described by Najera et al. [40]. Based on thermodynamic calculations to select suitable oxygen storage materials, they synthesized and characterized carriers with nanostructure that showed high activity and stability, showing the potential of the CLDR concept. In addition, reactor modelling evidenced the practical feasibility of the process [40,41].

The entire concept of the CLDR process stands or falls with the selection of a suitable storage material. Herein, cost, stability and above all reactivity are of the essence. Based on thermodynamic data for reduction and re-oxidation, a wide range of metals/metal oxides were considered [40,42]. While some of these, like Mo, Cr, Zn, Co, Nb and Ce, give reasonable CO2 conversion capacity, the highest oxygen storage capacity from CO2 is provided by Fe, namely 0.7 mol CO2/molFe, at temperatures > 600 °C. This makes CO2 conversion to CO by chemical looping over an Fe-containing material for oxygen storage a most promising technology. Nevertheless, issues still remain with respect to the process economics, in particular, how to keep up the activity during multiple cycles of reduction/oxidation? Several factors play a role in this. For one, the surface area of FeO influences the reactivity in CO2 splitting, as found by Loutzenhiser et al. [43]. However, high surface area iron oxides are more susceptible for sintering, an irreversible process, so they rapidly loose activity [44]. The iron oxide lost more than 70% of the initial activity during the first 8 redox cycles. Hence, the viability of the CO2 conversion process by CLDR, compared to other technologies, can only benefit from iron oxide sintering control during redox cycling to maintain its reactivity. The further optimization of the process thus relies on fundamental studies on the impact of structural and compositional design of the metal oxide and/or catalyst components at the nanoparticle level, as well as of the support on the overall performance.

Catalysts based on Ni are among the most investigated, even given their deactivation by carbon accumulation [45]. They make active and stable catalysts for dry reforming of methane, especially when they are well dispersed. Support materials can help to disperse Ni, and if they have redox properties, like solid solutions or mixed oxides based on ceria, they can also take care of carbon removal. Pure CeO2 for instance promotes Ni dispersion, while its redox couple Ce4+/Ce3+ easily gasifies carbon accumulated at the surface by supplying active oxygen. A Ni–CeO2/mineral clay catalyst, studied by Daza et al. [46], showed enhanced activity and limited coke formation in methane dry reforming, ascribed to the better dispersion of Ni and improved CO2 adsorption. Also, Potdar et al. [47] reported about a Ni–Ce catalyst with high surface area showing stable activity and resistance to coke formation in reforming because of high oxygen mobility. In a similar redox support approach, Ni has been modified with Fe, which also has high redox capacity, just like the Ce species [45]. In this type of design, the support carries both the catalytic and oxygen storage component, making it a multifunctional material. The different functions work together in both steps of the chemical looping dry reforming process: upon reduction, the mixed feed of CH4 + CO2 is converted over Ni to syngas, which reduces both Fe2O3 and CeO2, thereby producing CO2 and H2O. Ni ensures deeper reduction of the oxide materials. In the re-oxidation stage, the reduced material is regenerated by CO2 to produce CO. The benefit of combining catalyst and oxygen storage functions was obvious as the CO yield turned out to be 10-fold of the one for Fe2O3–CeO2 without Ni catalyst [48].

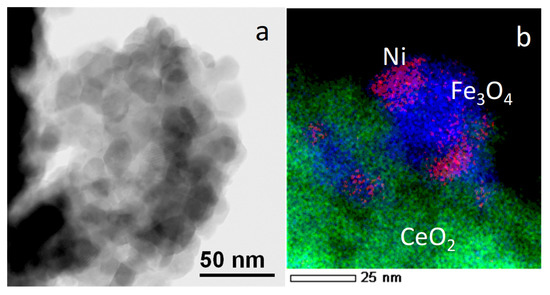

Figure 3 shows the multifunctional 5%Ni/Fe2O3–CeO2 sample in transmission electron microscopy (TEM). The high-resolution image displays crystallites with a size of ∼17 nm, all bearing a similar morphology (Figure 3a). Energy-dispersive X-ray spectroscopy (EDX)-STEM (Scanning Transmission Electron Microscopy) mapping provided the elemental distribution in the material, showing that Ni (red) prefers to be close to or on the Fe2O3 (blue) particles (Figure 3b).

Figure 3.

Transmission electron microscopy micrograph of 5%Ni/Fe2O3–CeO2 (a) and (b) higher magnification to show the energy-dispersive X-ray spectroscopy (EDX) element mappings of Fe (blue), Ce (green) and Ni (red), close to each other [48].

Together with DR, side reactions can occur depending on the operating temperature and partial pressure of the reactants. These comprise CH4 decomposition (Equation (1)) as well as the Boudouard reaction (Equation (2)), where CO transforms into surface carbon and CO2:

CH4 → C(s) + 2H2

2CO ↔ C(s) + CO2

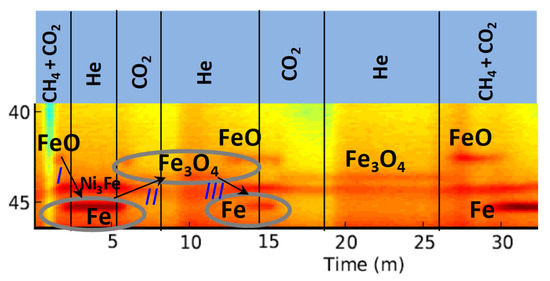

Re-oxidizing the reduced Ni/Fe2O3–CeO2 with CO2, while applying in situ X-ray diffraction (XRD), yields interesting details. A set of patterns was recorded during a few oxidation/inert/dry reforming cycles at 873 K (Figure 4). Reaction temperature was reached with a high heating rate up to 873 K, temperature which was then maintained. Depending on the gas environment present throughout the chemical looping experiment, He, CO2 or CO2 + CH4, the background intensity of the whole pattern varied because of differences in X-ray scattering. The first reduction treatment under CH4 + CO2 forms Fe with main diffraction at 45° and the Ni3Fe alloy after 100 s. Upon introduction of CO2 into the reactor after 5 min, Fe is converted to FeO and further to Fe3O4. At the same time, the Ni3Fe alloy phase loses some intensity, and formation of a small amount of NiFe2O4 spinel cannot be excluded. Diffractions for this spinel would yield shoulders to the Fe3O4 diffractions, but for this material, they likely remain undetected as the Ni loading in the sample is very small. The Fe3O4 phase appeared stable under CO2 and also shortly thereafter, already under He. However, while still under inert flow, the Fe3O4 peaks started fading and changed back into FeO and Fe diffractions as if again reduced. Simultaneously, the alloy phase diffraction became more intense. A second CO2 period reconverted FeO and Fe to Fe3O4, which then persisted throughout the entire 7 min of He flow. At the origin of these observations is carbon, formed during the reduction step and accumulated on the catalyst surface.

Figure 4.

In situ XRD patterns collected from Ni/Fe2O3–CeO2 during reduction/oxidation cycles at 873 K. Transitions are indicated by arrows: FeO reduction (I) and re-oxidation (II), disappearing Fe3O4 diffraction, re-emergence of first FeO and then Fe in He flow after CO2 re-oxidation (III). Gas environments are indicated above the two-dimensional (2D) patterns [48].

The in situ XRD interpretation is as follows: When introducing pure CO2 for the first time after reduction, it re-oxidizes iron and CeO2−δ, thereby replenishing their lattice oxygen. The latter then oxidizes the surface carbon. In principle, carbon could also be oxidized directly by CO2 according to the Boudouard reaction. However, this cycling in situ XRD experiment proves that oxidation of carbon deposits by lattice oxygen equally occurs, since even under inert flow, iron oxide is again reduced (Figure 4, step III). Apparently, the first CO2 pulse was not sufficiently long to both re-oxidize the material and remove all carbon from the surface. As a result, after the CO2 pulse, the remaining C gets removed with the help of lattice oxygen from the Fe2O3–CeO2 material, leading to reduction anew even without a reductive atmosphere. The subsequent longer CO2 pulse removes all carbon so that Fe is permanently oxidized back to Fe3O4.

The duration of the catalytic activity and hence the extent of carbon formation on the surface depend on the overall oxygen capacity of the material. Usually, coke formed on the catalyst surface is responsible for fouling of the active sites, thereby deactivating the nickel catalyst particles. In order to counter this, the material requires periodic regeneration, which is exactly what the concept of chemical looping is providing, since it comprises cycles of reduction and re-oxidation steps. The refill of the OSM upon re-oxidation is conveniently accompanied by surface carbon removal, which in parallel yields more CO than the theoretical value which stems from complete oxidation of Fe to Fe3O4.

Another example of a catalyst-assisted chemical looping process is steam reforming of methane (CLSRM), which is capable of generating both syngas and hydrogen in its half-cycles [49]. Whereas in the previous example, Ni was taking up the catalyst function, here, Fe2O3 and/or CeO2 fulfil this role. The used Fe@Ce material with core-shell architecture is key to this process. Using a ceria shell enclosing an iron oxide core as an oxygen carrier combines advantages of ceria and iron oxide: high ion conductivity for the former and high oxygen storage capacity for the latter. The activity of Fe@Ce was assessed in fixed-bed tests and compared to a uniform mix of Fe–Ce as a reference. Compared to the mixture, the core-shell Fe@Ce material yielded more syngas and hydrogen, and better selectivity for CO and methane conversion in the reduction process. The syngas and hydrogen yield of Fe@Ce was an approximately constant value of 16 and 6 mmol × g−1 compared to 14 and 5 mmol × g−1 for the CeO2 and Fe2O3 mixture. This indicates that the core-shell structure can selectively provide oxygen from the CeO2 shell, which eases the transport of oxygen ions between the core and the shell. Moreover, the selectivity to CO and the CH4 conversion for the core-shell oxygen carrier further improved for an increasing number of cycles, likely due to the enhancement of the oxygen ion conduction and resulting from the increasing contribution of a CeFeO3 phase. The carbon deposition for Fe@Ce amounted on average to only 29% of that for Fe–Ce, leading to higher-quality syngas with a H2/CO ratio close to 2 and higher-purity H2. The high resistance against C accumulation was ascribed to the ceria shell, having excellent oxygen ion conductivity. The latter ensures rapid migration and replenishment of oxygen ions at the surface. In addition, iron metal sites, which activate methane, are scarce on the surface, due to the CeO2 shell, leading to higher carbon resistance.

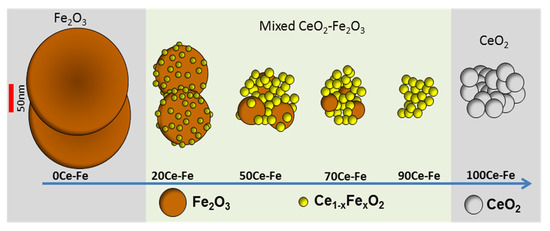

CeO2 itself is quite active towards methane oxidation through its lattice oxygen, and it has a reasonable capacity for H2O or CO2 re-oxidation [50,51]. Oxygen storage in and release from the bulk fluorite lattice are facilitated by its redox couple Ce4+ and Ce3+. In combination with iron oxide, CeO2 can modify and stabilize the structure, making it very suited as a promoter of iron oxide in a chemical looping process. When combining CeO2 with MeOx (Me = Mn, Fe, or Cu), a mixed oxide was formed, exhibiting higher reducibility than pure CeO2 [52,53]. When CeO2 interacts with Fe2O3, this also leads to enhanced reducibility of Fe2O3 [54]. Depending on the composition, part of the interaction is established through formation of a mixed oxide, wherein the ceria structure takes up a limited amount of Fe3+ cations. The evolution of the Fe2O3–CeO2 structure as a function of composition is shown in Figure 5 [53].

Figure 5.

Scheme of a series of mixed CeO2–Fe2O3 samples, composed on the basis of inductively coupled plasma (ICP) composition, XRD, STEM, EDX and EELS analysis [53].

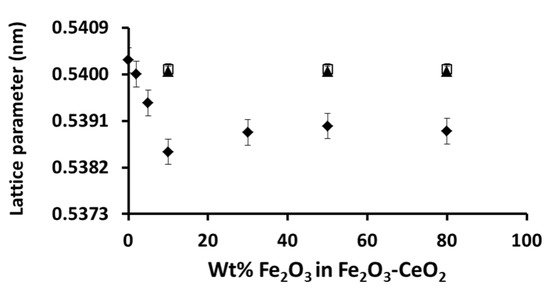

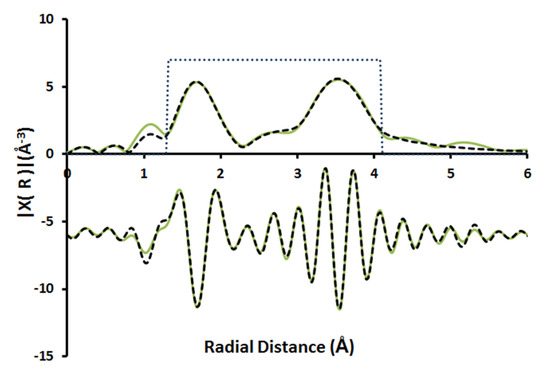

The question is how much Fe can actually be incorporated into ceria for different compound ratios? The CeO2 lattice parameter for the entire range of mixed oxide materials (Figure 6) levels off beyond 10 wt% Fe2O3–CeO2 [54]. In addition, the XRD pattern for 10 wt% Fe2O3–CeO2 shows no Fe2O3 contribution, meaning no separate crystalline phase is present, unless it is nanosized. In order to assess this maximal Fe amount in the lattice, the Ce-K edge Extended X-Ray Absorption Fine Structure (EXAFS) signal for 10 wt% Fe2O3–CeO2 was recorded and fitted. Two models were compared for the fit: one for the pure CeO2 fluorite structure and another one with a Fe-doped CeO2 structure or solid solution, denoted as Ce1−xFexO2−x, where x denotes the incorporated amount of Fe, taken as a parameter in the fit. A value of x = 0.21 ± 0.08 yielded the best correspondence (Figure 7), meaning that 21% of the Ce atoms in CeO2 are substituted by Fe. For 10 wt% Fe2O3–CeO2, this number indicates that 85% of the Fe forms a solid solution with ceria as Ce1−xFexO2−x. As the ceria lattice parameter does not change beyond 10 wt% Fe2O3, it can be safely assumed that, e.g., in 80 wt% Fe2O3–CeO2, the same 21 mol% of Ce is exchanged for Fe, which of course represents only a small fraction of all Fe in 80 wt% Fe2O3–CeO2.

Figure 6.

Unit cell parameters for ceria in a series of x wt% Fe2O3–CeO2 with variable Fe2O3 loading (diamond) as prepared, (triangle) CO2-reoxidation and (square) O2-reoxidation states. Error bars represent standard deviation (68% confidence interval) [54].

Figure 7.

Fourier-transformed k2-weighted Ce-K edge Extended X-Ray Absorption Fine Structure (EXAFS) spectrum for 10 wt% Fe2O3–CeO2 and modelling fit (dashed line), with an Fe incorporated CeO2 model Ce1−xFexO2−x, wherein x = 0.21. Upper part: Fourier transforms (FT) modulus, lower part: imaginary Im[FT[k2 χ(R)])]. Dotted rectangle: window fitting range. No phase correction was used. (-) EXAFS signal of 10 wt% Fe2O3–CeO2, (- - - -) fit and (∙∙∙∙) fitting window [54].

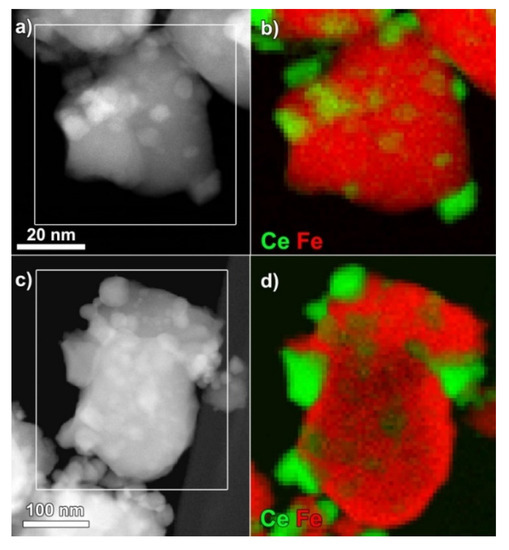

To identify the structural properties of Fe-rich material at the far end of the Fe2O3–CeO2 mixing range, 80 wt% Fe2O3–CeO2 was also investigated. Figure 8a shows a high angle annular dark field scanning TEM (HAADF-STEM) image for 80 wt% Fe2O3–CeO2, in which two types of particles are discerned: small ones, decorating larger ones. According to Electron energy loss spectroscopy (EELS) maps, the former are CeO2 (Figure 8b), while the latter pertain to Fe2O3 (~50 nm). After 100 cycles of chemical looping, the particles are strongly agglomerated, and show considerably larger size (Figure 8c). Nevertheless, even in this sintered condition, the decorative configuration of ceria surrounding iron oxide persists (Figure 8d).

Figure 8.

(a) Image of calcined 80 wt% Fe2O3–CeO2 via high angle annular dark field scanning TEM (HAADF -STEM), (b) corresponding EELS map for Fe and Ce, (c) image for cycled 80 wt% Fe2O3-CeO2 (100 H2–CO2 redox cycles) and (d) corresponding EELS map for Fe and Ce [54].

For the above-mentioned Fe2O3–CeO2 materials, the crystalline phases, sizes and morphological changes, before and after cycled operation (as in chemical looping), were determined using (S)TEM, XAS (X-ray absorption spectroscopy) and XRD. Next to sintering, two other types of deactivation were identified: first, Fe can get extracted from the Ce1−xFexO2 solid solution, and second, a perovskite (CeFeO3) can be formed. The extraction of Fe from the solid solution can proceed quite fast, leading to less reducibility for CeO2. However, the extraction sets free more Fe, which in turn can add to the overall oxygen storage capacity. For the latter, perovskite formation is only negative, as CeFeO3 is not reducible below 800 °C. The slowest deactivation process is undoubtedly sintering, occurring throughout operation. Because it steers crystallite sizes to grow, longer diffusion times are induced for oxygen to move from the bulk to the surface. So, a given reduction time will gradually lead to a lower degree of reduction reached, hence less CO yield upon re-oxidation.

Which of these deactivation types dominates is dependent on the material composition. Iron-rich samples are mostly prone to sintering as a predominant mechanism, while Fe extraction is less important based on composition. Similarly, there could be some perovskite forming, but its contribution to the overall composition will not affect the productivity. For ceria-rich samples, all three types of deactivation need to be taken into account. Looking at the CO yield, the best performing material for extended use in chemical looping is 80 wt% Fe2O3–CeO2. In this sample, sintering as a main deactivation mechanism is controlled by decorating Fe2O3 with CeO2 nanoparticles.

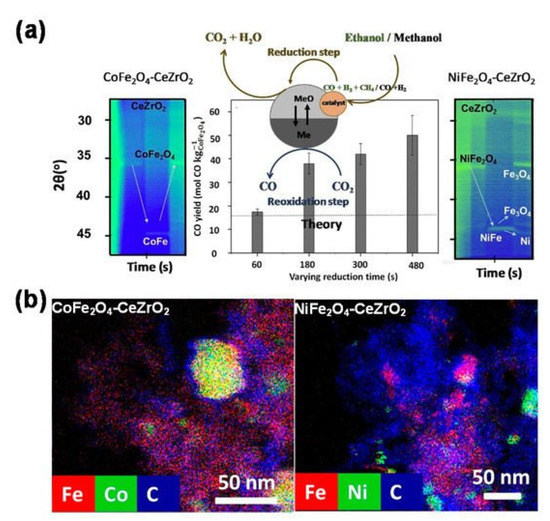

When looking for materials that combine a catalytic (A) with an oxygen storage function (Fe), spinel ferrites with composition AFe2O4 also come into the picture. Unlike modifying a Fe-based material by adding a catalyst, ferrite-based materials are prepared via co-precipitation of all elements. Among a series of chemical looping experiments with Me-ferrites (Me = Ni, Co, Cu, Mn, Zn), interesting CH4 dry reforming activity and redox stability were found for NiFe2O4 and CoFe2O4. As biomass conversion increases the availability of alcohols as possible feedstock, these two bifunctional materials were then tested for chemical looping alcohol reforming with ethanol and methanol into syngas. NiFe2O4–CeZrO2 and CoFe2O4–CeZrO2 were studied by Dharanipragada et al. [55] as bifunctional materials for catalyst-assisted chemical looping dry reforming (CCDR) with either a pure methanol feed or a mixed ethanol-water feed (1:1 molar ratio). The alcohols are fed in the chemical looping reduction step, where they are converted over the catalyst to CO and H2, aside from some CH4 in case water is co-fed. These gases reduce the oxygen storage component of the material, so that in the subsequent re-oxidation step, its regeneration with CO2 produces CO (Figure 9).

Figure 9.

Bifunctional Co- and Ni-ferrites modified with CeZrO2 for chemical looping dry reforming with alcohols as feed: (a) Transformation of solid and gaseous phases, (b) elemental maps of Co, Ni, Fe and C in 20 wt% CoFe2O4-CeZrO2 and NiFe2O4-CeZrO2 after methanol redox cycles [55].

Material with low CoFe2O4 content (20 wt%) presented good redox activity and stability, while the 80 wt% CoFe2O4-loaded material deactivated, due to Co and Fe3O4 segregation from the ferrite. As for the Ni-ferrite-CeZrO2 materials, these were all prone to sintering and phase segregation, which turned out to be irreversible. Carbon formation was observed in the methanol-based CCDR process for both types of ferrite materials, but far more over the Ni-ferrite (Figure 9b), demonstrating a significantly lower carbon resistance. As mentioned before, the presence of carbon deposits can enhance the CO yield upon re-oxidation with CO2, raising the yield above the theoretical value, as was verified experimentally (Figure 9a).

Materials, having dual functions of catalyst and oxygen storage, perform well in catalyst-assisted chemical looping. Based on the latter behavior, autothermal catalyst-assisted chemical looping with the same materials has been advanced as a novel strategy for CO production from CH4 and CO2 [56]. The process is built on two approaches, each with a dedicated material: 1/Fe3O4 for CO production by chemical looping and 2/a Ni-based catalyst for autothermal catalytic conversion of CH4, CO2 and O2 to syngas. The design of the process allows to convert three times as much CO2 than is produced in the reduction. By feeding CH4, CO2 and, in addition, some O2, simultaneously to the chemical looping reactor, the endothermicity of dry reforming is overcome. According to thermodynamic analysis, a molar ratio of CH4/O2 equal to 0.3 or 0.5 allows to achieve autothermal operation at 873 and 1023 K, respectively. If the ratio of reducing (CO + H2) to oxidizing (H2O + CO2) gases in the feed during the reduction is above 2 and the temperature over 873 K, a high degree of Fe3O4 reduction can be obtained. To prove this concept, a multifunctional 9 wt% NiO-16 wt% Fe2O3/MgAl2O4 was synthesized to test the process. In the reducing step, CH4 + CO2 + O2 (molar ratio of 1:1:0.5) is converted by the NiO catalyst into a CO and H2 mixture, which reduces Fe3O4, producing CO2 and H2O. At the same time, reduction induces interaction between Ni with Fe so that a Ni-Fe alloy is formed. Subsequent CO2 feeding leads to decomposition of the alloy into Ni and Fe3O4, in parallel to CO production by re-oxidation of reduced iron oxide. Although deactivation occurs for all materials during extended operation at 1023 K, principally due to sintering according to TEM imaging, the latter seems to be limited mainly to the first few cycles, after which operation stabilizes [56].

Recently, calcium ferrite Ca2Fe2O5 has been explored as an oxygen carrier for chemical looping and this material can reportedly provide a higher steam conversion to hydrogen than Fe2O3 [57,58,59,60]. However, the system has limited reactivity with CH4. High-purity H2 can however be produced from CH4 using approaches based on catalyst-assisted chemical looping. Hosseini et al. demonstrated that doping calcium ferrite with Ni or Cu significantly enhances their redox performance [61]. It was found that adding Cu to Ca2Fe2O5 increases the reducibility with CH4 and yields stable H2 production. They also showed that copper has high incorporation mobility in the material during air re-oxidation, which provides an effective way to control the Cu nanoparticles’ dispersion. Such exsolution and re-incorporation of copper is key to maintain the high reactivity. In contrast to Cu, Ni-doped calcium ferrite did not provide stability in H2 production. In situ XRD and STEM-EDS identified that during material reduction, a Ni-Fe alloy formed, which may lead to gradual sintering of Ni particles [61].

The same strategy of reversible exsolution to control dispersion of metallic nanoparticles was used by Carrillo et al. [62,63,64]. La0.6Sr0.4Cr0.8Co0.2O3 (LSCC) was selected as an oxygen carrier for CO2 conversion into CO. The perovskite was promoted with Co nanoparticles for the methane reforming reaction. The 30 nm Co nanoparticles exhibited microstructural stability and uniform dispersion during 28 redox cycles at 900 °C.

Ethylene makes an important building block and valuable commodity chemical for many compounds such as oxygenates, polymers and other chemical intermediates. It is mainly produced by steam cracking, for which ethane oxidative dehydrogenation (ODH) could be an alternative [65,66,67]. Herein, hydrogen is oxidized with oxygen, so that the ethane conversion equilibrium is shifted, and the overall reaction becomes exothermic. However, ethane ODH faces some practical challenges: (i) potential safety hazards arise when cofeeding oxygen and ethane, requiring dilution with inert gas, (ii) separating air for oxygen generation is capital- and energy-intensive and (iii) ethylene selectivity is reported to be limited at high single-pass ethane conversions.

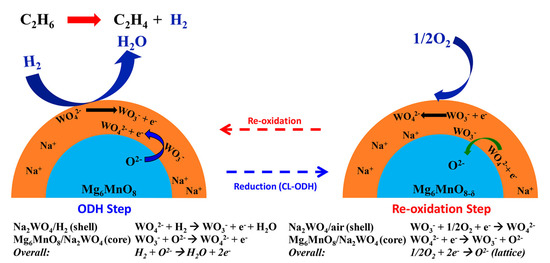

To overcome these challenges, it was proposed by Gao et al. [68] to use oxidative dehydrogenation in a chemical looping manner (CL-ODH) (see Figure 10) [69]. In this concept, CL-ODH resembles chemical looping redox processes, like oxygen uncoupling (CLOU) [70] and methane partial oxidation [71]. In CL-ODH, oxygen is delivered from the lattice of a redox catalyst to convert ethane to ethylene and water. The ODH drawbacks are then circumvented as air separation is not required, which removes the safety issues about mixing ethane with oxygen. Based on process simulations, the CL-ODH process leads to a reduction of CO2 emissions by up to 82% when compared to steam cracking, and less energy consumption. Mg6MnO8 promoted with sodium tungstate (Na2WO4) was shown to be an effective redox catalyst for CL-ODH. In order to achieve high ethylene selectivity, both Na and W were found to be necessary to form Na2WO4. With a Na:W ratio lower than 2:1, additional mixed tungsten oxide phases are formed, which leads to less ethylene selectivity.

Figure 10.

Scheme for oxidative dehydrogenation in a chemical looping manner of ethane over Mg6MnO8 redox catalysts, promoted with NaW (In each step, reduction/oxidation of Mn cations in the Mg6MnO8 core balance the electrons) [69].

An interesting process for methane conversion from stranded natural gas to valuable liquid aromatic compounds is provided by dehydroaromatization (DHA), a reaction which is limited by thermodynamics. Brady et al. [72] have presented a way to overcome this limitation by placing DHA in a chemical looping frame to enable reactive separation of H2 from the DHA products. They proposed a four-step cycle to achieve this: DHA over a Mo/H-ZSM-5 catalyst, removal of H2, Fe3O4/FeO redox pair regeneration and water removal on H-ZSM-5. Each of these steps was evaluated individually, to assess the process feasibility, and the results indicate that the proposed process allows to achieve an aromatics yield of over 40%.

It is still a challenge to control selectivity in partial oxidation of methane by lattice oxygen of metal oxides. Zvang et al. present the finding that distortion of FeO6 octahedra in La1−xCexFeO3 perovskites positively affects the surface oxygen exchange capability and mobility of bulk oxygen [73]. The distortion of the FeO6 octahedra can be promoted due to the difference between Ce–O and La–O bond lengths. The authors achieve a syngas productivity during the reduction cycle of 3 to up to 8 times higher than with LaFeO3 and CeFeO3. At the same time, a CO2 conversion of 92% was achieved during the re-oxidation cycle. Adjusting the octahedral distortion in these perovskites hence provides a means to modulate the active lattice oxygen, which affects their performance in chemical looping processes.

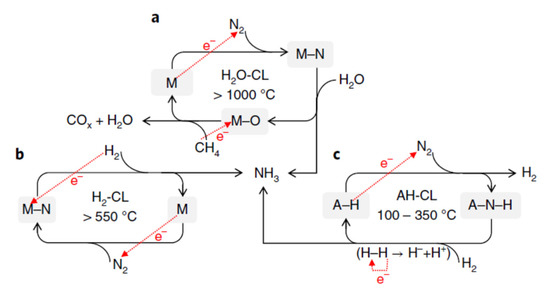

Catalyst-assisted chemical looping processes can also aim at N2 activation and conversion, wherein hydrogen species play a role, as highlighted in a recent publication [74]. Herein, ammonia is advanced as a promising “carbon-free” energy carrier, but its current industrial synthesis requires severe conditions. If it could be produced at lower temperatures and pressures, this would drastically increase its prospects as an energy carrier and chemical alike. Both alkali and alkaline earth metal imides can operate as nitrogen carriers and produce ammonia via a chemical looping process, operating at atmospheric pressure and 100 °C, according to Gao et al. [74]. The first step fixes nitrogen into imides by reduction with alkali or alkaline earth metal hydrides. The second step hydrogenates the imides to produce NH3, thereby regenerating the metal hydrides. Throughout this process, the hydrogen oxidation state switches between −1 (hydride), 0 (H2) and +1 (imide and NH3) (see Figure 11). This scheme for NH3 production is mediated by BaNH and catalyzed by Ni, making it another example of a catalyst-assisted chemical looping process.

Figure 11.

Ammonia synthesis by catalyst-assisted chemical looping: (a) H2O-CL process, (b) H2-CL process, (c) AH-CL process. Metal and the corresponding metal nitride and oxide are represented by M, M-N and M-O, respectively. A-H and A-N-H stand for alkali or alkaline earth metal hydride and imide, respectively [74].

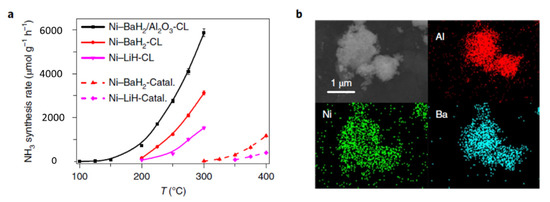

Figure 12 presents the rates of ammonia production in chemical looping and catalyst-assisted processes using Ni. The loop with neat LiH/Li2NH as a mediator produces ammonia at a rate of ~100 μmol NH3 g−1LiH h−1 at 350 °C, while the 50% Ni–LiH sample achieves 1530 μmol NH3 g−1LiH h−1 at 300 °C. At that same temperature, neat BaH2/BaNH used in a loop produces 200 μmol NH3 g−1BaH2 h−1, though a much higher value of 3120 μmol NH3 g−1BaH2 h−1 is accomplished by 50% Ni–BaH2. Even 5% Ni addition can boost the NH3 production rate from BaH2-CL six-fold.

Figure 12.

Ni-BaH2 and Ni-LiH performance in NH3 production. (a) Temperature-dependent production rates in chemical looping (CL) and thermo-catalytic processes (Catal). (b) Microscope images and elemental maps of spent Ni-BaH2/Al2O3 [74].

3. Combined Chemical Looping

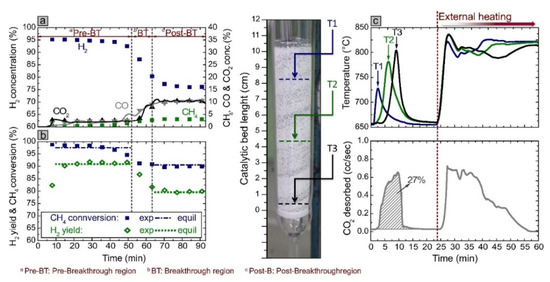

Integrating several processes into one overall scheme of combined chemical looping (CCL) has multiple advantages. As an example, sorption-enhanced steam reforming (SESR), advanced by Lyon and Cole [75], lowers the economic and environmental barriers that accompany conventional reforming, while offering high efficiency, autothermal operation, together with inherent separation of pure H2 and CO2 (Figure 13a) [19,76,77]. The exothermicity of the oxygen carrier re-oxidation supplies energy for the endothermic reaction of sorbent regeneration, so that heat requirements are minimal. According to thermodynamic calculations, a decrease of up to 55% in energy demand is possible compared to the conventional steam reforming process [78]. Production of high-purity H2 and pure CO2 as by-products, with a high degree of autothermicity, was equally demonstrated by Lemonidou’s group. They mixed NiO/ZrO2 and CaO/CaZrO3 with NiO/CaO = 0.5 in a fixed-bed reactor [79,80,81] to run the process, which combines catalytic steam reforming, calcium chemical looping and chemical looping combustion. Figure 14 displays the reformate gas composition on dry basis during the reduction/reforming step. The H2 yield during combined chemical looping steam reforming lies very close to equilibrium. As more and more product CO2 is taken up by the sorbent, the more the concentrations of CO, CO2 and CH4 start to increase at the expense of H2 production (BT: breakthrough). When the sorbent is completely saturated (Post-BT: post-breakthrough), the capture of CO2 stops, and the outlet gas composition equals the one for conventional steam reforming at these conditions. This is the time for switching the gas feed to air in order to re-oxidize Ni and release the CO2 from the sorbent. The temperature profile and CO2 release during this re-oxidation-calcination stage are depicted in Figure 14c, along with a picture where the measuring positions of temperature are marked. No additional heating was applied after introduction of air, as there was sufficient heat stemming from Ni re-oxidation to raise the temperature of the reactor from 650 to ∼800 °C (Figure 14c). The latter then facilitated the calcination of the sorbent, as evidenced by the CO2 production. When the Ni oxidation comes to an end, the reactor temperature starts to drop with a concomitant decline in the CO2 formation rate. In a practical application, so the authors remark, the heat from Ni re-oxidation could even be better utilized if materials were to be moved to another regeneration reactor, where they could be kept at high temperature.

Figure 13.

Schemes of combined chemical looping processes: (a) Sorption-enhanced chemical looping reforming of CH4, black arrows: NiO reduction, H2 production by CH4 reforming and water gas shift over Ni catalyst, carbonation, blue arrows: Ni oxidation, decarbonation. (b) Super-dry chemical looping reforming of CH4, black arrows: CO2 reforming over Ni catalyst, FeOx reduction, carbonation, blue arrows: decarbonation, CO production by Fe oxidation.

Figure 14.

(a) Outlet concentrations, and (b) yield of H2 and CH4 conversion versus time during reduction-steam reforming-carbonation. (c) CO2 formation and temperature profiles versus time during re-oxidation/calcination (reduction-reforming-carbonation: T = 650 °C, Steam/Carbon ratio = 3, NiO/CaO molar ratio = 0.5, GHSV = 250 h−1; T during regeneration: 650 → 800 °C, air flow, GHSV = 430 h−1) [80].

As mentioned above, the catalytic reaction of CH4 with CO2 or methane dry reforming (DRM) also benefits from the chemical looping concept. Recently, it was intensified in super-dry reforming (SDR), a process designed for intensified CO production from CH4 and CO2 [38,82]. Three different materials are needed for this process, each with a particular function: CaO/Al2O3 as a CO2 sorbent, Fe2O3/MgAl2O4 to transfer oxygen and Ni/MgAl2O4 as a CH4 reforming catalyst, complemented with CH4 and CO2 in a 1:3 ratio (Figure 13b). Here, the exothermicity of CaCO3 formation is coupled to two endothermic processes, CH4 reforming and Fe3O4 reduction, whereby the energy requirement is looped. The isothermal connection between these three processes results in higher CO production than with conventional dry reforming.

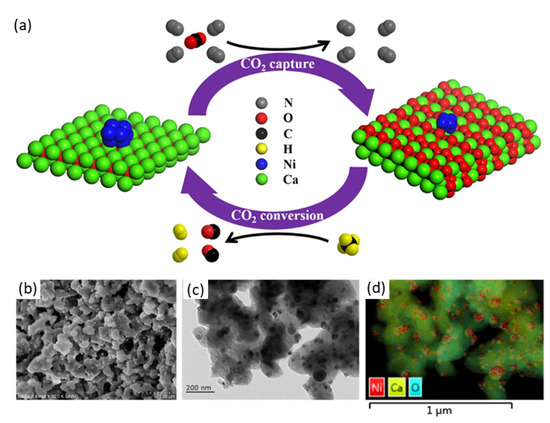

The most important asset of the calcium looping and methane reforming process as proposed lies in merging the capture of CO2 and its subsequent conversion inclusively in one combined process [83]. Figure 15a illustrates such operation, operating with a CaO-Ni multifunctional sorbent-catalyst. In the CO2 capture step, the CaO component selectively adsorbs CO2 from the feed stream and stores it as CaCO3.

Figure 15.

Illustration of the combined calcium looping and dry reforming process. (a) Process schematic, (b) particle shape and (c,d) structure and element map of the CaO-Ni multifunctional material (reduced CaO/Ni) [83].

In the CO2 conversion and CH4 reforming step, CaCO3 dissociates to release CO2, which is used in situ for reforming of CH4 on the Ni catalyst, so that syngas is produced. Hereafter, the material is back in its initial state, all set for a new cycle. An essential benefit of this process is that it can use feedstocks with any composition of CO2-containing gas to react with CH4, in particular flue gases with a CO2 content of up to 20 vol.%. The integration of CO2 capture and conversion in one process lowers the overall energy penalty by the improved process heat management and by taking out CO2 transport from emission point to utilization site.

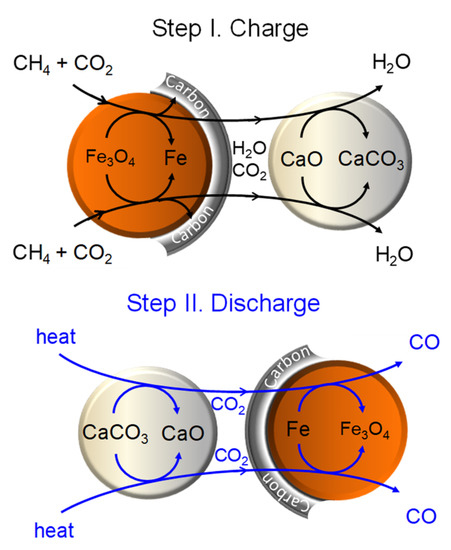

Another example of functional chemical looping development is found in coupling CO2 sorption to oxygen storage reduction/oxidation, e.g., for energy storage [84,85,86]. The working principle of such combined chemical looping system can be described as “chemical charge” and “discharge” cycles (Figure 16). During reduction (“charge”), a feed of CH4 and CO2 is sent over a mechanical mixture of Fe3O4 and CaO. Methane reduces Fe3O4 to metallic iron, while producing surface carbon as well as CO2, H2O and H2 (Equations (5) and (6)). The obtained H2 can be used for fuel cells. In parallel, CaO is carbonated to CaCO3 by interaction with CO2 (Equation (7)), typically at temperatures between 600 and 700 °C [87]:

CH4 + Fe3O4 → 2H2O + CO2 + 3Fe

CH4 → C + 2H2

CaO + CO2 → CaCO3

Figure 16.

Illustration and working scheme of “combined chemical looping” for energy storage and conversion [84].

Depending on the need, the “charged” condition of the material can be preserved, or immediately put to use. For the latter case of “discharge”, it is sufficient to increase the temperature of the sample by 50–150 °C, which will trigger decomposition of CaCO3 back into CaO and CO2 (Equation (8)) [88]:

CaCO3 → CaO + CO2

Simultaneously, the released CO2 will interact with metallic iron and with carbon deposited in the first step to produce CO:

4CO2 + 3Fe → Fe3O4 + 4CO

C + CO2 → 2CO

The CO that is generated can be used, e.g., in a solid oxide fuel cell (SOFC). Since CO intrinsically contains as much energy as hydrogen, it can indeed be oxidized electrochemically, CO + O2− = CO2 + 2e−, to produce electricity and CO2. The energetics of CO and H2 oxidation, calculated from thermochemical data at 1123 K, yield similar values for the standard Gibbs free energy, i.e., −185 kJ mol−1 for CO2 vs. −186 kJ mol−1 for H2O. Moreover, the CO oxidation reaction is slightly more exothermic than that of H2, i.e., −282 kJ mol−1 for CO2 vs. −249 kJ mol−1 for H2O, underlining the CO potential for fuel cell use.

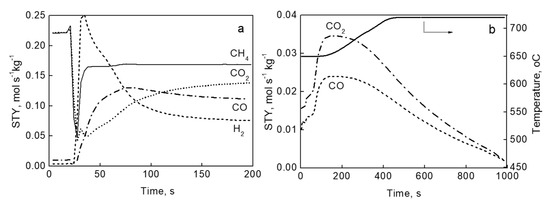

As exemplified before, adding a Ni catalyst can intensify the overall process. The mixture of CH4 and CO2 is converted to syngas over the catalyst by dry reforming. The latter will reduce iron oxide faster and deeper than the originally fed CH4. Figure 17a shows space-time yields of CH4, CO, CO2 and H2 as a function of time-on-stream.

Figure 17.

Space-time yield vs. time-on-stream for combined CO2 capture and Fe3O4 reduction over a NiO/Fe2O3–CeO2 and CaO-Al2O3 (1:5) mix. (a) CaO carbonation and Fe3O4 reduction with CH4 + CO2 (1:1) at 650 °C, and (b) CaCO3 decarbonation and CO production by iron and carbon oxidation by CO2. Temperature rise from 650 to 720 °C in He. Solid line: temperature profile [84].

Initially, CO2 decreases because it gets adsorbed by CaO and consumed in dry reforming. Once CaO is fully loaded with CO2, the CO2 space-time yield increases again to stabilize with the other products. Due to consumption of CO2, CH4 equally exhibits a minimum as it decomposes over Ni, forming surface carbon and hydrogen. The space-time yield for H2 rises and goes through a maximum before levelling off. Fe3O4 gets reduced by both CO and H2. If needed, the process can be halted at this point to store the energy, delaying the “discharge” in time. For putting the stored energy to use, it suffices to purge the reactor with inert and raise the temperature slightly, from 650 to 720 °C. This will release the CO2 by CaCO3 decomposition and consecutively produce CO by CO2 oxidation of iron and carbon (Figure 17b).

This concept is widely flexible in both energy storage/release and fuel type. Dilute gas streams can be used for charging, an attractive factor for present-day applications. A further asset is that energy use or discharge and charge can easily be separated in time. Moreover, it can be merged with the newly developed solid oxide metal-air redox battery, based on oxide-ion chemistry. As such, combined chemical looping enables an emerging and promising energy storage technology, capable of harvesting renewable energy with high efficiency and of managing grid stability [89,90,91].

4. Conclusions

Chemical looping offers unseen opportunities for power plants and industrial applications with CO2 capture. It is a very promising technology with large potential, well beyond combustion, and it allows to intensify processes both in fuel and chemical production technology. The flexibility of the chemical looping platform stems from the separation of a single reaction into two sub-reactions, connected by a solid carrier material. The design of suitable carrier materials is therefore key to developing novel chemical looping processes. The latter should essentially focus on acquiring understanding on how structural and compositional architecture of both the metal component and the support structure impact on the performance of the chemical looping process. Guided by this insight, catalytic sites and carrier material can be tailored to strongly enhance the process, as shown here for H2 or CO production via methane reforming.

The principle of chemical looping is fundamentally applicable to any catalytic reaction, if suitable carriers are found that allow transport of the desired functional group. Moreover, it can be merged with existing catalytic processes for improved selectivity and stability. The inherent product separation can have a significant impact on a broad range of chemical processes, aiming for higher efficiency and ‘greener’ chemistry. We hope that this review can trigger both experimental investigation and scientific discussions that can lead to accelerated installation of chemical looping processes.

Author Contributions

Writing-review and editing, H.P.; writing-review and editing, V.V.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Davis, S.J.; Lewis, N.S.; Shaner, M.; Aggarwal, S.; Arent, D.; Azevedo, I.L.; Benson, S.M.; Bradley, T.; Brouwer, J.; Chiang, Y.-M.; et al. Net-zero emissions energy systems. Science 2018, 360, eaas9793. [Google Scholar] [CrossRef] [PubMed]

- Martens, J.A.; Bogaerts, A.; De Kimpe, N.; Jacobs, P.A.; Marin, G.B.; Rabaey, K.; Saeys, M.; Verhelst, S. The Chemical Route to a Carbon Dioxide Neutral World. ChemSusChem 2017, 10, 1039–1055. [Google Scholar] [CrossRef]

- Wismann, S.T.; Engbæk, J.S.; Vendelbo, S.B.; Bendixen, F.B.; Eriksen, W.L.; Aasberg-Petersen, K.; Frandsen, C.; Chorkendorff, I.; Mortensen, P.M. Electrified methane reforming: A compact approach to greener industrial hydrogen production. Science 2019, 364, 756–759. [Google Scholar] [CrossRef]

- Vooradi, R.; Bertran, M.-O.; Frauzem, R.; Anne, S.B.; Gani, R. Sustainable chemical processing and energy-carbon dioxide management: Review of challenges and opportunities. Chem. Eng. Res. Des. 2018, 131, 440–464. [Google Scholar] [CrossRef]

- Takht Ravanchi, M.; Sahebdelfar, S. Catalytic conversions of CO2 to help mitigate climate change: Recent process develop-ments. Process. Saf. Environ. Prot. 2021, 145, 172–194. [Google Scholar] [CrossRef]

- Flores-Granobles, M.; Saeys, M. Minimizing CO2 emissions with renewable energy: A comparative study of emerging tech-nologies in the steel industry. Energy Environ. Sci. 2020, 13, 1923–1932. [Google Scholar] [CrossRef]

- Abuelgasim, S.; Wang, W.; Abdalazeez, A. A brief review for chemical looping combustion as a promising CO2 capture technology: Fundamentals and progress. Sci. Total Environ. 2021, 764, 142892. [Google Scholar] [CrossRef]

- Zhu, X.; Imtiaz, Q.; Donat, F.; Müller, C.R.; Li, F. Chemical looping beyond combustion—A perspective. Energy Environ. Sci. 2020, 13, 772–804. [Google Scholar] [CrossRef]

- Di Giuliano, A.; Gallucci, K. Sorption enhanced steam methane reforming based on nickel and calcium looping: A review. Chem. Eng. Process. Process. Intensif. 2018, 130, 240–252. [Google Scholar] [CrossRef]

- Kathe, M.; Empfield, A.; Sandvik, P.; Fryer, C.; Zhang, Y.; Blair, E.; Fan, L.-S. Utilization of CO2 as a partial substitute for methane feedstock in chemical looping methane–steam redox processes for syngas production. Energy Environ. Sci. 2017, 10, 1345–1349. [Google Scholar] [CrossRef]

- Dang, C.; Li, Y.; Yusuf, S.M.; Cao, Y.; Wang, H.; Yu, H.; Peng, F.; Li, F. Calcium cobaltate: A phase-change catalyst for stable hydrogen production from bio-glycerol. Energy Environ. Sci. 2018, 11, 660–668. [Google Scholar] [CrossRef]

- Zhao, X.; Zhou, H.; Sikarwar, V.S.; Zhao, M.; Park, A.-H.A.; Fennell, P.S.; Shen, L.; Fan, L.-S. Biomass-based chemical looping technologies: The good, the bad and the future. Energy Environ. Sci. 2017, 10, 1885–1910. [Google Scholar] [CrossRef]

- Zeng, L.; Cheng, Z.; Fan, J.A.; Fan, L.-S.; Gong, J. Metal oxide redox chemistry for chemical looping processes. Nat. Rev. Chem. 2018, 2, 349–364. [Google Scholar] [CrossRef]

- Li, D.; Xu, R.; Li, X.; Li, Z.; Zhu, X.; Li, K. Chemical Looping Conversion of Gaseous and Liquid Fuels for Chemical Production: A Review. Energy Fuels 2020, 34, 5381–5413. [Google Scholar] [CrossRef]

- Adanez, J.; Abad, A.; Garcia-Labiano, F.; Gayan, P.; De Diego, L.F. Progress in Chemical-Looping Combustion and Reforming technologies. Prog. Energy Combust. Sci. 2012, 38, 215–282. [Google Scholar] [CrossRef]

- Fan, L.-S.; Zeng, L.; Luo, S. Chemical-looping technology platform. AIChE J. 2014, 61, 2–22. [Google Scholar] [CrossRef]

- Yan, X.; Li, Y.; Ma, X.; Zhao, J.; Wang, Z. Performance of Li4SiO4 material for CO2 capture: A review. Int. J. Mol. Sci. 2019, 20, 928. [Google Scholar] [CrossRef]

- Kim, S.M.; Abdala, P.M.; Broda, M.; Hosseini, D.; Copéret, C.; Müller, C. Integrated CO2 Capture and Conversion as an Efficient Process for Fuels from Greenhouse Gases. ACS Catal. 2018, 8, 2815–2823. [Google Scholar] [CrossRef]

- Fan, L.-S. Chemical Looping Systems for Fossil Energy Conversions; John Wiley and Sons Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Criado, Y.A.; Arias, B.; Abanades, J.C. Calcium looping CO2 capture system for back-up power plants. Energy Environ. Sci. 2017, 10, 1994–2004. [Google Scholar] [CrossRef]

- Blamey, J.; Anthony, E.J.; Wang, J.; Fennell, P.S. The calcium looping cycle for large-scale CO2 capture. Prog. Energy Combust. Sci. 2010, 36, 260–279. [Google Scholar] [CrossRef]

- Tian, H.; Simonyi, T.; Poston, J.; Siriwardane, R. Effect of Hydrogen Sulfide on Chemical Looping Combustion of Coal-Derived Synthesis Gas over Bentonite-Supported Metal−Oxide Oxygen Carriers. Ind. Eng. Chem. Res. 2009, 48, 8418–8430. [Google Scholar] [CrossRef]

- Kane, T.; Guerrero Caballero, J.; Löfberg, A. Chemical looping selective oxidation of H2S using V2O5 impregnated over different supports as oxygen carriers. ChemCatChem 2020, 12, 2569–2579. [Google Scholar] [CrossRef]

- Zhu, J.; Sushkevich, V.L.; Knorpp, A.J.; Newton, M.A.; Mizuno, S.C.M.; Wakihara, T.; Okubo, T.; Liu, Z.; Van Bokhoven, J.A. Cu-Erionite Zeolite Achieves High Yield in Direct Oxidation of Methane to Methanol by Isothermal Chemical Looping. Chem. Mater. 2020, 32, 1448–1453. [Google Scholar] [CrossRef]

- Ishida, M.; Zheng, D.; Akehata, T. Evaluation of a chemical-looping-combustion power-generation system by graphic exergy analysis. Energy 1987, 12, 147–154. [Google Scholar] [CrossRef]

- Richter, H.J.; Knoche, K.F. Reversibility of Combustion Processes. ACS Symp. Ser. 1983, 235, 71–85. [Google Scholar] [CrossRef]

- Mattisson, T.; Keller, M.; Linderholm, C.; Moldenhauer, P.; Rydén, M.; Leion, H.; Lyngfelt, A. Chemical-looping technologies using circulating fluidized bed systems: Status of development. Fuel Process. Technol. 2018, 172, 1–12. [Google Scholar] [CrossRef]

- Huang, J.; Liu, W.; Yang, Y.; Liu, B. High-Performance Ni–Fe Redox Catalysts for Selective CH4 to Syngas Conversion via Chemical Looping. ACS Catal. 2018, 8, 1748–1756. [Google Scholar] [CrossRef]

- Mihai, O.; Chen, D.; Holmén, A. Catalytic Consequence of Oxygen of Lanthanum Ferrite Perovskite in Chemical Looping Reforming of Methane. Ind. Eng. Chem. Res. 2011, 50, 2613–2621. [Google Scholar] [CrossRef]

- Lyngfelt, A. Oxygen Carriers for Chemical-Looping Combustion. In Calcium and Chemical Looping Technology for Power Generation and Carbon Dioxide (CO2) Capture; Fennell, P., Anthony, B., Eds.; Woodhead Publishing: Cambridge, UK, 2015; Chapter 11; pp. 221–254. [Google Scholar]

- Solunke, R.D.; Veser, G. Integrating desulfurization with CO2-capture in chemical-looping combustion. Fuel 2011, 90, 608–617. [Google Scholar] [CrossRef]

- Dou, Y.; Sun, L.; Ren, J.; Dong, L. Opportunities and future challenges in hydrogen economy for sustainable development. In Hydrogen Economy; Scipioni, A., Manzardo, A., Ren, J., Eds.; Academic Press: Cambridge, MA, USA, 2017; Chapter 10; pp. 277–305. [Google Scholar]

- Nehrir, M.H.; Wang, C. Fuel cells. In Electric Renewable Energy Systems; Rashid, M.H., Ed.; Academic Press: Boston, MA, USA, 2016; Chapter 6; pp. 92–113. [Google Scholar]

- Song, C. Fuel processing for low-temperature and high-temperature fuel cells Challenges, and opportunities for sustainable development in the 21st century. Catal. Today 2002, 77, 17–49. [Google Scholar] [CrossRef]

- Choudhary, T.V.; Goodman, D.W. Co-free fuel processing for fuel cell applications. Catal. Today 2002, 77, 65–78. [Google Scholar] [CrossRef]

- Liu, W.; Lim, J.Y.; Saucedo, M.A.; Hayhurst, A.N.; Scott, S.A.; Dennis, J. Kinetics of the reduction of wüstite by hydrogen and carbon monoxide for the chemical looping production of hydrogen. Chem. Eng. Sci. 2014, 120, 149–166. [Google Scholar] [CrossRef]

- Galvita, V.; Sundmacher, K. Cyclic water gas shift reactor (CWGS) for carbon monoxide removal from hydrogen feed gas for PEM fuel cells. Chem. Eng. J. 2007, 134, 168–174. [Google Scholar] [CrossRef]

- Buelens, L.C.; Galvita, V.V.; Poelman, H.; Detavernier, C.; Marin, G.B. Super-dry reforming of methane intensifies CO2 utili-zation via le chatelier’s principle. Science 2016, 354, 449–452. [Google Scholar] [CrossRef]

- Galvita, V.V.; Poelman, H.; Marin, G.B. Hydrogen Production from Methane and Carbon Dioxide by Catalyst-Assisted Chemical Looping. Top. Catal. 2011, 54, 907–913. [Google Scholar] [CrossRef]

- Najera, M.; Solunke, R.; Gardner, T.; Veser, G. Carbon capture and utilization via chemical looping dry reforming. Chem. Eng. Res. Des. 2011, 89, 1533–1543. [Google Scholar] [CrossRef]

- Bhavsar, S.; Nájera, M.; Veser, G. Chemical Looping Dry Reforming as Novel, Intensified Process for CO2 Activation. Chem. Eng. Technol. 2012, 35, 1281–1290. [Google Scholar] [CrossRef]

- Hu, J.; Galvita, V.V.; Poelman, H.; Marin, G.B. Advanced Chemical Looping Materials for CO2 Utilization: A Review. Materials 2018, 11, 1187. [Google Scholar] [CrossRef]

- Loutzenhiser, P.G.; Gálvez, M.E.; Hischier, I.; Stamatiou, A.; Frei, A.; Steinfeld, A. CO2 splitting via two-step solar thermo-chemical cycles with zn/zno and FeO/Fe3O4 redox reactions ii: Kinetic analysis. Energy Fuels 2009, 23, 2832–2839. [Google Scholar] [CrossRef]

- Galvita, V.; Hempel, T.; Lorenz, H.; Rihko-Struckmann, L.K.; Sundmacher, K. Deactivation of Modified Iron Oxide Materials in the Cyclic Water Gas Shift Process for CO-Free Hydrogen Production. Ind. Eng. Chem. Res. 2008, 47, 303–310. [Google Scholar] [CrossRef]

- Theofanidis, S.A.; Galvita, V.V.; Poelman, H.; Marin, G.B. Enhanced Carbon-Resistant Dry Reforming Fe-Ni Catalyst: Role of Fe. ACS Catal. 2015, 5, 3028–3039. [Google Scholar] [CrossRef]

- Daza, C.E.; Kiennemann, A.; Moreno, S.; Molina, R. Dry reforming of methane using Ni–Ce catalysts supported on a modified mineral clay. Appl. Catal. A Gen. 2009, 364, 65–74. [Google Scholar] [CrossRef]

- Potdar, H.S.; Roh, H.-S.; Jun, K.-W.; Ji, M.; Liu, Z.-W. Carbon dioxide reforming of methane over co-precipitated Ni-Ce-ZrO2 catalysts. Catal. Lett. 2002, 84, 95–100. [Google Scholar]

- Galvita, V.V.; Poelman, H.; Detavernier, C.; Marin, G.B. Catalyst-assisted chemical looping for CO2 conversion to CO. Appl. Catal. B Environ. 2015, 164, 184–191. [Google Scholar] [CrossRef]

- Yin, X.; Wang, S.; Sun, R.; Jiang, S.; Shen, L.-H. A Ce–Fe Oxygen Carrier with a Core–Shell Structure for Chemical Looping Steam Methane Reforming. Ind. Eng. Chem. Res. 2020, 59, 9775–9786. [Google Scholar] [CrossRef]

- Galinsky, N.L.; Shafiefarhood, A.; Chen, Y.; Neal, L.; Li, F. Effect of support on redox stability of iron oxide for chemical looping conversion of methane. Appl. Catal. B Environ. 2015, 164, 371–379. [Google Scholar] [CrossRef]

- Tang, M.; Xu, L.; Fan, M. Progress in oxygen carrier development of methane-based chemical-looping reforming: A review. Appl. Energy 2015, 151, 143–156. [Google Scholar] [CrossRef]

- Zhu, X.; Li, K.; Wei, Y.; Wang, H.; Sun, L. Chemical-Looping Steam Methane Reforming over a CeO2–Fe2O3 Oxygen Carrier: Evolution of Its Structure and Reducibility. Energy Fuels 2014, 28, 754–760. [Google Scholar] [CrossRef]

- Galvita, V.V.; Poelman, H.; Bliznuk, V.; Detavernier, C.; Marin, G.B. CeO2-modified Fe2O3 for CO2 utilization via chemical looping. Ind. Eng. Chem. Res. 2013, 52, 8416–8426. [Google Scholar] [CrossRef]

- Dharanipragada, N.V.R.A.; Meledina, M.; Galvita, V.V.; Poelman, H.; Turner, S.; Van Tendeloo, G.; Detavernier, C.; Marin, G.B. Deactivation Study of Fe2O3–CeO2 during Redox Cycles for CO Production from CO2. Ind. Eng. Chem. Res. 2016, 55, 5911–5922. [Google Scholar] [CrossRef]

- Dharanipragada, N.A.; Galvita, V.V.; Poelman, H.; Buelens, L.C.; Detavernier, C.; Marin, G.B. Bifunctional Co- and Ni-ferrites for catalyst-assisted chemical looping with alcohols. Appl. Catal. B Environ. 2018, 222, 59–72. [Google Scholar] [CrossRef]

- Hu, J.; Buelens, L.; Theofanidis, S.-A.; Galvita, V.V.; Poelman, H.; Marin, G.B. CO2 conversion to CO by autothermal cata-lyst-assisted chemical looping. J. CO2 Util. 2016, 16, 8–16. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, S.; Hu, J.; Chen, A.; Rony, A.H.; Russell, C.K.; Xiang, W.; Fan, M.; Dyar, M.D.; Dklute, E.C. Ca2Fe2O5: A promising oxygen carrier for CO/CH4 conversion and almost-pure H2 production with inherent CO2 capture over a two-step chemical looping hydrogen generation process. Appl. Energy 2018, 211, 431–442. [Google Scholar] [CrossRef]

- Liu, S.; Xiang, D.; Xu, Y.; Sun, Z.; Cao, Y. Relationship between electronic properties of Fe3O4 substituted by Ca and Ba and their reactivity in chemical looping process: A first-principles study. Appl. Energy 2017, 202, 550–557. [Google Scholar] [CrossRef]

- Chan, M.S.; Liu, W.; Ismail, M.; Yang, Y.; Scott, S.A.; Dennis, J.S. Improving hydrogen yields, and hydrogen:steam ratio in the chemical looping production of hydrogen using Ca2Fe2O5. Chem. Eng. J. 2016, 296, 406–411. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, S.; Russell, C.K.; Hu, J.; Rony, A.H.; Tan, G.; Chen, A.; Duan, L.; Boman, J.; Tang, J.; et al. Improvement of H2-rich gas production with tar abatement from pine wood conversion over bi-functional Ca2Fe2O5 catalyst: Investigation of inner-looping redox reaction and promoting mechanisms. Appl. Energy 2018, 212, 931–943. [Google Scholar] [CrossRef]

- Hosseini, D.; Donat, F.; Abdala, P.M.; Kim, S.M.; Kierzkowska, A.M.; Müller, C.R. Reversible Exsolution of Dopant Improves the Performance of Ca2Fe2O5 for Chemical Looping Hydrogen Production. ACS Appl. Mater. Interfaces 2019, 11, 18276–18284. [Google Scholar] [CrossRef]

- Carrillo, A.J.; Kim, K.J.; Hood, Z.D.; Bork, A.H.; Rupp, J.L.M. La0.6Sr0.4Cr0.8Co0.2O3 Perovskite Decorated with Exsolved Co Nanoparticles for Stable CO2 Splitting and Syngas Production. ACS Appl. Energy Mater. 2020, 3, 4569–4579. [Google Scholar] [CrossRef]

- Kousi, K.; Neagu, D.; Bekris, L.; Papaioannou, E.I.; Metcalfe, I.S. Endogenous Nanoparticles Strain Perovskite Host Lattice Providing Oxygen Capacity and Driving Oxygen Exchange and CH4 Conversion to Syngas. Angew. Chem. Int. Ed. 2019, 59, 2510–2519. [Google Scholar] [CrossRef]

- Otto, S.-K.; Kousi, K.; Neagu, D.; Bekris, L.; Janek, J.; Metcalfe, I.S. Exsolved Nickel Nanoparticles Acting as Oxygen Storage Reservoirs and Active Sites for Redox CH4 Conversion. ACS Appl. Energy Mater. 2019, 2, 7288–7298. [Google Scholar] [CrossRef]

- Gärtner, C.A.; van Veen, A.C.; Lercher, J.A. Oxidative dehydrogenation of ethane: Common principles and mechanistic as-pects. ChemCatChem 2013, 5, 3196–3217. [Google Scholar] [CrossRef]

- Bañares, M.A. Supported metal oxide and other catalysts for ethane conversion: A review. Catal. Today 1999, 51, 319–348. [Google Scholar] [CrossRef]

- Nowicka, E.; Reece, C.; Althahban, S.M.; Mohammed, K.M.H.; Kondrat, S.A.; Morgan, D.J.; He, Q.; Willock, D.J.; Golunski, S.; Kiely, C.J.; et al. Elucidating the Role of CO2 in the Soft Oxidative Dehydrogenation of Propane over Ceria-Based Catalysts. ACS Catal. 2018, 8, 3454–3468. [Google Scholar] [CrossRef]

- Gao, Y.; Haeri, F.; He, F.; Li, F. Alkali metal-promoted LaxSr2–xFeO4−δ redox catalysts for chemical looping oxidative dehy-drogenation of ethane. ACS Catal. 2018, 8, 1757–1766. [Google Scholar] [CrossRef]

- Yusuf, S.; Neal, L.; Bao, Z.; Wu, Z.; Li, F. Effects of sodium and tungsten promoters on mg6mno8-based core–shell redox cat-alysts for chemical looping—oxidative dehydrogenation of ethane. ACS Catal. 2019, 9, 3174–3186. [Google Scholar] [CrossRef]

- Galinsky, N.; Sendi, M.; Bowers, L.; Li, F. CaMn1−xBxO3−δ (b=Al, V, Fe, Co and Ni) perovskite based oxygen carriers for chemical looping with oxygen uncoupling (clou). Appl. Energy 2016, 174, 80–87. [Google Scholar] [CrossRef]

- Kang, D.; Lim, H.S.; Lee, M.; Lee, J.W. Syngas production on a Ni-enhanced Fe2O3/Al2O3 oxygen carrier via chemical looping partial oxidation with dry reforming of methane. Appl. Energy 2018, 211, 174–186. [Google Scholar] [CrossRef]

- Brady, C.; Murphy, B.; Xu, B. Enhanced methane dehydroaromatization via coupling with chemical looping. ACS Catal. 2017, 7, 3924–3928. [Google Scholar] [CrossRef]

- Zhang, X.; Pei, C.; Chang, X.; Chen, S.; Liu, R.; Zhao, Z.-J.; Mu, R.; Gong, J. FeO6 Octahedral Distortion Activates Lattice Oxygen in Perovskite Ferrite for Methane Partial Oxidation Coupled with CO2 Splitting. J. Am. Chem. Soc. 2020, 142, 11540–11549. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Guo, J.; Wang, P.; Wang, Q.; Chang, F.; Pei, Q.; Zhang, W.; Liu, L.; Chen, P. Production of ammonia via a chemical looping process based on metal imides as nitrogen carriers. Nat. Energy 2018, 3, 1067–1075. [Google Scholar] [CrossRef]

- Lyon, R.K.; Cole, J.A. Unmixed combustion: An alternative to fire. Combust. Flame 2000, 121, 249–261. [Google Scholar] [CrossRef]

- Martavaltzi, C.S.; Lemonidou, A.A. Development of new CaO based sorbent materials for CO2 removal at high temperature. Microporous Mesoporous Mater. 2008, 110, 119–127. [Google Scholar] [CrossRef]

- Fernández, J.; Abanades, J. Optimized design and operation strategy of a CaCu chemical looping process for hydrogen production. Chem. Eng. Sci. 2017, 166, 144–160. [Google Scholar] [CrossRef][Green Version]

- Antzara, A.; Heracleous, E.; Bukur, D.B.; Lemonidou, A. Thermodynamic analysis of hydrogen production via chemical looping steam methane reforming coupled with in situ CO2 capture. Int. J. Greenh. Gas Control. 2015, 32, 115–128. [Google Scholar] [CrossRef]

- Martavaltzi, C.S.; Pampaka, E.P.; Korkakaki, E.S.; Lemonidou, A.A. Hydrogen Production via Steam Reforming of Methane with Simultaneous CO2 Capture over CaO−Ca12Al14O33. Energy Fuels 2010, 24, 2589–2595. [Google Scholar] [CrossRef]

- Antzara, A.; Heracleous, E.; Lemonidou, A.A. Energy efficient sorption enhanced-chemical looping methane reforming process for high-purity H2 production: Experimental proof-of-concept. Appl. Energy 2016, 180, 457–471. [Google Scholar] [CrossRef]

- Li, H.; Dang, C.; Yang, G.; Cao, Y.; Wang, H.; Peng, F.; Yu, H. Bi-functional particles for integrated thermo-chemical processes: Catalysis and beyond. Particuology 2021. [Google Scholar] [CrossRef]

- Verbeeck, K.; Buelens, L.C.; Galvita, V.V.; Marin, G.B.; Van Geem, K.M.; Rabaey, K. Upgrading the value of anaerobic digestion via chemical production from grid injected biomethane. Energy Environ. Sci. 2018, 11, 1788–1802. [Google Scholar]

- Tian, S.; Yan, F.; Zhang, Z.; Jiang, J. Calcium-looping reforming of methane realizes in situ CO2 utilization with improved energy efficiency. Sci. Adv. 2019, 5, eaav5077. [Google Scholar] [CrossRef] [PubMed]

- Galvita, V.V.; Poelman, H.; Marin, G.B. Combined chemical looping for energy storage and conversion. J. Power Sources 2015, 286, 362–370. [Google Scholar] [CrossRef]

- Galvita, V.V.; Poelman, H.; Marin, G.B. Combined Chemical Looping: New Possibilities for Energy Storage and Conversion. Energy Fuels 2017, 31, 11509–11514. [Google Scholar] [CrossRef]

- Saghafifar, M.; Schnellmann, M.A.; Scott, S.A. Chemical looping electricity storage. Appl. Energy 2020, 279, 115553. [Google Scholar] [CrossRef]

- Abanades, J.C.; Alvarez, D. Conversion limits in the reaction of CO2 with lime. Energy Fuels 2003, 17, 308–315. [Google Scholar] [CrossRef]

- Vorrias, I.; Atsonios, K.; Nikolopoulos, A.; Nikolopoulos, N.; Grammelis, P.; Kakaras, E. Calcium looping for CO2 capture from a lignite fired power plant. Fuel 2013, 113, 826–836. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, K. A comprehensive review on the development of solid-state metal–air batteries operated on oxide-ion chemistry. Adv. Energy Mater. 2021, 11, 2000630. [Google Scholar] [CrossRef]

- Xu, N.; Li, X.; Zhao, X.; Goodenough, J.B.; Huang, K. A novel solid oxide redox flow battery for grid energy storage. Energy Environ. Sci. 2011, 4, 4942–4946. [Google Scholar] [CrossRef]

- Menzler, N.H.; Hospach, A.; Niewolak, L.; Bram, M.; Tokariev, O.; Berger, C.M.; Orzessek, P.; Quadakkers, W.J.; Fang, Q.; Buchkremer, H.P. Power-To-Storage—The Use of an Anode-Supported Solid Oxide Fuel Cell as a High-Temperature Battery. ECS Trans. 2013, 57, 255–267. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).