Use of NaNO3/SiAl as Heterogeneous Catalyst for Fatty Acid Methyl Ester Production from Rapeseed Oil

Abstract

:1. Introduction

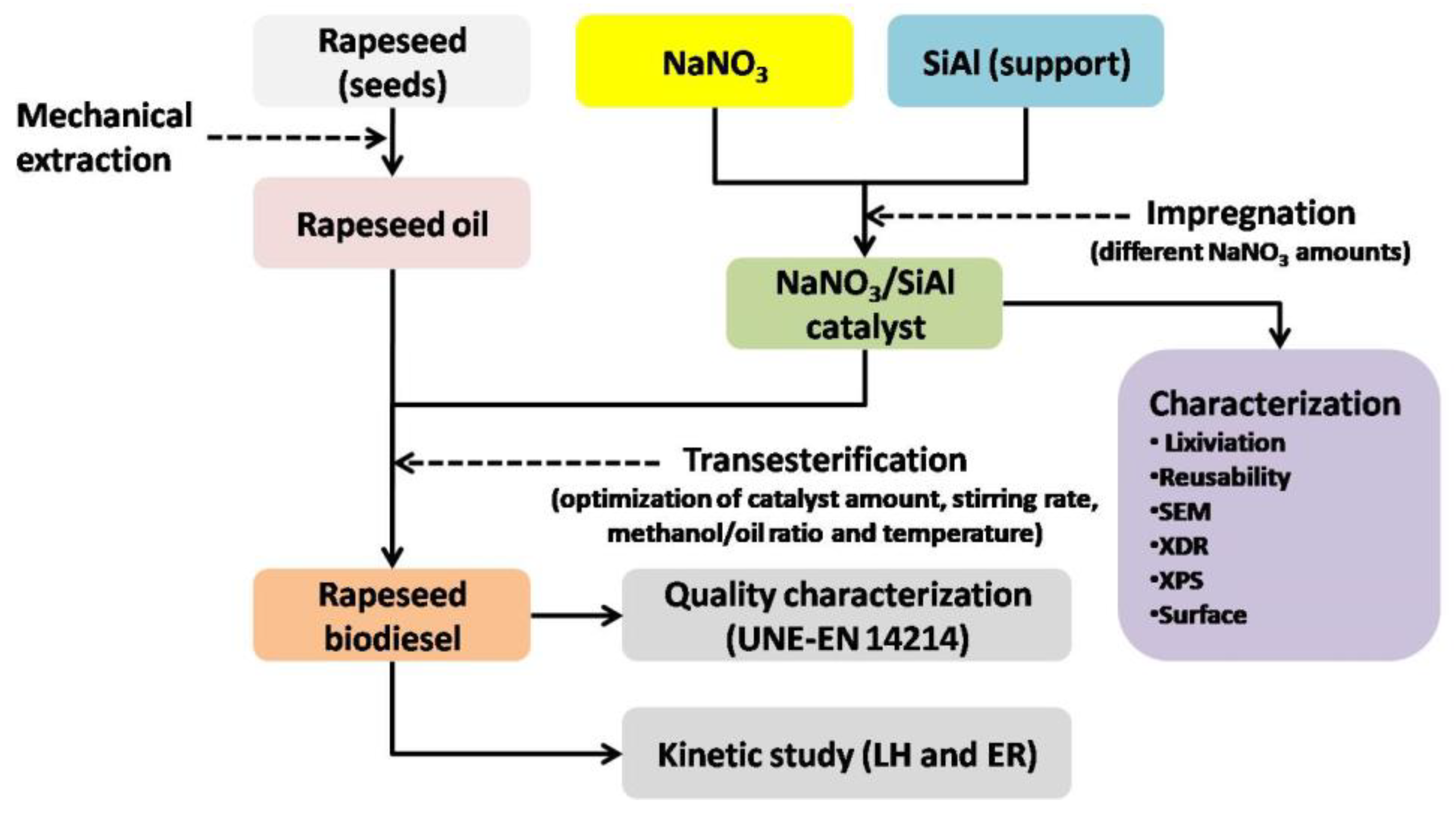

2. Materials and Methods

2.1. Catalyst Preparation

- Impregnation: Different NaNO3 solutions were prepared to obtain different impregnation amounts in the final catalyst. Thus, the suitable amount of solution (1.91 mL·g−1support) was added to a certain amount of support, impregnating the latter for 2 h with a stirring rate of 200 rpm.

- Solutions were dried at 100 °C.

- Activation was achieved through calcination at 600 °C for 25 h. Through this technique, different metal oxides and crystals are obtained.

2.2. Catalyst Characterization

2.2.1. Lixiviation Test

2.2.2. X-ray Diffraction Analysis

2.2.3. Scanning Electron Microscopy

2.2.4. Nitrogen Gas Adsorption-Desorption Isotherms

2.2.5. X-ray Photoelectron Spectroscopy Analysis

2.2.6. Reusability Tests

2.3. Transesterification Reaction

2.3.1. Raw Material Used

2.3.2. Chemical Reaction

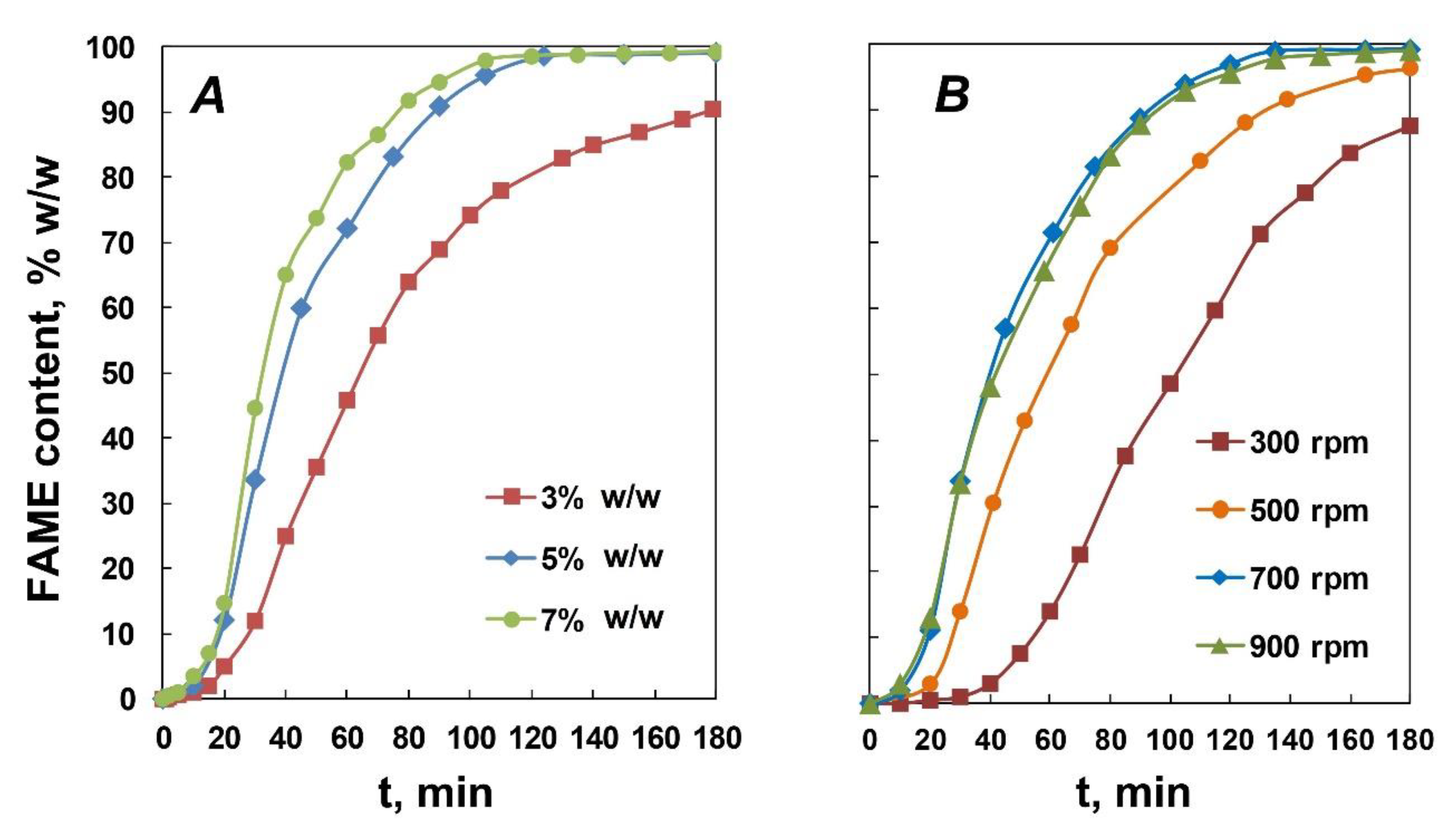

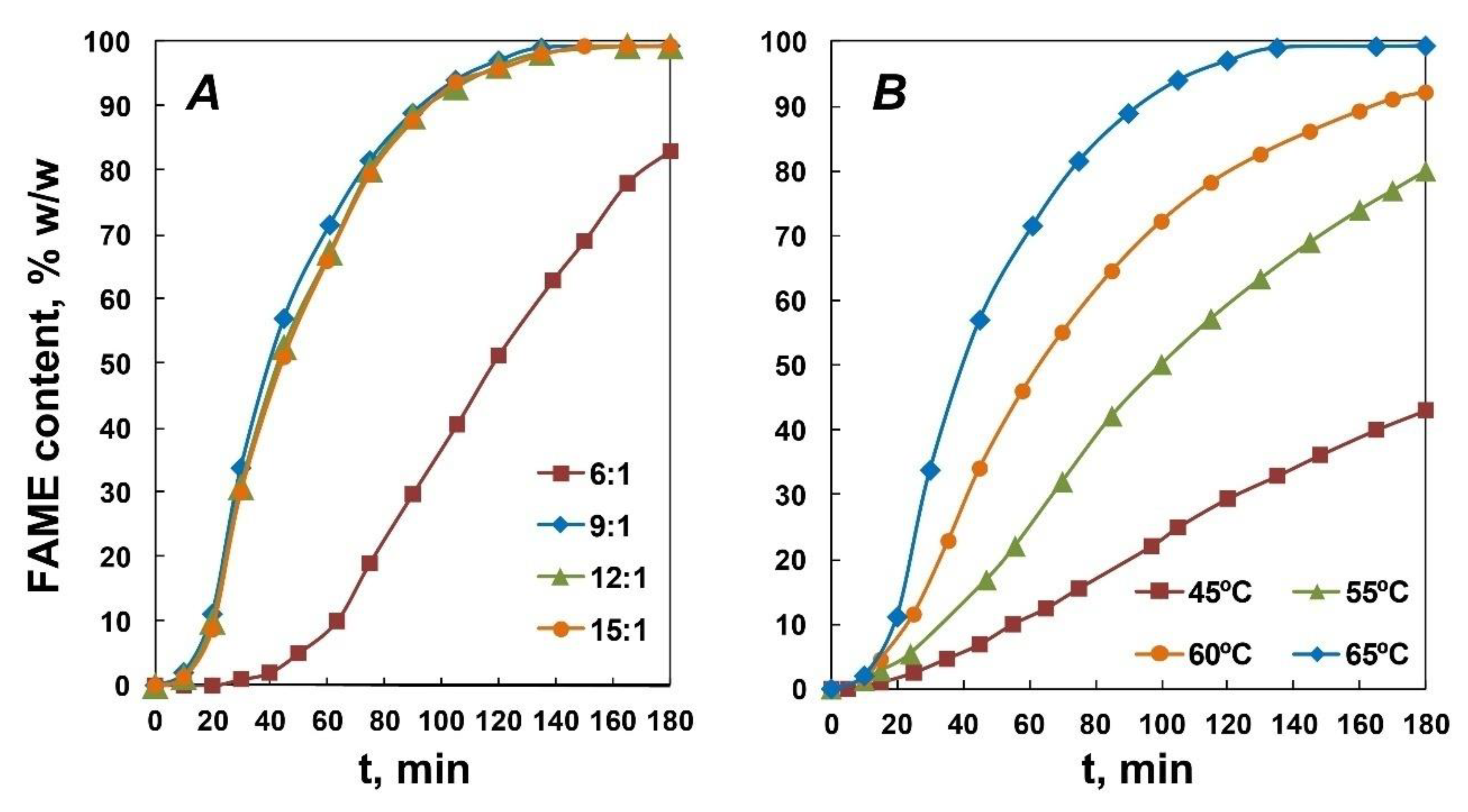

2.3.3. Study of the Effect of Variables on Heterogeneous Transesterification

- Catalyst amount: from 3 to 7% w/w;

- Stirring rate: from 300 to 900 rpm;

- Methanol/oil ratio: from 6:1 to 15:1;

- Temperature: from 45 to 65 °C.

2.3.4. Kinetic Study

2.3.5. Biodiesel Characterization

3. Results and Discussion

3.1. Effect of Impregnation on Catalyst Preparation

3.2. Lixiviation Tests

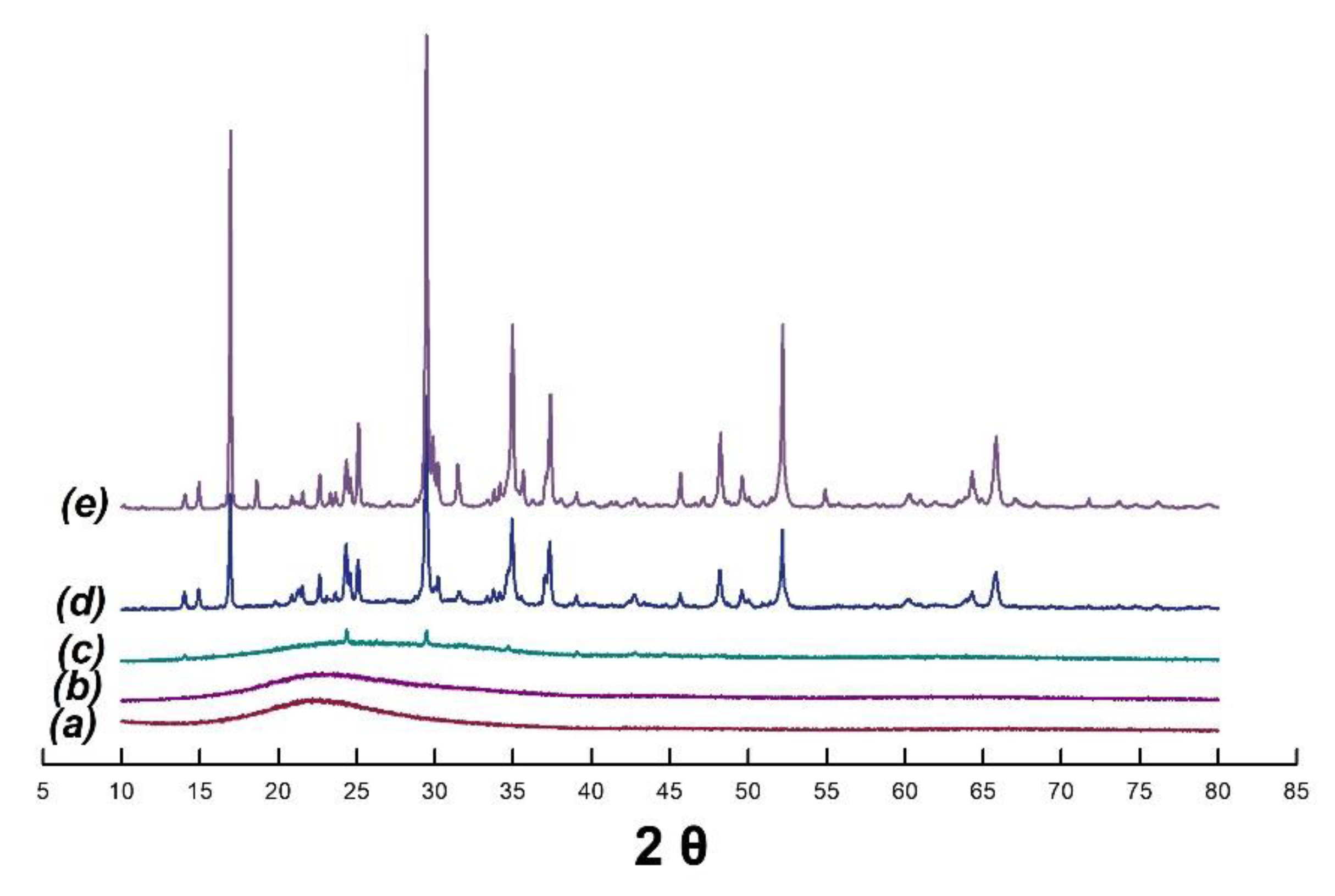

3.3. XRD Analysis

3.4. Reusability Tests of Heterogeneous Catalyst

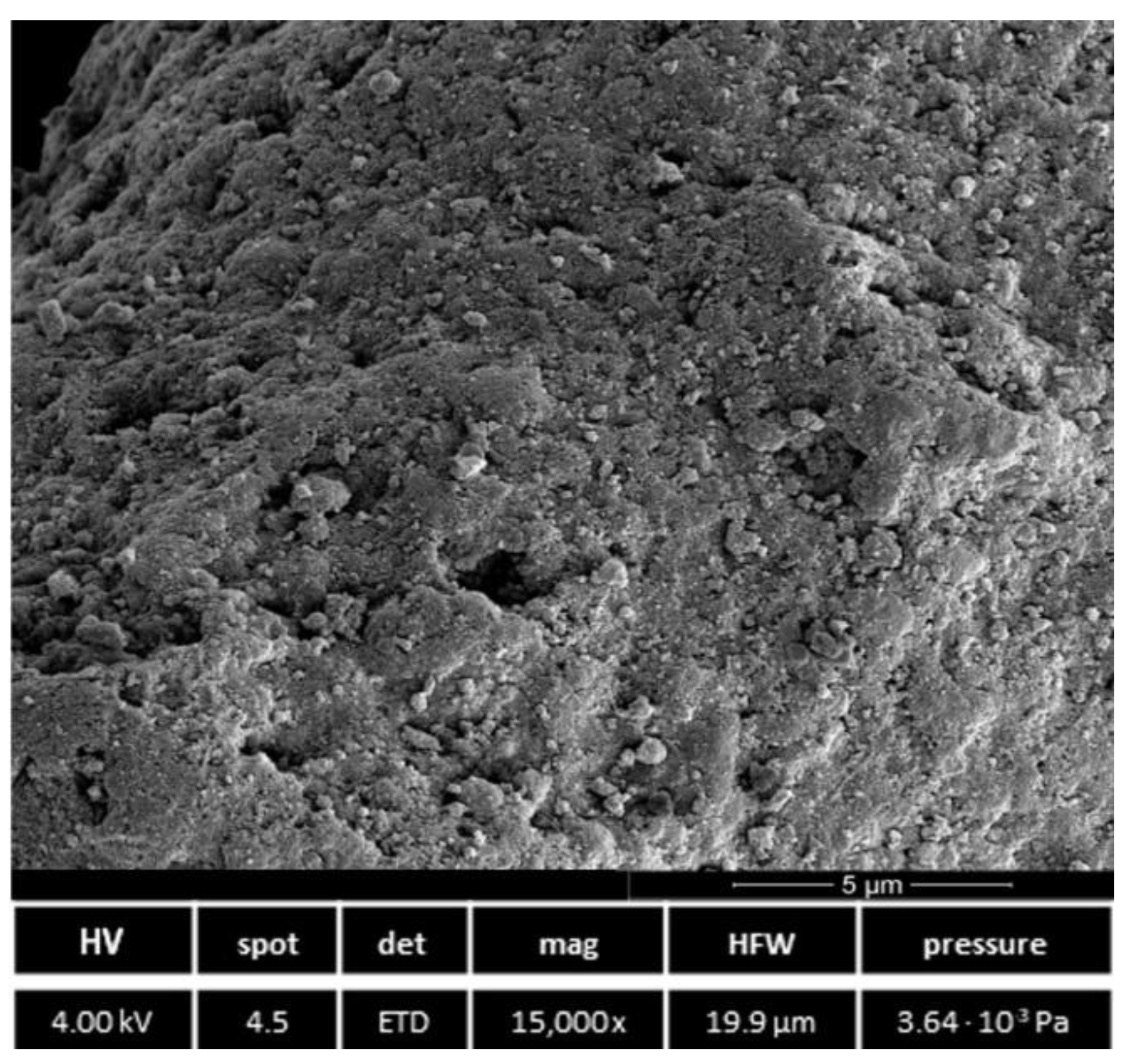

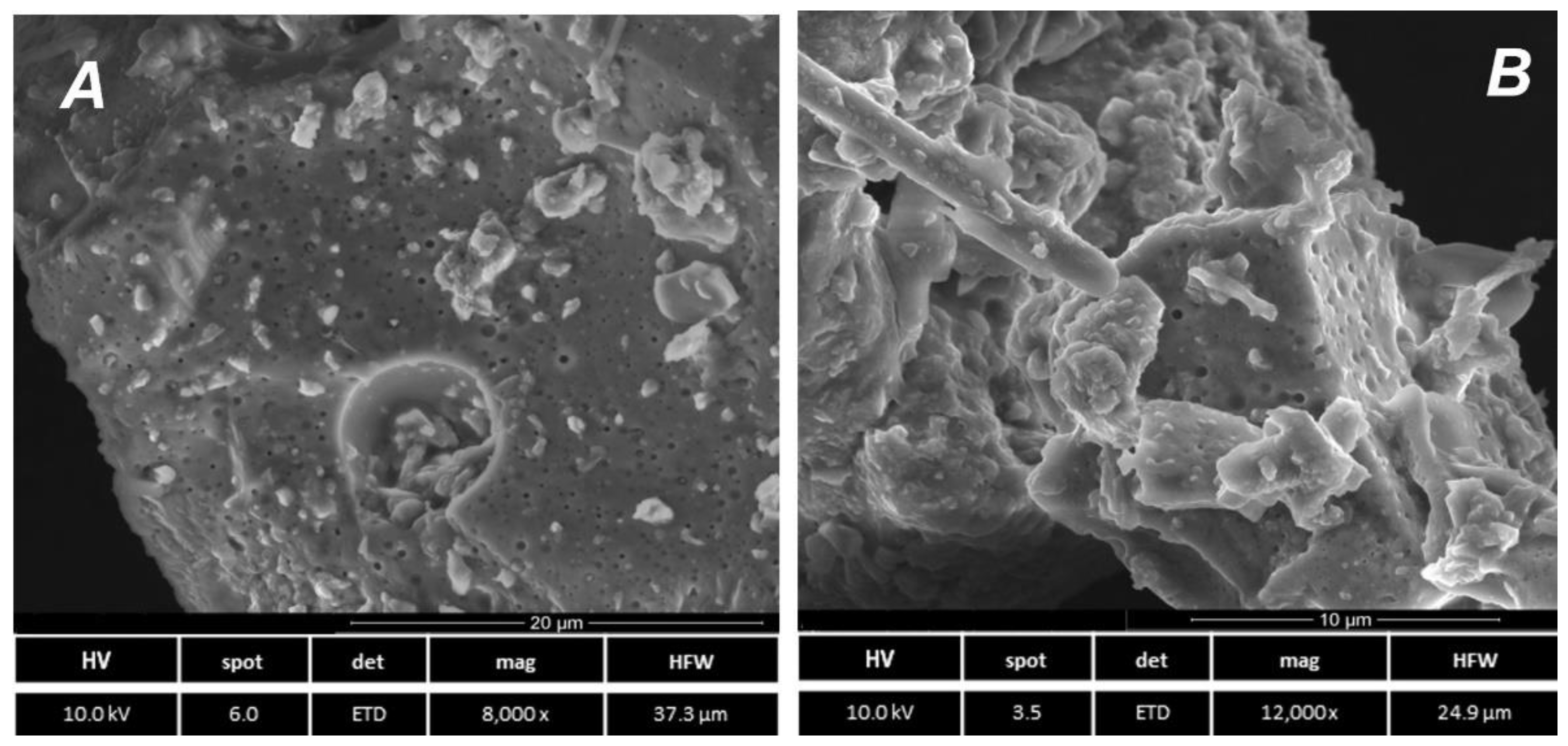

3.5. SEM Analysis

3.6. Surface Analysis

3.7. XPS Analysis

3.8. Influence of Variables during Transesterification

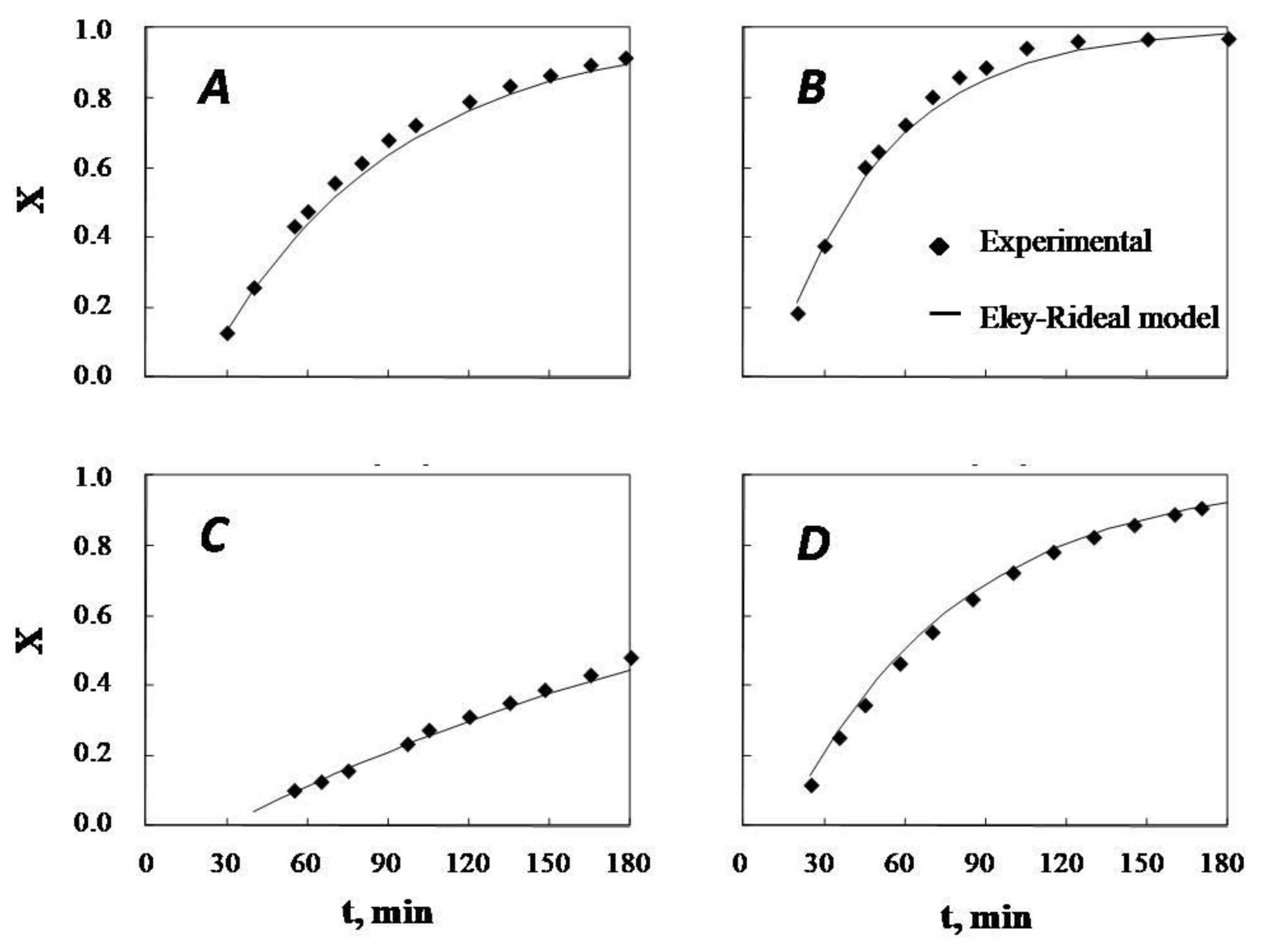

3.9. Kinetic Study

- The homogeneous catalysis contribution of the catalyst was negligible, as experimentally proved in this experiment.

- The external diffusion of the reagents from the liquid phase to the surface of the solid does not control the global reaction rate if the stirring rate is at least 700 rpm.

- In the time range considered for the kinetic study (once the induction point ended), the global reaction rate was influenced by the chemical reaction on the surface of the catalyst. As a consequence, both reagent adsorption and product desorption, as well as inner diffusion, do not affect the global reaction rate of the process.

- For this same time range, the catalyst distribution is homogeneous in the reaction medium for a methanol/oil ratio of 9:1 or higher.

- There is no weight loss of the catalyst and, therefore, it does not take part in any secondary reaction of the process.

3.10. FAME Quality Determination

4. Conclusions

- The preparation of heterogeneous catalysts supported on SiAl through impregnation with NaNO3, followed by calcination (600 °C for 25 h), lead to catalysts (NaNO3/SiAl) with high activity. Their activity increased with NaNO3/SiAl ratio, and 99.3% FAMEs were obtained with a ratio of 20/1 (NaNO3/SiAl 20/1). Its activity during the transesterification of rapeseed oil was maintained during the first three cycles, considerably decreasing its activity in subsequent cycles.

- The generation of silicate and aluminosilicate crystals in the heterogeneous catalysts was confirmed through XRD. There was an almost complete loss of SBET compared to the surface of the support, which could indicate the development of strong sintering processes during the preparation of the catalyst. The catalyst had a very heterogeneous surface, with crystal agglomeration and low porosity according to SBET analysis.

- Regarding the influence of variables on rapeseed oil transesterification by using NaNO3/SiAl 20/1, it can be concluded that higher values of the following parameters had almost no positive effect on reaction rate and effectiveness: amount of catalyst (5% w/w), methanol/oil ratio (9:1), and stirring rate (700 rpm). In contrast, temperature had a clear positive effect on kinetics.

- The use of the Eley-Rideal adsorption-reaction model properly predicted the transesterification kinetics studied in this case. At 65 °C, the reaction rate constant (k) and adsorption constant for methanol (KB) were 2.33·10−3 L2·gcat−1·mol−1·min−1 and 2.071 L mol−1, respectively. The activation energy (Ea) and adsorption molar heat for methanol (ΔHB) were 73.3 kJ·mol−1 and −8.28 kJ·mol−1, respectively.

- Finally, the properties of the biodiesel obtained under these circumstances, compared to basic homogeneous catalysis, were practically identical. Therefore, the properties of biodiesel depended on FAME content and distribution, regardless the process used to obtain it.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rodionova, M.V.; Poudyal, R.S.; Tiwari, I.; Voloshin, R.A.; Zharmukhamedov, S.K.; Nam, H.G.; Zayadan, B.K.; Bruce, B.D.; Hou, H.J.M.; Allakhverdiev, S.I. Biofuel production: Challenges and opportunities. Int. J. Hydrogen Energy 2017, 42, 8450–8461. [Google Scholar] [CrossRef]

- MacLeod, C.S.; Harvey, A.P.; Lee, A.F.; Wilson, K. Evaluation of the activity and stability of alkali-doped metal oxide catalysts for application to an intensified method of biodiesel production. Chem. Eng. J. 2008, 135, 63–70. [Google Scholar] [CrossRef]

- Rizwanul Fattah, I.M.; Ong, H.C.; Mahlia, T.M.I.; Mofijur, M.; Silitonga, A.S.; Ashrafur Rahman, S.M.; Ahmad, A. State of the Art of Catalysts for Biodiesel Production. Front. Energy Res. 2020, 8, 1–17. [Google Scholar] [CrossRef]

- Nisar, S.; Hanif, M.A.; Rashid, U.; Hanif, A.; Akhtar, M.N.; Ngamcharussrivichai, C. Trends in widely used catalysts for fatty acid methyl esters (Fame) production: A review. Catalysts 2021, 11, 1085. [Google Scholar] [CrossRef]

- Di Serio, M.; Tesser, R.; Pengmei, L.; Santacesaria, E. Heterogeneous Catalysts for Biodiesel Production. Energy Fuels 2008, 22, 207–217. [Google Scholar] [CrossRef]

- Endalew, A.K.; Kiros, Y.; Zanzi, R. Inorganic heterogeneous catalysts for biodiesel production from vegetable oils. Biomass Bioenergy 2011, 35, 3787–3809. [Google Scholar] [CrossRef]

- Dossin, T.; Reyniers, M.; Marin, G. Kinetics of heterogeneously MgO-catalyzed transesterification. Appl. Catal. B Environ. 2006, 62, 35–45. [Google Scholar] [CrossRef]

- UNE-EN 14214:2013 V2+A1:2018. Liquid Petroleum Products—Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications—Requirements and Test Methods; Asociación Española de Normalización: Madrid, Spain, 2018. [Google Scholar]

- Lee, D.-W.; Park, Y.-M.; Lee, K.-Y. Heterogeneous Base Catalysts for Transesterification in Biodiesel Synthesis. Catal. Surv. Asia 2009, 13, 63–77. [Google Scholar] [CrossRef]

- Hattori, H. Solid Base Catalysts: Generation, Characterization, and Catalytic Behavior of Basic Sites. J. Jpn. Pet. Inst. 2004, 47, 67–81. [Google Scholar] [CrossRef] [Green Version]

- Gryglewicz, S. Rapeseed oil methyl esters preparation using heterogeneous catalysts. Bioresour. Technol. 1999, 70, 249–253. [Google Scholar] [CrossRef]

- Watkins, R.S.; Lee, A.F.; Wilson, K. Li–CaOcatalysed tri-glyceride transesterification for biodiesel applications. Green Chem. 2004, 6, 335–340. [Google Scholar] [CrossRef]

- Granados, M.L.; Poves, M.D.Z.; Alonso, D.M.; Mariscal, R.; Galisteo, F.C.; Moreno-Tost, R.; Santamaría, J.; Fierro, J.L.G. Biodiesel from sunflower oil by using activated calcium oxide. Appl. Catal. B Environ. 2007, 73, 317–326. [Google Scholar] [CrossRef]

- Liu, X.; He, H.; Wang, Y.; Zhu, S.; Piao, X. Transesterification of soybean oil to biodiesel using CaO as a solid base catalyst. Fuel 2008, 87, 216–221. [Google Scholar] [CrossRef]

- Kouzu, M.; Kasuno, T.; Tajika, M.; Sugimoto, Y.; Yamanaka, S.; Hidaka, J. Calcium oxide as a solid base catalyst for transesterification of soybean oil and its application to biodiesel production. Fuel 2008, 87, 2798–2806. [Google Scholar] [CrossRef]

- Veljković, V.B.; Stamenković, O.S.; Todorović, Z.B.; Lazić, M.L.; Skala, D.U. Kinetics of sunflower oil methanolysis catalyzed by calcium oxide. Fuel 2009, 88, 1554–1562. [Google Scholar] [CrossRef]

- Patil, P.; Gude, V.G.; Pinappu, S.; Deng, S. Transesterification kinetics of Camelina sativa oil on metal oxide catalysts under conventional and microwave heating conditions. Chem. Eng. J. 2011, 168, 1296–1300. [Google Scholar] [CrossRef]

- Yoosuk, B.; Udomsap, P.; Puttasawat, B.; Krasae, P. Improving transesterification acitvity of CaO with hydration technique. Bioresour. Technol. 2010, 101, 3784–3786. [Google Scholar] [CrossRef]

- Yoo, S.J.; Lee, H.; Veriansyah, B.; Kim, J.; Kim, J.-D.; Lee, Y.-W. Synthesis of biodiesel from rapeseed oil using supercritical methanol with metal oxide catalysts. Bioresour. Technol. 2010, 101, 8686–8689. [Google Scholar] [CrossRef]

- Mazaheri, H.; Ong, H.C.; Amini, Z.; Masjuki, H.H.; Mofijur, M.; Su, C.H.; Badruddin, I.A.; Yunus Khan, T.M. An overview of biodiesel production via calcium oxide based catalysts: Current state and perspective. Energies 2021, 14, 3950. [Google Scholar] [CrossRef]

- Di Serio, M.; Ledda, M.; Cozzolino, M.; Minutillo, G.; Tesser, R.; Santacesaria, E. Transesterification of Soybean Oil to Biodiesel by Using Heterogeneous Basic Catalysts. Ind. Eng. Chem. Res. 2006, 45, 3009–3014. [Google Scholar] [CrossRef]

- Wang, L.; Yang, J. Transesterification of soybean oil with nano-MgO or not in supercritical and subcritical methanol. Fuel 2007, 86, 328–333. [Google Scholar] [CrossRef]

- Liu, X.; He, H.; Wang, Y.; Zhu, S. Transesterification of soybean oil to biodiesel using SrO as a solid base catalyst. Catal. Commun. 2007, 8, 1107–1111. [Google Scholar] [CrossRef]

- Bancquart, S.; Vanhove, C.; Pouilloux, Y.; Barrault, J. Glycerol transesterification with methyl stearate over solid basic catalysts. Appl. Catal. A Gen. 2001, 218, 1–11. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, Z.; Chen, Y.; Zhang, P.; Duan, S.; Liu, X.; Mao, Z. Preparation of Biodiesel Catalyzed by Solid Super Base of Calcium Oxide and Its Refining Process. Chin. J. Catal. 2006, 27, 391–396. [Google Scholar] [CrossRef]

- Li, X.; Lu, G.; Guo, Y.; Guo, Y.; Wang, Y.; Zhang, Z.; Liu, X.; Wang, Y. A novel solid superbase of Eu2O3/Al2O3 and its catalytic performance for the transesterification of soybean oil to biodiesel. Catal. Commun. 2007, 8, 1969–1972. [Google Scholar] [CrossRef]

- Yan, S.; Kim, M.; Salley, S.O.; Ng, K.Y.S. Oil transesterification over calcium oxides modified with lanthanum. Appl. Catal. A Gen. 2009, 360, 163–170. [Google Scholar] [CrossRef]

- Di Serio, M.; Tesser, R.; Casale, L.; D’Angelo, A.; Trifuoggi, M.; Santacesaria, E. Heterogeneous Catalysis in Biodiesel Production: The Influence of Leaching. Top. Catal. 2010, 53, 811–819. [Google Scholar] [CrossRef]

- Sánchez Faba, E.M.; Ferrero, G.O.; Dias, J.M.; Eimer, G.A. Alternative raw materials to produce biodiesel through alkaline heterogeneous catalysis. Catalysts 2019, 9, 690. [Google Scholar] [CrossRef] [Green Version]

- Granados, M.L.; Alonso, D.M.; Sádaba, I.; Mariscal, R.; Ocón, P. Leaching and homogeneous contribution in liquid phase reaction catalysed by solids: The case of triglycerides methanolysis using CaO. Appl. Catal. B Environ. 2009, 89, 265–272. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Singh, B.; Korstad, J. Latest developments on application of heterogenous basic catalysts for an efficient and eco friendly synthesis of biodiesel: A review. Fuel 2011, 90, 1309–1324. [Google Scholar] [CrossRef]

- Yan, S.; Lu, H.; Liang, B. Supported CaO Catalysts Used in the Transesterification of Rapeseed Oil for the Purpose of Biodiesel Production. Energy Fuels 2008, 22, 646–651. [Google Scholar] [CrossRef]

- Alonso, D.M.; Mariscal, R.; Granados, M.L.; Maireles-Torres, P. Biodiesel preparation using Li/CaO catalysts: Activation process and homogeneous contribution. Catal. Today 2009, 143, 167–171. [Google Scholar] [CrossRef]

- Wen, Z.; Yu, X.; Tu, S.-T.; Yan, J.; Dahlquist, E. Synthesis of biodiesel from vegetable oil with methanol catalyzed by Li-doped magnesium oxide catalysts. Appl. Energy 2010, 87, 743–748. [Google Scholar] [CrossRef]

- Macedo, C.C.S.; Abreu, F.R.; Tavares, A.P.; Alves, M.B.; Zara, L.F.; Rubim, J.C.; Suarez, P.A.Z. New heterogeneous metal-oxides based catalyst for vegetable oil trans-esterification. J. Braz. Chem. Soc. 2006, 17, S0103–S50532006000700014. [Google Scholar] [CrossRef]

- Babu, N.S.; Sree, R.; Prasad, P.S.S.; Lingaiah, N. Room-Temperature Transesterification of Edible and Nonedible Oils Using a Heterogeneous Strong Basic Mg/La Catalyst. Energy Fuels 2008, 22, 1965–1971. [Google Scholar] [CrossRef]

- Kawashima, A.; Matsubara, K.; Honda, K. Development of heterogeneous base catalysts for biodiesel production. Bioresour. Technol. 2008, 99, 3439–3443. [Google Scholar] [CrossRef] [PubMed]

- Leclercq, E.; Finiels, A.; Moreau, C. Transesterification of rapeseed oil in the presence of basic zeolites and related solid catalysts. J. Am. Oil Chem. Soc. 2001, 78, 1161–1165. [Google Scholar] [CrossRef]

- Suppes, G.J.; Dasari, M.A.; Doskocil, E.J.; Mandiky, P.J.; Goff, M.J. Transesterification of soybean oil with zeolite and metal catalysts. Appl. Catal. A Gen. 2004, 257, 213–223. [Google Scholar] [CrossRef]

- Xie, W.; Huang, X.; Li, H. Soybean oil methyl esters preparation using NaX zeolites loaded with KOH as a heterogeneous catalyst. Bioresour. Technol. 2007, 98, 936–939. [Google Scholar] [CrossRef] [PubMed]

- Fattahi, N.; Triantafyllidis, K.; Luque, R.; Ramazani, A. Zeolite-Based Catalysts: A Valuable Approach toward Ester Bond Formation. Catalysts 2019, 9, 758. [Google Scholar] [CrossRef] [Green Version]

- Ebiura, T.; Echizen, T.; Ishikawa, A.; Murai, K.; Baba, T. Selective transesterification of triolein with methanol to methyl oleate and glycerol using alumina loaded with alkali metal salt as a solid-base catalyst. Appl. Catal. A Gen. 2005, 283, 111–116. [Google Scholar] [CrossRef]

- Xie, W.; Peng, H.; Chen, L. Transesterification of soybean oil catalyzed by potassium loaded on alumina as a solid-base catalyst. Appl. Catal. A Gen. 2006, 300, 67–74. [Google Scholar] [CrossRef]

- Vyas, A.P.; Subrahmanyam, N.; Patel, P.A. Production of biodiesel through transesterification of Jatropha oil using KNO3/Al2O3 solid catalyst. Fuel 2009, 88, 625–628. [Google Scholar] [CrossRef]

- Xie, W.; Li, H. Alumina-supported potassium iodide as a heterogeneous catalyst for biodiesel production from soybean oil. J. Mol. Catal. A Chem. 2006, 255, 1–9. [Google Scholar] [CrossRef]

- Xie, W.; Peng, H.; Chen, L. Calcined Mg–Al hydrotalcites as solid base catalysts for methanolysis of soybean oil. J. Mol. Catal. A Chem. 2006, 246, 24–32. [Google Scholar] [CrossRef]

- Silva, C.C.C.M.; Ribeiro, N.F.P.; Souza, M.M.V.M.; Aranda, D.A.G. Biodiesel production from soybean oil and methanol using hydrotalcites as catalyst. Fuel Process. Technol. 2010, 91, 205–210. [Google Scholar] [CrossRef]

- Liu, Y.; Lotero, E.; Goodwin, J.G.; Mo, X. Transesterification of poultry fat with methanol using Mg–Al hydrotalcite derived catalysts. Appl. Catal. A Gen. 2007, 331, 138–148. [Google Scholar] [CrossRef]

- Zeng, H.; Feng, Z.; Deng, X.; Li, Y. Activation of Mg–Al hydrotalcite catalysts for transesterification of rape oil. Fuel 2008, 87, 3071–3076. [Google Scholar] [CrossRef]

- Navajas, A.; Campo, I.; Arzamendi, G.; Hernández, W.Y.; Bobadilla, L.F.; Centeno, M.A.; Odriozola, J.A.; Gandía, L.M. Synthesis of biodiesel from the methanolysis of sunflower oil using PURAL® Mg–Al hydrotalcites as catalyst precursors. Appl. Catal. B Environ. 2010, 100, 299–309. [Google Scholar] [CrossRef]

- Barakos, N.; Pasias, S.; Papayannakos, N. Transesterification of triglycerides in high and low quality oil feeds over an HT2 hydrotalcite catalyst. Bioresour. Technol. 2008, 99, 5037–5042. [Google Scholar] [CrossRef]

- Gao, L.; Xu, B.; Xiao, G.; Lv, J. Transesterification of Palm Oil with Methanol to Biodiesel over a KF/Hydrotalcite Solid Catalyst. Energy Fuels 2008, 22, 3531–3535. [Google Scholar] [CrossRef]

- Gao, L.; Teng, G.; Lv, J.; Xiao, G. Biodiesel Synthesis Catalyzed by the KF/Ca−Mg−Al Hydrotalcite Base Catalyst. Energy Fuels 2010, 24, 646–651. [Google Scholar] [CrossRef]

- Macala, G.S.; Robertson, A.W.; Johnson, C.L.; Day, Z.B.; Lewis, R.S.; White, M.G.; Iretskii, A.V.; Ford, P.C. Transesterification Catalysts from Iron Doped Hydrotalcite-like Precursors: Solid Bases for Biodiesel Production. Catal. Lett. 2008, 122, 205–209. [Google Scholar] [CrossRef]

- Shumaker, J.L.; Crofcheck, C.; Tackett, S.A.; Santillan-Jimenez, E.; Morgan, T.; Ji, Y.; Crocker, M.; Toops, T.J. Biodiesel synthesis using calcined layered double hydroxide catalysts. Appl. Catal. B Environ. 2008, 82, 120–130. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Brown, R.J.; Senadeera, W.; O’Hara, I.M.; Ristovski, Z.D. The use of artificial neural networks for identifying sustainable biodiesel feedstocks. Energies 2013, 6, 3764–3806. [Google Scholar] [CrossRef] [Green Version]

- Encinar, J.M.; González, J.F. Biodiesel and biolubricant production from different vegetable oils through transesterification. Eng. Rep. 2020, 2, 12190. [Google Scholar] [CrossRef]

- Fernández-Tirado, F.; Parra-López, C.; Romero-Gámez, M. Life cycle assessment of biodiesel in Spain: Comparing the environmental sustainability of Spanish production versus Argentinean imports. Energy Sustain. Dev. 2016, 33, 36–52. [Google Scholar] [CrossRef]

- Szabados, G.; Bereczky, Á. Experimental investigation of physicochemical properties of diesel, biodiesel and TBK-biodiesel fuels and combustion and emission analysis in CI internal combustion engine. Renew. Energy 2018, 121, 568–578. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Encinar, J.M.; González, J.F. Safflower biodiesel: Improvement of its oxidative stability by using BHA and TBHQ. Energies 2019, 12, 1940. [Google Scholar] [CrossRef] [Green Version]

- Nogales-Delgado, S.; Sánchez, N.; Encinar, J.M. Valorization of cynara Cardunculus, L. Oil as the basis of a biorefinery for biodiesel and biolubricant production. Energies 2020, 13, 5085. [Google Scholar] [CrossRef]

- UNE-EN 14112. Fat and Oil Derivatives—Fatty Acid Methyl Esters (FAME)—Determination of Oxidation Stability (Accelerated Oxidation Test); Asociación Española de Normalización: Madrid, Spain, 2017. [Google Scholar]

- UNE-EN 14111:2003. Fat and Oil Derivatives. Fatty Acid Methyl Esters (FAME). Determination of Iodine Value; Asociación Española de Normalización: Madrid, Spain, 2003. [Google Scholar]

- UNE-EN-ISO 3675. Crude Petroleum and Liquid Petroleum Products. Laboratory Determination of Density. Hydrometer Method; Asociación Española de Normalización: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN ISO 3104/AC:1999. Petroleum Products. Transparent and Opaque Liquids. Determination of Kinematic Viscosity and Calculation of Dynamic Viscosity (ISO 3104:1994); Asociación Española de Normalización: Madrid, Spain, 1999. [Google Scholar]

- UNE-EN 116:2015. Diesel and Domestic Heating Fuels—Determination of Cold Filter Plugging Point- Stepwise Cooling Bath Method; Asociación Española de Normalización: Madrid, Spain, 2015. [Google Scholar]

- UNE-EN 14104:2003. Oil and Fat Derivatives. Fatty Acid Methyl Esters (FAME). Determination of Acid Value; Asociación Española de Normalización: Madrid, Spain, 2003. [Google Scholar]

- UNE-EN 51023:1990. Petroleum Products. Determination of Flash and Fire Points. Cleveland Open Cup Method; Asociación Española de Normalización: Madrid, Spain, 1990. [Google Scholar]

- Ishak, N.; Estephane, J.; Dahdah, E.; Chalouhi, L.M.; Nassreddine, S.; El Khoury, B.; Aouad, S. Outstanding activity of a biodiesel coated K2O/fumed silica catalyst in the transesterification reaction. J. Environ. Chem. Eng. 2021, 9, 104665. [Google Scholar] [CrossRef]

- International Centre for Diffraction Data. Powder diffraction file: Na2SiO3 Cmc 21 PDF:01-072-0079, ICDD-PDF-2. 2010.

- International Centre for Diffraction Data. Powder diffraction file: Na2Si2O5 P21/a PDF:00-023-0529, ICDD-PDF-2. 2010.

- International Centre for Diffraction Data. Powder diffraction file: (Na2O)0.33NaAlSiO4 F-43m PDF:00-039-0101, ICDD-PDF-2. 2010.

- International Centre for Diffraction Data. Powder diffraction file: Na8(AlSiO4)6(NO3)2 P-43n PDF:00-039-0101, ICDD-PDF-2. 2010.

- González Velasco, J.R.; González Marcos, J.A.; González Marcos, M.P.; Gutiérrez Ortiz, M.A. Cinética Química Aplicada; Editorial Síntesis S. A.: Madrid, Spain, 1999; ISBN 8477386668. [Google Scholar]

- Ngamcharussrivichai, C.; Totarat, P.; Bunyakiat, K. Ca and Zn mixed oxide as a heterogeneous base catalyst for transesterification of palm kernel oil. Appl. Catal. A Gen. 2008, 341, 77–85. [Google Scholar] [CrossRef]

- Alonso, D.M.; Mariscal, R.; Moreno-Tost, R.; Poves, M.D.Z.; Granados, M.L. Potassium leaching during triglyceride transesterification using K/γ-Al2O3 catalysts. Catal. Commun. 2007, 8, 2074–2080. [Google Scholar] [CrossRef]

- Di Serio, M.; Mallardo, S.; Carotenuto, G.; Tesser, R.; Santacesaria, E. Mg/Al hydrotalcite catalyst for biodiesel production in continuous packed bed reactors. Catal. Today 2012, 195, 54–58. [Google Scholar] [CrossRef]

- Yusuff, A.S.; Owolabi, J.O. Synthesis and characterization of alumina supported coconut chaff catalyst for biodiesel production from waste frying oil. South Afr. J. Chem. Eng. 2019, 30, 42–49. [Google Scholar] [CrossRef]

- Wagner, C.D.; Davis, L.E.; Zeller, M.V.; Taylor, J.A.; Raymond, R.H.; Gale, L.H. Empirical atomic sensitivity factors for quantitative analysis by electron spectroscopy for chemical analysis. Surf. Interface Anal. 1981, 3, 211–225. [Google Scholar] [CrossRef]

- Koutsouki, A.A.; Tegou, E.; Badeka, A.; Kontakos, S.; Pomonis, P.J.; Kontominas, M.G. In situ and conventional transesterification of rapeseeds for biodiesel production: The effect of direct sonication. Ind. Crops Prod. 2016, 84, 399–407. [Google Scholar] [CrossRef]

- Encinar, J.M.; González, J.F.; Pardal, A.; Martínez, G. Rape oil transesterification over heterogeneous catalysts. Fuel Process. Technol. 2010, 91, 1530–1536. [Google Scholar] [CrossRef]

- Encinar, J.M.; Pardal, A.; Martínez, G. Transesterification of rapeseed oil in subcritical methanol conditions. Fuel Process. Technol. 2012, 94, 40–46. [Google Scholar] [CrossRef]

- Rathore, V.; Newalkar, B.L.; Badoni, R.P. Processing of vegetable oil for biofuel production through conventional and non-conventional routes. Energy Sustain. Dev. 2016, 31, 24–49. [Google Scholar] [CrossRef]

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biomass Bioenergy 2014, 61, 27–297. [Google Scholar] [CrossRef]

- Xiao, Y.; Gao, L.; Xiao, G.; Lv, J. Kinetics of the Transesterification Reaction Catalyzed by Solid Base in a Fixed-Bed Reactor. Energy Fuels 2010, 24, 5829–5833. [Google Scholar] [CrossRef]

- Hsieh, L.-S.; Kumar, U.; Wu, J.C.S. Continuous production of biodiesel in a packed-bed reactor using shell–core structural Ca(C3H7O3)2/CaCO3 catalyst. Chem. Eng. J. 2010, 158, 250–256. [Google Scholar] [CrossRef]

| Impregnated Amount, mmolNa·gsupport−1 | FAME Content, % w/w |

|---|---|

| 0 1 | 0 |

| 5 | <1 |

| 10 | 18.2 |

| 20 | 99.3 |

| 40 | 99.3 |

| Catalyst Amount, % w/w | Methanol/Oil Ratio | FAME Content, % w/w |

|---|---|---|

| Diluted species | 9 (a):1 | 3.25 |

| 7 (b) | 9 (c):1 | 98.8 |

| Sample | SiAl 1 (Support) | NaNO3/SiAl x/1 | |||

|---|---|---|---|---|---|

| 5/1 | 10/1 | 20/1 | 40/1 | ||

| SBET, m2·g−1 | 448.2 | 1.522 | 0.410 | 1.238 | 2.406 |

| SiAl | NaNO3/SiAl x/1 | ||||

|---|---|---|---|---|---|

| 5/1 | 10/1 | 20/1 | 40/1 | ||

| Na 1s | n.d. 1 | 9.20 | 14.01 | 20.48 | 25.40 |

| O 1s | 59.98 | 53.74 | 53.39 | 49.94 | 47.10 |

| Si 2p | 32.60 | 25.92 | 21.62 | 16.30 | 14.14 |

| Al 2p | 5.66 | 4.49 | 3.86 | 2.76 | 3.22 |

| C 1s | 1.76 | 6.64 | 5.73 | 9.39 | 9.49 |

| N 1s | n.d. | n.d. | 1.38 | 1.13 | 0.65 |

| Atomic ratios Na/Si/Al | 0/85.8/14.2 | 15.2/71.9/12.9 | 23.4/65.0/11.6 | 35.5/52.0/10.5 | 47.2/42.8/10.0 |

| Species, % | Without Use | Methanol Contact | After Transesterification |

|---|---|---|---|

| Na 1s | 20.48 | 22.48 | 7.27 |

| O 1s | 49.94 | 46.73 | 19.15 |

| Si 2p | 16.30 | 11.52 | 2.64 |

| Al 2p | 2.76 | 4.34 | 1.09 |

| C 1s | 9.39 | 14.93 | 69.86 |

| N 1s | 1.13 | n.d. 1 | n.d. |

| Atomic ratios Na/Si/Al | 35.5/52.0/10.5 | 41.6/46.9/11.5 | 50.4/30.2/19.4 |

| Catalyst Addition | 3% w/w W = 7.5 g | 5% w/w W = 12.5 g | 7% w/w W = 17.5 g |

|---|---|---|---|

| nA0 = 0.2753 mol CA0 = 0.7306 M θB = 9.2931 | |||

| Model | Langmuir-Hinshelwood | ||

| Kinetic parameters | k = 2.333 × 10−3 L2·gcat−1·mol−1·min−1 KA = 6.3 × 10−23 L·mol−1 KB = 2.071 L·mol−1 | ||

| R2 | 0.9992 | 0.9989 | 0.9996 |

| S | 0.0157 | 0.0235 | 0.0164 |

| Model | Eley-Rideal | ||

| Kinetic parameters | k = 2.333 × 10−3 L2·gcat−1·mol−1·min−1 KB = 2.071 L·mol−1 | ||

| R2 | 0.9992 | 0.9989 | 0.0006 |

| S | 0.0157 | 0.0236 | 0.0163 |

| nA0 = 0.2753 mol CA0 = 0.7306 M θB = 9.2931 | ||||

|---|---|---|---|---|

| 45 °C | 55 °C | 60 °C | 65 °C | |

| k·10−3 (L2·gcat−1·mol−1·min−1) | 0.432 | 1.001 | 1.354 | 2.333 |

| KB (L·mol−1) | 2.49 | 2.30 | 2.18 | 2.07 |

| R2 | 0.9992 | 0.9998 | 0.9996 | 0.9989 |

| s | 0.0179 | 0.0177 | 0.0098 | 0.0236 |

| Arrhenius | Van’t Hoff | |||

|---|---|---|---|---|

| Reference (Catalyst) | Ea (kJ·mol−1) | A0 (L2·gcat−1·mol−1·min−1) | Ea (kJ·mol−1) | A0 (L2·gcat−1·mol−1·min−1) |

| NaNO3/SiAl 20/1 | 73.3 | 4.6 × 108 | −8.28 | 0.109 |

| R2 | 0.992 | 0.992 | ||

| KF/Ca-Mg-Al [86] | 109.6 | 1.4 × 1014 | −36.2 | 1.2 × 10−6 |

| R2 | 0.967 | 0.906 | ||

| Ca(C3H7O3)2/CaCO3 [57] | 42.5 | 372.4 | n.d. 2 | n.d. |

| R2 | 0.999 1 | n.d. | ||

| FAME Profile | C14:0 | C16:0 | C16:1 | C18:0 | C18:1 | C18:2 | C18:3 | C22:0 |

|---|---|---|---|---|---|---|---|---|

| % w/w | 0.04 | 4.19 | 0.19 | 1.50 | 66.6 | 17.2 | 7.71 | <0.01 |

| Parameter | FAME % | IV gI2·100 g−1 | Density g·L−1 | Viscosity cSt | CFPP °C | AN mgKOH·g−1 | FP °C | CP °C |

| 99.3 | 101.3 | 879 | 4.43 | −7 | 0.28 | 175 | 190 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Encinar, J.M.; González, J.F.; Martínez, G.; Nogales-Delgado, S. Use of NaNO3/SiAl as Heterogeneous Catalyst for Fatty Acid Methyl Ester Production from Rapeseed Oil. Catalysts 2021, 11, 1405. https://doi.org/10.3390/catal11111405

Encinar JM, González JF, Martínez G, Nogales-Delgado S. Use of NaNO3/SiAl as Heterogeneous Catalyst for Fatty Acid Methyl Ester Production from Rapeseed Oil. Catalysts. 2021; 11(11):1405. https://doi.org/10.3390/catal11111405

Chicago/Turabian StyleEncinar, José María, Juan Félix González, Gloria Martínez, and Sergio Nogales-Delgado. 2021. "Use of NaNO3/SiAl as Heterogeneous Catalyst for Fatty Acid Methyl Ester Production from Rapeseed Oil" Catalysts 11, no. 11: 1405. https://doi.org/10.3390/catal11111405

APA StyleEncinar, J. M., González, J. F., Martínez, G., & Nogales-Delgado, S. (2021). Use of NaNO3/SiAl as Heterogeneous Catalyst for Fatty Acid Methyl Ester Production from Rapeseed Oil. Catalysts, 11(11), 1405. https://doi.org/10.3390/catal11111405