Current Status and Future Perspectives of Supports and Protocols for Enzyme Immobilization

Abstract

:1. Introduction

2. Novel Techniques for Lipase Immobilization

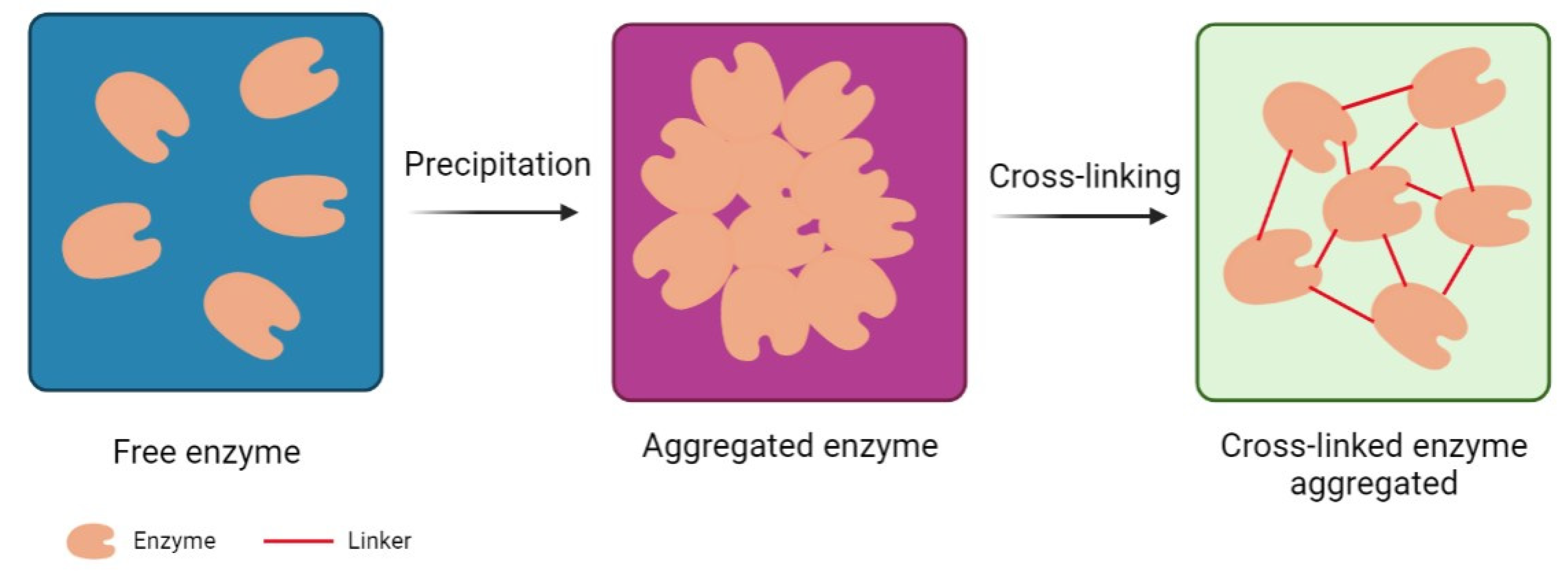

2.1. Crosslinked Enzyme Aggregates (CLEAs)

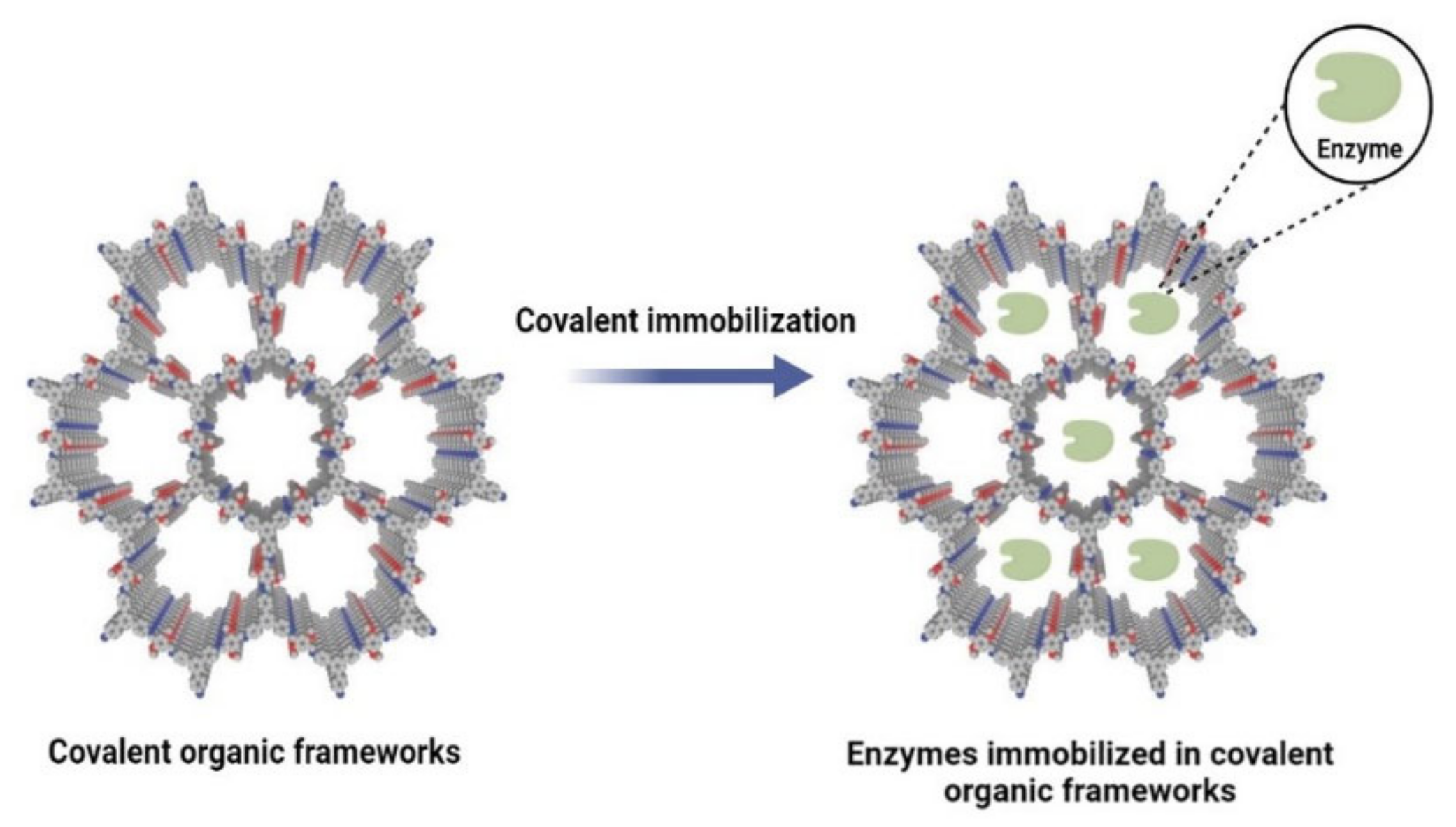

2.2. Covalent Organic Frameworks (COFs)

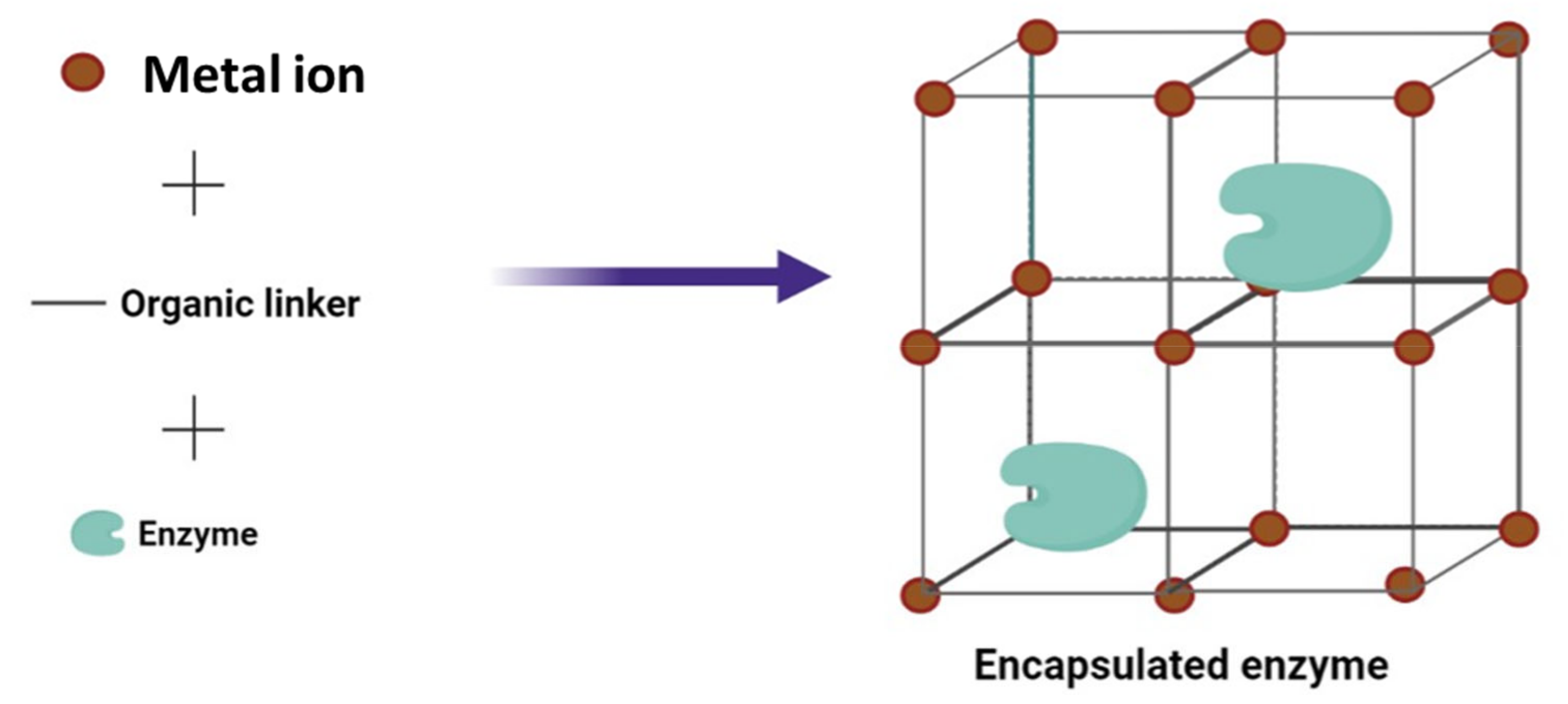

2.3. Metal-Organic Frameworks (MOFs)

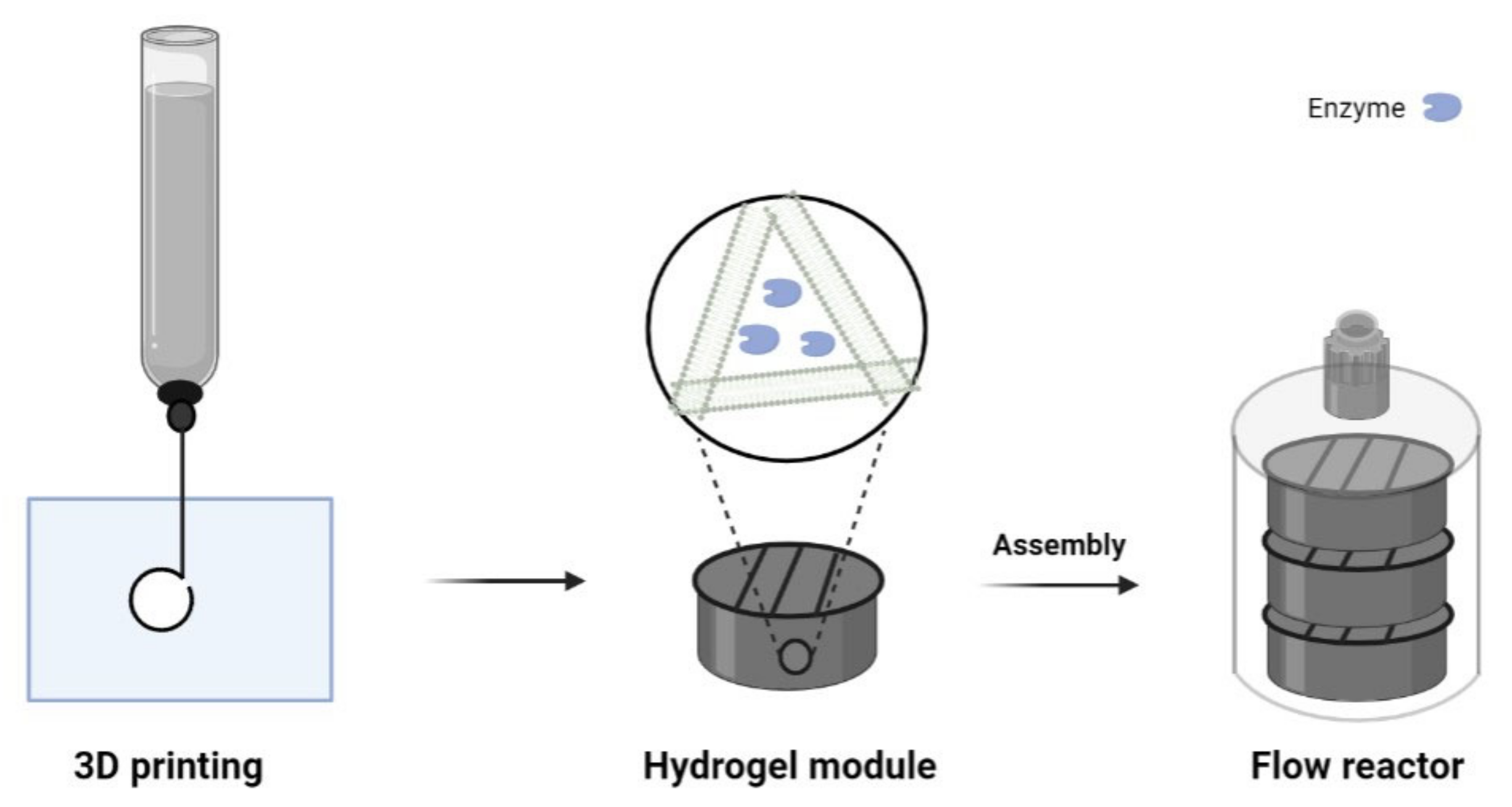

2.4. 3D Printing

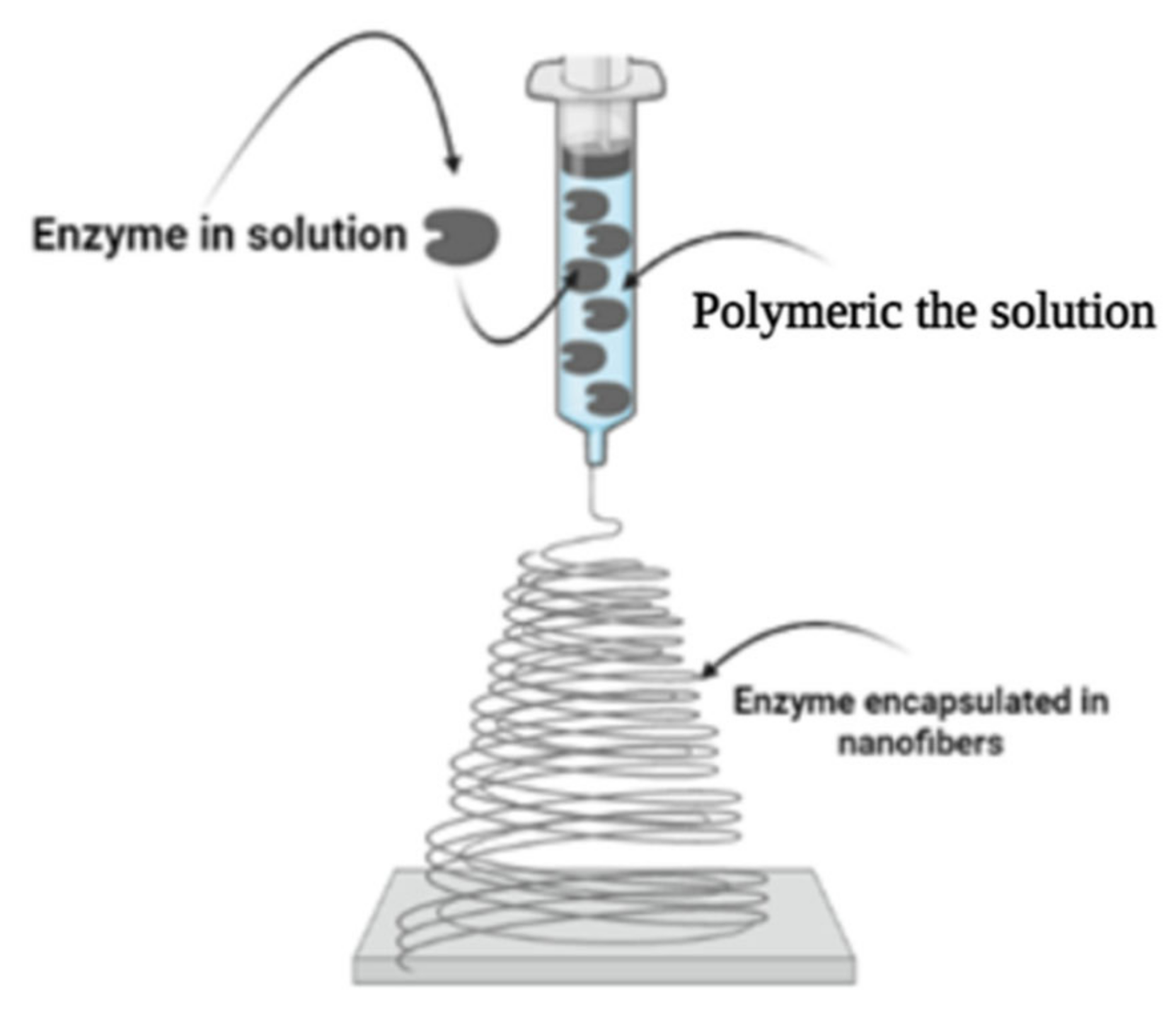

2.5. Electrospinning

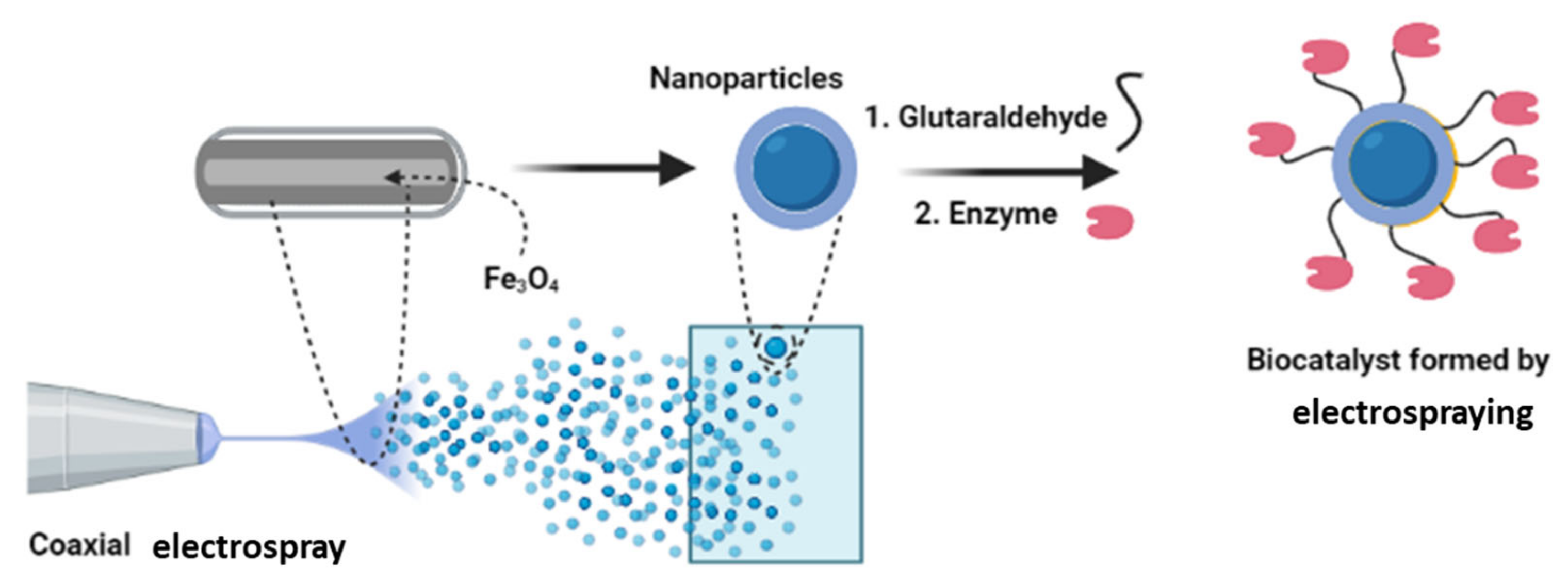

2.6. Electrospraying

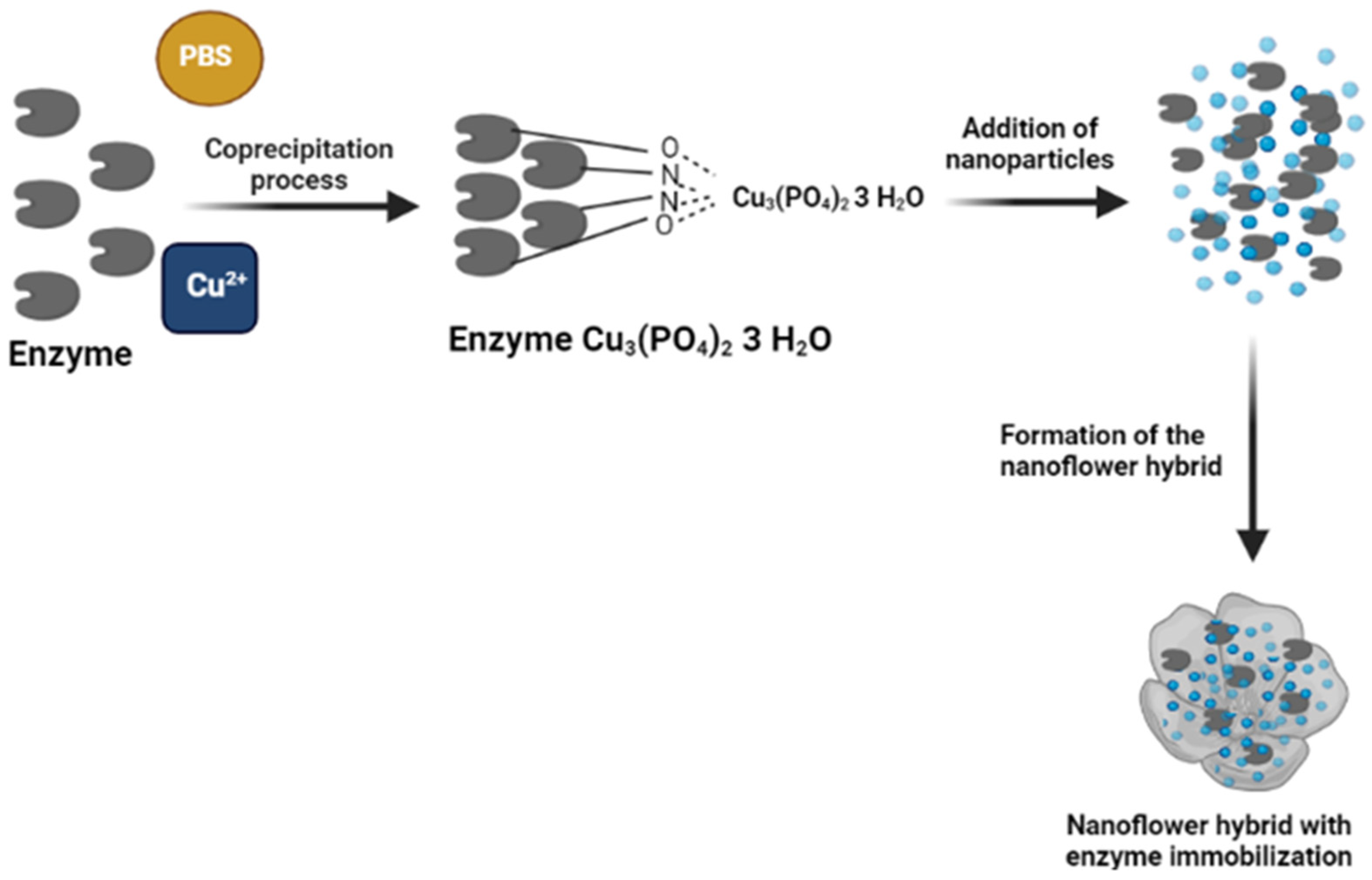

2.7. Hybrid Nanoflowers

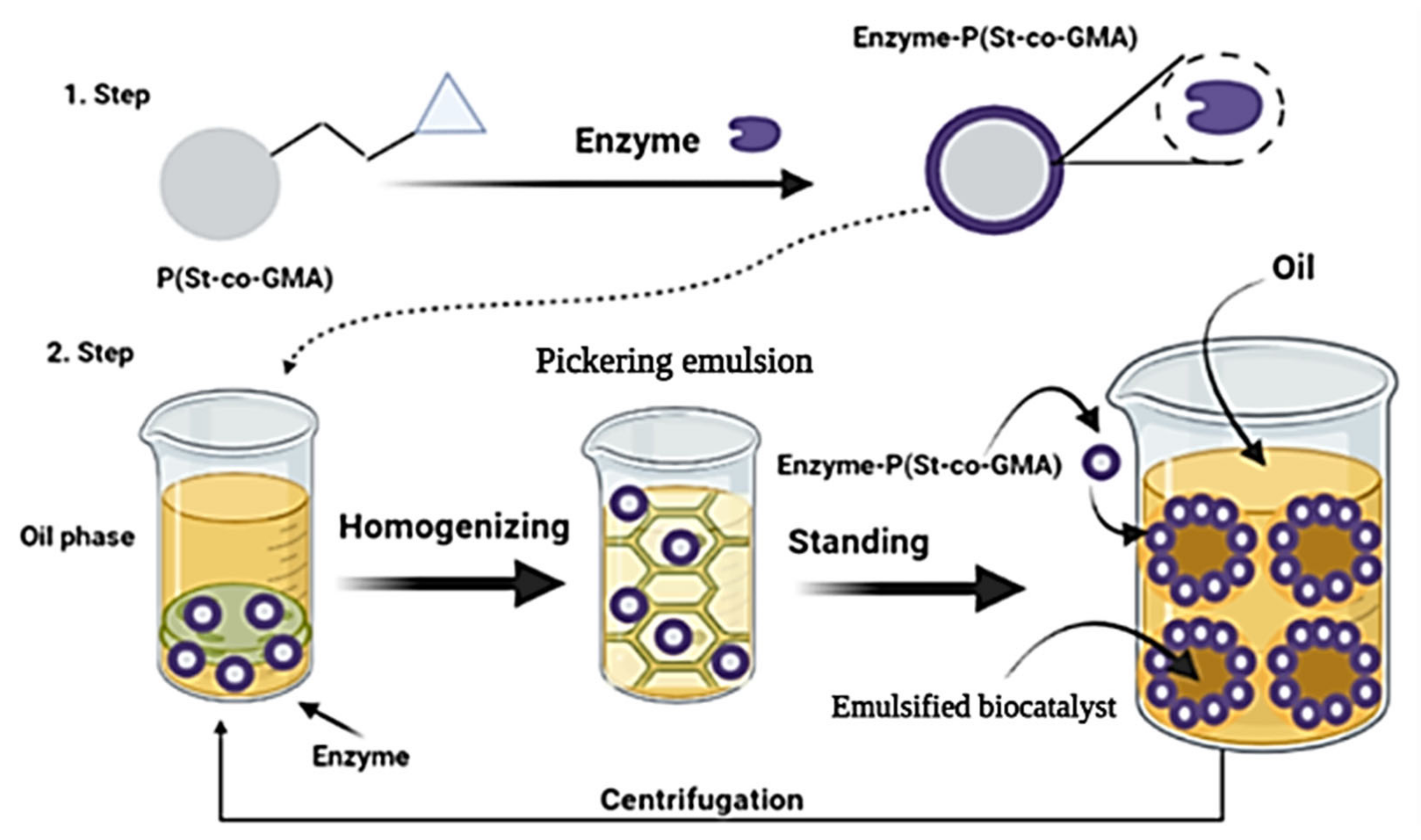

2.8. Pickering Emulsion Enzyme Encapsulation

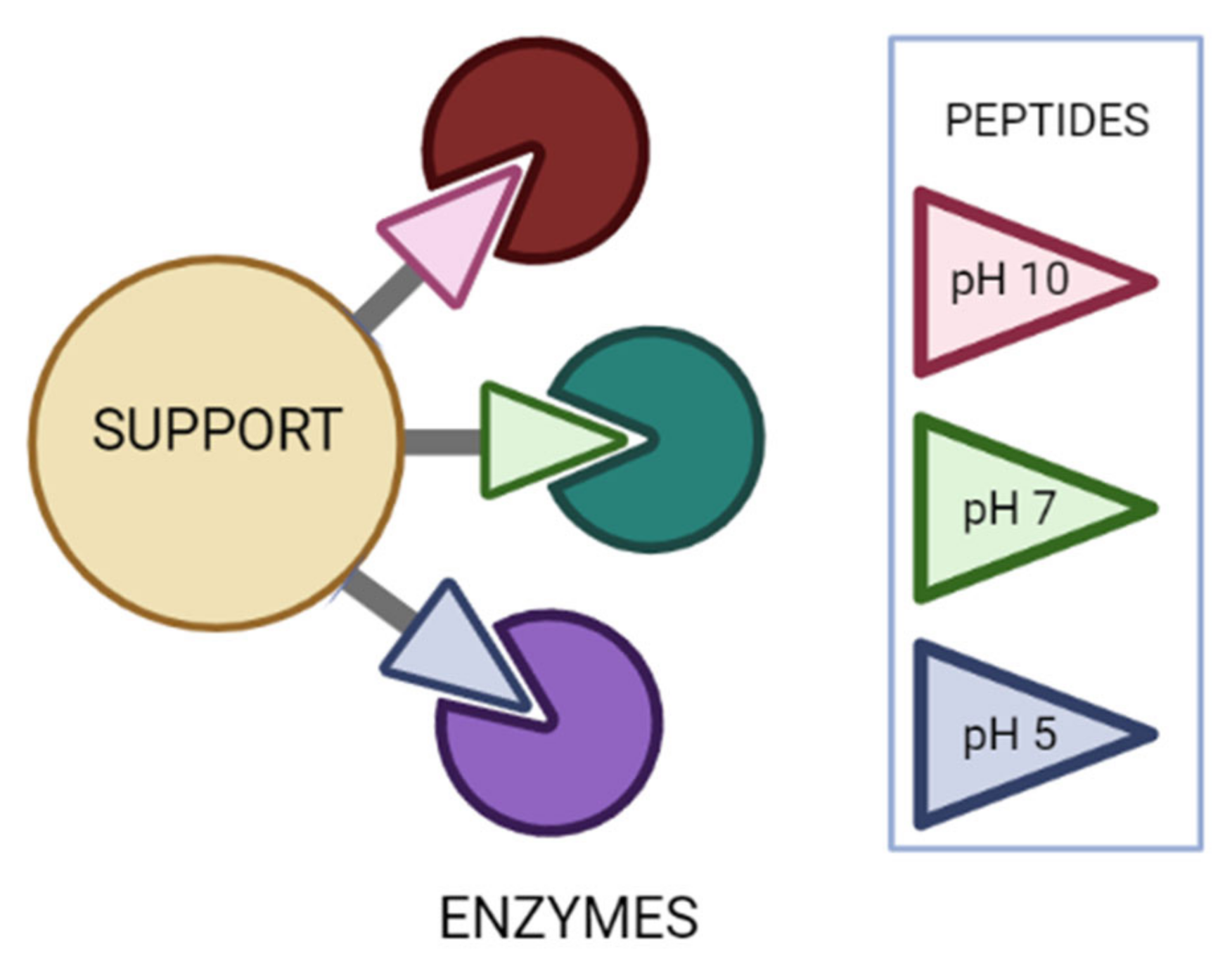

2.9. Peptide-Guided Immobilization

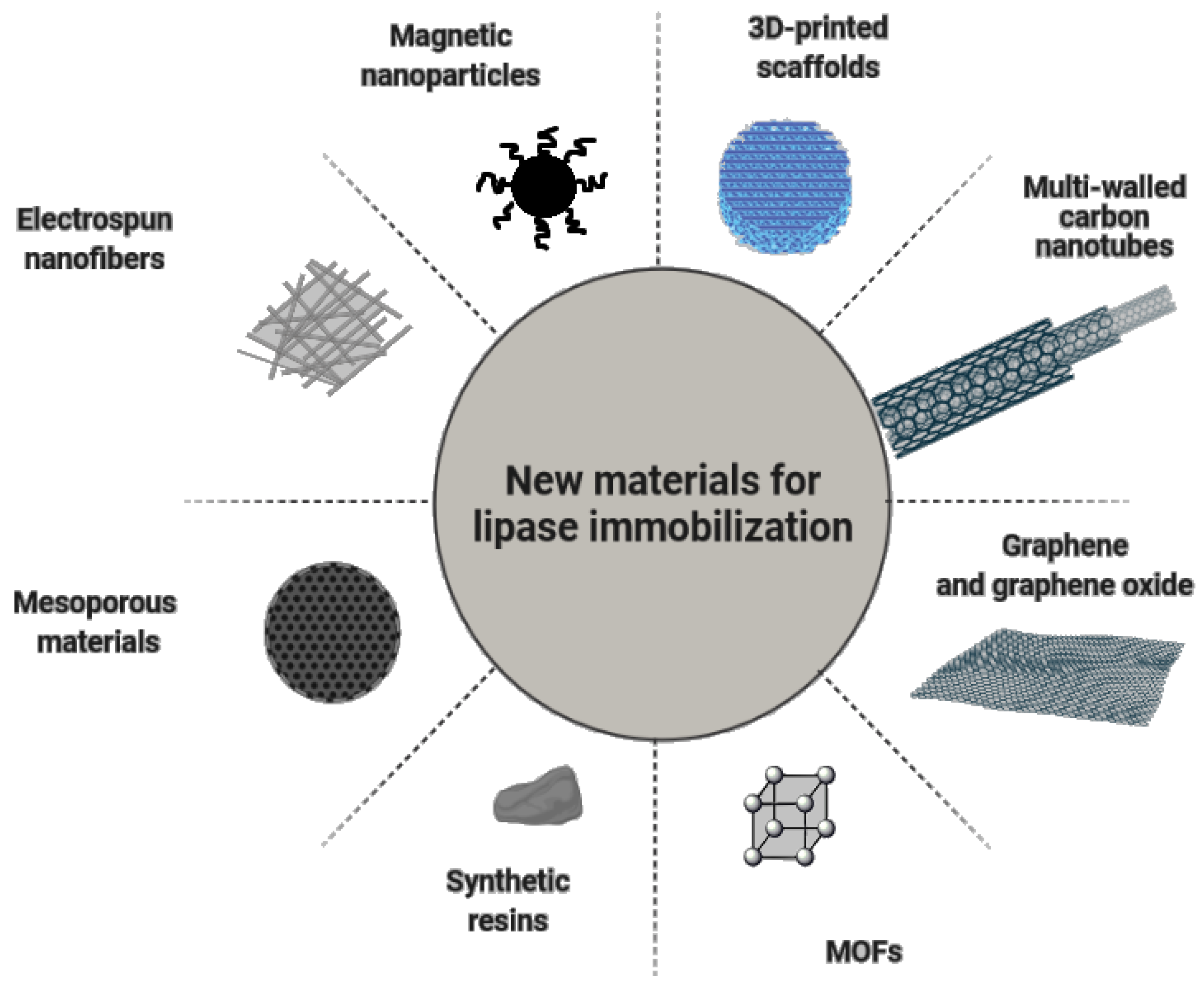

3. Novel Carriers for Immobilization

4. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bilal, M.; Iqbal, H.M.; Hu, H.; Wang, W.; Zhang, X. Metabolic engineering and enzyme-mediated processing: A biotechnological venture towards biofuel production—A review. Renew. Sustain. Energy Rev. 2018, 82, 436–447. [Google Scholar] [CrossRef]

- Roy, A.; Bharadvaja, N. Biotechnological approaches for the production of pharmaceutically important compound: Plumbagin. Curr. Pharm. Biotechnol. 2018, 19, 372–381. [Google Scholar] [CrossRef] [PubMed]

- Silveira, B.M.P.; Barcelos, M.C.S.; Vespermann, K.A.C.; Pelissari, F.M.; Molina, G. An overview of biotechnological processes in the food industry. In Bioprocessing for Biomolecules Production; John Wiley & Sons, Ltd.: Chichester, UK, 2019; pp. 1–19. [Google Scholar]

- Ashrafi, A.M.; Sýs, M.; Sedláčková, E.; Farag, A.S.; Adam, V.; Přibyl, J.; Richtera, L.; Sýs, A. Application of the enzymatic electrochemical biosensors for monitoring non-competitive inhibition of enzyme activity by heavy metals. Sensors 2019, 19, 2939. [Google Scholar] [CrossRef] [Green Version]

- Mariz, B.d.P.; Carvalho, S.; Batalha, I.L.; Pina, A.S. Artificial enzymes bringing together computational design and directed evolution. Org. Biomol. Chem. 2021, 19, 1915–1925. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, R.; Virgen-Ortíz, J.J.; dos Santos, J.C.; Berenguer-Murcia, A.; Alcantara, A.R.; Barbosa, O.; Ortiz, C.; Fernandez-Lafuente, R. Immobilization of lipases on hydrophobic supports: Immobilization mechanism, advantages, problems, and solutions. Biotechnol. Adv. 2019, 37, 746–770. [Google Scholar] [CrossRef] [Green Version]

- Schmid-Dannert, C.; López-Gallego, F. Advances and opportunities for the design of self-sufficient and spatially organized cell-free biocatalytic systems. Curr. Opin. Chem. Biol. 2018, 49, 97–104. [Google Scholar] [CrossRef]

- Schmieg, B.; Döbber, J.; Kirschhöfer, F.; Pohl, M.; Franzreb, M. Advantages of hydrogel-based 3D-printed enzyme reactors and their limitations for biocatalysis. Front. Bioeng. Biotechnol. 2019, 6, 211. [Google Scholar] [CrossRef] [Green Version]

- Bolina, I.C.A.; Gomes, R.A.B.; Mendes, A.A. Biolubricant production from several oleaginous feedstocks using lipases as catalysts: Current scenario and future perspectives. BioEnergy Res. 2021, 1–19. [Google Scholar] [CrossRef]

- Pohanka, M. Biosensors and bioassays based on lipases, principles and applications: A review. Molecules 2019, 24, 616. [Google Scholar] [CrossRef] [Green Version]

- Reis, P.; Holmberg, K.; Watzke, H.; Leser, M.; Miller, R. Lipases at interfaces: A review. Adv. Colloid Interface Sci. 2009, 147–148, 237–250. [Google Scholar] [CrossRef] [PubMed]

- Melani, N.; Tambourgi, E.B.; Silveira, E. Lipases: From production to applications. Sep. Purif. Rev. 2019, 49, 143–158. [Google Scholar] [CrossRef]

- Valério, R.B.R.; Cavalcante, A.L.G.; Mota, G.F.; de Sousa, I.G.; da Silva Souza, J.E.; Cavalcante, F.T.T.; de Aguiar Falcão, I.R.; da Silva Moreira, K. Understanding the biocatalytic potential of lipase from rhizopus chinensis. Biointerface Res. Appl. Chem. 2021, 12, 4230–4260. [Google Scholar] [CrossRef]

- Jaeger, K.-E.; Eggert, T. Lipases for biotechnology. Curr. Opin. Biotechnol. 2002, 13, 390–397. [Google Scholar] [CrossRef]

- Schmid, R.D.; Verger, R. Lipases: Interfacial enzymes with attractive applications. Angew. Chem. Int. Ed. 1998, 37, 1608–1633. [Google Scholar] [CrossRef]

- Verger, R. ‘Interfacial activation’ of lipases: Facts and artifacts. Trends Biotechnol. 1997, 15, 32–38. [Google Scholar] [CrossRef]

- Anderson, E.M.; Larsson, K.M.; Kirk, O. One biocatalyst–many applications: The use of candida antarctica b-lipase in organic synthesis. Biocatal. Biotransform. 1998, 16, 181–204. [Google Scholar] [CrossRef]

- Reetz, M.T. Biocatalysis in organic chemistry and biotechnology: Past, present, and future. J. Am. Chem. Soc. 2013, 135, 12480–12496. [Google Scholar] [CrossRef] [PubMed]

- Reetz, M.T. Lipases as practical biocatalysts. Curr. Opin. Chem. Biol. 2002, 6, 145–150. [Google Scholar] [CrossRef]

- Kublicki, M.; Koszelewski, D.; Brodzka, A.; Ostaszewski, R. Wheat germ lipase: Isolation, purification and applications. Crit. Rev. Biotechnol. 2021, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Sarmah, N.; Revathi, D.; Sheelu, G.; Rani, K.Y.; Sridhar, S.; Mehtab, V.; Sumana, C. Recent advances on sources and industrial applications of lipases. Biotechnol. Prog. 2017, 34, 5–28. [Google Scholar] [CrossRef]

- Miguez, J.P.; Gama, R.S.; Bolina, I.C.; de Melo, C.C.; Cordeiro, M.R.; Hirata, D.B.; Mendes, A.A. Enzymatic synthesis optimization of a cosmetic ester catalyzed by a homemade biocatalyst prepared via physical adsorption of lipase on amino-functionalized rice husk silica. Chem. Eng. Res. Des. 2018, 139, 296–308. [Google Scholar] [CrossRef]

- Monteiro, R.R.; Arana-Peña, S.; da Rocha, T.N.; Miranda, L.P.; Berenguer-Murcia, Á.; Tardioli, P.W.; dos Santos, J.C.; Fernandez-Lafuente, R. Liquid lipase preparations designed for industrial production of biodiesel. Is it really an optimal solution? Renew. Energy 2020, 164, 1566–1587. [Google Scholar] [CrossRef]

- Moreira, K.S.; Júnior, L.S.M.; Monteiro, R.R.C.; De Oliveira, A.L.B.; Valle, C.P.; Freire, T.M.; Fechine, P.B.A.; De Souza, M.C.M.; Fernandez-Lorente, G.; Guisan, J.M.; et al. Optimization of the production of enzymatic biodiesel from residual babassu oil (Orbignya sp.) via RSM. Catalysts 2020, 10, 414. [Google Scholar] [CrossRef] [Green Version]

- Cavalcante, F.T.T.; Neto, F.S.; Falcão, I.R.D.A.; Souza, J.E.D.S.; Junior, L.S.D.M.; Sousa, P.D.S.; Rocha, T.G.; de Sousa, I.G.; Gomes, P.H.D.L.; de Souza, M.C.M.; et al. Opportunities for improving biodiesel production via lipase catalysis. Fuel 2020, 288, 119577. [Google Scholar] [CrossRef]

- Lima, G.V.; da Silva, M.R.; Fonseca, T.D.S.; de Lima, L.B.; Oliveira, M.D.C.F.D.; de Lemos, T.L.G.; Zampieri, D.; dos Santos, J.C.S.; Rios, N.S.; Gonçalves, L.R.B.; et al. Chemoenzymatic synthesis of (S)-Pindolol using lipases. Appl. Catal. A Gen. 2017, 546, 7–14. [Google Scholar] [CrossRef]

- Coelho, A.L.S.; Orlandelli, R.C. Immobilized microbial lipases in the food industry: A systematic literature review. Crit. Rev. Food Sci. Nutr. 2020, 61, 1689–1703. [Google Scholar] [CrossRef] [PubMed]

- Quayson, E.; Amoah, J.; Hama, S.; Kondo, A.; Ogino, C. Immobilized lipases for biodiesel production: Current and future greening opportunities. Renew. Sustain. Energy Rev. 2020, 134, 110355. [Google Scholar] [CrossRef]

- Contesini, F.J.; Davanço, M.G.; Borin, G.P.; Vanegas, K.G.; Cirino, J.P.G.; De Melo, R.R.; Mortensen, U.H.; Hildén, K.; Campos, D.R.; Carvalho, P.D.O. Advances in recombinant lipases: Production, engineering, immobilization and application in the pharmaceutical industry. Catalysts 2020, 10, 1032. [Google Scholar] [CrossRef]

- Lima, P.J.M.; da Silva, R.M.; Neto, C.A.C.G.; e Silva, N.C.G.; Souza, J.E.D.S.; Nunes, Y.L.; dos Santos, J.C.S. An overview on the conversion of glycerol to value-added industrial products via chemical and biochemical routes. Biotechnol. Appl. Biochem. 2021. [Google Scholar] [CrossRef]

- Rocha, T.G.; Gomes, P.H.D.L.; de Souza, M.C.M.; Monteiro, R.R.C.; dos Santos, J.C.S. Lipase cocktail for optimized biodiesel production of free fatty acids from residual chicken oil. Catal. Lett. 2020, 151, 1155–1166. [Google Scholar] [CrossRef]

- Souza, J.E.S.; Monteiro, R.R.C.; Rocha, T.G.; Moreira, K.S.; Cavalcante, F.T.T.; Braz, A.K.D.S.; de Souza, M.C.M.; dos Santos, J.C.S. Sonohydrolysis using an enzymatic cocktail in the preparation of free fatty acid. 3 Biotech 2020, 10, 1–10. [Google Scholar] [CrossRef]

- De Souza, T.C.; Fonseca, T.D.S.; Silva, J.D.S.; Lima, P.J.M.; Neto, C.A.C.G.; Monteiro, R.R.C.; Rocha, M.V.P.; De Mattos, M.C.; Dos Santos, J.C.S.; Gonçalves, L.R.B. Modulation of lipase B from Candida antarctica properties via covalent immobilization on eco-friendly support for enzymatic kinetic resolution of rac-indanyl acetate. Bioprocess Biosyst. Eng. 2020, 43, 2253–2268. [Google Scholar] [CrossRef]

- Pinheiro, M.P.; Monteiro, R.R.; Silva, F.F.; Lemos, T.L.; Fernandez-Lafuente, R.; Gonçalves, L.R.; dos Santos, J.C. Modulation of Lecitase properties via immobilization on differently activated Immobead-350: Stabilization and inversion of enantiospecificity. Process. Biochem. 2019, 87, 128–137. [Google Scholar] [CrossRef]

- Filho, D.G.; Silva, A.G.; Guidini, C.Z. Lipases: Sources, immobilization methods, and industrial applications. Appl. Microbiol. Biotechnol. 2019, 103, 7399–7423. [Google Scholar] [CrossRef]

- Paulino, B.N.; Pessôa, M.G.; Molina, G.; Neto, A.A.K.; Oliveira, J.V.C.; Mano, M.C.R.; Pastore, G.M. Biotechnological production of value-added compounds by ustilaginomycetous yeasts. Appl. Microbiol. Biotechnol. 2017, 101, 7789–7809. [Google Scholar] [CrossRef]

- Maldonado, R.R. A review on geotrichum lipases: Production, purification, immobilization and applications. Chem. Biochem. Eng. Q. 2017, 30, 439–454. [Google Scholar] [CrossRef]

- Riegler-Berket, L.; Leitmeier, A.; Aschauer, P.; Dreveny, I.; Oberer, M. Identification of lipases with activity towards monoacylglycerol by criterion of conserved cap architectures. Biochim. Biophys. Acta Mol. Cell Biol. Lipids 2018, 1863, 679–687. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bauer, T.L.; Buchholz, P.C.F.; Pleiss, J. The modular structure of α/β-hydrolases. FEBS J. 2019, 287, 1035–1053. [Google Scholar] [CrossRef] [PubMed]

- Rios, N.; Pinheiro, B.; Pinheiro, M.P.; Bezerra, R.M.; dos Santos, J.C.S.; Gonçalves, L.R.B. Biotechnological potential of lipases from pseudomonas: Sources, properties and applications. Process. Biochem. 2018, 75, 99–120. [Google Scholar] [CrossRef]

- Cheng, C.; Jiang, T.; Wu, Y.; Cui, L.; Qin, S.; He, B. Elucidation of lid open and orientation of lipase activated in interfacial activation by amphiphilic environment. Int. J. Biol. Macromol. 2018, 119, 1211–1217. [Google Scholar] [CrossRef] [PubMed]

- Hama, S.; Noda, H.; Kondo, A. How lipase technology contributes to evolution of biodiesel production using multiple feedstocks. Curr. Opin. Biotechnol. 2018, 50, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Zheng, X.; Zhang, X.; Zhang, K.; Lin, Y.; Liang, S. Combined strategies for engineering a novel whole-cell biocatalyst of Candida rugosa lipase with improved characteristics. Biochem. Eng. J. 2019, 151. [Google Scholar] [CrossRef]

- Bresolin, D.; Estrella, A.S.; Da Silva, J.R.P.; Valerio, A.; Sayer, C.; de Araujo, P.H.H.; De Oliveira, D. Synthesis of a green polyurethane foam from a biopolyol obtained by enzymatic glycerolysis and its use for immobilization of lipase NS. Bioprocess. Biosyst. Eng. 2018, 42, 213–222. [Google Scholar] [CrossRef]

- Zhong, L.; Feng, Y.; Wang, G.; Wang, Z.; Bilal, M.; Lv, H.; Jia, S.; Cui, J. Production and use of immobilized lipases in/on nanomaterials: A review from the waste to biodiesel production. Int. J. Biol. Macromol. 2020, 152, 207–222. [Google Scholar] [CrossRef]

- Lv, L.; Dai, L.; Du, W.; Liu, D. Progress in enzymatic biodiesel production and commercialization. Processes 2021, 9, 355. [Google Scholar] [CrossRef]

- Bezerra, R.M.; Monteiro, R.R.C.; Neto, D.M.A.; da Silva, F.F.; de Paula, R.; de Lemos, T.L.; Fechine, P.B.; Correa, M.; Bohn, F.; Gonçalves, L.R.; et al. A new heterofunctional support for enzyme immobilization: PEI functionalized Fe3O4 MNPs activated with divinyl sulfone. Application in the immobilization of lipase from thermomyces lanuginosus. Enzym. Microb. Technol. 2020, 138, 109560. [Google Scholar] [CrossRef]

- Melo, A.D.Q.; Silva, F.F.M.; Dos Santos, J.C.S.; Fernández-Lafuente, R.; Lemos, T.L.G.; Filho, F.A.D. Synthesis of benzyl acetate catalyzed by lipase immobilized in nontoxic chitosan-polyphosphate beads. Molecules 2017, 22, 2165. [Google Scholar] [CrossRef] [Green Version]

- Bonazza, H.L.; Manzo, R.M.; Mammarella, E.J.; Dos Santos, J.C.S. Operational and thermal stability analysis of thermomyces lanuginosus lipase covalently immobilized onto modified chitosan supports. Appl. Biochem. Biotechnol. 2017, 184, s12010–s12017. [Google Scholar] [CrossRef]

- Villalba, M.; Verdasco-Martín, C.M.; dos Santos, J.C.S.; Fernandez-Lafuente, R.; Otero, C. Operational stabilities of different chemical derivatives of Novozym 435 in an alcoholysis reaction. Enzym. Microb. Technol. 2016, 90, 35–44. [Google Scholar] [CrossRef]

- Garcia-Galan, C.; dos Santos, J.C.; Barbosa, O.; Torres, R.; Pereira, E.B.; Corberan, V.C.; Gonçalves, L.R.; Fernandez-Lafuente, R. Tuning of Lecitase features via solid-phase chemical modification: Effect of the immobilization protocol. Process. Biochem. 2014, 49, 604–616. [Google Scholar] [CrossRef]

- Dos Santos, J.C.S.; Garcia-Galan, C.; Rodrigues, R.; Ana, H.B.D.S.; Goncalves, L.R.B.; Fernandez-Lafuente, R. Improving the catalytic properties of immobilized Lecitase via physical coating with ionic polymers. Enzym. Microb. Technol. 2014, 60, 1–8. [Google Scholar] [CrossRef]

- Da Fonseca, A.M.; Colares, R.P.; De Oliveira, M.M.; De Souza, M.C.M.; Monteiro, R.R.C.; Araújo, R.D.S.; Amorim, A.V.; Dos Santos, J.C.S.; Alcócer, J.C.A.; Pinto, O.R.D.O. Enzymatic biocatalyst using enzymes from pineapple (Ananas comosus) peel immobilized in hydrogel beads. Rev. Eletrônica Gestão Educ. Tecnol. Ambient. 2019, 23, 32. [Google Scholar] [CrossRef]

- Monteiro, R.; Dos Santos, J.; Alcántara, A.; Fernandez-Lafuente, R. Enzyme-coated micro-crystals: An almost forgotten but very simple and elegant immobilization strategy. Catalysts 2020, 10, 891. [Google Scholar] [CrossRef]

- Rueda, N.; dos Santos, J.; Torres, R.; Ortiz, C.; Barbosa, O.; Fernandez-Lafuente, R. Immobilization of lipases on heterofunctional octyl–glyoxyl agarose supports. Meth. Enzymol. 2016, 571, 73–85. [Google Scholar] [CrossRef]

- Monteiro, R.R.C.; Neto, D.M.A.; Fechine, P.B.A.; Lopes, A.A.S.; Gonçalves, L.R.B.; Dos Santos, J.C.S.; De Souza, M.C.M.; Fernandez-Lafuente, R. Ethyl butyrate synthesis catalyzed by lipases A and B from candida antarctica immobilized onto magnetic nanoparticles. improvement of biocatalysts’ performance under ultrasonic irradiation. Int. J. Mol. Sci. 2019, 20, 5807. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rios, N.S.; Morais, E.G.; Galvão, W.D.S.; Neto, D.M.A.; dos Santos, J.C.S.; Bohn, F.; Correa, M.A.; Fechine, P.B.A.; Fernandez-Lafuente, R.; Gonçalves, L.R.B. Further stabilization of lipase from Pseudomonas fluorescens immobilized on octyl coated nanoparticles via chemical modification with bifunctional agents. Int. J. Biol. Macromol. 2019, 141, 313–324. [Google Scholar] [CrossRef] [PubMed]

- Virgen-Ortíz, J.J.; dos Santos, J.C.; Ortiz, C.; Berenguer-Murcia, A.; Barbosa, O.; Rodrigues, R.; Fernandez-Lafuente, R. Lecitase ultra: A phospholipase with great potential in biocatalysis. Mol. Catal. 2019, 473, 110405. [Google Scholar] [CrossRef] [Green Version]

- Rueda, N.; dos Santos, J.C.S.; Torres, R.; Barbosa, O.; Ortiz, C.; Fernandez-Lafuente, R. Reactivation of lipases by the unfolding and refolding of covalently immobilized biocatalysts. RSC Adv. 2015, 5, 55588–55594. [Google Scholar] [CrossRef] [Green Version]

- Tom, R.J.; Sankaranarayanan, S.; Rodrigues, J.J.P.C. Smart energy management and demand reduction by consumers and utilities in an IoT-fog-based power distribution system. IEEE Internet Things J. 2019, 6, 7386–7394. [Google Scholar] [CrossRef]

- Wancura, J.H.C.; Rosset, D.V.; Tres, M.V.; Oliveira, J.V.; Mazutti, M.A.; Jahn, S.L. Production of biodiesel catalyzed by lipase from Thermomyces lanuginosus in its soluble form. Can. J. Chem. Eng. 2018, 96, 2361–2368. [Google Scholar] [CrossRef]

- Rueda, N.; dos Santos, J.C.S.; Rodriguez, M.D.; Albuquerque, T.L.; Barbosa, O.; Torres, R.T.R.; Ortiz, C.; Fernandez-Lafuente, R. Reversible immobilization of lipases on octyl-glutamic agarose beads: A mixed adsorption that reinforces enzyme immobilization. J. Mol. Catal. B Enzym. 2016, 128, 10–18. [Google Scholar] [CrossRef]

- Rueda, N.; Albuquerque, T.L.; Bartolome-Cabrero, R.; Fernandez-Lopez, L.; Torres, R.; Ortiz, C.; Dos Santos, J.C.S.; Barbosa, O.; Fernandez-Lafuente, R. Reversible immobilization of lipases on heterofunctional octyl-amino agarose beads prevents enzyme desorption. Molecules 2016, 21, 646. [Google Scholar] [CrossRef] [Green Version]

- Rios, N.S.; Neto, D.M.A.; dos Santos, J.C.S.; Fechine, P.B.A.; Fernández-Lafuente, R.; Gonçalves, L.R.B. Comparison of the immobilization of lipase from Pseudomonas fluorescens on divinylsulfone or p-benzoquinone activated support. Int. J. Biol. Macromol. 2019, 134, 936–945. [Google Scholar] [CrossRef]

- De Souza, T.C.; Fonseca, T.D.S.; da Costa, J.A.; Rocha, M.V.P.; de Mattos, M.C.; Fernandez-Lafuente, R.; Gonçalves, L.R.; dos Santos, J.C.S. Cashew apple bagasse as a support for the immobilization of lipase B from Candida antarctica: Application to the chemoenzymatic production of (R)-Indanol. J. Mol. Catal. B Enzym. 2016, 130, 58–69. [Google Scholar] [CrossRef]

- Fernandez-Lopez, L.; Rueda, N.; Bartolome-Cabrero, R.; Rodriguez, M.D.; Albuquerque, T.L.; dos Santos, J.C.; Barbosa, O.; Fernandez-Lafuente, R. Improved immobilization and stabilization of lipase from Rhizomucor miehei on octyl-glyoxyl agarose beads by using CaCl. Process. Biochem. 2016, 51, 48–52. [Google Scholar] [CrossRef]

- Dos Santos, J.C.S.; Rueda, N.; Goncalves, L.R.B.; Fernandez-Lafuente, R. Tuning the catalytic properties of lipases immobilized on divinylsulfone activated agarose by altering its nanoenvironment. Enzym. Microb. Technol. 2015, 77, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Rueda, N.; dos Santos, J.C.S.; Ortiz, C.; Barbosa, O.; Fernandez-Lafuente, R.; Torres, R.T.R. Chemical amination of lipases improves their immobilization on octyl-glyoxyl agarose beads. Catal. Today 2016, 259, 107–118. [Google Scholar] [CrossRef]

- Thangaraj, B.; Solomon, P.R. Immobilization of lipases—A Review. Part I: Enzyme immobilization. ChemBioEng Rev. 2019, 6, 157–166. [Google Scholar] [CrossRef]

- Moreira, K.D.S.; De Oliveira, A.L.B.; Júnior, L.S.D.M.; Monteiro, R.R.C.; Da Rocha, T.N.; de Menezes, F.L.; Fechine, L.; DeNardin, J.C.; Michea, S.; Freire, R.M.; et al. Lipase from rhizomucor miehei immobilized on magnetic nanoparticles: Performance in Fatty Acid Ethyl Ester (FAEE) optimized production by the taguchi method. Front. Bioeng. Biotechnol. 2020, 8, 693. [Google Scholar] [CrossRef]

- Monteiro, R.R.C.; Lima, P.J.M.; Pinheiro, B.; Freire, T.M.; Dutra, L.M.U.; Fechine, L.; Gonçalves, L.R.B.; De Souza, M.C.M.; Dos Santos, J.C.S.; Fernandez-Lafuente, R. Immobilization of lipase A from candida antarctica onto chitosan-coated magnetic nanoparticles. Int. J. Mol. Sci. 2019, 20, 4018. [Google Scholar] [CrossRef] [Green Version]

- Fernandez-Lopez, L.; Bartolome-Cabrero, R.; Rodriguez, M.D.; Dos Santos, C.S.; Rueda, N.; Fernandez-Lafuente, R. Stabilizing effects of cations on lipases depend on the immobilization protocol. RSC Adv. 2015, 5, 83868–83875. [Google Scholar] [CrossRef]

- Mateo, C.; Palomo, J.M.; Lorente, F.; Guisan, J.M.; Fernandez-Lafuente, R. Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzym. Microb. Technol. 2007, 40, 1451–1463. [Google Scholar] [CrossRef]

- Sheldon, R.A.; Woodley, J. Role of biocatalysis in sustainable chemistry. Chem. Rev. 2017, 118, 801–838. [Google Scholar] [CrossRef] [PubMed]

- Chapman, J.; Ismail, A.E.; Dinu, C.Z. Industrial applications of enzymes: Recent advances, techniques, and outlooks. Catalysts 2018, 8, 238. [Google Scholar] [CrossRef] [Green Version]

- Madhavan, A.; Sindhu, R.; Binod, P.; Sukumaran, R.K.; Pandey, A. Strategies for design of improved biocatalysts for industrial applications. Bioresour. Technol. 2017, 245, 1304–1313. [Google Scholar] [CrossRef]

- Bilal, M.; Asgher, M.; Parra, R.; Hu, H.; Wang, W.; Zhang, X.; Iqbal, H.M. Immobilized ligninolytic enzymes: An innovative and environmental responsive technology to tackle dye-based industrial pollutants—A review. Sci. Total Environ. 2016, 576, 646–659. [Google Scholar] [CrossRef]

- Liu, D.-M.; Chen, J.; Shi, Y.-P. Advances on methods and easy separated support materials for enzymes immobilization. TrAC Trends Anal. Chem. 2018, 102, 332–342. [Google Scholar] [CrossRef]

- Bilal, M.; Iqbal, H.M. Naturally-derived biopolymers: Potential platforms for enzyme immobilization. Int. J. Biol. Macromol. 2019, 130, 462–482. [Google Scholar] [CrossRef] [PubMed]

- Drout, R.J.; Robison, L.; Farha, O.K. Catalytic applications of enzymes encapsulated in metal–organic frameworks. Coord. Chem. Rev. 2018, 381, 151–160. [Google Scholar] [CrossRef]

- Ismail, A.R.; Baek, K.-H. Lipase immobilization with support materials, preparation techniques, and applications: Present and future aspects. Int. J. Biol. Macromol. 2020, 163, 1624–1639. [Google Scholar] [CrossRef] [PubMed]

- Karav, S.; Cohen, J.L.; Barile, D.; Bell, J.M.L.N. Recent advances in immobilization strategies for glycosidases. Biotechnol. Prog. 2016, 33, 104–112. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, H.H.; Kim, A.M. An overview of techniques in enzyme immobilization. Appl. Sci. Converg. Technol. 2017, 26, 157–163. [Google Scholar] [CrossRef]

- De Oliveira, U.M.F.; de Matos, L.J.B.L.; de Souza, M.C.M.; Pinheiro, B.B.; dos Santos, J.C.S.; Gonçalves, L.R.B. Efficient biotechnological synthesis of flavor esters using a low-cost biocatalyst with immobilized Rhizomucor miehei lipase. Mol. Biol. Rep. 2018, 46, 597–608. [Google Scholar] [CrossRef]

- Dos Santos, J.C.S.; Garcia-Galan, C.; Rodrigues, R.; de Sant’Ana, H.B.; Goncalves, L.R.B.; Fernandez-Lafuente, R. Stabilizing hyperactivated lecitase structures through physical treatment with ionic polymers. Process. Biochem. 2014, 49, 1511–1515. [Google Scholar] [CrossRef]

- Verdasco-Martín, C.M.; Villalba, M.; dos Santos, J.C.; Tobajas, M.; Fernandez-Lafuente, R.; Otero, C. Effect of chemical modification of Novozym 435 on its performance in the alcoholysis of camelina oil. Biochem. Eng. J. 2016, 111, 75–86. [Google Scholar] [CrossRef]

- Garcia-Galan, C.; Barbosa, O.; Hernandez, K.; Dos Santos, J.C.S.; Rodrigues, R.C.; Fernandez-Lafuente, R. Evaluation of styrene-divinylbenzene beads as a support to immobilize lipases. Molecules 2014, 19, 7629–7645. [Google Scholar] [CrossRef] [Green Version]

- Chi, M.-C.; Huang, Y.-F.; Lu, B.-Y.; Lin, M.-G.; Wang, T.-F.; Lin, L.-L. Magnetic cross-linked enzyme aggregates of a transpeptidase-specialized variant (N450D) of Bacillus licheniformis γ-Glutamyl transpeptidase: An efficient and stable biocatalyst for l-theanine synthesis. Catalysts 2021, 11, 243. [Google Scholar] [CrossRef]

- Sheldon, R.A. Cross-linked enzyme aggregates as industrial biocatalysts. Org. Process. Res. Dev. 2011, 15, 213–223. [Google Scholar] [CrossRef]

- Rehman, S.; Bhatti, H.N.; Bilal, M.; Asgher, M. Cross-linked enzyme aggregates (CLEAs) of Pencilluim notatum lipase enzyme with improved activity, stability and reusability characteristics. Int. J. Biol. Macromol. 2016, 91, 1161–1169. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wang, Y.; Liu, W.; Wang, J.; Chen, H. A novel cross-linked enzyme aggregates (CLEAs) of papain and neutrase-production, partial characterization and application. Int. J. Biol. Macromol. 2017, 95, 650–657. [Google Scholar] [CrossRef]

- Jin, W.; Xu, Y.; Yu, X.-W. Formation lipase cross-linked enzyme aggregates on octyl-modified mesocellular foams with oxidized sodium alginate. Colloids Surf. B Biointerfaces 2019, 184, 110501. [Google Scholar] [CrossRef]

- Ramos, M.D.; Miranda, L.P.; Fernandez-Lafuente, R.; Kopp, W.; Tardioli, P.W. Improving the yields and reaction rate in the ethanolysis of soybean oil by using mixtures of lipase CLEAs. Molecules 2019, 24, 4392. [Google Scholar] [CrossRef] [Green Version]

- Yan, L.; Ma, P.; Liu, Y.; Xiaoyan, M.; Chen, F.; Li, M. 3D coral-like gold/carbon paper electrode modified with covalent and cross-linked enzyme aggregates for electrochemical sensing of glucose. Microchem. J. 2020, 159, 105347. [Google Scholar] [CrossRef]

- De Sousa, M.; Gurgel, B.S.; Pessela, B.C.; Gonçalves, L.R. Preparation of CLEAs and magnetic CLEAs of a recombinant l-arabinose isomerase for d-tagatose synthesis. Enzym. Microb. Technol. 2020, 138, 109566. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Su, Y.; Liu, Y.; Sun, L.; Yu, M.; Wu, Y. Preparation and characterization of cross-linked enzyme aggregates (CLEAs) of recombinant thermostable alkylsulfatase (SdsAP) from Pseudomonas sp. Process. Biochem. 2016, 51, 2084–2089. [Google Scholar] [CrossRef]

- Hong, J.; Jung, D.; Park, S.; Oh, Y.; Oh, K.K.; Lee, S.H. Immobilization of laccase via cross-linked enzyme aggregates prepared using genipin as a natural cross-linker. Int. J. Biol. Macromol. 2021, 169, 541–550. [Google Scholar] [CrossRef]

- Mehde, A.A.; Mehdi, W.A.; Özacar, M.; Özacar, Z.Z. Evaluation of different saccharides and chitin as eco-friendly additive to improve the magnetic cross-linked enzyme aggregates (CLEAs) activities. Int. J. Biol. Macromol. 2018, 118, 2040–2050. [Google Scholar] [CrossRef] [PubMed]

- Wahab, M.K.H.A.; El-Enshasy, H.A.; Abu Bakar, F.D.; Murad, A.M.A.; Jahim, J.M.; Illias, R.M. Improvement of cross-linking and stability on cross-linked enzyme aggregate (CLEA)-xylanase by protein surface engineering. Process. Biochem. 2019, 86, 40–49. [Google Scholar] [CrossRef]

- Schoevaart, R.; Wolbers, M.; Golubovic, M.; Ottens, M.; Kieboom, A.; van Rantwijk, F.; van der Wielen, L.; Sheldon, R. Preparation, optimization, and structures of cross-linked enzyme aggregates (CLEAs). Biotechnol. Bioeng. 2004, 87, 754–762. [Google Scholar] [CrossRef] [PubMed]

- Doraiswamy, N.; Sarathi, M.; Pennathur, G. Cross-linked esterase aggregates (CLEAs) using nanoparticles as immobilization matrix. Prep. Biochem. Biotechnol. 2019, 49, 270–278. [Google Scholar] [CrossRef]

- Matijošytė, I.; Arends, I.; de Vries, S.; Sheldon, R.A. Preparation and use of cross-linked enzyme aggregates (CLEAs) of laccases. J. Mol. Catal. B Enzym. 2010, 62, 142–148. [Google Scholar] [CrossRef]

- Guajardo, N.; Ahumada, K.; de María, P.D. Immobilization of pseudomonas stutzeri lipase through cross-linking aggregates (CLEA) for reactions in deep eutectic solvents. J. Biotechnol. 2021, 337, 18–23. [Google Scholar] [CrossRef] [PubMed]

- Nadar, S.; Rathod, V.K. Magnetic macromolecular cross linked enzyme aggregates (CLEAs) of glucoamylase. Enzym. Microb. Technol. 2016, 83, 78–87. [Google Scholar] [CrossRef]

- Carneiro, E.; Bastos, A.; De Oliveira, U.; De Matos, L.; Adriano, W.; Monteiro, R.; Dos Santos, J.; Gonçalves, L. improving the catalytic features of the lipase from rhizomucor miehei immobilized on chitosan-based hybrid matrices by altering the chemical activation conditions. Química Nova 2020, 43, 1234–1239. [Google Scholar] [CrossRef]

- Reis, C.; Sousa, E.; Serpa, J.; Oliveira, R.; Santos, J. Design of immobilized enzyme biocatalysts: Drawbacks and opportunities. Química Nova 2019, 42, 768–783. [Google Scholar] [CrossRef]

- Barbosa, O.; Ortiz, C.; Berenguer-Murcia, A.; Torres, R.; Rodrigues, R.C.; Fernandez-Lafuente, R. Glutaraldehyde in bio-catalysts design: A useful crosslinker and a versatile tool in enzyme immobilization. RSC Adv. 2013, 4, 1583–1600. [Google Scholar] [CrossRef] [Green Version]

- Betancor, L.; López-Gallego, F.; Alonso-Morales, N.; Dellamora, G.; Mateo, C.; Fernandez-Lafuente, R.; Guisán, J.M. Glutaraldehyde in protein immobilization. Phytoremediation 2006, 22, 57–64. [Google Scholar] [CrossRef]

- De Oliveira, A.L.B.; Cavalcante, F.T.T.; Moreira, K.S.; Monteiro, R.R.C.; Rocha, T.G.; Souza, J.E.S.; da Fonseca, A.M.; Lopes, A.A.S.; Guimarães, A.P.; de Lima, R.K.C.; et al. Lipases immobilized onto nanomaterials as biocatalysts in biodiesel production: Scientific context, challenges, and opportunities. Rev. Virtual Quim. 2021, 13, 875–891. [Google Scholar] [CrossRef]

- Nunes, Y.L.; de Menezes, F.L.; de Sousa, I.G.; Cavalcante, A.L.G.; Cavalcante, F.T.T.; Moreira, K.d.S.; de Oliveira, A.L.B.; Mota, G.F.; Souza, J.E.D.S.; Falcão, I.R.D.A.; et al. Chemical and physical chitosan modification for designing enzymatic industrial biocatalysts: How to choose the best strategy? Int. J. Biol. Macromol. 2021, 181, 1124–1170. [Google Scholar] [CrossRef]

- Bezerra, R.M.; Neto, D.M.A.; Galvão, W.; Rios, N.; Carvalho, A.C.L.D.M.; Correa, M.; Bohn, F.; Fernandez-Lafuente, R.; Fechine, P.; de Mattos, M.C.; et al. Design of a lipase-nano particle biocatalysts and its use in the kinetic resolution of medicament precursors. Biochem. Eng. J. 2017, 125, 104–115. [Google Scholar] [CrossRef]

- Betancor, L.; Gallego, F.L.; Hidalgo, A.; Alonso-Morales, N.; Mateo, G.D.-O.C.; Fernández-Lafuente, R.; Guisán, J.M. Different mechanisms of protein immobilization on glutaraldehyde activated supports: Effect of support activation and immobilization conditions. Enzym. Microb. Technol. 2006, 39, 877–882. [Google Scholar] [CrossRef]

- Liao, Q.; Du, X.; Jiang, W.; Tong, Y.; Zhao, Z.; Fang, R.; Feng, J.; Tang, L. Cross-linked enzyme aggregates (CLEAs) of halohydrin dehalogenase from Agrobacterium radiobacter AD1: Preparation, characterization and application as a biocatalyst. J. Biotechnol. 2018, 272-273, 48–55. [Google Scholar] [CrossRef]

- Wang, S.; Zheng, D.; Yin, L.; Wang, F. Preparation, activity and structure of cross-linked enzyme aggregates (CLEAs) with nanoparticle. Enzym. Microb. Technol. 2017, 107, 22–31. [Google Scholar] [CrossRef] [PubMed]

- Grajales-Hernández, D.; Armendáriz-Ruiz, M.; Velasco-Lozano, S.; López-Gallego, F.; Mateos-Díaz, J.C. Chitosan-based CLEAs from Aspergillus niger type A feruloyl esterase: High-productivity biocatalyst for alkyl ferulate synthesis. Appl. Microbiol. Biotechnol. 2020, 104, 10033–10045. [Google Scholar] [CrossRef] [PubMed]

- Tikhonov, B.B.; Sulman, E.M.; Stadol’Nikova, P.Y.; Golikova, E.P.; Sidorov, A.I.; Matveeva, V.G. Immobilized enzymes from the class of oxidoreductases in technological processes: A review. Catal. Ind. 2019, 11, 251–263. [Google Scholar] [CrossRef]

- Cui, J.; Zhao, Y.; Tan, Z.; Zhong, C.; Han, P.; Jia, S. Mesoporous phenylalanine ammonia lyase microspheres with improved stability through calcium carbonate templating. Int. J. Biol. Macromol. 2017, 98, 887–896. [Google Scholar] [CrossRef]

- Kumar, A.; Wu, G.; Liu, Z. Synthesis and characterization of cross linked enzyme aggregates of serine hydroxyl methyltransferase from Idiomerina leihiensis. Int. J. Biol. Macromol. 2018, 117, 683–690. [Google Scholar] [CrossRef]

- Araya, E.; Urrutia, P.; Romero, O.; Illanes, A.; Wilson, L. Design of combined crosslinked enzyme aggregates (combi-CLEAs) of β-galactosidase and glucose isomerase for the one-pot production of fructose syrup from lactose. Food Chem. 2019, 288, 102–107. [Google Scholar] [CrossRef]

- Sheldon, R.A. CLEAs, Combi-CLEAs and ‘Smart’ magnetic CLEAs: Biocatalysis in a bio-based economy. Catalysts 2019, 9, 261. [Google Scholar] [CrossRef] [Green Version]

- Da Fonseca, A.M.; Dos Santos, J.C.S.; De Souza, M.C.M.; de Oliveira, M.M.; Colares, R.P.; De Lemos, T.L.G.; Filho, R.B. The use of new hydrogel microcapsules in coconut juice as biocatalyst system for the reaction of quinine. Ind. Crop. Prod. 2019, 145, 111890. [Google Scholar] [CrossRef]

- Muley, A.B.; Awasthi, S.; Bhalerao, P.P.; Jadhav, N.L.; Singhal, R.S. Preparation of cross-linked enzyme aggregates of lipase from Aspergillus niger: Process optimization, characterization, stability, and application for epoxidation of lemongrass oil. Bioprocess Biosyst. Eng. 2021, 44, 1383–1404. [Google Scholar] [CrossRef]

- Ahmed, I.; Jhung, S.H. Covalent organic framework-based materials: Synthesis, modification, and application in environmental remediation. Coord. Chem. Rev. 2021, 441, 213989. [Google Scholar] [CrossRef]

- Ning, J.; Gao, Y.; Cao, X.; Wei, H.; Wang, B.; Hao, L. Substituent engineering of covalent organic frameworks modulates the crystallinity and electrochemical reactivity. J. Energy Chem. 2021, 65, 490–496. [Google Scholar] [CrossRef]

- Xin, J.; Wang, X.; Li, N.; Liu, L.; Lian, Y.; Wang, M.; Zhao, R.-S. Recent applications of covalent organic frameworks and their multifunctional composites for food contaminant analysis. Food Chem. 2020, 330, 127255. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, R.S.B.; de Oliveira, A.B.V.; Sindra, H.C.; Archanjo, B.S.; Mendoza, M.E.; Carneiro, L.S.A.; Buarque, C.D.; Esteves, P.M. Heterogeneous catalysis by covalent organic frameworks (COF): Pd(OAc)2@COF-300 in cross-coupling reactions. ChemCatChem 2016, 8, 743–750. [Google Scholar] [CrossRef]

- Abuzeid, H.R.; El-Mahdy, A.F.; Kuo, S.-W. Covalent organic frameworks: Design principles, synthetic strategies, and diverse applications. Giant 2021, 6, 100054. [Google Scholar] [CrossRef]

- Gendy, E.A.; Ifthikar, J.; Ali, J.; Oyekunle, D.T.; Elkhlifia, Z.; Shahib, I.I.; Khodair, A.I.; Chen, Z. Removal of heavy metals by covalent organic frameworks (COFs): A review on its mechanism and adsorption properties. J. Environ. Chem. Eng. 2021, 9, 105687. [Google Scholar] [CrossRef]

- Wang, H.; Wanga, T.; Maa, R.; Wua, K.; Lia, H.; Fengb, B.; Lib, C.; Shenb, Y. Facile synthesis of sulfonated covalent organic framework for the adsorption of heavy metal ions. J. Taiwan Inst. Chem. Eng. 2020, 112, 122–129. [Google Scholar] [CrossRef]

- Bao, T.; Wang, S.; Zhang, N.; Zhang, J. Facile synthesis and immobilization of functionalized covalent organic framework-1 for electrochromatographic separation. J. Chromatogr. A 2021, 1645, 462130. [Google Scholar] [CrossRef]

- Gong, K.; Zhang, D.; Wang, Y.; Li, C.; Zhang, H.; Li, H.; Feng, H. Biguanide-functionalized hierarchical porous covalent organic frameworks for efficient catalysis of condensation reactions. Mol. Catal. 2021, 509, 111663. [Google Scholar] [CrossRef]

- Khan, N.A.; Wu, H.; Jinqiu, Y.; Mengyuan, W.; Yang, P.; Long, M.; Rahman, A.U.; Ahmad, N.M.; Zhang, R.; Jiang, Z. Incorporating covalent organic framework nanosheets into polyamide membranes for efficient desalination. Sep. Purif. Technol. 2021, 274, 119046. [Google Scholar] [CrossRef]

- Segura, J.L.; Mancheño, M.J.; Zamora, F. Covalent organic frameworks based on Schiff-base chemistry: Synthesis, properties and potential applications. Chem. Soc. Rev. 2016, 45, 5635–5671. [Google Scholar] [CrossRef] [PubMed]

- Bagheri, A.R.; Aramesh, N.; Sher, F.; Bilal, M. Covalent organic frameworks as robust materials for mitigation of environmental pollutants. Chemosphere 2021, 270, 129523. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Luo, B.; Zhang, H.; Li, Z.; Zhu, N.; Lan, F.; Wu, Y. Surfactant-free synthesis of covalent organic framework nanospheres in water at room temperature. J. Colloid Interface Sci. 2021, 606, 1333–1339. [Google Scholar] [CrossRef]

- Yang, Q.; Luo, M.; Liu, K.; Cao, H.; Yan, H. Covalent organic frameworks for photocatalytic applications. Appl. Catal. B Environ. 2020, 276, 119174. [Google Scholar] [CrossRef]

- Feng, X.; Ding, X.; Jiang, D. Covalent organic frameworks. Chem. Soc. Rev. 2012, 41, 6010–6022. [Google Scholar] [CrossRef] [PubMed]

- Pan, F.; Tong, C.; Wang, Z.; Xu, F.; Wang, X.; Weng, B.; Pan, D.; Zhu, R. Novel sulfhydryl functionalized covalent organic frameworks for ultra-trace Hg2+ removal from aqueous solution. J. Mater. Sci. Technol. 2021, 93, 89–95. [Google Scholar] [CrossRef]

- Huang, M.; Chong, J.; Hu, C.; Yang, Y. Ratiometric fluorescent detection of temperature and MnO4—Using a modified covalent organic framework. Inorg. Chem. Commun. 2020, 119, 108094. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, Q. Recent progress in covalent organic frameworks as light-emitting materials. Mater. Today Energy 2021, 20, 100635. [Google Scholar] [CrossRef]

- Gan, J.; Bagheri, A.R.; Aramesh, N.; Gul, I.; Franco, M.; Almulaiky, Y.Q.; Bilal, M. Covalent organic frameworks as emerging host platforms for enzyme immobilization and robust biocatalysis—A review. Int. J. Biol. Macromol. 2020, 167, 502–515. [Google Scholar] [CrossRef]

- Sun, Q.; Fu, C.-W.; Aguila, B.; Perman, J.A.; Wang, S.; Huang, H.-Y.; Xiao, F.-S.; Ma, S. Pore environment control and enhanced performance of enzymes infiltrated in covalent organic frameworks. J. Am. Chem. Soc. 2018, 140, 984–992. [Google Scholar] [CrossRef]

- Oliveira, F.L.; França, A.D.S.; De Castro, A.M.; Souza, R.O.M.A.; Esteves, P.M.; Goncalves, R.S.B. Enzyme immobilization in covalent organic frameworks: Strategies and applications in biocatalysis. Chem. Plus Chem. 2020, 85. [Google Scholar] [CrossRef] [PubMed]

- Yusran, Y.; Li, H.; Guan, X.; Fang, Q.; Qiu, S. Covalent Organic Frameworks for Catalysis. Energy Chem. 2020, 2, 100035. [Google Scholar] [CrossRef]

- Sun, Q.; Aguila, B.; Lan, P.C.; Ma, S. Tuning pore heterogeneity in covalent organic frameworks for enhanced enzyme accessibility and resistance against denaturants. Adv. Mater. 2019, 31, e1900008. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, F.L.; De Souza, S.P.; Bassut, J.; Álvarez, H.M.; Garcia-Basabe, Y.; De Souza, R.O.M.A.; Esteves, P.M.; Goncalves, R.S.B. Enzyme-decorated covalent organic frameworks as nanoporous platforms for heterogeneous biocatalysis. Chem. A Eur. J. 2019, 25, 15863–15870. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.-W.; Cai, C.-X.; Xing, X.; Li, J.; Hu, Z.-E.; Xie, Z.-B.; Wang, N.; Yu, X.-Q. Magnetic COFs as satisfied support for lipase immobilization and recovery to effectively achieve the production of biodiesel by great maintenance of enzyme activity. Biotechnol. Biofuels 2021, 14, 1–12. [Google Scholar] [CrossRef]

- El-Kaderi, H.M.; Hunt, J.R.; Mendoza-Cortés, J.L.; Côté, A.P.; Taylor, R.E.; O’Keeffe, M.; Yaghi, O.M. Designed synthesis of 3D covalent organic frameworks. Science 2007, 316, 268–272. [Google Scholar] [CrossRef] [Green Version]

- Sharma, R.K.; Yadav, P.; Yadav, M.; Gupta, R.; Rana, P.; Srivastava, A.; Zbořil, R.; Varma, R.S.; Antonietti, M.; Gawande, M.B. Recent development of covalent organic frameworks (COFs): Synthesis and catalytic (organic-electro-photo) applications. Mater. Horizons 2019, 7, 411–454. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, S.; Chen, Y.; Zhang, Z.; Ma, S. Covalent organic frameworks for separation applications. Chem. Soc. Rev. 2020, 49, 708–735. [Google Scholar] [CrossRef]

- Nguyen, H.L.; Gropp, C.; Yaghi, O.M. Reticulating 1D ribbons into 2D covalent organic frameworks by imine and imide linkages. J. Am. Chem. Soc. 2020, 142, 2771–2776. [Google Scholar] [CrossRef]

- Wen, A.; Li, G.; Wu, D.; Yu, Y.; Yang, Y.; Hu, N.; Wang, H.; Chen, J.; Wu, Y. Sulphonate functionalized covalent organic framework-based magnetic sorbent for effective solid phase extraction and determination of fluoroquinolones. J. Chromatogr. A 2019, 1612, 460651. [Google Scholar] [CrossRef]

- Su, D.; Feng, B.; Xu, P.; Zeng, Q.; Shan, B.; Song, Y. Covalent organic frameworks and electron mediator-based open circuit potential biosensor for in vivo electrochemical measurements. Anal. Methods 2018, 10, 4320–4328. [Google Scholar] [CrossRef]

- Samui, A.; Happy; Sahu, S.K. Integration of α-amylase into covalent organic framework for highly efficient biocatalyst. Microporous Mesoporous Mater. 2020, 291. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, X.; Deng, C. Rational synthesis of novel recyclable Fe3O4@MOF nanocomposites for enzymatic digestion. Chem. Commun. 2015, 51, 8116–8119. [Google Scholar] [CrossRef] [PubMed]

- Wiśniewski, J.R.; Mann, M. Consecutive proteolytic digestion in an enzyme reactor increases depth of proteomic and phosphoproteomic analysis. Anal. Chem. 2012, 84, 2631–2637. [Google Scholar] [CrossRef]

- Wang, L.; Liang, H.; Xu, M.; Wang, L.; Xie, Y.; Song, Y. Ratiometric electrochemical biosensing based on double-enzymes loaded on two-dimensional dual-pore COFETTA-TPAL. Sens. Actuators B Chem. 2019, 298. [Google Scholar] [CrossRef]

- Zhang, G.; Jin, L.; Zhang, R.; Bai, Y.; Zhu, R.; Pang, H. Recent advances in the development of electronically and ionically conductive metal-organic frameworks. Coord. Chem. Rev. 2021, 439, 213915. [Google Scholar] [CrossRef]

- Whelan, É.; Steuber, F.W.; Gunnlaugsson, T.; Schmitt, W. Tuning photoactive metal–organic frameworks for luminescence and photocatalytic applications. Coord. Chem. Rev. 2021, 437, 213757. [Google Scholar] [CrossRef]

- Wang, S.; McGuirk, C.M.; D’Aquino, A.; Mason, J.A.; Mirkin, C.A. Metal–Organic framework nanoparticles. Adv. Mater. 2018, 30, e1800202. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Q. Metal-Organic Framework Composites for Catalysis. Matter 2019, 1, 57–89. [Google Scholar] [CrossRef] [Green Version]

- Chuhadiya, S.; Himanshu; Suthar, D.; Patel, S.; Dhaka, M. Metal organic frameworks as hybrid porous materials for energy storage and conversion devices: A review. Coord. Chem. Rev. 2021, 446, 214115. [Google Scholar] [CrossRef]

- Li, R.; Zhang, W.; Zhou, K. Metal–Organic-framework-based catalysts for photoreduction of CO. Adv. Mater. 2018, 30, e1705512. [Google Scholar] [CrossRef]

- Li, D.-Z.; Chen, L.; Liu, G.; Yuan, Z.-Y.; Li, B.-F.; Zhang, X.; Wei, J.-Q. Porous metal–organic frameworks for methane storage and capture: Status and challenges. New Carbon Mater. 2021, 36, 468–496. [Google Scholar] [CrossRef]

- Zhu, Q.-L.; Xu, Q. Metal–organic framework composites. Chem. Soc. Rev. 2014, 43, 5468–5512. [Google Scholar] [CrossRef]

- Chen, Y.-Z.; Zhang, R.; Jiao, L.; Jiang, H.-L. Metal–organic framework-derived porous materials for catalysis. Coord. Chem. Rev. 2018, 362, 1–23. [Google Scholar] [CrossRef]

- Dutta, A.; Pan, Y.; Liu, J.-Q.; Kumar, A. Multicomponent isoreticular metal-organic frameworks: Principles, current status and challenges. Coord. Chem. Rev. 2021, 445, 214074. [Google Scholar] [CrossRef]

- Dybtsev, D.N.; Bryliakov, K.P. Asymmetric catalysis using metal-organic frameworks. Coord. Chem. Rev. 2021, 437, 213845. [Google Scholar] [CrossRef]

- Guo, W.; Cheng, J.; Song, Y.; Liu, S.; Ali, K.A.; Kumar, S. Three-dimensional numerical simulation of light penetration in an optimized flow field composed of microalgae cells, carbon dioxide bubbles and culture medium. Bioresour. Technol. 2019, 292, 121979. [Google Scholar] [CrossRef] [PubMed]

- Kong, X.-J.; Li, J.-R. An Overview of Metal–Organic frameworks for green chemical engineering. Engineering 2021, 7, 1115–1139. [Google Scholar] [CrossRef]

- Qi, L.; Luo, Z.; Lu, X. Biomimetic mineralization inducing lipase–metal–organic framework nanocomposite for pickering interfacial biocatalytic system. ACS Sustain. Chem. Eng. 2019, 7, 7127–7139. [Google Scholar] [CrossRef]

- Qin, Y.; Wan, Y.; Guo, J.; Zhao, M. Two-dimensional metal-organic framework nanosheet composites: Preparations and applications. Chin. Chem. Lett. 2021. [Google Scholar] [CrossRef]

- Nemiwal, M.; Gosu, V.; Zhang, T.C.; Kumar, D. Metal organic frameworks as electrocatalysts: Hydrogen evolution reactions and overall water splitting. Int. J. Hydrogen Energy 2021, 46, 10216–10238. [Google Scholar] [CrossRef]

- Konnerth, H.; Matsagar, B.M.; Chen, S.S.; Prechtl, M.H.; Shieh, F.-K.; Wu, K.C.-W. Metal-organic framework (MOF)-derived catalysts for fine chemical production. Coord. Chem. Rev. 2020, 416, 213319. [Google Scholar] [CrossRef]

- Lin, C.; Xu, K.; Zheng, R.; Zheng, Y. Immobilization of amidase into a magnetic hierarchically porous metal–organic framework for efficient biocatalysis. Chem. Commun. 2019, 55, 5697–5700. [Google Scholar] [CrossRef]

- Marsh, C.; Shearer, G.C.; Knight, B.T.; Paul-Taylor, J.; Burrows, A.D. Supramolecular aspects of biomolecule interactions in metal–organic frameworks. Coord. Chem. Rev. 2021, 439, 213928. [Google Scholar] [CrossRef]

- Vahabi, A.H.; Norouzi, F.; Sheibani, E.; Rahimi-Nasrabadi, M. Functionalized Zr-UiO-67 metal-organic frameworks: Structural landscape and application. Coord. Chem. Rev. 2021, 445, 214050. [Google Scholar] [CrossRef]

- He, J.; Sun, S.; Zhou, Z.; Yuan, Q.; Liu, Y.; Liang, H. Thermostable enzyme-immobilized magnetic responsive Ni-based metal–organic framework nanorods as recyclable biocatalysts for efficient biosynthesis of S-adenosylmethionine. Dalton Trans. 2019, 48, 2077–2085. [Google Scholar] [CrossRef]

- Jiao, L.; Jiang, H.-L. Metal-organic-framework-based single-atom catalysts for energy applications. Chem 2019, 5, 786–804. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Hu, H.; Wang, Z.; Du, Y.; Zhong, L.; Zhang, C.; Jiang, Y.; Jia, S.; Cui, J. Three-dimensional ordered magnetic macroporous metal-organic frameworks for enzyme immobilization. J. Colloid Interface Sci. 2021, 590, 436–445. [Google Scholar] [CrossRef]

- Farmakes, J.; Schuster, I.; Overby, A.; Alhalhooly, L.; Lenertz, M.; Li, Q.; Ugrinov, A.; Choi, Y.; Pan, Y.; Yang, Z. Enzyme immobilization on graphite oxide (GO) surface via one-pot synthesis of GO/metal–organic framework composites for large-substrate biocatalysis. ACS Appl. Mater. Interfaces 2020, 12, 23119–23126. [Google Scholar] [CrossRef] [PubMed]

- Pei, X.; Wu, Y.; Wang, J.; Chen, Z.; Liu, W.; Su, W.; Liu, F. Biomimetic mineralization of nitrile hydratase into a mesoporous cobalt-based metal–organic framework for efficient biocatalysis. Nanoscale 2019, 12, 967–972. [Google Scholar] [CrossRef]

- Song, J.; He, W.; Shen, H.; Zhou, Z.; Li, M.; Su, P.; Yang, Y. Construction of multiple enzyme metal–organic frameworks biocatalyst via DNA scaffold: A promising strategy for enzyme encapsulation. Chem. Eng. J. 2019, 363, 174–182. [Google Scholar] [CrossRef]

- Cui, J.D.; Feng, Y.; Jia, S. Silica encapsulated catalase@metal-organic framework composite: A highly stable and recyclable biocatalyst. Chem. Eng. J. 2018, 351, 506–514. [Google Scholar] [CrossRef]

- Li, Q.; Chen, Y.; Bai, S.; Shao, X.; Jiang, L.; Li, Q. Immobilized lipase in bio-based metal-organic frameworks constructed by biomimetic mineralization: A sustainable biocatalyst for biodiesel synthesis. Colloids Surfaces B Biointerfaces 2020, 188, 110812. [Google Scholar] [CrossRef]

- Li, P.; Modica, J.A.; Howarth, A.J.; Vargas L., E.; Moghadam, P.Z.; Snurr, R.Q.; Mrksich, M.; Hupp, J.T.; Farha, O.K. Toward Design Rules for Enzyme Immobilization in Hierarchical Mesoporous Metal-Organic Frameworks. Chem 2016, 1, 154–169. [Google Scholar] [CrossRef] [Green Version]

- Gkaniatsou, E.; Sicard, C.; Ricoux, R.; Benahmed, L.; Bourdreux, F.; Zhang, Q.; Serre, C.; Mahy, J.; Steunou, N. Enzyme encapsulation in mesoporous metal—Organic frameworks for selective biodegradation of harmful dye molecules. Angew. Chem. Int. Ed. 2018, 57, 16141–16146. [Google Scholar] [CrossRef]

- Li, P.; Chen, Q.; Wang, T.C.; Vermeulen, N.A.; Mehdi, B.L.; Dohnalkova, A.; Browning, N.D.; Shen, D.; Anderson, R.; Gómez-Gualdrón, D.A.; et al. Hierarchically engineered mesoporous metal-organic frameworks toward cell-free immobilized enzyme systems. Chem 2018, 4, 1022–1034. [Google Scholar] [CrossRef] [Green Version]

- Mehta, J.; Bhardwaj, N.; Bhardwaj, S.K.; Kim, K.-H.; Deep, A. Recent advances in enzyme immobilization techniques: Metal-organic frameworks as novel substrates. Coord. Chem. Rev. 2016, 322, 30–40. [Google Scholar] [CrossRef]

- Liu, X.; Qi, W.; Wang, Y.; Su, R.; He, Z. A facile strategy for enzyme immobilization with highly stable hierarchically porous metal–organic frameworks. Nanoscale 2017, 9, 17561–17570. [Google Scholar] [CrossRef]

- Tranchemontagne, D.J.; Mendoza-Cortes, J.; O’Keeffe, M.; Yaghi, O. Secondary building units, nets and bonding in the chemistry of metal–organic frameworks. Chem. Soc. Rev. 2009, 38, 1257–1283. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, K.; Wu, C.-D. Designed fabrication of biomimetic metal–organic frameworks for catalytic applications. Coord. Chem. Rev. 2019, 378, 445–465. [Google Scholar] [CrossRef]

- Li, N.; Qiao, D.; Zhao, S.; Lin, Q.; Zhang, B.; Xie, F. 3D printing to innovate biopolymer materials for demanding applications: A review. Mater. Today Chem. 2021, 20, 100459. [Google Scholar] [CrossRef]

- Palmara, G.; Frascella, F.; Roppolo, I.; Chiappone, A.; Chiadò, A. Functional 3D printing: Approaches and bioapplications. Biosens. Bioelectron. 2020, 175, 112849. [Google Scholar] [CrossRef] [PubMed]

- Jayapiriya, U.S.; Goel, S. Surface modified 3D printed carbon bioelectrodes for glucose/O2 enzymatic biofuel cell: Comparison and optimization. Sustain. Energy Technol. Assessments 2020, 42, 100811. [Google Scholar] [CrossRef]

- Jiang, P.; Ji, Z.; Wang, X.; Zhou, F. Surface functionalization—A new functional dimension added to 3D printing. J. Mater. Chem. C 2020, 8, 12380–12411. [Google Scholar] [CrossRef]

- Sans, V. Emerging trends in flow chemistry enabled by 3D printing: Robust reactors, biocatalysis and electrochemistry. Curr. Opin. Green Sustain. Chem. 2020, 25, 100367. [Google Scholar] [CrossRef]

- Belgrano, F.D.S.; Diegel, O.; Pereira, N.; Hatti-Kaul, R. Cell immobilization on 3D-printed matrices: A model study on propionic acid fermentation. Bioresour. Technol. 2018, 249, 777–782. [Google Scholar] [CrossRef]

- Yoon, H.S.; Yang, K.; Kim, Y.M.; Nam, K.; Roh, Y.H. Cellulose nanocrystals as support nanomaterials for dual droplet-based freeform 3D printing. Carbohydr. Polym. 2021, 272, 118469. [Google Scholar] [CrossRef] [PubMed]

- Kirchmajer, D.M.; Iii, R.G.; Panhuis, M.I.H. An overview of the suitability of hydrogel-forming polymers for extrusion-based 3D-printing. J. Mater. Chem. B 2015, 3, 4105–4117. [Google Scholar] [CrossRef]

- Peng, M.; Mittmann, E.; Wenger, L.; Hubbuch, J.; Engqvist, M.K.M.; Niemeyer, C.M.; Rabe, K.S. 3D-Printed phenacrylate decarboxylase flow reactors for the chemoenzymatic synthesis of 4-hydroxystilbene. Chem. A Eur. J. 2019, 25, 15998–16001. [Google Scholar] [CrossRef] [Green Version]

- Shen, X.; Yang, M.; Cui, C.; Cao, H. In situ immobilization of glucose oxidase and catalase in a hybrid interpenetrating polymer network by 3D bioprinting and its application. Colloids Surfaces A Physicochem. Eng. Asp. 2019, 568, 411–418. [Google Scholar] [CrossRef]

- Ye, J.; Chu, T.; Chu, J.; Gao, B.; He, B. A Versatile Approach for Enzyme Immobilization Using Chemically Modified 3D-Printed Scaffolds. ACS Sustain. Chem. Eng. 2019, 7, 18048–18054. [Google Scholar] [CrossRef]

- De Santis, P.; Meyer, L.-E.; Kara, S. The rise of continuous flow biocatalysis – fundamentals, very recent developments and future perspectives. React. Chem. Eng. 2020, 5, 2155–2184. [Google Scholar] [CrossRef]

- Valotta, A.; Maier, M.C.; Soritz, S.; Pauritsch, M.; Koenig, M.; Brouczek, D.; Schwentenwein, M.; Gruber-Woelfler, H. 3D printed ceramics as solid supports for enzyme immobilization: An automated DoE approach for applications in continuous flow. J. Flow Chem. 2021, 1–15. [Google Scholar] [CrossRef]

- Zhang, J.; Gao, B.; Lva, K.; Kumissaya, L.; Wub, B.; Chua, J.; Heab, B. Specific immobilization of lipase on functionalized 3D printing scaffolds via enhanced hydrophobic interaction for efficient resolution of racemic 1-indanol. Biochem. Biophys. Res. Commun. 2021, 546, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, L.K.; Botti, R.F.; Innocentini, M.D.D.M.; Marques, R.F.C.; Colombo, P.; de Paula, A.V.; Flumignan, D.L. 3D printed geopolymer: An efficient support for immobilization of Candida rugosa lipase. Chem. Eng. J. 2021, 414, 128843. [Google Scholar] [CrossRef]

- Molinero-Fernández, A.; López, M.; Escarpa, A. Electrochemical microfluidic micromotors-based immunoassay for C-Reactive protein determination in preterm neonatal samples with sepsis suspicion. Anal. Chem. 2020, 92, 5048–5054. [Google Scholar] [CrossRef]

- Lin, F.; Zhao, X.; Wang, J.; Yu, S.; Deng, Y.; Geng, L.; Li, H. A novel microfluidic chip electrophoresis strategy for simultaneous, label-free, multi-protein detection based on a graphene energy transfer biosensor. Analyst 2014, 139, 2890–2895. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Herr, A. Protein immobilization techniques for microfluidic assays. Biomicrofluidics 2013, 7, 041501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maxwell, E.J.; Mazzeo, A.D.; Whitesides, G.M. Paper-based electroanalytical devices for accessible diagnostic testing. MRS Bull. 2013, 38, 309–314. [Google Scholar] [CrossRef] [Green Version]

- Pereiro, I.; Tabnaoui, S.; Fermigier, M.; du Roure, O.; Descroix, S.; Viovy, J.-L.; Malaquin, L. Magnetic fluidized bed for solid phase extraction in microfluidic systems. Lab a Chip 2017, 17, 1603–1615. [Google Scholar] [CrossRef] [PubMed]

- Pereiro, I.; Bendali, A.; Tabnaoui, S.; Alexandre, L.; Srbova, J.; Bilkova, Z.; Deegan, S.; Joshi, L.; Viovy, J.-L.; Malaquin, L.; et al. A new microfluidic approach for the one-step capture, amplification and label-free quantification of bacteria from raw samples. Chem. Sci. 2016, 8, 1329–1336. [Google Scholar] [CrossRef] [Green Version]

- Sasso, L.A.; Johnston, I.H.; Zheng, M.; Gupte, R.K.; Undar, A.; Zahn, J.D. Automated microfluidic processing platform for multiplexed magnetic bead immunoassays. Microfluid. Nanofluidics 2012, 13, 603–612. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cavalcante, F.; Falcão, I.d.A.; Souza, J.D.S.; Rocha, T.; de Sousa, I.; Cavalcante, A.; de Oliveira, A.; de Sousa, M.; dos Santos, J. Designing of nanomaterials-based enzymatic biosensors: Synthesis, properties, and applications. Electrochem 2021, 2, 149–184. [Google Scholar] [CrossRef]

- Aldhahri, M.M.; Almulaiky, Y.Q.; El-Shishtawy, R.M.; Al-Shawafi, W.; Alngadh, A.; Maghrabi, R. Facile immobilization of enzyme via co-electrospinning: A simple method for enhancing enzyme reusability and monitoring an activity-based organic semiconductor. ACS Omega 2018, 3, 6346–6350. [Google Scholar] [CrossRef]

- Brites, M.D.M.; Cerón, A.A.; Costa, S.M.; Oliveira, R.C.; Ferraz, H.G.; Catalani, L.H.; Costa, S.A. Bromelain immobilization in cellulose triacetate nanofiber membranes from sugarcane bagasse by electrospinning technique. Enzym. Microb. Technol. 2019, 132, 109384. [Google Scholar] [CrossRef]

- Li, D.; Wang, Q.; Huang, F.; Wei, Q. Electrospun nanofibers for enzyme immobilization. In Electrospinning: Nanofabrication and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 765–781. ISBN 9780323512701. [Google Scholar]

- Alonso-González, M.; Corral-González, A.; Felix, M.; Romero, A.; Martin-Alfonso, J. Developing active poly(vinyl alcohol)-based membranes with encapsulated antimicrobial enzymes via electrospinning for food packaging. Int. J. Biol. Macromol. 2020, 162, 913–921. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Wang, P.; Zhang, H. Electrospinning of nanofibers: Potentials and perspectives for active food packaging. Compr. Rev. Food Sci. Food Saf. 2020, 19, 479–502. [Google Scholar] [CrossRef]

- Wang, Z.-G.; Wan, L.-S.; Liu, Z.-M.; Huang, X.-J.; Xu, Z.-K. Enzyme immobilization on electrospun polymer nanofibers: An overview. J. Mol. Catal. B Enzym. 2009, 56, 189–195. [Google Scholar] [CrossRef]

- Fan, Y.; Tian, X.; Zheng, L.; Jin, X.; Zhang, Q.; Xu, S.; Liu, P.; Yang, N.; Bai, H.; Wang, H. Yeast encapsulation in nanofiber via electrospinning: Shape transformation, cell activity and immobilized efficiency. Mater. Sci. Eng. C 2020, 120, 111747. [Google Scholar] [CrossRef]

- El-Shishtawy, R.M.; Aldhahri, M.; Almulaiky, Y.Q. Dual immobilization of α-amylase and horseradish peroxidase via electrospinning: A proof of concept study. Int. J. Biol. Macromol. 2020, 163, 1353–1360. [Google Scholar] [CrossRef]

- Jun, S.-H.; Yang, J.; Jeon, H.; Kim, H.S.; Pack, S.P.; Jin, E.; Kim, J. Stabilized and immobilized carbonic anhydrase on electrospun nanofibers for enzymatic CO2 conversion and utilization in expedited microalgal growth. Environ. Sci. Technol. 2020, 54, 1223–1231. [Google Scholar] [CrossRef]

- Kamaci, U.D.; Peksel, A. enhanced catalytic activity of immobilized phytase into polyvinyl alcohol-sodium alginate based electrospun nanofibers. Catal. Lett. 2020, 151, 821–831. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, K.; Hsu, R.; Hsieh, C.; Wang, H.; Ting, Y. Enzymatic degradation of ginkgolic acid by laccase immobilized on novel electrospun nanofiber mat. J. Sci. Food Agric. 2020, 100, 2705–2712. [Google Scholar] [CrossRef]

- Jhuang, J.-R.; Lin, S.-B.; Chen, L.-C.; Lou, S.-N.; Chen, S.-H.; Chen, H.-H. Development of immobilized laccase-based time temperature indicator by electrospinning zein fiber. Food Packag. Shelf Life 2019, 23, 100436. [Google Scholar] [CrossRef]

- Syukri, M.S.M.; Rahman, R.A.; Mohamad, Z.; Illias, R.M.; Mahmood, N.A.N.; Jaafar, N.R. Optimization strategy for laccase immobilization on polyethylene terephthalate grafted with maleic anhydride electrospun nanofiber mat. Int. J. Biol. Macromol. 2020, 166, 876–883. [Google Scholar] [CrossRef] [PubMed]

- Zdarta, J.; Staszak, M.; Jankowska, K.; Kaźmierczak, K.; Degórska, O.; Nguyen, L.N.; Kijeńska-Gawrońska, E.; Pinelo, M.; Jesionowski, T. The response surface methodology for optimization of tyrosinase immobilization onto electrospun polycaprolactone–chitosan fibers for use in bisphenol A removal. Int. J. Biol. Macromol. 2020, 165, 2049–2059. [Google Scholar] [CrossRef]

- Alvarado-Ramírez, L.; Rostro-Alanis, M.; Rodríguez-Rodríguez, J.; Castillo-Zacarías, C.; Sosa-Hernández, J.E.; Barceló, D.; Iqbal, H.M.; Parra-Saldívar, R. Exploring current tendencies in techniques and materials for immobilization of laccases—A review. Int. J. Biol. Macromol. 2021, 181, 683–696. [Google Scholar] [CrossRef] [PubMed]

- Kuang, L.; Zhang, Q.; Li, J.; Tian, H. Preparation of lipase–electrospun SiO2 nanofiber membrane bioreactors and their targeted catalytic ability at the macroscopic oil–water interface. J. Agric. Food Chem. 2020, 68, 8362–8369. [Google Scholar] [CrossRef]

- Işik, C.; Arabaci, G.; Doğaç, Y.I.; Deveci, I.; Teke, M. Synthesis and characterization of electrospun PVA/Zn2+ metal composite nanofibers for lipase immobilization with effective thermal, pH stabilities and reusability. Mater. Sci. Eng. C 2019, 99, 1226–1235. [Google Scholar] [CrossRef] [PubMed]

- Anandharamakrishnan, C.; Parthasarathi, S. (Eds.) Food Nanotechnology; CRC Press: Boca Raton, FL, USA, 2019; ISBN 9781315153872. [Google Scholar]

- Coelho, S.C.; Estevinho, B.N.; Rocha, F. Encapsulation in food industry with emerging electrohydrodynamic techniques: Electrospinning and electrospraying—A review. Food Chem. 2020, 339, 127850. [Google Scholar] [CrossRef] [PubMed]

- Morato, N.M.; Holden, D.T.; Cooks, R.G. High-throughput label-free enzymatic assays using desorption electrospray-ionization mass spectrometry. Angew. Chem. Int. Ed. 2020, 59, 20459–20464. [Google Scholar] [CrossRef] [PubMed]

- Soares, R.M.; Siqueira, N.; Prabhakaram, M.P.; Ramakrishna, S. Electrospinning and electrospray of bio-based and natural polymers for biomaterials development. Mater. Sci. Eng. C 2018, 92, 969–982. [Google Scholar] [CrossRef]

- Bhushani, J.A.; Anandharamakrishnan, C. Electrospinning and electrospraying techniques: Potential food based applications. Trends Food Sci. Technol. 2014, 38, 21–33. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Ting, Y.; Kuo, H.-C.; Hsieh, C.-W.; Hsu, H.-Y.; Wu, C.-N.; Cheng, K.-C. Enzymatic degradation of ginkgolic acids by laccase immobilized on core/shell Fe3O4/nylon composite nanoparticles using novel coaxial electrospraying process. Int. J. Biol. Macromol. 2021, 172, 270–280. [Google Scholar] [CrossRef] [PubMed]

- Che, S.; Wang, J.; Ji, X.; Su, Z.; Wang, S.; Zhang, S. Positional assembly of multi-enzyme cascade reaction in polyelectrolyte doped microcapsule through electrospray and layer-by-layer assembly. Synth. Syst. Biotechnol. 2020, 5, 206–213. [Google Scholar] [CrossRef]

- Rentería-Ortega, M.; Salgado-Cruz, M.D.L.P.; Morales-Sánchez, E.; Alamilla-Beltrán, L.; Valdespino-León, M.; Calderón-Domínguez, G. Glucose oxidase release of stressed chia mucilage-sodium alginate capsules prepared by electrospraying. J. Food Process. Preserv. 2021, 45, e15484. [Google Scholar] [CrossRef]

- Ibili, H.; Dasdemir, M.; Çankaya, T.; Orhan, M.; Güneşoğlu, C.; Anul, S.A. Investigation of poly(lactic acid) nanocapsules containing the plant extract via coaxial electrospraying method for functional nonwoven applications. J. Ind. Text. 2021. [Google Scholar] [CrossRef]

- Xing, X.; Han, Y.; Jiang, Q.; Sun, Y.; Wang, X.; Qu, G.; Sun, G.; Li, Y. Immobilization of laccases onto cellulose nanocrystals derived from waste newspaper: Relationship between immobilized laccase activity and dialdehyde content. Cellulose 2021, 1–13. [Google Scholar] [CrossRef]

- Lim, L.-T. Electrospinning and electrospraying technologies for food and packaging applications. In Electrospun Polymers and Composites; Woodhead Publishing: Cambridge, UK, 2020; pp. 217–259. [Google Scholar] [CrossRef]

- Liu, N.; Li, D.; Wang, W.; Hollmann, F.; Xu, L.; Ma, Y.; Yang, B.; Bai, W.; Sun, X.; Wang, Y. Production and immobilization of lipase PCL and its application in synthesis of α-linolenic acid-rich diacylglycerol. J. Food Biochem. 2018, 42, e12574. [Google Scholar] [CrossRef] [Green Version]

- Rostamabadi, H.; Falsafi, S.R.; Rostamabadi, M.M.; Assadpour, E.; Jafari, S.M. Electrospraying as a novel process for the synthesis of particles/nanoparticles loaded with poorly water-soluble bioactive molecules. Adv. Colloid Interface Sci. 2021, 290, 102384. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wu, H.; Su, Z. Enzyme-based hybrid nanoflowers with high performances for biocatalytic, biomedical, and environmental applications. Coord. Chem. Rev. 2020, 416, 213342. [Google Scholar] [CrossRef]

- Tang, Q.; Zhang, L.; Tan, X.; Jiao, L.; Wei, Q.; Li, H. Bioinspired synthesis of organic–inorganic hybrid nanoflowers for robust enzyme-free electrochemical immunoassay. Biosens. Bioelectron. 2019, 133, 94–99. [Google Scholar] [CrossRef] [PubMed]

- Cheon, H.J.; Adhikari, M.D.; Chung, M.; Tran, T.D.; Kim, J.; Kim, M.I. Magnetic nanoparticles-embedded enzyme-inorganic hybrid nanoflowers with enhanced peroxidase-like activity and substrate channeling for glucose biosensing. Adv. Heal. Mater. 2019, 8, e1801507. [Google Scholar] [CrossRef]

- Chui, C.-Y.; Ye, H. Fundamental concepts and insights into electrospraying for biomedical applications. In Biomedical Applications of Electrospinning and Electrospraying; Woodhead Publishing: Cambridge, UK, 2021; pp. 185–206. [Google Scholar] [CrossRef]

- Li, H.; Hou, J.; Duan, L.; Ji, C.; Zhang, Y.; Chen, V. Graphene oxide-enzyme hybrid nanoflowers for efficient water soluble dye removal. J. Hazard. Mater. 2017, 338, 93–101. [Google Scholar] [CrossRef]

- Lee, S.W.; Cheon, S.A.; Kim, M.I.; Park, T.J. Organic–inorganic hybrid nanoflowers: Types, characteristics, and future prospects. J. Nanobiotechnology 2015, 13, 1–10. [Google Scholar] [CrossRef] [Green Version]

- An, S.S.; Park, H.G.; Kim, M.I.; Batule, B.; Park, K.S. Ultrafast sonochemical synthesis of protein-inorganic nanoflowers. Int. J. Nanomed. 2015, ume 10, 137–142. [Google Scholar] [CrossRef] [Green Version]

- Batule, B.S.; Park, K.S.; Gautam, S.; Cheon, H.J.; Kim, M.I.; Park, H.G. Intrinsic peroxidase-like activity of sonochemically synthesized protein copper nanoflowers and its application for the sensitive detection of glucose. Sens. Actuators B Chem. 2018, 283, 749–754. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, Y.; Yang, C.; Ma, C.; Tang, J. Enzyme-inorganic hybrid nanoflowers: Classification, synthesis, functionalization and potential applications. Chem. Eng. J. 2021, 415, 129075. [Google Scholar] [CrossRef]

- Soni, S.; Dwivedee, B.P.; Banerjee, U.C. An ultrafast sonochemical strategy to synthesize lipase-manganese phosphate hybrid nanoflowers with promoted biocatalytic performance in the kinetic resolution of β-Aryloxyalcohols. Chem. Nano Mat. 2018, 4, 1007–1020. [Google Scholar] [CrossRef]

- Chung, M.; Nguyen, T.L.; Tran, T.Q.N.; Yoon, H.H.; Kim, I.T.; Kim, M.I. Ultrarapid sonochemical synthesis of enzyme-incorporated copper nanoflowers and their application to mediatorless glucose biofuel cell. Appl. Surf. Sci. 2018, 429, 203–209. [Google Scholar] [CrossRef]

- Park, K.S.; Batule, B.S.; Chung, M.; Kang, K.S.; Park, T.J.; Kim, M.I.; Park, H.G. A simple and eco-friendly one-pot synthesis of nuclease-resistant DNA–inorganic hybrid nanoflowers. J. Mater. Chem. B 2017, 5, 2231–2234. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Zhao, J.; Zhang, Z.; Jiang, Y.; Bilal, M.; Jiang, Y.; Jia, S.; Cui, J. Self-assembly of activated lipase hybrid nanoflowers with superior activity and enhanced stability. Biochem. Eng. J. 2020, 158, 107582. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, X.; Kong, D.; Li, G.; Li, Q. Immobilization of thermophilic lipase in inorganic hybrid nanoflower through biomimetic mineralization. Colloids Surfaces B Biointerfaces 2020, 197, 111450. [Google Scholar] [CrossRef] [PubMed]

- Lei, J.; Qi, L.; Luo, Z. Pickering emulsion-based microreactors for size-selective interfacial enzymatic catalysis. Front. Bioeng. Biotechnol. 2020, 8, 950. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Yin, W.; Chen, J.; Wang, W.; Guo, T.; Meng, T. Hollow colloidosomes with an enzyme confined in a porous shell as Pickering interfacial biocatalysts for efficient bioconversions. Green Chem. 2020, 23, 740–744. [Google Scholar] [CrossRef]

- Yang, Y.; Fang, Z.; Chen, X.; Zhang, W.; Xie, Y.; Chen, Y.; Liu, Z.; Yuan, W. An overview of pickering emulsions: Solid-particle materials, classification, morphology, and applications. Front. Pharmacol. 2017, 8, 287. [Google Scholar] [CrossRef] [Green Version]

- Jiang, H.; Li, Y.; Hong, L.; Ngai, T. Submicron inverse pickering emulsions for highly efficient and recyclable enzymatic Catalysis. Chem. Asian J. 2018, 13, 3533–3539. [Google Scholar] [CrossRef]

- Albert, C.; Beladjine, M.; Tsapis, N.; Fattal, E.; Agnely, F.; Huang, N. Pickering emulsions: Preparation processes, key parameters governing their properties and potential for pharmaceutical applications. J. Control. Release 2019, 309, 302–332. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, Z.; Shi, J.; Tang, H.; Xiang, X.; Huang, F.; Zheng, M.-M. Carbon nanoparticle-stabilized pickering emulsion as a sustainable and high-performance interfacial catalysis platform for enzymatic esterification/transesterification. ACS Sustain. Chem. Eng. 2019, 7, 7619–7629. [Google Scholar] [CrossRef]

- Sun, T.; Dong, Z.; Wang, J.; Huang, F.-H.; Zheng, M.-M. Ultrasound-assisted interfacial immobilization of lipase on hollow mesoporous silica spheres in a pickering emulsion system: A hyperactive and sustainable biocatalyst. ACS Sustain. Chem. Eng. 2020, 8, 17280–17290. [Google Scholar] [CrossRef]

- Wang, J.; Huang, R.; Qi, W.; Su, R.; He, Z. Oriented enzyme immobilization at the oil/water interface enhances catalytic activity and recyclability in a pickering emulsion. Langmuir 2017, 33, 12317–12325. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Zhang, M.; Zhang, X.; Xin, H.; Yang, H. Pickering emulsion as an efficient platform for enzymatic reactions without stirring. ACS Sustain. Chem. Eng. 2016, 4, 6838–6843. [Google Scholar] [CrossRef]

- Lou, W.-Y.; Fernández-Lucas, J.; Ge, J.; Wu, C. Editorial: Enzyme or whole cell immobilization for efficient biocatalysis: Focusing on novel supporting platforms and immobilization techniques. Front. Bioeng. Biotechnol. 2021, 9. [Google Scholar] [CrossRef]

- Sarkar, A.; Zhang, S.; Holmes, M.; Ettelaie, R. Colloidal aspects of digestion of Pickering emulsions: Experiments and theoretical models of lipid digestion kinetics. Adv. Colloid Interface Sci. 2018, 263, 195–211. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guan, T.; Liu, B.; Wang, R.; Huang, Y.; Luo, J.; Li, Y. The enhanced fatty acids flavor release for low-fat cheeses by carrier immobilized lipases on O/W Pickering emulsions. Food Hydrocoll. 2021, 116, 106651. [Google Scholar] [CrossRef]

- Wang, T.; Chen, K.; Li, Z.; Jiang, L.; Yu, D.; Cheng, J.; Wang, L. Construction of an enzyme—Pickering emulsion catalytic system and its application in the interfacial catalytic reaction of rice bran oil deacidification. LWT 2021, 150, 111921. [Google Scholar] [CrossRef]

- Yuan, S.; Liu, Q.; Zhu, L.; Ning, J.; Yang, H.; Ning, K.; He, Y. Emulsion hydrogel microbeads encapsulating extractants prepared by O/W/O double pickering emulsions for the recovery of Cu(II) from water. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 625, 126932. [Google Scholar] [CrossRef]

- Zhang, T.; Xu, J.; Chen, J.; Wang, Z.; Wang, X.; Zhong, J. Protein nanoparticles for Pickering emulsions: A comprehensive review on their shapes, preparation methods, and modification methods. Trends Food Sci. Technol. 2021, 113, 26–41. [Google Scholar] [CrossRef]

- Jiang, H.; Liu, L.; Li, Y.; Yin, S.-W.; Ngai, T. Inverse pickering emulsion stabilized by binary particles with contrasting characteristics and functionality for interfacial biocatalysis. ACS Appl. Mater. Interfaces 2020, 12, 4989–4997. [Google Scholar] [CrossRef]

- Dong, H.; Zhang, W.; Zhou, S.; Huang, J.; Wang, P. Engineering bioscaffolds for enzyme assembly. Biotechnol. Adv. 2021, 107721. [Google Scholar] [CrossRef]

- Zhang, Q.; Bolisetty, S.; Cao, Y.; Handschin, S.; Adamcik, J.; Peng, Q.; Mezzenga, R. Selective and efficient removal of fluoride from water: In situ engineered amyloid fibril/ZrO 2 hybrid membranes. Angew. Chem. Int. Ed. 2019, 58, 6012–6016. [Google Scholar] [CrossRef]

- Torres, M.; Sothiselvam, S.; Lu, T.K.; de la Fuente-Nunez, C. Peptide design principles for antimicrobial applications. J. Mol. Biol. 2019, 431, 3547–3567. [Google Scholar] [CrossRef] [PubMed]

- Hu, B.; Zhu, M. Reconstitution of cellulosome: Research progress and its application in biorefinery. Biotechnol. Appl. Biochem. 2019, 66, 720–730. [Google Scholar] [CrossRef]

- Smith, S.P.; A Bayer, E. Insights into cellulosome assembly and dynamics: From dissection to reconstruction of the supramolecular enzyme complex. Curr. Opin. Struct. Biol. 2013, 23, 686–694. [Google Scholar] [CrossRef]

- Kumada, Y.; Kuroki, D.; Yasui, H.; Ohse, T.; Kishimoto, M. Characterization of polystyrene-binding peptides (PS-tags) for site-specific immobilization of proteins. J. Biosci. Bioeng. 2010, 109, 583–587. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Zhang, W.; Wang, Y.; Liu, D.; Wang, P. Biofilm polysaccharide display platform: A natural, renewable, and biocompatible material for improved lipase performance. J. Agric. Food Chem. 2020, 68, 1373–1381. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Zhang, W.; Xuan, Q.; Zhou, Y.; Zhou, S.; Huang, J.; Wang, P. Binding peptide-guided immobilization of lipases with significantly improved catalytic performance using escherichia coli BL21(DE3) biofilms as a platform. ACS Appl. Mater. Interfaces 2021, 13, 6168–6179. [Google Scholar] [CrossRef]

- Mulinari, J.; Oliveira, J.V.; Hotza, D. Lipase immobilization on ceramic supports: An overview on techniques and materials. Biotechnol. Adv. 2020, 42, 107581. [Google Scholar] [CrossRef]

- Zdarta, J.; Meyer, A.S.; Jesionowski, T.; Pinelo, M. Developments in support materials for immobilization of oxidoreductases: A comprehensive review. Adv. Colloid Interface Sci. 2018, 258, 1–20. [Google Scholar] [CrossRef]

- Adeel, M.; Bilal, M.; Rasheed, T.; Sharma, A.; Iqbal, H.M. Graphene and graphene oxide: Functionalization and nano-bio-catalytic system for enzyme immobilization and biotechnological perspective. Int. J. Biol. Macromol. 2018, 120, 1430–1440. [Google Scholar] [CrossRef] [PubMed]

- Kashefi, S.; Borghei, S.M.; Mahmoodi, N.M. Covalently immobilized laccase onto graphene oxide nanosheets: Preparation, characterization, and biodegradation of azo dyes in colored wastewater. J. Mol. Liq. 2018, 276, 153–162. [Google Scholar] [CrossRef]

- Ying, W.; Shi, Z.; Yang, H.; Xu, G.; Zheng, Z.; Yang, J. Effect of alkaline lignin modification on cellulase–lignin interactions and enzymatic saccharification yield. Biotechnol. Biofuels 2018, 11, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Pandey, D.; Daverey, A.; Arunachalam, K. Biochar: Production, properties and emerging role as a support for enzyme immobilization. J. Clean. Prod. 2020, 255, 120267. [Google Scholar] [CrossRef]

- Mokhtar, N.F.; Rahman, R.N.Z.R.A.; Noor, N.D.M.; Shariff, F.M.; Ali, M.S.M. The immobilization of lipases on porous support by adsorption and hydrophobic interaction method. Catalysts 2020, 10, 744. [Google Scholar] [CrossRef]

- Cui, J.D.; Ren, S.; Sun, B.; Jia, S. Optimization protocols and improved strategies for metal-organic frameworks for immobilizing enzymes: Current development and future challenges. Coord. Chem. Rev. 2018, 370, 22–41. [Google Scholar] [CrossRef]

- Fopase, R.; Paramasivam, S.; Kale, P.; Paramasivan, B. Strategies, challenges and opportunities of enzyme immobilization on porous silicon for biosensing applications. J. Environ. Chem. Eng. 2020, 8, 104266. [Google Scholar] [CrossRef]

- Alnoch, R.C.; Dos Santos, L.A.; De Almeida, J.M.; Krieger, N.; Mateo, C. Recent trends in biomaterials for immobilization of lipases for application in non-conventional media. Catalysts 2020, 10, 697. [Google Scholar] [CrossRef]

- Liu, J.; Ma, R.-T.; Shi, Y.-P. “Recent advances on support materials for lipase immobilization and applicability as biocatalysts in inhibitors screening methods”-A review. Anal. Chim. Acta 2019, 1101, 9–22. [Google Scholar] [CrossRef]

- Bilal, M.; Fernandes, C.D.; Mehmood, T.; Nadeem, F.; Tabassam, Q.; Ferreira, L.F.R. Immobilized lipases-based nano-biocatalytic systems—A versatile platform with incredible biotechnological potential. Int. J. Biol. Macromol. 2021, 175, 108–122. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Liu, X.; Wang, L.; Zhou, L.; Huang, Z.; Ma, L.; He, Y.; Shi, L.; Gao, J. Virus-like organosilica nanoparticles for lipase immobilization: Characterization and biocatalytic applications. Biochem. Eng. J. 2019, 144, 125–134. [Google Scholar] [CrossRef]

- Tacias-Pascacio, V.G.; Virgen-Ortíz, J.J.; Jiménez-Pérez, M.; Yates, M.; Torrestiana-Sanchez, B.; Rosales-Quintero, A.; Fernandez-Lafuente, R. Evaluation of different lipase biocatalysts in the production of biodiesel from used cooking oil: Critical role of the immobilization support. Fuel 2017, 200, 1–10. [Google Scholar] [CrossRef]

- Zare, A.; Bordbar, A.-K.; Jafarian, F.; Tangestaninejad, S. Candida rugosa lipase immobilization on various chemically modified Chromium terephthalate MIL-101. J. Mol. Liq. 2018, 254, 137–144. [Google Scholar] [CrossRef]

- Xiang, X.; Suo, H.; Xu, C.; Hu, Y. Covalent immobilization of lipase onto chitosan-mesoporous silica hybrid nanomaterials by carboxyl functionalized ionic liquids as the coupling agent. Colloids Surfaces B Biointerfaces 2018, 165, 262–269. [Google Scholar] [CrossRef]

- Asmat, S.; Anwer, A.H.; Husain, Q. Immobilization of lipase onto novel constructed polydopamine grafted multiwalled carbon nanotube impregnated with magnetic cobalt and its application in synthesis of fruit flavours. Int. J. Biol. Macromol. 2019, 140, 484–495. [Google Scholar] [CrossRef]

- Wan, D.; Tian, L.; Li, X.; Li, B.; Zhang, Q. A versatile strategy for enzyme immobilization: Fabricating lipase/inorganic hybrid nanostructures on macroporous resins with enhanced catalytic properties. Biochem. Eng. J. 2018, 139, 101–108. [Google Scholar] [CrossRef]

- Asmat, S.; Husain, Q. Exquisite stability and catalytic performance of immobilized lipase on novel fabricated nanocellulose fused polypyrrole/graphene oxide nanocomposite: Characterization and application. Int. J. Biol. Macromol. 2018, 117, 331–341. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Sun, Y. Poly(carboxybetaine methacrylate)-grafted silica nanoparticle: A novel carrier for enzyme immobilization. Biochem. Eng. J. 2018, 132, 122–129. [Google Scholar] [CrossRef]

- Cai, Q.; Hu, C.; Yang, N.; Wang, Q.; Wang, J.; Pan, H.; Hu, Y.; Ruan, C. Enhanced activity and stability of industrial lipases immobilized onto spherelike bacterial cellulose. Int. J. Biol. Macromol. 2017, 109, 1174–1181. [Google Scholar] [CrossRef]

- Liu, X.; Fang, Y.; Yang, X.; Li, Y.; Wang, C. Electrospun nanofibrous membranes containing epoxy groups and hydrophilic polyethylene oxide chain for highly active and stable covalent immobilization of lipase. Chem. Eng. J. 2018, 336, 456–464. [Google Scholar] [CrossRef]

- Gricajeva, A.; Kazlauskas, S.; Kalėdienė, L.; Bendikienė, V. Analysis of Aspergillus sp. lipase immobilization for the application in organic synthesis. Int. J. Biol. Macromol. 2018, 108, 1165–1175. [Google Scholar] [CrossRef]

- Orrego, A.H.; Ghobadi, R.; Moreno-Perez, S.; Mendoza, A.J.; Fernández-Lorente, G.; Guisan, J.M.; Rocha-Martin, J. Stabilization of immobilized lipases by intense intramolecular cross-linking of their surfaces by using aldehyde-dextran polymers. Int. J. Mol. Sci. 2018, 19, 553. [Google Scholar] [CrossRef] [Green Version]

- Sipponen, M.H.; Farooq, M.; Koivisto, J.; Pellis, A.; Seitsonen, J.; Österberg, M. Spatially confined lignin nanospheres for biocatalytic ester synthesis in aqueous media. Nat. Commun. 2018, 9, 1–7. [Google Scholar] [CrossRef]

- Elias, N.; Chandren, S.; Razak, F.I.A.; Jamalis, J.; Widodo, N.; Wahab, R.A. Characterization, optimization and stability studies on Candida rugosa lipase supported on nanocellulose reinforced chitosan prepared from oil palm biomass. Int. J. Biol. Macromol. 2018, 114, 306–316. [Google Scholar] [CrossRef]

- Otari, S.; Patel, S.K.; Kalia, V.C.; Lee, J.-K. One-step hydrothermal synthesis of magnetic rice straw for effective lipase immobilization and its application in esterification reaction. Bioresour. Technol. 2020, 302, 122887. [Google Scholar] [CrossRef] [PubMed]