Cu/ZSM5-Geopolymer 3D-Printed Monoliths for the NH3-SCR of NOx

Abstract

1. Introduction

2. Results and Discussion

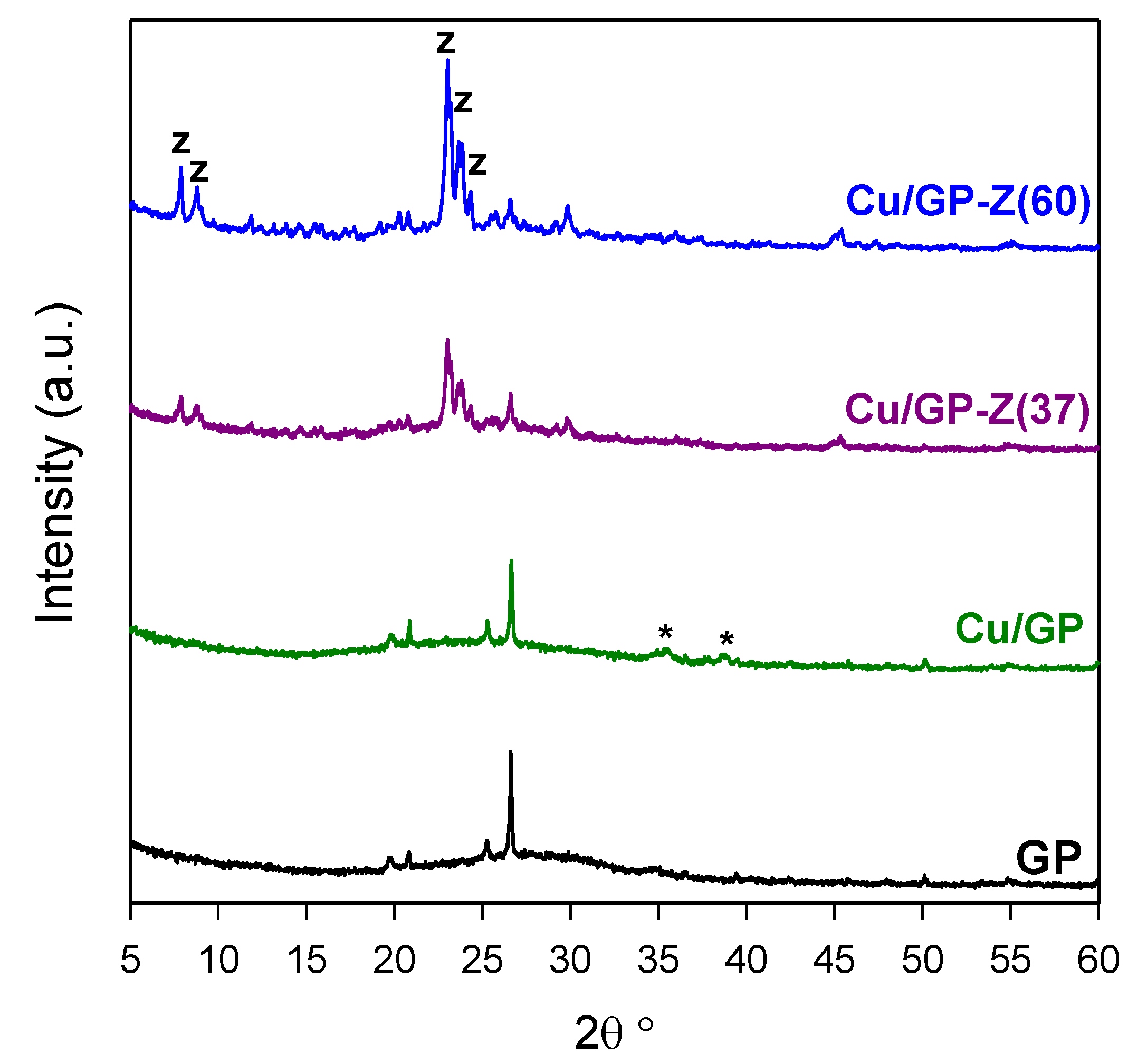

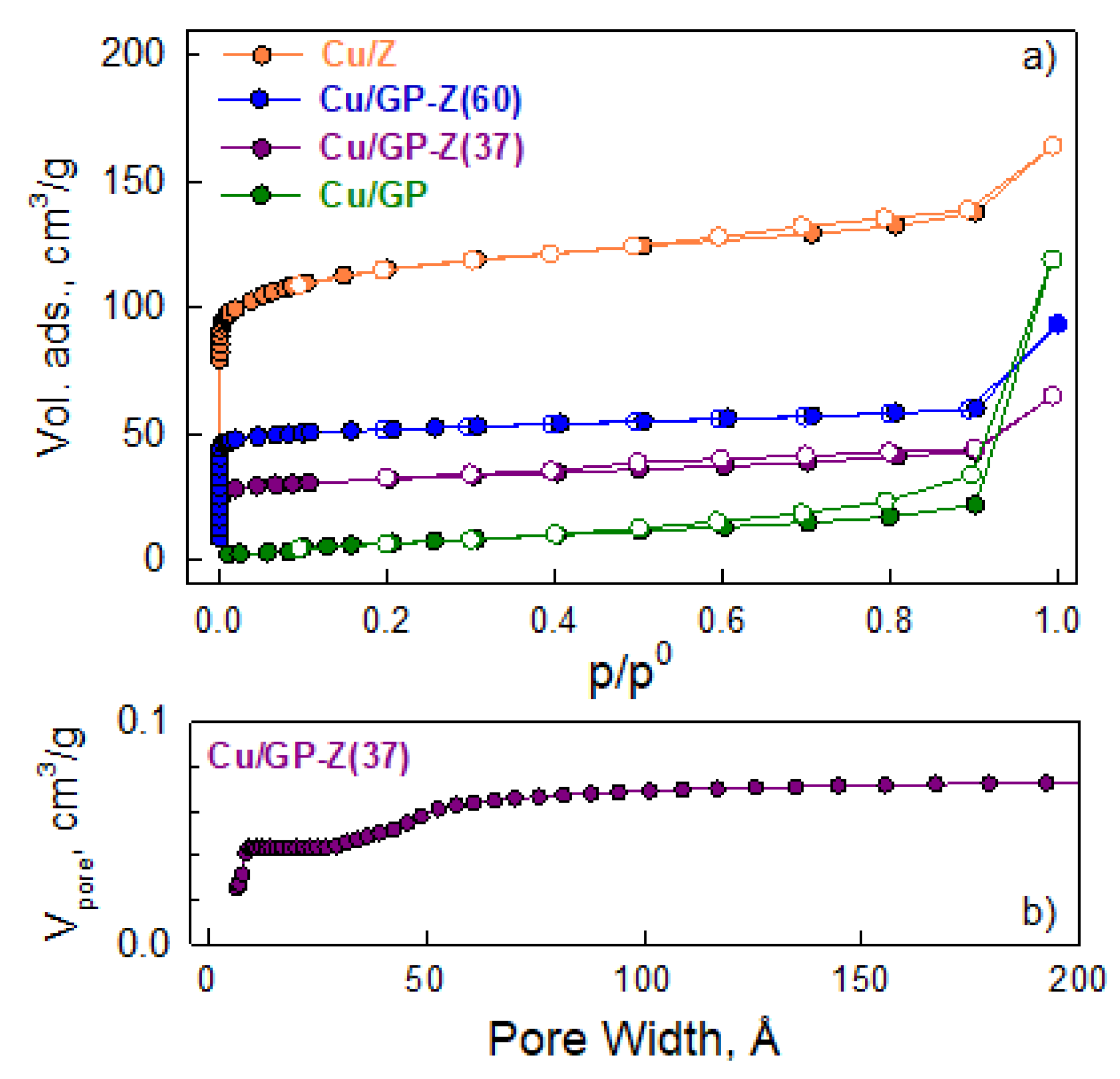

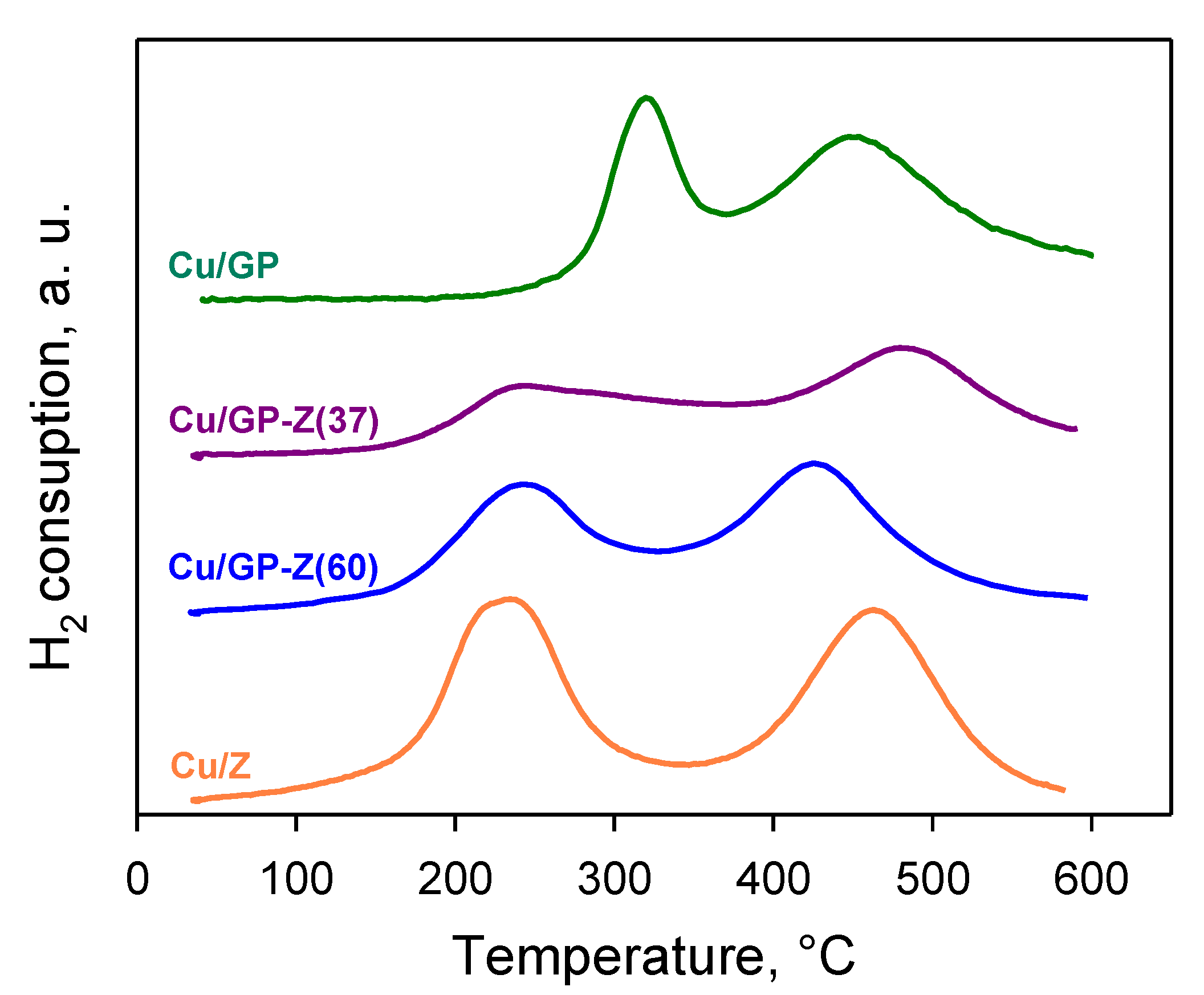

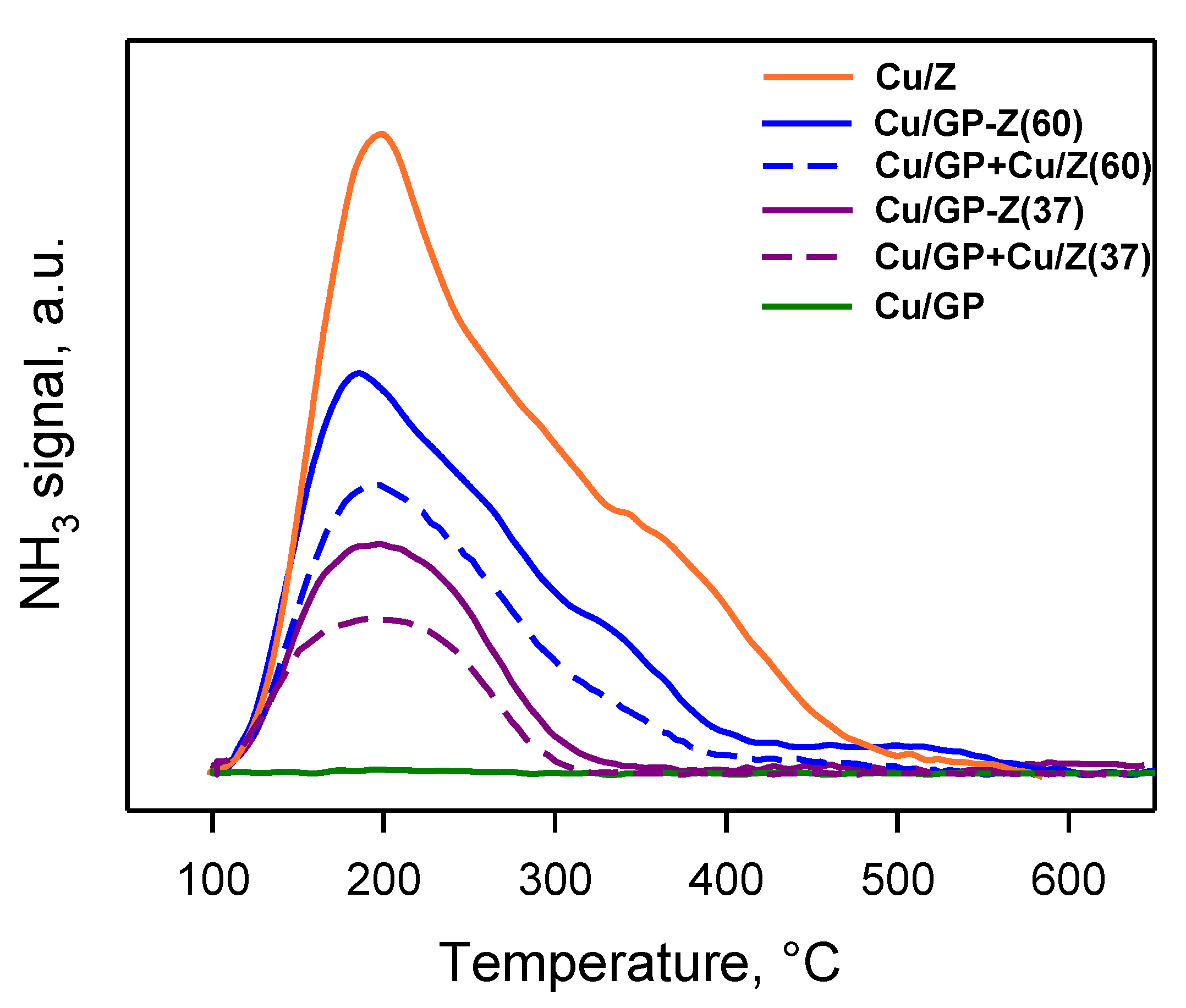

2.1. Catalyst Characterization

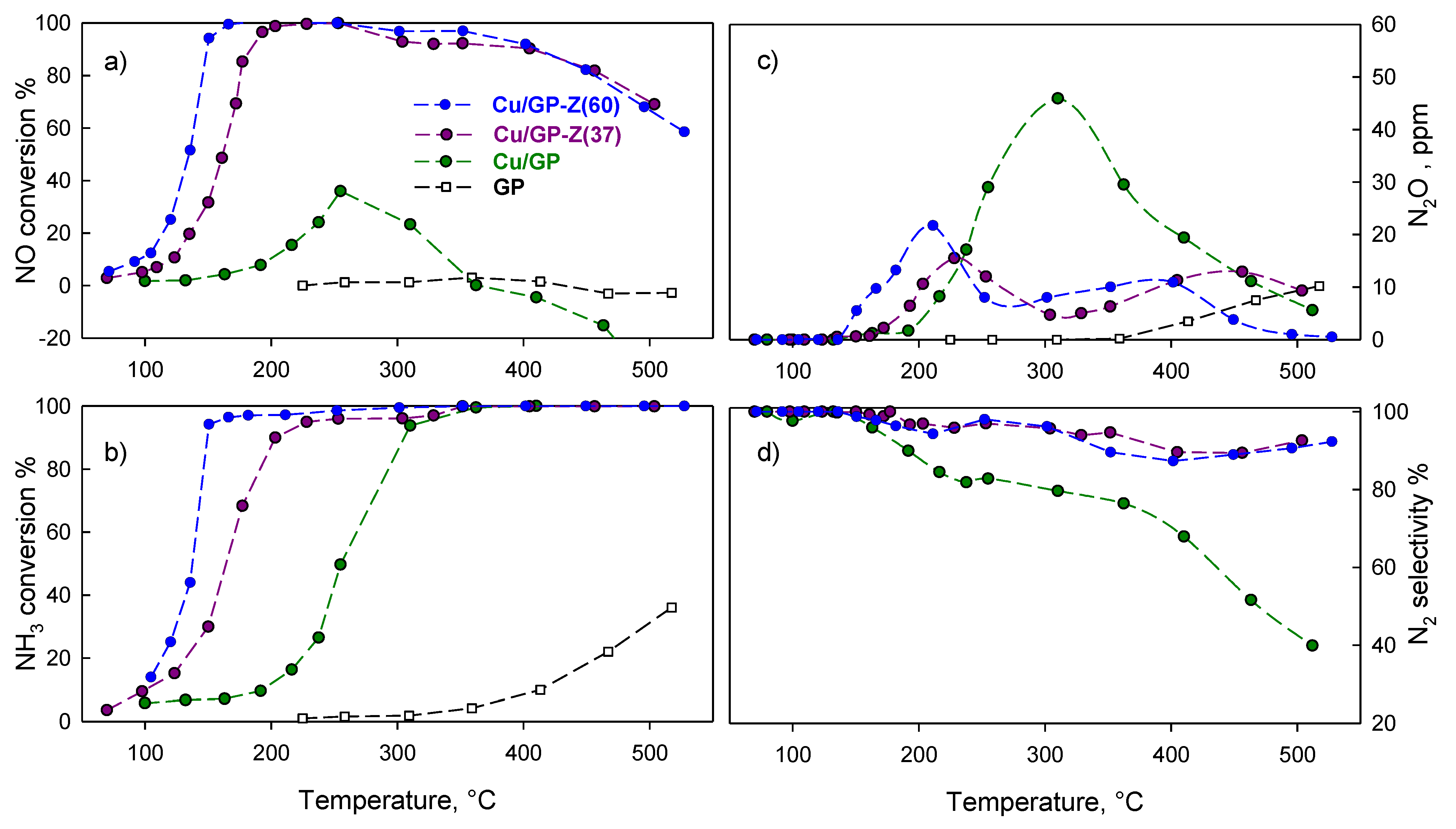

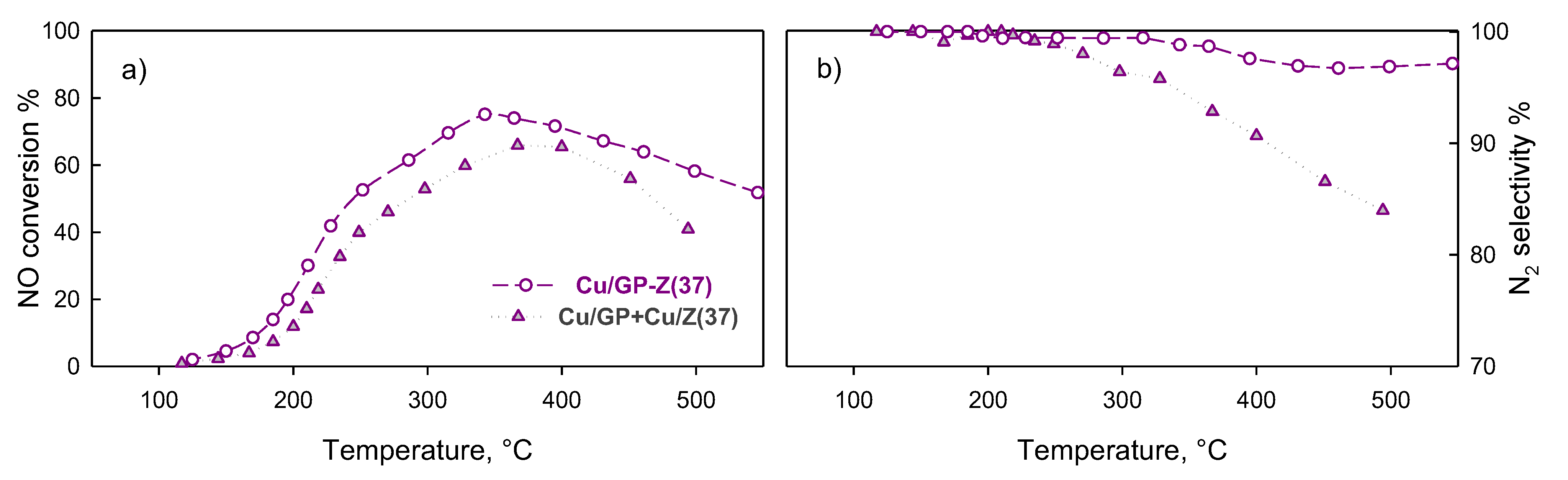

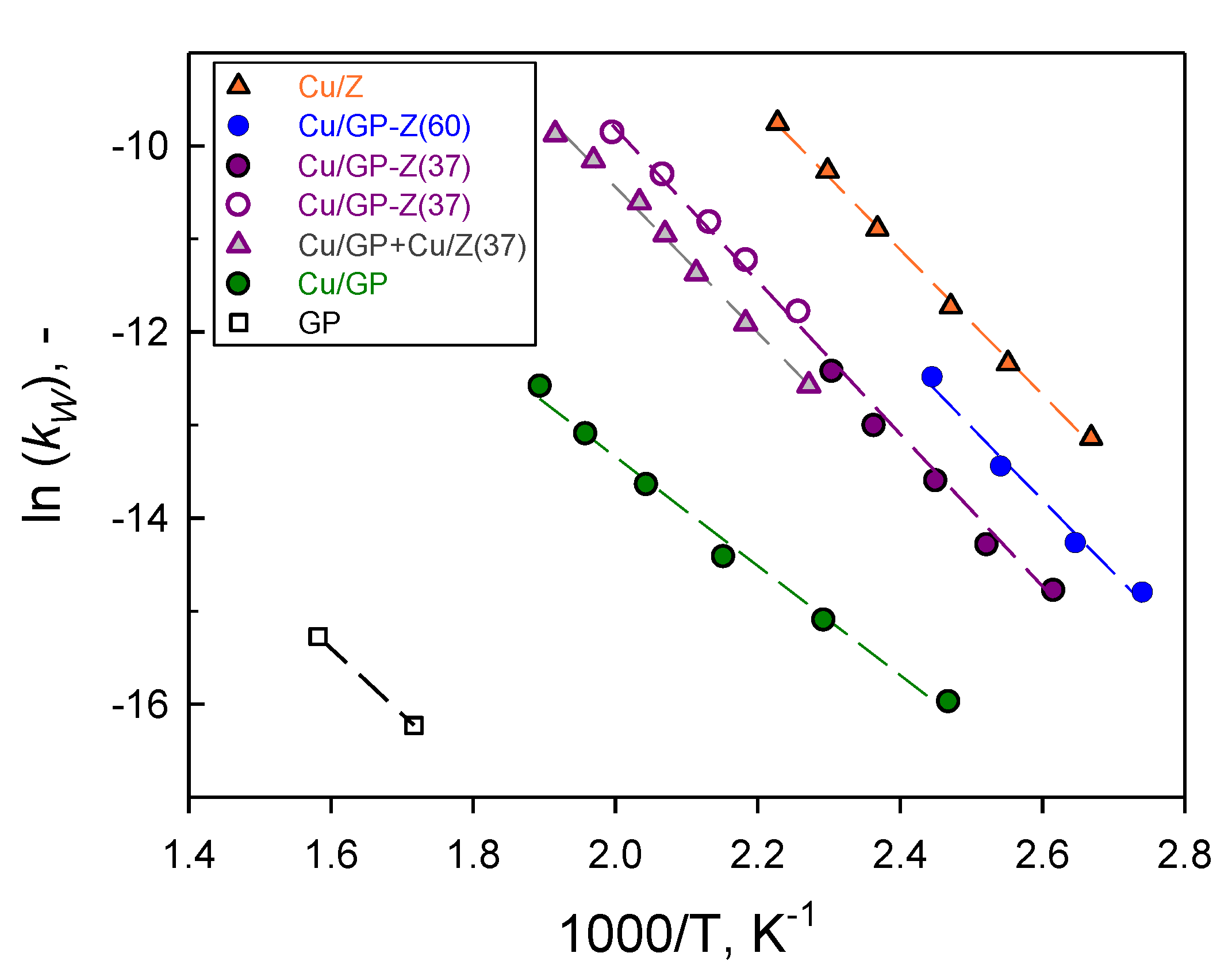

2.2. NH3-SCR Tests

3. Materials and Methods

3.1. Catalysts Preparation

3.2. Catalyst Characterization

3.3. NH3-SCR Tests

3.4. NH3-TPD

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, W.; Qi, S.; Pantaleo, G.; Liotta, L.F. WO3-V2O5 active oxides for NOx SCR by NH3: Preparation methods, catalysts’ composition, and deactivation mechanism-A review. Catalysts 2019, 9, 527. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Chen, P.; Zhu, B. Research status and prospect on vanadium-based catalysts for NH3-SCR denitration. Materials 2018, 11, 1632. [Google Scholar] [CrossRef] [PubMed]

- Tamilselvan, P.; Nallusamy, N.; Rajkumar, S. A comprehensive review on performance, combustion and emission characteristics of biodiesel fuelled diesel engines. Renew Sustain. Energy Rev. 2017, 79, 1134–1159. [Google Scholar] [CrossRef]

- Mohan, S.; Dinesha, P.; Kumar, S. NOx reduction behaviour in copper zeolite catalysts for ammonia SCR systems: A review. Chem. Eng. J. 2020, 384, 123253. [Google Scholar] [CrossRef]

- Namchot, W.; Jitkarnka, S. Upgrading of waste tyre-derived oil from waste tyre pyrolysis over Ni catalyst supported on HZSM5 zeolite. Chem. Eng. Trans. 2015, 45, 775–780. [Google Scholar]

- Hamoud, H.I.; Valtchev, V.; Daturi, M. Selective catalytic reduction of NOx over Cu- and Fe-exchanged zeolites and their mechanical mixture. Appl. Catal. B Environ. 2019, 250, 419–428. [Google Scholar] [CrossRef]

- Martín, N.; Vennestrøm, P.N.R.; Thøgersen, J.R.; Moliner, M.; Corma, A. Fe-Containing Zeolites for NH3-SCR of NOx: Effect of Structure, Synthesis Procedure, and Chemical Composition on Catalytic Performance and Stability. Chem. A Eur. J. 2017, 23, 13404–13414. [Google Scholar] [CrossRef]

- Lisi, L.; Pirone, R.; Russo, G.; Stanzione, V. Cu-ZSM5 based monolith reactors for NO decomposition. Chem. Eng. J. 2009, 154, 341–347. [Google Scholar] [CrossRef]

- Nova, I.; Bounechada, D.; Maestri, R.; Tronconi, E.; Heibel, A.K.; Collins, T.A.; Boger, T. Influence of the substrate properties on the performances of NH3-SCR monolithic catalysts for the aftertreatment of diesel exhaust: An experimental and modeling study. Ind. Eng. Chem. Res. 2011, 50, 299–309. [Google Scholar] [CrossRef]

- Gargiulo, N.; Caputo, D.; Totarella, G.; Lisi, L.; Cimino, S. Me-ZSM5 monolith foams for the NH3-SCR of NO. Catal. Today 2018, 304, 112–118. [Google Scholar] [CrossRef]

- Peng, C.; Yan, R.; Peng, H.; Mi, Y.; Liang, J.; Liu, W.; Wang, X.; Song, G.; Wu, P.; Liu, F. One-pot synthesis of layered mesoporous ZSM5 plus Cu ion-exchange: Enhanced NH3-SCR performance on Cu-ZSM5 with hierarchical pore structures. J. Hazard. Mater. 2020, 385, 121593. [Google Scholar] [CrossRef]

- Sarno, M.; Scudieri, C. H2 production improvement during pyrolysis catalyzed by zeolites. Chem. Eng. Trans. 2018, 65, 157–162. [Google Scholar]

- Davis, M.E. Ordered porous materials for emerging applications. Nature 2002, 417, 813–821. [Google Scholar] [CrossRef] [PubMed]

- Colombo, P.; Degischer, H.P. Highly porous metals and ceramics. Mater. Sci. Technol. 2010, 26, 1145–1158. [Google Scholar] [CrossRef]

- Colombo, P.; Vakifahmetoglu, C.; Costacurta, S. Fabrication of ceramic components with hierarchical porosity. J. Mater. Sci. 2010, 45, 5425–5455. [Google Scholar] [CrossRef]

- Tian, Q.; Sasaki, K. Structural characterizations of fly ash-based geopolymer after adsorption of various metal ions. Environ. Technol. 2021, 42, 941–951. [Google Scholar] [CrossRef]

- dos Santos, L.K.; Botti, R.F.; de Mello Innocentini, M.D.; Marques, R.F.C.; Colombo, P.; de Paula, A.V.; Flumignan, D.L. 3D printed geopolymer: An efficient support for immobilization of Candida rugosa lipase. Chem. Eng. Sci. 2021, 414, 128843. [Google Scholar] [CrossRef]

- Petlitckaia, S.; Barré, Y.; Piallat, T.; Grauby, O.; Ferry, D.; Poulesquen, A. Functionalized geopolymer foams for cesium removal from liquid nuclear waste. J. Clean. Prod. 2020, 269, 122400. [Google Scholar] [CrossRef]

- Luukkonen, T.; Sarkkinen, M.; Kemppainen, K.; Rämö, J.; Lassi, U. Metakaolin geopolymer characterization and application for ammonium removal from model solutions and landfill leachate. Appl. Clay Sci. 2016, 119, 266–276. [Google Scholar] [CrossRef]

- Sazama, P.; Bortnovsky, O.; Dědeček, J.; Tvaržková, Z.; Sobalík, Z. Geopolymer based catalysts-new group of catalytic materials. Catal. Today. 2011, 164, 92–99. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, Y.J.; He, P.Y.; Li, C.J.; Liu, L.C. Facile synthesis of cost-effective iron enhanced hetero-structure activated carbon/geopolymer composite catalyst for NH3-SCR: Insight into the role of iron species. Appl. Catal. A Gen. 2020, 605, 117804. [Google Scholar] [CrossRef]

- Hu, M.; Zhu, X.; Long, F. Alkali-activated fly ash-based geopolymers with zeolite or bentonite as additives. Cem. Concr. Compos. 2009, 31, 762–768. [Google Scholar] [CrossRef]

- Rożek, P.; Król, M.; Mozgawa, W. Geopolymer-zeolite composites: A review. J. Clean. Prod. 2019, 230, 557–579. [Google Scholar] [CrossRef]

- Zhang, J.; He, Y.; Wang, Y.P.; Mao, J.; Cui, X.M. Synthesis of a self-supporting faujasite zeolite membrane using geopolymer gel for separation of alcohol/water mixture. Mater. Lett. 2014, 116, 167–170. [Google Scholar] [CrossRef]

- He, Y.; Cui, X.M.; Liu, X.D.; Wang, Y.P.; Zhang, J.; Liu, K. Preparation of self-supporting NaA zeolite membranes using geopolymers. J. Membr. Sci. 2013, 447, 66–72. [Google Scholar] [CrossRef]

- Villa, C.; Pecina, E.T.; Torres, R.; Gómez, L. Geopolymer synthesis using alkaline activation of natural zeolite. Constr. Build. Mater. 2010, 24, 2084–2090. [Google Scholar] [CrossRef]

- Wang, D.; Liu, Z.; Wang, H.; Xie, Z.; Tang, Y. Shape-controlled synthesis of monolithic ZSM5 zeolite with hierarchical structure and mechanical stability. Microporous Mesoporous Mater. 2010, 132, 428–434. [Google Scholar] [CrossRef]

- Li, C.J.; Zhang, Y.J.; Chen, H.; He, P.Y. Highly-effective production of renewable energy dimethyl ether over geopolymer-based ferrierite. Fuel 2021, 293, 120486. [Google Scholar] [CrossRef]

- Papa, E.; Medri, V.; Amari, S.; Manaud, J.; Benito, P.; Vaccari, A.; Landi, E. Zeolite-geopolymer composite materials: Production and characterization. J. Clean. Prod. 2018, 171, 76–84. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Guenster, J. Additive Manufacturing of Ceramics: Issues, potentialities and opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Shahzad, A.; Lazoglu, I. Direct ink writing (DIW) of structural and functional ceramics: Recent achievements and future challenges. Compos. Part B Eng. 2021, 225, 109249. [Google Scholar] [CrossRef]

- Cepollaro, E.M.; Cimino, S.; Lisi, L.; Botti, R.; Colombo, P.; Franchin, G. Cu-exchanged 3D-printed geopolymer/ZSM5 monolith for selective catalytic reduction of NOx. Chem. Eng. Trans. 2021, 84, 67–72. [Google Scholar]

- Huang, K.; Elsayed, H.; Franchin, G.; Colombo, P. Additive Manufacturing of SiOC scaffolds with tunable structure-performance relationship. J. Eur. Ceram. Soc. 2021, 41, 7552–7559. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Pelanconi, M.; Ortona, A.; Abu Al-Rub, R.K. Additive manufacturing of architected catalytic ceramic substrates based on triply periodic minimal surfaces. J. Am. Ceram. Soc. 2019, 102, 6176–6193. [Google Scholar] [CrossRef]

- Skorina, T. Ion exchange in amorphous alkali-activated aluminosilicates: Potassium based geopolymers. Appl. Clay Sci. 2014, 87, 205–211. [Google Scholar] [CrossRef]

- Uehara, M.; Sato, T.; Yamazaki, A. Suppression of Alkali Silica Reaction Using H+-type Geopolymer. Q. Rep. RTRI. 2018, 59, 90–96. [Google Scholar] [CrossRef][Green Version]

- Bortnovsky, O.; Dědeček, J.; Tvarůžková, Z.; Sobalík, Z.; Šubrt, J. Metal ions as probes for characterization of geopolymer materials. J. Am. Ceram. Soc. 2008, 91, 3052–3057. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers–Inorganic Polymer New Materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Kim, B.; Lee, S. Review on characteristics of metakaolin-based geopolymer and fast setting. J. Korean Ceram. Soc. 2020, 57, 368–377. [Google Scholar] [CrossRef]

- He, P.; Fu, S.; Yuan, J.; Rao, J.; Xu, J.; Wang, P.; Jia, D. Celsian formation from barium-exchanged geopolymer precursor: Thermal evolution. J. Eur. Ceram. Soc. 2017, 37, 4179–4185. [Google Scholar] [CrossRef]

- Allahverdi, A.; Skvara, F. Sulfuric acid attack on hardened paste of geopolymer cements—Part 1. Mechanism of corrosion at relatively high concentrations. Ceram. Silik. 2005, 49, 225–229. [Google Scholar]

- Allahverdi, A.; Skvara, F. Sulfuric acid attack on hardened paste of geopolymer cements—Part 2. Corrosion mechanism at mild and relatively low concentrations. Ceram. Silik. 2006, 50, 1–4. [Google Scholar]

- Ma, T.; Imai, H.; Yamawaki, M.; Terasaka, K.; Li, X. Selective Synthesis of Gasoline-Ranged Hydrocarbons from Syngas over Hybrid Catalyst Consisting of Metal-Loaded ZSM5 Coupled with Copper-Zinc Oxide. Catalysts 2014, 4, 116–128. [Google Scholar] [CrossRef]

- Wang, H.; Jia, J.; Liu, S.; Chen, H.; Wei, Y.; Wang, Z.; Zheng, L.; Wang, Z.; Zhang, R. Highly efficient NO abatement over Cu-ZSM5 with special nanosheet features. Environ. Sci. Technol. 2021, 55, 5422–5434. [Google Scholar] [CrossRef] [PubMed]

- Saha, B.; Vedachalam, S.; Dalai, A.K. Performance of geopolymer as adsorbent on desulphurization of heavy gas oil. Can. J. Chem. Eng. 2021, 18. [Google Scholar] [CrossRef]

- Cimino, S.; Totarella, G.; Tortorelli, M.; Lisi, L. Combined poisoning effect of K+ and its counter-ion (Cl− or NO3−) on MnOx/TiO2 catalyst during the low temperature NH3-SCR of NO. Chem. Eng. J. 2017, 330, 92–101. [Google Scholar] [CrossRef]

| Sample | Cu Load wt% | Exchange Capacity % | SBET m2 g−1 | Vmicro cm3 g−1 | Vtot cm3 g−1 | |

|---|---|---|---|---|---|---|

| H-ZSM5 | - | 430 | 0.17 | 0.25 | ||

| Cu/Z | 3.2 | 90 | 415 | 0.16 | 0.24 | |

| GP–Z(60) | Acid-treated | - | 264 | 0.11 | 0.17 | |

| Cu-exchanged | 2.9 | 253 | 0.11 | 0.19 | ||

| GP–Z(37) | Acid-treated | - | 133 | 0.05 | 0.14 | |

| Cu-exchanged | 1.5 | 122 | 0.04 | 0.11 | ||

| GP | - | 11 | - | 0.13 | ||

| Cu/GP | 3.0 | 20 | 27 | - | 0.18 | |

| TPR | TPD | |||

|---|---|---|---|---|

| Sample | H2/Cu | Temperature (°C) | Desorbed NH3 | |

| mol/mol | Peak 1 | Peak 2 | mmol g−1 | |

| Cu/Z | 1.08 | 239 | 460 | 1.17 |

| Cu/GP–Z(60) | 0.95 | 242 | 436 | 0.69 |

| Cu/GP–Z(37) | 1.04 | 238 | 477 | 0.31 |

| Cu/GP | 0.97 | 320 | 453 | - |

| Catalyst | Form | F/Wcat dm3gcat−1h−1 | Ea kJ mol −1 | kw (150 °C) cm3gcat−1s−1 | kwz (150 °C) cm3gzeolite−1s−1 |

|---|---|---|---|---|---|

| Cu/Z | Powder | 200 | 64.8 | 20 | 20 |

| Cu/Z Foam a | Monolith | 40 | 74.6 | 3.4 | 3.4 |

| Cu/GP–Z(60) | Monolith | 13 | 65.1 | 6.0 | 10 |

| Cu/GP–Z(37) | Monolith | 14 | 68.1 | 2.8 | 7.6 |

| Cu/GP–Z(37) | Powder | 200 | 68.1 | 2.8 | 7.6 |

| Cu/GP+Cu/Z(37) b | Powder | 200 | 65.0 | 1.7 | 4.6 |

| Cu/GP | Monolith | 15 | 48.8 | 0.2 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cepollaro, E.M.; Botti, R.; Franchin, G.; Lisi, L.; Colombo, P.; Cimino, S. Cu/ZSM5-Geopolymer 3D-Printed Monoliths for the NH3-SCR of NOx. Catalysts 2021, 11, 1212. https://doi.org/10.3390/catal11101212

Cepollaro EM, Botti R, Franchin G, Lisi L, Colombo P, Cimino S. Cu/ZSM5-Geopolymer 3D-Printed Monoliths for the NH3-SCR of NOx. Catalysts. 2021; 11(10):1212. https://doi.org/10.3390/catal11101212

Chicago/Turabian StyleCepollaro, Elisabetta Maria, Renata Botti, Giorgia Franchin, Luciana Lisi, Paolo Colombo, and Stefano Cimino. 2021. "Cu/ZSM5-Geopolymer 3D-Printed Monoliths for the NH3-SCR of NOx" Catalysts 11, no. 10: 1212. https://doi.org/10.3390/catal11101212

APA StyleCepollaro, E. M., Botti, R., Franchin, G., Lisi, L., Colombo, P., & Cimino, S. (2021). Cu/ZSM5-Geopolymer 3D-Printed Monoliths for the NH3-SCR of NOx. Catalysts, 11(10), 1212. https://doi.org/10.3390/catal11101212