Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review

Abstract

1. Introduction

2. Microalgae Oil as Feedstock for Biodiesel Production

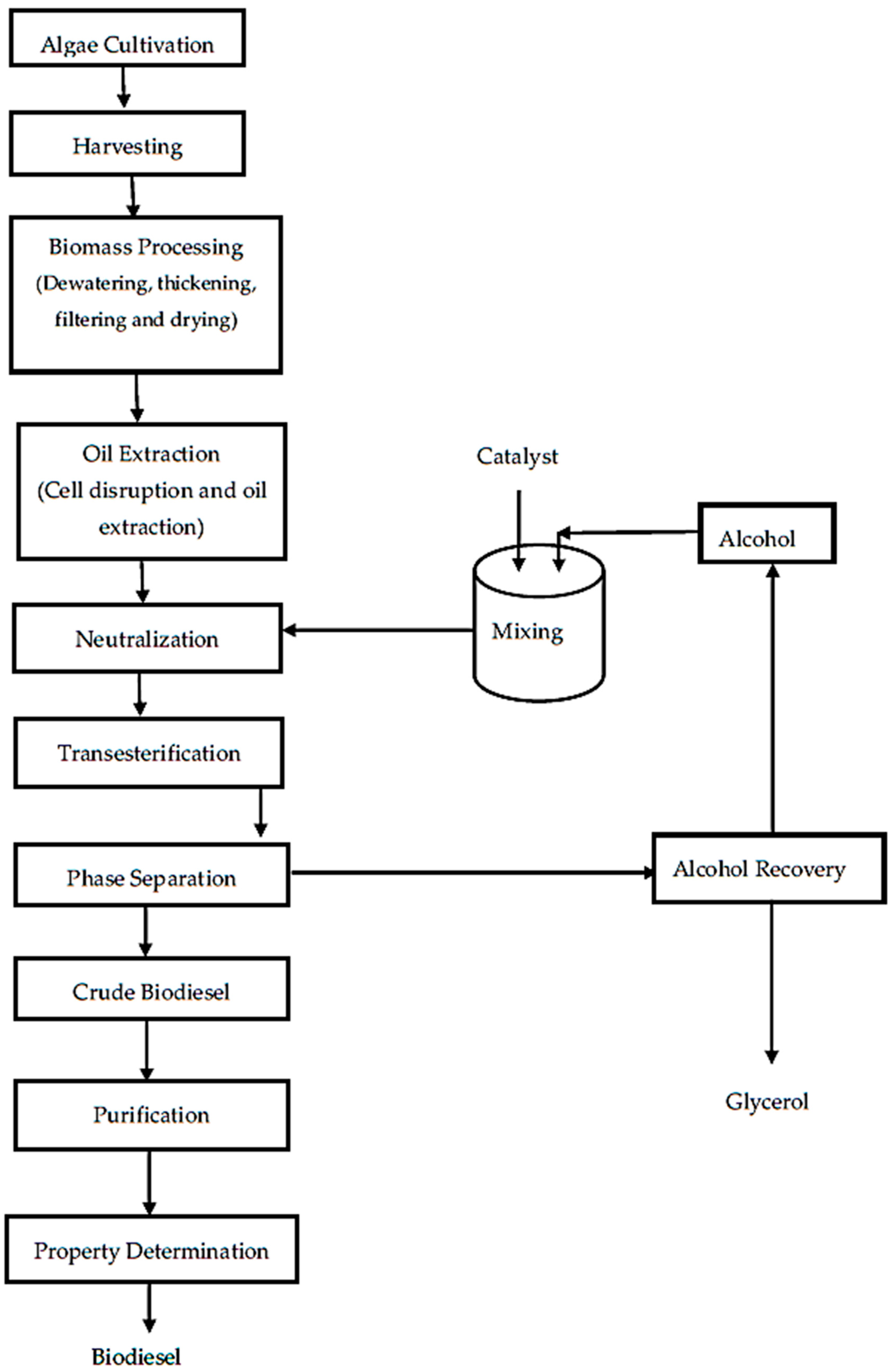

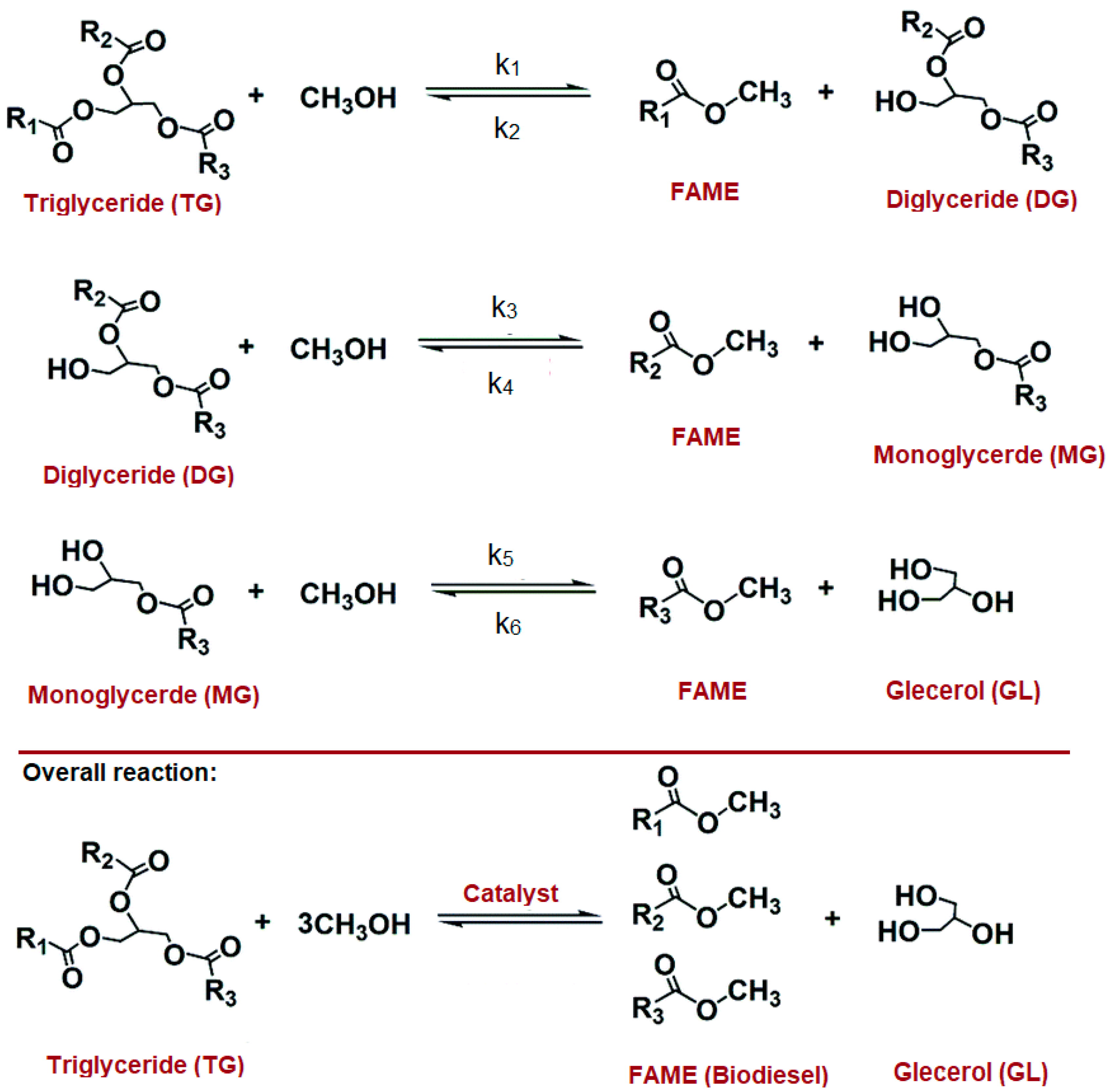

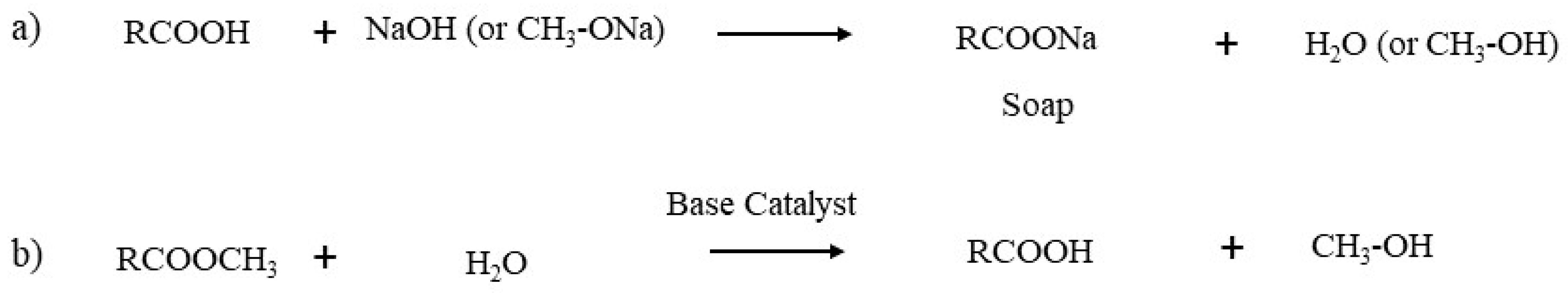

3. Outline of Biodiesel Production Process from Microalgae

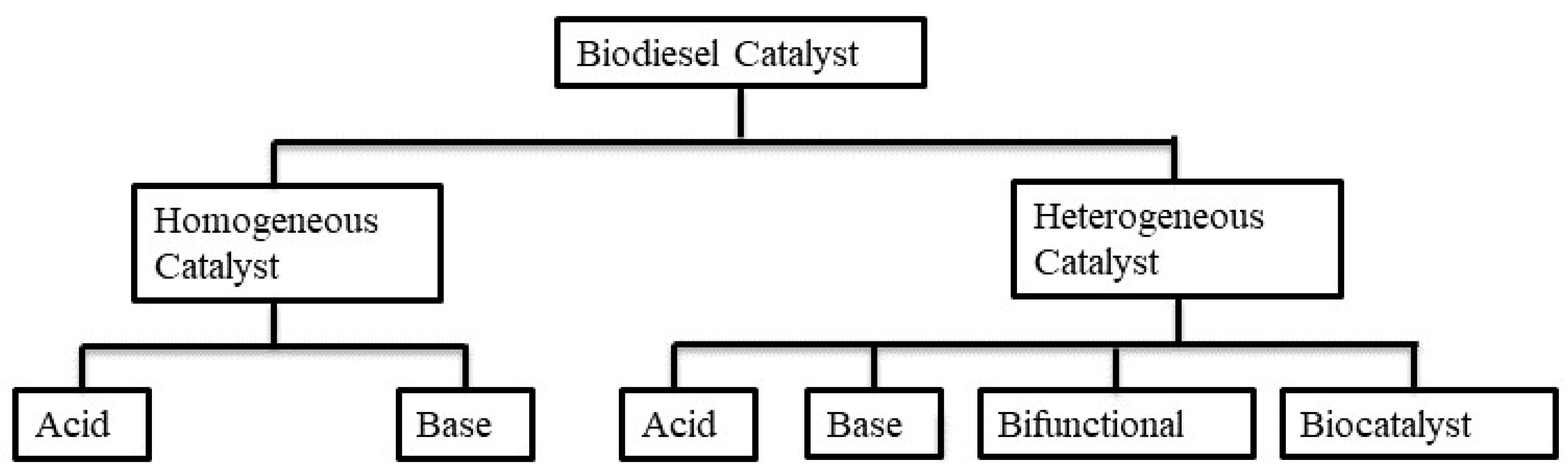

4. Heterogeneous Catalysts for Biodiesel Production

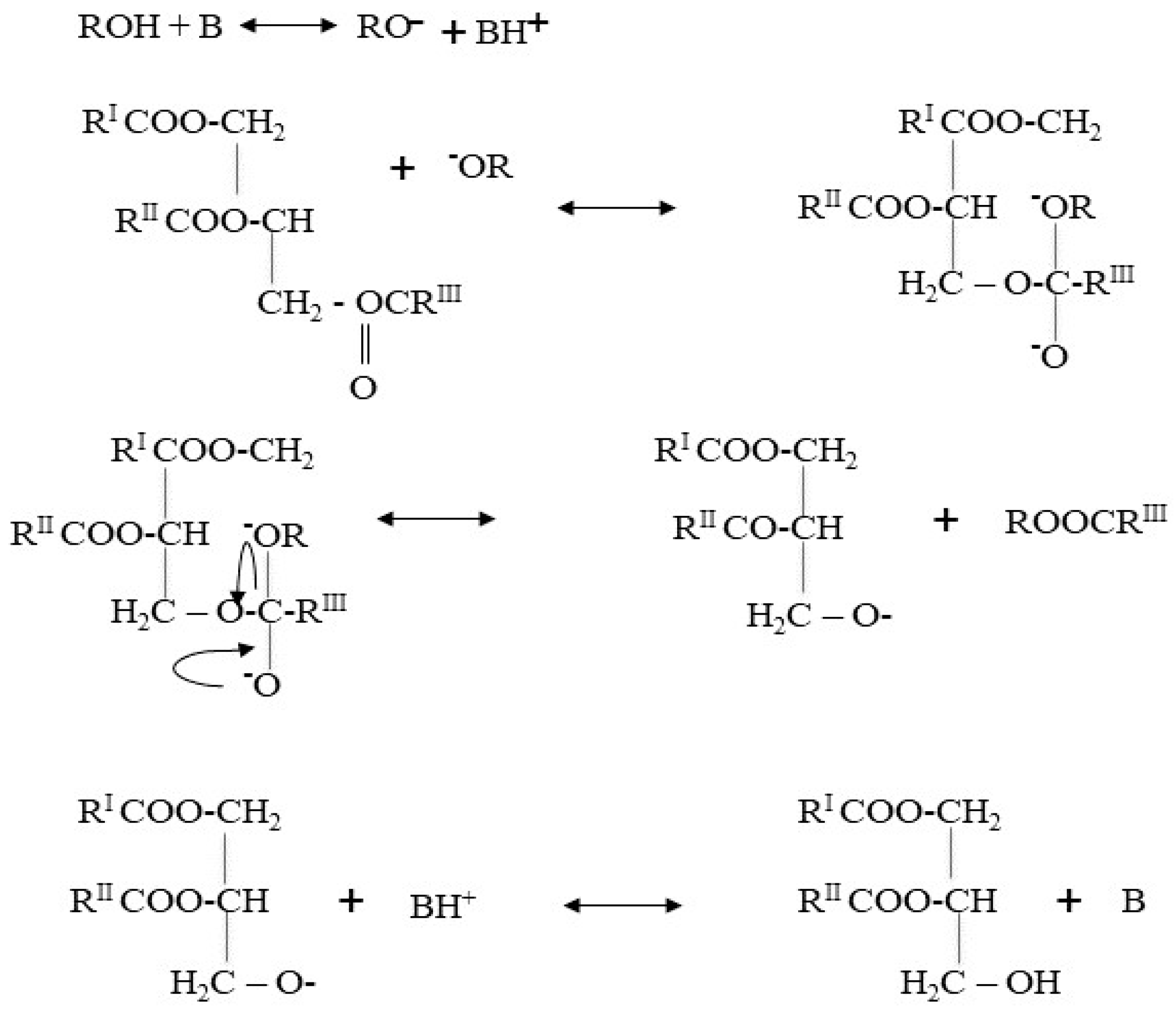

4.1. Basic Solid Catalysts

4.1.1. MgO as a Base Heterogeneous Catalyst

4.1.2. CaO as a Base Heterogeneous Catalyst

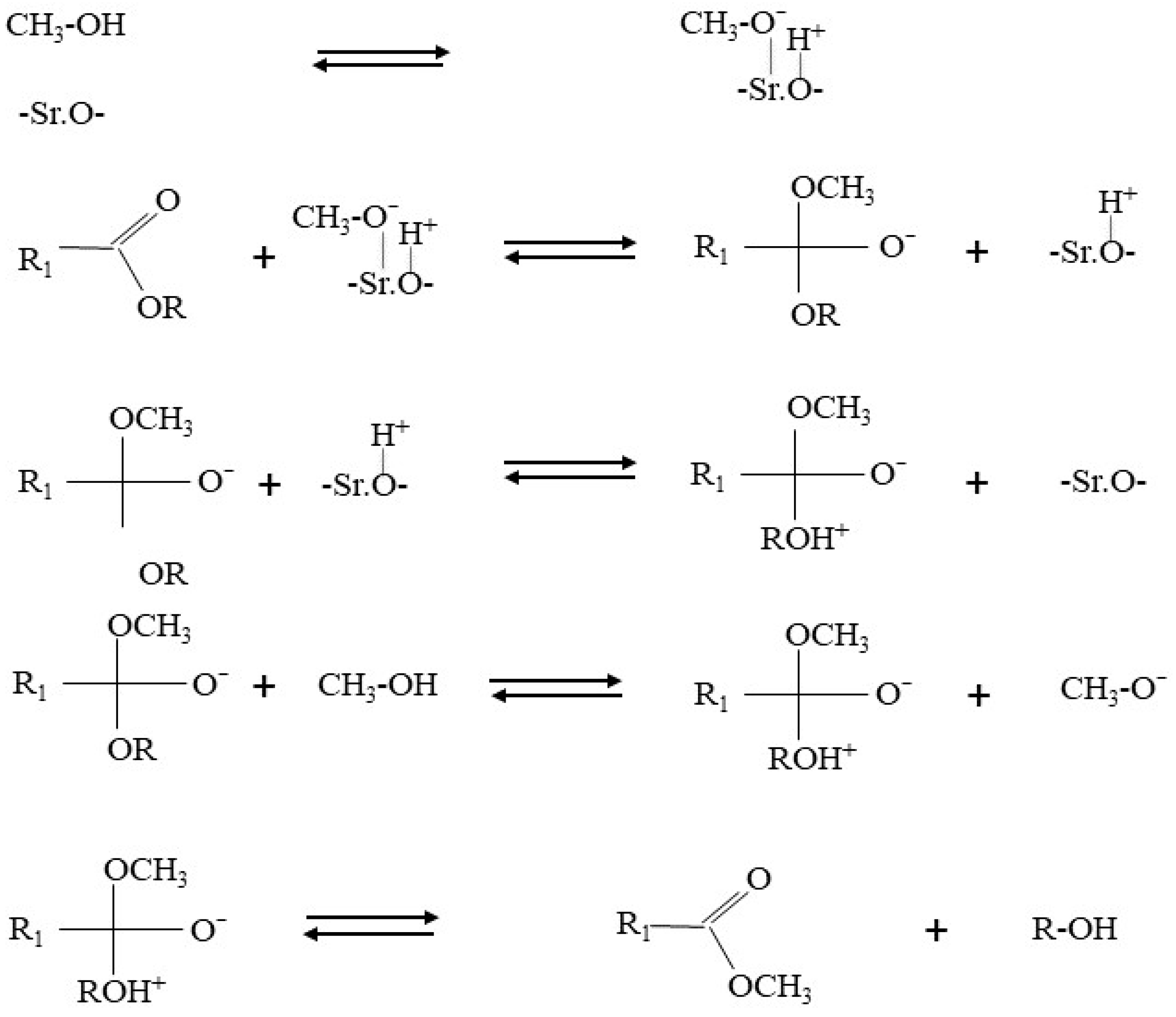

4.1.3. SrO as a Base Heterogeneous Catalyst

4.1.4. Biodiesel Production with Mixed Metal Oxide and Derivatives

4.1.5. Biodiesel Production with Transition Metal Oxides and Derivatives

4.1.6. Waste Material-Based Heterogeneous Catalysts

4.2. Acidic Solid Catalysts

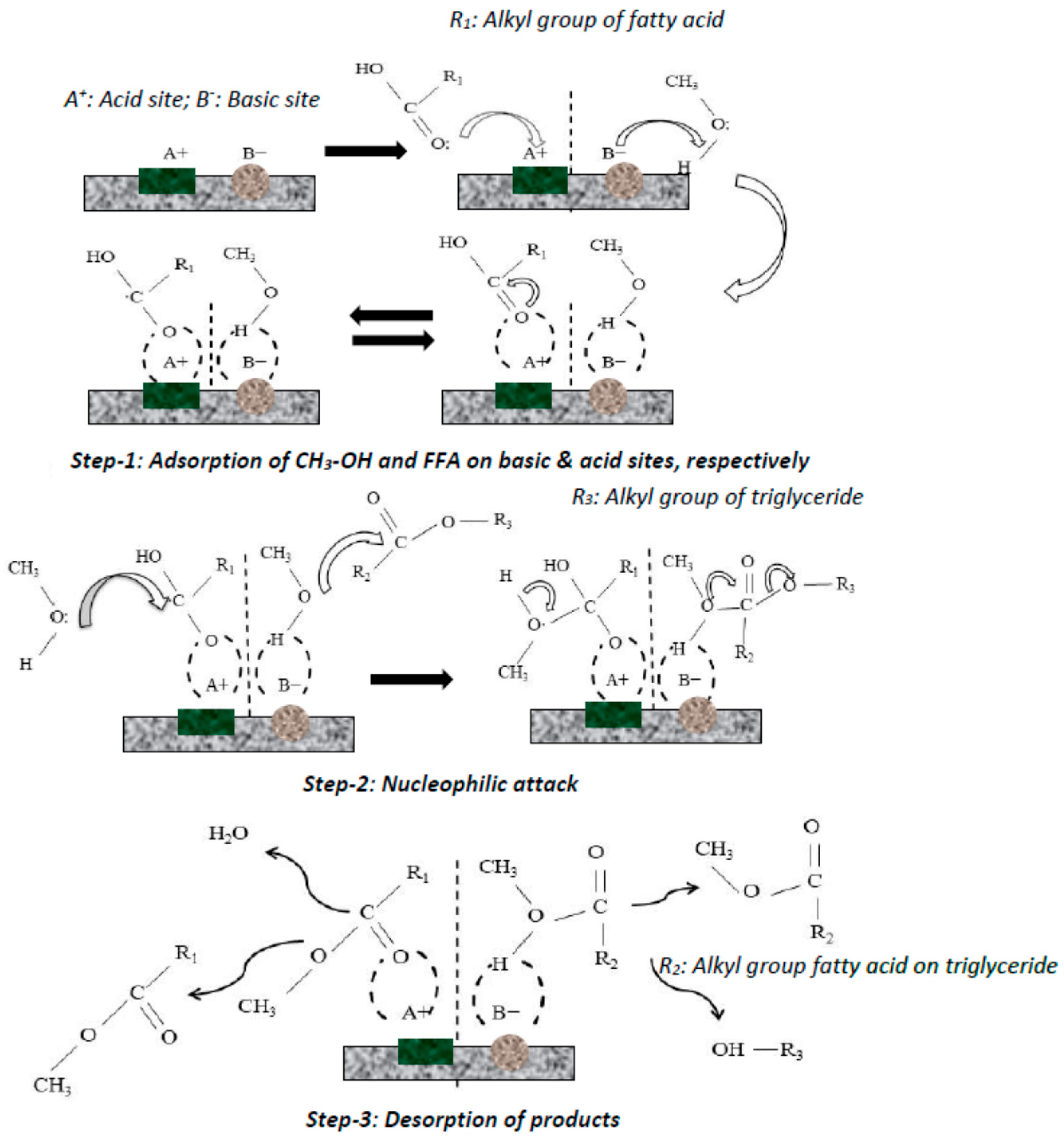

4.3. Acid−Base Solid Catalysts

5. Biocatalysts

6. Summary of the Effect of a Heterogeneous Catalyst on the Yield of Biodiesel

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wong, W.Y.; Lim, S.; Pang, Y.L.; Shuit, S.H.; Chen, W.H.; Lee, K.T. Synthesis of renewable heterogeneous acid catalyst from oil palm empty fruit bunch for glycerol-free biodiesel production. Sci. Total Environ. 2020. [Google Scholar] [CrossRef]

- Sharma, S.; Saxena, V.; Baranwal, A.; Chandra, P.; Pandey, L.M. Engineered nanoporous materials mediated heterogeneous catalysts and their implications in biodiesel production. Mater. Sci. Energy Technol. 2018. [Google Scholar] [CrossRef]

- De Bhowmick, G.; Subramanian, G.; Mishra, S.; Sen, R. Raceway pond cultivation of a marine microalga of Indian origin for biomass and lipid production: A case study. Algal Res. 2014, 6, 201–209. [Google Scholar] [CrossRef]

- Wilbanks, T.J.; Fernandez, S. Climate Change and Infrastructure, Urban Systems, and Vulnerabilities: Technical Report for the US Department of Energy in Support of the National Climate Assessment; National Climate Assessment Regional Technical Input Report Series; Island Press: Washington, DC, USA, 2014. [Google Scholar]

- Nayak, M.; Karemore, A.; Sen, R. Performance evaluation of microalgae for concomitant wastewater bioremediation, CO2 biofixation and lipid biosynthesis for biodiesel application. Algal Res. 2016, 16, 216–223. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Role of renewable energy sources in environmental protection: A review. Renew. Sustain. Energy Rev. 2011, 15, 1513–1524. [Google Scholar] [CrossRef]

- Ahmadi, M.H.; Ghazvini, M.; Nazari, M.A.; Ahmadi, M.A.; Pourfayaz, F.; Lorenzini, G.; Ming, T. Renewable energy harvesting with the application of nanotechnology: A review. Int. J. Energy Res. 2019, 43, 1387–1410. [Google Scholar] [CrossRef]

- Bouraiou, A.; Necaibia, A.; Boutasseta, N.; Mekhilef, S.; Dabou, R.; Ziane, A.; Sahouane, N.; Attoui, I.; Mostefaoui, M.; Touaba, O. Status of renewable energy potential and utilization in Algeria. J. Clean. Prod. 2020. [Google Scholar] [CrossRef]

- Furlan, C.; Mortarino, C. Forecasting the impact of renewable energies in competition with non-renewable sources. Renew. Sustain. Energy Rev. 2018, 81, 1879–1886. [Google Scholar] [CrossRef]

- Singh, R.; Bux, F.; Sharma, Y.C. Optimization of biodiesel synthesis from microalgal (Spirulina platensis) oil by using a novel heterogeneous catalyst, β-strontium silicate (β-Sr2SiO4). Fuel 2020. [Google Scholar] [CrossRef]

- Mohtasham, J. Review article-renewable energies. Energy Procedia 2015, 74, 1289–1297. [Google Scholar] [CrossRef]

- Azarpour, A.; Suhaimi, S.; Zahedi, G.; Bahadori, A. A review on the drawbacks of renewable energy as a promising energy source of the future. Arab. J. Sci. Eng. 2013. [Google Scholar] [CrossRef]

- Manzanera, M.; Molina-Munoz, M.; Gonzalez-Lopez, J. Biodiesel: An alternative fuel. Recent Pat. Biotechnol. 2008. [Google Scholar] [CrossRef] [PubMed]

- Asri, N.P.; Machmudah, S.; Wahyudiono, S.; Budikarjono, K.; Roesyadi, A.; Goto, M. Palm oil transesterification in sub- and supercritical methanol with heterogeneous base catalyst. Chem. Eng. Process. Process Intensif. 2013. [Google Scholar] [CrossRef]

- Uddin, M.R.; Ferdous, K.; Uddin, M.R.; Khan, M.R.; Islam, M.A. Synthesis of biodiesel from waste cooking oil. Chem. Eng. Sci. 2013. [Google Scholar] [CrossRef]

- Aransiola, E.F.; Ojumu, T.V.; Oyekola, O.O.; Madzimbamuto, T.F.; Ikhu-Omoregbe, D.I.O. A review of current technology for biodiesel production: State of the art. Biomass Bioenergy 2014, 61, 276–297. [Google Scholar] [CrossRef]

- Helwani, Z.; Othman, M.R.; Aziz, N.; Fernando, W.J.N.; Kim, J. Technologies for production of biodiesel focusing on green catalytic techniques: A review. Fuel Process. Technol. 2009. [Google Scholar] [CrossRef]

- Feng, Y.; He, B.; Cao, Y.; Li, J.; Liu, M.; Yan, F.; Liang, X. Biodiesel production using cation-exchange resin as heterogeneous catalyst. Bioresour. Technol. 2010. [Google Scholar] [CrossRef]

- Nahar, G.; Kendall, K. Biodiesel formulations as fuel for internally reforming solid oxide fuel cell. Fuel Process. Technol. 2011. [Google Scholar] [CrossRef]

- Dhawane, S.H.; Kumar, T.; Halder, G. Recent advancement and prospective of heterogeneous carbonaceous catalysts in chemical and enzymatic transformation of biodiesel. Energy Convers. Manag. 2018, 167, 176–202. [Google Scholar] [CrossRef]

- Sharma, Y.C.; Singh, B.; Upadhyay, S.N. Advancements in development and characterization of biodiesel: A review. Fuel 2008, 87, 2355–2373. [Google Scholar] [CrossRef]

- Rizwanul Fattah, I.M.; Ong, H.C.; Mahlia, T.M.I.; Mofijur, M.; Silitonga, A.S.; Rahman, S.M.A.; Ahmad, A. State of the art of catalysts for biodiesel production. Front. Energy Res. 2020, 8, 101. [Google Scholar] [CrossRef]

- Sianipar, R.N.R.; Ariyani, D.; Nata, I.F. Conversion of palm oil sludge to biodiesel using alum and KOH as catalysts. Sustain. Environ. Res. 2017. [Google Scholar] [CrossRef]

- Chamola, R.; Khan, M.F.; Raj, A.; Verma, M.; Jain, S. Response surface methodology based optimization of in situ transesterification of dry algae with methanol, H2SO4 and NaOH. Fuel 2019. [Google Scholar] [CrossRef]

- Shi, W.; Li, J.; He, B.; Yan, F.; Cui, Z.; Wu, K.; Lin, L.; Qian, X.; Cheng, Y. Biodiesel production from waste chicken fat with low free fatty acids by an integrated catalytic process of composite membrane and sodium methoxide. Bioresour. Technol. 2013. [Google Scholar] [CrossRef] [PubMed]

- Celante, D.; Schenkel, J.V.D.; de Castilhos, F. Biodiesel production from soybean oil and dimethyl carbonate catalyzed by potassium methoxide. Fuel 2018. [Google Scholar] [CrossRef]

- Fukuda, H.; Kondo, A.; Noda, H. Biodiesel fuel production by transesterification of oils. J. Biosci. Bioeng. 2001, 92, 405–416. [Google Scholar] [CrossRef]

- Granados, M.L.; Poves, M.D.Z.; Alonso, D.M.; Mariscal, R.; Galisteo, F.C.; Moreno-Tost, R.; Santamaría, J.; Fierro, J.L.G. Biodiesel from sunflower oil by using activated calcium oxide. Appl. Catal. B Environ. 2007. [Google Scholar] [CrossRef]

- Ji, J.; Wang, J.; Li, Y.; Yu, Y.; Xu, Z. Preparation of biodiesel with the help of ultrasonic and hydrodynamic cavitation. Ultrasonics 2006. [Google Scholar] [CrossRef]

- Karmee, S.K.; Chadha, A. Preparation of biodiesel from crude oil of Pongamia pinnata. Bioresour. Technol. 2005. [Google Scholar] [CrossRef]

- Lee, J.S.; Saka, S. Biodiesel production by heterogeneous catalysts and supercritical technologies. Bioresour. Technol. 2010, 101, 7191–7200. [Google Scholar] [CrossRef]

- Dossin, T.F.; Reyniers, M.F.; Berger, R.J.; Marin, G.B. Simulation of heterogeneously MgO-catalyzed transesterification for fine-chemical and biodiesel industrial production. Appl. Catal. B Environ. 2006. [Google Scholar] [CrossRef]

- Mbaraka, I.K.; Shanks, B.H. Conversion of oils and fats using advanced mesoporous heterogeneous catalysts. JAOCS J. Am. Oil Chem. Soc. 2006, 83, 79–91. [Google Scholar] [CrossRef]

- Colombo, K.; Ender, L.; Barros, A.A.C. The study of biodiesel production using CaO as a heterogeneous catalytic reaction. Egypt. J. Pet. 2017, 26, 341–349. [Google Scholar] [CrossRef]

- Wang, L.; Yang, J. Transesterification of soybean oil with nano-MgO or not in supercritical and subcritical methanol. Fuel 2007. [Google Scholar] [CrossRef]

- Endalew, A.K.; Kiros, Y.; Zanzi, R. Heterogeneous catalysis for biodiesel production from Jatropha curcas oil (JCO). Energy 2011, 36, 2693–2700. [Google Scholar] [CrossRef]

- Kansedo, J.; Lee, K.T.; Bhatia, S. Cerbera odollam (sea mango) oil as a promising non-edible feedstock for biodiesel production. Fuel 2009. [Google Scholar] [CrossRef]

- Viriya-Empikul, N.; Krasae, P.; Nualpaeng, W.; Yoosuk, B.; Faungnawakij, K. Biodiesel production over Ca-based solid catalysts derived from industrial wastes. Fuel 2012. [Google Scholar] [CrossRef]

- Razzak, S.A.; Hossain, M.M.; Lucky, R.A.; Bassi, A.S.; De Lasa, H. Integrated CO2 capture, wastewater treatment and biofuel production by microalgae culturing—A review. Renew. Sustain. Energy Rev. 2013, 27, 622–653. [Google Scholar] [CrossRef]

- Zhang, X.; Rong, J.; Chen, H.; He, C.; Wang, Q. Current status and outlook in the application of microalgae in biodiesel production and environmental protection. Front. Energy Res. 2014, 2, 32. [Google Scholar] [CrossRef]

- Mata, T.M.; Martins, A.A.; Caetano, N.S. Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 2010, 14, 217–232. [Google Scholar] [CrossRef]

- Rittmann, B.E. Opportunities for renewable bioenergy using microorganisms. Biotechnol. Bioeng. 2008, 100, 203–212. [Google Scholar] [CrossRef]

- Meher, L.C.; Vidya Sagar, D.; Naik, S.N. Technical aspects of biodiesel production by transesterification—A review. Renew. Sustain. Energy Rev. 2006, 10, 248–268. [Google Scholar] [CrossRef]

- Schenk, P.M.; Thomas-Hall, S.R.; Stephens, E.; Marx, U.C.; Mussgnug, J.H.; Posten, C.; Kruse, O.; Hankamer, B. Second generation biofuels: High-efficiency microalgae for biodiesel production. BioEnergy Res. 2008. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Demirbas, M.F. Biofuels from algae for sustainable development. Appl. Energy 2011. [Google Scholar] [CrossRef]

- Hidalgo, P.; Toro, C.; Ciudad, G.; Schober, S.; Mittelbach, M.; Navia, R. Evaluation of different operational strategies for biodiesel production by direct transesterification of microalgal biomass. Energy Fuels 2014, 28, 3814–3820. [Google Scholar] [CrossRef]

- Williams, P.J.L.B.; Laurens, L.M.L. Microalgae as biodiesel & biomass feedstocks: Review & analysis of the biochemistry, energetics & economics. Energy Environ. Sci. 2010, 3, 554–590. [Google Scholar]

- Kim, J.; Yoo, G.; Lee, H.; Lim, J.; Kim, K.; Kim, C.W.; Park, M.S.; Yang, J.W. Methods of downstream processing for the production of biodiesel from microalgae. Biotechnol. Adv. 2013, 31, 862–876. [Google Scholar] [CrossRef]

- Galadima, A.; Muraza, O. Biodiesel production from algae by using heterogeneous catalysts: A critical review. Energy 2014, 78, 72–83. [Google Scholar] [CrossRef]

- Babu, B.V. Biomass pyrolysis: A state-of-the-art review. Biofuels Bioprod. Biorefin. 2008, 2, 393–414. [Google Scholar] [CrossRef]

- Bahadur, N.P.; Boocock, D.G.B.; Konar, S.K. Liquid hydrocarbons from catalytic pyrolysis of sewage sludge lipid and canola oil: Evaluation of fuel properties. Energy Fuels 1995. [Google Scholar] [CrossRef]

- Boateng, A.A.; Mullen, C.A.; Goldberg, N.; Hicks, K.B.; Jung, H.J.G.; Lamb, J.F.S. Production of bio-oil from alfalfa stems by fluidized-bed fast pyrolysis. Ind. Eng. Chem. Res. 2008. [Google Scholar] [CrossRef]

- Nautiyal, P.; Subramanian, K.A.; Dastidar, M.G. Production and characterization of biodiesel from algae. Fuel Process. Technol. 2014. [Google Scholar] [CrossRef]

- Ma, F.; Hanna, M.A. Biodiesel production: A review. Bioresour. Technol. 1999, 70, 1–15. [Google Scholar] [CrossRef]

- Haas, M. The interplay between feedstock quality and esterification technology in biodiesel production. Lipid Technol. 2004, 16, 7–11. [Google Scholar]

- Diasakou, M.; Louloudi, A.; Papayannakos, N. Kinetics of the non-catalytic transesterification of soybean oil. Fuel 1998. [Google Scholar] [CrossRef]

- Kusdiana, D.; Saka, S. Kinetics of transesterification in rapeseed oil to biodiesel fuel as treated in supercritical methanol. Fuel 2001. [Google Scholar] [CrossRef]

- Borges, M.E.; Díaz, L. Recent developments on heterogeneous catalysts for biodiesel production by oil esterification and transesterification reactions: A review. Renew. Sustain. Energy Rev. 2012, 16, 2839–2849. [Google Scholar] [CrossRef]

- Guldhe, A.; Moura, C.V.R.; Singh, P.; Rawat, I.; Moura, E.M.; Sharma, Y.; Bux, F. Conversion of microalgal lipids to biodiesel using chromium-aluminum mixed oxide as a heterogeneous solid acid catalyst. Renew. Energy 2017. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Wu, X.; Leung, M.K.H. A review on biodiesel production using catalyzed transesterification. Appl. Energy 2010, 87, 1083–1095. [Google Scholar] [CrossRef]

- Ono, Y.; Baba, T. Selective reactions over solid base catalysts. Catal. Today 1997, 38, 321–337. [Google Scholar] [CrossRef]

- Yoo, S.J.; Lee, H.S.; Veriansyah, B.; Kim, J.; Kim, J.D.; Lee, Y.W. Synthesis of biodiesel from rapeseed oil using supercritical methanol with metal oxide catalysts. Bioresour. Technol. 2010. [Google Scholar] [CrossRef] [PubMed]

- Chouhan, A.P.S.; Sarma, A.K. Modern heterogeneous catalysts for biodiesel production: A comprehensive review. Renew. Sustain. Energy Rev. 2011, 15, 4378–4399. [Google Scholar] [CrossRef]

- López, D.E.; Goodwin, J.G.; Bruce, D.A.; Lotero, E. Transesterification of triacetin with methanol on solid acid and base catalysts. Appl. Catal. A Gen. 2005. [Google Scholar] [CrossRef]

- Di Serio, M.; Tesser, R.; Dimiccoli, M.; Cammarota, F.; Nastasi, M.; Santacesaria, E. Synthesis of biodiesel via homogeneous Lewis acid catalyst. J. Mol. Catal. A Chem. 2005. [Google Scholar] [CrossRef]

- Liu, X.; He, H.; Wang, Y.; Zhu, S.; Piao, X. Transesterification of soybean oil to biodiesel using CaO as a solid base catalyst. Fuel 2008. [Google Scholar] [CrossRef]

- Kouzu, M.; Hidaka, J.S. Transesterification of vegetable oil into biodiesel catalyzed by CaO: A review. Fuel 2012, 93, 1–12. [Google Scholar] [CrossRef]

- Veljković, V.B.; Stamenković, O.S.; Todorović, Z.B.; Lazić, M.L.; Skala, D.U. Kinetics of sunflower oil methanolysis catalyzed by calcium oxide. Fuel 2009. [Google Scholar] [CrossRef]

- Viola, E.; Blasi, A.; Valerio, V.; Guidi, I.; Zimbardi, F.; Braccio, G.; Giordano, G. Biodiesel from fried vegetable oils via transesterification by heterogeneous catalysis. Catal. Today 2012, 179, 185–190. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, Z.; Chen, Y.; Zhang, P.; Duan, S.; Liu, X.; Mao, Z. Preparation of biodiesel catalyzed by solid super base of calcium oxide and its refining process. Chin. J. Catal. 2006. [Google Scholar] [CrossRef]

- Kawashima, A.; Matsubara, K.; Honda, K. Acceleration of catalytic activity of calcium oxide for biodiesel production. Bioresour. Technol. 2009. [Google Scholar] [CrossRef] [PubMed]

- Puna, J.F.; Gomes, J.F.; Correia, M.J.N.; Soares Dias, A.P.; Bordado, J.C. Advances on the development of novel heterogeneous catalysts for transesterification of triglycerides in biodiesel. Fuel 2010. [Google Scholar] [CrossRef]

- Liu, X.; He, H.; Wang, Y.; Zhu, S. Transesterification of soybean oil to biodiesel using SrO as a solid base catalyst. Catal. Commun. 2007. [Google Scholar] [CrossRef]

- Umdu, E.S.; Tuncer, M.; Seker, E. Transesterification of Nannochloropsis oculata microalga’s lipid to biodiesel on Al2O3 supported CaO and MgO catalysts. Bioresour. Technol. 2009, 100, 2828–2831. [Google Scholar] [CrossRef]

- Zabeti, M.; Daud, W.M.A.W.; Aroua, M.K. Biodiesel production using alumina-supported calcium oxide: An optimization study. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Wen, Z.; Yu, X.; Tu, S.T.; Yan, J.; Dahlquist, E. Biodiesel production from waste cooking oil catalyzed by TiO2-MgO mixed oxides. Bioresour. Technol. 2010. [Google Scholar] [CrossRef]

- Li, Y.; Lian, S.; Tong, D.; Song, R.; Yang, W.; Fan, Y.; Qing, R.; Hu, C. One-step production of biodiesel from Nannochloropsis sp. on solid base Mg-Zr catalyst. Appl. Energy 2011. [Google Scholar] [CrossRef]

- Lee, A.F.; Bennett, J.A.; Manayil, J.C.; Wilson, K. Heterogeneous catalysis for sustainable biodiesel production via esterification and transesterification. Chem. Soc. Rev. 2014, 43, 7887–7916. [Google Scholar] [CrossRef]

- Deka, D.C.; Basumatary, S. High quality biodiesel from yellow oleander (Thevetia peruviana) seed oil. Biomass Bioenergy 2011. [Google Scholar] [CrossRef]

- Cho, Y.B.; Seo, G. High activity of acid-treated quail eggshell catalysts in the transesterification of palm oil with methanol. Bioresour. Technol. 2010. [Google Scholar] [CrossRef]

- Verziu, M.; Coman, S.M.; Richards, R.; Parvulescu, V.I. Transesterification of vegetable oils over CaO catalysts. Catal. Today 2011, 167, 64–70. [Google Scholar] [CrossRef]

- Encinar, J.M.; González, J.F.; Pardal, A.; Martínez, G. Rape oil transesterification over heterogeneous catalysts. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Liu, C.; Lv, P.; Yuan, Z.; Yan, F.; Luo, W. The nanometer magnetic solid base catalyst for production of biodiesel. Renew. Energy 2010. [Google Scholar] [CrossRef]

- Wen, Z.; Yu, X.; Tu, S.T.; Yan, J.; Dahlquist, E. Synthesis of biodiesel from vegetable oil with methanol catalyzed by Li-doped magnesium oxide catalysts. Appl. Energy 2010. [Google Scholar] [CrossRef]

- Mutreja, V.; Singh, S.; Ali, A. Biodiesel from mutton fat using KOH impregnated MgO as heterogeneous catalysts. Renew. Energy 2011. [Google Scholar] [CrossRef]

- Ngamcharussrivichai, C.; Nunthasanti, P.; Tanachai, S.; Bunyakiat, K. Biodiesel production through transesterification over natural calciums. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Ilgen, O. Dolomite as a heterogeneous catalyst for transesterification of canola oil. Fuel Process. Technol. 2011. [Google Scholar] [CrossRef]

- Taufiq-Yap, Y.H.; Lee, H.V.; Hussein, M.Z.; Yunus, R. Calcium-based mixed oxide catalysts for methanolysis of Jatropha curcas oil to biodiesel. Biomass Bioenergy 2011. [Google Scholar] [CrossRef]

- Gao, L.; Teng, G.; Xiao, G.; Wei, R. Biodiesel from palm oil via loading KF/Ca-Al hydrotalcite catalyst. Biomass Bioenergy 2010, 34, 1283–1288. [Google Scholar] [CrossRef]

- Silva, C.C.C.M.; Ribeiro, N.F.P.; Souza, M.M.V.M.; Aranda, D.A.G. Biodiesel production from soybean oil and methanol using hydrotalcites as catalyst. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Deng, X.; Fang, Z.; Liu, Y.H.; Yu, C.L. Production of biodiesel from Jatropha oil catalyzed by nanosized solid basic catalyst. Energy 2011. [Google Scholar] [CrossRef]

- Samart, C.; Chaiya, C.; Reubroycharoen, P. Biodiesel production by methanolysis of soybean oil using calcium supported on mesoporous silica catalyst. Energy Convers. Manag. 2010. [Google Scholar] [CrossRef]

- Guo, F.; Peng, Z.G.; Dai, J.Y.; Xiu, Z.L. Calcined sodium silicate as solid base catalyst for biodiesel production. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Boro, J.; Thakur, A.J.; Deka, D. Solid oxide derived from waste shells of Turbonilla striatula as a renewable catalyst for biodiesel production. Fuel Process. Technol. 2011. [Google Scholar] [CrossRef]

- Wei, Z.; Xu, C.; Li, B. Application of waste eggshell as low-cost solid catalyst for biodiesel production. Bioresour. Technol. 2009. [Google Scholar] [CrossRef]

- Lotero, E.; Liu, Y.; Lopez, D.E.; Suwannakarn, K.; Bruce, D.A.; Goodwin, J.G. Synthesis of biodiesel via acid catalysis. Ind. Eng. Chem. Res. 2005. [Google Scholar] [CrossRef]

- Meher, L.C.; Churamani, C.P.; Arif, M.; Ahmed, Z.; Naik, S.N. Jatropha curcas as a renewable source for bio-fuels—A review. Renew. Sustain. Energy Rev. 2013, 26, 397–407. [Google Scholar] [CrossRef]

- Furuta, S.; Matsuhashi, H.; Arata, K. Biodiesel fuel production with solid superacid catalysis in fixed bed reactor under atmospheric pressure. Catal. Commun. 2004. [Google Scholar] [CrossRef]

- Helwani, Z.; Othman, M.R.; Aziz, N.; Kim, J.; Fernando, W.J.N. Solid heterogeneous catalysts for transesterification of triglycerides with methanol: A review. Appl. Catal. A Gen. 2009, 363, 1–10. [Google Scholar] [CrossRef]

- Muthu, H.; Selvabala, V.S.; Varathachary, T.K.; Selvaraj, D.K.; Nandagopal, J.; Subramanian, S. Synthesis of biodiesel from neem oil using sulfated zirconia via tranesterification. Braz. J. Chem. Eng. 2010. [Google Scholar] [CrossRef]

- Shu, Q.; Gao, J.; Nawaz, Z.; Liao, Y.; Wang, D.; Wang, J. Synthesis of biodiesel from waste vegetable oil with large amounts of free fatty acids using a carbon-based solid acid catalyst. Appl. Energy 2010, 87, 2589–2596. [Google Scholar] [CrossRef]

- Brucato, A.; Busciglio, A.; Di Stefano, F.; Grisafi, F.; Micale, G.; Scargiali, F. High temperature solid-catalized transesterification for biodiesel production. Chem. Eng. Trans. 2010, 19, 31–36. [Google Scholar]

- Yan, S.; Dimaggio, C.; Mohan, S.; Kim, M.; Salley, S.O.; Ng, K.Y.S. Advancements in heterogeneous catalysis for biodiesel synthesis. Top. Catal. 2010. [Google Scholar] [CrossRef]

- Kiss, A.A.; Dimian, A.C.; Rothenberg, G. Solid acid catalysts for biodiesel production—Towards sustainable energy. Adv. Synth. Catal. 2006. [Google Scholar] [CrossRef]

- Park, Y.M.; Lee, D.W.; Kim, D.K.; Lee, J.S.; Lee, K.Y. The heterogeneous catalyst system for the continuous conversion of free fatty acids in used vegetable oils for the production of biodiesel. Catal. Today 2008. [Google Scholar] [CrossRef]

- Peng, B.X.; Shu, Q.; Wang, J.F.; Wang, G.R.; Wang, D.Z.; Han, M.H. Biodiesel production from waste oil feedstocks by solid acid catalysis. Process Saf. Environ. Prot. 2008. [Google Scholar] [CrossRef]

- Kafuku, G.; Lee, K.T.; Mbarawa, M. The use of sulfated tin oxide as solid superacid catalyst for heterogeneous transesterification of Jatropha curcas oil. Chem. Pap. 2010. [Google Scholar] [CrossRef]

- Kafuku, G.; Lam, M.K.; Kansedo, J.; Lee, K.T.; Mbarawa, M. Heterogeneous catalyzed biodiesel production from Moringa oleifera oil. Fuel Process. Technol. 2010. [Google Scholar] [CrossRef]

- Kafuku, G.; Lam, M.K.; Kansedo, J.; Lee, K.T.; Mbarawa, M. Croton megalocarpus oil: A feasible non-edible oil source for biodiesel production. Bioresour. Technol. 2010. [Google Scholar] [CrossRef]

- Yee, K.F.; Lee, K.T.; Ceccato, R.; Abdullah, A.Z. Riccardo Ceccato Production of biodiesel from Jatropha curcas L. oil catalyzed by SO42-/ZrO2 catalyst: Effect of interaction between process variables. Bioresour. Technol. 2011, 102, 4285–4289. [Google Scholar] [CrossRef]

- Zanette, A.F.; Barella, R.A.; Pergher, S.B.C.; Treichel, H.; Oliveira, D.; Mazutti, M.A.; Silva, E.A.; Oliveira, J.V. Screening, optimization and kinetics of Jatropha curcas oil transesterification with heterogeneous catalysts. Renew. Energy 2011. [Google Scholar] [CrossRef]

- Semwal, S.; Arora, A.K.; Badoni, R.P.; Tuli, D.K. Biodiesel production using heterogeneous catalysts. Bioresour. Technol. 2011, 102, 2151–2161. [Google Scholar] [CrossRef] [PubMed]

- Rabiah Nizah, M.F.; Taufiq-Yap, Y.H.; Rashid, U.; Teo, S.H.; Shajaratun Nur, Z.A.; Islam, A. Production of biodiesel from non-edible Jatropha curcas oil via transesterification using Bi2O3-La2O3 catalyst. Energy Convers. Manag. 2014. [Google Scholar] [CrossRef]

- Lin, V.S.-Y.; Nieweg, J.A.; Kern, C.; Trewyn, B.G.; Wiench, J.W.; Pruski, M. Acid-base mesoporous calcia-silica catalysts for cooperative conversion of bio-based feedstocks into biodiesel. Prepr. Symp. Am. Chem. Soc. Div. Fuel Chem. 2006, 51, 426–427. [Google Scholar]

- Wan Omar, W.N.N.; Amin, N.A.S. Biodiesel production from waste cooking oil over alkaline modified zirconia catalyst. Fuel Process. Technol. 2011. [Google Scholar] [CrossRef]

- Lin, V.S.Y.; Nieweg, J.A.; Verkade, J.G.; Venkat, R.; Reddy, C.; Kern, C. New Composite Based Catalysts for Biodiesel Production. Patent WO 2008/013551 A1, 31 January 2008. [Google Scholar]

- Lee, H.V.; Juan, J.C.; Taufiq-Yap, Y.H. Preparation and application of binary acid-base CaO-La2O3 catalyst for biodiesel production. Renew. Energy 2015. [Google Scholar] [CrossRef]

- Salinas, D.; Guerrero, S.; Araya, P. Transesterification of canola oil on potassium-supported TiO2 catalysts. Catal. Commun. 2010. [Google Scholar] [CrossRef]

- Jiménez-López, A.; Jiménez-Morales, I.; Santamaría-González, J.; Maireles-Torres, P. Biodiesel production from sunflower oil by tungsten oxide supported on zirconium doped MCM-41 silica. J. Mol. Catal. A Chem. 2011. [Google Scholar] [CrossRef]

- Cannilla, C.; Bonura, G.; Rombi, E.; Arena, F.; Frusteri, F. Highly effective MnCeOx catalysts for biodiesel production by transesterification of vegetable oils with methanol. Appl. Catal. A Gen. 2010. [Google Scholar] [CrossRef]

- Gonçalves, A.P.V.; Lopes, J.M.; Lemos, F.; Ramôa Ribeiro, F.; Prazeres, D.M.F.; Cabrai, J.M.S.; Aires-Barros, M.R. Zeolites as supports for enzymatic hydrolysis reactions. Comparative study of several zeolites. J. Mol. Catal. B Enzym. 1996. [Google Scholar] [CrossRef]

- Huge-Jensen, B.; Galluzzo, D.R.; Jensen, R.G. Studies on free and immobilized lipases from Mucor miehei. J. Am. Oil Chem. Soc. 1988. [Google Scholar] [CrossRef]

- Oliveira, A.C.; Rosa, M.F.; Cabral, J.M.S.; Aires-Barros, M.R. Immobilization of saccharomyces cerevisiae cells and rhizomocur miehei lipase for the production and extractive biocatalysis of ethanol. Bioprocess Eng. 1997. [Google Scholar] [CrossRef]

- Fukuda, H.; Hama, S.; Tamalampudi, S.; Noda, H. Whole-cell biocatalysts for biodiesel fuel production. Trends Biotechnol. 2008, 26, 668–673. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, P.M.; Brask, J.; Fjerbaek, L. Enzymatic biodiesel production: Technical and economical considerations. Eur. J. Lipid Sci. Technol. 2008, 110, 692–700. [Google Scholar] [CrossRef]

- Sarno, M.; Iuliano, M. Active biocatalyst for biodiesel production from spent coffee ground. Bioresour. Technol. 2018. [Google Scholar] [CrossRef]

- Saranya, G.; Ramachandra, T.V. Novel biocatalyst for optimal biodiesel production from diatoms. Renew. Energy 2020. [Google Scholar] [CrossRef]

- Chen, G.; Liu, J.; Yao, J.; Qi, Y.; Yan, B. Biodiesel production from waste cooking oil in a magnetically fluidized bed reactor using whole-cell biocatalysts. Energy Convers. Manag. 2017. [Google Scholar] [CrossRef]

- Zhong, L.; Feng, Y.; Wang, G.; Wang, Z.; Bilal, M.; Lv, H.; Jia, S.; Cui, J. Production and use of immobilized lipases in/on nanomaterials: A review from the waste to biodiesel production. Int. J. Biol. Macromol. 2020, 152, 207–222. [Google Scholar] [CrossRef]

- Akubude, V.C.; Nwaigwe, K.N.; Dintwa, E. Production of biodiesel from microalgae via nanocatalyzed transesterification process: A review. Mater. Sci. Energy Technol. 2019. [Google Scholar] [CrossRef]

- Liu, D.M.; Dong, C. Recent advances in nano-carrier immobilized enzymes and their applications. Process Biochem. 2020, 92, 464–475. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, O.K.; Lee, E.Y. Nano-immobilized biocatalysts for biodiesel production from renewable and sustainable resources. Catalysts 2018, 8, 68. [Google Scholar]

- Miao, C.; Yang, L.; Wang, Z.; Luo, W.; Li, H.; Lv, P.; Yuan, Z. Lipase immobilization on amino-silane modified superparamagnetic Fe3O4 nanoparticles as biocatalyst for biodiesel production. Fuel 2018. [Google Scholar] [CrossRef]

- Nematian, T.; Salehi, Z.; Shakeri, A. Conversion of bio-oil extracted from Chlorella vulgaris micro algae to biodiesel via modified superparamagnetic nano-biocatalyst. Renew. Energy 2020. [Google Scholar] [CrossRef]

- Narayanan, C.M.; Pandey, A. Studies on biodiesel synthesis using nanosilica immobilised lipase in inverse fluidized bed bioreactors. J. Adv. Chem. 2018. [Google Scholar] [CrossRef]

- Banerjee, S.; Rout, S.; Banerjee, S.; Atta, A.; Das, D. Fe2O3 nanocatalyst aided transesterification for biodiesel production from lipid-intact wet microalgal biomass: A biorefinery approach. Energy Convers. Manag. 2019. [Google Scholar] [CrossRef]

- Antunes, W.M.; de Oliveira Veloso, C.; Henriques, C.A. Transesterification of soybean oil with methanol catalyzed by basic solids. Catal. Today 2008. [Google Scholar] [CrossRef]

- Sreeprasanth, P.S.; Srivastava, R.; Srinivas, D.; Ratnasamy, P. Hydrophobic, solid acid catalysts for production of biofuels and lubricants. Appl. Catal. A Gen. 2006. [Google Scholar] [CrossRef]

- Yang, Z.; Xie, W. Soybean oil transesterification over zinc oxide modified with alkali earth metals. Fuel Process. Technol. 2007. [Google Scholar] [CrossRef]

- Xu, L.; Yang, X.; Yu, X.; Guo, Y. Maynurkader preparation of mesoporous polyoxometalate-tantalum pentoxide composite catalyst for efficient esterification of fatty acid. Catal. Commun. 2008. [Google Scholar] [CrossRef]

- Petchmala, A.; Laosiripojana, N.; Jongsomjit, B.; Goto, M.; Panpranot, J.; Mekasuwandumrong, O.; Shotipruk, A. Transesterification of palm oil and esterification of palm fatty acid in near- and super-critical methanol with SO4-ZrO2 catalysts. Fuel 2010. [Google Scholar] [CrossRef]

- McNeff, C.V.; McNeff, L.C.; Yan, B.; Nowlan, D.T.; Rasmussen, M.; Gyberg, A.E.; Krohn, B.J.; Fedie, R.L.; Hoye, T.R. A continuous catalytic system for biodiesel production. Appl. Catal. A Gen. 2008. [Google Scholar] [CrossRef]

- Sani, Y.M.; Daud, W.M.A.W.; Abdul Aziz, A.R. Solid acid-catalyzed biodiesel production from microalgal oil—The dual advantage. J. Environ. Chem. Eng. 2013, 1, 113–121. [Google Scholar] [CrossRef]

- Dong, T.; Wang, J.; Miao, C.; Zheng, Y.; Chen, S. Two-step in situ biodiesel production from microalgae with high free fatty acid content. Bioresour. Technol. 2013. [Google Scholar] [CrossRef] [PubMed]

| Catalyst | Feedstock | Optimum Reaction Conditions | Biodiesel Yield | Reference | |||

|---|---|---|---|---|---|---|---|

| Temp. | Time | Methanol/Oil | Catalyst Amount | ||||

| CaO from eggshells | Palm oil | 65 °C | 2 h | 12:1 | 1.5 wt% | 98% | [81] |

| CaO | Sunflower oil | 80 °C | 5.5 h | 6:1 | 1 wt% | 91% | [82] |

| KNO3 /CaO | Rapeseed oil | 65 °C | 3 h | 6:1 | 1 wt% | 98% | [83] |

| CaO/Al2O3 | Palm oil | 64.29 °C | 5 h | 12.14:1 | 5.97 wt% | 98.64% | [76] |

| CaO/Fe3O4 | Jatropha curcas oil | 70 °C | 1.3 h | 15:1 | 2 wt% | 95% | [84] |

| Li/MgO | Soybean oil | 60 °C | 2 h | 12:1 | 9 wt% | 93.9% | [85] |

| KOH/MgO | Mutton fat | 65 °C | 0.3 h | 22:1 | 4 wt% | 98% | [86] |

| Dolomite | Palm kernel oil | 60 °C | 3 h | 30:1 | 6 wt% | 98% | [87] |

| Dolomite | Canola oil | 67.5 °C | 3 h | 6:1 | 3 wt% | 91.78% | [88] |

| CaMgO and CaZnO | Jatropha curcas oil | 65 °C | 6 h | 15:1 | 4 wt% | 80% | [89] |

| KF/Ca-Al hydrotalcite | Palm oil | 65 °C | 5 h | 12:1 | 5 wt% | 97.98% | [90] |

| Mg-Al hydrotalcite | Soybean oil | 230 °C | 1 h | 13:5 | 5 wt% | 90% | [91] |

| Mg-Al hydrotalcite | Jatropha oil | 45 °C | 1.5 h | 4:1 | 1 wt% | 95.2% | [92] |

| CaO/mesoporous silica | Soybean oil | 60 °C | 8 h | 16:1 | 5 wt% | 95.2% | [93] |

| Sodium silicate | Soybean oil | 60 °C | 1 h | 7.5:1 | 3 wt% | ≈100% | [94] |

| Catalyst | Feedstock | Optimum Reaction Conditions | Biodiesel Yield | Reference | |||

|---|---|---|---|---|---|---|---|

| Temp | Time | Methanol/Oil | Catalyst Amount | ||||

| SO42−/TiO2-SiO2 | Acidified cottonseed oil | 200 °C | 6 h | 9:1 | 3 wt% | 92% | [107] |

| SO42−/ZrO | Cerberra odollam | 180 °C | 3 h | 8:1 | 6 wt% | 84% | [37] |

| SO42−/SnO2−-SiO2 | Jatropha curcas | 180 °C | 2 h | 15:1 | 3 wt% | 97% | [108] |

| SO42−/SnO2−-SiO2 | Moringa oleifera | 150 °C | 2.5 h | 5:1 | 3 wt% | 84% | [109] |

| SO42−/SnO2−-SiO2 | Croton megalocarpus | 180 °C | 2 h | 15:1 | 3 wt% | 95% | [110] |

| ZrO2-Al2O3 | Jatropha curcas | 150 °C | 4 h | 9:1 | 7.61 wt% | 90.32% | [111] |

| KSF clay Amberlyst | Jatropha curcas | 160 °C | 6 h | 12:1 | 5 wt% | 70% | [112] |

| Sulfated zirconia (SZ) | Neem oil | 65 °C | 2 h | 9:1 | 1 wt% | 95% | [101] |

| Carbon-based solid acid catalyst | Waste vegetable oil | 220 °C | 4.4 h | 16.8:1 | 0.2 wt% | 94.8% | [102] |

| Catalyst | Feedstock | FFA (wt%) | Optimum Reaction Conditions | Biodiesel Yield | Reference | |||

|---|---|---|---|---|---|---|---|---|

| Temp °C | Time h | Methanol/Oil | Catalyst Amount | |||||

| Bi2O3-La2O3 | Jatropha curcas | 14.5 | 150 | 4 | 15:1 | 2 wt% | 93% | [114] |

| CaO-La2O3 | Jatropha curcas | 14.5 | 160 | 3 | 25:1 | 3 wt% | 98.76% | [118] |

| K/TiO2 | Canola oil | - | 70 | 5 | 36:1 | 6 wt% | 100% | [119] |

| MgO/TiO2 | Waste cooking oil | 3.6 | 170 | 6 | 50:1 | 10 wt% | 91.6% | [85] |

| WO3/Zr MCM-41 | Sunflower oil | 9.1 | 115.5 | 2.5 | 12:1 | 10 wt% | 79.7% | [120] |

| Sr/ZrO2 | Waste cooking palm oil | 5.08 | 115.4 | 1.2 | 29:1 | 2.7 wt% | 79.7% | [116] |

| MnCeOx | Sunflower oil | 0.07 | 140 | 5 | 12:1 | 1 wt% | ≈86% | [121] |

| Feedstock | Catalyst | Optimum Reaction Conditions | Yield (wt%) | Reference |

|---|---|---|---|---|

| Sunflower oil | Fe–Zn double metal cyanide (DMC) | MeOH/Oil = 15:1, Cat. = 3 wt%, t = 8 h, T =170 °C | 92 | [63] |

| Sunflower oil | ZrO2 supported La2O3 catalyst | MeOH/Oil = 3:1, Cat. = 2 wt%, t = 5 h, T = 60 °C | 84.9 | [138] |

| Soybean oil | ZnO loaded with Sr(NO3)2 | MeOH/Oil = 12:1, Cat. = 5 wt%, t = 4 h, T = 65 °C | 94.7 | [139] |

| Soybean oil | S–ZrO2 | MeOH/Oil = 20:1, Cat. = 5 wt%, t = 1 h, T = 120 °C | 98.6 | [140] |

| Palm oil | CaO from eggshells | MeOH/Oil = 18:1, Cat. = 10 wt%, t = 2 h, T = 65 °C | 98 | [81] |

| Palm oil | CaO/Al2O3 | MeOH/Oil = 12:1, Cat. = 1.3 wt%, t = 5 h, T = 64.29 °C | 98.64 | [76] |

| Palm oil | KF/Ca–Al hydrotalcite | MeOH/Oil = 12:1, Cat. = 4 wt%, t = 5 h, T = 65 °C | 97.98 | [90] |

| Rapeseed oil | KNO3/CaO | MeOH/Oil = 6:1, Cat. = 1 wt%, t = 3 h, T = 65 °C | 98 | [83] |

| Waste cooking oil | MgO/TiO2 | MeOH/Oil = 50:1, Cat. = 10 wt%, t = 6 h, T = 170 °C | 91.6 | [77] |

| Jatropha oil | Mg–Al hydrotalcite | MeOH/Oil = 4:1, Cat. = 1 wt%, t = 1.5 h, T = 45 °C | 95.2 | [141] |

| Soybean oil | Sodium silicate | MeOH/Oil = 7.5:1, Cat. = 3 wt%, t = 1 h, T = 60 °C | 100 | [94] |

| Moringa oleifera oil | SO42−/SnO2-SiO2 | MeOH/Oil = 19.5:1, Cat. = 3 wt%, t = 2.5 h, T = 150 °C | 84 | [109] |

| Purified palm oil | SO4–ZrO2 | MeOH/Oil = 25:1, Cat. = 0.5 wt%, t = 10 min, T = 250 °C | 90 | [142] |

| Sunflower oil | SO42−/ZrO2/SiO2 | Ethanol/Oil = 12:1, Cat. = 4.6 wt%, t = 6 h, T = 200 °C | 91.5 | [120] |

| Cottonseed oil | Carbon based solid acid | MeOH/Oil = 16.8:1, Cat. = 0.2 wt%, t = 4.5 h, T = 220 °C | 94.8 | [102] |

| Croton megalocarpus oil | SO42−/SnO2-SiO2 | MeOH/Oil = 15:1, Cat. = 3 wt%, t = 2 h, T = 180 °C | 95 | [110] |

| Algae oil | Zirconia, titania | Not reported | 90.20 | [143] |

| Algae oil | 4% NiO, 18% MoO3/alumina | T = 370 °C | 99.00 | [144] |

| Algae oil | Amberlyst-15 | Not reported | 98 | [145] |

| Algae oil | Hierarchical H-Beta zeolites | Not reported | 99.5 | [144] |

| Algae oil | Microporous titania | Not reported | 94.7 | [144] |

| Microalgal’s lipid | Modified Alumina | Not reported | 97.5 | [75] |

| Freshwater microalgae oil | Modified titania | Not reported | 95 | [64] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faruque, M.O.; Razzak, S.A.; Hossain, M.M. Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review. Catalysts 2020, 10, 1025. https://doi.org/10.3390/catal10091025

Faruque MO, Razzak SA, Hossain MM. Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review. Catalysts. 2020; 10(9):1025. https://doi.org/10.3390/catal10091025

Chicago/Turabian StyleFaruque, Mohammed O., Shaikh A. Razzak, and Mohammad M. Hossain. 2020. "Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review" Catalysts 10, no. 9: 1025. https://doi.org/10.3390/catal10091025

APA StyleFaruque, M. O., Razzak, S. A., & Hossain, M. M. (2020). Application of Heterogeneous Catalysts for Biodiesel Production from Microalgal Oil—A Review. Catalysts, 10(9), 1025. https://doi.org/10.3390/catal10091025