Expression and Characterization of a GH16 Family β-Agarase Derived from the Marine Bacterium Microbulbifer sp. BN3 and Its Efficient Hydrolysis of Agar Using Raw Agar-Producing Red Seaweeds Gracilaria sjoestedtii and Gelidium amansii as Substrates

Abstract

1. Introduction

2. Results and Discussion

2.1. β-Agarase Gene Derived from Microbulbifer sp. BN3 Strain

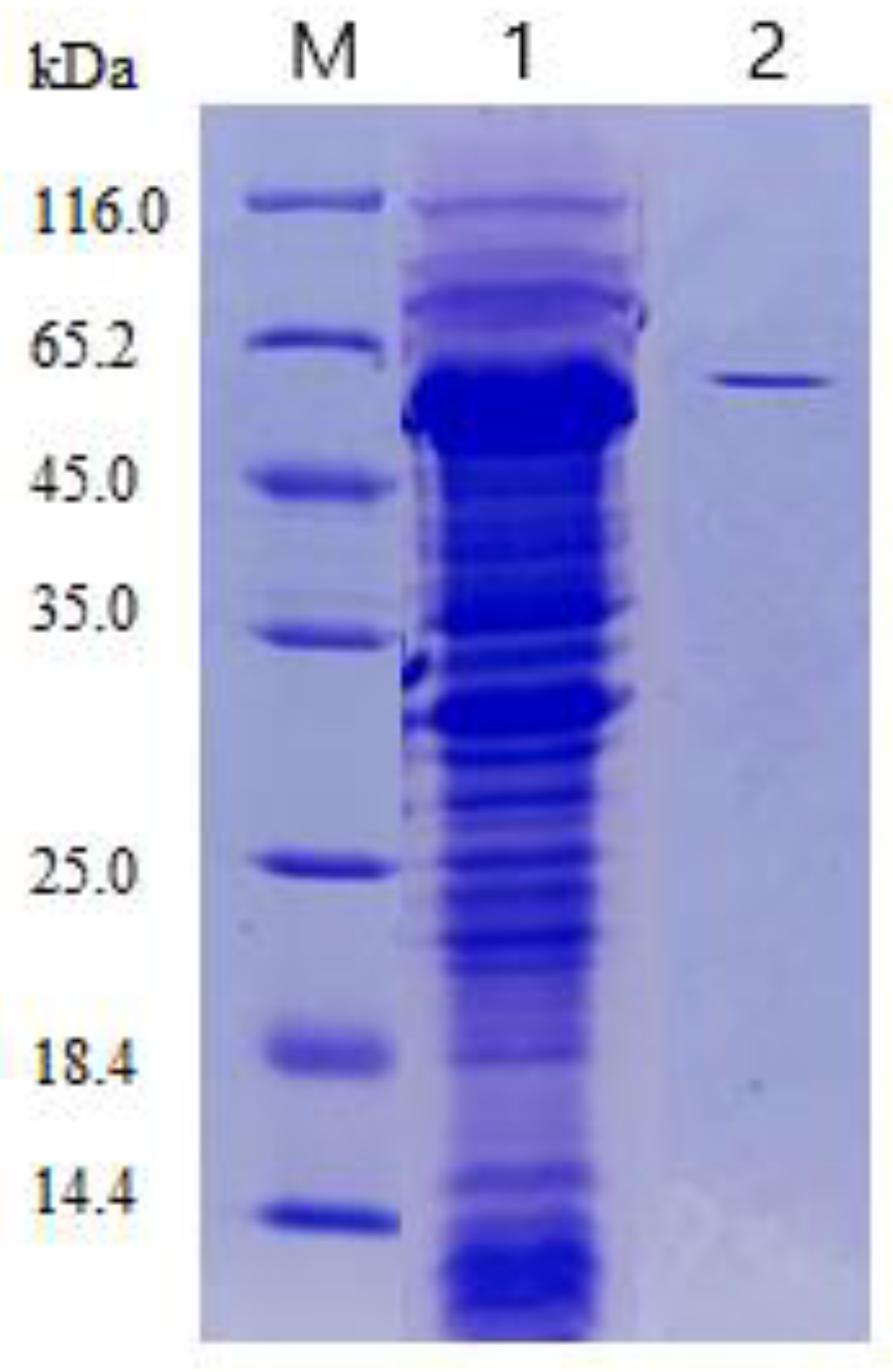

2.2. Expression and Purification of rAga-ms-R

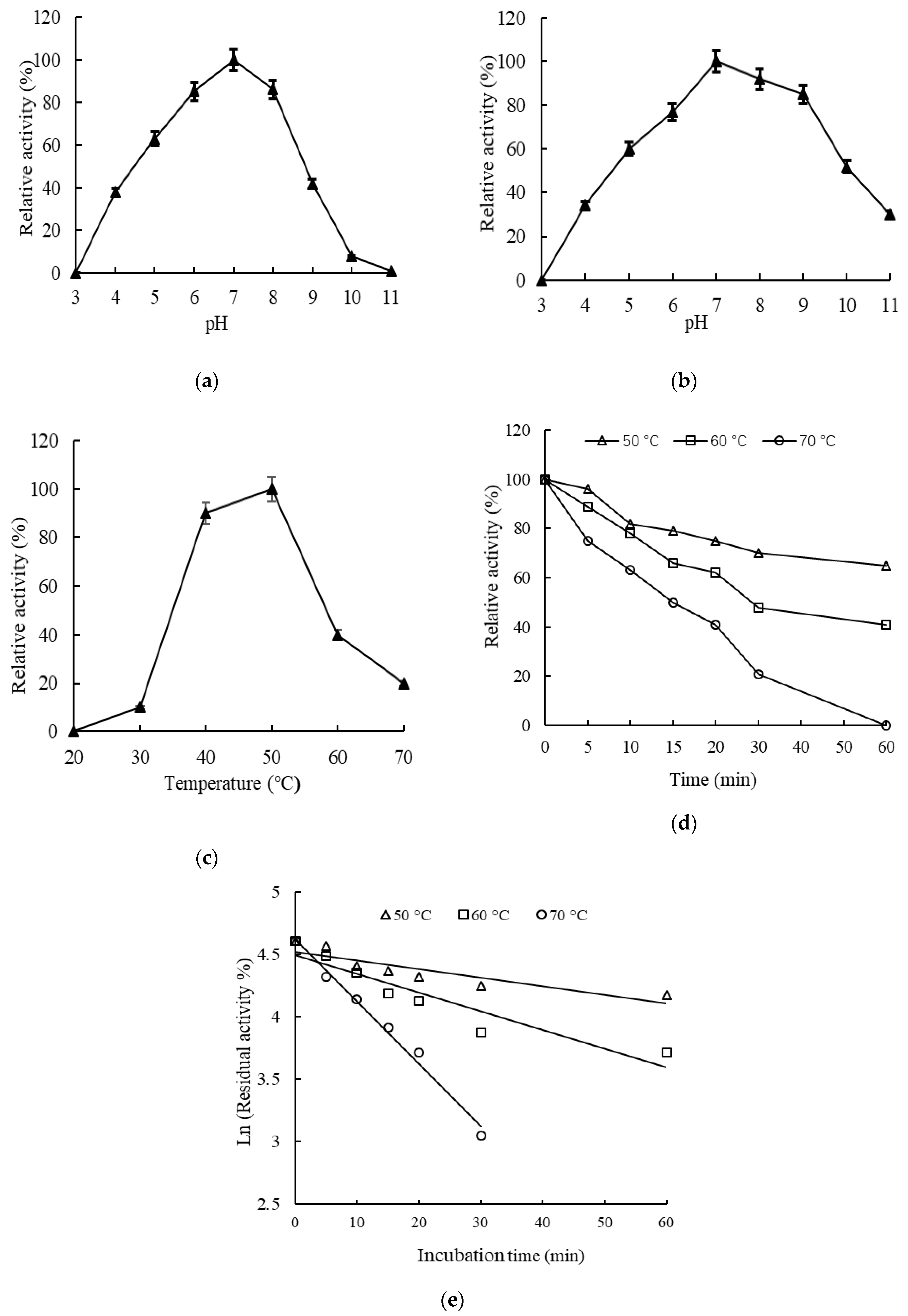

2.3. Enzymatic Characterization of rAga-ms-R

2.4. Km Values of rAga-ms-R

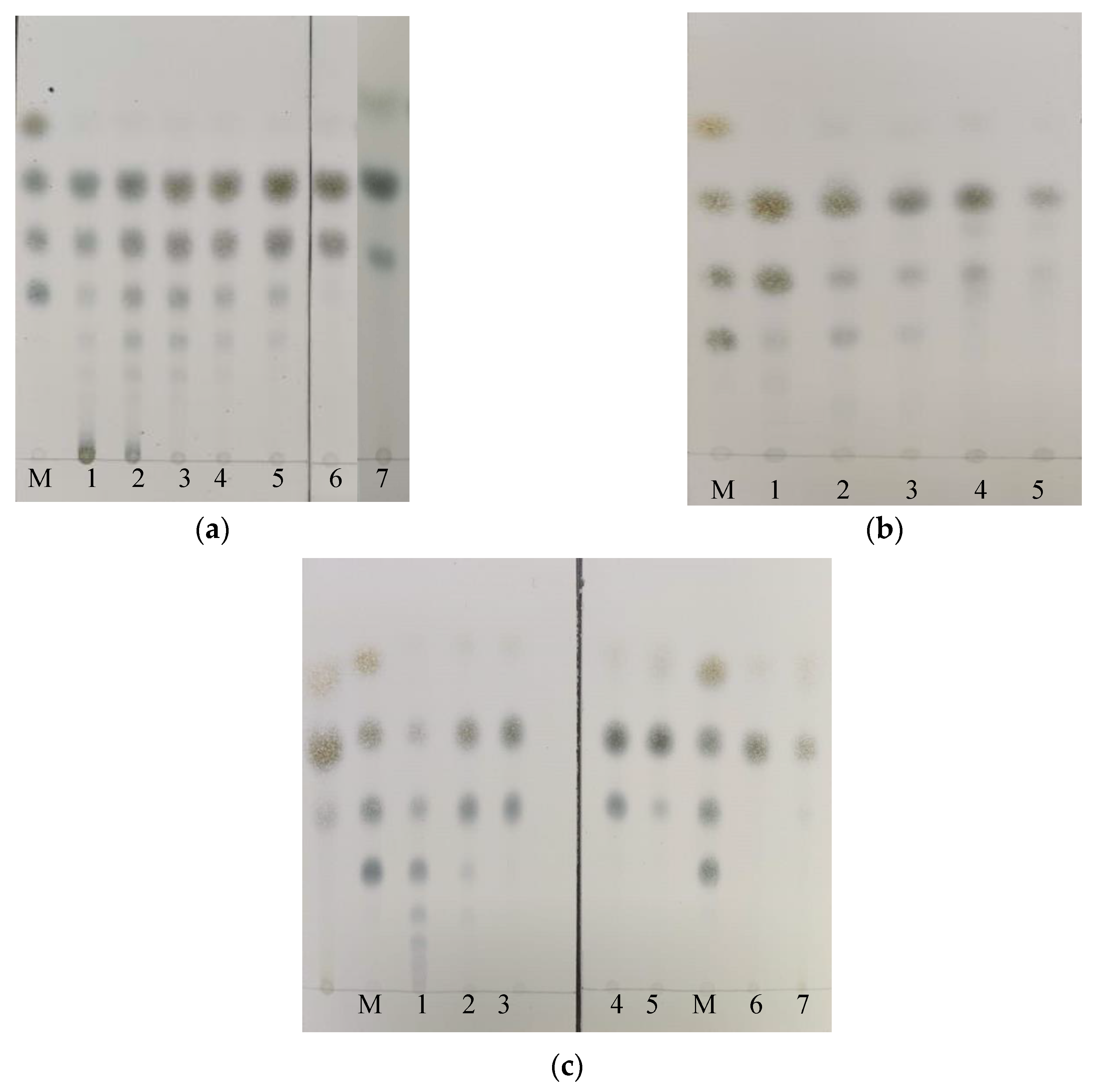

2.5. Analysis of Hydrolysis Products

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Gene Cloning of Agarase

3.2.2. Heterologous Expression of Aga-ms-R in Brevibacillus

3.2.3. Purification of rAga-ms-R

3.2.4. Definition of Enzyme Activity and Protein Quantification

3.2.5. Biochemical Characterization of rAga-ms-R

3.2.6. Analyses of Products of Hydrolysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ajisaka, K.; Agawa, S.; Nagumo, S.; Kurato, K.; Yokoyama, T.; Arai, K.; Miyazaki, T. Evaluation and comparison of the antioxidative potency of various carbohydrates using different methods. J. Agric. Food Chem. 2009, 57, 3102–3107. [Google Scholar] [CrossRef]

- Fu, X.T.; Kim, S.M. Agarase: Review of major sources, categories, purification method, enzyme characteristics and applications. Mar. Drugs 2010, 8, 200–218. [Google Scholar] [CrossRef] [PubMed]

- Flament, D.; Barbeyron, T.; Jam, M.; Potin, P.; Czjzek, M.; Kloareg, B.; Michel, G. Alpha-agarases define a new family of glycoside hydrolases, distinct from beta-agarase families. Appl. Environ. Microbiol. 2007, 73, 4691–4694. [Google Scholar] [CrossRef] [PubMed]

- Arnott, S.; Fulmer, A.; Scott, W.E.; Dea, I.C.; Moorhouse, R.; Rees, D.A. The agarose double helix and its function in agarose gel structure. J. Mol. Biol. 1974, 90, 269–284. [Google Scholar] [CrossRef]

- Jahromi, S.T.; Barzkar, N. Future direction in marine bacterial agarases for industrial applications. Appl. Microbiol. Biotechnol. 2018, 102, 6847–6863. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, C.R.; Hong, S.K. Implications of agar and agarase in industrial applications of sustainable marine biomass. Appl. Microbiol. Biotechnol. 2020, 104, 2815–2832. [Google Scholar] [CrossRef]

- Yun, E.J.; Yu, S.; Kim, K.H. Current knowledge on agarolytic enzymes and the industrial potential of agar-derived sugars. Appl. Microbiol. Biotechnol. 2017, 101, 5581–5589. [Google Scholar] [CrossRef]

- Mariyanna, L.; Shinde, M.; Junna, L. Purification and characterization of β-agarase from agar-liquefying soi bacterium Acinetobacter sp., AG LSL-1. Process Biochem. 2009, 44, 999–1003. [Google Scholar]

- Chen, X.L.; Hou, Y.P.; Jin, M.; Zeng, R.Y.; Lin, H.T. Expression and characterization of a novel thermostable and pH-stable β-agarase from deep- sea bacterium Flammeovirga Sp. OC4. J. Agric. Food Chem. 2016, 64, 7251–7258. [Google Scholar] [CrossRef]

- Khan, S.; Ullah, M.W.; Siddique, R.; Nabi, G.; Manan, S.; Yousaf, M.; Hou, H. Role of recombinant DNA technology to improve life. Int. J. Genomics 2016, 2016, 2405954. [Google Scholar] [CrossRef]

- An, K.; Shi, X.; Cui, F.; Cheng, J.; Liu, N.; Zhao, X.; Zhang, X.H. Characterization and overexpression of a glycosyl hydrolase family 16 beta-agarase YM01–1 from marine bacterium Catenovulum agarivorans YM01T. Protein Expr. Purif. 2018, 143, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Cui, F.; Dong, S.; Shi, X.; Zhao, X.; Zhang, X.H. Overexpression and characterization of a novel thermostable β-agarase YM01–3, from marine bacterium Catenovulum agarivorans YM01(T). Mar. Drugs 2014, 12, 2731–2747. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.; Tamaru, Y.; Araki, T. A unique beta-agarase, AgaA, from a marine bacterium, Vibrio sp. strain PO-303. Appl. Microbiol. Biotechnol. 2007, 74, 1248–1255. [Google Scholar] [CrossRef] [PubMed]

- Liao, L.; Xu, X.W.; Jiang, X.W.; Cao, Y.; Yi, N.; Huo, Y.Y.; Wu, Y.H.; Zhu, X.F.; Zhang, X.Q.; Wu, M. Cloning, expression, and characterization of a new beta-agarase from Vibrio sp. strain CN41. Appl. Environ. Microbiol. 2011, 77, 7077–7079. [Google Scholar] [CrossRef] [PubMed]

- Ohta, Y.; Hatada, Y.; Nogi, Y.; Li, Z.; Ito, S.; Horikoshi, K. Cloning, expression, and characterization of a glycoside hydrolase family 86 beta-agarase from a deep-sea Microbulbifer-like isolate. Appl. Microbiol. Biotechnol. 2004, 66, 266–275. [Google Scholar] [CrossRef] [PubMed]

- Li, R.K.; Chen, Z.; Ying, X.J.; Ng, T.B.; Ye, X.Y. A novel GH16 beta-agarase isolated from a marine bacterium, Microbulbifer sp. BN3 and its characterization and high-level expression in Pichia pastoris. Int. J. Biol. Macromol. 2018, 119, 1164–1170. [Google Scholar] [CrossRef] [PubMed]

- Beygmoradi, A.; Homaei, A. Marine microbes as a valuable resource for brand new industrial biocatalysts. Biocatal. Agric. Biotechnol. 2017, 11, 131–152. [Google Scholar] [CrossRef]

- Wang, W.; Liu, P.; Hao, C.; Wu, L.; Wan, W.; Mao, X. Neoagaro-oligosaccharide monomers inhibit inflammation in LPS-stimulated macrophages through suppression of MAPK and NF-κB pathways. Sci. Rep. 2017, 7, 44252. [Google Scholar] [CrossRef]

- Lee, M.H.; Jang, J.H.; Yoon, G.Y.; Lee, S.J.; Lee, M.G.; Kang, T.H.; Han, H.D.; Kim, H.S.; Choi, W.S.; Park, W.S.; et al. Neoagarohexaose-mediated activation of dendritic cells via Toll-like receptor 4 leads to stimulation of natural killer cells and enhancement of antitumor immunity. BMB Rep. 2017, 50, 263–268. [Google Scholar] [CrossRef]

- Allouch, J.; Jam, M.; Helbert, W.; Barbeyron, T.; Kloareg, B.; Henrissat, B.; Czjzek, M. The three-dimensional structures of two beta-agarases. J. Biol. Chem. 2003, 278, 47171–47180. [Google Scholar] [CrossRef]

- Henshaw, J.; Horne, B.A.; van Bueren, A.L.; Money, V.A.; Bolam, D.N.; Czjzek, M.; Ekborg, N.A.; Weiner, R.M.; Hutcheson, S.W.; Davies, G.J.; et al. Family 6 carbohydrate binding modules in beta-agarases display exquisite selectivity for the non-reducing termini of agarose chains. J. Biol. Chem. 2006, 281, 17099–17107. [Google Scholar] [CrossRef] [PubMed]

- Mamo, G.; Hatti, K.R.; Mattiasson, B. Fusion of carbohydrate binding modules from Thermotoga neapolitana with a family 10 xylanase from Bacillus halodurans S7. Extremophiles 2007, 11, 169–177. [Google Scholar] [CrossRef]

- Boraston, A.B.; Bolam, D.N.; Gilbert, H.J.; Davies, G.J. Carbohydrate-binding modules: Fine-tuning polysaccharide recognition. Biochem. J. 2004, 382, 769–781. [Google Scholar] [CrossRef] [PubMed]

- Inoue, A. Characterization of PL-7 family alginate lyases from marine organisms and their applications. Methods Enzymol. 2018, 605, 499–524. [Google Scholar] [CrossRef] [PubMed]

- Chi, W.J.; Park, D.Y.; Seo, Y.B.; Chang, Y.K.; Lee, S.Y.; Hong, S.K. Cloning, expression, and biochemical characterization of a novel GH16 β-agarase AgaG1 from Alteromonas sp. GNUM-1. Appl. Microbiol. Biotechnol. 2014, 98, 4545–4555. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Xu, J.; Liu, D.; Liu, H.; Lu, X.; Yu, W. Characterization of an α-agarase from Thalassomonas sp. LD5 and its hydrolysate. Appl. Microbiol. Biotechnol. 2018, 102, 2203–2212. [Google Scholar] [CrossRef] [PubMed]

- Han, W.; Cheng, Y.; Wang, D.; Wang, S.; Liu, H.; Gu, J.; Wu, Z.; Li, F. Biochemical characteristics and substrate degradation pattern of a novel exo-type β-agarase from the polysaccharide-degrading marine bacterium Flammeovirga sp. Strain MY04. Appl. Environ. Microbiol. 2016, 82, 4944–4954. [Google Scholar] [CrossRef]

- Shi, Y.L.; Lu, X.Z.; Yu, W.G. A new β-agarase from marine bacterium Janthinobacterium sp. SY12. World J. Microbiol. Biotechnol. 2008, 24, 2659–2664. [Google Scholar] [CrossRef]

- Dong, J.; Hashikawa, S.; Konishi, T.; Tamaru, Y.; Araki, T. Cloning of the novel gene encoding beta-agarase C from a marine bacterium, Vibrio sp. strain PO-303, and characterization of the gene product. Appl. Environ. Microbiol. 2006, 72, 6399–6401. [Google Scholar] [CrossRef]

- Minegishi, H.; Shimane, Y.; Echigo, A.; Ohta, Y.; Hatada, Y.; Kamekura, M.; Maruyama, T.; Usami, R. Thermophilic and halophilic β-agarase from a halophilic archaeon Halococcus sp. 197A. Extremophiles 2013, 17, 931–939. [Google Scholar] [CrossRef]

- Fu, W.; Han, B.; Duan, D.; Liu, W.; Wang, C. Purification and characterization of agarases from a marine bacterium Vibrio sp. F-6. J. Ind. Microbiol. Biotechnol. 2008, 35, 915–922. [Google Scholar] [CrossRef]

- Su, Q.; Jin, T.; Yu, Y.; Yang, M.; Mou, H.; Li, L. Extracellular expression of a novel β-agarase from Microbulbifer sp. Q7, isolated from the gut of sea cucumber. AMB Express. 2017, 7, 220. [Google Scholar] [CrossRef]

- Chen, Z.W.; Lin, H.J.; Huang, W.C.; Hsuan, S.L.; Lin, J.H.; Wang, J.P. Molecular cloning, expression, and functional characterization of the β-agarase AgaB-4 from Paenibacillus agarexedens. AMB Express. 2018, 8, 49. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.; Chen, X.; Chan, Z.; Zeng, R. Expression and characterization of a thermostable and pH-stable β-agarase encoded by a new gene from Flammeovirga pacifica WPAGA1. Process Biochem. 2015, 50, 1068–1075. [Google Scholar] [CrossRef]

- Lin, B.; Liu, Y.; Lu, G.; Zhao, M.; Hu, Z. An agarase of glycoside hydrolase family 16 from marine bacterium Aquimarina agarilytica ZC1. FEMS Microbiol. Lett. 2017, 364. [Google Scholar] [CrossRef]

- Liu, N.; Mao, X.; Du, Z.; Mu, B.; Wei, D. Cloning and characterisation of a novel neoagarotetraose-forming-β-agarase, AgWH50A from Agarivorans gilvus WH0801. Carbohydr. Res. 2014, 388, 147–151. [Google Scholar] [CrossRef] [PubMed]

- Chi, W.J.; Lee, C.R.; Dugerjonjuu, S.; Park, J.S.; Kang, D.K.; Hong, S.K. Biochemical characterization of a novel iron-dependent GH16 β-agarase, AgaH92, from an agarolytic bacterium Pseudoalteromonas sp. H9. FEMS Microbiol. Lett. 2015, 362, fnv035. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Oh, C.; Nikapitiya, C.; Lee, Y.; Whang, I.; Kim, S.J.; Kang, D.H.; Lee, J. Cloning, purification and biochemical characterization of beta agarase from the marine bacterium Pseudoalteromonas sp. AG4. J. Ind. Microbiol. Biotechnol. 2010, 37, 483–494. [Google Scholar] [CrossRef] [PubMed]

- Zeng, C.; Zhang, L.; Miao, S.; Zhang, Y.; Zeng, S.; Zheng, B. Preliminary characterization of a novel β-agarase from Thalassospira profundimonas. Springerplus 2016, 5, 1086. [Google Scholar] [CrossRef]

- Lee, Y.; Oh, C.; De, Z.M.; Kim, H.; Wickramaarachchi, W.D.N.; Whang, I.; Kang, D.H.; Lee, J. Molecular cloning, overexpression, and enzymatic characterization of glycosyl hydrolase family 16 β-Agarase from marine bacterium Saccharophagus sp. AG21 in Escherichia coli. J. Microbiol. Biotechnol. 2013, 23, 913–922. [Google Scholar] [CrossRef]

- Wang, J.; Mou, H.; Jiang, X.; Guan, H. Characterization of a novel beta-agarase from marine Alteromonas sp. SY37–12 and its degrading products. Appl. Microbiol. Biotechnol. 2006, 71, 833–839. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, R.; Takisada, M.; Suzuki, T.; Kirimura, K.; Usami, S. Neoagarobiose as a novel moisturizer with whitening effect. Biosci. Biotechnol. Biochem. 1997, 61, 162–163. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.P.; Wu, H.T.; Wang, G.H.; Wu, D.Y.; Wang, I.E.; Chien, M.C.; Pang, H.Y.; Kuo, J.T.; Liaw, L.L. Inspecting the genome sequence and agarases of Microbulbifer pacificus LD25 from a saltwater hot spring. J. Biosci. Bioeng. 2019, 127, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Li, R.K.; Hu, Y.J.; Ng, T.B.; Guo, B.Q.; Zhou, Z.H.; Xiu, J.Z.; Ye, X.Y. Expression and biochemical characterization of a novel chitinase ChiT-7 from the metagenome in the soil of a mangrove tidal flat in China. Int. J. Biol. Macromol. 2020, 158, 1125–1134. [Google Scholar] [CrossRef]

| Purification Step | Total Activity (U) | Total Protein (mg) | Specific Activity (U/mg) | Purification Fold | Recovery (%) |

|---|---|---|---|---|---|

| Crude extract | 336.6 | 15.68 | 17.71 | 1 | 100 |

| (NH4)2SO4 precipitation | 282.7 | 7.9 | 35.79 | 2.02 | 83.99 |

| DEAE FF | 231.7 | 2.3 | 100.75 | 5.69 | 68.84 |

| Metal Ion/Chemical (5 mmol/L) | Relative Activity (%) | Metal Ion/Chemical (5 mmol/L) | Relative Activity (%) |

|---|---|---|---|

| Control | 100 | Fe3+ | 15 ± 2.9 |

| K+ | 97 ± 3.1 | Mn2+ | 66 ± 2.6 |

| Na+ | 110 ± 2.7 | Zn2+ | 79 ± 3.1 |

| Ca2+ | 99 ± 1.9 | Mg2+ | 105 ± 2.5 |

| Li2+ | 101 ± 2.9 | Fe2+ | 65 ± 2.8 |

| Co+ | 54 ± 3.0 | EDTA | 87 ± 3.0 |

| Ni2+ | 72 ± 3.3 | SDS | 83 ± 1.8 |

| Cu2+ | 25 ± 3.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.K.; Ying, X.J.; Chen, Z.L.; Ng, T.B.; Zhou, Z.M.; Ye, X.Y. Expression and Characterization of a GH16 Family β-Agarase Derived from the Marine Bacterium Microbulbifer sp. BN3 and Its Efficient Hydrolysis of Agar Using Raw Agar-Producing Red Seaweeds Gracilaria sjoestedtii and Gelidium amansii as Substrates. Catalysts 2020, 10, 885. https://doi.org/10.3390/catal10080885

Li RK, Ying XJ, Chen ZL, Ng TB, Zhou ZM, Ye XY. Expression and Characterization of a GH16 Family β-Agarase Derived from the Marine Bacterium Microbulbifer sp. BN3 and Its Efficient Hydrolysis of Agar Using Raw Agar-Producing Red Seaweeds Gracilaria sjoestedtii and Gelidium amansii as Substrates. Catalysts. 2020; 10(8):885. https://doi.org/10.3390/catal10080885

Chicago/Turabian StyleLi, Ren Kuan, Xi Juan Ying, Zhi Lin Chen, Tzi Bun Ng, Zhi Min Zhou, and Xiu Yun Ye. 2020. "Expression and Characterization of a GH16 Family β-Agarase Derived from the Marine Bacterium Microbulbifer sp. BN3 and Its Efficient Hydrolysis of Agar Using Raw Agar-Producing Red Seaweeds Gracilaria sjoestedtii and Gelidium amansii as Substrates" Catalysts 10, no. 8: 885. https://doi.org/10.3390/catal10080885

APA StyleLi, R. K., Ying, X. J., Chen, Z. L., Ng, T. B., Zhou, Z. M., & Ye, X. Y. (2020). Expression and Characterization of a GH16 Family β-Agarase Derived from the Marine Bacterium Microbulbifer sp. BN3 and Its Efficient Hydrolysis of Agar Using Raw Agar-Producing Red Seaweeds Gracilaria sjoestedtii and Gelidium amansii as Substrates. Catalysts, 10(8), 885. https://doi.org/10.3390/catal10080885