Outlook on the Role of Microbial Fuel Cells in Remediation of Environmental Pollutants with Electricity Generation

Abstract

1. Introduction

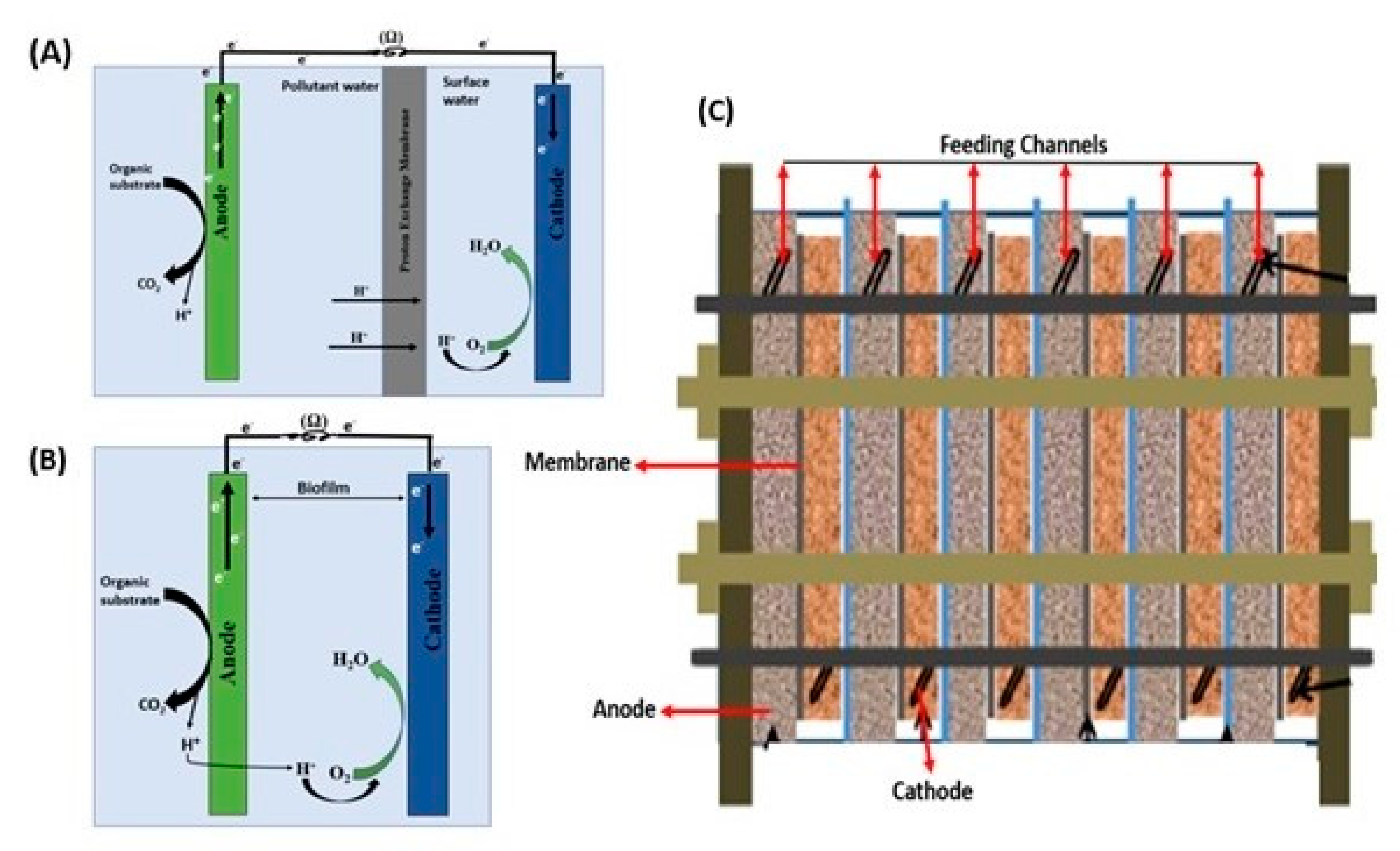

2. Basic Setup and Type of Microbial Fuel Cells (MFCs) Based on Configurations

3. Pollutant Removal through MFCs

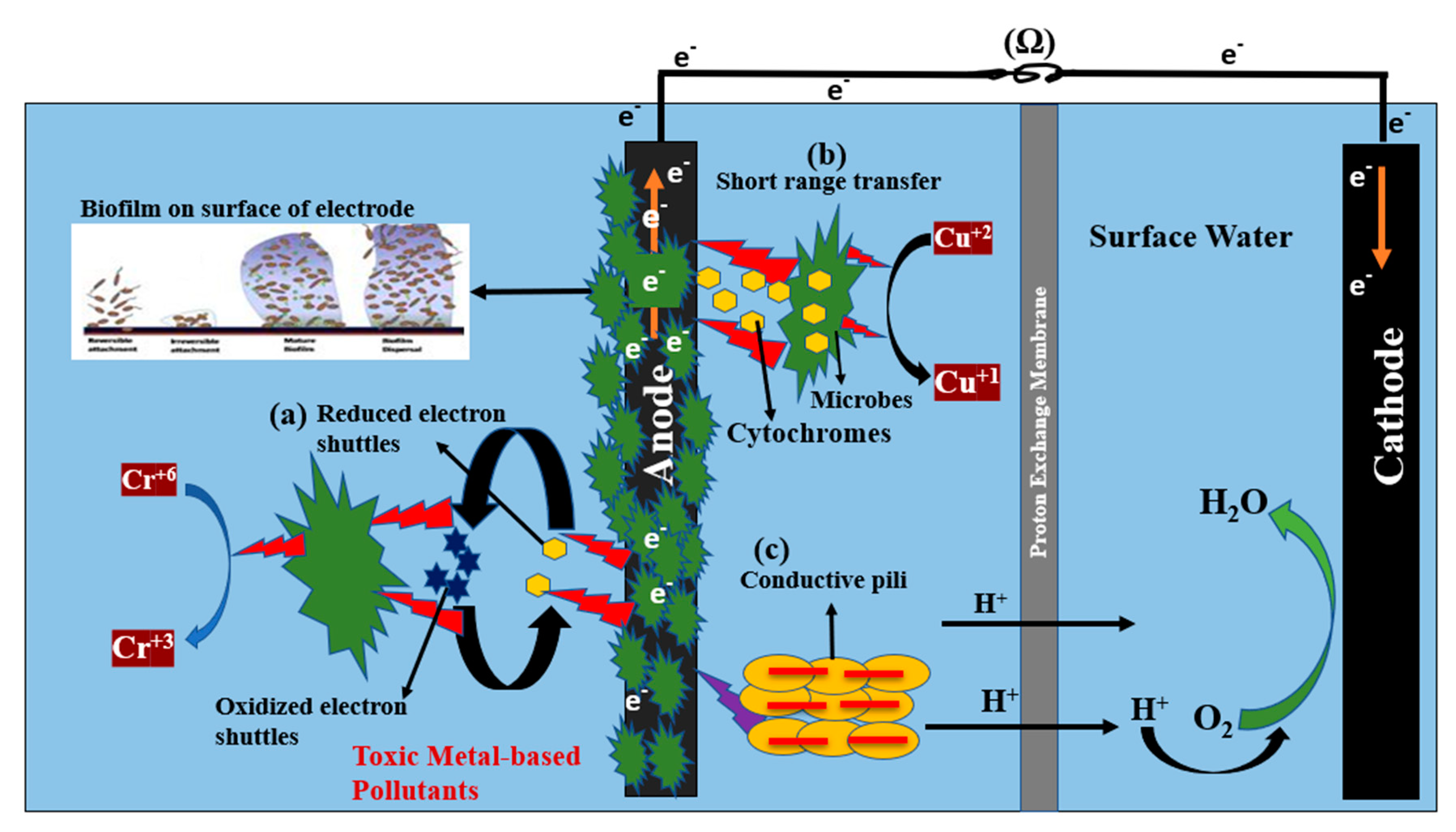

3.1. Degradation of Toxic Metal through MFCs

| Target Metal Pollutants | Type of MFCs | Type of Electrodes | Inoculum/Microbes | Operating Time (hr) | Temp (°C) | pH | Initial Conc. | Removal Efficiency (%) | Power Density | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Anode | Cathode | ||||||||||

| Cr (VI) | DMFC | Graphite plates | Graphite plates | Domestic wastewater | 150 | 25 | 2 | 100 mg/L | 100 | 150 mW/m2 | [69] |

| Cr (VI) | DMFC | Unpolished graphite plate | Natural rutile-coated polished graphite | Anaerobic sludge | 26 | 22 | 2 | 26 mg/L | 97 | - | [70] |

| Se | SMFC | Non-wet proofed carbon cloth | Wet proofed carbon cloth | Mixed culture (Acetate and glucose use as source) | <48 | 30 | - | 75 mg Se/l 200 mg Se/l | 99 | - | [71] |

| V (V) | DMFC | Carbon fiber felt | Carbon fiber felt | Anaerobic granular sludge | 72 | 35 | 1 | 25 mL | 87.9 | 578.3 mW/m2 | [72] |

| Cr (VI) | DMFC | Graphite plate | Graphite granular | Indigenous bacteria from Cr (VI)- | 173 | 22–26 | 2 | 39.2 mg/L | 2.4 ± 0.2 mg g VSS−1/h | 6.9 mW/m3 | [73] |

| Cu (II) | DMFC | Graphite felt | Graphite plate | Anaerobic sludge | 144 | 35 | - | 500 mg/L | 70 | 314 mW/m3 | [74] |

| Cu (II) | DMFC | Graphite felt | Graphite plate | Anaerobic sludge with Copper | 144 | 35 | - | 500 mg/L | 70 | 314 mW/m3 | [74] |

| Cu (II) | DMFC | Graphite plate | Graphite felt | Anaerobic sludge | 20 | 35 | 3.5 | 200 mg/L | >99 | 314 mW/m3 | [75] |

| Cu (II) | DMFC | Graphite plate | Graphite plate | Anaerobic sludge | 20 | 35 | 4.7 | 6412.5 ± 26.7 mg Cu2+/L | >99 | 339 mW/m3 | [75] |

| Hg (II) | DMFC | Graphite felt | Carbon paper | Anaerobic sludge | 10 | 30 | 2 | 100 mg/L | 98.22–99.54 | 433.1 mW/m2 | [76] |

| Cr (VI) | DMFC | Graphite felts | Graphite felts | Anaerobic sludge | 144 and 192 | 35 | - | 5 mg/L 25 mg/L | 5 mg/L With 93, 25 mg/L With 61 | - | [44] |

| Cu (II), Pb (II) | DMFC | Carbon felt | Carbon felt | Dilute synthetic sample | 14–36 days | 25 | 3 | 1.1 mg/L Cu2+, 2.5 mg/L Pb2+ | Pb 92 Cu 99 | 17.1 to 25.2 mW/m2 | [77] |

| Cd (II), Zn (II) | DMFC | Carbon felt | Carbon felt | Dilute synthetic sample | 56 days | 25 °C | 3 | 7.4 mg/L Cd2+ 19.5 mg/L Zn2+ | Cd 82 Zn 89 | - | [77] |

| Cr (VI) | DMFC | Carbon fiber felt | Carbon fiber felt | Anaerobic sludge | 240 | 30 | 6 | 100 mg/L | 75.4 ± 1.9 | 970.2 ± 60.5 mW/m2 | [78] |

| Ag | DMFC | Carbon brush | Carbon cloth | Sludge mixture | 8 | 25 | 7 | 50–200 ppm | 99.91 | 4.25 W/m2 | [79] |

| V (V) | DMFC | Carbon fiber felt | Carbon fiber felt | Anaerobic sludge | 240 | 30 | 6 | 100 mg/L | 67.9 ± 3.1 | 970.2 ± 60.5 mW/m2 | [78] |

| Cr (VI) | BMFC | Graphite felt | Graphite rod | Shewanella oneidensis MR-1 | 192 | 30 | 7 | 200 mg/L | 67 | 32.5 mW/m2 | [36] |

| Pb, Se | DMFC | Carbon cloth | Carbon cloth with Pt coating. | Oil sands tailings affected water | 800 | 21 ± 0.5 | 1 | 581 ± 26 Se, 35.8 ± 13 Pb. | 97.8 Se, 32.5 Pb | 392 ± 15 mW/m2 | [80] |

| Au (III) | DMFC | Carbon brush | Carbon cloth | Tetrachloroaurate wastewater | 12 | 25 | 2.8 | 2000 ppm | 99.89 ± 0.00 | 6.58 W/m2 | [81] |

| Cr (VI) | DMFC | Activated charcoal | Activated charcoal | Algae biomass | 96 | - | 2 | 200 mL | 98 | 207 mW/m2 | [47] |

| Ag+ | DMFC | Carbon cloth | Graphite | NH3 chelated silver waste water | 21 | - | 6.2 | - | 99.9 | 317 mW/m2 | [82] |

| Co | DMFC | Graphite felt | Graphite felt | Lithium cobalt oxide Solution | - | 35 | 1 | 200 mg/L | 62.5 ± 1.8 | 298 ± 31 mW/m3 | [83] |

| Cu (II) | DMFC | Carbon cloth | Carbon cloth | Klebsiella sp. MC-1 | 75 | 25 × 5 | 5 | 50 mg/L | 99.1 | 412 W/m2 | [84] |

| Cd (II), Zn (II) | SMFC | Carbon cloth (no wet proofing) | carbon cloth (30 wet proofing) | Sewage sludge | - | 32 | 6.8 | 200 mM Cd; 400 mM Zn | Cd 90 Zn 97 | 3.6 W/m2 | [85] |

| Au (III) | MFC | Pt-graphite | Pt-graphite | Shewanella genus | - | 25 | 2 | 200 ppm | 60 | - | [85] |

| V | Tubular MFC | Carbon fiber felt | Carbon fiber felt | Anaerobic sludge | 72 | 25 | 7 | 500 mg/L | 25 | 0.572 W/m2 | [49] |

| Ag+ | Tubular MFC | Carbon cloth | Graphite felt | Anaerobic sludge | 21 | 26 | 9.2 | 1000 mg/L | 99 | 0.3 W/m2 | [49] |

| Ag+ | Tubular MFC | graphite plate | Graphite felt | Anaerobic sludge | 26 | - | 2 | 200 mg/L | 95 | 0.109 W/m2 | [49] |

| Ag+ | Tubular MFC | Carbon brush | Carbon cloth | Anaerobic sludge | 8 | - | 7 | 200 mg/L | 99 | 4.25 W/m2 | [49] |

| Se | SMFC | Carbon cloth | Carbon cloth | Anaerobic sludge | 48 | 25 | 7 | 75 mg/L | 99 | 2.90 W/m2 | [49] |

| Au | Tubular MFC | Carbon brush | Carbon cloth | - | - | - | 2 | 200 mg/L | 99.8 | 6.58 W/m2 | [49] |

| Co | Tubular MFC | Graphite felt | Graphite felt | Anaerobic sludge | 48 | 30 | 1–3 | 1000 mg/L | 99.15 | - | [49] |

| Cr (VI) | Tubular MFC | Graphite plates | Graphite plates | Anaerobic sludge | 150 | 25 | 2–6 | 200 mg/L | 100 | 0.150 W/m2 | [49] |

| Cr (VI) | Tubular MFC | Graphite plates | Graphite plates | Anaerobic sludge | 26 | 25 | 2 | 26 mg/L | 97 | - | [49] |

| Cr (VI) | Tubular MFC | Carbon cloth | Carbon cloth | Anaerobic sludge | 48 | 25 | 2 | 100 mg/L | 99 | 0.767 W/m2 | [49] |

| Cu (II) | Tubular MFC | Graphite plate | Graphite foil | - | 6 days | - | 3 | 1 mg/L | 99.8 | 0.80 W/m2 | [49] |

| Cu (II) | Tubular MFC | Graphite felt | Graphite felt | Anaerobic sludge | - | 25 | 2–5 | 10–200 mg/L | >99 | 0.319 W/m2 | [49] |

| Cu (II) | Tubular MFC | Graphite felt | Graphite felt | - | 480 | 27 | 2 | 600 mg/L | 92 | [49] | |

| Cu (II) | Tubular MFC | Graphite plate | Graphite plate | Anaerobic sludge | 264 | 25 | 4.7 | 200 mg/L | >96 | 339 mW/m3 | [49] |

| Cd (II) | DMFC | Graphite granules | Carbon felt | Contaminated soil | 143 days | 25 | 6.8 | 100 mg/L | 31 | 7.5 mW/cm2 | [51] |

| Pb (II) | DMFC | Graphite granules | Carbon felt | Contaminated soil | 108 days | 25 | 6.9 | 900 mg/L | 44.1 | 3.6 mW/cm2 | [51] |

| Cr (VI), Cu (II) | Sedimental MFC | Graphite felt | Graphite felt | Sediment sample | 90 days | 37 | 2 | 250 mg/L | 96 | 400–450 mW/m2 | [50] |

| V (V) | DMFC | Carbon fiber felt | Carbon fiber felt | Dysgonomonas and Klebsiella | 7 days | 22 ± 2 | - | 200 mg/L | 60.7 | 529 ± 12 mW/m2 | [52] |

| Cr (VI) | DMFC | Graphite brushes | Graphite granules | Anaerobic sludge | - | 25 | 7 | 10 mg/L | 94 | 6.4 W/m3 | [54] |

| Cr (VI) | DMFC | Graphite brushes | Graphite granules | Primary clarifier effluent | 2 | 22 ± 3 | 7 | 20 mg/L | 76 | 970 mW/m2 | [54] |

| Cr (VI) | SMFC | Carbon brush | Carbon cloth | - | - | 30 | 7 | 100 mg/L | 99 | 419 mW/m2 | [54] |

| Cu (II) | DMFC | Graphite felt | Graphite plate | Activated sludge | 28 days | 35 | - | 100 mg/L | 96 | 140 mW/m2 | [54] |

| V (V) | DMFC | Carbon fiber felt | Carbon fiber felt | - | - | 30 | - | - | 68 | 970 mW/m2 | [54] |

| Cu2+ | SMFC | Carbon brush | Carbon cloth | Anaerobic sludge bed. | 5 | 35 ± 1 | 6 | 12.5 m/Lg | 98.3 | 0.2 W/m3 | [86] |

| Zn (II) | SMFC | Carbon cloth | Carbon cloth | Activated sludge | - | 25 | - | - | 97 | 3600 mW/m2 | [54] |

| Cr (VI), Cd (II) | DMFC | Carbon rod | Graphite felt | Anaerobic pure culture | 24 | 30 | 5.8–6.0 | Cr (VI) 385 μM and Cd (II) 179 μM. | 73 for Cr, 61 for Cd. | 14.2 mW/m2 | [55] |

| Ni | DMFC | Graphite felt | Graphite plate | Anaerobic sludge | 24 | 30±1 | 7.1 | 26.4 mg/L | 95 | - | [26] |

| Cd (II) | DMFC | Graphite felt | Graphite felt | Mixed microbial culture | 7 days | 25 | 7.1 | 50 mg/ml | 60 | 700–750 mW/m2 | [53] |

| Hg (II) | DMFC | Graphite felt | Graphite felt | Mixed microbial culture | 15 days | 25 | 6.8 | 25 mg/ml | 55 | 800 mW/m2 | [53] |

| Toxic TI | SMFC | Carbon felt | Plain carbon paper | Anaerobic sludge | 72 | 22 ± 2 | - | 100 μg/L | 67 | 457.8 ± 15.2 mW/m2 | [56] |

| Cu (II) | DMFC | Carbon brush | Reduced Graphene oxide | Geobacter sp. and Pseudomonas sp. | - | 25 | 6 | 12 mg/L | 98 | 0.95 W/m2 | [60] |

| Cr (VI) | DMFC | Carbon felt | Carbon felt | Shewanelladecoloration- S12, K. pneumonia | 3.5 | 30 | 2 | 10 mg/L | 99.9 | 52.1 mW/cm2 | [59] |

| Cr (VI) | DMFC | Graphite plate | Graphite plate | Anaerobic cultures mixed with Cr (VI) | 45 days | 22–24 | - | 80 mg/L | 0.46 mg Cr (VI)/g VSS·h | 55.5 mW/m2 | [87] |

| Cu (II) | DMFC | Porous graphite felt | Carbon rod | Microbial culture | 72 | 20± 3 | 2 | 50 mg/L, | 55 | - | [88] |

| Ni | DMFC | Graphite felt | Graphite felt | Mixed microbial culture | 30 days | 25 ± 1 | 7 | 32.9 g/180 ml | - | 150–200 m W/m2 | [61] |

| Pt | DMFC | Graphite plate | Graphite plate | Anaerobic sludge bed | 24 | 25 | 7 | 16.88 mg/L. | 90 | 844.0 mW/m2 | [57] |

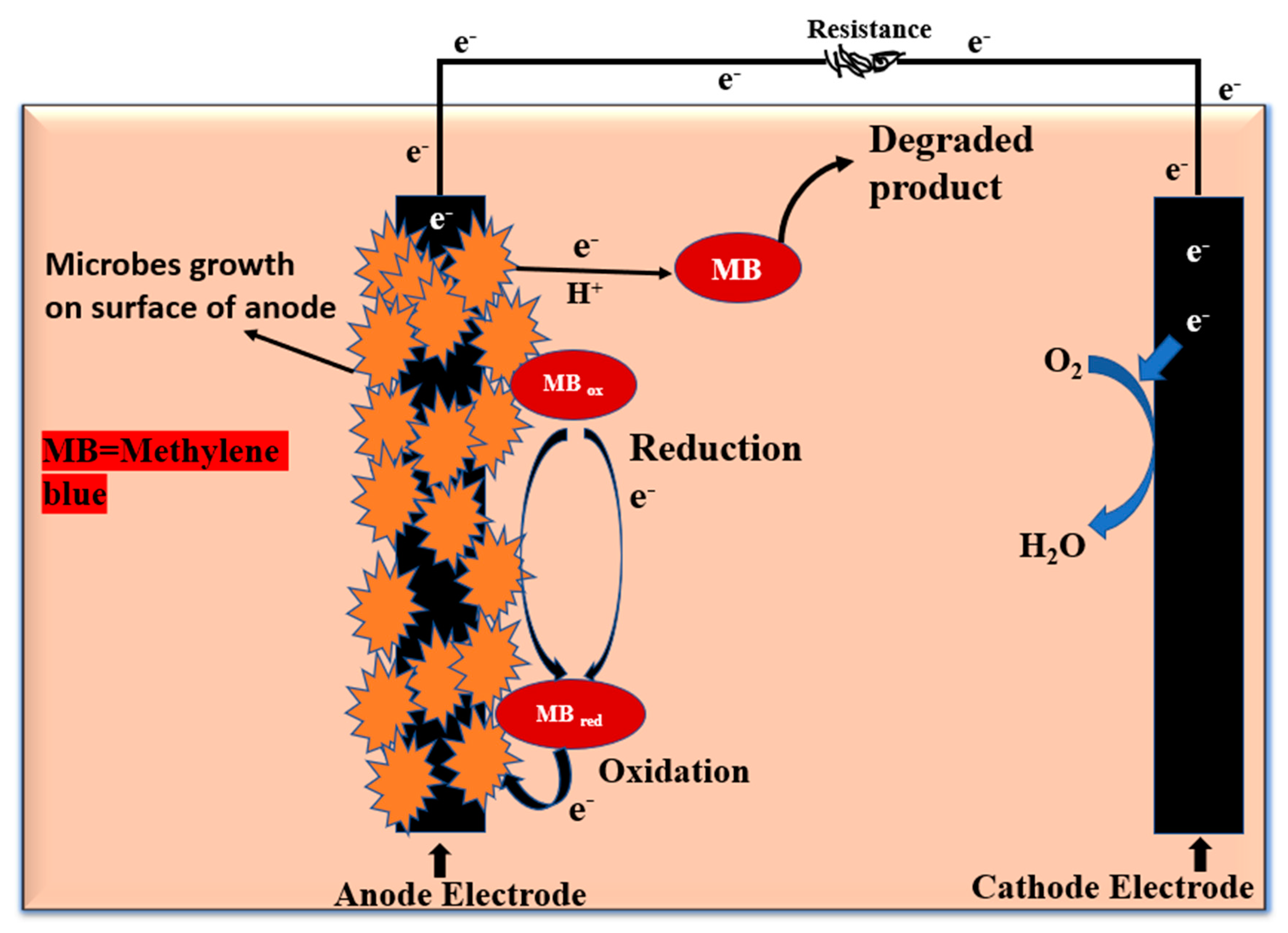

3.2. Organic Dye-Based Pollutant Removal through MFCs

| Target Dye-Based Pollutant | Type of MFCs | Type of Electrodes | Inoculum/Microbes | Operating Time (Hr) | Temp. (°C) | Initial pH | Initial Conc. (mg/L) | Removal Efficiency (%) | Power Density | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Anode | Cathode | ||||||||||

| Acid orange 7 | DMFC | Graphite rod | Graphite rod | Microbial consortium | 336 | 25 | 7.00 | 0.06 | 78 | 0.31 ± 0.03 W/m3 | [120] |

| Methyl orange Orange I Orange II | DMFC | Carbon felt | Carbon felt | - | 18 | 30 | 3–9 | - | - | 34.77 mW/m2 | [121] |

| Methyl orange | DMFC | Unpolished graphite | Rutile– coated graphite cathode | Anaerobic sludge | 24 | 25 ± 1 | - | 10–20 | 73.4 | 0.13 ± 0.03 W/m2 | [122] |

| Model textile dyes | SMFC | Activated carbon | Hydrophobic carbon cloth | Proteus hauseri ZMd44 | 480 | 30 | - | 450–560 | 75 | 103 mW/m2 | [123] |

| Amaranth | DMFC | Granular graphite | Spectrographic pure graphite | - | 12 | - | 3.00 | 75 | 82.59 | 137.37 mW/m2 | [89] |

| Active brilliant red X-3 B | DMFC | Porous carbon paper | Porous carbon paper | Aerobic sludges | 12 | - | 7.00 | 300 | 90 | 213.93 mW/m2 | [91] |

| Congo red | SMFC | Carbon papers (non-wet proofed porous) | Carbon papers with Pt (wet porous) | Mixture of aerobic and sludge | - | 30 ± 1 | - | 300 | 90 | 324 mW/m2 | [101] |

| Acid orange 7 | DMFC | Carbon cloth | Carbon cloth | Shewanella oneidensis | 30 | 25 | 7.0 | 350 | >98 | - | [124] |

| Methylene blue | WMFC | Carbon | Carbon | Marine sludge | 96 | 25 | 4–6.1 | 500 | 93.15 | 15.73 mW/m2 | [125] |

| Congo red | SMFC | Plain carbon papers (non-wet proofed) | Carbon paper (wet-proofed) | Culture of aerobic and sludge | 26 | 30 ± 1 | - | - | 85 | 107 mW/m2 | [126] |

| Active brilliant red dye | DMFC | Granular-activated carbon | Stainless steel mesh | Anaerobic sludg | 72 | 25 ± 2 | - | - | 85.65 | 610 mW/m2 | [103] |

| Dye | DMFC | Granular activated carbon | Stainless steel mesh | Anaerobic sludge (Geobacter Sulfurreducensand) | 72 | 25 ± 2 | - | 150 | 91 | 610 mW/m2 | [103] |

| Azo dye | DMFC | Graphite-granules | Graphite-granules | Anaerobic sludge | 48 | - | 3–7 | - | 85 | 34.77 mW/m2 | [127] |

| Congo red | SMFC | Graphite felt | Carbon paper | Anaerobic sludge | 2880 | 30 ± 1 | 7 | 300 | 70 | 72.4 mW/m2 | [104] |

| Acid orange 7 | SMFC | Carbon Fabric | Carbon fabric | Azo dye acclimated mixed microbial | 60 | 26 | 8.2 | - | >90 | - | [128] |

| Methyl orange | DMFC | Carbon paper/graphene | Carbon paper | Anaerobic sludge | 180 | 30 ± 1 | 6.8–7 | - | 51 | 368 mW/m2 | [105] |

| Acid navy blue R | DMFC | Graphite rods | Graphite rods | Anaerobic sludge | - | 25 | - | 3000 | - | 0.125 mW/m2 | [129] |

| Thionine-based textile dye | SMFC | Porous carbon cloth | Porous carbon cloth | Proteus hauseri ZMd44 | 12 | 25 | 7 | 40 | - | 83.39 ± 0.28 mW/m2 | [130] |

| Navy blue r(ANB) dyes | SMFC | Graphite rod | Graphite rod | Aerobic and anaerobic Sludge | 48 | 27 ± 2 | 7.5–8.0 | 200 | - | 2236 mW/m2 | [131] |

| Acid orange 7 | SMFC | Carbon felt | Carbon felt | Mixed culture anaerobic sludge | 2160 | - | - | 75 | 90 | 174.3 ± 5.8 mW/m2 | [106] |

| Azo dye | DMFC | Activate carbon | Stainless steel mesh | Concentrated anaerobic sludge | 72 | 25 ± 2 | - | 300 | 96.5 | 0.852 W/m3, | [103] |

| Azo dye | SMFC | Carbon felt | Carbon plate | Mixed anaerobic sludge | 6 | 25 | 7.1 | 50 | 80.6 | 167.4 ± 11.6 W/m2 | [107] |

| Thionine-based textile Dyes | SMFC | Porous carbon cloth | Porous carbon cloth | Proteus hauseri | 48 | 30 | - | 40 | 50 | 83.4 mW/m2 | [107] |

| Congo red | DMFC | - | - | Shewanella oneidensis MR-1 | 24 | 28–40 | 6.0–8.5 | 2 g/L | 99.25 | - | [132] |

| Real dye textile wastewater | SMFC | Carbon fibres | Carbon fibres | Algal media | 720 | 25–26 | 7.5 | - | 42 | 123.2 ± 27.5 mW/m3 | [109] |

| Azo dye | DMFC | Carbon felt | Carbon felt | Anaerobic sludge | 72 | 28 ± 2 | - | - | 95.1 | 20.64 mW/m2 | [108] |

| Dyes | DMFC | Carbon rod | Carbon rod | Mixed culture (Pseudomonas aurogenosa and Pseudomonas fluresence) | 2 | - | - | 2500 | - | 469.48 mW/m2 | [133] |

| Methyl orange | DMFC | Carbon paper | Carbon paper | Mixed anaerobic sludge | 36 | - | - | - | 84.5 | 0.119 W/m2 | [111] |

| Congo red | DMFC | Graphite rod | Graphite rod | Mixed anaerobic sludge | 72 | 20 ± 3 | 7.00 | - | 90 | 808.3 mW/m3 | [134] |

| Azo dye | DMFC | Graphite brush | Activated carbon | Mixed-waste sludge | 720 | - | 6–8.5 | 260 | 85 | - | [135] |

| Methyl orange | DMFC | Graphite/polyester composite electrode | Graphite/polyester composite electrodes | P. aeruginosa. | 12 | 32 | 7.00 | - | 89.55 | 1575 ± 223.26 mW/m2 | [115] |

| Acid orange 7 | DMFC | Carbon felt | Carbon plate | Azo dye orange II | 1460 | - | 7.00 | 150 | 96 | 32.84 ± 23.57 W/m2 | [110] |

| Green dye | DMFC | Stainless steel meshes | Chromium plate | Geobacter sulfurreducens | 168 | 35 | 6.8 | - | 80 | 0.04 mW/m2 | [112] |

| Textile diazo dye | DMFC | Graphite felt | Graphite cloth | Proteobacteria, Deltaproteobacteria and Desulfovibrio | 24 | 30 | 7.0 | 100 | 90 | 258 ± 10 mW/m2 | [113] |

| Azo dye | WMFC | Carbon felt | Carbon felt | Mixed-culture sludge | 463 days | 28 ± 2 | 7.00 | 500 | 94–95 | 8.67 mW/m2 | [136] |

| Methyl orange | DMFC | Carbon brush | Graphite plate | Anaerobic sludge | 2 | 27 | 7 | 25 | 94.7 | - | [116] |

| Thionine-based textile dye | SMFC | Porous carbon cloth without catalyst | Porous carbon cloth with polytetrafluoroethylene as catalyst | Proteus hauseri ZMd44 | 120 | 25 | 7 | 40 | - | 83.39 ± 0.28 mW/m2 | [137] |

| Congo red | DMFC | Plain carbon felts | Carbon felt | Anaerobic sludge | 720 | 35 | - | 100 | 86.4 | 400 mW/m2 | [137] |

| Congo red | SMFC | Carbon paper | Carbon paper | Mixture of aerobic and anaerobic sludge | 36 | 30 | - | 300 | 98 | 103 mW/m2 | [36] |

| Congo red | SMFC | Graphite fibre brush | Graphite fibre with platinum | Anaerobic sludge | 24 | 25 | 7.00 | 200 | ≥88 | 23.50 mW/m2 | [117] |

4. Mechanism of Electricity Generation and Pollutant Removal in MFCs

5. Future Perspectives and Conclusive Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ab-Razak, N.H.; Praveena, S.M.; Aris, A.Z.; Hashim, Z. Drinking water studies: A review on heavy metal, application of biomarker and health risk assessment (a special focus in Malaysia). J. Epidemiol. Glob. Health 2015, 4, 297–310. [Google Scholar] [CrossRef]

- Sankhla, M.S.; Kumari, M.; Nandan, M.; Kumar, R.; Agrawal, P. Heavy metals contamination in water and their hazardous effect on human health—A review. Int. J. Curr. Microbiol. Appl. Sci. 2016, 5, 759–766. [Google Scholar] [CrossRef]

- Ahmad, A.; Khatoon, A.; Laskar, M.; Islam, A.; Mohammad, A.W.; Yong, N. Use of 2-hydroxy-3-methoxybenzaldehyde functionalized amberlite xad-16 for preconcentration and determination of trace metal ions by flame atomic absorption spectrometry. Der Pharma Chem. 2013, 1, 12–23. [Google Scholar]

- Yaqoob, A.A.; Parveen, T.; Umar, K.; Ibrahim, M.N.M. Role of nanomaterials in the treatment of wastewater: A review. Water 2020, 12, 495. [Google Scholar] [CrossRef]

- Azimi, A.; Azari, A.; Rezakazemi, M.; Ansarpour, M. Removal of heavy metals from industrial wastewaters: A review. ChemBioEng Rev. 2017, 4, 37–59. [Google Scholar] [CrossRef]

- Slate, A.J.; Whitehead, K.A.; Brownson, D.A.; Banks, C.E. Microbial fuel cells: An overview of current technology. Renew. Sustain. Energy Rev. 2019, 101, 60–81. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Ahmad, H.; Parveen, T.; Ahmad, A.; Oves, M.; Ismail, I.M.; Qari, H.A.; Umar, K.; Ibrahim, M.N.M. Recent Advances in Metal Decorated Nanomaterials and Their Various Biological Applications: A Review. Front. Chem. 2020, 8, 341. [Google Scholar] [CrossRef]

- Moradi, F.; Maleki, V.; Saleh-Ghadimi, S.; Kooshki, F.; Pourghassem, G.B. Potential roles of chromium on inflammatory biomarkers in diabetes: A Systematic. Clin. Exp. Pharmacol. 2019, 46, 975–983. [Google Scholar] [CrossRef]

- Saghazadeh, A.; Rezaei, N. Systematic review and meta-analysis links autism and toxic metals and highlights the impact of country development status: Higher blood and erythrocyte levels for mercury and lead, and higher hair antimony, cadmium, lead, and mercury. Prog. Neuro-Psychopharmacol. Biol. Psychiatry 2017, 79, 340–368. [Google Scholar] [CrossRef]

- Rajeswari, T.R.; Sailaja, N. Impact of heavy metals on environmental pollution. J. Chem. Pharm. Sci. 2014, 3, 175–181. [Google Scholar]

- Yaqoob, A.A.; Umar, K.; Ibrahim, M.N.M. Silver nanoparticles: Various methods of synthesis, size affecting factors and their potential applications—A review. Appl. Nanosci. 2020, 10, 1–10. [Google Scholar] [CrossRef]

- Alina, M.; Azrina, A.; Yunus, M.A.; Zakiuddin, M.S.; Izuan, M.E.H.; Rizal, M.R. Heavy metals (mercury, arsenic, cadmium, plumbum) in selected marine fish and shellfish along the Straits of Malacca. Int. Food Res. J. 2012, 19, 135–140. [Google Scholar]

- Areerachakul, N.; Sakulkhaemaruethai, S.; Johir, M.; Kandasamy, J.; Vigneswaran, S. Photocatalytic degradation of organic pollutants from wastewater using aluminium doped titanium dioxide. J. Water Process. Eng. 2019, 27, 177–184. [Google Scholar] [CrossRef]

- Phiri, I.; Ko, J.M.; Mushonga, P.; Kugara, J.; Onani, M.O.; Msamadya, S.; Kim, S.J.; Bon, C.Y.; Mugobera, S.; Siyaduba-Choto, K. Simultaneous removal of cationic, anionic and organic pollutants in highly acidic water using magnetic nanocomposite alginate beads. J. Water Process. Eng. 2019, 31, 100884. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Serrà, A.; Ibrahim, M.N.M. Advances and Challenges in Developing Efficient Graphene Oxide-Based ZnO Photocatalysts for Dye Photo-Oxidation. Nanomaterials 2020, 10, 932. [Google Scholar] [CrossRef]

- Dassanayake, K.; Jayasinghe, G.; Surapaneni, A.; Hetherington, C. A review on alum sludge reuse with special reference to agricultural applications and future challenges. Waste Manag. 2015, 38, 321–335. [Google Scholar] [CrossRef]

- Gouda, S.; Kerry, R.G.; Das, G.; Paramithiotis, S.; Shin, H.S.; Patra, J.K. Revitalization of plant growth promoting rhizobacteria for sustainable development in agriculture. Microbiol. Res. 2018, 206, 131–140. [Google Scholar] [CrossRef]

- Demirbas, A. Agricultural based activated carbons for the removal of dyes from aqueous solutions: A review. J. Hazard. Mater. 2019, 167, 1–9. [Google Scholar] [CrossRef]

- Nidheesh, P.; Zhou, M.; Oturan, M.A. An overview on the removal of synthetic dyes from water by electrochemical advanced oxidation processes. Chemosphere 2018, 197, 210–227. [Google Scholar] [CrossRef]

- Ahmad, A.; Mohd-Setapar, S.H.; Chuong, C.S.; Khatoon, A.; Wani, W.A.; Kumar, R.; Rafatullah, M. Recent advances in new generation dye removal technologies: Novel search for approaches to reprocess wastewater. RSC Adv. 2015, 39, 30801–30818. [Google Scholar] [CrossRef]

- Geissen, V.; Mol, H.; Klumpp, E.; Umlauf, G.; Nadal, M.; Van der Ploeg, M.; Van de Zee, S.E.; Ritsema, C.J. Emerging pollutants in the environment: A challenge for water resource management. Int. Soil Water Conserv. Res. 2015, 3, 57–65. [Google Scholar] [CrossRef]

- Gita, S.; Hussan, A.; Choudhury, T. Impact of textile dyes waste on aquatic environments and its treatment. Environ. Ecol. 2017, 35, 2349–2353. [Google Scholar]

- Upadhyay, K.; Pandey, A.C.; Manzoor, J. Impact of Dyes on the Chemistry of Water and its Implications: A Review. Biol. Bull. 2017, 3, 1–7. [Google Scholar]

- Bashir, M.J.; Amr, S.S.A.; Aziz, S.Q.; Aun, N.C.; Sethupathi, S. Wastewater treatment processes optimization using response surface methodology (RSM) compared with conventional methods: Review and comparative study. Middle-East J. Sci. Res. 2015, 23, 244–252. [Google Scholar]

- Rahimnejad, M.; Adhami, A.; Darvari, S.; Zirepour, A.; Oh, S.E. Microbial fuel cell as new technology for bioelectricity generation: A review. Alex. Eng. J. 2015, 54, 745–756. [Google Scholar] [CrossRef]

- Drendel, G.; Mathews, E.R.; Semenec, L.; Franks, A.E. Microbial Fuel Cells, Related Technologies, and Their Applications. Appl. Sci. 2018, 8, 2384. [Google Scholar] [CrossRef]

- Kim, K.Y.; Yang, W.; Logan, B.E. Impact of electrode configurations on retention time and domestic wastewater treatment efficiency using microbial fuel cells. Water Res. 2015, 80, 41–46. [Google Scholar] [CrossRef]

- Araneda, I.; Tapia, N.F.; Lizama Allende, K.; Vargas, I.T. Constructed Wetland-Microbial Fuel Cells for Sustainable Greywater Treatment. Water 2018, 10, 940. [Google Scholar] [CrossRef]

- Palanisamy, G.; Jung, H.Y.; Sadhasivam, T.; Kurkuri, M.D.; Kim, S.C.; Roh, S.H. A comprehensive review on microbial fuel cell technologies: Processes, utilization, and advanced developments in electrodes and membranes. J. Clean. Prod. 2019, 221, 598–621. [Google Scholar] [CrossRef]

- Santoro, C.; Arbizzani, C.; Erable, B.; Ieropoulos, I. Microbial fuel cells: From fundamentals to applications. A review. J. Power Sources 2017, 356, 225–244. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Umar, K.; Zahoor, A.; Ibrahim, M.N.M.; Akil, A.; Showkat, B.A. Synthesis of Ag@Polycarbazole Nanocomposite using Ferric Acetate as an Oxidant. Asian J. Chem. 2020, 5, 1069–1074. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Liu, H.; Liao, M. Novel Porous Nitrogen Doped Graphene/Carbon Black Composites as Efficient Oxygen Reduction Reaction Electrocatalyst for Power Generation in Microbial Fuel Cell. Nanomaterials 2019, 9, 836. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Lu, H.; Rufford, T.E.; Gaddam, R.R.; Duignan, T.T.; Fan, X.; Zhao, X.S. A flexible graphene–carbon fiber composite electrode with high surface area-normalized capacitance. Sustain. Energy Fuels 2019, 3, 1827–1832. [Google Scholar] [CrossRef]

- Logan, B.E.; Rabaey, K. Conversion of wastes into bioelectricity and chemicals by using microbial electrochemical technologies. Science 2012, 337, 686–690. [Google Scholar] [CrossRef]

- Cai, T.; Meng, L.; Chen, G.; Xi, Y.; Jiang, N.; Song, J.; Zheng, S.; Liu, Y.; Zhen, G.; Huang, M. Application of advanced anodes in microbial fuel cells for power generation: A review. Chemosphere 2020, 21, 125985. [Google Scholar] [CrossRef]

- Kumar, S.S.; Kumar, V.; Malyan, S.K.; Sharma, J.; Mathimani, T.; Maskarenj, M.S.; Ghosh, P.C.; Pugazhendhi, A. Microbial fuel cells (MFCs) for bioelectrochemical treatment of different wastewater streams. Fuel 2019, 254, 115526. [Google Scholar] [CrossRef]

- Song, H.L.; Zhu, Y.; Li, J. Electron transfer mechanisms, characteristics and applications of biological cathode microbial fuel cells–A mini review. Arab. J. Chem. 2019, 12, 2236–2243. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, Q.; Lee, D.J.; Ngo, H.H. Feasible use of microbial fuel cells for pollution treatment. Renew. Energy 2018, 129, 824–829. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Ibrahim, M.N.M. A Review Article of Nanoparticles; Synthetic Approaches and Wastewater Treatment Methods. Int. Res. J. Eng. Technol. 2019, 6, 1–7. [Google Scholar]

- Wu, Q.; Jiao, S.; Ma, M.; Peng, S. Microbial fuel cell system: A promising technology for pollutant removal and environmental remediation. Environ. Sci. Pollut. Res. 2020, 20, 1–6. [Google Scholar] [CrossRef]

- Aarthy, M.; Rajesh, T.; Thirunavoukkarasu, M. Critical review on microbial fuel cells for concomitant reduction of hexavalent chromium and bioelectricity generation. J. Chem. Technol. Biotechnol. 2020, 95, 1298–1307. [Google Scholar] [CrossRef]

- Leiva, E.; Leiva-Aravena, E.; Rodríguez, C.; Serrano, J.; Vargas, I. Arsenic removal mediated by acidic pH neutralization and iron precipitation in microbial fuel cells. Sci. Total Environ. 2018, 645, 471–481. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Logan, B.E. Copper anode corrosion affects power generation in microbial fuel cells. J. Chem. Technol. Biotechnol. 2014, 89, 471–474. [Google Scholar] [CrossRef]

- Ryu, E.Y.; Kim, M.; Lee, S.J. Characterization of microbial fuel cells enriched using Cr (VI)-containing sludge. J. Microbiol. Biotechnol. 2011, 21, 187–191. [Google Scholar] [CrossRef] [PubMed]

- Stein, N.E.; Hamelers, H.V.; Buisman, C.N. Influence of membrane type, current and potential on the response to chemical toxicants of a microbial fuel cell based biosensor. Sens. Actuators B Chem. 2012, 163, 1–7. [Google Scholar] [CrossRef]

- Xafenias, N.; Zhang, Y.; Banks, C.J. Enhanced performance of hexavalent chromium reducing cathodes in the presence of Shewanella oneidensis MR-1 and lactate. Environ. Sci. Technol. 2013, 47, 4512–4520. [Google Scholar] [CrossRef]

- Singhvi, P.; Chhabra, M. Simultaneous chromium removal and power generation using algal biomass in a dual chambered salt bridge microbial fuel cell. J. Bioremediat. Biodegrad. 2013, 4. [Google Scholar] [CrossRef]

- Varia, J.C.; Martinez, S.S.; Velasquez-Orta, S.; Bull, S. Microbiological influence of metal ion electrodeposition: Studies using graphite electrodes, [AuCl4]− and Shewanella putrefaciens. Electrochim. Acta 2014, 115, 344–351. [Google Scholar] [CrossRef]

- Nancharaiah, Y.; Mohan, S.V.; Lens, P. Metals removal and recovery in bioelectrochemical systems: A review. Bioresour. Technol. 2015, 195, 102–114. [Google Scholar] [CrossRef]

- Abbas, S.Z.; Rafatullah, M.; Ismail, N. Removal of metals (chromium and copper) and power generation through sediment microbial fuel cell. Int. J. Env. Technol. Sci. 2016, 2, 56–60. [Google Scholar]

- Habibul, N.; Hu, Y.; Sheng, G.P. Microbial fuel cell driving electrokinetic remediation of toxic metal contaminated soils. J. Hazard. Mater. 2016, 318, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Qiu, R.; Zhang, B.; Li, J.; Lv, Q.; Wang, S.; Gu, Q. Enhanced vanadium (V) reduction and bioelectricity generation in microbial fuel cells with biocathode. J. Power Sources 2017, 359, 379–383. [Google Scholar] [CrossRef]

- Gai, R.; Liu, Y.; Liu, J.; Yan, C.; Jiao, Y.; Cai, L.; Zhang, L. Behavior of copper, nickel, cadmium and mercury ions in anode chamber of microbial fuel cells. Int. J. Electrochem. Sci. 2018, 13, 3050–3062. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, L.; Zularisam, A.; Hai, F.I. Microbial fuel cell is emerging as a versatile technology: A review on its possible applications, challenges and strategies to improve the performances. Int. J. Energy Res. 2018, 42, 369–394. [Google Scholar] [CrossRef]

- Huang, L.; Zhou, P.; Quan, X.; Logan, B.E. Removal of binary Cr (VI) and Cd (II) from the catholyte of MFCs and determining their fate in EAB using fluorescence probes. Bioelectrochemistry 2018, 122, 61–68. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, B.; Jiang, Y.; Li, Y.; He, C. Spontaneous thallium (I) oxidation with electricity generation in single-chamber microbial fuel cells. Appl. Energy 2018, 209, 33–42. [Google Scholar] [CrossRef]

- Liu, Y.; Song, P.; Gai, R.; Yan, C.; Jiao, Y.; Yin, D.; Cai, L.; Zhang, L. Recovering platinum from wastewater by charring biofilm of microbial fuel cells (MFCs). J Saudi Chem. Soc. 2019, 23, 338–345. [Google Scholar] [CrossRef]

- Zhang, T.; Hu, L.; Zhang, M.; Jiang, M.; Fiedler, H.; Bai, W.; Wang, X.; Zhang, D.; Li, Z. Cr (VI) removal from soils and groundwater using an integrated adsorption and microbial fuel cell (A-MFC) technology. Environ. Pollut. 2019, 252, 1399–1405. [Google Scholar] [CrossRef]

- Li, F.; Jin, C.; Choi, C.; Lim, B. Simultaneous Removal and/or Recovery of Cr (Vi) And Cr (Iii) Using A Double Mfc Technique. Environ. Eng. Manag. J. 2019, 18, 235–242. [Google Scholar]

- Wu, Y.; Wang, L.; Jin, M.; Kong, F.; Qi, H.; Nan, J. Reduced graphene oxide and biofilms as cathode catalysts to enhance energy and metal recovery in microbial fuel cell. Bioresour. Technol. 2019, 283, 129–137. [Google Scholar] [CrossRef]

- Liu, Y.; Shen, L.; Song, P.; Chang, D.; Lu, Z.; Liu, Y.; Cai, L.; Zhang, L. Nickel (II) removal from wastewater by Microbial Fuel Cell. Int. J. Electrochem. Sci. 2019, 14, 196–204. [Google Scholar] [CrossRef]

- Mathuriya, A.S.; Yakhmi, J. Microbial fuel cells to recover heavy metals. Environ. Chem. Lett. 2014, 12, 483–494. [Google Scholar] [CrossRef]

- Heming, W.; Xueyong, S.; Huihui, Z.; Pan, T.; Fanxin, K. Removal of hexavalent chromium in dual-chamber microbial fuel cells separated by different ion exchange membranes. J. Hazard. Mater. 2020, 384, 121459. [Google Scholar]

- Jingran, Z.; Xian, C.; Wang, H.; Xizi, L.; Xianning, L. Simultaneous enhancement of heavy metal removal and electricity generation in soil microbial fuel cell. Ecotoxicol. Environ. Saf. 2020, 192, 110314. [Google Scholar]

- Ankisha, V.; Amitap, K.; Meenu, C.; Tessy, V. Microbial fuel cell for simultaneous removal of uranium (VI) and nitrate. Chem. Eng. J. 2020, 388, 124157. [Google Scholar]

- Hsu, L.; Mohamed, A.; Ha, P.T.; Bloom, J.; Ewing, T.; Arias-Thode, M.; Chadwick, B.; Beyenal, H. The influence of energy harvesting strategies on performance and microbial community for sediment microbial fuel cells. J. Electrochem. Soc. 2017, 64, H3109–H3114. [Google Scholar] [CrossRef]

- Shukla, M.A.Y.; Vaghela, K.; Jain, N. Eco-friendly approach for environment pollution: A review on bioremediation. Int. J. Curr. Adv. Res. 2017, 6, 6956–6961. [Google Scholar]

- Do, M.; Ngo, H.; Guo, W.; Liu, Y.; Chang, S.; Nguyen, D.; Nghiem, L.; Ni, B. Challenges in the application of microbial fuel cells to wastewater treatment and energy production: A mini review. Sci. Total Environ. 2018, 639, 910–920. [Google Scholar] [CrossRef]

- Wang, G.; Huang, L.; Zhang, Y. Cathodic reduction of hexavalent chromium [Cr (VI)] coupled with electricity generation in microbial fuel cells. Biotechnol. Lett. 2008, 30, 1959. [Google Scholar] [CrossRef]

- Li, Y.; Lu, A.; Ding, H.; Jin, S.; Yan, Y.; Wang, C. Cr (VI) reduction at rutile-catalyzed cathode in microbial fuel cells. Electrochem. Commun. 2009, 11, 1496–1499. [Google Scholar] [CrossRef]

- Catal, T.; Bermek, H.; Liu, H. Removal of selenite from wastewater using microbial fuel cells. Biotechnol. Lett. 2009, 31, 1211–1216. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.G.; Zhou, S.G.; Zhao, H.Z.; Shi, C.H.; Kong, L.C.; Sun, J.J. Factors affecting the performance of microbial fuel cells for sulfide and vanadium (V) treatment. Bioprocess Biosyst. Eng. 2010, 33, 187–194. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Chen, J.; Quan, X.; Yang, F. Enhancement of hexavalent chromium reduction and electricity production from a biocathode microbial fuel cell. Bioprocess Biosyst. Eng. 2010, 33, 937–945. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.C.; Li, W.; Liang, M.; Xu, N.; Ni, J.R.; Wu, W.M. A membrane-free baffled microbial fuel cell for cathodic reduction of Cu (II) with electricity generation. Bioresour. Technol. 2011, 102, 4774–4778. [Google Scholar] [CrossRef]

- Tao, H.C.; Liang, M.; Li, W.; Zhang, L.J.; Ni, J.R.; Wu, W.M. Removal of copper from aqueous solution by electrodeposition in cathode chamber of microbial fuel cell. J. Hazard Mater. 2011, 189, 186–192. [Google Scholar] [CrossRef]

- Wang, Z.; Lim, B.; Choi, C. Removal of Hg2+ as an electron acceptor coupled with power generation using a microbial fuel cell. Bioresour. Technol. 2011, 102, 6304–6307. [Google Scholar] [CrossRef]

- Modin, O.; Wang, X.; Wu, X.; Rauch, S.; Fedje, K.K. Bioelectrochemical recovery of Cu, Pb, Cd, and Zn from dilute solutions. J. Hazard. Mater. 2012, 235, 291–297. [Google Scholar] [CrossRef]

- Zhang, B.; Feng, C.; Ni, J.; Zhang, J.; Huang, W. Simultaneous reduction of vanadium (V) and chromium (VI) with enhanced energy recovery based on microbial fuel cell technology. J. Power Sources 2012, 204, 34–39. [Google Scholar] [CrossRef]

- Choi, C.; Cui, Y. Recovery of silver from wastewater coupled with power generation using a microbial fuel cell. Bioresour. Technol. 2012, 107, 522–525. [Google Scholar] [CrossRef]

- Jiang, Y.; Ulrich, A.C.; Liu, Y. Coupling bioelectricity generation and oil sands tailings treatment using microbial fuel cells. Bioresour. Technol. 2013, 139, 349–354. [Google Scholar] [CrossRef]

- Choi, C.; Hu, N. The modeling of gold recovery from tetrachloroaurate wastewater using a microbial fuel cell. Bioresour. Technol. 2013, 133, 589–598. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.H.; Wang, B.S.; Pan, B.; Chen, Q.Y.; Yan, W. Electricity production from a bio-electrochemical cell for silver recovery in alkaline media. Appl. Energy. 2013, 112, 1337–1341. [Google Scholar] [CrossRef]

- Huang, L.; Li, T.; Liu, C.; Quan, X.; Chen, L.; Wang, A. Synergetic interactions improve cobalt leaching from lithium cobalt oxide in microbial fuel cells. Bioresour. Technol. 2013, 128, 539–546. [Google Scholar] [CrossRef] [PubMed]

- Ya-li, F.; Wei-da, W.; Xin-hua, T.; Hao-ran, L.; Zhuwei, D.; Zhi-chao, Y. Isolation and characterization of an electrochemically active and cyanide-degrading bacterium isolated from a microbial fuel cell. RSC Adv. 2014, 4, 36458–36463. [Google Scholar] [CrossRef]

- Abourached, C.; Catal, T.; Liu, H. Efficacy of single-chamber microbial fuel cells for removal of cadmium and zinc with simultaneous electricity production. Water Res. 2014, 51, 228–233. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, X.; Jin, M.; Li, Y.; Li, S.; Kong, F. Copper removal and microbial community analysis in single-chamber microbial fuel cell. Bioresour. Technol. 2018, 253, 372–377. [Google Scholar] [CrossRef]

- Preethi, J.; Vigneshwaran, S.; Meenakshi, S. Performance of chitosan engraved iron and lanthanum mixed oxyhydroxide for the detoxification of hexavalent chromium. Inter. J. Biol. Macromol. 2019, 130, 491–498. [Google Scholar] [CrossRef]

- Wu, D.; Huang, L.; Quan, X.; Puma, G.L. Electricity generation and bivalent copper reduction as a function of operation time and cathode electrode material in microbial fuel cells. J. Power Sources. 2016, 307, 705–714. [Google Scholar] [CrossRef]

- Fu, L.; You, S.J.; Zhang, G.; Yang, F.L.; Fang, X. Degradation of azo dyes using in-situ Fenton reaction incorporated into H2O2-producing microbial fuel cell. Chem. Eng. J. 2010, 160, 164–169. [Google Scholar] [CrossRef]

- Chen, B.Y.; Zhang, M.M.; Ding, Y.; Chang, C.T. Feasibility study of simultaneous bioelectricity generation and dye decolorization using naturally occurring decolorizers. J. Taiwan Inst Chem Eng. 2010, 6, 682–688. [Google Scholar] [CrossRef]

- Sun, J.; Bi, Z.; Hou, B.; Cao, Y.; Hu, Y. Further treatment of decolorization liquid of azo dye coupled with increased power production using microbial fuel cell equipped with an aerobic biocathode. Water Res. 2011, 45, 283–291. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Hu, Y.; Hou, B. Electrochemical characteriztion of the bioanode during simultaneous azo dye decolorization and bioelectricity generation in an air-cathode single chambered microbial fuel cell. Electrochim. Acta 2011, 56, 6874–6879. [Google Scholar] [CrossRef]

- Hou, B.; Sun, J.; Hu, Y. Effect of enrichment procedures on performance and microbial diversity of microbial fuel cell for Congo red decolorization and electricity generation. Appl. Microbiol. Biotechnol. 2011, 4, 1563–1572. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.H.; Sheng, G.P.; Sun, M.; Zang, G.L.; Li, W.W.; Tong, Z.H.; Dong, F.; Lam, M.H.-W.; Yu, H.Q. Enhanced reductive degradation of methyl orange in a microbial fuel cell through cathode modification with redox mediators. Appl. Microbiol. Biotechnol. 2011, 89, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.Y.; Wang, Y.M.; Ng, I.S.; Liu, S.Q.; Hung, J.Y. Deciphering simultaneous bioelectricity generation and dye decolorization using Proteus hauseri. J. Biosci. Bioeng. 2012, 113, 502–507. [Google Scholar] [CrossRef] [PubMed]

- Hou, B.; Hu, Y.; Sun, J. Performance and microbial diversity of microbial fuel cells coupled with different cathode types during simultaneous azo dye decolorization and electricity generation. Bioresour. Technol. 2012, 111, 105–110. [Google Scholar] [CrossRef] [PubMed]

- Parmar, N.D.; Shukla, S.R. Decolourization of dye wastewater by microbial methods—A review. India J. Chem. Technol. 2019, 4, 315–323. [Google Scholar]

- Krzeminski, P.; Tomei, M.C.; Karaolia, P.; Langenhoff, A.; Almeida, C.M.R.; Felis, E.; Gritten, F.; Andersen, H.R.; Fernandes, T.; Manaia, C.M. Performance of secondary wastewater treatment methods for the removal of contaminants of emerging concern implicated in crop uptake and antibiotic resistance spread: A review. Sci. Total Environ. 2019, 648, 1052–1081. [Google Scholar] [CrossRef]

- Bakhshian, S.; Kariminia, H.R.; Roshandel, R. Bioelectricity generation enhancement in a dual chamber microbial fuel cell under cathodic enzyme catalyzed dye decolorization. Bioresour. Technol. 2011, 102, 6761–6765. [Google Scholar] [CrossRef]

- Ali, I. New generation adsorbents for water treatment. Chem. Rev. 2012, 112, 5073–5091. [Google Scholar] [CrossRef]

- Hou, B.; Sun, J.; Hu, Y. Simultaneous Congo red decolorization and electricity generation in air-cathode single-chamber microbial fuel cell with different microfiltration, ultrafiltration and proton exchange membranes. Bioresour. Technol. 2011, 102, 4433–4438. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.K.; Dash, P.; Mohanty, A.; Abbassi, R.; Mishra, B.K. Performance assessment of innovative constructed wetland-microbial fuel cell for electricity production and dye removal. Ecol. Eng. 2012, 47, 126–131. [Google Scholar] [CrossRef]

- Fang, Z.; Song, H.L.; Cang, N.; Li, X.N. Performance of microbial fuel cell coupled constructed wetland system for decolorization of azo dye and bioelectricity generation. Bioresour. Technol. 2013, 144, 165–171. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Li, Y.; Hu, Y.; Hou, B.; Zhang, Y.; Li, S. Understanding the degradation of Congo red and bacterial diversity in an air–cathode microbial fuel cell being evaluated for simultaneous azo dye removal from wastewater and bioelectricity generation. Appl. Microbiol. Biotechnol. 2013, 97, 3711–3719. [Google Scholar] [CrossRef]

- Guo, W.; Cui, Y.; Song, H.; Sun, J. Layer-by-layer construction of graphene-based microbial fuel cell for improved power generation and methyl orange removal. Bioprocess Biosyst. Eng. 2014, 37, 1749–1758. [Google Scholar] [CrossRef]

- Thung, W.E.; Ong, S.A.; Ho, L.N.; Wong, Y.S.; Ridwan, F.; Oon, Y.L.; Oon, Y.S.; Lehl, H.K. A highly efficient single chambered up-flow membrane-less microbial fuel cell for treatment of azo dye Acid Orange 7-containing wastewater. Bioresour. Technol. 2015, 197, 284–288. [Google Scholar] [CrossRef]

- Chen, B.Y.; Ma, C.M.; Han, K.; Yueh, P.L.; Qin, L.J.; Hsueh, C.C. Influence of textile dye and decolorized metabolites on microbial fuel cell-assisted bioremediation. Bioresour. Technol. 2016, 200, 1033–1038. [Google Scholar] [CrossRef]

- Oon, Y.S.; Ong, S.A.; Ho, L.N.; Wong, Y.S.; Oon, Y.L.; Lehl, H.K.; Thung, W.E.; Nordin, N. Microbial fuel cell operation using monoazo and diazo dyes as terminal electron acceptor for simultaneous decolourisation and bioelectricity generation. J. Hazard. Mater. 2017, 325, 170–177. [Google Scholar] [CrossRef]

- Logroño, W.; Pérez, M.; Urquizo, G.; Kadier, A.; Echeverría, M.; Recalde, C.; Rákhely, G. Single chamber microbial fuel cell (SCMFC) with a cathodic microalgal biofilm: A preliminary assessment of the generation of bioelectricity and biodegradation of real dye textile wastewater. Chemosphere 2017, 176, 378–388. [Google Scholar] [CrossRef]

- Thung, W.E.; Ong, S.A.; Ho, L.N.; Wong, Y.S.; Ridwan, F.; Lehl, H.K.; Oon, Y.L.; Oon, Y.S. Biodegradation of acid orange 7 in a combined anaerobic-aerobic up-flow membrane-less microbial fuel cell: Mechanism of biodegradation and electron transfer. Chem. Eng. J. 2018, 336, 397–405. [Google Scholar] [CrossRef]

- Han, H.X.; Shi, C.; Yuan, L.; Sheng, G.P. Enhancement of methyl orange degradation and power generation in a photoelectrocatalytic microbial fuel cell. Appl. Energy 2017, 204, 382–389. [Google Scholar] [CrossRef]

- Khalid, S.; Alvi, F.; Fatima, M.; Aslam, M.; Riaz, S.; Farooq, R.; Zhang, Y. Dye degradation and electricity generation using microbial fuel cell with graphene oxide modified anode. Mater. Lett. 2018, 220, 272–276. [Google Scholar] [CrossRef]

- Miran, W.; Jang, J.; Nawaz, M.; Shahzad, A.; Lee, D.S. Sulfate-reducing mixed communities with the ability to generate bioelectricity and degrade textile diazo dye in microbial fuel cells. J. Hazard. Mater. 2018, 352, 70–79. [Google Scholar] [CrossRef] [PubMed]

- Sarma, M.K.; Quadir, M.G.A.; Bhaduri, R.; Kaushik, S.; Goswami, P. Composite polymer coated magnetic nanoparticles based anode enhances dye degradation and power production in microbial fuel cells. Biosens. Bioelectron. 2018, 119, 94–102. [Google Scholar] [CrossRef]

- Narayanasamy, S.; Jayaprakash, J. Improved performance of Pseudomonas aeruginosa catalyzed MFCs with graphite/polyester composite electrodes doped with metal ions for azo dye degradation. Chem. Eng. J. 2018, 343, 258–269. [Google Scholar] [CrossRef]

- You, Y.; Huang, S.; Zhao, X.; Li, H.; Cheng, F.; Wu, J.; Zhang, Y.; Zhou, S. Hybrid microbial electrolytic/UV system for highly efficient organic pollutants removal. J. Environ. Sci. 2019, 83, 39–45. [Google Scholar] [CrossRef]

- Dai, Q.; Zhang, S.; Liu, H.; Huang, J.; Li, L. Sulfide-mediated azo dye degradation and microbial community analysis in a single-chamber air cathode microbial fuel cell. Bioelectrochemistry 2020, 131, 107349. [Google Scholar] [CrossRef]

- Sonu, K.; Zainab, S.; Monika, S. Up-scaling microbial fuel cell systems for the treatment of real textile dye wastewater and bioelectricity recovery. Int. J. Environ. Stud. 2020, 1–11. [Google Scholar] [CrossRef]

- Yoong, L.O.; Soon-An, O.; Li-Ngee, H.; Yee-Shian, W.; Farrah, A.D.; Yoong-Sin, O.; Tean-Peng, T.; Harvinder, K.L.; Wei-Eng, T. Constructed wetland–microbial fuel cell for azo dyes degradation and energy recovery: Influence of molecular structure, kinetics, mechanisms and degradation pathways. Sci. Total Environ. 2020, 720, 137370. [Google Scholar]

- Mu, Y.; Rabaey, K.; Rozendal, R.A.; Yuan, Z.; Keller, J. Decolorization of azo dyes in bioelectrochemical systems. Environ. Sci. Technol. 2009, 43, 5137–5143. [Google Scholar] [CrossRef]

- Liu, L.; Li, F.B.; Feng, C.; Li, X.Z. Microbial fuel cell with an azo-dye-feeding cathode. Appl. Microbiol. Biotechnol. 2009, 85, 175. [Google Scholar] [CrossRef] [PubMed]

- Ding, H.; Li, Y.; Lu, A.; Jin, S.; Quan, C.; Wang, C. Photocatalytically improved azo dye reduction in a microbial fuel cell with rutile-cathode. Bioresour. Technol. 2010, 101, 3500–3505. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.Y.; Zhang, M.M.; Chang, C.T.; Ding, Y.; Lin, K.L.; Chiou, C.S. Assessment upon azo dye decolorization and bioelectricity generation by Proteus hauseri. Bioresour. Technol. 2010, 101, 4737–4741. [Google Scholar] [CrossRef] [PubMed]

- Fernando, E.; Keshavarz, T.; Kyazze, G. Enhanced bio-decolourisation of acid orange 7 by Shewanella oneidensis through co-metabolism in a microbial fuel cell. Int. Biodeterior. Biodegrad. 2012, 72, 1–9. [Google Scholar] [CrossRef]

- Di, L.; Li, Y.; Nie, L.; Wang, S.; Kong, F. Influence of plant radial oxygen loss in constructed wetland combined with microbial fuel cell on nitrobenzene removal from aqueous solution. J. Hazard. Mater. 2020, 18, 122542. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Li, Y.; Hu, Y.; Hou, B.; Xu, Q.; Zhang, Y. Enlargement of anode for enhanced simultaneous azo dye decolorization and power output in air-cathode microbial fuel cell. Biotechnol. Lett. 2012, 34, 2023–2029. [Google Scholar] [CrossRef]

- Solanki, K.; Subramanian, S.; Basu, S. Microbial fuel cells for azo dye treatment with electricity generation: A review. Bioresour. Technol. 2013, 131, 564–571. [Google Scholar] [CrossRef]

- Fernando, E.; Keshavarz, T.; Kyazze, G. Complete degradation of the azo dye Acid Orange-7 and bioelectricity generation in an integrated microbial fuel cell, aerobic two-stage bioreactor system in continuous flow mode at ambient temperature. Bioresour. Technol. 2014, 156, 155–162. [Google Scholar] [CrossRef]

- Khan, M.Z.; Singh, S.; Sultana, S.; Sreekrishnan, T.R.; Ahammad, S.Z. Studies on the biodegradation of two different azo dyes in bioelectrochemical systems. New J. Chem. 2015, 39, 5597–5604. [Google Scholar] [CrossRef]

- Chen, B.Y.; Xu, B.; Yueh, P.L.; Han, K.; Qin, L.J.; Hsueh, C.C. Deciphering electron-shuttling characteristics of thionine-based textile dyes in microbial fuel cells. J. Taiwan Inst. Chem. Eng. 2015, 51, 63–70. [Google Scholar] [CrossRef]

- Khan, M.D.; Abdulateif, H.; Ismail, I.M.; Sabir, S.; Khan, M.Z. Bioelectricity generation and bioremediation of an azo-dye in a microbial fuel cell coupled activated sludge process. PLoS ONE 2015, 10, e0138448. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Liu, L.; Liu, C.; Hao, Y.; Yang, H.; Yuan, B. Methylene blue enhances the anaerobic decolorization and detoxication of azo dye by Shewanella onediensis MR-1. Biochem. Eng. J. 2016, 110, 115–124. [Google Scholar] [CrossRef]

- Kawale, H.D.; Ranveer, A.C.; Chavan, A.R. Electricity generation from wastewater using a microbial fuel cell by using mixed bacterial culture. J. Biochem. Technol. 2017, 7, 1123–1127. [Google Scholar]

- Yuan, G.E.; Li, Y.; Lv, J.; Zhang, G.; Yang, F. Integration of microbial fuel cell and catalytic oxidation reactor with iron phthalocyanine catalyst for Congo red degradation. Biochem. Eng. J. 2017, 120, 118–124. [Google Scholar] [CrossRef]

- Long, X.; Pan, Q.; Wang, C.; Wang, H.; Li, H.; Li, X. Microbial fuel cell-photoelectrocatalytic cell combined system for the removal of azo dye wastewater. Bioresour. Technol. 2017, 244, 182–191. [Google Scholar] [CrossRef]

- Oon, Y.L.; Ong, S.A.; Ho, L.N.; Wong, Y.S.; Dahalan, F.A.; Oon, Y.S. Up-flow constructed wetland-microbial fuel cell for azo dye, saline, nitrate remediation and bioelectricity generation: From waste to energy approach. Bioresour. Technol. 2018, 266, 97–108. [Google Scholar] [CrossRef]

- Xu, B.; Sun, Q.J.; Lan, J.C.W.; Chang, M.H.; Hsueh, C.C.; Chen, B.Y. Deciphering electron-shuttling characteristics of microalgal metabolites upon bioelectricity-generating community in microbial fuel cells. Biochem. Eng. J. 2019, 144, 148–156. [Google Scholar] [CrossRef]

- Almatouq, A.; Babatunde, A.O.; Khajah, M.; Webster, G.; Alfodari, M. Microbial community structure of anode electrodes in microbial fuel cells and microbial electrolysis cells. J. Water Process Eng. 2020, 34, 101140. [Google Scholar] [CrossRef]

- Sophia, A.C.; Saikant, S. Reduction of chromium (VI) with energy recovery using microbial fuel cell technology. J. Water Process Eng. 2016, 11, 39–45. [Google Scholar] [CrossRef]

- Bond, D.R.; Holmes, D.E.; Tender, L.M.; Lovley, D.R. Electrode-reducing microorganisms that harvest energy from marine sediments. Science 2002, 295, 483–485. [Google Scholar] [CrossRef]

- Zhang, B.; Li, W.; Guo, Y.; Zhang, Z.; Shi, W.; Cui, F.; Lens, P.N.; Tay, J.H. Microalgal-bacterial consortia: From interspecies interactions to biotechnological applications. Renew. Sustain. Energy Rev. 2020, 118, 109563. [Google Scholar] [CrossRef]

- Estevez-Canales, M.; Kuzume, A.; Borjas, Z.; Füeg, M.; Lovley, D.; Wandlowski, T.; Esteve-Núñez, A. A severe reduction in the cytochrome C content of Geobacter sulfurreducens eliminates its capacity for extracellular electron transfer. Environ. Microbiol. Rep. 2015, 7, 219–226. [Google Scholar] [CrossRef] [PubMed]

- Lovley, D.R. Live wires: Direct extracellular electron exchange for bioenergy and the bioremediation of energy-related contamination. Energy Environ. Sci. 2011, 4, 4896–4906. [Google Scholar] [CrossRef]

- Shrestha, P.M.; Rotaru, A.E. Plugging in or going wireless: Strategies for interspecies electron transfer. Front. Microbiol. 2014, 5, 1–8. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, X.; Tao, X.; Yao, C.; Tsang, D.C.; Cao, X. Interaction with low molecular weight organic acids affects the electron shuttling of biochar for Cr (VI) reduction. J. Hazard Mater. 2019, 378, 120705. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Lee, K.S.; Sorcar, S.; Razzaq, A.; Craig, A.; Craig, A.G.; Su-Il, I. Wastewater treatment and electricity generation from a sunlight-powered single chamber microbial fuel cell. J. Photochem. Photobiol. A Chem. 2018, 358, 432–440. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, L.; Wahid, Z.A.; Din, M.F.M. Exoelectrogens in microbial fuel cells toward bioelectricity generation: A review. Int. J. Energy Res. 2015, 39, 1048–1067. [Google Scholar] [CrossRef]

- Orellana, R.; Leavitt, J.J.; Comolli, L.R.; Csencsits, R.; Janot, N.; Flanagan, K.A.; Gray, A.S.; Leang, C.; Izallalen, M.; Mester, T. U (VI) reduction by diverse outer surface c-type cytochromes of Geobacter sulfurreducens. Appl. Environ. Microbiol. 2013, 79, 6369–6374. [Google Scholar] [CrossRef]

- Bermek, H.; Catal, T.; Akan, S.S.; Ulutaş, M.S.; Kumru, M.; Özgüven, M.; Liu, H.; Özçelik, B.; Akarsubaşı, A.T. Olive mill wastewater treatment in single-chamber air-cathode microbial fuel cells. World J. Microbiol. Biotechnol. 2014, 30, 1177–1185. [Google Scholar] [CrossRef]

- Mathuriya, A.S.; Sharma, V. Bioelectricity production from paper industry waste using a microbial fuel cell by Clostridium species. J. Biochem. Technol. 2009, 1, 49–52. [Google Scholar]

- Singh, H.M.; Pathak, A.K.; Chopra, K.; Tyagi, V.; Anand, S.; Kothari, R. Microbial fuel cells: A sustainable solution for bioelectricity generation and wastewater treatment. Biofuels 2019, 10, 11–31. [Google Scholar] [CrossRef]

- Xiao, L.; Damien, J.; Luo, J.; Jang, H.D.; Huang, J.; He, Z. Crumpled graphene particles for microbial fuel cell electrodes. J. Power Sources 2012, 208, 187–192. [Google Scholar] [CrossRef]

- Gnana, K.G.; Kirubaharan, C.J.; Udhayakumar, S.; Ramachandran, K.; Karthikeyan, C.; Renganathan, R.; Nahm, K.S. Synthesis, structural, and morphological characterizations of reduced graphene oxide-supported polypyrrole anode catalysts for improved microbial fuel cell performances. ACS Sustain. Chem. Eng. 2014, 10, 2283–2290. [Google Scholar] [CrossRef]

- Khan, N.; Khan, M.D.; Nizami, A.S.; Rehan, M.; Shaida, A.; Ahmad, A.; Khan, M.Z. Energy generation through bioelectrochemical degradation of pentachlorophenol in microbial fuel cell. RSC Adv. 2018, 37, 20726–20736. [Google Scholar] [CrossRef]

- Hung, Y.H.; Liu, T.Y.; Chen, H.Y. Renewable Coffee Waste-Derived Porous Carbons as Anode Materials for High-Performance Sustainable Microbial Fuel Cells. ACS Sustain. Chem. Eng. 2019, 7, 16991–16999. [Google Scholar] [CrossRef]

- Jafar, A.; Lei, W.; Hassan, W.; Ridha, D.; Oladoja, N.A.; Gang, P. FeS@rGO nanocomposites as electrocatalysts for enhanced chromium removal and clean energy generation by microbial fuel cell. Chem. Eng. J. 2020, 384, 123335. [Google Scholar]

- Wei, J.; Liang, P.; Huang, X. Recent progress in electrodes for microbial fuel cells. Bioresour. Technol. 2011, 102, 9335–9344. [Google Scholar] [CrossRef]

- Liu, J.; Qiao, Y.; Guo, C.X.; Lim, S.; Song, H.; Li, C.M. Graphene/carbon cloth anode for high-performance mediatorless microbial fuel cells. Bioresour. Technol. 2012, 114, 275–280. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Y.; Shi, F.; Zhang, J.; Zhu, J.J. High biocurrent generation in Shewanella-inoculated microbial fuel cells using ionic liquid functionalized graphene nanosheets as an anode. Chem Commun. 2013, 49, 6668–6670. [Google Scholar] [CrossRef]

- Zhao, C.; Gai, P.; Liu, C.; Wang, X.; Xu, H.; Zhang, J. Polyaniline networks grown on graphene nanoribbons-coated carbon paper with a synergistic effect for high-performance microbial fuel cells. J. Mater. Chem A. 2013, 1, 12587–12594. [Google Scholar] [CrossRef]

- Wang, Y.; Li, B.; Zeng, L.; Cui, D.; Xiang, X.; Li, W. Polyaniline/mesoporous tungsten trioxide composite as anode electrocatalyst for high-performance microbial fuel cells. Biosens. Bioelectron. 2013, 41, 582–588. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Xing, D.; Lu, L.; Wei, M.; Liu, B.; Ren, N. Ferric iron enhances electricity generation by Shewanella oneidensis MR-1 in MFCs. Bioresour. Technol. 2013, 135, 630–634. [Google Scholar] [CrossRef] [PubMed]

- Mehdinia, A.; Ziaei, E.; Jabbari, A. Facile microwave-assisted synthesized reduced graphene oxide/tin oxide nanocomposite and using as anode material of microbial fuel cell to improve power generation. Int. J. Hydrog. Energy 2014, 39, 10724–10730. [Google Scholar] [CrossRef]

- Kirubaharan, C.J.; Santhakumar, K.; Senthilkumar, N.; Jang, J.H. Nitrogen doped graphene sheets as metal free anode catalysts for the high performance microbial fuel cells. Inter. J. Hydrog. Energy 2015, 40, 13061–13070. [Google Scholar] [CrossRef]

- Qiao, Y.; Wen, G.Y.; Wu, X.S.; Zou, L. L-Cysteine tailored porous graphene aerogel for enhanced power generation in microbial fuel cells. RSC Adv. 2015, 5, 58921–58927. [Google Scholar] [CrossRef]

- Sulonen, M.L.; Kokko, M.E.; Lakaniemi, A.M.; Puhakka, J.A. Electricity generation from tetrathionate in microbial fuel cells by acidophiles. J. Hazard. Mater. 2015, 284, 182–189. [Google Scholar] [CrossRef]

- Huang, L.; Li, X.; Ren, Y.; Wang, X. A monolithic three-dimensional macroporous graphene anode with low cost for high performance microbial fuel cells. RSC Adv. 2016, 6, 21001–21010. [Google Scholar] [CrossRef]

- Huang, H.; Cheng, S.; Yang, J.; Li, C.; Sun, Y.; Cen, K. Effect of nitrate on electricity generation in single-chamber air cathode microbial fuel cells. Chem. Eng. J. 2018, 337, 661–670. [Google Scholar] [CrossRef]

- Rahimnejad, M.; Bakeri, G.; Najafpour, G.; Ghasemi, M.; Oh, S.-E. A review on the effect of proton exchange membranes in microbial fuel cells. Biofuel Res. J. 2014, 1, 7–15. [Google Scholar] [CrossRef]

- Dong, Y.; Qu, Y.; He, W.; Du, Y.; Liu, J.; Han, X.; Feng, Y. A 90-liter stackable baffled microbial fuel cell for brewery wastewater treatment based on energy self-sufficient mode. Bioresour. Technol. 2015, 195, 66–72. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Ibrahim, M.N.M.; Rafatullah, M.; Chua, Y.S.; Ahmad, A.; Umar, K. Recent Advances in Anodes for Microbial Fuel Cells: An Overview. Materials 2020, 13, 2078. [Google Scholar] [CrossRef] [PubMed]

| Type of Electrodes | Microbes | Power Density | Reference | |

|---|---|---|---|---|

| Anode | Cathode | |||

| Plain carbon paper | Plain carbon paper | C. acetobutylicum and C. Thermohydrosulfuricum | 7.18 mW/m2 | [156] |

| Activated Carbon | Hydrophobic carbon cloth | Proteus hauseri ZMd44 | 103 mW/m2 | [123] |

| Graphite felts | Graphite felts | Actinobacteria, Β-Proteobacteria, | - | [44] |

| Graphite plates | Platinum meshes | Shewanella oneidensis | 1410 mW/m2 | [157] |

| Activated carbon cloth | Graphite foil | D. desulfurisers strain | 0.51 mW/cm2 | [157] |

| Carbon cloth/graphene | Carbon cloth | P. aeruginosa | 52.5 mW/m2 | [158] |

| Activated carbon | Carbon cloth | - | 1.7 mW/m3 | [151] |

| Graphite felt | Graphite rod | Shewanella oneidensis MR-1 | 32.5 mW/m2 | [46] |

| Granular activated carbon | Stainless steel mesh | Geobacter Sulfurreducens and Beta Proteobacteria | 610 mW/m2 | [46] |

| Carbon paper/graphene sheet | Carbon cloth | S. oneidensis MR-1 | 610 mW/m2 | [159] |

| Polyaniline (PANI) networks onto graphene nanoribbons (GNRs)-coated on carbon paper | Carbon paper | S. oneidensis MR-1 | 856 mW/m2 | [160] |

| Carbon felt | - | E. coli | 0.98 W/m2 | [161] |

| Carbon cloth | Carbon cloth with Pt as catalyst | Shewanella oneidensis MR-1 | 158.1 mW/m2 | [162] |

| rGO/SnO2/Carbon cloth composite | Pt rode | E. coli | 1624 mW/m2 | [163] |

| Polymer coated magnetic compositeelectrode | Toray carbon paper | Synechococcus sp. | 4.9 ± 0.5 W/m3 | [128] |

| Carbon cloth/Reduced graphene/polypyrrole | Carbon paper | E. coli | 1068 mW/m2 | [152] |

| Carbon cloth | Carbon cloth | Klebsiella sp. MC-1 | 412 mW/m2 | [84] |

| Pt-graphite | Pt-graphite | Shewanella genus | - | [48] |

| Carbon cloth/N-doped graphene nanosheets | Carbon cloth | E. coli | 1008 mW/m2 | [164] |

| Carbon cloth/graphene | Carbon cloth | S. putrefaciens CN32 | 679.7 mW/m2 | [165] |

| Porous carbon cloth | Porous carbon cloth | Proteus hauseri ZMd44 | 83.39 ± 0.28 mW/m2 | [130] |

| Graphite plate | Graphite plate | Acidithiobacillus spp. and Ferroplasma sp. | 17.6 mW/m2 | [166] |

| Porous carbon cloth | Porous carbon cloth | Proteus hauseri | 83.4 mW/m2 | [107] |

| 3D-Graphene | Carbon cloth/Pt | E. coli | 1516 ± 87 mW/m2 | [167] |

| Carbon fiber felt | Carbon fiber felt | Dysgonomonas and Klebsiella | 529 ± 12 mW/m2 | [52] |

| Carbon rod | Carbon rod | Pseudomonas Aurogenosa and Pseudomonas fluresence | 469.48 mW/m2 | [133] |

| Stainless steel meshes | Chromium plate | Geobacter sulfurreducens | 0.04 mW/cm2 | [112] |

| Graphite felt | Graphite cloth | Deltaproteobacteria and Desulfovibrio | 258 ± 10 mW/m2 | [113] |

| Graphite/polyester composite electrodes | Graphite/polyester composite electrodes | P. aeruginosa. | 1575 ± 223.26 mW/m2 | [115] |

| Carbon brushes | Activated carbon paper | Geobacter species | 28.4 ± 1.2 W/m3. | [168] |

| Carbon felt | Carbon felt | Shewanella decoloration S12, K. pneumonia | 52.1 mW/cm2 | [59] |

| Carbon brush | Reduced graphene oxide | Geobacter and Pseudomonas | 0.95 W/m2 | [60] |

| Porous carbon cloth without catalyst | Porous carbon cloth with polytetrafluoroethylene as catalyst | Proteus hauseri ZMd44 | 83.39 ± 0.28 mW/m2 | [137] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yaqoob, A.A.; Khatoon, A.; Mohd Setapar, S.H.; Umar, K.; Parveen, T.; Mohamad Ibrahim, M.N.; Ahmad, A.; Rafatullah, M. Outlook on the Role of Microbial Fuel Cells in Remediation of Environmental Pollutants with Electricity Generation. Catalysts 2020, 10, 819. https://doi.org/10.3390/catal10080819

Yaqoob AA, Khatoon A, Mohd Setapar SH, Umar K, Parveen T, Mohamad Ibrahim MN, Ahmad A, Rafatullah M. Outlook on the Role of Microbial Fuel Cells in Remediation of Environmental Pollutants with Electricity Generation. Catalysts. 2020; 10(8):819. https://doi.org/10.3390/catal10080819

Chicago/Turabian StyleYaqoob, Asim Ali, Asma Khatoon, Siti Hamidah Mohd Setapar, Khalid Umar, Tabassum Parveen, Mohamad Nasir Mohamad Ibrahim, Akil Ahmad, and Mohd Rafatullah. 2020. "Outlook on the Role of Microbial Fuel Cells in Remediation of Environmental Pollutants with Electricity Generation" Catalysts 10, no. 8: 819. https://doi.org/10.3390/catal10080819

APA StyleYaqoob, A. A., Khatoon, A., Mohd Setapar, S. H., Umar, K., Parveen, T., Mohamad Ibrahim, M. N., Ahmad, A., & Rafatullah, M. (2020). Outlook on the Role of Microbial Fuel Cells in Remediation of Environmental Pollutants with Electricity Generation. Catalysts, 10(8), 819. https://doi.org/10.3390/catal10080819