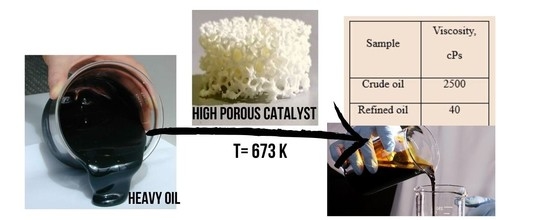

Development of (γ-Al2O3-Zeolite Y)/α-Al2O3-HPCM Catalyst based on Highly Porous α-Al2O3-HPCM Support for Decreasing Oil Viscosity

Abstract

:1. Introduction

2. Results and Discussion

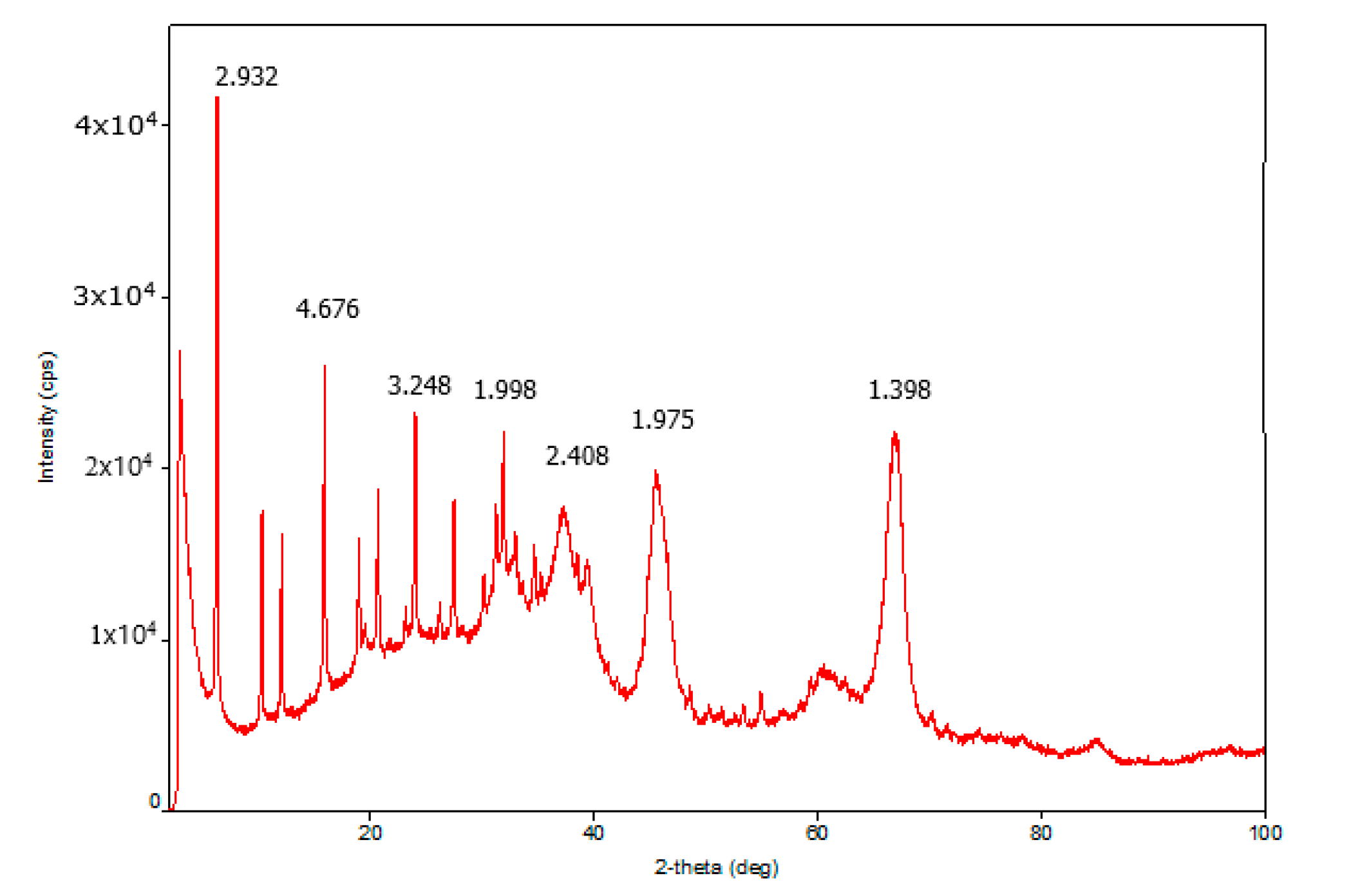

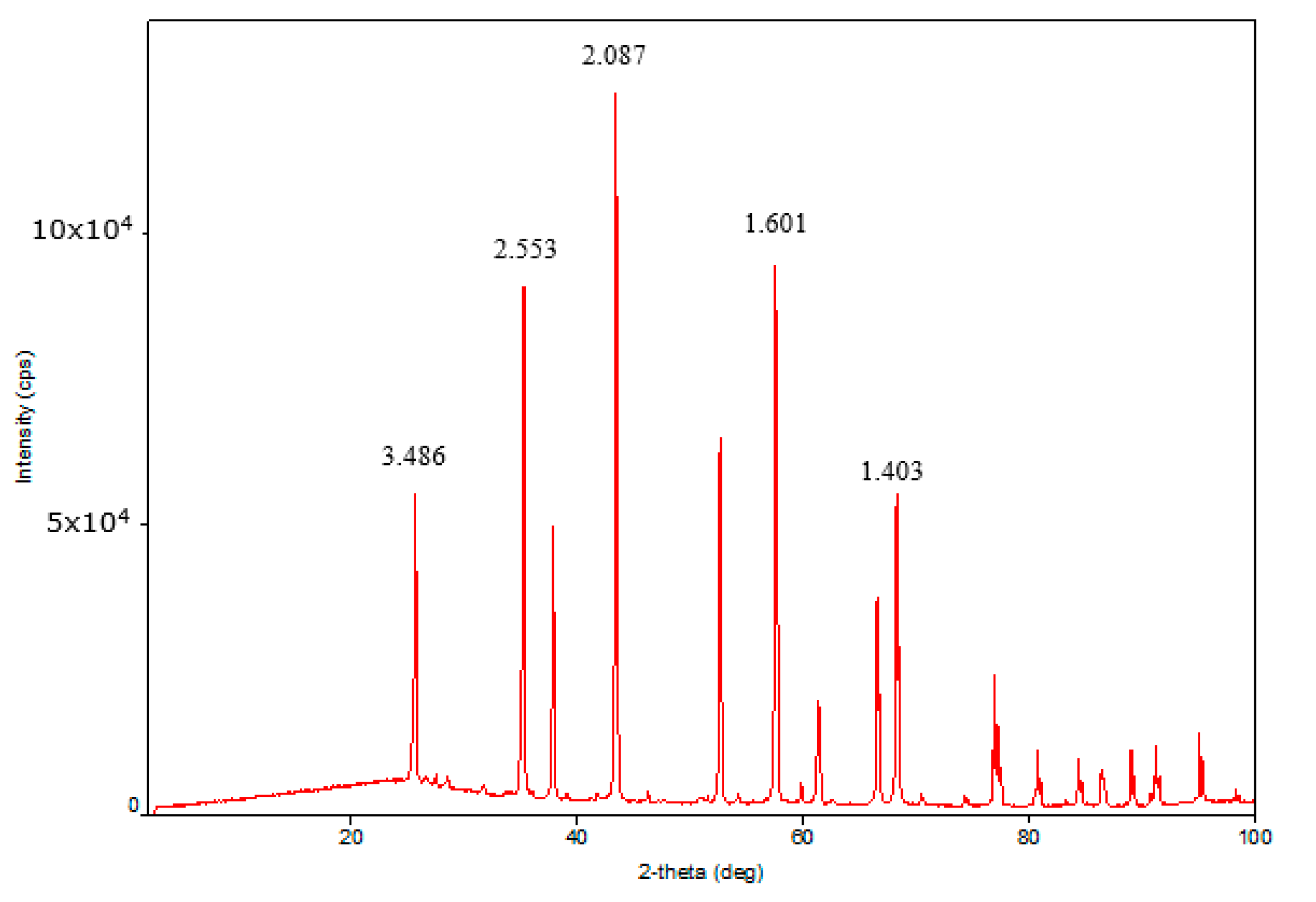

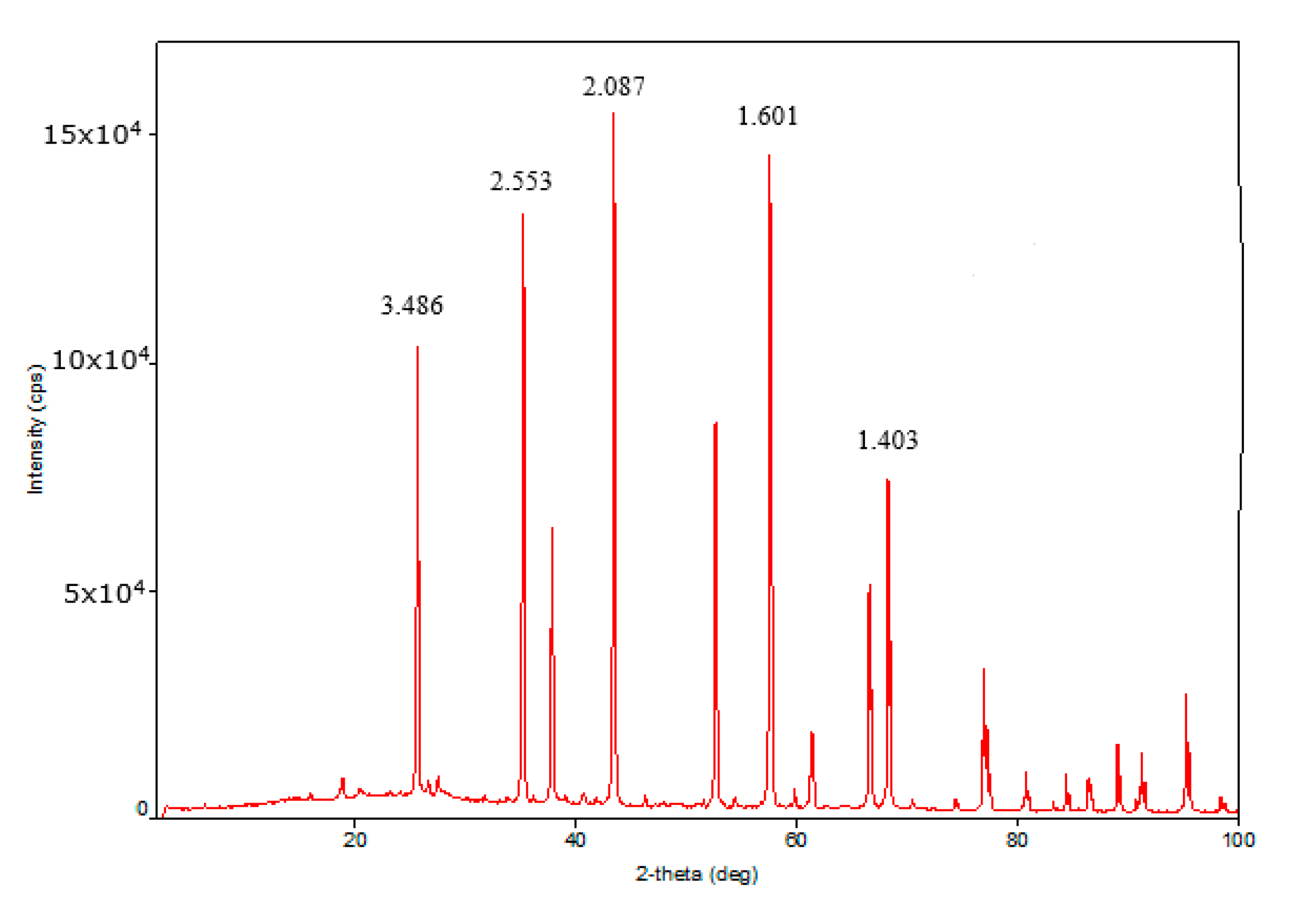

2.1. X-ray Diffraction Analysis

2.2. Textural Characteristics

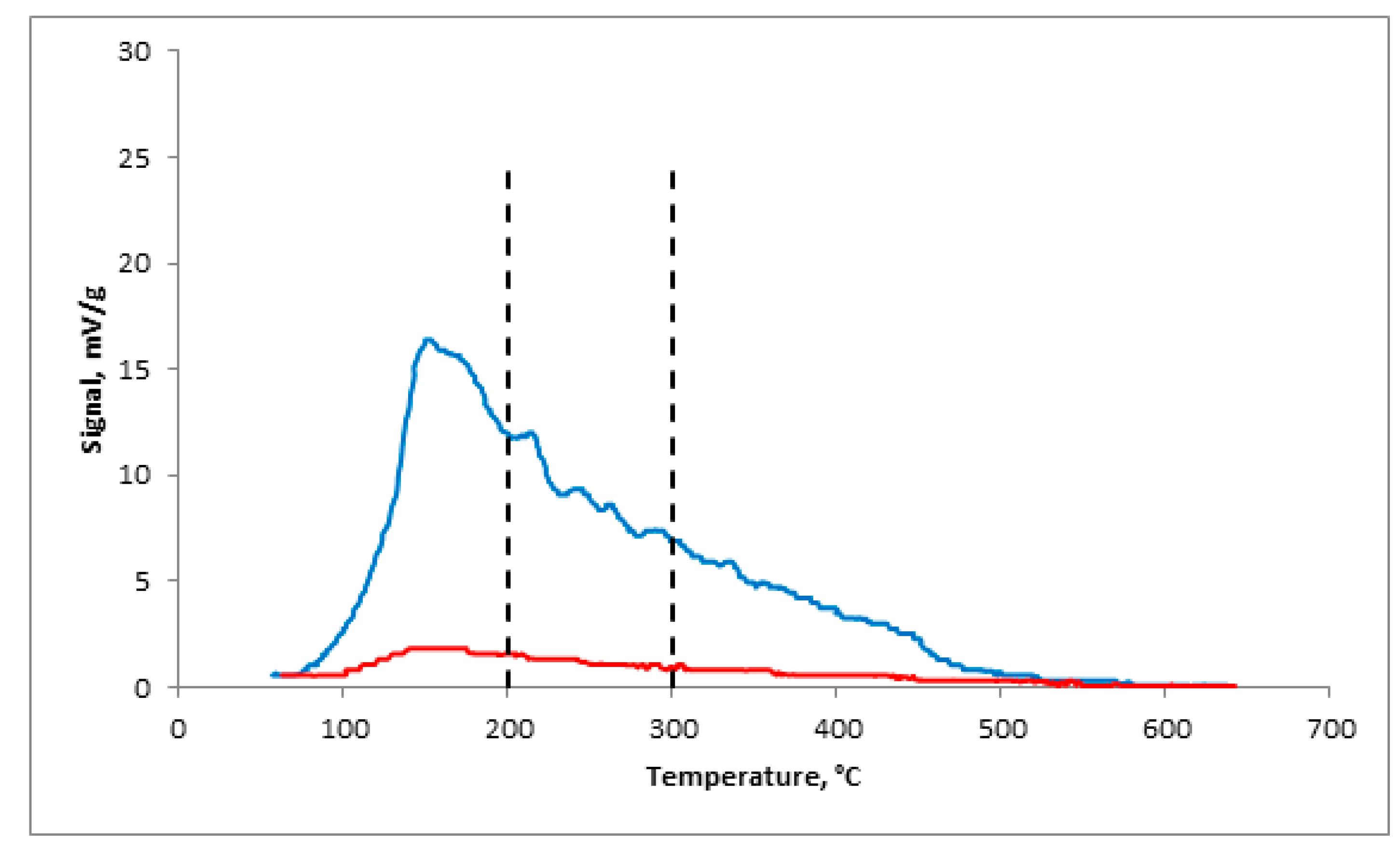

2.3. Concentrations of Acid Centers

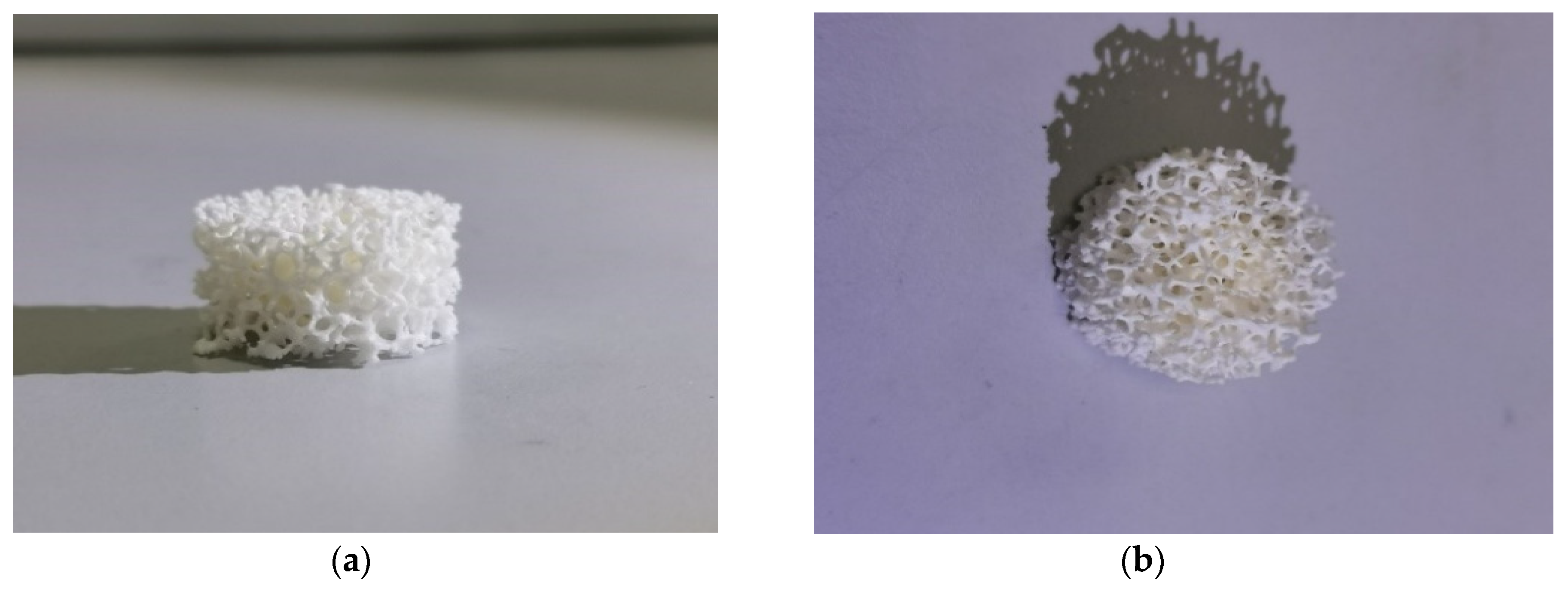

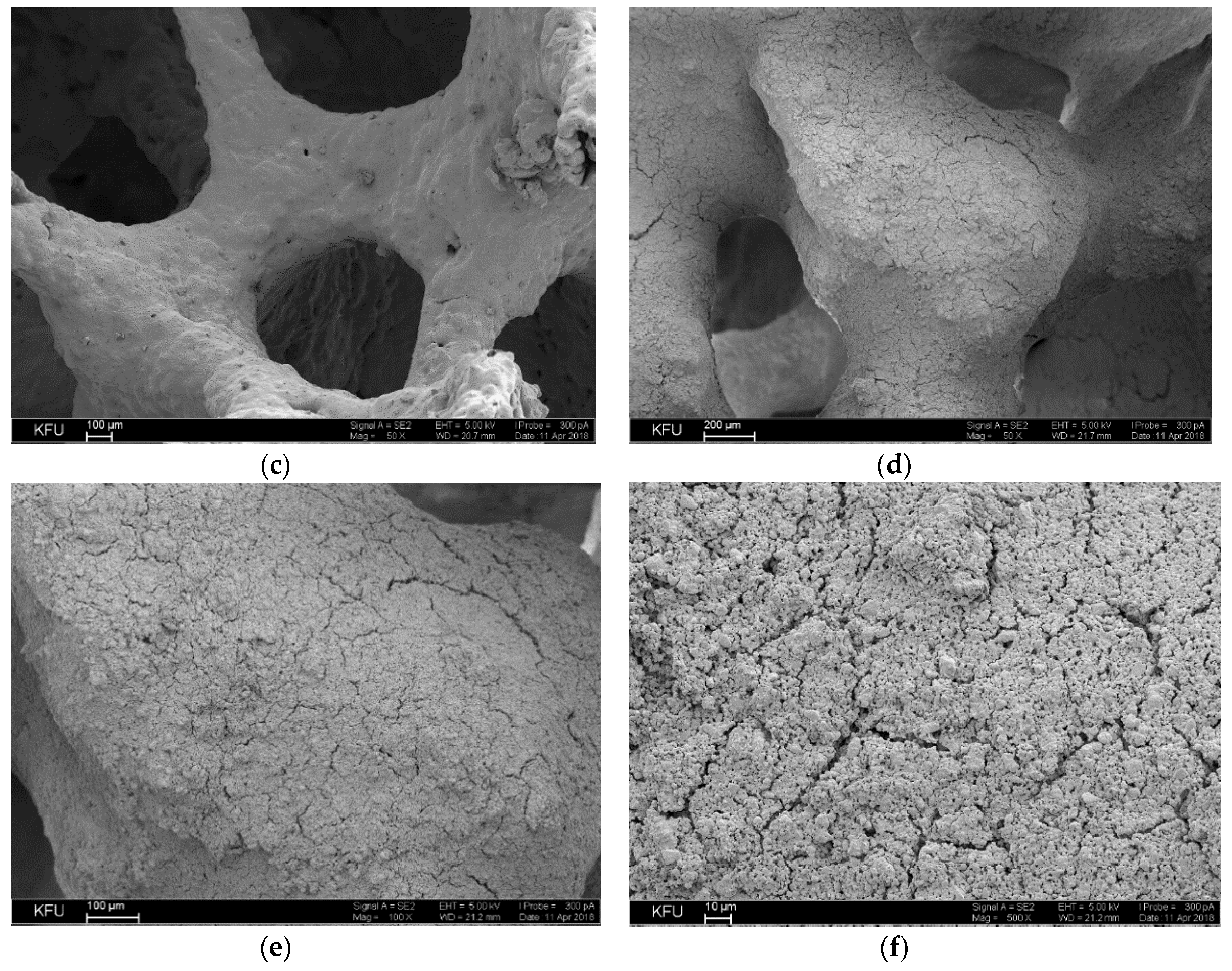

2.4. Surface Morphology of Highly Porous Catalyst

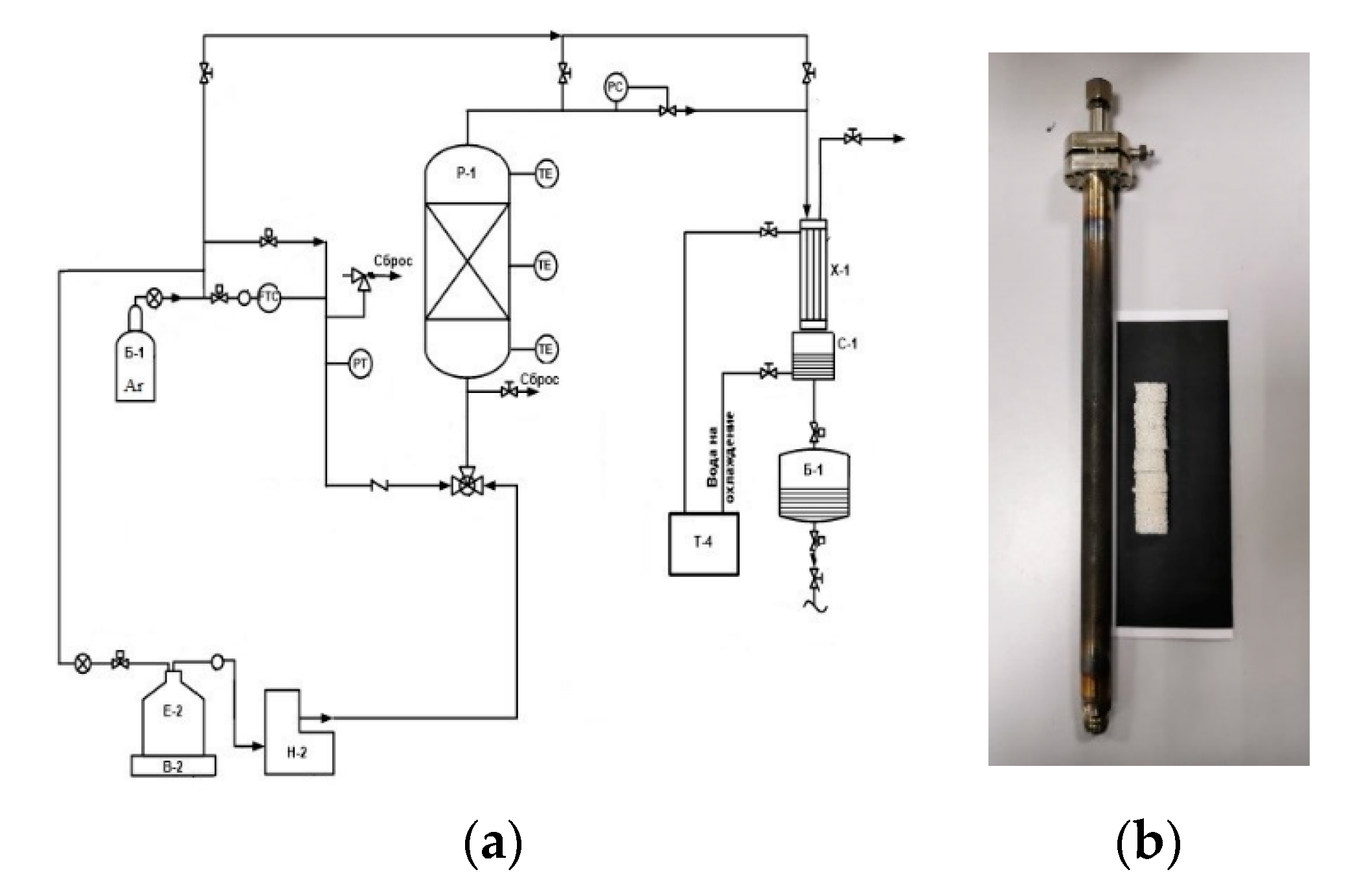

2.5. Performance Features

3. Experiment

3.1. Catalyst Preparation

3.2. Characterization of Experimental Samples

3.3. Heavy Oil Viscosity Reduction Tests

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Taheri-Shakib, J.; Shekarifard, A.; Naderi, H. Heavy crude oil upgrading using nanoparticles by applying electromagnetic technique. Fuel 2018, 232, 704–711. [Google Scholar] [CrossRef]

- Carrillo, J.A.; Corredor, L.M. Upgrading of heavy crude oils: Castilla. Fuel Process. Technol. 2013, 109, 156–162. [Google Scholar] [CrossRef]

- Castañeda, L.C.; Muñoz, J.A.D.; Ancheyta, J. Combined process schemes for upgrading of heavy petroleum. Fuel 2012, 100, 110–127. [Google Scholar] [CrossRef]

- Kondoh, H.; Tanaka, K.; Nakasaka, Y.; Tago, T.; Masuda, T. Catalytic cracking of heavy oil over TiO2–ZrO2 catalysts under superheated steam conditions. Fuel 2016, 167, 288–294. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Dinkov, R.; Nikolova, R.; Mitkova, M.; Stanulov, K.; Sharpe, R.; Russell, C.A.; Obryvalina, A.; Telyashev, R.; et al. Reactivity and stability of vacuum residual oils in their thermal conversion. Fuel 2014, 123, 133–142. [Google Scholar] [CrossRef]

- Becker, P.J.; Serrand, N.; Celse, B.; Guillaume, D.; Dulot, H. Comparing hydrocracking models: Continuous lumping vs. single events. Fuel 2016, 165, 306–315. [Google Scholar] [CrossRef]

- Khalil, U.; Muraza, O.; Kondoh, H.; Watanabe, G.; Nakasaka, Y.; Al-Amer, A.; Masuda, T. Robust surface-modified Beta zeolite for selective production of lighter fuels by steam-assisted catalytic cracking from heavy oil. Fuel 2016, 168, 61–67. [Google Scholar] [CrossRef]

- Zhao, L.; Gao, J.; Xu, C.; Shen, B. Alkali-treatment of ZSM-5 zeolites with different SiO2/Al2O3 ratios and light olefin production by heavy oil cracking. Fuel Process. Technol. 2011, 92, 414–420. [Google Scholar] [CrossRef]

- Dik, P.P.; Danilova, I.G.; Golubev, I.S.; Kazakov, M.O.; Nadeina, K.A.; Budukva, S.V.; Pereyma, V.Y.; Klimov, O.V.; Prosvirin, I.P.; Gerasimov, E.Y.; et al. Hydrocracking of vacuum gas oil over NiMo/zeolite-Al2O3: Influence of zeolite properties. Fuel 2019, 237, 178–190. [Google Scholar] [CrossRef]

- Decolatti, H.P.; Dalla Costa, B.O.; Querini, C.A. Dehydration of glycerol to acrolein using H-ZSM5 zeolite modified by alkali treatment with NaOH. Microporous Mesoporous Mater. 2015, 204, 180–189. [Google Scholar] [CrossRef]

- Awayssa, O.; Al-Yassir, N.; Aitani, A.; Al-Khattaf, S. Modified HZSM-5 as FCC additive for enhancing light olefins yield from catalytic cracking of VGO. Appl. Catal. A Gen. 2014, 477, 172–183. [Google Scholar] [CrossRef]

- Lai, S.; She, Y.; Zhan, W.; Guo, Y.; Guo, Y.; Wang, L.; Lu, G. Performance of Fe-ZSM-5 for selective catalytic reduction of NOx with NH3: Effect of the atmosphere during the preparation of catalysts. J. Mol. Catal. A Chem. 2016, 424, 232–240. [Google Scholar] [CrossRef]

- Han, M.J.; Jiao, Y.L.; Zhou, C.H.; Guo, Y.L.; Guo, Y.; Lu, G.Z.; Wang, L.; Zhan, W.C. Catalytic activity of Cu–SSZ-13 prepared with different methods for NH 3-SCR reaction. Rare Met. 2019, 38, 210–220. [Google Scholar] [CrossRef]

- Grecco, S.T.F.; de Carvalho, D.R.; Zandonai, C.H.; Fernandes-Machado, N.R.C.; Lião, L.M.; Urquieta-González, E.A.; do Carmo Rangel, M. Catalytic cracking of crude soybean oil on Beta nanozeolites. J. Mol. Catal. A Chem. 2016, 422, 89–102. [Google Scholar] [CrossRef]

- Khalil, U.; Muraza, O.; Kondoh, H.; Watanabe, G.; Nakasaka, Y.; Al-Amer, A.; Masuda, T. Production of lighter hydrocarbons by steam-assisted catalytic cracking of heavy oil over silane-treated Beta zeolite. Energy Fuels 2016, 30, 1304–1309. [Google Scholar] [CrossRef]

- Zhou, J.; Teng, J.; Ren, L.; Wang, Y.; Liu, Z.; Liu, W.; Yang, W.; Xie, Z. Full-crystalline hierarchical monolithic ZSM-5 zeolites as superiorly active and long-lived practical catalysts in methanol-to-hydrocarbons reaction. J. Catal. 2016, 340, 166–176. [Google Scholar] [CrossRef]

- Liu, S.; Ren, J.; Zhu, S.; Zhang, H.; Lv, E.; Xu, J.; Li, Y.W. Synthesis and characterization of the Fe-substituted ZSM-22 zeolite catalyst with high n-dodecane isomerization performance. J. Catal. 2015, 330, 485–496. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, K.; Zhang, L.; Wu, H.; Guo, J. Synthesis of mesoporous γ-Al2O3 by using cellulose nanofiber as template for hydrodesulfurization of dibenzothiophene. Fuel 2019, 253, 431–440. [Google Scholar] [CrossRef]

- Parkhomchuk, E.V.; Sashkina, K.A.; Semekina, V.S.; Okunev, A.G.; Lavrenov, A.V.; Likholobov, V.A. The Catalyst for the Heavy Oil Refinery. Russia Patent No. 2,506,997, 22 April 2014. [Google Scholar]

| Sample | SBET (m2/g)/Vpore (cm3/g) | Distribution SBET (m2/g) и Vpore (cm3/g) and Their Proportion (%) Accruing to Pore Diameter (nm) | |||||

|---|---|---|---|---|---|---|---|

| < 5 | 5–10 | > 10 | |||||

| m2/g | % | m2/g/ | % | m2/g/ | % | ||

| cm3/g | cm3/g | cm3/g | |||||

| Granular catalyst | 270/ | 62.23/ | 23/ | 147.3/ | 55/ | 60.47/ | 22/ |

| 0.595 | 0.054 | 9 | 0.279 | 47 | 0.262 | 44 | |

| Highly porous support | 0.74/ | - | - | - | - | - | - |

| 0.001 | - | - | - | - | - | - | |

| Highly porous catalyst | 15.1/ | 8.8746/ | 59/ | 5.0533/ | 33/ | 1.1721/ | 8/ |

| 0.0241 | 0.00755 | 31 | 0.00963 | 40 | 0.00693 | 29 | |

| Sample | Ntota.c., mkmol/g | Nк.ц., mkmol/g (%) | ||

|---|---|---|---|---|

| Weak | Medium | Strong | ||

| Td < 200 °C | 200 ≤ Td < 300 °C | Td ≥ 300 °C | ||

| Granular catalyst | 324.5 | 130.1 (40.1) | 127.9 (39.4) | 92.5 (28.5) |

| Highly porous support | 0 | 0 | 0 | 0 |

| Highly porous catalyst | 11.1 | 4.2 (37.8) | 3.2 (28.5) | 3.7 (33.7) |

| Sample | Temperature (°C) | Oil Feed Rate (mL/h) | Viscosity (cPs) | Amount of Gas Phase (mL/h) |

|---|---|---|---|---|

| Crude oil | 2500 | |||

| Thermal method | ||||

| Refined oil | 400 | 15 | 41 | 185 |

| Catalytic method in the presence of granular catalyst | ||||

| Refined oil | 400 | 20 | 196 | 285 |

| Catalytic method in the presence of highly porous catalyst | ||||

| Refined oil | 400 | 20 | 40 | 137 |

| Component | Thermal Method | Catalytic Method in the Presence of High Porous Catalyst |

|---|---|---|

| Methane | 60.42 | 57.68 |

| Ethane | 17.75 | 16.23 |

| Propane | 10.01 | 7.53 |

| Propene | 1.47 | 0.09 |

| Isobutane | 0.69 | 12.60 |

| Trans-2-butene | 2.37 | 0.33 |

| 1-butene | 2.78 | 2.20 |

| Cis-2 butene | 0.41 | 0.27 |

| Isopentane | 1.30 | 0.88 |

| Pentane | 1.38 | 0.66 |

| Butadiene-1,3 | 0.51 | 0.24 |

| ∑C6 | 0.51 | 1.01 |

| ∑C7 | 0.40 | 0.28 |

| Sample | Group Composition (% Mass) | ||||||

|---|---|---|---|---|---|---|---|

| Oils | Resins | Asphaltenes | |||||

| Benzene | Alcohol Benzene | Amount | Pure Acids | Asphaltenic Acids | Amount | ||

| Crude oil | 49.65 | 27.22 | 12.9 | 40.12 | 5.34 | 4.89 | 10.23 |

| Thermal method | |||||||

| Refined oil | 59.7 | 20.48 | 8.93 | 29.41 | 5.52 | 5.31 | 10.83 |

| Catalytic method in the presence of the granular catalyst | |||||||

| Refined oil | 63.83 | 16.26 | 7.29 | 23.55 | 6.15 | 6.53 | 12.86 |

| Catalytic method in the presence of highly porous (γ-Al2O3+zeolite Y)/α-Al2O3-HPCM catalyst | |||||||

| Refined oil | 66.54 | 13.97 | 9.24 | 23.21 | 3.88 | 6.37 | 10.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirgizov, A.; Valieva, G.; Laskin, A.; Il’yasov, I.; Lamberov, A. Development of (γ-Al2O3-Zeolite Y)/α-Al2O3-HPCM Catalyst based on Highly Porous α-Al2O3-HPCM Support for Decreasing Oil Viscosity. Catalysts 2020, 10, 250. https://doi.org/10.3390/catal10020250

Kirgizov A, Valieva G, Laskin A, Il’yasov I, Lamberov A. Development of (γ-Al2O3-Zeolite Y)/α-Al2O3-HPCM Catalyst based on Highly Porous α-Al2O3-HPCM Support for Decreasing Oil Viscosity. Catalysts. 2020; 10(2):250. https://doi.org/10.3390/catal10020250

Chicago/Turabian StyleKirgizov, Alexey, Gulnaz Valieva, Artem Laskin, Il’dar Il’yasov, and Alexander Lamberov. 2020. "Development of (γ-Al2O3-Zeolite Y)/α-Al2O3-HPCM Catalyst based on Highly Porous α-Al2O3-HPCM Support for Decreasing Oil Viscosity" Catalysts 10, no. 2: 250. https://doi.org/10.3390/catal10020250

APA StyleKirgizov, A., Valieva, G., Laskin, A., Il’yasov, I., & Lamberov, A. (2020). Development of (γ-Al2O3-Zeolite Y)/α-Al2O3-HPCM Catalyst based on Highly Porous α-Al2O3-HPCM Support for Decreasing Oil Viscosity. Catalysts, 10(2), 250. https://doi.org/10.3390/catal10020250