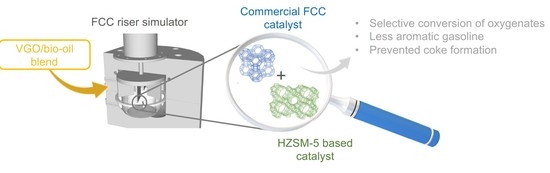

A Hybrid FCC/HZSM-5 Catalyst for the Catalytic Cracking of a VGO/Bio-Oil Blend in FCC Conditions

Abstract

:1. Introduction

2. Results and Discussion

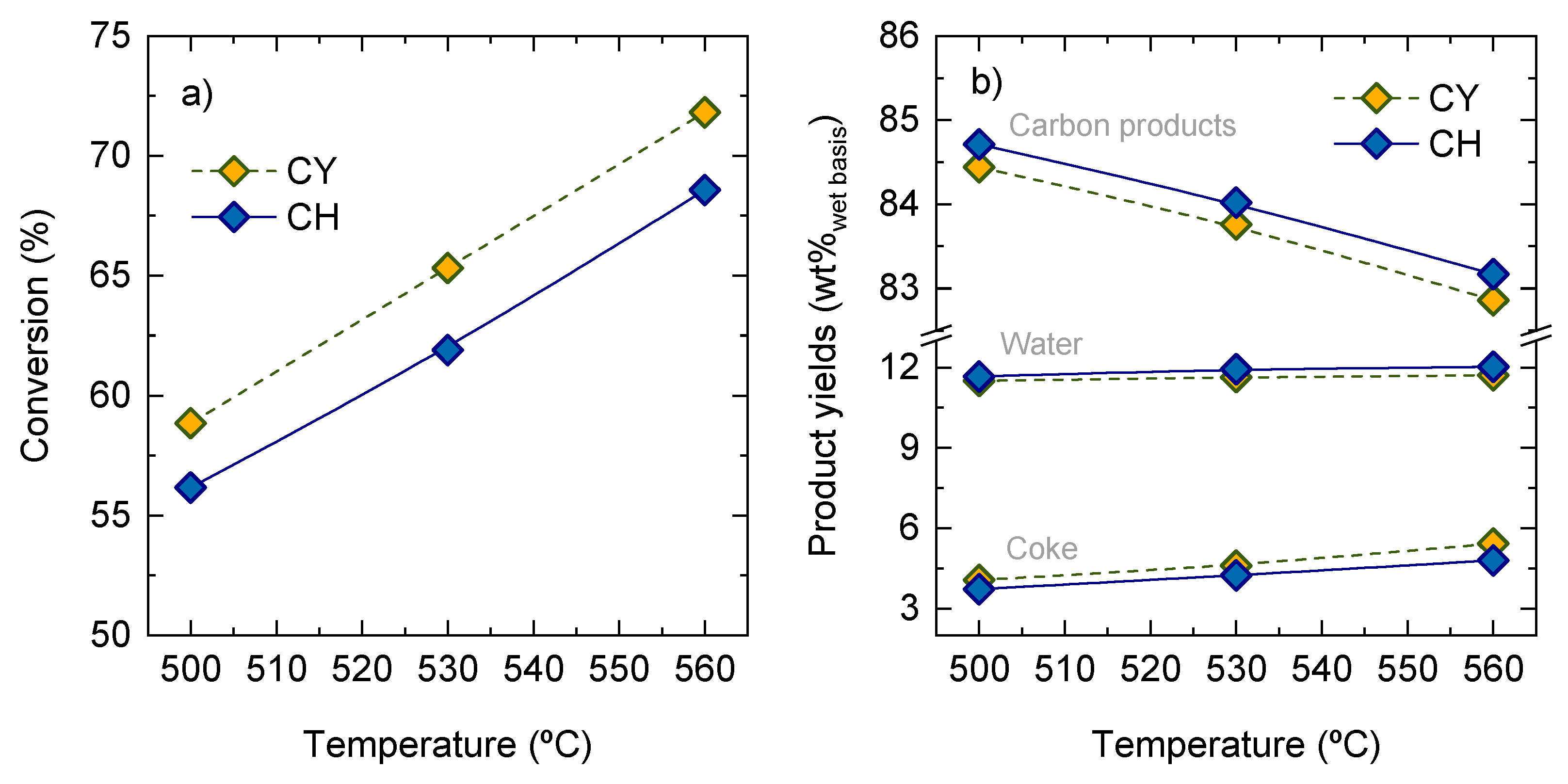

2.1. Effect of Reaction Temperature on Conversion and Main Cracking Product Yields on a Wet Basis

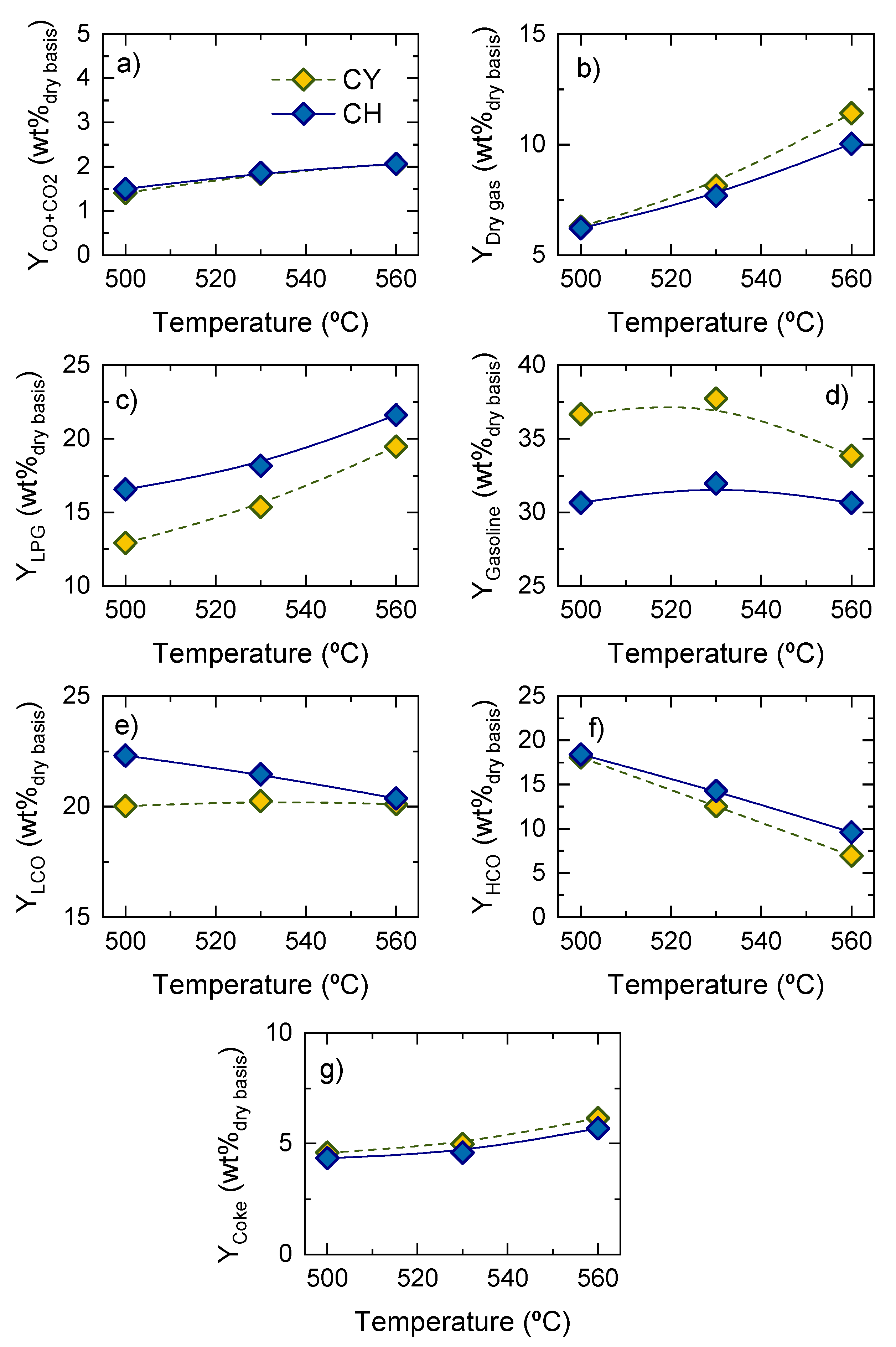

2.2. Effect of Reaction Temperature on Conversion and Product Lump Distribution on a Dry Basis

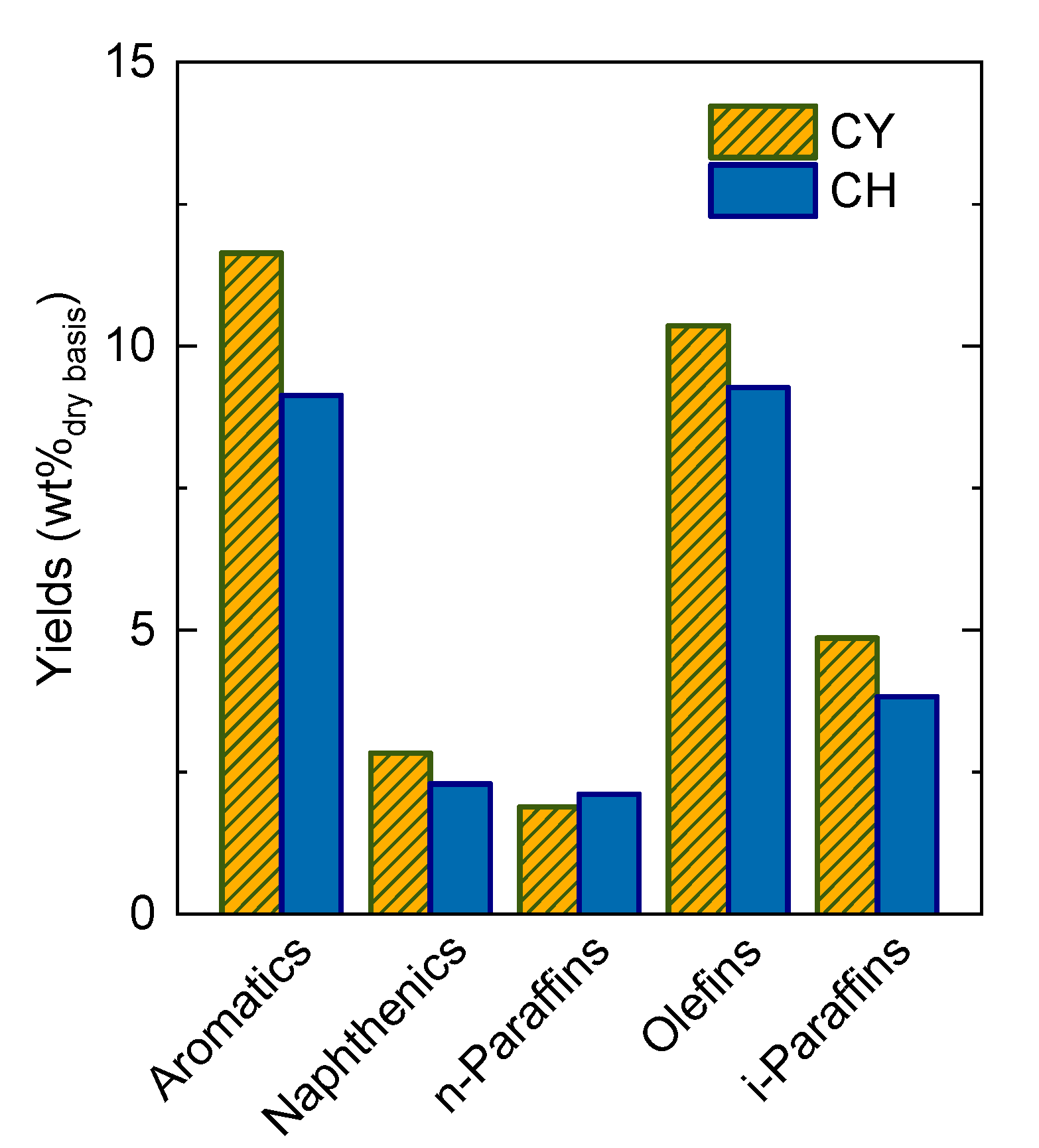

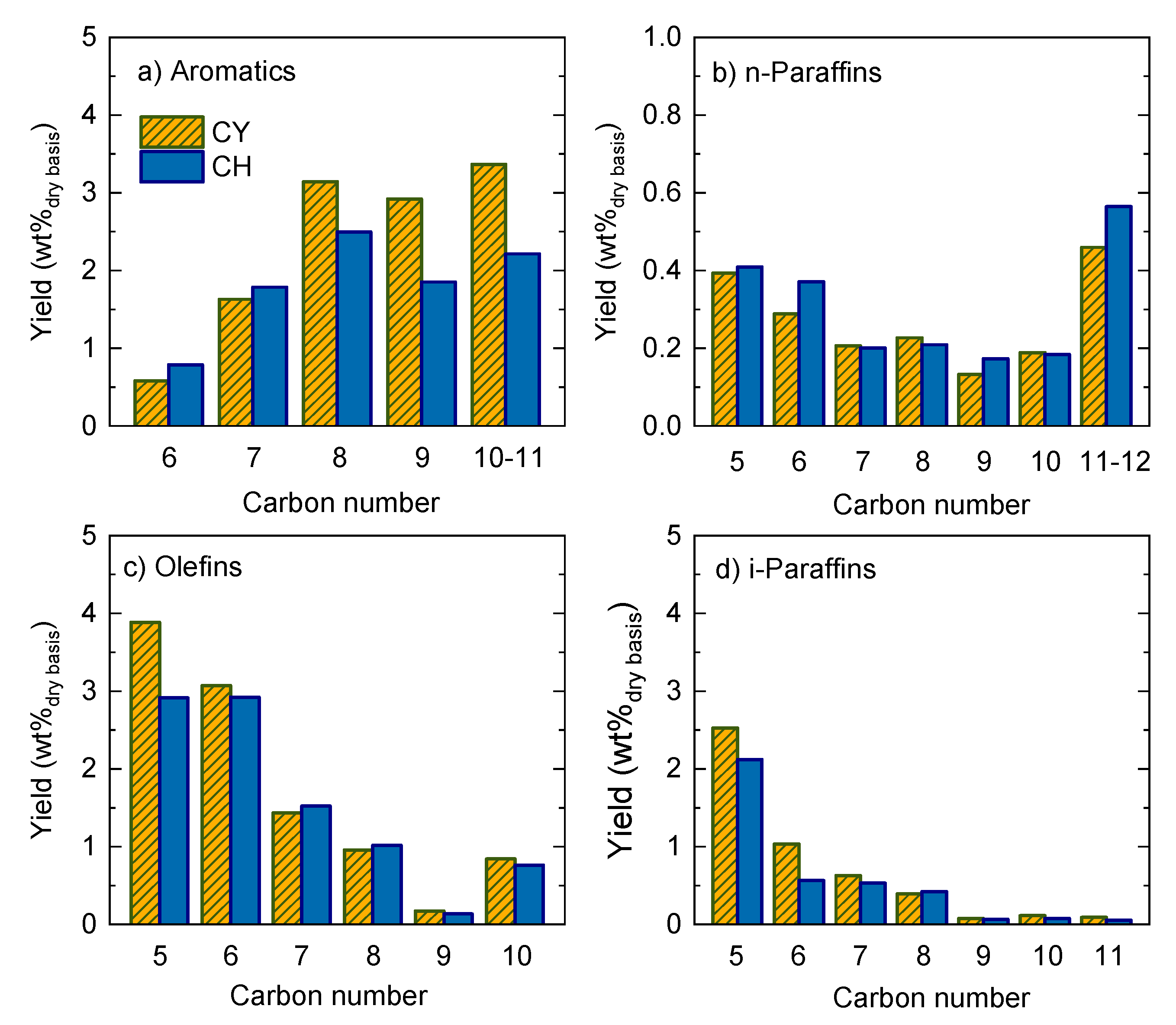

2.3. Composition of the Gasoline Fraction

3. Materials and Methods

3.1. Catalyst Synthesis and Characterization

3.2. Feedstock

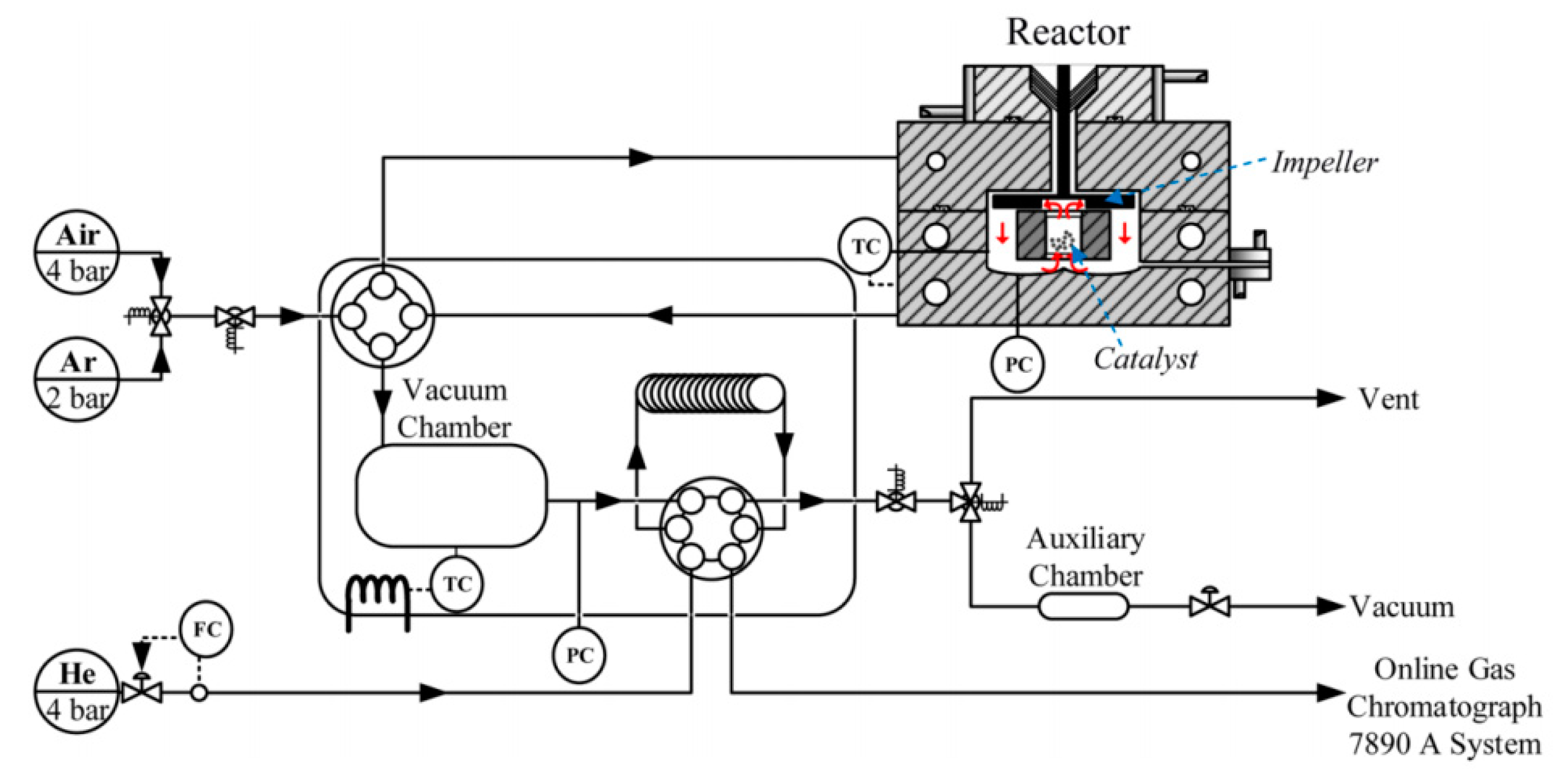

3.3. Catalytic Cracking Runs and Product Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- De Bhowmick, G.; Sarmah, A.K.; Sen, R. Lignocellulosic biorefinery as a model for sustainable development of biofuels and value added products. Bioresour. Technol. 2018, 247, 1144–1154. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Zhang, X.; Liu, Q.; Zhang, Q.; Chen, L.; Ma, L. A review of conversion of lignocellulose biomass to liquid transport fuels by integrated refining strategies. Fuel. Process. Technol. 2020, 208, 106485. [Google Scholar] [CrossRef]

- Valle, B.; Remiro, A.; García-Gómez, N.; Gayubo, A.G.; Bilbao, J. Recent research progress on bio-oil conversion into bio-fuels and raw chemicals: A review. J. Chem. Technol. Biotechnol. 2018, 94, 670–689. [Google Scholar] [CrossRef]

- Hansen, S.; Mirkouei, A.; Diaz, L.A. A comprehensive state-of-technology review for upgrading bio-oil to renewable or blended hydrocarbon fuels. Renew. Sustain. Energy Rev. 2020, 118, 109548. [Google Scholar] [CrossRef]

- Dai, L.; Zhou, N.; Li, H.; Deng, W.; Cheng, Y.; Wang, Y.; Liu, Y.; Cobb, K.; Lei, H.; Chen, P.; et al. Recent advances in improving lignocellulosic biomass-based bio-oil production. J. Anal. Appl. Pyrolysis. 2020, 149, 104845. [Google Scholar] [CrossRef]

- Lazzari, E.; Schena, T.; Marcelo, M.C.A.; Primaz, C.T.; Silva, A.N.; Ferrão, M.F.; Bjerk, T.R.; Caramão, E.B. Classification of biomass through their pyrolytic bio-oil composition using FTIR and PCA analysis. Ind. Crop. Prod. 2018, 111, 856–864. [Google Scholar] [CrossRef]

- Hita, I.; Cordero-Lanzac, T.; García-Mateos, F.J.; Azkoiti, M.J.; Rodríguez-Mirasol, J.; Cordero, T.; Bilbao, J. Enhanced production of phenolics and aromatics from raw bio-oil using HZSM-5 zeolite additives for PtPd/C and NiW/C catalysts. Appl. Catal. B Environ. 2019, 259, 118112. [Google Scholar] [CrossRef]

- Carpenter, D.; Westover, T.L.; Czernik, S.; Jablonski, W. Biomass Feedstocks for Renewable Fuel Production: A Review of the Impacts of Feedstock and Pretreatment on the Yield and Product Distribution of Fast Pyrolysis Bio-Oils and Vapors. Green Chem. 2014, 16, 384–406. [Google Scholar] [CrossRef]

- Wang, C.; Ding, H.; Zhang, Y.; Zhu, X. Analysis of property variation and stability on the aging of bio-oil from fractional condensation. Renew. Energy 2020, 148, 720–728. [Google Scholar] [CrossRef]

- Mei, Y.; Chai, M.; Shen, C.; Liu, B.; Liu, R. Effect of methanol addition on properties and aging reaction mechanism of bio-oil during storage. Fuel 2019, 244, 499–507. [Google Scholar] [CrossRef]

- Meng, J.; Moore, A.; Tilotta, D.; Kelley, S.; Park, S. Toward Understanding of Bio-Oil Aging: Accelerated Aging of Bio-Oil Fractions. ACS Sustain. Chem. Eng. 2014, 2, 2011–2018. [Google Scholar] [CrossRef]

- Hita, I.; Cordero-Lanzac, T.; Bonura, G.; Cannilla, C.; Arandes, J.M.; Frusteri, F.; Bilbao, J. Hydrodeoxygenation of raw bio-oil towards platform chemicals over FeMoP/zeolite catalysts. J. Ind. Eng. Chem. 2019, 80, 392–400. [Google Scholar] [CrossRef] [Green Version]

- Hita, I.; Cordero-Lanzac, T.; Bonura, G.; Frusteri, F.; Bilbao, J.; Castaño, P. Dynamics of carbon formation during the catalytic hydrodeoxygenation of raw bio-oil. Sustain. Energy Fuels 2020. [Google Scholar] [CrossRef]

- Stefanidis, S.D.; Kalogiannis, K.G.; Lappas, A. Co-processing bio-oil in the refinery for drop-in biofuels via fluid catalytic cracking. Wiley Interdiscip. Rev. Energy Environ. 2017, 7, e281. [Google Scholar] [CrossRef]

- Hita, I.; Arabiourrutia, M.; Olazar, M.; Bilbao, J.; Arandes, J.M.; Castaño, P. Opportunities and barriers for producing high quality fuels from the pyrolysis of scrap tires. Renew. Sustain. Energy Rev. 2016, 56, 745–759. [Google Scholar] [CrossRef]

- Wu, L.; Yang, Y.; Yan, T.; Wang, Y.; Zheng, L.; Qian, K.; Hong, F. Sustainable design and optimization of co-processing of bio-oil and vacuum gas oil in an existing refinery. Renew. Sustain. Energy Rev. 2020, 130, 109952. [Google Scholar] [CrossRef]

- Fogassy, G.; Thegarid, N.; Toussaint, G.; Van Veen, A.C.; Schuurman, Y.; Mirodatos, C. Biomass derived feedstock co-processing with vacuum gas oil for second-generation fuel production in FCC units. Appl. Catal. B Environ. 2010, 96, 476–485. [Google Scholar] [CrossRef]

- Bertero, M.; Sedran, U. Coprocessing of Bio-oil in Fluid Catalytic Cracking. In Recent Advances in Thermo-Chemical Conversion of Biomass; Elsevier BV: Amsterdam, The Netherlands, 2015; pp. 355–381. [Google Scholar]

- Pinho, A.; De Almeida, M.B.; Mendes, F.L.; Ximenes, V.L.; Casavechia, L.C. Co-processing raw bio-oil and gasoil in an FCC Unit. Fuel Process. Technol. 2015, 131, 159–166. [Google Scholar] [CrossRef]

- Lindfors, C.; Paasikallio, V.; Kuoppala, E.; Reinikainen, M.; Oasmaa, A.; Solantausta, Y. Co-processing of Dry Bio-oil, Catalytic Pyrolysis Oil, and Hydrotreated Bio-oil in a Micro Activity Test Unit. Energy Fuels 2015, 29, 3707–3714. [Google Scholar] [CrossRef]

- Ibarra, Á.; Rodríguez, E.; Sedran, U.; Arandes, J.M.; Bilbao, J. Synergy in the Cracking of a Blend of Bio-oil and Vacuum Gasoil under Fluid Catalytic Cracking Conditions. Ind. Eng. Chem. Res. 2016, 55, 1872–1880. [Google Scholar] [CrossRef]

- Pinho, A.D.R.; De Almeida, M.B.; Mendes, F.L.; Casavechia, L.C.; Talmadge, M.S.; Kinchin, C.M.; Chum, H.L. Fast pyrolysis oil from pinewood chips co-processing with vacuum gas oil in an FCC unit for second generation fuel production. Fuel 2017, 188, 462–473. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Venderbosch, R.; Fang, Y. Co-processing of crude and hydrotreated pyrolysis liquids and VGO in a pilot scale FCC riser setup. Fuel Process. Technol. 2018, 181, 157–165. [Google Scholar] [CrossRef]

- Ibarra, Á.; Hita, I.; Azkoiti, M.J.; Arandes, J.M.; Bilbao, J. Catalytic cracking of raw bio-oil under FCC unit conditions over different zeolite-based catalysts. J. Ind. Eng. Chem. 2019, 78, 372–382. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Y.; Zheng, L.; Wang, P.; Han, X. Techno-economic analysis of bio-oil co-processing with vacuum gas oil to transportation fuels in an existing fluid catalytic cracker. Energy Convers. Manag. 2019, 197, 111901. [Google Scholar] [CrossRef]

- Bhatt, A.; Zhang, Y.; Heath, G. Bio-oil co-processing can substantially contribute to renewable fuel production potential and meet air quality standards. Appl. Energy 2020, 268, 114937. [Google Scholar] [CrossRef]

- Ibarra, Á.; Hita, I.; Arandes, J.M.; Bilbao, J. Influence of the Composition of Raw Bio-Oils on Their Valorization in Fluid Catalytic Cracking Conditions. Energy Fuels 2019, 33, 7458–7465. [Google Scholar] [CrossRef]

- Corma, A.; Martínez, C.; Sauvanaud, L. New materials as FCC active matrix components for maximizing diesel (light cycle oil, LCO) and minimizing its aromatic content. Catal. Today 2007, 127, 3–16. [Google Scholar] [CrossRef]

- Awayssa, O.; Al-Yassir, N.; Aitani, A.M.; Al-Khattaf, S. Modified HZSM-5 as FCC additive for enhancing light olefins yield from catalytic cracking of VGO. Appl. Catal. A Gen. 2014, 477, 172–183. [Google Scholar] [CrossRef]

- Degnan, T.; Chitnis, G.; Schipper, P. History of ZSM-5 fluid catalytic cracking additive development at Mobil. Microporous Mesoporous Mater. 2000, 35, 245–252. [Google Scholar] [CrossRef]

- Nishu; Liu, R.; Rahman, M.; Sarker, M.; Chai, M.; Li, C.; Cai, J. A review on the catalytic pyrolysis of biomass for the bio-oil production with ZSM-5: Focus on structure. Fuel Process. Technol. 2020, 199, 106301. [Google Scholar] [CrossRef]

- Gayubo, A.G.; Valle, B.; Aguayo, A.; Olazar, M.; Bilbao, J. Olefin Production by Catalytic Transformation of Crude Bio-Oil in a Two-Step Process. Ind. Eng. Chem. Res. 2010, 49, 123–131. [Google Scholar] [CrossRef]

- Ibarra, Á.; Veloso, A.; Bilbao, J.; Arandes, J.M.; Castaño, P. Dual coke deactivation pathways during the catalytic cracking of raw bio-oil and vacuum gasoil in FCC conditions. Appl. Catal. B Environ. 2016, 182, 336–346. [Google Scholar] [CrossRef] [Green Version]

- Valle, B.; Gayubo, A.G.; Alonso-Vicario, A.; Aguayo, A.; Bilbao, J. Hydrothermally stable HZSM-5 zeolite catalysts for the transformation of crude bio-oil into hydrocarbons. Appl. Catal. B Environ. 2010, 100, 318–327. [Google Scholar] [CrossRef]

- Ibáñez, M.; Valle, B.; Bilbao, J.; Gayubo, A.G.; Castaño, P. Effect of operating conditions on the coke nature and HZSM-5 catalysts deactivation in the transformation of crude bio-oil into hydrocarbons. Catal. Today 2012, 195, 106–113. [Google Scholar] [CrossRef]

- Valle, B.; Castaño, P.; Olazar, M.; Bilbao, J.; Gayubo, A.G. Deactivating species in the transformation of crude bio-oil with methanol into hydrocarbons on a HZSM-5 catalyst. J. Catal. 2012, 285, 304–314. [Google Scholar] [CrossRef]

- Arandes, J.M.; Abajo, I.; Fernández, I.; Azkoiti, M.J.; Bilbao, J. Effect of HZSM-5 Zeolite Addition to a Fluid Catalytic Cracking Catalyst. Study in a Laboratory Reactor Operating under Industrial Conditions. Ind. Eng. Chem. Res. 2000, 39, 1917–1924. [Google Scholar] [CrossRef]

- Epelde, E.; Aguayo, A.; Olazar, M.; Bilbao, J.; Gayubo, A.G. Modifications in the HZSM-5 zeolite for the selective transformation of ethylene into propylene. Appl. Catal. A Gen. 2014, 479, 17–25. [Google Scholar] [CrossRef]

- Makibar, J.; Fernández-Akarregui, A.R.; Amutio, M.; Lopez, G.; Olazar, M. Performance of a conical spouted bed pilot plant for bio-oil production by poplar flash pyrolysis. Fuel Process. Technol. 2015, 137, 283–289. [Google Scholar] [CrossRef]

- de Lasa, H. Novel Riser Reactor Simulator. U.S. Patent No. 5,102,628, 1992. accessed in August 2020. [Google Scholar]

- Passamonti, F.; De La Puente, G.; Sedran, U. Comparison between MAT Flow Fixed Bed and Batch Fluidized Bed Reactors in the Evaluation of FCC Catalysts. 2. Naphtha Composition. Energy Fuels 2009, 23, 3510–3516. [Google Scholar] [CrossRef]

- Mortensen, P.M.; Grunwaldt, J.-D.; Jensen, P.A.; Knudsen, K.; Jensen, A.D. A review of catalytic upgrading of bio-oil to engine fuels. Appl. Catal. A Gen. 2011, 407, 1–19. [Google Scholar] [CrossRef]

| 500 °C | 530 °C | 560 °C | |

|---|---|---|---|

| CY | 0.675 | 0.765 | 0.897 |

| CH | 0.628 | 0.707 | 0.795 |

| - | CY Used | ∆ (%) | CH Used | ∆ (%) |

|---|---|---|---|---|

| SBET (m2 g−1) | 85 | −31 | 92 | −27 |

| Vpore (cm3 g−1) | 0.18 | −50 | 0.2 | −40 |

| Vmicropore (cm3 g−1) | 0.02 | −50 | 0.03 | −30 |

| dp (Å) | 208 | 80 | 170 | 60 |

| Total acidity (μmolNH3 g−1) | 24 | −20 | 26 | −24 |

| Average acid strength (kJ mol−1) | 71 | −29 | 65 | −32 |

| Brönsted/Lewis (B/L) ratio (mol mol−1) | 0.33 | −50 | 0.28 | −59 |

| - | Catalyst | 500 °C | 530 °C | 560 °C |

|---|---|---|---|---|

| C2=/C2 Total. | CY | 0.63 | 0.66 | 0.65 |

| CH | 0.78 | 0.80 | 0.75 | |

| C3=/C3 Total | CY | 0.75 | 0.73 | 0.72 |

| CH | 0.75 | 0.74 | 0.73 | |

| C4=/C4 Total | CY | 0.48 | 0.49 | 0.51 |

| CH | 0.60 | 0.60 | 0.61 |

| - | Catalyst | 500 °C | 530 °C | 560 °C |

|---|---|---|---|---|

| Xoxygenates | CY | 82.6 | 87.1 | 91.2 |

| CH | 86.0 | 89.5 | 93.4 | |

| DOD | CY | 91.0 | 93.0 | 95.0 |

| CH | 92.5 | 95.1 | 96.7 | |

| Yfuel | CY | 62.2 | 59.3 | 51.9 |

| CH | 60.3 | 56.9 | 50.3 | |

| Ox/C | CY | 0.10 | 0.09 | 0.08 |

| CH | 0.09 | 0.08 | 0.08 |

| - | CY | CZ |

|---|---|---|

| SBET (m2 g−1) | 122 | 143 |

| Vpore (cm3 g−1) | 0.35 | 0.24 |

| Vmicropore (cm3 g−1) | 0.04 | 0.02 |

| dp (Å) | 117.3 | 62.2 |

| Unit cell size (Å) | 24.30 | - |

| Total acidity (μmolNH3 g−1) | 30 | 50 |

| Average acid strength (kJ mol−1) | 100 | 78 |

| B/L ratio (mol mol−1) | 0.75 | 0.22 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibarra, Á.; Hita, I.; Arandes, J.M.; Bilbao, J. A Hybrid FCC/HZSM-5 Catalyst for the Catalytic Cracking of a VGO/Bio-Oil Blend in FCC Conditions. Catalysts 2020, 10, 1157. https://doi.org/10.3390/catal10101157

Ibarra Á, Hita I, Arandes JM, Bilbao J. A Hybrid FCC/HZSM-5 Catalyst for the Catalytic Cracking of a VGO/Bio-Oil Blend in FCC Conditions. Catalysts. 2020; 10(10):1157. https://doi.org/10.3390/catal10101157

Chicago/Turabian StyleIbarra, Álvaro, Idoia Hita, José M. Arandes, and Javier Bilbao. 2020. "A Hybrid FCC/HZSM-5 Catalyst for the Catalytic Cracking of a VGO/Bio-Oil Blend in FCC Conditions" Catalysts 10, no. 10: 1157. https://doi.org/10.3390/catal10101157

APA StyleIbarra, Á., Hita, I., Arandes, J. M., & Bilbao, J. (2020). A Hybrid FCC/HZSM-5 Catalyst for the Catalytic Cracking of a VGO/Bio-Oil Blend in FCC Conditions. Catalysts, 10(10), 1157. https://doi.org/10.3390/catal10101157