Digital Tech Integration in Industrial Engineer Training via Affordable Academic Tools

Abstract

1. Introduction

- RQ1:

- How can low-cost open-source technologies be integrated into FAPs to foster Industry 4.0 skills?

- RQ2:

- What is the educational impact and perceived usability of these implementations among students?

2. Educational Framework for Industry 4.0 Competencies

2.1. Competencies and Knowledge Areas for Industry 4.0

- Personal competencies, understood as the ability to act in a reflective and autonomous manner, making informed decisions independently.

- Social competencies, referring to the ability to communicate effectively, collaborate, and establish social connections and structures with other individuals and organizations.

- Action-related competencies, defined as the ability to plan, organize, and implement actions effectively, applying knowledge and concepts in practical contexts to achieve the intended goals.

- Domain-related competencies, alludes to the ability to reach and use techniques, dialects, and instruments that are especially important for a business or trade area.

2.2. Pedagogical Approaches for Engineering Education

- Behaviorism: This model can be condensed into three words: stimulus, behavior, and reinforcement. It is based on applying reinforcement to encourage desired behaviors and punishment to discourage undesired ones. Education is seen as gradually building skills and information into discrete components [66].

- Cognitivism: This model understands learning as a reorganization of existing cognitive structures. It explains the acquisition of new knowledge through recombination acting on mental schemes [67].

- Cultural-historical: This approach conceives personal development as a cultural construction that occurs through interaction with others in a given culture by means of shared social activities. Every intellectual function must be explained based on its essential relationship with historical and cultural conditions [68].

- Socio-cultural: Similar to the previous model, this approach is based on accumulated knowledge of the social community and interaction between the individual and society. Learning occurs mainly through participation in activities rather than through formal instruction.

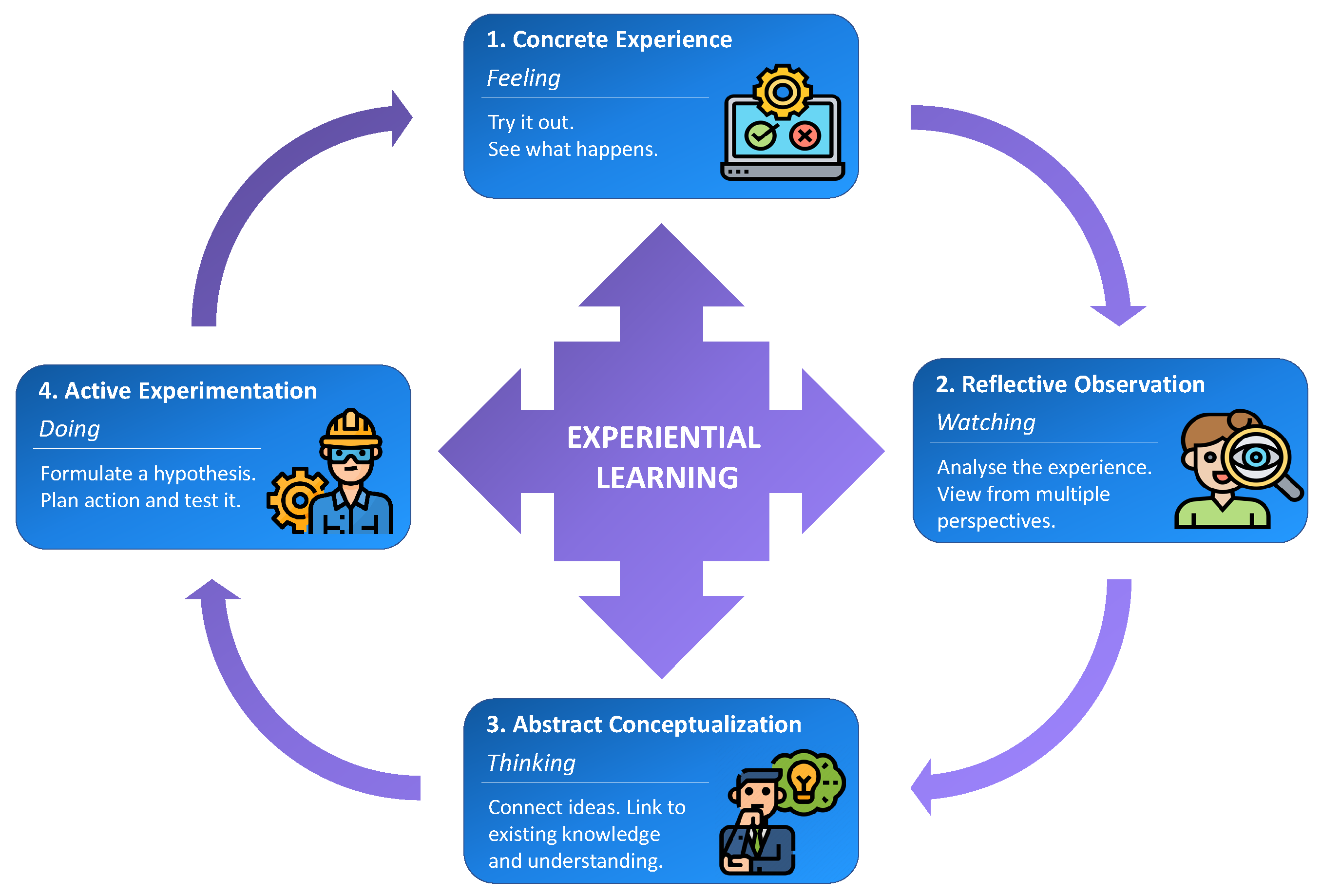

2.3. Experiential Learning as a Framework for Final Academic Projects

- Concrete experience: Immediate and specific experiences that initiate observation. Learners engage in an activity and recall how they felt during the process.

- Reflective observation: Reflection on the experience to analyze outcomes, generate alternatives, and deepen understanding.

- Abstract conceptualization: Development of generalizations and conceptual models based on reflection, enabling pattern recognition and knowledge organization.

- Active experimentation: Application of new concepts in different contexts to validate and refine understanding, focusing on functional goals and improvement.

3. Industry 4.0 Technologies

- Big Data and Analytics: In Industry 4.0 every element of the production process is a source of data, and the analysis of that data can guide decision making and can allow the creation of systems that self-regulate in real time, thereby improving product quality and process efficiency.

- Autonomous Robots: Advances in robotics allow robots to perform increasingly complex tasks and rely less and less on human workers to make decisions.

- Simulation: Traditionally, when a system, machine or production process was to be tested, a physical model was built. With increasingly powerful computers, it is possible to create a digital twin [87,88,89,90,91,92] to replace the physical model, which allows more tests to be performed in less time, thus achieving better quality products more efficiently.

- Horizontal and Vertical System Integration: Data sharing between different points in the value chain is key in Industry 4.0; the greater the flow of data, the greater the degree of cohesion between departments, factories, and companies [93].

- The Industrial Internet of Things (IIoT): The connection of sensors and other production and control elements to a network allows a greater degree of automation and interaction between devices. This also helps to implement solutions for the safety and well-being of workers [94].

- Cybersecurity: In Industry 4.0, production systems are highly connected, making them more vulnerable to a computer attack. As exposure to the outside world increases, the security of information and communication systems must increase.

- The Cloud: The processing and storage of data on servers becomes a necessity when data sharing goes beyond company boundaries.

- Additive Manufacturing: In an industry characterized by flexibility, additive manufacturing technologies such as 3D printing make it possible to produce small batches of customized products.

- Augmented Reality: Augmented reality can provide real-time information to workers to facilitate their work or can even be used for virtual training [95].

Internet of Things in Education

4. Low-Cost Technologies for Academic Use

4.1. Smartphones

- High computational power.

- Capability to network with other devices.

- Sensors such as cameras, gyroscopes, etc.

- Display and speaker (especially necessary in augmented reality applications).

4.2. Android

4.3. Arduino

4.4. NFC

- Reader/Writer Mode. In this mode the NFC device can read or write data to passive devices (without own power supply) such as an NFC tag.

- Card Emulation Mode. The NFC device behaves like a smart card; this mode allows NFC-enabled devices such as smartphones to be used as credit cards or ID cards.

- Peer-to-peer Mode. Allows bidirectional communication between devices for data exchange.

5. Case Study: NFC Access Control System Using Android and Arduino

5.1. Generic Proposal Approach

5.1.1. Web Server

- Use a MySQL relational database hosted on a free web hosting service to store user information and system data.

- Implement communication between the Android application and the database through PHP scripts and the Volley library, using JSON format for data exchange.

- Apply basic security practices, including the use of mysqliprepared statements to prevent SQL injection.

- Support essential operations via HTTP requests, including:

- –

- User log in: Validate credentials and grant access to user data.

- –

- User sign up: Register new users in the database.

- –

- User data query: Retrieve stored information after authentication.

- –

- User data update: Modify existing records based on user input.

- Exclude advanced security mechanisms such as HTTPS encryption and password hashing, as these are beyond the scope of the academic proposal.

5.1.2. Android Application

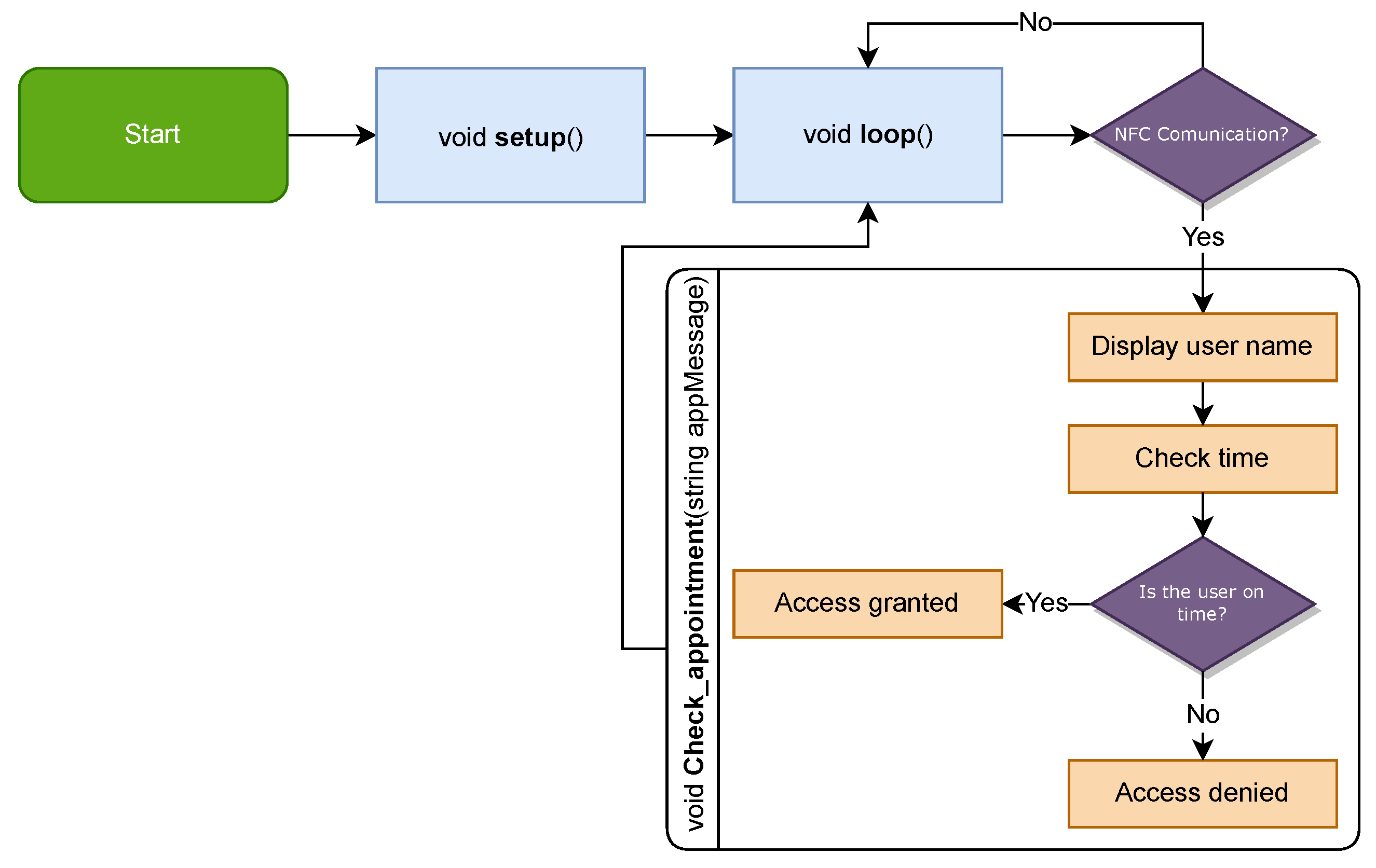

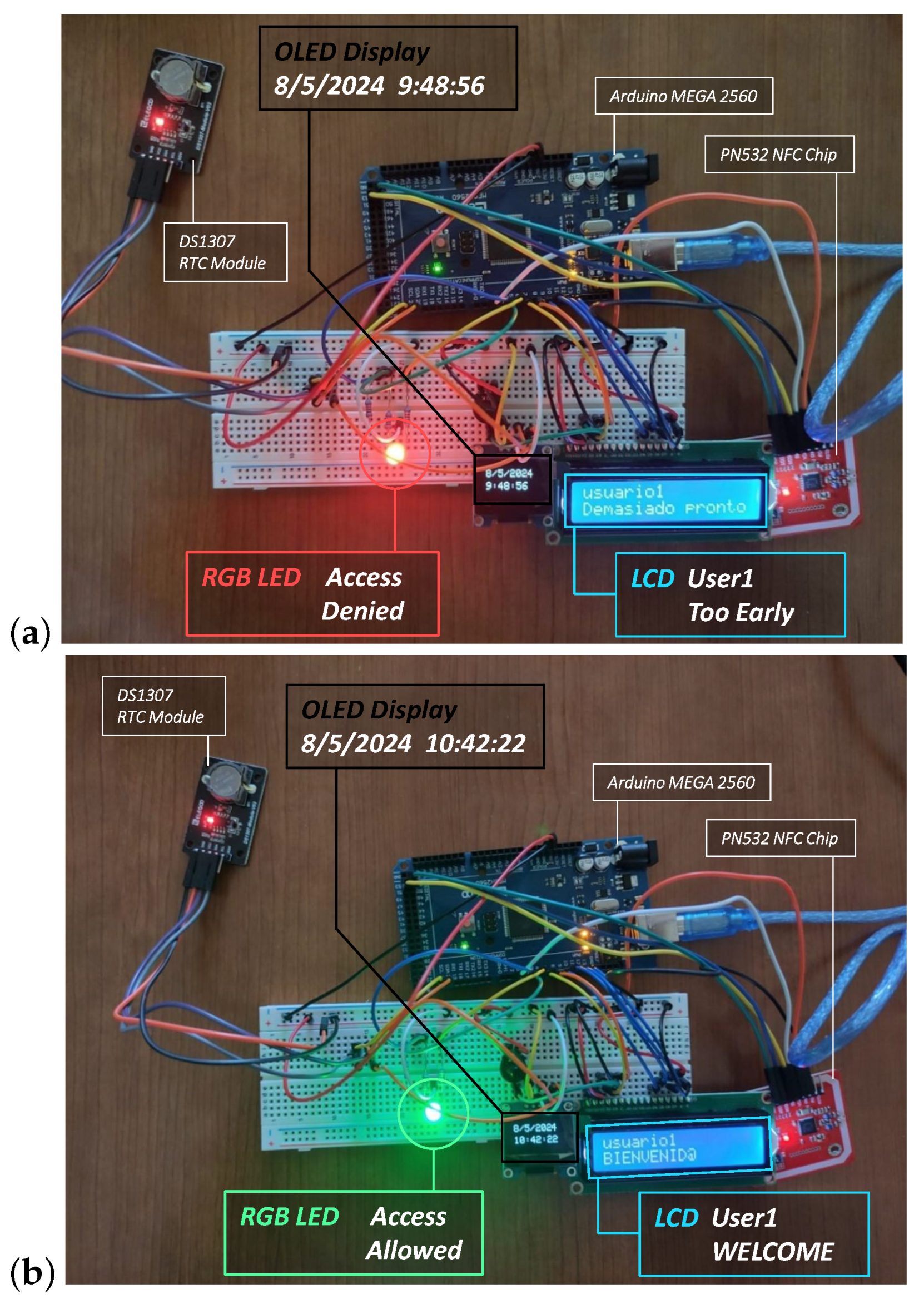

5.1.3. Arduino Control Terminal

5.2. FAP Proposals

5.2.1. NFC Access Control and Payment System for Parking

5.2.2. NFC Access Control and Appointment System for Establishments

6. Results

6.1. Results for the NFC Access Control and Payment System for Parking

6.1.1. Android App for the NFC Parking System

6.1.2. Web Server for the NFC Parking System

- Input: It is used when the user sets the entrance to the car park through the mobile application. In this case, the license plate of the vehicle and the time of entry are sent to the database, thus updating the user’s status.

- Output: It is used when the user sets the exit from the car park. For this case, the values of balance, status, entry time, and license plate are passed. The balance (after payment) and the user status with respect to the car park will be and the entry time will be reset, after payment of the parking fee.

- Recharge: It is used to check the current balance and to add money to the user’s virtual wallet.

6.1.3. Arduino Terminal for the NFC Parking System

- void setup() runs once at the beginning and initializes the configuration for all electronic components.

- void loop() is the main function that runs continuously after setup(). It displays the current time on the LCD and checks for NFC communication. If no NFC device is detected, the loop repeats; otherwise, it calls Barrier_control().

- void Barrier_control(string username) manages access control. When an NFC device is detected, the Arduino displays the user’s name and current time on the LCD and sends the timestamp to the Android application for server update.

6.1.4. Experimental Tests for the NFC Parking System

6.2. Results for the NFC Access Control and Appointment System for Establishment

6.2.1. Android Apps for the NFC Access Control and Appointment System

6.2.2. Web Server for the NFC Access Control and Appointment System

- Registration check user. It is used to check that the user name chosen is not previously reserved by a previously registered user.

- Check user appointments. Checks the database to see if the user has a booked appointment.

- Book appointments. Used by user app to add or delete citations from the database.

- Available appointments. Used to consult the database and show the user the available appointments.

- Booked appointments. Used by administrator app to consult the database for the appointments booked by the users.

- Remove appointments. Used by administrator app to remove appointments from the database.

- Add appointments. Used by administrator app to add new available appointments in the database.

6.2.3. Arduino Terminal for the NFC Access Control and Appointment System

6.2.4. Experimental Tests for the NFC Access Control and Appointment System

7. Empirical Study

7.1. Study Design, Participants, and Procedure

- A six-item perception questionnaire on a 5-point Likert scale, which included the following items:

- –

- Q1: I consider it is important for my future to be trained in key Industry 4.0 technologies such as NFC technology.

- –

- Q2: I find interesting the proposal for the realization of projects based on NFC technology using low-cost tools such as Android and/or Arduino for the improvement of the industrial engineering student’s training.

- –

- Q3: The development of projects on NFC technology integrating Arduino and/or Android is related to the contents of the course curriculum.

- –

- Q4: Developing projects on NFC technology integrating the use of smartphones and Arduino electronic circuits would complement my training.

- –

- Q5: I would like to develop a project similar to those shown in the case studies for my future thesis.

- –

- Q6: I find it technically complicated to develop the projects shown as examples in the case studies.

- System Usability Scale in Spanish, consisting of 10 items rated on a 5-point Likert scale [121]. The total score was converted to a 0–100 scale, where scores of 68 or higher are considered acceptable.

7.2. Analysis of the Results

8. Discussion

8.1. Pedagogical Rationale and Framework

8.2. Integration of Low-Cost Technologies (RQ1)

8.3. Educational Impact and Usability (RQ2)

8.4. Curricular and Institutional Challenges

8.5. Limitations and Future Directions

9. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Lorenzo, N.; Gallon, R.; Palau, R.; Mogas, J. New objectives for smart classrooms from industry 4.0. Technol. Knowl. Learn. 2021, 26, 719–731. [Google Scholar] [CrossRef]

- Zhu, X.; Ge, S.; Wang, N. Digital transformation: A systematic literature review. Comput. Ind. Eng. 2021, 162, 107774. [Google Scholar] [CrossRef]

- Klingenberg, C.O.; Borges, M.A.V.; Antunes, J.A.V., Jr. Industry 4.0 as a data-driven paradigm: A systematic literature review on technologies. J. Manuf. Technol. Manag. 2021, 32, 570–592. [Google Scholar] [CrossRef]

- Roda-Sanchez, L.; Olivares, T.; Garrido-Hidalgo, C.; de la Vara, J.L.; Fernández-Caballero, A. Human-robot interaction in Industry 4.0 based on an Internet of Things real-time gesture control system. Integr.-Comput.-Aided Eng. 2021, 28, 159–175. [Google Scholar] [CrossRef]

- Roda-Sanchez, L.; Garrido-Hidalgo, C.; García, A.S.; Olivares, T.; Fernández-Caballero, A. Comparison of RGB-D and IMU-based gesture recognition for human-robot interaction in remanufacturing. Int. J. Adv. Manuf. Technol. 2023, 124, 3099–3111. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Garrido-Hidalgo, C.; Roda-Sanchez, L.; Fernández-Caballero, A.; Olivares, T.; Ramírez, F.J. Internet-of-Things framework for scalable end-of-life condition monitoring in remanufacturing. Integr.-Comput.-Aided Eng. 2024, 31, 1–17. [Google Scholar] [CrossRef]

- Lucena, J.C.; Schneider, J. Engineers, development, and engineering education: From national to sustainable community development. Eur. J. Eng. Educ. 2008, 33, 247–257. [Google Scholar] [CrossRef]

- Long, L.N.; Blanchette, S.; Kelley, T.D.; Hohnka, M. The Crucial Need to Modernize Engineering Education. In Proceedings of the 2019 IEEE Aerospace Conference, Big Sky, MT, USA, 2–9 March 2019; pp. 1–9. [Google Scholar] [CrossRef]

- Male, S.A.; Bush, M.B.; Chapman, E.S. Perceptions of Competency Deficiencies in Engineering Graduates. Australas. J. Eng. Educ. 2010, 16, 55–68. [Google Scholar] [CrossRef]

- Bao Iturbe, C.; Lopez Ochoa, L.; Juarez Castello, M.; Castresana Pelayo, J. Educating the engineer of 2020: Adapting engineering education to the new century. In Proceedings of the 3rd International Technology, Education and Development Conference, Valencia, Spain, 9–11 March 2009; pp. 1110–1121. [Google Scholar]

- Akkari, A.C.S.; Rocha, M.F.M.d.; Farias Novaes, R.F.d. Cognitive ergonomics and the Industry 4.0. In Brazilian Technology Symposium; Springer: Cham, Switzerland, 2017; pp. 275–280. [Google Scholar]

- Biały, W.; Gajdzik, B.; Jimeno, C.L.; Romanyshyn, L. Engineer 4.0 in a metallurgical enterprise. Multidiscip. Asp. Prod. Eng. 2019, 2, 172–182. [Google Scholar] [CrossRef]

- Forcael, E.; Garcés, G.; Erazo, P.B.; Bastías, L. How do we teach? A practical guide for engineering educators. Int. J. Eng. Educ. 2018, 34, 1451–1466. [Google Scholar]

- Litzinger, T.; Lattuca, L.; Hadgraft, R.; Newstetter, W.; Alley, M.; Atman, C.; DiBiasio, D.; Finelli, C.; Diefes-Dux, H.; Kolmos, A.; et al. Engineering education and the development of expertise. Eng. Educ. 2011, 100, 123–150. [Google Scholar] [CrossRef]

- Akşit, M. The role of computer science and software technology in organizing universities for Industry 4.0 and beyond. In Proceedings of the 2018 Federated Conference on Computer Science and Information Systems, Poznan, Poland, 9–12 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 5–11. [Google Scholar]

- Sommer, L. Industrial revolution-industry 4.0: Are German manufacturing SMEs the first victims of this revolution? J. Ind. Eng. Manag. 2015, 8, 1512–1532. [Google Scholar] [CrossRef]

- Lima, R.M.; Mesquita, D.; Sousa, R.M.; Monteiro, M.T.T.; Cunha, J. Curriculum Analysis Process: Analysing Fourteen Industrial Engineering Programs. 2019. Available online: http://repositorium.sdum.uminho.pt/handle/1822/66284 (accessed on 20 October 2025).

- Valenzuela, J.; Smith, J.; Reece, B.; Shannon, D. Integrating Computer Programming Technologies Into The Industrial Engineering Curriculum. In Proceedings of the 2010 Annual Conference & Exposition, Louisville, KY, USA, 20–23 June 2010; pp. 15–759. [Google Scholar]

- Turns, J.; Atman, C.J.; Adams, R.S.; Barker, T.J. Research on Engineering Student Knowing: Trends and Opportunities. J. Eng. Educ. 2005, 94, 27–40. [Google Scholar] [CrossRef]

- Narvaez Rojas, C.; Alomia Peñafiel, G.A.; Loaiza Buitrago, D.F.; Tavera Romero, C.A. Society 5.0: A Japanese concept for a superintelligent society. Sustainability 2021, 13, 6567. [Google Scholar] [CrossRef]

- Abele, E.; Metternich, J.; Tisch, M.; Chryssolouris, G.; Sihn, W.; ElMaraghy, H.; Hummel, V.; Ranz, F. Learning Factories for Research, Education, and Training. Procedia CIRP 2015, 32, 1–6. [Google Scholar] [CrossRef]

- Baena, F.; Guarin, A.; Mora, J.; Sauza, J.; Retat, S. Learning Factory: The Path to Industry 4.0. Procedia Manuf. 2017, 9, 73–80. [Google Scholar] [CrossRef]

- Bhedasgaonkar, R.C.; Chavan, M.S.; Kubade, P.R.; Patil, S.B. Course Level PBL: An Excellent Teaching Method for Increasing Skill Levels and Learning Motivation in First Year of Engineering Students. J. Eng. Educ. Transform. 2020, 33, 101–106. [Google Scholar]

- Bremgartner, V.; de Magalhães Netto, J.F.; de Menezes, C.S. Adaptation resources in virtual learning environments under constructivist approach: A systematic review. In Proceedings of the 2015 IEEE Frontiers in Education Conference, El Paso, TX, USA, 21–24 October 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Jaeger, M.; Adair, D. Impact of PBL on engineering students’ motivation in the GCC region: Case study. In Proceedings of the 2018 Advances in Science and Engineering Technology International Conferences, Abu Dhabi, United Arab Emirates, 6 February–5 April 2018; pp. 1–7. [Google Scholar] [CrossRef]

- Le, T.Q.; Do, T.T.A. Active Teaching Techniques for Engineering Students to Ensure The Learning Outcomes of Training Programs by CDIO Approach. Int. J. Adv. Sci. Eng. Inf. Technol. 2019, 9, 266–273. [Google Scholar] [CrossRef]

- Sun, Z.; Xie, K.; Anderman, L.H. The role of self-regulated learning in students’ success in flipped undergraduate math courses. Internet High. Educ. 2018, 36, 41–53. [Google Scholar] [CrossRef]

- Sloat, K.C.; Tharp, R.G.; Gallimore, R. The incremental effectiveness of classroom-based teacher-training techniques. Behav. Ther. 1977, 8, 810–818. [Google Scholar] [CrossRef]

- Leonard, D. Learning Theories, A to Z; ABC-Clio ebook; Greenwood Press: Westport, CT, USA, 2002. [Google Scholar]

- Bajaj, R.; Sharma, V. Smart Education with artificial intelligence based determination of learning styles. Procedia Comput. Sci. 2018, 132, 834–842. [Google Scholar] [CrossRef]

- Konak, A.; Clark, T.K.; Nasereddin, M. Using Kolb’s Experiential Learning Cycle to improve student learning in virtual computer laboratories. Comput. Educ. 2014, 72, 11–22. [Google Scholar] [CrossRef]

- Kolb, D. Experiential Learning: Experience as the Source of Learning and Development; Prentice Hall: Englewood Cliffs, NJ, USA, 1984; Volume 1. [Google Scholar]

- Felder, R. Learning and Teaching Styles in Engineering Education. J. Eng. Educ. 1988, 78, 674–681. [Google Scholar]

- Fleming, N. Teaching and Learning Styles: VARK Strategies; N.D. Fleming: Hong Kong, China, 2006. [Google Scholar]

- Mayer, R.E.; Heiser, J.; Lonn, S. Cognitive constraints on multimedia learning: When presenting more material results in less understanding. J. Educ. Psychol. 2001, 93, 187–198. [Google Scholar] [CrossRef]

- Coşkun, S.; Kayıkcı, Y.; Gençay, E. Adapting Engineering Education to Industry 4.0 Vision. Technologies 2019, 7, 10. [Google Scholar] [CrossRef]

- Briede, B.; Popova, N. Self-directed learning of university engineering students in context of fourth industrial revolution. In Proceedings of the 19th International Scientific Conference on Engineering for Rural Development, Jelgava, Latvia, 20–22 May 2020; Volume 19, pp. 1594–1600. [Google Scholar]

- Keys, B.; Wolfe, J. The Role of Management Games and Simulations in Education and Research. J. Manag. 1990, 16, 307–336. [Google Scholar] [CrossRef]

- Teunissen, P.W.; Dornan, T. Lifelong learning at work. BMJ 2008, 336, 667–669. [Google Scholar] [CrossRef]

- Fleming, G.C.; Klopfer, M.; Katz, A.; Knight, D. What engineering employers want: An analysis of technical and professional skills in engineering job advertisements. J. Eng. Educ. 2024, 113, 251–279. [Google Scholar] [CrossRef]

- Towle, A.; Cottrell, D. Self directed learning. Arch. Dis. Child. 1996, 74, 357–359. [Google Scholar] [CrossRef]

- Segura, E.; Belmonte, L.; Fernández-Caballero, A.; Morales, R. Economics 4.0: A proposal of a training complement for the development of final degree projects in industrial engineering programs at Universidad de Castilla-La Mancha in the new Industry 4.0 era. In Proceedings of the 14th International Technology, Education and Development Conference, Valencia, Spain, 2–4 March 2020; pp. 2917–2924. [Google Scholar] [CrossRef]

- Belmonte, L.; Segura, E.; Fernández-Caballero, A.; Morales, R. A proposal to improve practical skills learning in mobile robotics through LEGO Mindstorms NXT. In Proceedings of the 14th International Technology, Education and Development Conference, Valencia, Spain, 2–4 March 2020; pp. 2933–2942. [Google Scholar] [CrossRef]

- Belmonte, L.; Segura, E.; Fernández-Caballero, A.; Morales, R. Towards Industry 4.0: Using LEGO Mindstorms and Android for the development of final degree projects in industrial engineering programs. In Proceedings of the 14th International Technology, Education and Development Conference, Valencia, Spain, 2–4 March 2020; pp. 2958–2967. [Google Scholar] [CrossRef]

- Belmonte, L.M.; Segura, E.; de la Rosa, F.L.; Gómez-Sirvent, J.L.; Fernández-Caballero, A.; Morales, R. Training industrial engineers in Logistics 4.0. Comput. Ind. Eng. 2023, 184, 109550. [Google Scholar] [CrossRef]

- Belmonte, L.; Segura, E.; Fernández-Caballero, A.; Lucas, A.; Morales, R. Use of low-cost technology in final degree projects for the training of engineers in the framework of industry 4.0: A case study of a mobile robot prototype for fused deposition modelling. In Proceedings of the 17th International Technology, Education and Development Conference, Valencia, Spain, 6–8 March 2023; pp. 5351–5360. [Google Scholar] [CrossRef]

- Belmonte, L.; Segura, E.; Fernández-Caballero, A.; Vigo-Bustos, F.; García, A.; Morales, R. Artificial intelligence training of future industry 4.0 engineers using lego mindstorms in final degree projects: Autonomous vehicle protype as case study. In Proceedings of the 17th International Technology, Education and Development Conference, Valencia, Spain, 6–8 March 2023; pp. 5371–5380. [Google Scholar] [CrossRef]

- Feisel, L.; Rosa, A. The Role of the Laboratory in Undergraduate Engineering Education. J. Eng. Educ. 2005, 94, 121–130. [Google Scholar] [CrossRef]

- Paravizo, E.; Chaim, O.C.; Braatz, D.; Muschard, B.; Rozenfeld, H. Exploring gamification to support manufacturing education on Industry 4.0 as an enabler for innovation and sustainability. Procedia Manuf. 2018, 21, 438–445. [Google Scholar] [CrossRef]

- Carrington, D.; Kim, S.K. Teaching software design with open source software. In Proceedings of the 2003 33rd Annual Frontiers in Education, Westminster, CO, USA, 5–8 November 2003; IEEE: Piscataway, NJ, USA, 2003; Volume 3. [Google Scholar]

- Petrenko, M.; Poshyvanyk, D.; Rajlich, V.; Buchta, J. Teaching software evolution in open source. Computer 2007, 40, 25–31. [Google Scholar] [CrossRef]

- Khaddar, M.A.E.; Boulmalf, M. Smartphone: The Ultimate IoT and IoE Device. In Smartphones from an Applied Research Perspective; Mohamudally, N., Ed.; IntechOpen: Rijeka, Croatia, 2017; Chapter 7; pp. 1–26. [Google Scholar] [CrossRef]

- Shih, S.T.; Li, I.C. A Light Monitoring System with Smartphone Control based on Industry 4.0. In Proceedings of the 2021 International Symposium on Intelligent Signal Processing and Communication Systems, Hualien City, Taiwan, 16–19 November 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–2. [Google Scholar]

- Bryant, P.; Gradwell, G.; Claveau, D. Autonomous UAS controlled by onboard smartphone. In Proceedings of the 2015 International Conference on Unmanned Aircraft Systems, Denver, CO, USA, 9–12 June 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 451–454. [Google Scholar]

- Keefe, R.F.; Zimbelman, E.G.; Wempe, A.M. Use of smartphone sensors to quantify the productive cycle elements of hand fallers on industrial cable logging operations. Int. J. For. Eng. 2019, 30, 132–143. [Google Scholar] [CrossRef]

- Madsen, E.S.; Bilberg, A.; Hansen, D.G. Industry 4.0 and digitalization call for vocational skills, applied industrial engineering, and less for pure academics. In Proceedings of the 5th P&OM World Conference, Production and Operations Management, Havana, Cuba, 6–10 September 2016; Volume 40, pp. 1–10. [Google Scholar]

- Brezeanu, T.; Lazarou, E. Alignment between engineering curriculum and skills development for industry 4.0. In Proceedings of the eLearning and Software for Education, Bucharest, Romania, 21–22 April 2020; University Publishing House: Bucharest, Romania, 2020; Volume 2, pp. 328–334. [Google Scholar] [CrossRef]

- Beagon, U.; Bowe, B. Understanding professional skills in engineering education: A phenomenographic study of faculty conceptions. J. Eng. Educ. 2023, 112, 1109–1144. [Google Scholar] [CrossRef]

- Deters, J.R.; Paretti, M.C.; Perry, L.A.; Ott, R. What does it mean to be “prepared for work”? Perceptions of new engineers. J. Eng. Educ. 2023, 113, 103–123. [Google Scholar] [CrossRef]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A Scenario-Based Approach to Learning for the Future of Production. Procedia CIRP 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Huba, M.; Kozak, S. From e-Learning to Industry 4.0. In Proceedings of the 2016 International Conference on Emerging eLearning Technologies and Applications, Stary Smokovec, Slovakia, 24–25 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Kagermann, H. Change Through Digitization—Value Creation in the Age of Industry 4.0. In Management of Permanent Change; Springer Fachmedien Wiesbaden: Berlin/Heidelberg, Germany, 2014; pp. 23–45. [Google Scholar] [CrossRef]

- Hassan, O.A. Learning theories and assessment methodologies–an engineering educational perspective. Eur. J. Eng. Educ. 2011, 36, 327–339. [Google Scholar] [CrossRef]

- Skinner, B. The Technology of Teaching; ERIC: New York, NY, USA, 1968.

- Lefa, B. The Piaget theory of cognitive development: An educational implications. Educ. Psychol. 2014, 1, 1–8. [Google Scholar]

- Tudge, J.; Scrimsher, S. Lev S. Vygotsky on education: A cultural-historical, interpersonal, and individual approach to development. In Educational Psychology: A Century of Contributions; Routledge: Abingdon, UK, 2014; pp. 207–228. [Google Scholar]

- Lavado-Anguera, S.; Velasco-Quintana, P.J.; Terrón-López, M.J. Project-Based Learning (PBL) as an Experiential Pedagogical Methodology in Engineering Education: A Review of the Literature. Educ. Sci. 2024, 14, 617. [Google Scholar] [CrossRef]

- Reyes-Zárate, G.G.; Garay-Rondero, C.L. Experiential Learning for Industry 4.0 in Higher Education: A Challenge-Based Learning Case Study. In Proceedings of the 6th International Conference on Intelligent Human Systems Integration (IHSI 2023), Venice, Italy, 22–24 February 2023; pp. 880–887. [Google Scholar] [CrossRef]

- Sundman, J.; Feng, X.; Shrestha, A.; Johri, A.; Varis, O.; Taka, M. Experiential learning for sustainability: A systematic review and research agenda for engineering education. Eur. J. Eng. Educ. 2025, 50, 239–259. [Google Scholar] [CrossRef]

- González-Pérez, L.I.; Ramírez-Montoya, M.S. Components of Education 4.0 in 21st Century Skills Frameworks: Systematic Review. Sustainability 2022, 14, 1493. [Google Scholar] [CrossRef]

- Morris, T.H. Experiential learning—A systematic review and revision of Kolb’s model. Interact. Learn. Environ. 2020, 28, 1064–1077. [Google Scholar] [CrossRef]

- Lal, B.; Nawaz, M.; Zabiri, H.; Li, C.S.; Kumar, P. Experiential Learning in Engineering Education: A Bibliometric Analysis of Perceptions and Transformations. Int. J. Teach. Learn. Educ. 2025, 4, 632879. [Google Scholar] [CrossRef]

- Portero, F.B.; Medina, R.P. Estudio teórico sobre Metodologías Activas en la educación básica. Rev. Espac. 2025, 46, 68–80. [Google Scholar] [CrossRef]

- Harb, J.N.; Durrant, S.O.; Terry, R.E. Use of the Kolb learning cycle and the 4MAT system in engineering education. J. Eng. Educ. 1993, 82, 70–77. [Google Scholar] [CrossRef]

- Sharp, J.E.; Harb, J.N.; Terry, R.E. Combining Kolb learning styles and writing to learn in engineering classes. J. Eng. Educ. 1997, 86, 93–101. [Google Scholar] [CrossRef]

- Cagiltay, N.E. Using learning styles theory in engineering education. Eur. J. Eng. Educ. 2008, 33, 415–424. [Google Scholar] [CrossRef]

- Ogot, M.; Okudan, G.E. Systematic creativity methods in engineering education: A learning styles perspective. Int. J. Eng. Educ. 2006, 22, 566–577. [Google Scholar]

- Ludwig, P.M.; Nagel, J.K.; Lewis, E.J. Student learning outcomes from a pilot medical innovations course with nursing, engineering, and biology undergraduate students. Int. J. Stem Educ. 2017, 4, 33. [Google Scholar] [CrossRef] [PubMed]

- Kolb, D.A.; Boyatzis, R.E.; Mainemelis, C. Experiential learning theory: Previous research and new directions. In Perspectives on Thinking, Learning, and Cognitive Styles; Routledge: Abingdon, UK, 2014; pp. 227–248. [Google Scholar]

- Alves, C.; Putnik, G. Experiential Learning of CAD Systems Interoperability in Social Network-based Education. Procedia CIRP 2019, 84, 209–214. [Google Scholar] [CrossRef]

- Bonavolonta, F.; D’Arco, M.; Liccardo, A.; Tamburis, O. Remote laboratory design and implementation as a measurement and automation experiential learning opportunity. IEEE Instrum. Meas. Mag. 2019, 22, 62–67. [Google Scholar] [CrossRef]

- Centea, D.; Srinivasan, S.; Singh, I.; Wanyama, T. A Collaborative Approach in Designing Curriculum for Industry 4.0 Software Integration Implementation. In Advances in Intelligent Systems and Computing; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 135–144. [Google Scholar] [CrossRef]

- Hwang, J.S. The fourth industrial revolution (Industry 4.0): Intelligent manufacturing. SMT Mag. 2016, 3, 616–630. [Google Scholar]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- de Paula Ferreira, W.; Armellini, F.; De Santa-Eulalia, L.A. Simulation in Industry 4.0: A state-of-the-art review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Belmonte, L.M.; García, A.S.; Segura, E.; Novais, P.; Morales, R.; Fernández-Caballero, A. Virtual Reality Simulation of a Quadrotor to Monitor Dependent People at Home. IEEE Trans. Emerg. Top. Comput. 2021, 9, 1301–1315. [Google Scholar] [CrossRef]

- Bustamante, A.; Belmonte, L.M.; Pereira, A.; Morales, R.; Fernández-Caballero, A. Skeleton-Based Posture Recognition for Home Care From Virtual Unmanned Aerial Vehicle. Expert Syst. 2025, 42, e70108. [Google Scholar] [CrossRef]

- De las Morenas, J.; Belmonte, L.M.; Morales, R. Streamlined Bearing Fault Detection Using Artificial Intelligence in Permanent Magnet Synchronous Motors. Machines 2025, 13, 357. [Google Scholar] [CrossRef]

- De las Morenas, J.; Belmonte, L.M.; Morales, R. Designing an AI-driven digital twin architecture for building energy prediction. J. Build. Eng. 2025, 113, 113966. [Google Scholar] [CrossRef]

- Tiwari, S. Supply chain integration and Industry 4.0: A systematic literature review. Benchmarking Int. J. 2021, 28, 990–1030. [Google Scholar] [CrossRef]

- Bavaresco, R.; Arruda, H.; Rocha, E.; Barbosa, J.; Li, G.P. Internet of Things and occupational well-being in Industry 4.0: A systematic mapping study and taxonomy. Comput. Ind. Eng. 2021, 161, 107670. [Google Scholar] [CrossRef]

- Segura, Á.; Diez, H.V.; Barandiaran, I.; Arbelaiz, A.; Álvarez, H.; Simões, B.; Posada, J.; García-Alonso, A.; Ugarte, R. Visual computing technologies to support the Operator 4.0. Comput. Ind. Eng. 2020, 139, 105550. [Google Scholar] [CrossRef]

- Todorova, A.; Kostadinova, I.; Stefanova, S. Developing Sustainability Problem-Solving Skills Through Internet of Things Projects. Sustainability 2025, 17, 10367. [Google Scholar] [CrossRef]

- Cáceres-Tello, J.; Galán-Hernández, J.J.; Morales Cevallo, M.B.; López-Meneses, E. Citizen Science and STEM Education with AI–IoT Forecasting and Reproducible Learning from Open Urban Air Quality Data. Appl. Sci. 2025, 15, 12183. [Google Scholar] [CrossRef]

- Ghashim, I.A.; Arshad, M. Internet of Things (IoT)-Based Teaching and Learning: Modern Trends and Open Challenges. Sustainability 2023, 15, 15656. [Google Scholar] [CrossRef]

- Kraśniewski, A. Integrating Project-Based Learning into Innovative Studies in IoT Engineering. Int. J. Electron. Telecommun. 2025, 71, 161–169. [Google Scholar] [CrossRef]

- Plaga, S.; Wiedermann, N.; Anton, S.D.; Tatschner, S.; Schotten, H.; Newe, T. Securing future decentralised industrial IoT infrastructures: Challenges and free open source solutions. Future Gener. Comput. Syst. 2019, 93, 596–608. [Google Scholar] [CrossRef]

- Kim, M.; Lee, J.; Jeong, J. Open Source Based Industrial IoT Platforms for Smart Factory: Concept, Comparison and Challenges. In International Conference on Computational Science and Its Applications—ICCSA 2019; Misra, S., Gervasi, O., Murgante, B., Stankova, E., Korkhov, V., Torre, C., Rocha, A.M.A., Taniar, D., Apduhan, B.O., Tarantino, E., Eds.; Springer: Cham, Switzerland, 2019; pp. 105–120. [Google Scholar]

- Schizas, N.; Karras, A.; Karras, C.; Sioutas, S. TinyML for Ultra-Low Power AI and Large Scale IoT Deployments: A Systematic Review. Future Internet 2024, 14, 363. [Google Scholar] [CrossRef]

- Karras, A.; Giannaros, A.; Karras, C.; Theodorakopoulos, L.; Mammassis, C.S.; Krimpas, G.A.; Sioutas, S. TinyML Algorithms for Big Data Management in Large-Scale IoT Systems. Future Internet 2024, 16, 42. [Google Scholar] [CrossRef]

- Sheikh, A.A.; Ganai, P.T.; Malik, N.A.; Dar, K.A. Smartphone: Android Vs IOS. SIJ Trans. Comput. Sci. Eng. Appl. 2013, 1, 31–38. [Google Scholar] [CrossRef]

- Elder, A. College students’ cell phone use, beliefs, and effects on their learning. Coll. Stud. J. 2013, 47, 585–592. [Google Scholar]

- NetMarketShare. Market Share for Mobile, Browsers, Operating Systems and Search Engines. 2024. Available online: https://netmarketshare.com/ (accessed on 25 October 2025).

- Android. Android—Secure & Reliable Mobile Operating System. 2024. Available online: https://www.android.com/ (accessed on 24 October 2025).

- Arnold, K.; Gosling, J.; Holmes, D. The Java Programming Language, 4th ed.; Addison Wesley Professional: Boston, MA, USA, 2005. [Google Scholar]

- Google Developers. Android Mobile App Developer Tools. 2024. Available online: https://developer.android.com/ (accessed on 24 October 2025).

- Jackson, W. The future of Android IoT APIs: Android TV, Glass, Auto, and Wear. In Pro Android Wearables; Springer: Berlin/Heidelberg, Germany, 2015; pp. 521–538. [Google Scholar]

- Tigrek, S.; Obadat, M. Teaching smartphones programming using Android Java: Pedagogy and innovation. In Proceedings of the 2012 International Conference on Information Technology Based Higher Education and Training, Istanbul, Turkey, 21–23 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1–7. [Google Scholar] [CrossRef]

- El-Abd, M. A review of embedded systems education in the Arduino age: Lessons learned and future directions. Int. J. Eng. Pedagog. 2017, 7, 79––93. [Google Scholar] [CrossRef]

- Kim, S.M.; Choi, Y.; Suh, J. Applications of the open-source hardware Arduino platform in the mining industry: A review. Appl. Sci. 2020, 10, 5018. [Google Scholar] [CrossRef]

- Blum, J. Exploring Arduino: Tools and Techniques for Engineering Wizardry; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Satapathy, L.M.; Bastia, S.K.; Mohanty, N. Arduino based home automation using Internet of Things (IoT). Int. J. Pure Appl. Math. 2018, 118, 769–778. [Google Scholar]

- Shajahan, A.H.; Anand, A. Data acquisition and control using Arduino-Android platform: Smart plug. In Proceedings of the 2013 International Conference on Energy Efficient Technologies for Sustainability, Nagercoil, India, 10–12 April 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 241–244. [Google Scholar]

- Madlmayr, G.; Langer, J.; Kantner, C.; Scharinger, J. NFC Devices: Security and Privacy. In Proceedings of the 2008 Third International Conference on Availability, Reliability and Security, Barcelona, Spain, 4–7 March 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 642–647. [Google Scholar] [CrossRef]

- Lazaro, A.; Villarino, R.; Girbau, D. A Survey of NFC Sensors Based on Energy Harvesting for IoT Applications. Sensors 2018, 18, 3746. [Google Scholar] [CrossRef] [PubMed]

- Albattath, A.; Alghofaili, Y.; Elkhediri, S. NFC Technology: Assessment Effective of Security towards Protecting NFC Devices & Services. In Proceedings of the 2020 International Conference on Computing and Information Technology, Tabuk, Saudi Arabia, 9–10 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Brooke, J. SUS–A quick and dirty usability scale. Usability Eval. Ind. 1996, 189, 4–7. [Google Scholar]

- Sevilla-Gonzalez, M.D.R.; Moreno Loaeza, L.; Lazaro-Carrera, L.S.; Bourguet Ramirez, B.; Vázquez Rodríguez, A.; Peralta-Pedrero, M.L.; Almeda-Valdes, P. Spanish Version of the System Usability Scale for the Assessment of Electronic Tools: Development and Validation. Jmir Hum. Factors 2020, 7, e21161. [Google Scholar] [CrossRef] [PubMed]

- Jaladara, H.S.; Pahlevi, R.R.; Nuha, H.H. System Usability Scale Analysis of Infusion Fluid Level Monitoring and Notification System Using IoT. In Proceedings of the 2022 IEEE International Conference on Communication, Networks and Satellite, Solo, Indonesia, 3–5 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 112–117. [Google Scholar] [CrossRef]

- Muharram, R.H.A.; Sudarmilah, E. Design and development of automatic fish feeding application based on Arduino Uno and Android. In Proceedings of the AIP Conference Proceedings, Sorong, Indonesia, 8 September 2022; AIP Publishing: Melville, NY, USA, 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Clark, N.; Dabkowski, M.; Driscoll, P.J.; Kennedy, D.; Kloo, I.; Shi, H. Empirical Decision Rules for Improving the Uncertainty Reporting of Small Sample System Usability Scale Scores. Int. J. Hum. Comput. Interact. 2021, 37, 1191–1206. [Google Scholar] [CrossRef]

| Component | Description |

|---|---|

| Arduino Mega 2560 | Generic Arduino board based on ATmega 2560 microcontroller. It has 4 hardware serial ports, an ICSP connector, 54 digital inputs and outputs, of which 15 can be used as PWM outputs and 15 analog inputs. |

| PN532 NFC Chip | Low-cost NFC module that allows reading and writing NFC tags, card emulation and peer-to-peer communication. |

| DS3232 Chip | I2C real time clock with battery operated, temperature compensated crystal oscillator. Provides date and time to the Arduino board. |

| LCD Display 1602 | Alphanumeric LCD display with 2 rows and 16 columns with blue LED backlight. Parallel interface. |

| Field | Description |

|---|---|

| User ID | Unique number automatically assigned to each user who registers in the mobile application. |

| Name | Application user name (maximum 9 characters). |

| Nick name | Name that the user wants to use to log in to the application. |

| License plate | License plate number of the vehicle to be used to access the car park. |

| User’s e-mail address. | |

| Password | User’s password. |

| Balance | Remaining money associated with the mobile application held by a user. Its initial value is 0 euros. |

| Time of clocking | Time at which the user has entered or left the car park. |

| Status | Indicates the status of the user with respect to the parking, it can be outside the parking lot or inside it. |

| Field | Description |

|---|---|

| User ID | Name used to identify the user, no two users can have the same name. |

| Date | Format two-digit day, separator, two-digit month, separator, four-digit year (DD/MM/YYYY). |

| Time | Format ISO 8601-1:2019 (hh:mm:ss). |

| Booked | Boolean variable, indicates whether the appointment is reserved. |

| Item | Parking System | Establishment System | ||

|---|---|---|---|---|

| Mean | Std | Mean | Std | |

| 1 | 4.00 | 0.93 | 3.96 | 0.97 |

| 2 | 2.16 | 1.04 | 2.02 | 0.94 |

| 3 | 4.06 | 0.96 | 4.08 | 0.85 |

| 4 | 2.62 | 1.34 | 2.40 | 1.25 |

| 5 | 3.90 | 0.79 | 3.98 | 0.80 |

| 6 | 1.92 | 0.90 | 2.04 | 0.99 |

| 7 | 3.80 | 0.95 | 3.72 | 0.97 |

| 8 | 1.88 | 0.82 | 2.12 | 0.96 |

| 9 | 3.74 | 1.14 | 4.00 | 0.86 |

| 10 | 3.70 | 1.18 | 3.88 | 0.96 |

| Total score | 68.05 | 12.49 | 68.20 | 11.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Belmonte, L.M.; Segura, E.; Gómez-Sirvent, J.L.; López de la Rosa, F.; de las Morenas, J.; Fernández-Caballero, A.; Morales, R. Digital Tech Integration in Industrial Engineer Training via Affordable Academic Tools. Computers 2025, 14, 547. https://doi.org/10.3390/computers14120547

Belmonte LM, Segura E, Gómez-Sirvent JL, López de la Rosa F, de las Morenas J, Fernández-Caballero A, Morales R. Digital Tech Integration in Industrial Engineer Training via Affordable Academic Tools. Computers. 2025; 14(12):547. https://doi.org/10.3390/computers14120547

Chicago/Turabian StyleBelmonte, Lidia M., Eva Segura, José L. Gómez-Sirvent, Francisco López de la Rosa, Javier de las Morenas, Antonio Fernández-Caballero, and Rafael Morales. 2025. "Digital Tech Integration in Industrial Engineer Training via Affordable Academic Tools" Computers 14, no. 12: 547. https://doi.org/10.3390/computers14120547

APA StyleBelmonte, L. M., Segura, E., Gómez-Sirvent, J. L., López de la Rosa, F., de las Morenas, J., Fernández-Caballero, A., & Morales, R. (2025). Digital Tech Integration in Industrial Engineer Training via Affordable Academic Tools. Computers, 14(12), 547. https://doi.org/10.3390/computers14120547