Abstract

Design is a challenging task that is crucial to all product development. Advances in design computing may allow machines to move from a supporting role to generators of design content. Generative Design systems produce designs by algorithms and offer the potential for the exploration of vast design spaces, the fostering of creativity, the combination of objective and subjective requirements, and the revolutionary integration of conceptual and detailed design phases. The application of generative methods to the design of discrete, physical, engineered products has not yet been reviewed. This paper reviews the Generative Product Design systems developed since 1998 in order to identify significant approaches and trends. Systems are analyzed according to their primary goal, generative method, the design phase they focus on, whether the generation is automatic or interactive, the number of design options they generate, and the types of design requirements involved in the generation process. Progress using this approach is recognized, and a number of challenges that must be addressed in order to achieve widespread acceptance are identified. Possible solutions are offered, including innovative approaches in Human–Computer Interaction.

1. Introduction

Design is a highly complex task that involves creativity, specialist knowledge, experience, and also judgment with regard to both the objective and the aesthetic aspects of a problem domain. Traditionally, designs for every type of artifact have been created manually by human designers using physical representations such as sketches and models but, with the rise of computing technology, machines now contribute to the design process in ways undreamt of even decades ago. The 1980s saw Computer-Aided Design (CAD) become ubiquitous as a tool for human designers, bringing with it advantages for design representation and manipulation. However, despite its great utility, CAD only supports human design decisions; more recently, machines have begun to participate in the creative process itself. In Generative Design (GD) systems, designs are produced by algorithms [1,2,3]. This may be done automatically or interactively with a human designer, and it may only constitute part of an overall design, but the point is that actual design content is generated by a machine.

The potential benefits of GD are numerous and include the fostering of creativity and innovation in human designers by producing forms never seen before [4], the automatic generation of thousands of different design options to allow comprehensive exploration of design spaces too large for humans to explore manually [4,5], the integration of objective engineering requirements into the hitherto subjective conceptual design [6], and the objective formalization of subjective characteristics such as brand appearance [7].

Recent industrial success stories from NASA [8] and Airbus [9] have led to Generative Design being hailed as “the next wave of intelligent design automation” by the Harvard Business Review [10]. In many ways, this is a technology whose time has come, and its growth in the industry is related to the wider IR 4.0 context with advances in cloud computing and additive manufacturing [11]: the often intense processing demands of GD can be met using the computing power of the cloud; the extended design space of some GD algorithms produce forms realizable only by additive manufacturing.

Although the industry is now beginning to utilize its potential, the basic concepts and techniques for Generative Design systems were originally developed in academic research decades ago, with the first major research conducted within the context of architectural design [12,13,14,15]. However, a more recent research trend is the application of generative methods to the design of products [4,5] such as motorcycles, office chairs, and monitor stands [4,6,16].

Since a product can be anything manufactured by an enterprise for sale to customers [17], it is clear that this is a significant application area, as borne out by the fact that in the US alone, the 2019 consumer goods market had an estimated worth of $655 billion [18]. Review papers exist for architectural GD systems (e.g., [19,20]) but there are none specifically for product design. The current paper aims to address this. We will refer to this specific research subfield as Generative Product Design or GPD.

This paper will review the various GPD systems developed to date. Section 2 will describe the materials and methods used in this review. Section 3 will provide the background and context necessary to understand the systems and to appreciate their novelty and potential with regard to the design process. Section 4 presents the results of the review, starting with the development of GPD systems over the last 20 years and ending with a table distilling the important attributes of each system and summarizing the results to reveal trends, commonalities, and also deficiencies. Section 5 will discuss the current level of achievement in this field and the challenges that must be addressed in order to realize the potential of GPD. Suggestions for ways to do so will be given at the end.

2. Materials and Methods

2.1. Literature Databases

Scopus and Google Scholar were queried using the search term “generative product design”. Results were filtered using the inclusion criteria described next in Section 2.2. Every reference in the bibliography of all selected papers was also located and considered for inclusion.

2.2. Inclusion Criteria

It is important to be clear about the selection criteria used for this review. Each element of the term “Generative Product Design” was considered significant in identifying relevant literature. First, the work under review must identify as a Generative Design system, if not in the title then in the text itself. Second, they must actually be generative systems. At minimum, this means that algorithms will be used to generate designs rather than direct human input. Caetano et al. [1] define GD simply as “a design approach that uses algorithms to generate designs”. The exact nature and extent of this will be covered presently. Third, they must generate products rather than any other kind of artifact. Here, this will be discrete, physical products with some level of engineering requirements. This means that, for example, software systems, oil production, and purely decorative ornaments will not be covered. Architectural design will also not be covered although many of the concepts from architectural GD apply here. Finally, they must be serious design systems. It is important to distinguish designs from mere forms: designs have requirements and specifications, and they are created by and for humans in a design process. Here, the design process must be taken seriously, especially with regard to either fitting into it or even revising it, as a number of GPD systems claim to do. The preceding criteria will exclude a number of research areas that might initially appear to be relevant. For example, shape synthesis [21,22] and shape optimization [23] are two research areas that generate object forms by algorithms. However, few identify as generative systems and, more importantly, they do not consider how they will meet the needs of designers and fit into the design process. Although shape synthesis and shape optimization are not considered to constitute a GPD system on their own, they may be integral parts of one. Some of the systems described later do use topology optimization techniques, for example.

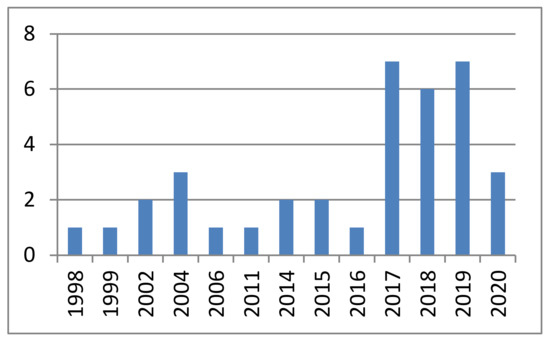

Although more than 100 references were obtained and read, only 37 met these criteria, with most being excluded for not taking the design process seriously. The references range in publication date from 1998 to 2020 and it can be seen in Figure 1 that this research topic has seen popularity in two main phases. This will be explained in more detail in Section 4.

Figure 1.

References by Year of Publication.

There are 23 references to journal articles, 11 are conference papers, 2 are book chapters, and 1 is a Ph.D. thesis. As seen in Table 1 below, the journals are all appropriate for the topic with “Computer-Aided Design” being the most popular with four references. This journal is a high-quality Q1 source established in 1968, suggesting that GPD is a worthwhile topic of study. The next most popular (Design Studies, Journal of Mech. Design, and Env. and Planning B) are of similar quality. The conferences are also all appropriate, with “Design Computing and Cognition” being the most popular, as seen in Table 2.

Table 1.

List of Source Journals.

Table 2.

List of Conference Proceedings.

2.3. Analysis Protocol

Papers fulfilling the inclusion criteria were analyzed according to the following seven attributes:

- the types of products generated by the system,

- the primary goal of the system,

- the design stage the system is intended for use in,

- the generative method used,

- whether the generation is automatic or interactive,

- the number of design options they generate,

- system evaluation and performance.

These attributes were then tabulated for all 37 systems in order to reveal trends and clusters of similar systems, as described in the discussion in Section 5. The attributes themselves come from identifying common stated issues when reading the selected references and also from known issues in the wider design literature which are discussed next.

3. Background

3.1. Product Design and Development

Our criterion for taking the design process seriously is very important since it can reveal much of the transformative potential of GPD systems and also provides useful criteria for analysis later. Since this criterion references the traditional product development process, it is prudent to briefly review the main stages of traditional design.

As stated by Ulrich et al. [17], most product development begins with the identification of a business opportunity that can be met with a new product. Product requirements, which may range from objective concerns such as functionality, cost, and structural integrity, to subjective ones such as aesthetics or conformity to brand identity, are formulated and converted to measurable specifications. The design process then proceeds iteratively to formulate, refine, and test candidate products in terms of form and properties. When stopping criteria are reached, a final design will be selected and manufactured for sale. Since there is no general formula for all but the most mundane design tasks [24], exploration of options and multiple iterations are usually unavoidable. In itself, exploration of as many options as possible is considered worthwhile so that superior designs are not overlooked [17]. This can be considered due diligence on the part of the design team.

The design phase is usually divided into conceptual and detailed design stages, often called early- and late-stage design [17]. The conceptual design stage is where major differences in product form are formulated and explored. Traditionally, this has been done using hand-drawn sketches that are fast and intuitive and possess a level of ambiguity considered advantageous for creativity [25]. Full CAD models are not normally used at the concept stage for the exact opposite reasons—they are slow to produce, less intuitive than sketches, and require exact dimensions that are simply not yet known. This distinction in terms of representation and specificity has consequences: major aesthetic requirements could be satisfied at the conceptual stage but performance specifications could not. Only at the detailed design stage, with the production of a fully-dimensioned CAD model with materials selected, can precise objective information about the product form (e.g., cost, weight, volume) be calculated and its physical properties simulated and tested (e.g., structural analysis using Finite Element Analysis). In other words, to determine whether the concept is feasible, given the design requirements. Testing may determine that conceptual designs require significant revision and more design iterations but by definition, there is no way to be sure at the conceptual stage itself. Due to this, a major theme in GPD is the blending of concept, detailed design, and testing so that information traditionally only available later can be used to inform early concepts with the intention of reducing wasted iterations [5]. More extreme formulations of GD aim to eliminate distinctions between the phases, leading to exploration only among options known to have feasible performance [6,26].

It should be noted that CAD and generative design methods are far from the only way for computers to aid the conceptual design process. Many other computer-aided tools have been proposed, including analysis of bipartite directed complex networks built on causal relationships between design variables [27], the application of the Algorithm for Inventive Problem Solving (ARIZ) [28], and Function-Behavior-State modeling [29]. CAD is emphasized here because parametric CAD models are a primary design representation used in GPD, as will be seen.

It should also be noted that Caetano et al.’s [1] simple definition of GD does not specify the scope of the algorithmic contribution to any particular design. It might aim to address a certain component of an object or, in principle at least, to achieve total automation. However, Johnson [24] makes convincing arguments that even if such a development were desirable, total design automation is certainly not possible now and would require the development of strong AI in the future. Even in the case of partial automation, the basic GD definition does not specify what types of design requirements are to be addressed by the generative algorithms used (i.e., objective or subjective requirements). Algorithms do exist for optimizing a number of objective requirements, such as structural integrity and heat dissipation, and these are commonly in use in design and Computer-Aided Engineering (CAE) even now. However, aesthetic requirements are more difficult to automate. Although efforts have been made to automate some aspects of aesthetic preference and to incorporate it into the generative algorithm, the general view is that humans must ultimately decide between the appearance of competing designs. It should be noted that even algorithms to optimize objective requirements usually still require people to explore tradeoffs when multiple conflicting requirements exist (interactive). The result of all this is that for now, and for the foreseeable future, GD involves humans and the design work will be shared between man and machine. A major point of analysis in what follows will be precisely how the work is shared [30]. The foregoing ideas are well summarized by McCormack et al. [3] who deserve quotation at length:

“In traditional design, the role of the designer is to explore a solution space… There is a direct relationship between the designer’s intentions and that of the designed artifact. In contrast, design using generative methods involves the creation and modification of rules or systems that interact to generate the finished design autonomously. Hence, the designer does not directly manipulate the produced artifact, rather the rules and systems involved in the artifact’s production. The design process becomes one of meta-design where a finished design is the result of the emergent properties of the interacting system. The ‘art’ of designing in this mode is in mastering the relation between process specification, environment, and generated artifact. Since this is an art, there is no formalized or instruction-based method that can be used to guide this relationship. The role of the human designer remains, as with conventional design, central to the design process.” (ibid pp7).

3.2. Performance and Evaluation

In research topics such as face recognition [31] performance is straightforward to assess, making it easy to review methods and say which is best. For a number of reasons, the same is not true for evaluating designs, and this is acknowledged as a significant issue within design studies [17,24]. Subjective and aesthetic requirements must ultimately be assessed by human judgment, necessitating surveys of user opinion with results differing depending on the chosen audience. Few engineering design problems are entirely without subjective requirements, but even if we consider problems with fully computable, objective requirements, assessment is still challenging. Only simple design problems, with a single objective requirement, can have a single, provably optimal design, and even then, multiple maxima or minima usually exist [32]. The same necessity for human input and the existence of multiple design options is also inescapable. Most real-world design situations have multiple competing and contradictory objectives. There is no single “best” design, only a number of tradeoffs between requirements and so, again, humans are required to evaluate multiple options, even if they did not create them manually [32]. Therefore, a combination of human evaluation and objective performance is required when evaluating designs produced by GPD systems.

3.3. Generative Representations and Methods

In an attempt to develop an integrated framework for GD systems, Singh [20] identified five main generative methods: Shape Grammars, L-systems, Cellular Automata, Genetic Algorithms, and Swarm Intelligence. Although the grid-based nature of Cellular Automata is appropriate for the architectural design context that Singh addresses, they are unsuitable for product design and have not been used. However, the other generative methods have been applied to product design and therefore deserve a brief overview.

Genetic Algorithms (GAs) are meta-heuristics inspired by the evolutionary processes found in the biological natural selection. By employing biologically-inspired operators such as mutation, crossover, and selection, GAs are most often used to generate good-quality solutions to optimization and search problems [33].

Shape Grammars (SGs) [34,35] are production systems consisting of a finite set of shapes with transformation rules that are applied step-by-step to an initial shape in order to generate designs. Unlike most production systems, SGs are spatial, rather than symbolic. Applying shape rules generates designs, and the rules themselves describe the generated designs as a design grammar. Due to this, shape grammars are used both generatively and as tools for analysis to formalize existing designs.

L-systems [36] are also production systems that can be used to generate designs by recursively rewriting strings of symbols. They differ from SGs in that they operate on strings that represent a design symbolically rather than spatially.

Swarm intelligence is a property of a system that emerges when a large number of simple agents interact with their environment locally to produce coherent patterns of behavior at higher levels [37]. Swarm intelligence systems are intended to solve problems without the need for centralized control or a global level model.

In addition to those methods identified by Singh [20], techniques specifically appropriate to product design have also been used. The most significant is parametric modeling, which is used in most modern CAD [1,38]. Feature-based parametric modeling describes solid models symbolically in terms of a set of parameters and their relations such that changes in one parameter will update the whole model. Parametric models are more familiar to designers than the techniques listed by Singh and many existing workflows and software including simulation and analysis use them. However, parametric representations are not inherently generative and must be adapted to serve as such. In practice, this means that algorithms must be developed to operate directly on the parameters of the model. Conversion from other generative representations such as shape grammars is possible but not always straightforward.

Certain engineering techniques have also been adapted for use in the generative design process. Topology Optimization (Top Opt) [39] is an iterative method for achieving the best structural performance by identifying the optimum distribution of material within the volume of a structure with respect to its applied loads, boundary conditions, and other constraints. Topology Optimization usually works by subtracting mass while still maintaining performance. The advantage of Topology Optimization with regard to GD is not just performance but aesthetics too: the forms generated by Topology Optimization would never be created by a human designer and lead to “alien” results that might foster creativity. It is noted however that some consider the results too unfamiliar for many commercial applications. Aside from Topology Optimization, Autodesk identifies trabecular structures and lattices as generative methods [40] but so far these have not been used to generate any products published in academic journals.

4. Results

The results of this review are presented in the following sections. First, a narrative describing trends over time for the 37 GPD systems is given. Then, the systems just described are analyzed according to product type, overall purpose, design stage application, interactivity, generative method, number of designs produced, and system evaluation. This is summarized in Table 3. Then, each of these attributes is summarized to reveal patterns and trends.

Table 3.

Summary of Generative Product Design systems.

4.1. The Development of Generative Product Design Systems

The earliest generative design systems, specifically for products, utilized shape grammars as a generative representation. In 1998, Agarwal and Cagan devised a parametric shape grammar for coffee makers with the stated goal of exploring multiple options at the conceptual design stage [41]. This particular class of product was considered challenging because coffee makers share the same functional relationship between their components but they are distinguished commercially by form and appearance. The manually-constructed grammar consisted of 100 shape rules which were used interactively to generate a small number of significantly different example coffee maker forms. Since the intention was to support the conceptual design stage, the generated designs did not accommodate engineering requirements. Although highly-cited, this system can be considered primarily as a proof of concept rather than a practical tool. No explicit mechanism for managing the interactive design exploration phase was provided: for example, no decision history tree or gallery of design alternatives. Notably, the system was not tested by real designers. Even as a proof of principle, certain issues with the approach are clear. Shape grammars must be laboriously created by hand and the skills and mindset required may not be easily accessible to most designers. It is a significantly unfamiliar approach which is further complicated by the fact that basic shape grammars do not handle 3D forms easily. The grammar here required three 2D views to describe the entire 3D object. Aside from the effort required for grammar construction, exploration of options generated manually may not comprehensively cover the design space due to the time and effort involved.

Recognizing that there exists “no formal method for applying rules” [42] (pp.1) in shape grammars, subsequent work by the same authors in 1999 attempted to incorporate information usually only available at the detailed design stage into the conceptual process [42]. Extending the coffee maker grammar developed earlier, product cost information based on shape volume calculations was available at each decision point, with the intention of allowing better-informed rule selections. This is something that the traditional sketch-based process cannot provide. However, unlike CAD models, the limited nature of shape grammars for 3D representation means that volume calculations must be devised for each product individually. Again, no interface or testing by designers was described.

Interest grew in the use of SGs to formalize the important aesthetic issue of brand identity so that generated product designs would conform to it. In 2002, a 12-rule shape grammar was devised to capture the essence of Dove soap [19,43]. Two iconic vehicles, the Harley-Davidson motorcycle [7] and Buick car [44] were modeled using grammars of 45 and 63 rules, respectively. The distinctive Coca Cola bottle was analyzed into 14 rules in 2004 [45]. In each case, a small number of new design options were generated as examples and inspection shows them to conform to brand identity, but no real testing with either consumers or designers was performed. As before, the process of devising shape grammars was laborious and time-consuming, and required specialist thinking. Their use in generation by manually selecting rules was also time-consuming.

The time-consuming nature of the manual generation process using SGs began to be addressed by automated approaches. In 2004, a population of L-systems for a table design was automatically evolved using a GA [46]. The fitness function used to select superior designs was based on the table’s simulated physical properties which included balance, height, surface area, stability, and amount of material used. A few examples of unusual table designs generated automatically were presented but not tested. In 2006, a similar evolutionary approach was used to automatically evolve the Coca Cola bottle shape grammar [47] using a target product volume as a fitness function.

This early work can be considered more proof of principle than a useful GPD system. In 2011, Krish published a more practical GDP system that would influence many later works [5] and can account for the bimodal distribution of GPD research papers by year shown in Figure 2. Krish addressed the design process seriously and specifically intended the system for use at the early conceptual stage. The main goal was to generate large numbers of different design options automatically rather than interactively as most earlier works had done, which would place the designer more in the role of evaluator than creator. This work also marked a shift in generative representation and method from SGs to Parametric CAD models. Unlike SGs, the design space determined by the parameter ranges of the CAD model is straightforward and can therefore be sampled randomly to generate design variations. Krish implemented this simple approach as a plug-in for existing CAD packages and was able to generate large numbers of significantly different designs for an MP3 player and coffee table from a single base model. It is important to realize that although design variations are generated without direct human input, the whole process must still be set up manually; a base CAD model must be created and suitably parameterized. Parametric CAD will almost certainly be more familiar and accessible to designers than SGs, but its ease of use may come at the cost of generative novelty: the design space may be too restricted when creativity and innovation are key requirements. Again, however, no testing of the system by designers or evaluation of the designs by potential customers was carried out.

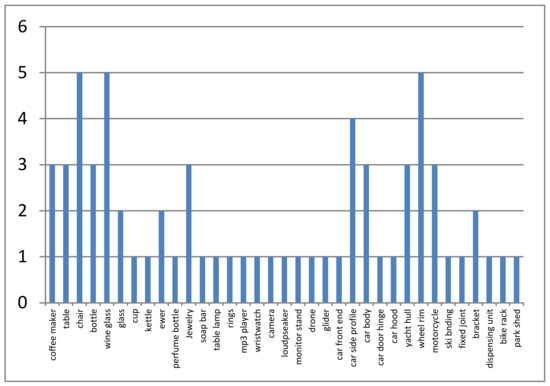

Figure 2.

Product types produced using generative methods.

Krish aimed for automated generation of designs but firmly targeted the conceptual level, meaning that engineering requirements were not explicitly part of the generation process. However, the integration of concept exploration and engineering information only available after detailed design (first addressed in [42]) began to attract interest. Using chair design, Barros et al. [48] integrated conceptual design by SGs with detailed design by conversion to CAD model and structural testing using the Finite Element Method (FEM). The intention was to allow the interactive exploration and customization of designs according to both aesthetics and engineering criteria. However, like most preceding systems, the work presented the generative method primarily and provided few examples of designs produced. No practical interface for exploration was given and the system was not tested in a real design environment.

Engineering concerns also drove other work in automatic generation. Dhokia et al. [49] applied Swarm Intelligence in the form of a multi-agent termite nest to the design of a bracket. The intention was to simultaneously design, structurally optimize, and evaluate the additive manufacturability of the part. The product form was represented by voxels and termites deposited material according to functional constraints and design objectives. An FEA solver was used to evaluate structural integrity and manufacturability was assessed based on support material and tool accessibility. In the same year, Gulanova et al. [50] proposed an application of GD to the automotive industry using a car front end represented as a class A surface. Both of these systems aimed for a single optimal design rather than generating multiple options.

Although shape grammars and interactive generation were less popular at this time, some work was still being done to address their earlier limitations. In [51], a design grammar specifically for 3D forms called Dynamic Shape Representation (DSR) was proposed and used to manually generate a number of chair design variations. An interface is shown but few details are given.

In 2017, research started to take the practical design process and the needs of designers more seriously. The emphasis on generating multiple design options and the transition to CAD as primary representation first described by Krish [5] became more evident. In work conducted by the research arm of the CAD industry giant, Autodesk, Kazi et al. [25] developed the DreamSketch system. Like Krish, this was aimed explicitly at supporting the creative, conceptual stage of design by generating multiple design options based on CAD models. Unlike Krish, the designer’s traditional primary conceptual tool, the handmade sketch [52], was used to input ideas into the machine first so as to fit more seamlessly into standard workflows. Digital sketching captured product profiles as 2D Bezier curves, which were then extruded into 3D solids as a basis for generation. The actual generative component of the system was provided by Topology Optimization. Although Topology Optimization is an engineering method, no engineering requirements were integrated into the generative process. Rather, the tendency of Topology Optimization to generate unexpected and distinctly non-human forms was exploited for reasons of novelty and creative inspiration. To make Dreamsketch a serious tool, a decent interface for interacting with design variations was provided. Dreamsketch is notable for being the first GPD system to be tested by real designers as an alternative to the traditional approach. Using a drone, table, glider, and bike rack as case studies, generally favorable reviews were given.

A key drawback of DreamSketch was the time taken for Topology Optimization to generate variations, making it impractical for real-time interaction. Subsequent work in Autodesk research [6] retained the intention of generating large numbers of design options but instead focused on offline and automatic, rather than real-time and interactive, generation and on how large numbers of design options could be meaningfully evaluated by human designers. DreamLens differs from DreamSketch in that it explicitly attempts to cover engineering requirements as well as the aesthetic concerns characteristic of the conceptual stage. DreamLens requires a basic set of geometries, constraints, and forces as input which are used by a Topology Optimization simulation engine to generate a design. Since Topology Optimization aims to optimize a single design, variations in form require the parameters of the problem definition to be varied. In this manner, 16,800 feasible variations of a monitor stand design were generated, requiring 36 days of processing time. The DreamLens interface displays both single and multi-attribute property controllers to allow designers to explore tradeoffs between competing requirements. DreamLens extended the more realistic testing of DreamSketch and studied actual designers using challenging tasks such as “Find models most suitable for 3D printing”, “Find designs which satisfy multiple parties”, “Find inspiration from ‘non-standard’ designs” (ibid pp 9–10). DreamLens was met with generally positive reviews.

Concurrently with Autodesk research, a group of researchers, centered around Khan and Gunpinar, extended Krish’s method by addressing deficiencies in its random sampling approach. The same goal of automatically generating multiple conceptual design options for inspiring creativity was used. Also, the same basic approach of sampling a design space defined by the allowed parameter ranges of a base CAD model was taken. However, random sampling was considered unable to ensure the comprehensive generation of all distinct design options within a design space. Since this due diligence is a key responsibility for designers [17], the problem is a significant one and, to address it, Khan and Gunpinar developed several methods intended to ensure uniform sampling of design spaces or, stated in the negative, to avoid generating similar designs. This task is non-trivial because it is based on what human observers would consider perceptually distinct product forms. In 2018, Gunpinar and Gunpinar conceptualized distinct object forms as those fulfilling a space-filling property in a design space [53]. Space-filling was implemented with a particle tracing algorithm controlled by genetic operators rewarding the minimization of the Audze–Eglais potential energy between them. Clustering by k-medoids was then used to determine shapes representative of distinct regions within the design space. Eight CAD models (ewer body, car body, car hood, yacht hull, wine glass, bottle, wheel rim, park shed) were generated in this way and evaluated by human users. For comparison, the same models were also generated by Krish’s method and a small improvement in user satisfaction was observed for the particle tracing method. Later that year, Khan and Gunpinar [54] replaced particle tracing with Teaching-Learning-Based Optimization (TLBO) for the same problem of design diversity on models of a wheel rim, wine glass, and yacht hull. Geometric constraints on design space were obtained from user interviews in what was called customer-centered design sampling. In similar work, Khan et al. [55] focused on the development of a psycho-physical distance metric for candidate designs which was based around capturing user preferences using geometric constraints. Also inspired by Krish [5], Khan and Awan [56] addressed the same problem of generative diversity by aiming to fulfill space-filling criteria. Their Space-Filling Generative Design Technique (Sf-GDT) differs from the other approaches in its use of the parameter-free Jaya algorithm, weighted grid search, and Deb’s heuristic for handling constraints. Designs for a speaker, motorbike, and ceiling lamp were generated using Sf-GDT and Krish’s original method. User testing showed significantly greater satisfaction for Sf-GDT designs.

Nordin’s work in 2018 [57] is notable because it shows successful deployment of GDP in a real industrial context, and documents this in detail within an academic journal. Nordin presents two case studies where bespoke GPD systems were developed for real-world clients. The first was a disc-dispensing unit with engineering requirements and the second was the industrial design of a camera. Techniques used were parametric CAD models evolved using GAs combined with rigid body simulation and FEA. According to engineering criteria, the generated designs were optimal and client acceptance was obtained with high levels of satisfaction.

Although Tyflopoulos [39] still aimed to generate a single optimal design for a ski accessory using FEM and Topology Optimization, by 2019, the trend of generating multiple options was well established. The recent rise of deep learning techniques [58] found its way into GDP in the work of Oh et al. [59,60] where a combination of Topology Optimization and Generative Adversarial Networks (GANs) was used to generate multiple wheel rim designs satisfying both engineering and aesthetic requirements. The aesthetic filtering carried out by the GANs was based on the assumption that existing designs are more aesthetically pleasing than arbitrary Topology Optimization output. To implement this assumption, a library of existing designs and a distance function were used. This is another example of the kind of blending of design phases favored by Autodesk. The same combination of aesthetics and engineering is found in Khan et al.’s GenYacht system [61] which aimed to aid novice yacht hull designers in exploring multiple options based on appearance and hydrostatic performance. Like Alcaide-Marzal et al. [2], Khan intentionally chose to make the generative system interactive instead of automatic but was able to generate options quickly enough for practical use. Though not stated, this is perhaps because the fully-automated generation on parametric CAD models was disappointing. The same integrated approach for generating multiple options is in found Gunpinar et al.’s [62] system for car profile designs which combines aesthetic evaulation with performance information from Computational Fluid Dynamics (CFD).

Work by Dogan et al. [63] also focused on 2D Bezier curves instead of full 3D models. This system integrated the approaches of Gunpinar and Khan for design diversity with the kind of comprehensive interface developed in DreamLens for design exploration. The system is initialized manually by tracing a profile and constraints from existing designs and then variations are generated automatically and explored using the interface. The system was used to generate ewer, glass, and car side profiles which were finally converted to 3D models.

In an interesting recent synthesis, Alcaide-Marzal et al. [2] aimed to support aesthetic decisions at the conceptual stage. This work presented the Conceptual Generative Model (CGM) a combination of the grammar-oriented approach characteristics of early works with more recent attempts to use parametric CAD models. Multiple design options to support creativity and to overcome fixation were a key objective but unlike the automatic generation in works derived from Krish [5] and Autodesk [6,25], an interactive approach was intentionally taken. However, the time-consuming interactive generation found in early works, like by Agarwal [41], was overcome by combining a genotype/phenotype model to automatically operate on a parametric CAD model to quickly and easily produce variations. The CGM system was not tested on real designers but comprehensive comparisons with the models produced by earlier techniques (perfume bottle, table lamp, jewelry ring, coffee maker, office chair, wheel rim, motorcycle) demonstrated it to be worthy of development.

The GPD systems just described are summarized in Table 3 below.

4.2. Product Types

So far, 35 different types of products have been generated by GPD. These products can be broadly divided into those found indoors (left half of Figure 2) and those found outdoors (right half of Figure 2) with a fairly even distribution. The most popular product types are wheel rims, chairs, and wine glasses. Table 3 reveals that more challenging product types have become addressed since 2017.

4.3. Overall Purpose

Seven distinct purposes for GPD systems were identified and are listed in Table 4 below. The most popular purpose was to generate large numbers of designs. Of the 17 systems that sought to automatically generate a large number of conceptual designs, 7 were specifically concerned with perceptual distinctiveness and the comprehensive covering of the design space. The remaining 10 were focused simply on generating novel forms. Five systems sought to generate large numbers of conceptual designs interactively. Seven systems tackled the highly challenging task of automatically generating large numbers of designs that combined conceptual and detailed design stages, and therefore subjective and objective requirements. Four systems were most concerned with generating multiple conceptual designs with a distinctive brand identity.

Table 4.

Overall GPD system purpose.

4.4. Design Stage Application

Of the 37 GPD systems, 22 maintained the traditional distinction between conceptual and detailed design stages and attempted to improve the conceptual stage by generating large numbers of distinct and novel options for overall form. These systems handled subjective requirements only, either in terms of general aesthetics or specific brand appearance. However, 15 systems attempted the more radical goal of combining conceptual and detailed design by also making objective design information and processes available to designers from the start. In practice, this ranged from displaying data about product cost and mechanical properties to generating options by Topology Optimization ensuring that all design options were feasible within objective requirements. For most systems, the human designer handled the subjective requirements and the machine processed the objective ones. However, for some conceptual-stage systems, subjective requirements were also addressed by computer: explicitly by using a psycho-physical distance metric [55], and implicitly by embedding brand appearance into the shape grammar [44,45,46,47]. For one combined-stage system [59] subjective aesthetics were also processed by the machine by using GANs to learn existing design appearance.

4.5. Interactive and Automatic Generation

A total of 26 systems generated designs automatically, with the intention that the designer would move to a role more oriented towards evaluation than direct creation. This is the more revolutionary potential for machines in design. However, 11 systems sought simply to better support human designers as direct creators. This was mainly due to doubts over the machine capability to replace human creativity, experience, and judgment. Note that this attribute is not identical to the design stage application: there are some conceptual design systems that worked automatically and others interactively.

4.6. Generative Representation and Methods

As seen in Table 5, generation based on parametric CAD representation was the most popular GPD method. Of the 15 CAD-based systems reviewed, 8 were based on sampling the parameter space in different ways (i.e., randomly or by Sf-GDT, TLBO, Particle Tracing), and the remaining 7 were based on Topology Optimization. The next most significant method is grammar-based GPD. Here, 11 of the 14 grammar-based systems used pure shape grammars, 2 combined other objective information into the generation process, and 1 is an independent grammar-based system called DSR. There were only two hybrid CAD/grammar systems but one of them is the most recently published work in GPD [42] and it seems that this method will become more popular in the future as researchers seek to combine the advantages of both main methods.

Table 5.

GPD methods.

As discussed in Section 3.3, five generative methods used in generative architectural design were identified by Singh [20]. Four of these five methods were also found in generative product design, with the exception of Cellular Automata, which is more suitable for 2D problems, and not 3D product forms. However, generative design based on the transformation of parametric CAD models is the most popular method for GPD and this was not identified by Singh as being used in architectural generative design.

4.7. Multiple or Single Design Options

The overwhelming majority of GPD systems (33) produced multiple options rather than a single/optimal design since this is a key potential of all generative design systems. Most of the systems reviewed presented figures and illustrations demonstrating tens to hundreds of design options but only [6] and [59] stated the exact numbers generated which were 16,800 and 2004, respectively. The systems producing single designs intended their output to be optimal according to objective rather than subjective criteria.

4.8. Performance and Evaluation

Of the GPD systems, 19 demonstrated success prima facie by showing numerous example designs generated using the proposed method. However, 10 systems were evaluated in practice by real users ranging from designers, engineers, and potential customers. These systems all received high subjective ratings on average. Of the systems evaluated by users, Nordin’s [57] work in an actual industry setting was the most impressive since it was able to produce objectively optimal designs and achieve client satisfaction. DreamSketch [6] and DreamLens [25] achieved the most challenging and realistic testing in an academic context by using design professionals and were rated very highly. Eight remaining systems measured success using a number of objective criteria specific to the method or product under study. This is shown in Table 6.

Table 6.

GPD system performance.

5. Discussion

It should be clear from the preceding that GDP has considerable potential but also that fully realizing it will require work.

5.1. Achievement of Goals and Limitations

For the 37 GPD systems reviewed, each had different objectives and different methods for demonstrating success. At the simplest level, every system reviewed demonstrated success by presenting generated product designs that, prima facie, achieved their particular goals. Additionally, 10 systems whose purpose was to generate multiple conceptual designs, demonstrated success with user testing by designers and customers. In all cases, high user ratings were achieved. Eight systems with primarily objective engineering requirements were also able to demonstrate success by generating provably optimal designs using a number of objective criteria specific to the method or product under study.

These findings can be considered to constitute a moderate level of success for a developing research domain. However, to properly progress, assessment of GPD systems with regard to their particular goals must be improved. With the exception of the research by Nordin [57] and Autodesk [6,25], system testing in a realistic design context has so far been neglected. Although it is quite straightforward to develop a software system able to generate some kind of object form, assessing its quality is not so easy. At least two questions must be asked: (i) how good is the design in itself, and (ii) how effective is the generative system in realistic use? Both questions apply to all forms of design automation and neither is easy to answer in the general case [17,24]. Some progress towards assessing design quality in GDP research might be made by developing the kind of standardized test sets found in research areas like computer vision and image processing. An accepted set of product design problems (in terms of requirements, goals, and constraints) might aid the comparison between competing generative methods. This is also a non-trivial undertaking because evaluations must be made on comparable systems and the various GPD systems just reviewed all have different purposes and purviews. For example, systems intended to automate conceptual design should not be assessed for their ability to optimize structural integrity. However, if the basic categories of a system identified in this review are used seriously then a fair comparison might be possible and some kind of order might be given to the somewhat ad hoc nature of current GPD research.

Important issues to address when considering system evaluation are those of creativity and design novelty. This is especially salient because a primary selling point of GPD is the ability to yield novel designs. It is important to be precise about the concepts involved. Novelty is multifaceted, with both historical creativity and psychological creativity having been identified [75]. Creativity and innovation are different but interrelated and novelty is only one of the two main parameters. To be creative, an idea should be both novel and useful [76]. Innovation requires that a product should be both novel and successful in its objectives. When assessing the output of GPD systems, it is crucial that researchers follow the most recent practices for assessing and validating novelty [77,78,79]. This is an important shortcoming of all the systems reviewed here.

5.2. CAD-Based Methods and Evaluating Multiple Design Options

The use of parametric CAD representations and the generation of large numbers of design options for humans to explore are two important current trends. For these trends to develop further, certain inherent limitations must be addressed. Parametric representations can simultaneously have too much variation and yet not enough [24]. Varying even simple shape parameters can yield many local variations but unless topology changes, true diversity is limited. For some cases of “variations on a theme” this may be desirable, but for real innovation, it is inherently limiting. Therefore, the combination of topological variation yielded by design grammars and ease of local variation parametric models used in CGM [4] seems a promising direction to pursue. Additionally, parametric CAD models still require manual creation initially and the task of representing a complex form as a set of parameters is non-trivial [5]. Libraries of existing forms may help address this, though of course, the same possible limitations in true innovation may be likely. Additionally, the advantages of hand sketches vs. CAD models have not been resolved. Digital sketching should be further explored to allow generative systems to integrate with existing design workflows and their teams [6,80,81].

Generating large numbers of design options is a key goal of most of the systems reviewed and this brings with it the need to better navigate and make sense of vast design spaces. This problem is currently being addressed by a number of researchers in other fields and their visualization methods for parametric spaces could be utilized by GPD systems [82,83,84,85].

It should also be noted that CAD models can be considered virtual prototypes. However, whether prototypes (including both physical and virtual prototypes) aid or obstruct creativity and the general design process is still debated [86].

5.3. More Efficient Human–Computer Interaction

Since human designers are still crucial in GDP, it is appropriate to consider how human input might be used more efficiently. Recent advances in HCI may hold the key. Brain activity, measured by electroencephalogram (EEG) and gaze (captured by eye-tracking) have been recently studied for their potential to directly reveal aesthetic preferences [87,88]. Brain signals from frontal regions known to be involved in decision-making have been processed and used to train classifiers able to distinguish between like and dislike of presented objects. In other words, where a machine can display an image and detect whether the viewer likes or dislikes it without conscious effort or action from the user. Eye-tracking has also been used for the same purpose [89]. Though less accurate for distinguishing emotions, it has the advantage that the gaze locations could be used to localize the object part that the user is reacting to. A combination of these technologies could help overcome two key issues in GDP. First, the aesthetic exploration of vast numbers of design options might be made faster and more effective if these options were presented according to evaluations determined by EEG and eye-tracking. Instead of manually selecting promising candidates, the designer could simply view an initial option and the system would present similar options based on their intuitive reaction. Eye-tracking could provide a finer level of discrimination by determining object parts that are liked or disliked and select the next candidate accordingly. All evaluations would be recorded and a final list of favored options could automatically be compiled. Individual preferences and styles could be learned. This could easily be integrated with the techniques for determining distinct designs developed by Khan and Gunpinar. Second, this same EEG/eye-tracker setup could be integrated into systems that generate designs interactively. In other words, after setting up the generative system, the designer simply has to have an effortless “dialogue” with the machine to actually generate a design that they like. Instead of manually selecting generation rules, the system would generate options on object regions localized by the eye-tracker. If EEG shows that the designer likes the result then the process will continue. If not, then the generative option is backtracked and another generative option is tried until the designer is pleased. Again, preferences can be learned and used to continually improve the efficiency of this process. Some very basic work has been conducted in this area [87,88] and it warrants greater attention, particularly since practical drawbacks of EEG, such as expense, and lengthy setup, are being overcome by the increased quality of consumer-grade headsets. Additionally, a number of recent VR headsets combine EEG and eye-tracking.

5.4. Generative Design Specialists

Aside from integrating GD techniques into existing design workflows, there is also the potential, and possibly the necessity, to consider training and hiring specialists in meta-design [3,26]. As was stated earlier, the mindset required for GD may not be easily accessible to many established designers. For example, the manual construction of a shape grammar may be alien and frustrating compared to the ease and intuitiveness of sketching by hand even though it could ultimately yield more benefits. Perhaps this type of task could be given to specialists within a design team who could allow the advantages of GPD to stand out more clearly.

5.5. Impacts of GPD

The systems reviewed here demonstrate considerable progress and promise but it is still too early to predict the precise impact that GPD will have on the product development process. It can be reasonably expected that Computer-Aided Design tools will continue to grow in ubiquity [17,24] but whether the revolutionary impact of GPD, predicted by the Harvard Business Review [10] and by Autodesk [8,9], is realized will depend on significant changes in mindset within the design community and industry. As recently observed by Dean and Loy [90]: “Product Design has a digital future, but the changes in thinking and practice required of discipline leaders involve a paradigm shift, rather than an evolution. Rather than challenging existing cultures and conventional mass manufacturing expertise to create incremental change, it will be necessary to propose new digital product design themes that align with computer-based disciplines.” (pp.1).

Such a paradigm shift might be achieved if GPD research is able to demonstrate clear industrial practicability and effectiveness. As noted earlier, the potential is there but GPD researchers must evaluate their systems in more realistic design contexts. The future impacts of GPD research will therefore depend on greater integration between academic development and industry. Most of the GPD systems published in academic journals have not been accepted by the industry. And conversely, the most notable industrial success stories are by Autodesk but they have not published all the details of their systems in academic journals. Researchers must make a greater effort to work with the industry and with real designers to develop GPD tools and methods.

6. Conclusions

This paper reviewed the Generative Product Design systems developed since 1998 in order to identify significant approaches and trends. Systems were analyzed according to their primary goal, generative method, the design phase they focus on, whether the generation is automatic or interactive, the number of design options they generate, and the types of design requirements involved in the generation process. Progress using this approach was recognized, and a number of challenges that must be addressed in order to achieve widespread acceptance were identified.

Author Contributions

Writing—original draft preparation, J.M.; writing—review and editing, J.T. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by PPPI, Universiti Malaysia Sabah.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Caetano, I.; Santos, L.; Leitão, A. Computational design in architecture: Defining parametric, generative, and algorithmic design. Front. Arch. Res. 2020, 9, 287–300. [Google Scholar] [CrossRef]

- McKnight, M. Generative design: What it is? How is it being used? Why it’s a game changer. KnE Eng. 2017, 2, 176–181. [Google Scholar] [CrossRef]

- McCormack, J.P.; Dorin, A.; Innocent, T.C. Generative design: A paradigm for design research. In Futureground; Redmond, J., Durling, D., de Bono, A., Eds.; Monash University: Melbourne, Australia, 2005; Volume 2. [Google Scholar]

- Alcaide-Marzal, J.; Diego-Mas, J.A.; Acosta-Zazueta, G. A 3D shape generative method for aesthetic product design. Des. Stud. 2020, 66, 144–176. [Google Scholar] [CrossRef]

- Krish, S. A practical generative design method. Comput. Des. 2011, 43, 88–100. [Google Scholar] [CrossRef]

- Matejka, J.; Glueck, M.; Bradner, E.; Hashemi, A.; Grossman, T.; Fitzmaurice, G. Dream lens: Exploration and visualization of large-scale generative design datasets. In Proceedings of the 2018 CHI Conference on Human Factors in Computing Systems (CHI ’18), Montreal QC, Canada, 21–26 April 2018; Association for Computing Machinery: New York, NY, USA, 2018; pp. 1–12. [Google Scholar]

- Pugliese, M.J.; Cagan, J. Capturing a rebel: Modeling the harley-davidson brand through a motorcycle shape grammar. Res. Eng. Des. 2002, 13, 139–156. [Google Scholar] [CrossRef]

- Autodesk NASA. Available online: https://www.autodesk.com/campaigns/generative-design/lander/ (accessed on 31 July 2020).

- Autodesk Airbus. Available online: https://www.autodesk.com/customer-stories/airbus/ (accessed on 31 July 2020).

- The Next Wave of Intelligent Design Automation. Available online: https://hbr.org/sponsored/2018/06/the-next-wave-of-intelligent-design-automation (accessed on 31 July 2020).

- Rosen, D.W. Design for additive manufacturing: A method to explore unexplored regions of the design space. In Proceedings of the 2007 International Solid Freeform Fabrication Symposium, University of Texas, Austin, TX, USA, 26–28 July 2007; pp. 402–415. [Google Scholar] [CrossRef]

- Frazer, J.H. An Evolutionary Architecture; Architectural Association Publications: London, UK, 1995. [Google Scholar]

- Caldas, L.G. Generation of energy-efficient architecture solutions applying GENE_ARCH: An evolution-based generative design system. Adv. Eng. Inform. 2008, 22, 59–70. [Google Scholar] [CrossRef]

- Abdelmohsen, S. Reconfiguring architectural space using generative design and digital fabrication: A project based course. In Proceedings of the XVII Conference of the Iberoamerican Society of Digital Graphics—SIGraDi: Knowledge-Based Design, Universidad Tecnica Federico Santa Maria, Valparaíso, Chile, 20–22 November 2013; Editora Edgard Blucher, Ltd.: São Paulo, Brazil, 2013; pp. 391–395. [Google Scholar]

- Chaszar, A.; Joyce, S.C. Generating freedom: Questions of flexibility in digital design and architectural computation. Int. J. Arch. Comput. 2016, 14, 167–181. [Google Scholar] [CrossRef]

- A Contemplation on Topology Optimisation. Available online: https://www.digitalengineering247.com/article/a-contemplation-on-topology-optimization/ (accessed on 31 July 2020).

- Ulrich, K.; Eppinger, S.; Yang, M.C. Product Design and Development, 7th ed.; McGraw-Hill: Hightstown, NJ, USA, 2020. [Google Scholar]

- US Product Market. Available online: https://www.selectusa.gov/consumer-goods-industry-united-states/ (accessed on 31 July 2020).

- Nisztuk, M.; Myszkowski, P.B. Usability of contemporary tools for the computational design of architectural objects: Review, features evaluation and reflection. Int. J. Arch. Comput. 2017, 16, 58–84. [Google Scholar] [CrossRef]

- Singh, V.; Gu, N. Towards an integrated generative design framework. Des. Stud. 2012, 33, 185–207. [Google Scholar] [CrossRef]

- Balashova, E.; Singh, V.; Wang, J.; Teixeira, B.; Chen, T.; Funkhouser, T. Structure-aware shape synthesis. In 2018 International Conference on 3D Vision (3DV); Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2018; pp. 140–149. [Google Scholar]

- Soltani, A.A.; Huang, H.; Wu, J.; Kulkarni, T.D.; Tenenbaum, J.B. Synthesizing 3D Shapes via modeling multi-view depth maps and silhouettes with deep generative networks. In 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR); Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2017; pp. 2511–2519. [Google Scholar]

- Brujic, D.; Mattone, M.; Ristić, M.; Maggiore, P.; Di Sciuva, M.M. Shape optimisation in CAE. J. Cryst. Growth 2005, 1, 511–514. [Google Scholar] [CrossRef]

- Johnson, B.R. Design Computing: An Overview of an Emergent Field; Routledge: Abingdon, UK, 2016. [Google Scholar]

- Kazi, R.H.; Grossman, T.; Cheong, H.; Hashemi, A.; Fitzmaurice, G. DreamSketch: Early stage 3D design explorations with sketching and generative design. In Proceedings of the 30th Annual ACM Symposium on User Interface Software and Technology (UIST ’17), Quebec City, QC, Canada, 22–25 October 2017; Association for Computing Machinery: New York, NY, USA, 2017; pp. 401–414. [Google Scholar]

- Shea, K.; Aish, R.; Gourtovaia, M. Towards integrated performance-driven generative design tools. Autom. Constr. 2005, 14, 253–264. [Google Scholar] [CrossRef]

- Becattini, N.; Cascini, G. Mapping causal relationships and conflicts among design parameters and system requirements. Comput. Des. Appl. 2013, 10, 643–662. [Google Scholar] [CrossRef]

- Baldussu, A.; Becattini, N.; Cascini, G. Network of contradictions analysis and structured identification of critical control parameters. Procedia Eng. 2011, 9, 3–17. [Google Scholar] [CrossRef]

- Tomiyama, T.; Umeda, Y.; Yoshikawa, H. A CAD for functional design. CIRP Ann. 1993, 42, 143–146. [Google Scholar] [CrossRef]

- Lubart, T. How can computers be partners in the creative process: Classification and commentary on the special issue. Int. J. Hum. Comput. Stud. 2005, 63, 365–369. [Google Scholar] [CrossRef]

- Moung, E.G. Face recognition state-of-the-art, enablers, challenges and solutions: A review. Int. J. Adv. Trends Comput. Sci. Eng. 2020, 9, 96–105. [Google Scholar] [CrossRef]

- Schulz, A.; Wang, H.; Crinspun, E.; Solomon, J.; Matusik, W. Interactive exploration of design trade-offs. ACM Trans. Graph. 2018, 37, 1–14. [Google Scholar] [CrossRef]

- Gero, J.S.; Kazakov, V. A Genetic engineering approach to genetic algorithms. Evol. Comput. 2001, 9, 71–92. [Google Scholar] [CrossRef]

- Stiny, G. Introduction to shape grammars. Environ. Plann. B Plann. Des. 1980, 7, 343–351. [Google Scholar] [CrossRef]

- Gu, N.; Behbahani, P.A. Shape grammars: A key generative design algorithm. In Handbook of the Mathematics of the Arts and Sciences; Springer Science and Business Media LLC: Berlin, Germany, 2018; pp. 1–21. [Google Scholar]

- Lindenmayer, A.; Rozenberg, G. Developmental Systems and languages. In Proceedings of the Fourth Annual ACM Symposium on Theory of Computing, New York, NY, USA, 20–22 May 2012; Springer International Publishing: Cham, Switzerland, 1972; pp. 214–221. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R.C.; Shi, Y. Swarm Intelligence, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Camba, J.; Contero, M.; Company, P. Parametric CAD modeling: An analysis of strategies for design reusability. Comput. Des. 2016, 74, 18–31. [Google Scholar] [CrossRef]

- Tyflopoulos, E.; Tollnes, F.D.; Steinert, M.; Olsen, A. State of the art of generative design and topology optimization and potential research needs. In Proceedings of the NordDesign 2018, Linköping, Sweden, 14–17 August 2018. [Google Scholar]

- Autodesk Generative Design. Available online: https://www.autodesk.com/solutions/generative-design/ (accessed on 31 July 2020).

- Agarwal, M.; Cagan, J. A blend of different tastes: The language of coffeemakers. Environ. Plan. B Plan. Des. 1998, 25, 205–226. [Google Scholar] [CrossRef]

- Agarwal, M.; Cagan, J.; Constantine, K.G. Influencing generative design through continuous evaluation: Associating costs with the coffeemaker shape grammar. Artif. Intell. Eng. Des. Anal. Manuf. 1999, 13, 253–275. [Google Scholar] [CrossRef]

- Chau, H.H. Preserving Brand Identity in Engineering Design Using a Grammatical Approach. Ph.D. Thesis, Leeds University, Leeds, UK, 2002. [Google Scholar]

- McCormack, J.P.; Cagan, J.; Vogel, C.M. Speaking the Buick language: Capturing, understanding, and exploring brand identity with shape grammars. Des. Stud. 2004, 25, 1–29. [Google Scholar] [CrossRef]

- Chau, H.H.; Chen, X.; McKay, A.; De Pennington, A. Evaluation of a 3D shape grammar implementation. In Design Computing and Cognition ‘04; Springer Science and Business Media LLC: Berlin, Germany, 2004; pp. 357–376. [Google Scholar]

- Hornby, G.S. Functional scalability through generative representations: The evolution of table designs. Environ. Plan. B Plan. Des. 2004, 31, 569–587. [Google Scholar] [CrossRef]

- McKay, A.; De Pennington, A. Combining evolutionary algorithms and shape grammars to generate branded product design. In Design Computing and Cognition ‘06; Springer Science and Business Media LLC: Berlin, Germany, 2007; pp. 521–539. [Google Scholar]

- Barros, M.; Duarte, J.M.P.; Chaparro, B.M. Integrated generative design tools for the mass customization of furniture. In Design Computing and Cognition ‘12; Springer Science and Business Media LLC: Berlin, Germany, 2014; pp. 285–300. [Google Scholar]

- Dhokia, V.; Essink, W.P.; Flynn, J.M. A generative multi-agent design methodology for additively manufactured parts inspired by termite nest building. CIRP Ann. 2017, 66, 153–156. [Google Scholar] [CrossRef]

- Gulanová, L.; Gulan, L.; Forrai, M.; Hirz, M. Generative engineering design methodology used for the development of surface-based components. Comput. Des. Appl. 2017, 14, 642–649. [Google Scholar] [CrossRef]

- Cui, J.; Tang, M.X. Towards generative systems for supporting product design. Int. J. Des. Eng 2017, 7, 1–16. [Google Scholar] [CrossRef]

- Olsen, L.; Samavati, F.F.; Sousa, M.C.; Jorge, J. Sketch-based modeling: A survey. Comput. Graph. 2009, 33, 85–103. [Google Scholar] [CrossRef]

- Gunpinar, E.; Gunpinar, S. A shape sampling technique via particle tracing for CAD models. Graph. Model. 2018, 96, 11–29. [Google Scholar] [CrossRef]

- Khan, S.; Gunpinar, E. Sampling CAD models via an extended teaching–learning-based optimization technique. Comput. Des. 2018, 100, 52–67. [Google Scholar] [CrossRef]

- Khan, S.; Gunpinar, E.; Moriguchi, M.; Suzuki, H. Evolving a psycho-physical distance metric for generative design exploration of diverse shapes. J. Mech. Des. 2019, 141, 1–16. [Google Scholar] [CrossRef]

- Khan, S.; Awan, M.J. A generative design technique for exploring shape variations. Adv. Eng. Inform. 2018, 38, 712–724. [Google Scholar] [CrossRef]

- Nordin, A. Challenges in the industrial implementation of generative design systems: An exploratory study. Artif. Intell. Eng. Des. Anal. Manuf. 2018, 32, 16–31. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; The MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Oh, S.; Jung, Y.; Kim, S.; Lee, I.; Kang, N. Deep generative design: Integration of topology optimization and generative models. J. Mech. Des. 2019, 141. [Google Scholar] [CrossRef]

- Oh, S.; Jung, Y.; Lee, I.; Kang, N. Design automation by integrating generative adversarial networks and topology optimization. In Volume 2A: 44th Design Automation Conference; ASME International: New York, NY, USA, 2018. [Google Scholar]

- Khan, S.; Gunpinar, E.; Sener, B. GenYacht: An interactive generative design system for computer-aided yacht hull design. Ocean. Eng. 2019, 191, 106462. [Google Scholar] [CrossRef]

- Gunpinar, E.; Coskun, U.C.; Ozsipahi, M.; Gunpinar, S. A generative design and drag coefficient prediction system for sedan car side silhouettes based on computational fluid dynamics. Comput. Des. 2019, 111, 65–79. [Google Scholar] [CrossRef]

- Doğan, K.M.; Suzuki, H.; Gunpinar, E.; Kim, M.-S. A generative sampling system for profile designs with shape constraints and user evaluation. Comput. Des. 2019, 111, 93–112. [Google Scholar] [CrossRef]

- Kielarova, S.W.; Pradujphongphet, P.; Bohez, I.L.J. An approach of generative design system: Jewelry design application. In Proceedings of the IEEE International Conference on Industrial Engineering and Engineering Management, Selangor Darul Ehsan, Malaysia, 9–12 December 2014; pp. 1329–1333. [Google Scholar]

- Garcia, S.; Romão, L. A design tool for generic multipurpose chair design. Commun. Comput. Inf. Sci. 2015, 527, 600–619. [Google Scholar] [CrossRef]

- Kielarova, S.W.; Pradujphongphet, P.; Bohez, E.L. New interactive-generative design system: Hybrid of shape grammar and evolutionary design—An application of jewelry design. In International Conference in Swarm Intelligence; Springer: Cham, Switzerland, 2015; pp. 302–313. [Google Scholar]

- Burnap, A.; Liu, Y.; Pan, Y.; Lee, H.; González, R.; Papalambros, P.Y. Estimating and exploring the product form design space using deep generative models. In Proceedings of the ASME Design Engineering Technical Conference, Charlotte, NC, USA, 21–24 August 2016. [Google Scholar]

- Alejandra, B.; Juan, B.; Miguel, C.; Pablo, P. Generic generative design systems to imprint personalities in consumer products: Preliminary results. In Proceedings of the International Conference on Engineering Design, Vancouver, BC, Canada, 21–25 August 2017; pp. 493–502. [Google Scholar]

- Sansri, S.; Wannarumon, S. Multi-objective shape optimization in generative design: Art deco double clip brooch jewelry design. In IT Convergence and Security 2017; Springer: Singapore, 2017; pp. 248–255. [Google Scholar]

- Doğan, K.M.; Suzuki, H.; Gunpinar, E.; Kim, M.-S. Example based sampling of design space for facilitating diverse product designs. In ACM International Conference Proceeding Series; Association for Computing Machinery, Inc.: New York, NY, USA, 2018; pp. 276–281. [Google Scholar]

- Li, H.; Lachmayer, R. Automated exploration of design solution space applying the generative design approach. In Design Society: International Conference on Engineering Design; Cambridge University Press: Cambridge, UK, 2019; Volume 1, pp. 1085–1094. [Google Scholar]

- Dai, Y.; Li, Y.; Liu, L.-J. New product design with automatic scheme generation. Sens. Imaging Int. J. 2019, 20, 29. [Google Scholar] [CrossRef]

- Kallioras, N.A.; Lagaros, N.D. DzAIN: Deep learning based generative design. Procedia Manuf. 2020, 44, 591–598. [Google Scholar] [CrossRef]

- Petrov, R.; Cvetkov, P.; Maksimov, A.; Klyavin, O. On the problem of optimizing the door hinge of electro car by generative design methods. Int. J. Mech. 2020, 14, 119–124. [Google Scholar]

- Boden, M.A. Computer models of creativity. AI Mag. 2009, 30, 23. [Google Scholar] [CrossRef]

- Sarkar, P.; Chakrabarti, A. Assessing design creativity. Des. Stud. 2011, 32, 348–383. [Google Scholar] [CrossRef]

- Fiorineschi, L.; Frillici, F.S.; Rotini, F. A-posteriori novelty assessments for sequential design sessions. In Proceedings of the International Design Conference, 2018, University of Florence, Florence, Italy, 13–14 June 2018; pp. 1079–1090. [Google Scholar]

- Fiorineschi, L.; Frillici, F.S.; Rotini, F. Impact of missing attributes on the novelty metric of Shah et al. Res. Eng. Des. 2020, 31, 221–234. [Google Scholar] [CrossRef]

- Jagtap, S. Design creativity: Refined method for novelty assessment. Int. J. Des. Creat. Innov. 2018, 7, 99–115. [Google Scholar] [CrossRef]

- Bae, S.-H.; Balakrishnan, R.; Singh, K. ILoveSketch: As-natural-as possible sketching system for creating 3D curve models. In Proceedings of the 21st Annual ACM Symposium on User Interface Software and Technology, Monterey, CA, USA, 19–22 October 2008; ACM: New York, NY, USA, 2008; pp. 151–160. [Google Scholar]

- Company, P.; Contero, M.; Varley, P.A.C.; Aleixos, N.; Naya, F. Computer-aided sketching as a tool to promote innovation in the new product development process. Comput. Ind. 2009, 60, 592–603. [Google Scholar] [CrossRef]

- Shireen, N.; Erhan, H.; Sánchez, R.; Popovic, J.; Woodbury, R.; Riecke, B.E. Design space exploration in parametric systems. In Proceedings of the 8th ACM Conference on Creativity and Cognition, Atlanta, GA, USA, 3–6 November 2011; ACM: New York, NY, USA, 2011; pp. 249–258. [Google Scholar]

- Erhan, H.; Wang, I.; Shireen, N. Interacting with thousands: A parametric-space exploration method in generative design. In Proceedings of the 34th Annual Conference of the Association for Computer Aided Design in Architecture, Los Angeles, CA, USA, 23–25 October 2014; pp. 619–626. [Google Scholar]

- Shireen, N. ParaXplore interfaces: Parametric interfaces for parallel exploration in design. In Proceedings of the 2016 ACM Companion on Interactive Surfaces and Spaces, Niagara Falls, ON, Canada, 6–9 November 2016; pp. 7–12. [Google Scholar]

- Oppenlaender, J.; Shireen, N.; Mackeprang, M.; Erhan, H.; Goncalves, J.; Hosio, S. Crowd-powered interfaces for creative design thinking. In Proceedings of the 2019 Conference on Creativity and Cognition, San Diego, CA, USA, 23–26 June 2019; pp. 722–729. [Google Scholar]

- Carfagni, M.; Fiorineschi, L.; Furferi, R.; Governi, L.; Rotini, F. The role of additive technologies in the prototyping issues of design. Rapid Prototyp. J. 2018, 24, 1101–1116. [Google Scholar] [CrossRef]

- Chew, L.H.; Teo, J.; Mountstephens, J. Aesthetic preference recognition of 3D shapes using EEG. Cogn. Neurodynamics 2015, 10, 165–173. [Google Scholar] [CrossRef]

- Teo, J.; Hou, C.L.; Mountstephens, J. Deep learning for EEG-Based preference classification. In Proceedings of the AIP Conference Proceedings, Vladivostok, Russia, 18–22 September 2017; Volume 1891, p. 20141. [Google Scholar]

- Lim, J.Z.; Mountstephens, J.; Teo, J. Emotion recognition using eye-tracking: Taxonomy, review and current challenges. Sensors 2020, 20, 2384. [Google Scholar] [CrossRef]

- Dean, L.; Loy, J. Generative product design futures. Des. J. 2020, 23, 331–349. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).