Integrating Large Language Models into Digital Manufacturing: A Systematic Review and Research Agenda

Abstract

1. Introduction

2. Methodology

2.1. Selection Database

2.2. Search String

- The first block covers classic and advanced AI techniques. AI, machine learning and deep learning for AI in general, and language models (LLM, GPT, BERT) link up with technological advances in natural language processing.

- The second block defines the overall context, i.e., digital manufacturing and the supply chain. Digital manufacturing, smart manufacturing, intelligent manufacturing, Industry 4.0, and cyber–physical systems are all linked to the industry of the future.

- The third block presents industrial functions, including operations management, supply chain management, and logistics.

- The fourth block presents the objectives of technology use (e.g., efficiency, optimization, automation).

2.3. Data Filtering (Inclusion and Exclusion Criteria)

2.4. Data Collection Process

3. Bibliometric Analysis

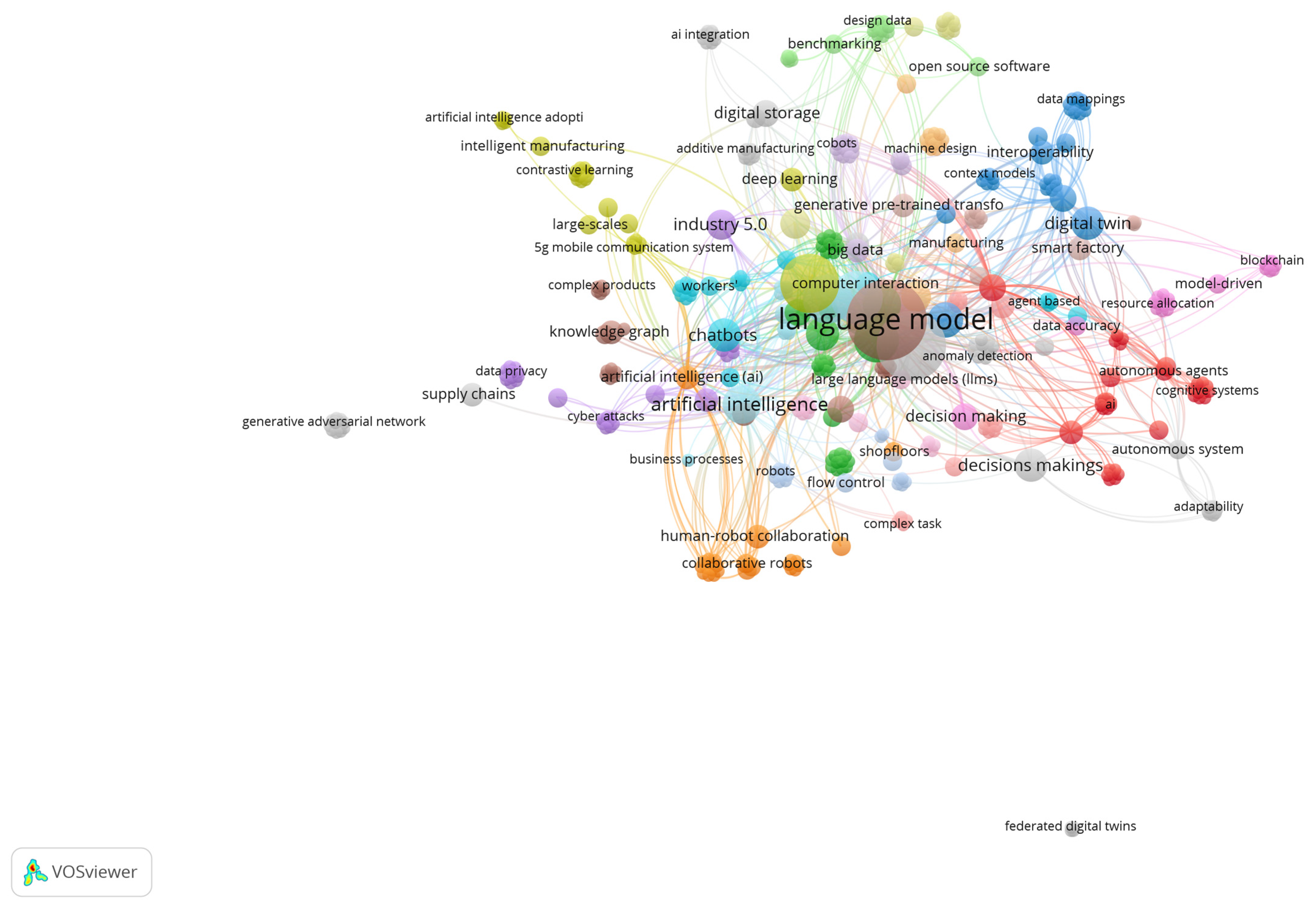

3.1. Keyword Analysis

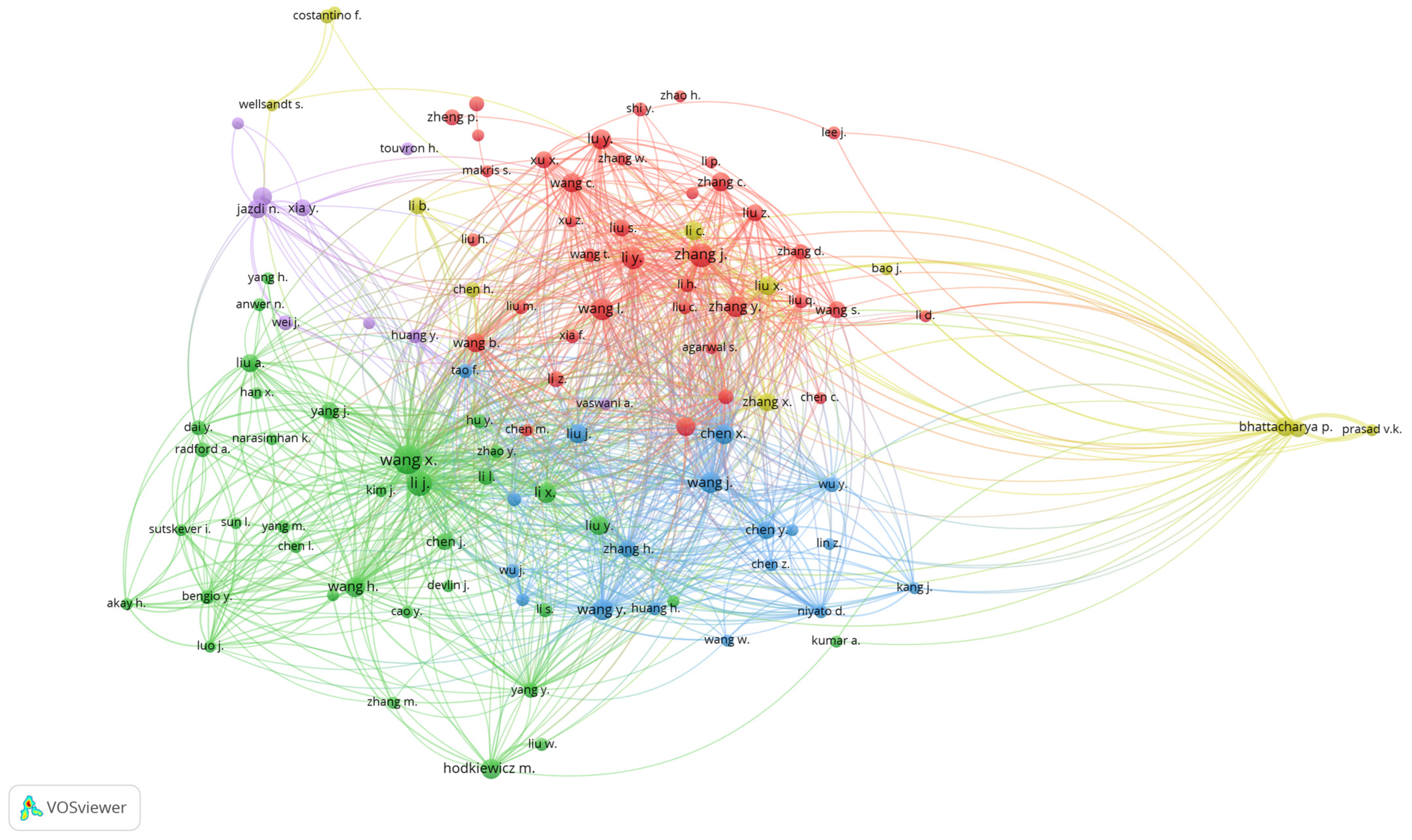

3.2. Co-Citation Analysis: Cited Authors

3.3. Bibliographic Coupling

| Clusters | Authors | Articles | Citations |

|---|---|---|---|

| Cluster 1 | [44] | NLP in SMEs for Industry 4.0: Opportunities and challenges | 4 |

| [9] | Data is all you need: Finetuning LLMs for Chip Design via an Automated design-data augmentation framework | 12 | |

| [38] | Knowledge sharing in manufacturing using LLM-powered tools: user study and model benchmarking | 14 | |

| [45] | An Intelligent Chatbot Assistant for Comprehensive Troubleshooting Guidelines and Knowledge Repository in Printed Circuit Board Production | 0 | |

| [46] | Interoperable information modelling leveraging asset administration shell and a large language model for quality control toward zero defect manufacturing | 0 | |

| [47] | Dual data mapping with fine-tuned large language models and asset administration shells toward interoperable knowledge representation | 1 | |

| [48] | The impact of artificial intelligence adoption on Chinese manufacturing enterprises’ innovativeness: new insights from a labor structure perspective | 1 | |

| [39] | Generation of Asset Administration Shell With Large Language Model Agents: Toward Semantic Interoperability in Digital Twins in the Context of Industry 4.0 | 17 | |

| Cluster 2 | [49] | Decomposing maintenance actions into sub-tasks using natural language processing: A case study in an Italian automotive company | 0 |

| [50] | LLM-Enhanced Human–Machine Interaction for Adaptive Decision-Making in Dynamic Manufacturing Process Environments | 0 | |

| [51] | A survey of LLM-augmented knowledge graph construction and application in complex product design | 4 | |

| [34] | Knowledge extraction for additive manufacturing process via named entity recognition with LLMs | 5 | |

| [10] | Evaluating the Performance of ChatGPT in the Automation of Maintenance Recommendations for Prognostics and Health Management | 3 | |

| [52] | Towards a GPT-Based Lean Manufacturing Consultant for Manufacturing Optimization | 0 | |

| [53] | Digital twin designs with generative AI: crafting a comprehensive framework for manufacturing systems | 1 | |

| [36] | Exploring the Potential of Large Language Models in Supply Chain Management: A Study Using Big Data | 11 | |

| Cluster 3 | [40] | Agentic AI: Autonomous Intelligence for Complex Goals—A Comprehensive Survey | 10 |

| [54] | Multimodal Large Language Model-Based Fault Detection and Diagnosis in Context of Industry 4.0 | 2 | |

| [55] | Accelerating Industry 4.0 and 5.0: The Potential of Generative Artificial Intelligence | 1 | |

| [56] | A blockchain-based LLM-driven energy-efficient scheduling system towards distributed multi-agent manufacturing scenario of new energy vehicles within the circular economy | 2 | |

| [57] | Enhancing Bottleneck Analysis in Ship Manufacturing with Knowledge Graphs and Large Language Models | 0 | |

| [58] | LLM experiments with simulation: Large Language Model Multi-Agent System for Simulation Model Parametrization in Digital Twins | 0 | |

| [59] | Chat with MES: LLM-driven user interface for manipulating garment manufacturing system through natural language | 0 | |

| Cluster 4 | [60] | A Conceptual Framework for a Latest Information-Maintaining Method Using Retrieval-Augmented Generation and a Large Language Model in Smart Manufacturing: Theoretical Approach and Performance Analysis | 0 |

| [35] | Assessment of a large language model based digital intelligent assistant in assembly manufacturing | 4 | |

| [61] | Application of a digital intelligent assistant to support industrial processes: The case of adaptive allocation in the face of cyber attacks | 0 | |

| [6] | Framework for LLM applications in manufacturing | 3 | |

| [62] | A generative pre-trained transformer industrial bot to improve operators’ working experience in a small Industry 5.0 factory | 0 | |

| [63] | Deriving inferences through natural language from structured datasets for asset lifecycle management | 0 | |

| Cluster 5 | [64] | A Survey on Applications of Large Language Model-Driven Digital Twins for Intelligent Network Optimization | 0 |

| [65] | Digitization of the enterprise—prospects for process automation with using RPA and GPT integration | 3 | |

| [66] | Large Language Models in Human–Robot Collaboration with Cognitive Validation Against Context-induced Hallucinations | 0 | |

| [67] | A novel approach to voice of customer extraction using GPT-3.5 Turbo: linking advanced NLP and Lean Six Sigma 4.0 | 6 | |

| [37] | Towards autonomous system: Flexible modular production system enhanced with large language model agents | 31 | |

| Cluster 6 | [13] | Push-pull digital thread for digital transformation of manufacturing systems | 7 |

| [14] | Integrating large language models for improved failure mode and effects analysis (FMEA): a framework and case study | 4 | |

| [41] | An LLM-based approach for enabling seamless Human–Robot collaboration in assembly | 23 | |

| [68] | An advanced retrieval-augmented generation system for manufacturing quality control | 3 | |

| [69] | A survey of emerging applications of large language models for problems in mechanics, product design, and manufacturing | 3 | |

| Cluster 7 | [70] | Enhancing Human–Robot Collaborative Assembly in Manufacturing Systems Using Large Language Models | 3 |

| [71] | Large Language Model-Enabled Multi-Agent Manufacturing Systems | 1 | |

| [42] | When Large Language Model Agents Meet 6G Networks: Perception, Grounding, and Alignment | 12 | |

| [72] | Large-scale foundation models for intelligent manufacturing applications: a survey | 0 | |

| Cluster 8 | [7] | Literacy Deep Reinforcement Learning-Based Federated Digital Twin Scheduling for the Software-Defined Factory | 0 |

| [43] | A Survey of the Real-Time Metaverse: Challenges and Opportunities | 13 | |

| [73] | Applying Large Language Model Analysis and Backend Web Services in Regulatory Technologies for Continuous Compliance Checks | 1 | |

| [74] | Explainable AI for Industry 5.0: Vision, Architecture, and Potential Directions | 9 | |

| Cluster 9 | [75] | SAMBA: A reference framework for Human-in-the-Loop in adaptive Smart Manufacturing | 0 |

| [76] | Human resource managers’ perceptions on the impact of AI on the South African workforce | 0 |

4. Thematic Analysis

- With:

- i: warehouse (sources)

- j: clients (destinations)

- Cij: Unit cost of transport between i and j

- xij: Quantity of products transported from i to j

- xij ≥ 0 (the quantity transported cannot be negative)

- -

- Knowledge graphs (KGs): used to facilitate the design of complex assets. Indeed, combining LLMs with KGs enhances the structuring of heterogeneous data, optimizes operational design tasks, and enables reliable decision-making [51].

- -

- RAGs: this combination (LLMs + RAGs) facilitates the detection of errors and failures during product manufacturing by processing not only internal, but also external knowledge [68]. This enables the overcoming of limitations inherent in conventional approaches while enhancing the recommendations provided [68].

- -

- GPT-4, to interact with conversational interfaces and access any type of reliable information relevant to problem-solving in the industrial sector [38].

5. Integrative Framework

- -

- Axis 1—Optimization of Manufacturing Processes: This focus area addresses the contribution of LLMs to improving operational efficiency in smart factories. In other words, it encompasses several functions of LLMs, including the automation of industrial operations, adaptability, interoperability, and quality control. This functional basis of LLMs enables innovation and knowledge structuring. Hence, the second axis is presented below.

- -

- Axis 2—Data structuring and innovation: This second axis focuses on the ability of LLMs to innovate while structuring the knowledge needed to make informed decisions. The first two areas, exploring technical and cognitive advantages, respectively, transform the role of employees. Hence, the third area involves the ethical challenges associated with integrating LLMs and human–machine interaction.

- -

- Axis 3—Human–machine interaction and ethical challenges: This axis highlights the role of employees in digital manufacturing processes and the challenges associated with the use of LLMs.

- A1: optimization of manufacturing processes

- A2: data structuring and innovation

- A3: human–machine interaction and ethical challenges

6. Agenda for Future Research

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vallée, S.; Ertz, M.; Ouerghemmi, C.; Périn, A. Fostering Sustainability Through Digital Evolution: Evaluating Industry 5.0 Preparedness in Quebec’s Regional SMEs. In Accelerating the Socio-Ecological Transition: Strategies and Innovations for Sustainable Development; Cheriet, M., Boucher, J.-F., Gondim de Almeida Guimarães, L., Frayret, J.-M., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 259–293. [Google Scholar] [CrossRef]

- Karp, E. Manufacturers Are Adopting Tech, Diversifying Talent—But They Need to Step It Up. IndustryWeek. Available online: https://www.industryweek.com/leadership/strategic-planning-execution/article/21280539/manufacturers-are-adopting-tech-diversifying-talentbut-they-need-to-step-it-up (accessed on 25 July 2025).

- Aarti, D. Digital Transformation in Manufacturing Market Research Report—Forecast Till 2034. Available online: https://www.marketresearchfuture.com/reports/digital-transformation-in-manufacturing-market-32040 (accessed on 25 July 2025).

- Simon, H.A. The New Science of Management Decision; Harper & Brothers: New York, NY, USA, 1960; Volume 3. [Google Scholar]

- Dirican, C. The Impacts of Robotics, Artificial Intelligence On Business and Economics. Procedia Soc. Behav. Sci. 2015, 195, 564–573. [Google Scholar] [CrossRef]

- Garcia, C.I.; DiBattista, M.A.; Letelier, T.A.; Halloran, H.D.; Camelio, J.A. Framework for LLM Applications in Manufacturing. Manuf. Lett. 2024, 41, 253–263. [Google Scholar] [CrossRef]

- Ahn, J.; Yun, S.; Kwon, J.-W.; Kim, W.-T. Literacy Deep Reinforcement Learning-Based Federated Digital Twin Scheduling for the Software-Defined Factory. Electron 2024, 13, 4452. [Google Scholar] [CrossRef]

- Duarte, F. Number of ChatGPT Users (July 2025). Exploding Topics. Available online: https://explodingtopics.com/blog/chatgpt-users (accessed on 25 July 2025).

- Chang, K.; Wang, K.; Yang, N.; Wang, Y.; Jin, D.; Zhu, W.; Chen, Z.; Li, C.; Yan, H.; Zhou, Y.; et al. Data Is All You Need: Finetuning LLMs for Chip Design via an Automated Design-Data Augmentation Framework. In Proceedings of the Design Automation Conference, San Francisco, CA, USA, 23–27 June 2024; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024. [Google Scholar] [CrossRef]

- Lukens, S.; Ali, A. Evaluating the Performance of ChatGPT in the Automation of Maintenance Recommendations for Prognostics and Health Management. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Salt Lake City, UT, USA, 28 October–2 November 2023; Kulkarni, C.S., Roychoudhury, I., Eds.; Prognostics and Health Management Society: Alexandria, VA, USA,, 2023; Volume 15. [Google Scholar] [CrossRef]

- Zhao, W.X.; Zhou, K.; Li, J.; Tang, T.; Wang, X.; Hou, Y.; Min, Y.; Zhang, B.; Zhang, J.; Dong, Z.; et al. A Survey of Large Language Models. arXiv 2025, arXiv:2303.18223. [Google Scholar] [CrossRef]

- Jadhav, Y.; Farimani, A.B. Large Language Model Agent as a Mechanical Designer. arXiv 2024, arXiv:2404.17525. [Google Scholar] [CrossRef]

- Akay, H.; Lee, S.H.; Kim, S.-G. Push-Pull Digital Thread for Digital Transformation of Manufacturing Systems. CIRP Ann. 2023, 72, 401–404. [Google Scholar] [CrossRef]

- El Hassani, I.; Masrour, T.; Kourouma, N.; Motte, D.; Tavčar, J. Integrating Large Language Models for Improved Failure Mode and Effects Analysis (FMEA): A Framework and Case Study. In Proceedings of the Design Society, Cavtat, Croatia, 20–23 May 2024; Storga, M., Skec, S., Martinec, T., Marjanovic, D., Pavkovic, N., Skec, M.M., Eds.; Cambridge University Press: Cambridge, UK, 2024; Volume 4, pp. 2019–2028. [Google Scholar] [CrossRef]

- Wang, X.; Liu, A.; Kara, S. Machine Learning for Engineering Design toward Smart Customization: A Systematic Review. J. Manuf. Syst. 2022, 65, 391–405. [Google Scholar] [CrossRef]

- Barros, C.F.; Azevedo, B.B.; Neto, V.V.G.; Kassab, M.; Kalinowski, M.; do Nascimento, H.A.D.; Bandeira, M.C. Large Language Model for Qualitative Research—A Systematic Mapping Study. arXiv 2024, arXiv:2411.14473. [Google Scholar]

- Gao, T.; Yen, H.; Yu, J.; Chen, D. Enabling Large Language Models to Generate Text with Citations. arXiv 2023, arXiv:2305.14627. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, Q.; Yu, Y.; Zhou, G.; Zeng, K.; Chang, F.; Ding, K. A Survey on Potentials, Pathways and Challenges of Large Language Models in New-Generation Intelligent Manufacturing. Robot. Comput.-Integr. Manuf. 2025, 92, 102883. [Google Scholar] [CrossRef]

- Fan, H.; Liu, X.; Fuh, J.Y.H.; Lu, W.F.; Li, B. Embodied Intelligence in Manufacturing: Leveraging Large Language Models for Autonomous Industrial Robotics. J. Intell. Manuf. 2025, 36, 1141–1157. [Google Scholar] [CrossRef]

- Wan, Y.; Liu, Y.; Chen, Z.; Chen, C.; Li, X.; Hu, F.; Packianather, M. Making Knowledge Graphs Work for Smart Manufacturing: Research Topics, Applications and Prospects. J. Manuf. Syst. 2024, 76, 103–132. [Google Scholar] [CrossRef]

- Gabsi, A.E.H. Integrating Artificial Intelligence in Industry 4.0: Insights, Challenges, and Future Prospects—A Literature Review. Ann. Oper. Res. 2024, 341, 1–28. [Google Scholar] [CrossRef]

- Passalacqua, M.; Pellerin, R.; Magnani, F.; Doyon-Poulin, P.; Del-Aguila, L.; Boasen, J.; Léger, P.-M. Human-Centred AI in Industry 5.0: A Systematic Review. Int. J. Prod. Res. 2025, 63, 2638–2669. [Google Scholar] [CrossRef]

- Mayer, A.; Greif, L.; Häußermann, T.M.; Otto, S.; Kastner, K.; El Bobbou, S.; Chardonnet, J.-R.; Reichwald, J.; Fleischer, J.; Ovtcharova, J. Digital Twins, Extended Reality, and Artificial Intelligence in Manufacturing Reconfiguration: A Systematic Literature Review. Sustainability 2025, 17, 2318. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, H.; Jiang, H.; Pan, Y.; Liu, Z.; Wu, Z.; Shu, P.; Tian, J.; Yang, T.; Xu, S. Large Language Models for Manufacturing. arXiv 2024, arXiv:2410.21418. [Google Scholar]

- Ferdaus, M.M.; Abdelguerfi, M.; Ioup, E.; Niles, K.N.; Pathak, K.; Sloan, S. Towards Trustworthy AI: A Review of Ethical and Robust Large Language Models. arXiv 2024, arXiv:2407.13934. [Google Scholar] [CrossRef]

- Zhui, L.; Fenghe, L.; Xuehu, W.; Qining, F.; Wei, R. Ethical Considerations and Fundamental Principles of Large Language Models in Medical Education: Viewpoint. J. Med. Internet Res. 2024, 26, e60083. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, K.; Leng, J.; Liu, C.; Fan, J.; Zheng, P. Integrating Large Language Model and Digital Twins in the Context of Industry 5.0: Framework, Challenges and Opportunities. Robot. Comput.-Integr. Manuf. 2025, 94, 102982. [Google Scholar] [CrossRef]

- Mulrow, C.D. Systematic Reviews: Rationale for Systematic Reviews. Br. Med. J. 1994, 309, 597. [Google Scholar] [CrossRef]

- Walker, K. A Systematic Review of the Corporate Reputation Literature: Definition, Measurement, and Theory. Corp. Reput. Rev. 2010, 12, 357–387. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep Learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27 June–2 July 2016; pp. 770–778. [Google Scholar]

- Echchakoui, S. Why and How to Merge Scopus and Web of Science during Bibliometric Analysis: The Case of Sales Force Literature from 1912 to 2019. J. Mark. Anal. 2020, 8, 165–184. [Google Scholar] [CrossRef]

- Small, H. Visualizing Science by Citation Mapping. J. Am. Soc. Inf. Sci. 1999, 50, 799–813. [Google Scholar] [CrossRef]

- Liu, X.; Erkoyuncu, J.A.; Fuh, J.Y.H.; Lu, W.F.; Li, B. Knowledge Extraction for Additive Manufacturing Process via Named Entity Recognition with LLMs. Rob. Comput. Integr. Manuf. 2025, 93, 102900. [Google Scholar] [CrossRef]

- Colabianchi, S.; Costantino, F.; Sabetta, N. Assessment of a Large Language Model Based Digital Intelligent Assistant in Assembly Manufacturing. Comput. Ind. 2024, 162, 104129. [Google Scholar] [CrossRef]

- Srivastava, S.K.; Routray, S.; Bag, S.; Gupta, S.; Zhang, J.Z. Exploring the Potential of Large Language Models in Supply Chain Management: A Study Using Big Data. J. Glob. Inf. Manag. 2024, 32, 1–29. [Google Scholar] [CrossRef]

- Xia, Y.; Shenoy, M.; Jazdi, N.; Weyrich, M. Towards Autonomous System: Flexible Modular Production System Enhanced with Large Language Model Agents. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation, Stuttgart, Germany, 12–15 September 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023; Volume 2023. [Google Scholar] [CrossRef]

- Kernan Freire, S.; Wang, C.; Foosherian, M.; Wellsandt, S.; Ruiz-Arenas, S.; Niforatos, E. Knowledge Sharing in Manufacturing Using LLM-Powered Tools: User Study and Model Benchmarking. Front. Artif. Intell. 2024, 7, 1293084. [Google Scholar] [CrossRef]

- Xia, Y.; Xiao, Z.; Jazdi, N.; Weyrich, M. Generation of Asset Administration Shell With Large Language Model Agents: Toward Semantic Interoperability in Digital Twins in the Context of Industry 4.0. IEEE Access 2024, 12, 84863–84877. [Google Scholar] [CrossRef]

- Acharya, D.B.; Kuppan, K.; Divya, B. Agentic AI: Autonomous Intelligence for Complex Goals—A Comprehensive Survey. IEEE Access 2025, 13, 18912–18936. [Google Scholar] [CrossRef]

- Gkournelos, C.; Konstantinou, C.; Makris, S. An LLM-Based Approach for Enabling Seamless Human-Robot Collaboration in Assembly. CIRP Ann. 2024, 73, 9–12. [Google Scholar] [CrossRef]

- Xu, M.; Niyato, D.; Kang, J.; Xiong, Z.; Mao, S.; Han, Z.; Kim, D.I.; Letaief, K.B. When Large Language Model Agents Meet 6G Networks: Perception, Grounding, and Alignment. IEEE Wirel. Commun. 2024, 31, 63–71. [Google Scholar] [CrossRef]

- Hatami, M.; Qu, Q.; Chen, Y.; Kholidy, H.; Blasch, E.; Ardiles-Cruz, E. A Survey of the Real-Time Metaverse: Challenges and Opportunities. Future Internet 2024, 16, 379. [Google Scholar] [CrossRef]

- Bourdin, M.; Paviot, T.; Pellerin, R.; Lamouri, S. NLP in SMEs for Industry 4.0: Opportunities and Challenges. In Procedia Computer Science; Goncalves Martinho, R.F., Cruz da Cunha, M.M., Eds.; Elsevier, B.V.: Amsterdam, The Netherlands, 2024; Volume 239, pp. 396–403. [Google Scholar] [CrossRef]

- Rittikulsittichai, S.; Siriborvornratanakul, T. An Intelligent Chatbot Assistant for Comprehensive Troubleshooting Guidelines and Knowledge Repository in Printed Circuit Board Production. IEEE Trans. Artif. Intell. 2025, 6, 1259–1268. [Google Scholar] [CrossRef]

- Shi, D.; Liedl, P.; Bauernhansl, T. Interoperable Information Modelling Leveraging Asset Administration Shell and Large Language Model for Quality Control toward Zero Defect Manufacturing. J. Manuf. Syst. 2024, 77, 678–696. [Google Scholar] [CrossRef]

- Shi, D.; Meyer, O.; Oberle, M.; Bauernhansl, T. Dual Data Mapping with Fine-Tuned Large Language Models and Asset Administration Shells toward Interoperable Knowledge Representation. Rob. Comput. Integr. Manuf. 2025, 91, 102837. [Google Scholar] [CrossRef]

- Wu, Q.; Qalati, S.A.; Tajeddini, K.; Wang, H. The Impact of Artificial Intelligence Adoption on Chinese Manufacturing Enterprises’ Innovativeness: New Insights from a Labor Structure Perspective. Ind. Manag. Data Sys. 2025, 125, 849–874. [Google Scholar] [CrossRef]

- Giordano, V.; Fantoni, G. Decomposing Maintenance Actions into Sub-Tasks Using Natural Language Processing: A Case Study in an Italian Automotive Company. Comput. Ind. 2025, 164, 104186. [Google Scholar] [CrossRef]

- Keskin, Z.; Joosten, D.; Klasen, N.; Huber, M.; Liu, C.; Drescher, B.; Schmitt, R.H. LLM-Enhanced Human-Machine Interaction for Adaptive Decision-Making in Dynamic Manufacturing Process Environments. IEEE Access 2025, 13, 44650–44661. [Google Scholar] [CrossRef]

- Liang, X.; Wang, Z.; Li, M.; Yan, Z. A Survey of LLM-Augmented Knowledge Graph Construction and Application in Complex Product Design. In Procedia CIRP; Erkoyuncu, J.A., Farsi, M., Addepalli, P., Eds.; Elsevier, B.V.: Amsterdam, The Netherlands, 2024; Volume 128, pp. 870–875. [Google Scholar] [CrossRef]

- Magnus, C.S.; Venschott, M. Towards a GPT-Based Lean Manufacturing Consultant for Manufacturing Optimization. In Procedia CIRP; Putnik, G.D., Ed.; Elsevier, B.V.: Amsterdam, The Netherlands, 2024; Volume 130, pp. 167–176. [Google Scholar] [CrossRef]

- Mata, O.; Ponce, P.; Perez, C.; Ramirez, M.; Anthony, B.; Russel, B.; Apte, P.; MacCleery, B.; Molina, A. Digital Twin Designs with Generative AI: Crafting a Comprehensive Framework for Manufacturing Systems. J. Intell. Manuf. 2025. [Google Scholar] [CrossRef]

- Alsaif, K.M.; Albeshri, A.A.; Khemakhem, M.A.; Eassa, F.E. Multimodal Large Language Model-Based Fault Detection and Diagnosis in Context of Industry 4.0. Electronics 2024, 13, 4912. [Google Scholar] [CrossRef]

- Boareto, P.A.; Szejka, A.L.; Loures, E.F.R.; Deschamps, F.; Santos, E.A.P. Accelerating Industry 4.0 and 5.0: The Potential of Generative Artificial Intelligence. In Communications in Computer and Information Science; Dassisti, M., Madani, K., Panetto, H., Eds.; Springer Science and Business Media Deutschland GmbH: Berlin/Heidelberg, Germany, 2025; Volume 2372, pp. 456–472. [Google Scholar] [CrossRef]

- Liu, C.; Nie, Q. A Blockchain-Based LLM-Driven Energy-Efficient Scheduling System towards Distributed Multi-Agent Manufacturing Scenario of New Energy Vehicles within the Circular Economy. Comput. Ind. Eng. 2025, 201, 110889. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, T.; Zhou, B.; Liang, X.; Du, J.; Bao, J. Enhancing Bottleneck Analysis in Ship Manufacturing with Knowledge Graphs and Large Language Models. Machines 2025, 13, 224. [Google Scholar] [CrossRef]

- Xia, Y.; Dittler, D.; Jazdi, N.; Chen, H.; Weyrich, M. LLM Experiments with Simulation: Large Language Model Multi-Agent System for Simulation Model Parametrization in Digital Twins. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation, Valencia, Spain, 10–13 September 2024; Facchinetti, T., Cenedese, A., Bello, L.L., Vitturi, S., Sauter, T., Tramarin, F., Eds.; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024. [Google Scholar] [CrossRef]

- Yuan, Z.; Li, M.; Liu, C.; Han, F.; Huang, H.; Dai, H.-N. Chat with MES: LLM-Driven User Interface for Manipulating Garment Manufacturing System through Natural Language. J. Manuf. Syst. 2025, 80, 1093–1107. [Google Scholar] [CrossRef]

- Choi, H.; Jeong, J. A Conceptual Framework for a Latest Information-Maintaining Method Using Retrieval-Augmented Generation and a Large Language Model in Smart Manufacturing: Theoretical Approach and Performance Analysis. Machines 2025, 13, 94. [Google Scholar] [CrossRef]

- Colabianchi, S. Application of a Digital Intelligent Assistant to Support Industrial Processes: The Case of Adaptive Allocation in the Face of Cyber Attacks. In Procedia Computer Science; Solina, V., Longo, F., Romero, D., Eds.; Elsevier, B.V.: Amsterdam, The Netherlands, 2025; Volume 253, pp. 1555–1564. [Google Scholar] [CrossRef]

- Kiangala, K.S.; Wang, Z. A Generative Pre-Trained Transformer Industrial Bot to Improve Operators’ Working Experience in a Small Industry 5.0 Factory. Int. J. Adv. Manuf. Technol. 2025, 136, 3525–3541. [Google Scholar] [CrossRef]

- Bhattacharjee, S.; Pandhare, V. Deriving Inferences through Natural Language from Structured Datasets for Asset Lifecycle Management. In Procedia Computer Science; Arena, S., Roda, I., Voisin, A., Parlikad, A.K., Emmanouilidis, C., Eds.; Elsevier, B.V.: Amsterdam, The Netherlands, 2024; Volume 58, pp. 145–150. [Google Scholar] [CrossRef]

- Guo, Z.; Tang, F.; Luo, L.; Zhao, M.; Kato, N. A Survey on Applications of Large Language Model-Driven Digital Twins for Intelligent Network Optimization. IEEE Commun. Surv. Tutor. 2025. [Google Scholar] [CrossRef]

- Jasinska, K.; Lewicz, M.; Rostalski, M. Digitization of the Enterprise—Prospects for Process Automation with Using RPA and GPT Integration. In Procedia Computer Science; Howlett, R., Tsihrintzis, G.A., Toro, C., Rios, S.A., Jain, L.C., Eds.; Elsevier, B.V.: Amsterdam, The Netherlands, 2023; Volume 225, pp. 3243–3254. [Google Scholar] [CrossRef]

- Ranasinghe, N.; Mohammed, W.M.; Stefanidis, K.; Martinez Lastra, J.L. Large Language Models in Human-Robot Collaboration with Cognitive Validation Against Context-Induced Hallucinations. IEEE Access 2025, 13, 77418–77430. [Google Scholar] [CrossRef]

- Shahin, M.; Chen, F.F.; Hosseinzadeh, A.; Maghanaki, M.; Eghbalian, A. A Novel Approach to Voice of Customer Extraction Using GPT-3.5 Turbo: Linking Advanced NLP and Lean Six Sigma 4.0. Int. J. Adv. Manuf. Technol. 2024, 131, 3615–3630. [Google Scholar] [CrossRef]

- Heredia Álvaro, J.A.; Barreda, J.G. An Advanced Retrieval-Augmented Generation System for Manufacturing Quality Control. Adv. Eng. Inf. 2025, 64, 103007. [Google Scholar] [CrossRef]

- Mustapha, K.B. A Survey of Emerging Applications of Large Language Models for Problems in Mechanics, Product Design, and Manufacturing. Adv. Eng. Inf. 2025, 64, 103066. [Google Scholar] [CrossRef]

- Lim, J.; Patel, S.; Evans, A.; Pimley, J.; Li, Y.; Kovalenko, I. Enhancing Human-Robot Collaborative Assembly in Manufacturing Systems Using Large Language Models. In Proceedings of the IEEE International Conference on Automation Science and Engineering, Auckland, New Zealand, 20–24 August 2024; IEEE Computer Society: Los Alamitos, CA, USA, 2024; pp. 2581–2587. [Google Scholar] [CrossRef]

- Lim, J.; Vogel-Heuser, B.; Kovalenko, I. Large Language Model-Enabled Multi-Agent Manufacturing Systems. In Proceedings of the IEEE International Conference on Automation Science and Engineering, Bari, Italy, 28 August–1 September 2024; IEEE Computer Society: Los Alamitos, CA, USA, 2024; pp. 3940–3946. [Google Scholar] [CrossRef]

- Zhang, H.; Semujju, S.D.; Wang, Z.; Lv, X.; Xu, K.; Wu, L.; Jia, Y.; Wu, J.; Liang, W.; Zhuang, R.; et al. Large Scale Foundation Models for Intelligent Manufacturing Applications: A Survey. J. Intell. Manuf. 2025. [Google Scholar] [CrossRef]

- Li, J.; Maiti, A. Applying Large Language Model Analysis and Backend Web Services in Regulatory Technologies for Continuous Compliance Checks. Future Internet 2025, 17, 100. [Google Scholar] [CrossRef]

- Trivedi, C.; Bhattacharya, P.; Prasad, V.K.; Patel, V.; Singh, A.; Tanwar, S.; Sharma, R.; Aluvala, S.; Pau, G.; Sharma, G. Explainable AI for Industry 5.0: Vision, Architecture, and Potential Directions. IEEE Open J. Ind. Appl. 2024, 5, 177–208. [Google Scholar] [CrossRef]

- Bianchini, F.; Calamo, M.; De Luzi, F.; Macrì, M.; Marinacci, M.; Mathew, J.G.; Monti, F.; Rossi, J.; Leotta, F.; Mecella, M. SAMBA: A Reference Framework for Human-in-the-Loop in Adaptive Smart Manufacturing. In Procedia Computer Science; Solina, V., Longo, F., Romero, D., Eds.; Elsevier, B.V.: Amsterdam, The Netherlands, 2025; Volume 253, pp. 2257–2267. [Google Scholar] [CrossRef]

- Poisat, P.; Cullen, M.; Calitz, A.P. Human Resource Managers’ Perceptions on the Impact of AI on the South African Workforce. S. Asian J. Hum. Resour. Manag. 2024, 22, 13. [Google Scholar] [CrossRef]

- Li, Y.; Starly, B. Building a Knowledge Graph to Enrich ChatGPT Responses in Manufacturing Service Discovery. J. Ind. Infor. Integr. 2024, 40, 100612. [Google Scholar] [CrossRef]

- Anadón, M.; Guillemette, F. La Recherche Qualitative Est-Elle Nécessairement Inductive. Rech. Qual. 2007, 5, 26–37. [Google Scholar]

- Thomas, J.; Harden, A. Methods for the Thematic Synthesis of Qualitative Research in Systematic Reviews. BMC Med. Res. Methodol. 2008, 8, 45. [Google Scholar] [CrossRef] [PubMed]

- Pecheranskyi, I.; Oliinyk, O.; Medvedieva, A.; Danyliuk, V.; Hubernator, O. Perspectives of Generative AI in the Context of Digital Transformation of Society, Audio-Visual Media and Mass Communication: Instrumentalism, Ethics and Freedom. Indian J. Inf. Source. Serv. 2024, 14, 48–53. [Google Scholar] [CrossRef]

| Inclusion criteria |

|

| Exclusion criteria |

|

| Clusters | Keyword | Occurrences | Total Link Strength |

|---|---|---|---|

| Cluster 1 | Automation | 1 | 5 |

| Benchmarking | 1 | 7 | |

| Cobot | 1 | 5 | |

| Cyber–physical system (CPS) | 1 | 5 | |

| Digital twins (DTS) | 1 | 5 | |

| Explainable artificial intelligence (EXAI) | 1 | 5 | |

| Factory | 1 | 7 | |

| Industrial settings | 1 | 7 | |

| Industry 5.0 | 5 | 29 | |

| Information retrieval | 1 | 7 | |

| Knowledge sharing | 1 | 7 | |

| Natural language interface | 1 | 7 | |

| Cluster 2 | Adaptive automation | 1 | 3 |

| Chatbot | 3 | 15 | |

| Cybersecurity | 1 | 3 | |

| Experimental design | 1 | 5 | |

| Industrial-gpt | 1 | 4 | |

| Industry 4.0 | 13 | 73 | |

| Langchain | 2 | 11 | |

| Llama 2 | 1 | 7 | |

| OpenAI | 1 | 4 | |

| PCB manufacturing | 1 | 7 | |

| Retrieval-augmented generation (rag) | 1 | 7 | |

| User-centric evaluation | 1 | 7 | |

| Cluster 3 | Digital twin | 6 | 29 |

| Fuzzy topsis | 1 | 4 | |

| Intelligent automation | 1 | 4 | |

| Intelligent management | 1 | 5 | |

| Morphological matrix | 1 | 4 | |

| Multi-agent system | 1 | 4 | |

| Multi-objective optimization | 1 | 5 | |

| Network optimization | 1 | 5 | |

| Real-time optimization | 1 | 5 | |

| S4 framework | 1 | 4 | |

| Simulation | 1 | 4 | |

| Cluster 4 | Asset administration shell | 4 | 23 |

| Entity matching | 1 | 5 | |

| Information modeling | 1 | 7 | |

| Interoperability | 2 | 12 | |

| Knowledge representation | 1 | 5 | |

| Knowledge-based systems | 1 | 4 | |

| Ontology | 1 | 7 | |

| Quality control | 2 | 11 | |

| Retrieval-augmented generation | 2 | 10 | |

| Semantic interoperability | 1 | 6 | |

| Zero defect manufacturing | 1 | 7 | |

| Cluster 5 | Artificial intelligence | 5 | 27 |

| Audiovisual production | 1 | 6 | |

| Business processes | 1 | 4 | |

| Communication | 1 | 6 | |

| Decision-making | 1 | 2 | |

| Digital transformation | 2 | 8 | |

| Human-in-the-loop | 1 | 3 | |

| Manufacturing system | 1 | 2 | |

| Society 5.0 | 1 | 6 | |

| Workforce impact | 1 | 4 | |

| Cluster 6 | Association rule mining | 1 | 5 |

| Big data | 1 | 7 | |

| Chat-bot | 1 | 7 | |

| Embeddings | 1 | 7 | |

| Human–computer interaction | 1 | 7 | |

| Industrial applications | 1 | 5 | |

| IoT | 1 | 7 | |

| Maintenance work order | 1 | 5 | |

| Natural language processing | 4 | 21 | |

| Text mining | 1 | 5 | |

| Cluster 7 | Creativity | 1 | 10 |

| Deep learning | 1 | 3 | |

| Engineering design | 1 | 10 | |

| Generative pre-trained transformer | 2 | 13 | |

| Intelligent digital twins | 1 | 10 | |

| Intelligent maintenance | 1 | 10 | |

| Mechanical engineering | 1 | 10 | |

| Mechanics | 1 | 10 | |

| Pre-trained language models | 1 | 10 | |

| Process optimization | 1 | 3 | |

| Cluster 8 | 5G networks | 1 | 5 |

| Artificial intelligence (AI) | 3 | 13 | |

| Conversational artificial intelligence | 1 | 4 | |

| Edge computing | 1 | 5 | |

| Generative pre-trained transformer (GPT) | 1 | 4 | |

| Human–robot collaboration (HRC) | 1 | 4 | |

| Human–robot interaction (HRI) | 1 | 4 | |

| Industrial chatbot | 1 | 4 | |

| Large language models (LLMs) | 1 | 4 | |

| Cluster 9 | Bottleneck mining | 1 | 3 |

| ChatGPT | 3 | 15 | |

| Design: challenges and innovation | 1 | 2 | |

| Digital supply chain | 1 | 3 | |

| Knowledge graph | 3 | 8 | |

| Lean Six Sigma | 1 | 5 | |

| Manufacturing service discovery | 1 | 3 | |

| Ship manufacturing process | 1 | 3 | |

| Text mining and analysis | 1 | 5 | |

| Cluster 10 | Anomaly detection | 1 | 9 |

| Data visualization | 1 | 9 | |

| Data-driven decision-making | 1 | 9 | |

| Large language models (LLMs) | 2 | 16 | |

| Manufacturing | 2 | 19 | |

| Natural language queries | 1 | 9 | |

| Production process optimization | 1 | 9 | |

| Real-time sensor data | 1 | 9 | |

| Shop floor analytics | 1 | 9 | |

| Cluster 11 | Autonomous system | 1 | 5 |

| Continuous learning | 1 | 5 | |

| GPT | 1 | 5 | |

| Intelligent agent | 1 | 5 | |

| Knowledge integration | 1 | 5 | |

| Real-time data processing | 1 | 5 | |

| Retrieval-augmented generation-large language Model architecture | 1 | 5 | |

| Smart factory | 3 | 13 | |

| System performance modeling | 1 | 5 | |

| Cluster 12 | Additive manufacturing | 1 | 5 |

| Domain knowledge management | 1 | 5 | |

| Fused deposition modeling | 1 | 5 | |

| Human–robot collaboration | 1 | 2 | |

| Large language models | 13 | 70 | |

| Manufacturing systems | 1 | 2 | |

| Named entity recognition | 1 | 5 | |

| Retrieval augmented generation | 1 | 5 | |

| Cluster 13 | Compliance checks | 1 | 8 |

| Eworks | 1 | 8 | |

| Internet of Things | 1 | 8 | |

| Regulatory science | 1 | 8 | |

| Regulatory technologies | 1 | 8 | |

| Tool calling | 1 | 8 | |

| Web services | 1 | 8 | |

| Cluster 14 | Bert | 1 | 3 |

| Federated digital twins | 1 | 5 | |

| Flexible job-shop | 1 | 5 | |

| Large language model | 12 | 56 | |

| Scheduling | 1 | 5 | |

| Supply chain management | 1 | 3 | |

| The software-defined factory | 1 | 5 | |

| Cluster 15 | Fault detection | 1 | 9 |

| Fault diagnosis | 1 | 9 | |

| Hybrid systems | 1 | 9 | |

| Machine learning | 2 | 13 | |

| Real-time systems | 1 | 9 | |

| Smes | 1 | 4 | |

| Cluster 16 | Blockchain | 1 | 5 |

| Circular economy | 1 | 5 | |

| Distributed manufacturing | 1 | 5 | |

| Energy-efficient scheduling | 1 | 5 | |

| Multi-agent | 1 | 5 | |

| Cluster 17 | Failure mode and effect analysis (FMEA) | 1 | 4 |

| Generative AI | 5 | 35 | |

| Knowledge management | 1 | 4 | |

| Large language model (LLM) | 1 | 4 | |

| Product quality | 1 | 4 | |

| Cluster 18 | Human–computer interaction | 1 | 4 |

| Interactive manufacturing execution system | 1 | 4 | |

| LLM-agent | 1 | 4 | |

| Text2sql | 1 | 4 | |

| Cluster 19 | AI integration | 1 | 4 |

| Digital shadow | 1 | 4 | |

| Manufacturing data model | 1 | 4 | |

| Total clusters | 19 | ||

| Links | 588 | ||

| Total link strength | 618 | ||

| Clusters | Authors | Theme Cluster |

|---|---|---|

| Cluster 1 | Agarwal S., Chen, C., Chen, M., Lee, J., Li, D., Li, H., Li, P., Li, Y., Li, Z., Liu, C., Liu, H., Liu, M., Liu, Q., Liu, S., Liu, Z., Lu, Y., Makris, S., Shi, Y., Vogel-Heuser, B., Wang, B., Wang, C., Wang, I., Wang, S., Wang, T., Wang, Z., Wuest, T., Xia, F., Xu, X., Xu, Z., Zhang, C., Zhang, D., Zhang, J., Zhang, I., Zhang, S., Zhang, W., Zhang Y., Zhao, H., Zheng, P. | Digital engineering and smart manufacturing systems |

| Cluster 2 | Akay, H., Anwer, N., Bengio, Y., Cao, Y., Chen, J., Chen, I., Dai, Y., Devlin, J., Han, X., Hodkiewicz, M., Hu, X., Hu, Y., Kim, J., Kumar, A., Li, J., Li, I., Li, S., Li, X., Liu, A., Liu, W., Liu, Y., Luo, J., Narasimahan, K., Radford, A., Sun, I., Sutskever, I., Wang, H., Wang X., Yang, H., Yang, J., Yang, M., Yang, Y., Zhang, M., Zhao, M., Zhao, Y., Zhou, Y. | Artificial intelligence and learning |

| Cluster 3 | Chen X., Chen Y., Chen Z., Huang H., Kang, J., Lin, Z., Liu, J., Niyato, D., Tao, F., Wang, J., Wang, W., Wang, Y., Wu, H., Wu, J., Wu, Y., Zhang H., Zhang, Z., Zhou, H. | Energy optimization and sustainability in industrial processes |

| Cluster 4 | Bao, J., Bhattacharya, P., Chen, H., Colabianchi, S., Costantino, F., Li, B., Li, C., Liu, X., Prasad, V.K., Tanwar, S., Wellsandt, S., Zhang, X. | Sustainability and supply chain management to improve organizational performance |

| Cluster 5 | Diedrich, C., Huang, Y., Jazdi, N., Touvron, H., Vaswani, A., Wei, J., Weyrich, M., Xia, Y., Zhao, W.X. | Cybersecurity of industrial systems |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouerghemmi, C.; Ertz, M. Integrating Large Language Models into Digital Manufacturing: A Systematic Review and Research Agenda. Computers 2025, 14, 318. https://doi.org/10.3390/computers14080318

Ouerghemmi C, Ertz M. Integrating Large Language Models into Digital Manufacturing: A Systematic Review and Research Agenda. Computers. 2025; 14(8):318. https://doi.org/10.3390/computers14080318

Chicago/Turabian StyleOuerghemmi, Chourouk, and Myriam Ertz. 2025. "Integrating Large Language Models into Digital Manufacturing: A Systematic Review and Research Agenda" Computers 14, no. 8: 318. https://doi.org/10.3390/computers14080318

APA StyleOuerghemmi, C., & Ertz, M. (2025). Integrating Large Language Models into Digital Manufacturing: A Systematic Review and Research Agenda. Computers, 14(8), 318. https://doi.org/10.3390/computers14080318