The Integration of the Internet of Things, Artificial Intelligence, and Blockchain Technology for Advancing the Wine Supply Chain

Abstract

1. Introduction

2. Background Research

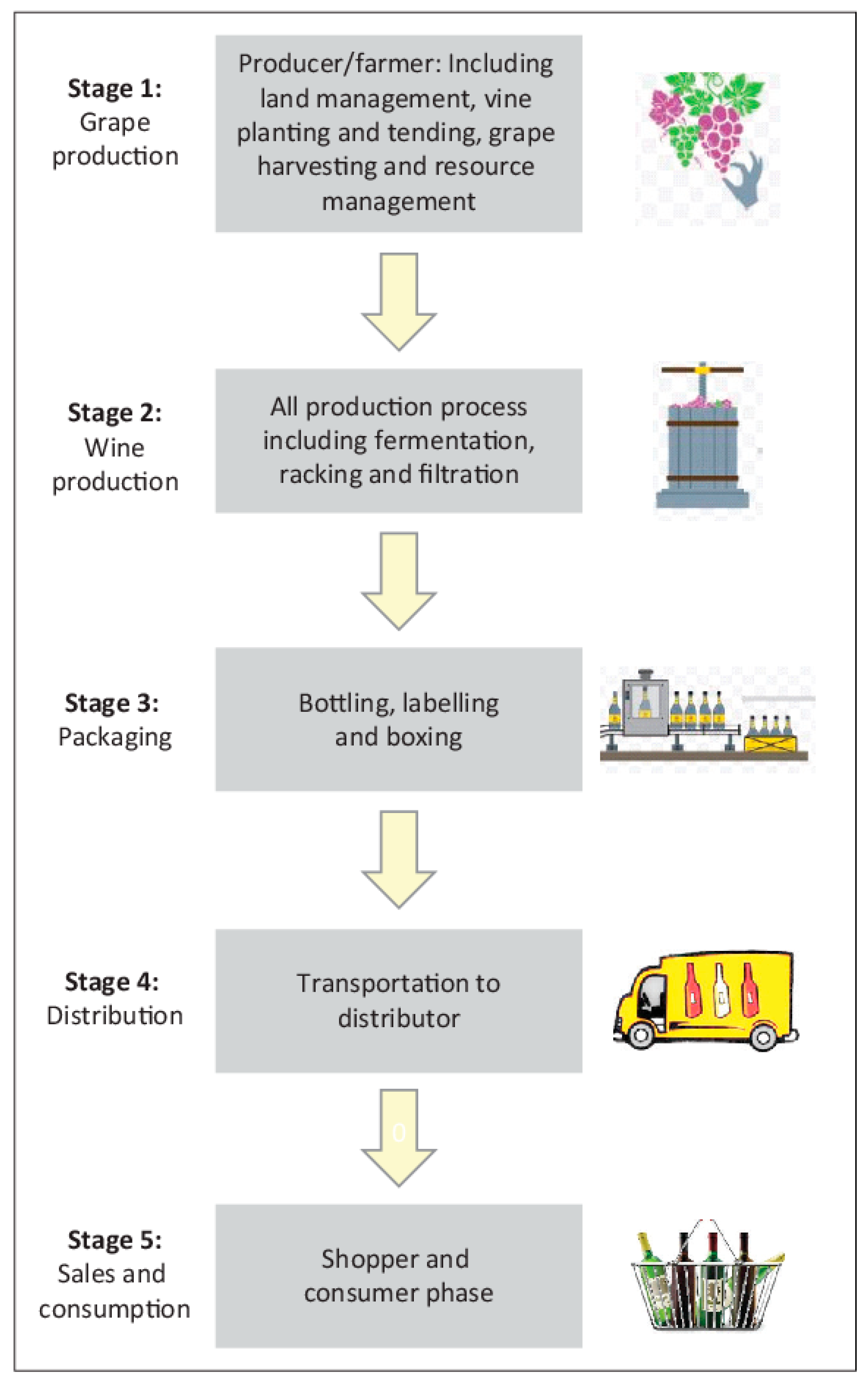

2.1. Wine Supply Chain

2.2. IoT, AI, and BCT in the Wine Industry

2.2.1. IoT in the Wine Supply Chain

2.2.2. AI in the Wine Supply Chain

2.2.3. BCT in the Wine Supply Chain

2.2.4. IoT, AI, and BCT Integration in the Wine Supply Chain

2.2.5. Some Practical Applications

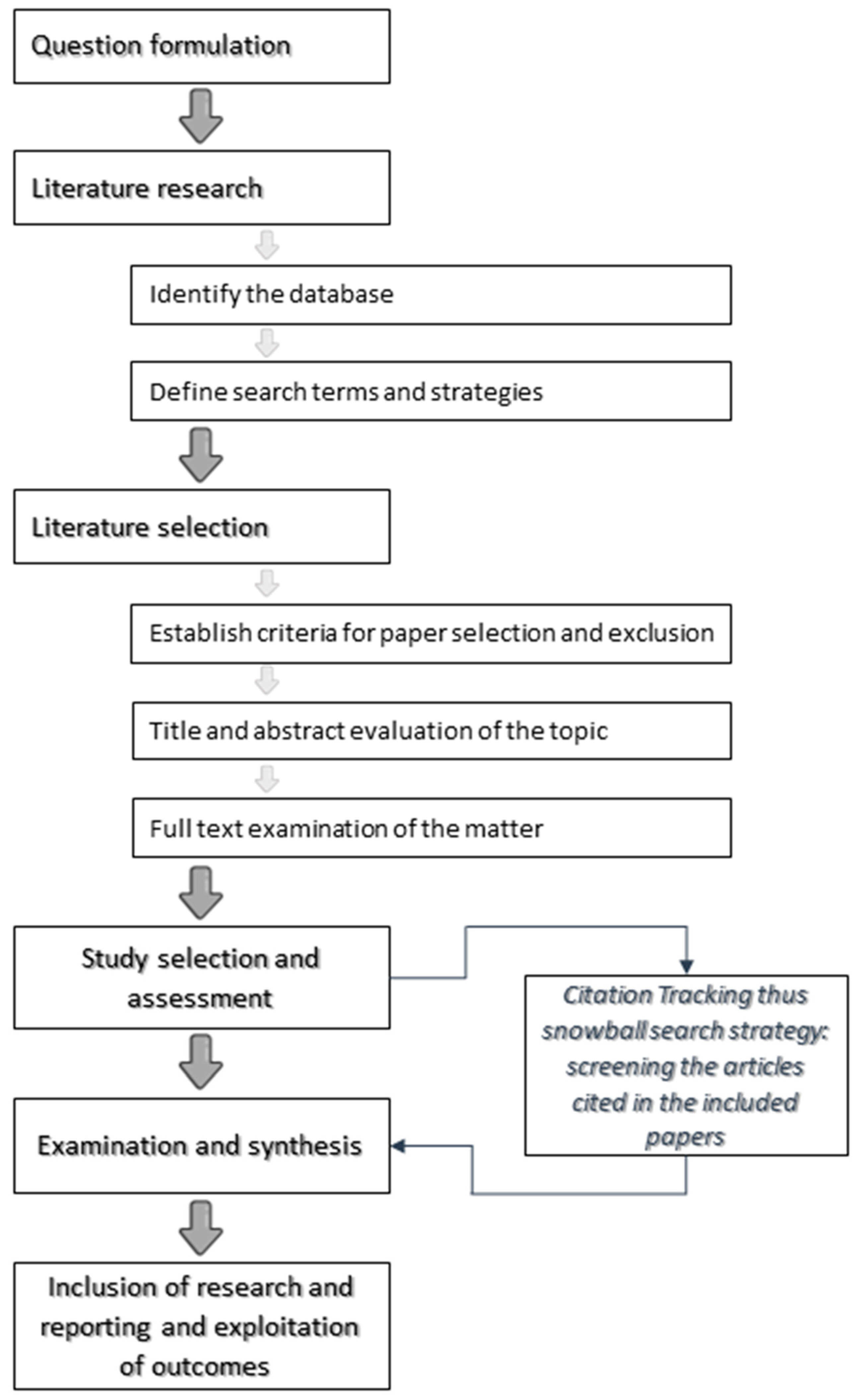

3. Methodology

- All selected papers were written in English;

- The filter ‘TITLE-ABS-KEY’ (scanning in titles, abstracts, and keywords) was applied in the Google Scholar database;

- The search was not restricted to a specific timeframe (even though it was expected to uncover papers from 2008, the year BCT was created);

- The sources of data chosen were only academic journal papers [94];

- Using Boolean operators, we then selected a list of keywords to include in the search query (specifically, AND to reduce the number of papers retrieved and OR to increase it).

- They did not integrate IoT into BCT;

- They did not include AI(ML) in IoT-BCT models;

- The issues of safety, economic, and environmental sustainability were not discussed in the IoT-BCT architecture;

- None of them are associated with the wine industry.

4. Results and Discussion

4.1. The Increase of Wine Safety under IoT, AI, and BCT

4.2. The Impact of IoT, AI, and BCT on the Environmental Sustainability of the Wine Supply Chain

4.3. The Benefits of BCT on the Local Economy of the Wine Industry

4.4. Challenges in Integration of IoT, AI, and BCT in the Wine Industry

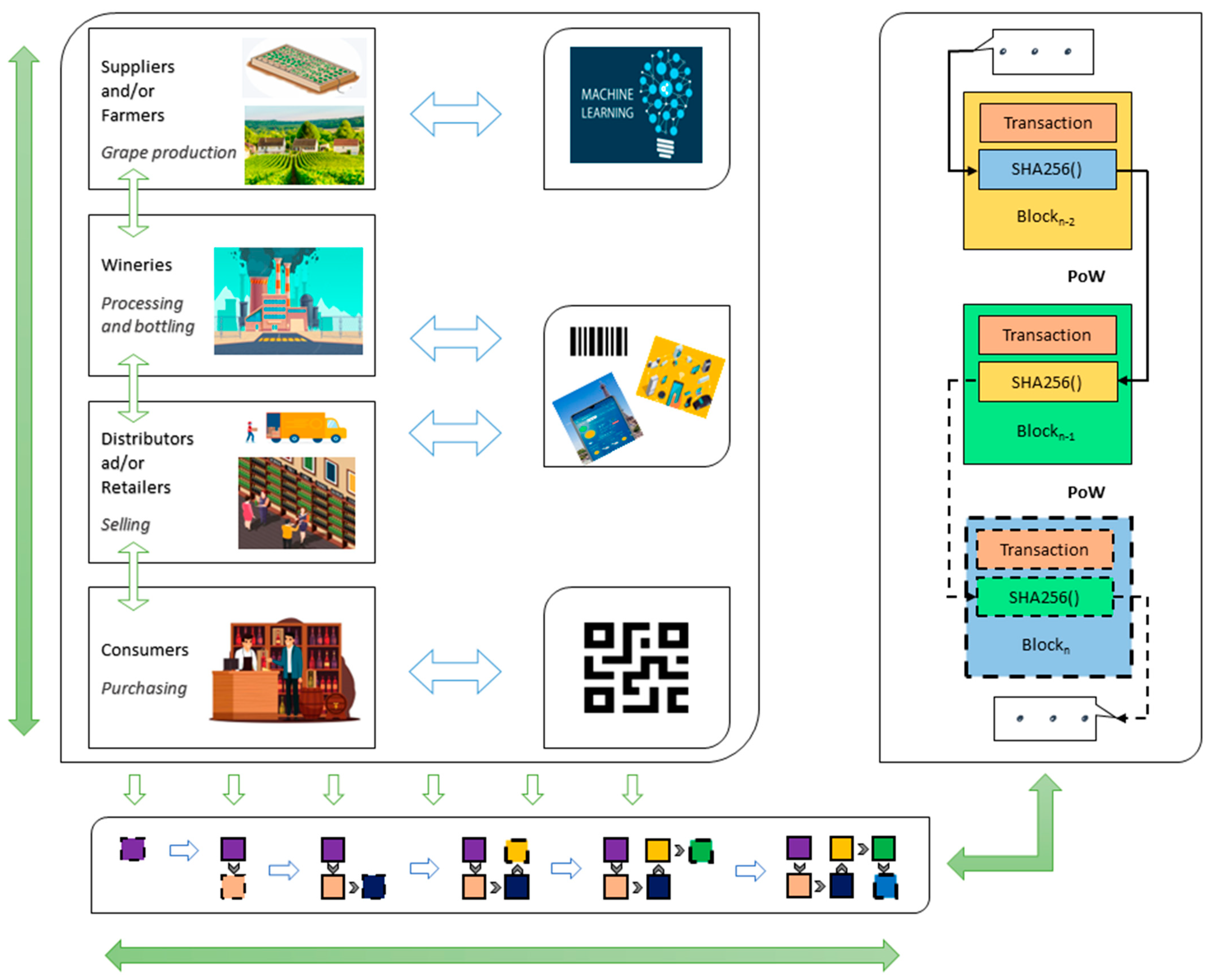

4.5. Proposed Framework

4.5.1. Chain Actors

4.5.2. IoT Devices

4.5.3. ML Module

4.5.4. BCT Module

4.5.5. Transaction in the System

5. Conclusion and Implication for Theory and Practice

6. Limitations and Future Works

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Harutyunyan, M.; Malfeito-Ferreira, M. The Rise of Wine among Ancient Civilizations across the Mediterranean Basin. Heritage 2022, 5, 788–812. [Google Scholar] [CrossRef]

- Imazio, S.; Maghradze, D.; De Lorenzis, G.; Bacilieri, R.; Laucou, V.; This, P.; Scienza, A.; Failla, O. From the cradle of grapevine domestication: Molecular overview and description of Georgian grapevine (Vitis vinifera L.) germplasm. Tree Genet. Genomes 2013, 9, 641–658. [Google Scholar] [CrossRef]

- McGovern, P.; Jalabadze, M.; Batiuk, S.; Callahan, M.P.; Smith, K.E.; Hall, G.R.; Kvavadze, E.; Maghradze, D.; Rusishvili, N.; Bouby, L.; et al. Early Neolithic wine of Georgia in the South Caucasus. Proc. Natl. Acad. Sci. USA 2017, 114, E10309–E10318. [Google Scholar] [CrossRef] [PubMed]

- Hamon, C.; Jalabadze, M.; Agapishvili, T.; Baudouin, E.; Koridze, I.; Messager, E. Gadachrili Gora: Architecture and organi-sation of a Neolithic settlement in the middle Kura Valley (6th millennium BC, Georgia). Quat. Int. 2016, 395, 154–169. [Google Scholar] [CrossRef]

- Casadó-Marín, L.; Anzil, V. The semiotics of wine. Analysis of wine-related cultural consensus in two Spanish wine-producing regions. Int. J. Gastron. Food Sci. 2022, 28, 100536. [Google Scholar] [CrossRef]

- Strickland, P. Innovative Wine Tourism Marketing Strategies in the Victorian Wine Industry A Wine Stakeholders’ Perspective. Ph.D. Thesis, Department of Management & Marketing, La Trobe Business School—ASSC, La Trobe University, Victoria, Australia, 2022. [Google Scholar]

- Fiore, M.; Alaimo, L.S.; Chkhartishvil, N. The amazing bond among wine consumption, health and hedonistic well-being. Br. Food J. 2020, 122, 2707–2723. [Google Scholar] [CrossRef]

- Ohana-Levi, N.; Netzer, Y. Long-Term Trends of Global Wine Market. Agriculture 2023, 13, 224. [Google Scholar] [CrossRef]

- Maicas, S. Advances in Wine Fermentation. Fermentation 2021, 7, 187. [Google Scholar] [CrossRef]

- Spadoni, R.; Nanetti, M.; Bondanese, A.; Rivaroli, S. Innovative solutions for the wine sector: The role of startups. Wine Econ. Policy 2019, 8, 165–170. [Google Scholar] [CrossRef]

- Higgins, L.M.; Wolf, M.M.; Wolf, M.J. Technological change in the wine market? The role of QR codes and wine apps in consumer wine purchases. Wine Econ. Policy 2014, 3, 19–27. [Google Scholar] [CrossRef]

- Adamashvili, N.; Colantuono, F.; Conto, F.; Fiore, M. Investigating the role of community of practice for sharing knowledge in agriculture sectoR. J. Glob. Bus. Adv. 2020, 13, 162. [Google Scholar] [CrossRef]

- Luzzani, G.; Grandis, E.; Frey, M.; Capri, E. Blockchain Technology in Wine Chain for Collecting and Addressing Sustainable Performance: An Exploratory Study. Sustainability 2021, 13, 12898. [Google Scholar] [CrossRef]

- Tsolakis, N.; Schumacher, R.; Dora, M.; Kumar, M. Artificial intelligence and blockchain implementation in supply chains: A pathway to sustainability and data monetisation? Ann. Oper. Res. 2022, 327, 157–210. [Google Scholar] [CrossRef]

- Danese, P.; Mocellin, R.; Romano, P. Designing blockchain systems to prevent counterfeiting in wine supply chains: A multiple-case study. Int. J. Oper. Prod. Manag. 2021, 41, 1–33. [Google Scholar] [CrossRef]

- Lehmann, R.J.; Reiche, R.; Schiefer, G. Future internet and the agri-food sector: State-of-the-art in literature and research. Comput. Electron. Agric. 2012, 89, 158–174. [Google Scholar] [CrossRef]

- Lamine, C. Sustainability and Resilience in Agrifood Systems: Reconnecting Agriculture, Food and the Environment. Sociol. Rural. 2014, 55, 41–61. [Google Scholar] [CrossRef]

- Folinas, D.; Manikas, I.; Manos, B. Traceability data management for food chains. Br. Food J. 2006, 108, 622–633. [Google Scholar] [CrossRef]

- Bhat, S.A.; Huang, N.-F. Big Data and AI Revolution in Precision Agriculture: Survey and Challenges. IEEE Access 2021, 9, 110209–110222. [Google Scholar] [CrossRef]

- Hamam, M.; Chinnici, G.; Di Vita, G.; Pappalardo, G.; Pecorino, B.; Maesano, G.; D’amico, M. Circular Economy Models in Agro-Food Systems: A Review. Sustainability 2021, 13, 3453. [Google Scholar] [CrossRef]

- Maesano, G.; Milani, M.; Nicolosi, E.; D’amico, M.; Chinnici, G. A Network Analysis for Environmental Assessment in Wine Supply Chain. Agronomy 2022, 12, 211. [Google Scholar] [CrossRef]

- Goncharuk, A.G. Wine value chains: Challenges and prospects. J. Appl. Manag. Invest. 2017, 6, 11–27. [Google Scholar]

- Naudé, R.T.; Badenhorst-Weiss, J.A. The challenges behind producing a bottle of wine: Supply chain risks. J. Transp. Supply Chain Manag. 2020, 14, 1–15. [Google Scholar] [CrossRef]

- Petti, L.; Raggi, A.; De Camillis, C.; Matteucci, P.; Sára, B.; Pagliuca, G. Life cycle approach in an organic wine-making firm: An Italian case-study. In Proceedings of the Fifth Australian Conference on Life Cycle Assessment, Melbourne, Australia, 22–24 November 2006; pp. 22–24. [Google Scholar]

- Ting, S.; Tse, Y.K.; Ho, G.; Chung, S.H.; Pang, G. Mining logistics data to assure the quality in a sustainable food supply chain: A case in the red wine industry. Int. J. Prod. Econ. 2014, 152, 200–209. [Google Scholar] [CrossRef]

- Ohmart, C.P. What does sustainability really mean? Wines Vines 2004, 85, 3. [Google Scholar]

- Christ, K.L.; Burritt, R.L. Critical environmental concerns in wine production: An integrative review. J. Clean. Prod. 2013, 53, 232–242. [Google Scholar] [CrossRef]

- Fondazione Symbola. 2020 Il Futuro del Vino Italiano. Qualità, Sostenibilità e Territorio. ISBN 978-88-99265-56-4. Available online: https://www.prosecco.it/wpcontent/uploads/2020/05/2020_0430_per-download.pdf (accessed on 4 April 2020).

- Matos, F.; Alcobia, T.; Matos, A.J. Blockchain technology and traceability in the wine supply chain industry. In Proceedings of the ECIAIR 2021 3rd European Conference on the Impact of Artificial Intelligence and Robotics, Academic Conferences and Publishing Limited, Online, 18–19 November 2021; p. 90. [Google Scholar]

- Silvestri, R.; Adamashvili, N.; Fiore, M.; Galati, A. How blockchain technology generates a trust-based competitive advantage in the wine industry: A resource based view perspective. Eur. Bus. Rev. 2023, 35, 713–736. [Google Scholar] [CrossRef]

- Chandes, J.; Estampe, D.; Berthomier, R.; Courrie, L.-A.; Han, L.; Marquevielle, S. Logistics Performance of Actors in the Wine Supply Chain. Supply Chain Forum Int. J. 2003, 4, 12–27. [Google Scholar] [CrossRef][Green Version]

- Adamo, C. A Global Perspective of the Wine Supply Chain: The Case of Argentinean Wineries and the US Market. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2004. [Google Scholar]

- Kunnapapdeelert, S. Analyzing the effect of supply chain strategies and collaboration on performance improvement using MIMIC model. Int. J. Ind. Eng. Manag. 2021, 12, 216–225. [Google Scholar] [CrossRef]

- Kadlubek, M. Supply chain in the strategic approach with the aspect of quality. Int. J. Qual. Res. 2022, 16, 1255–1268. [Google Scholar] [CrossRef]

- Chopra, S.; Meindl, P. Supply Chain Management: Strategy, Planning, and Operation, 3rd ed.; Pearson Education, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Canavari, M.; Akgüngör, S.; Borsellino, V.; Mauracher, C.; Naspetti, S.; Stanton, J.L.; Stranieri, S.; Drejerska, N.; Fiore, M.; Galati, A.; et al. Editorial. Econ. Agro-Aliment. 2019, 3, 577–585. [Google Scholar] [CrossRef]

- Khan, M.; Parvaiz, G.S.; Dedahanov, A.T.; Abdurazzakov, O.S.; Rakhmonov, D.A. The Impact of Technologies of Traceability and Transparency in Supply Chains. Sustainability 2022, 14, 16336. [Google Scholar] [CrossRef]

- Khan, P.W.; Byun, Y.C.; Park, N. IoT-blockchain enabled optimized provenance system for food industry 4.0 using advanced deep learning. Sensors 2020, 20, 2990. [Google Scholar] [CrossRef]

- Adamashvili, N.; State, R.; Tricase, C.; Fiore, M. Blockchain-Based Wine Supply Chain for the Industry Advancement. Sustainability 2021, 13, 13070. [Google Scholar] [CrossRef]

- Li, S.; Xu, L.D.; Zhao, S. The internet of things: A survey. Inf. Syst. Front. 2015, 17, 243–259. [Google Scholar] [CrossRef]

- Newsroom, G. Gartner Says Worldwide IoT Security Spending Will Reach $1.5 Billion in 2018. Available online: https://www.gartneR.com/newsroom/id/3869181 (accessed on 5 March 2024).

- Haroon, A.; Ali, M.; Asim, Y.; Naeem, W.; Kamran, M.; Javaid, Q. Constraints in the IoT: The World in 2020 and Beyond. Int. J. Adv. Comput. Sci. Appl. 2016, 7, 252–271. [Google Scholar] [CrossRef]

- Liang, K.; Thomasson, J.; Shen, M.; Armstrong, P.; Ge, Y.; Lee, K.; Herrman, T. Ruggedness of 2D code printed on grain tracers for implementing a prospective grain traceability system to the bulk grain delivery system. Food Control 2013, 33, 359–365. [Google Scholar] [CrossRef]

- Fan, B.; Qian, J.; Wu, X.; Du, X.; Li, W.; Ji, Z.; Xin, X. Improving continuous traceability of food stuff by using barcode-RFID bidirectional transformation equipment: Two field experiments. Food Control 2019, 98, 449–456. [Google Scholar] [CrossRef]

- Bosona, T.; Gebresenbet, G. Food traceability as an integral part of logistics management in food and agricultural supply chain. Food Control 2013, 33, 32–48. [Google Scholar] [CrossRef]

- Li, Z.; Liu, G.; Liu, L.; Lai, X.; Xu, G. IoT-based tracking and tracing platform for prepackaged food supply chain. Ind. Manag. Data Syst. 2017, 117, 1906–1916. [Google Scholar] [CrossRef]

- Pal, A.; Kant, K. IoT-Based Sensing and Communications Infrastructure for the Fresh Food Supply Chain. Computer 2018, 51, 76–80. [Google Scholar] [CrossRef]

- Jabbari, A.; Kaminsky, P. Blockchain and Supply Chain Management. Department of Industrial Engineering and Operations Research University of California, Berkeley. January 2018. Available online: https://og.mhi.org/downloads/learning/cicmhe/blockchain-and-supply-chain-management.pdf (accessed on 5 March 2024).

- Montecchi, M.; Plangger, K.; Etter, M. It’s real, trust me! Establishing supply chain provenance using blockchain. Bus. Horiz. 2019, 62, 283–293. [Google Scholar] [CrossRef]

- Luvisi, A.; Pagano, M.; Bandinelli, R.; Rinaldelli, E.; Gini, B.; Scartòn, M.; Manzoni, G.; Triolo, E. Virtual vineyard for grapevine management purposes: A RFID/GPS application. Comput. Electron. Agric. 2011, 75, 368–371. [Google Scholar] [CrossRef]

- Kamilaris, A.; Fonts, A.; Prenafeta-Boldύ, F.X. The rise of blockchain technology in agriculture and food supply chains. Trends Food Sci. Technol. 2019, 91, 640–652. [Google Scholar] [CrossRef]

- Cimino, M.G.; Marcelloni, F. Enabling traceability in the wine supply chain. In Methodologies and Technologies for Networked Enterprises; Springer: Berlin/Heidelberg, Germany, 2012; pp. 397–412. [Google Scholar] [CrossRef]

- Bonello, F.; Cravero, M.C.; Dell’oro, V.; Tsolakis, C.; Ciambotti, A. Wine Traceability Using Chemical Analysis, Isotopic Parameters, and Sensory Profiles. Beverages 2018, 4, 54. [Google Scholar] [CrossRef]

- Monteiro, J.; Barata, J. Artificial Intelligence in Extended Agri-Food Supply Chain: A Short Review Based on Bibliometric Analysis. Procedia Comput. Sci. 2021, 192, 3020–3029. [Google Scholar] [CrossRef]

- Ramdinthara, I.Z.; Bala, P.S.; Gowri, A.S. AI-Based Yield Prediction and Smart Irrigation. Internet Things Anal. Agric. 2022, 3, 113–140. [Google Scholar]

- Newlands, N.K. Artificial Intelligence and Big Data Analytics in Vineyards: A Review. Grapes Wine 2022, 8, 65. [Google Scholar]

- Yu, H.; Liu, S.; Qin, H.; Zhou, Z.; Zhao, H.; Zhang, S.; Mao, J. Artificial intelligence-based approaches for traditional fermented alcoholic beverages’ development: Review and prospect. Crit. Rev. Food Sci. Nutr. 2022, 1–11. [Google Scholar] [CrossRef]

- Alsobeh, A.; Shatnawi, A. Integrating Data-Driven Security, Model Checking, and Self-adaptation for IoT Systems Using BIP Components: A Conceptual Proposal Model. In International Conference on Advances in Computing Research; Springer Nature: Cham, Switzerland, 2023; pp. 533–549. [Google Scholar]

- Gonzalez Viejo, C.; Torrico, D.D.; Dunshea, F.R.; Fuentes, S. Emerging Technologies Based on Artificial Intelligence to Assess the Quality and Consumer Preference of Beverages. Beverages 2019, 5, 62. [Google Scholar] [CrossRef]

- Anica-Popa, I.; Anica-Popa, L.; Radulescu, C.; Vrincianu, M. The Integration of Artificial Intelligence in Retail: Benefits, Challenges and a Dedicated Conceptual Framework. Amfiteatru Econ. 2021, 23, 120–136. [Google Scholar] [CrossRef]

- Vieira, A.A.; Figueira, J.R.; Fragoso, R. A multi-objective simulation-based decision support tool for wine supply chain design and risk management under sustainability goals. Expert Syst. Appl. 2023, 232, 120757. [Google Scholar] [CrossRef]

- Patel, N.; Trivedi, S. Leveraging Predictive Modeling, Machine Learning Personalization, NLP Customer Support, and AI Chatbots to Increase Customer Loyalty. Empir. Quests Manag. Essences 2020, 3, 1–24. [Google Scholar]

- Lin, W.; Huang, X.; Fang, H.; Wang, V.; Hua, Y.; Wang, J.; Yin, H.; Yi, D.; Yau, L. Blockchain Technology in Current Agricultural Systems: From Techniques to Applications. IEEE Access 2020, 8, 143920–143937. [Google Scholar] [CrossRef]

- Ciruela-Lorenzo, A.M.; Del-Aguila-Obra, A.R.; Padilla-Meléndez, A.; Plaza-Angulo, J.J. Digitalization of Agri-Cooperatives in the Smart Agriculture Context. Proposal of a Digital Diagnosis Tool. Sustainability 2020, 12, 1325. [Google Scholar] [CrossRef]

- Jennath, H.S.; Adarsh, S.; Anoop, V.S. Distributed IoT and Applications: A Survey. In Integrated Intelligent Computing, Communication and Security; Krishna, A., Srikantaiah, K., Naveena, C., Eds.; Studies in Computational Intelligence; Springer: Singapore, 2019; Volume 771. [Google Scholar]

- Andoni, M.; Robu, V.; Flynn, D.; Abram, S.; Geach, D.; Jenkins, D.; McCallum, P.; Peacock, A. Blockchain technology in the energy sector: A systematic review of challenges and opportunities. Renew. Sustain. Energy Rev. 2018, 100, 143–174. [Google Scholar] [CrossRef]

- Feng, H.; Wang, X.; Duan, Y.; Zhang, J.; Zhang, X. Applying blockchain technology to improve agri-food traceability: A review of development methods, benefits and challenges. J. Clean. Prod. 2020, 260, 121031. [Google Scholar] [CrossRef]

- Christensen, C.M.; Meronuck, R.A. Quality Maintenance in Stored Grains and Seeds; U of Minnesota Press: Minneapolis, MN, USA, 1986. [Google Scholar]

- Tripoli, M.; Schmidhuber, J. Emerging Opportunities for the Application of Blockchain in the Agri-Food Industry; Licence: CC, BY-NC-SA; FAO: Rome, Italy; ICTSD: Geneva, Switzerland, 2018; Volume 3. [Google Scholar]

- Fernandez, A.; Waghmare, A.; Tripathi, S. Agricultural Supply Chain using Blockchain. In Proceedings of the International Conference on Intelligent Manufacturing and Automation, Mumbai, India, 27–28 March 2020; Lecture Notes in Mechanical Engineering. Vasudevan, H., Kottur, V., Raina, A., Eds.; Springer: Singapore, 2020; pp. 127–134. [Google Scholar]

- Caballero, R.; Rivera, B. Blockchain: An Alternative to Enable Traceability in the Agricultural Supply Chain in Panama. In Proceedings of the 7th International Engineering, Sciences and Technology Conference (IESTEC), Panama, Panama, 9–11 October 2019; pp. 46–51. [Google Scholar]

- Katsikouli, P.; Wilde, A.S.; Dragoni, N.; Høgh-Jensen, H. On the benefits and challenges of blockchains for managing food supply chains. J. Sci. Food Agric. 2020, 101, 2175–2181. [Google Scholar] [CrossRef] [PubMed]

- Mirabelli, G.; Solina, V. Blockchain and agricultural supply chains traceability: Research trends and future challenges. Procedia Manuf. 2020, 42, 414–421. [Google Scholar] [CrossRef]

- Demestichas, K.; Peppes, N.; Alexakis, T.; Adamopoulou, E. Blockchain in Agriculture Traceability Systems: A Review. Appl. Sci. 2020, 10, 4113. [Google Scholar] [CrossRef]

- Song, L.; Wang, X.; Merveille, N. Research on Blockchain for Sustainable E-Agriculture. In Proceedings of the IEEE Technology & Engineering Management Conference (TEMSCON), Novi, MI, USA, 3–6 June 2020; pp. 1–5. [Google Scholar]

- Kadariya, J.; Smith, T.C.; Thapaliya, D. Staphylococcus aureus and staphylococcal food-borne disease: An ongoing challenge in public health. BioMed Res. Int. 2014, 2014, 827965. [Google Scholar] [CrossRef]

- Scharff, R.L. Economic Burden from Health Losses due to Foodborne Illness in the United States. J. Food Prot. 2012, 75, 123–131. [Google Scholar] [CrossRef] [PubMed]

- Kshetri, N.; Loukoianova, E. Blockchain Adoption in Supply Chain Networks in Asia. IT Prof. 2019, 21, 11–15. [Google Scholar] [CrossRef]

- Pouliot, S.; Sumner, D.A. Traceability, recalls, industry reputation and product safety. Eur. Rev. Agric. Econ. 2013, 40, 121–142. [Google Scholar] [CrossRef]

- Vangala, A.; Das, A.K.; Kumar, N.; Alazab, M. Smart secure sensing for IoT-based agriculture: Blockchain perspective. IEEE Sens. J. 2020, 21, 17591–17607. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Zhang, L.; Gao, R.X.; Wu, D. Deep learning for smart manufacturing: Methods and applications. J. Manuf. Syst. 2018, 48, 144–156. [Google Scholar] [CrossRef]

- Liu, M.; Yu, F.R.; Teng, Y.; Leung, V.C.; Song, M. Performance optimization for blockchain-enabled industrial internet of things (IoT) systems: A deep reinforcement learning approach. IEEE Trans. Ind. Inform. 2019, 15, 3559–3570. [Google Scholar] [CrossRef]

- Bhat, S.A.; Huang, N.-F.; Sofi, I.B.; Sultan, M. Agriculture-Food Supply Chain Management Based on Blockchain and IoT: A Narrative on Enterprise Blockchain Interoperability. Agriculture 2021, 12, 40. [Google Scholar] [CrossRef]

- Caro, M.P.; Ali, M.S.; Vecchio, M.; Giaffreda, R. Blockchain-based traceability in Agri-Food supply chain management: A practical implementation. In Proceedings of the 2018 IoT Vertical and Topical Summit on Agriculture—Tuscany (IOT Tuscany), Tuscany, Italy, 8–9 May 2018; pp. 1–4. [Google Scholar]

- Montes, J.M.; Larios, V.M.; Avalos, M.; Ramírez, C.E. Applying Blockchain to Supply Chain Operations at IBM Implementing Agile Practices in a Smart City Environment. Res. Comput. Sci. 2018, 147, 65–75. [Google Scholar] [CrossRef]

- García, M.Q.; Schmitz, A.; Martín, A.M.D. La transformación del retail: El papel de la tecnología en la crisis de la COVID-19. Distrib. Consumo 2021, 3, 36. [Google Scholar]

- IBM. eProvenance Annuncia VinAssure™, la Nuova Piattaforma Basata Sulla Tecnologia IBM Blockchain per Ottimizzare la Supply Chain del Vino. 10 December 2020. Available online: https://it.newsroom.ibm.com/VinAssure (accessed on 16 February 2024).

- Galati, A.; Vrontis, D.; Giorlando, B.; Giacomarra, M.; Crescimanno, M. Exploring the common blockchain adoption enablers: The case of three Italian wineries. Int. J. Wine Bus. Res. 2021, 33, 578–596. [Google Scholar] [CrossRef]

- Vin Vikup (n.d.). How Will NFT Help Protect Collectible Alcohol from Counterfeiting. Available online: https://vikupvin.ru/robert-mondavi-vypuskaet-vina-s-nft-tokenami/?ysclid=lsoxk1qnyu391769507&fbclid=IwAR1Z8-2pkdV4DNHQZjujkH7RhSHOORkhLs0FK1c2qsXlwvuojiQg4QavC1Q (accessed on 16 February 2024).

- Mercer, C. Angélus and Cult Wines Explore NFT Trend. 27 July 2021. Available online: https://www.decanteR.com/wine-news/angelus-and-cult-wines-explore-nft-trend-462488/ (accessed on 16 February 2024).

- Venco, E. Tappo Digitalele Aziende Vinicole Usano Sempre più gli NFT. 30 April 2022. Available online: https://www.linkiesta.it/2022/04/vino-nft/ (accessed on 16 February 2024).

- Leonidou, E.; Christofi, M.; Vrontis, D.; Thrassou, A. An integrative framework of stakeholder engagement for innovation management and entrepreneurship development. J. Bus. Res. 2020, 119, 245–258. [Google Scholar] [CrossRef]

- Rosado-Pinto, F.; Loureiro, S.M.C. The growing complexity of customer engagement: A systematic review. Euro. Med. J. Bus. 2020, 15, 167–203. [Google Scholar] [CrossRef]

- Karaosman, H.; Morales-Alonso, G.; Brun, A. From a Systematic Literature Review to a Classification Framework: Sustainability Integration in Fashion Operations. Sustainability 2016, 9, 30. [Google Scholar] [CrossRef]

- Christofi, M.; Vrontis, D.; Cadogan, J.W. ‘Micro-foundational ambidexterity and multinational enterprises: A systematic review and a conceptual framework’. Int. Bus. Rev. 2019, in press corrected proof. [Google Scholar] [CrossRef]

- Vrontis, D.; Christofi, M. R & D internationalization and innovation: A systematic review, integrative framework and future research directions. J. Bus. Res. 2021, 128, 812–823. [Google Scholar]

- Christofi, M.; Vrontis, D.; Thrassou, A.; Shams, S.M.R. Triggering technological innovation through cross-border mergers and acquisitions: A micro-foundational perspective. Technol. Forecast. Soc. Chang. 2019, 146, 148–166. [Google Scholar] [CrossRef]

- Rana, R.L.; Adamashvili, N.; Tricase, C. The Impact of Blockchain Technology Adoption on Tourism Industry: A Systematic Literature Review. Sustainability 2022, 14, 7383. [Google Scholar] [CrossRef]

- Correia, E.; Carvalho, H.; Azevedo, S.G.; Govindan, K. Maturity Models in Supply Chain Sustainability: A Systematic Literature Review. Sustainability 2017, 9, 64. [Google Scholar] [CrossRef]

- Rastogi, L.; Yazdifar, H.; Alam, A.; Eskandari, R.; Bahloul, M.A. A review of the relationship between leadership style and innovation: Insights and directions for future research. J. Glob. Bus. Adv. 2019, 12, 625–647. [Google Scholar] [CrossRef]

- Giacomarra, M.; Galati, A.; Crescimanno, M.; Vrontis, D. Geographical cues: Evidences from new and old world countries’ wine consumers. Br. Food J. 2020, 122, 1252–1267. [Google Scholar] [CrossRef]

- Masi, D.; Day, S.; Godsell, J. Supply Chain Configurations in the Circular Economy: A Systematic Literature Review. Sustainability 2017, 9, 1602. [Google Scholar] [CrossRef]

- Moher, D.; Shamseer, L.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; PRISMA-P Group. Preferred reporting items for systematic review and meta analysis protocols (PRISMA-P) 2015 statement. Syst. Rev. 2015, 4, 1. [Google Scholar] [CrossRef]

- De Menezes, L.M.; Kelliher, C. Flexible working and performance: A systematic review of the evidence for a business case. Int. J. Manag. Rev. 2011, 13, 452–474. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D., Bryman, A., Eds.; Sage Publications: London, UK, 2009; pp. 671–689. [Google Scholar]

- Tröster, R.; Hiete, M. Success of voluntary sustainability certification schemes—A comprehensive review. J. Clean. Prod. 2018, 196, 1034–1043. [Google Scholar] [CrossRef]

- Pittaway, L.; Robertson, M.; Munir, K.; Denyer, D.; Neely, A. Networking and innovation: A systematic review of the evidence. Int. J. Manag. Rev. 2004, 5–6, 137–168. [Google Scholar] [CrossRef]

- Takacs, B.; Borrion, A. The Use of Life Cycle-Based Approaches in the Food Service Sector to Improve Sustainability: A Systematic Review. Sustainability 2020, 12, 3504. [Google Scholar] [CrossRef]

- Livoreil, B.; Glanville, J.; Haddaway, N.R.; Bayliss, H.; Bethel, A.; de Lachapelle, F.F.; Robalino, S.; Savilaakso, S.; Zhou, W.; Petrokofsky, G.; et al. Systematic searching for environmental evidence using multiple tools and sources. Environ. Évid. 2017, 6, 1–14. [Google Scholar] [CrossRef]

- Broome, M.E. Integrative literature reviews for the development of concepts. In Concept Development in Nursing; Rodgers, B.L., Knafl, K.A., Eds.; W.B. Saunders: Philadelphia, PA, USA, 1993; pp. 231–250. [Google Scholar]

- Govindan, K.; Bouzon, M. From a literature review to a multi-perspective framework for reverse logistics barriers and drivers. J. Clean. Prod. 2018, 187, 318–337. [Google Scholar] [CrossRef]

- Lin, J.; Shen, Z.; Miao, C.; Zhang, A.; Chai, Y. 2018. Blockchain and IoT based Food Traceability for Smart Agriculture. In Proceedings of the ICCSE’18: 3rd International Conference on Crowd Science and Engineering, Singapore, 28–31 July 2018; p. 6. [Google Scholar] [CrossRef]

- Zhang, R.; Xue, R.; Liu, L. Security and Privacy on Blockchain. ACM Comput. Surv. 2019, 52, 1–34. [Google Scholar] [CrossRef]

- Casino, F.; Dasaklis, T.K.; Patsakis, C. Enhanced Vendor-managed Inventory through Blockchain. In Proceedings of the 2019 4th South-East Europe Design Automation, Computer Engineering, Computer Networks and Social Media Conference (SEEDA-CECNSM), Piraeus, Greece, 20–22 September 2019; pp. 1–8. [Google Scholar]

- Blanchard, D. Supply Chain Management Best Practices; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Torky, M.; Hassanein, A.E. Integrating blockchain and the internet of things in precision agriculture: Analysis, opportunities, and challenges. Comput. Electron. Agric. 2020, 178, 105476. [Google Scholar] [CrossRef]

- Tian, F. An agri-food supply chain traceability system for China based on RFID & blockchain technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016. [Google Scholar]

- Singh, P.; Singh, N. Blockchain With IoT and AI: A Review of Agriculture and Healthcare. Int. J. Appl. Evol. Comput. 2020, 11, 13–27. [Google Scholar] [CrossRef]

- Hu, S.; Huang, S.; Huang, J.; Su, J. Blockchain and edge computing technology enabling organic agricultural supply chain: A framework solution to trust crisis. Comput. Ind. Eng. 2020, 153, 107079. [Google Scholar] [CrossRef]

- Kumarathunga, M. Improving Farmers’ Participation in Agri Supply Chains with Blockchain and Smart Contracts. In Proceedings of the 2020 Seventh International Conference on Software Defined Systems (SDS), Paris, France, 20–23 April 2020; pp. 139–144. [Google Scholar]

- Zhou, Q.; Wang, Y.; Fu, X. Information asymmetry, blockchain and food safety. Res. China Mark. Superv. 2016, 11, 53–56. [Google Scholar] [CrossRef]

- Gambill, A.B. Creating Sustainable Food Systems with Trademarks and Technology. Bus. Entrep. Tax L. Rev. 2022, 6, 58. [Google Scholar]

- Centobelli, P.; Cerchione, R.; Del Vecchio, P.; Oropallo, E.; Secundo, G. Blockchain technology for bridging trust, traceability and transparency in circular supply chain. Inf. Manag. 2021, 59, 103508. [Google Scholar] [CrossRef]

- Ilie-Zudor, E.; Ekárt, A.; Kemeny, Z.; Buckingham, C.; Welch, P.; Monostori, L. Advanced predictive-analysis-based decision support for collaborative logistics networks. Supply Chain Manag. Int. J. 2015, 20, 369–388. [Google Scholar] [CrossRef]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain technology and its relationships to sustainable supply chain management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Alicke, K.; Glatzel, C.; Hoberg, K.; Karlsson, P.-M. Big Data and The Supply Chain: The Big Supply Chain Analytics Landscape Part 1 (of 2), McKinsey&Company Operations Extranet, February. 2016. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/big-data-and-the-supply-chain-the-big-supply-chain-analytics-landscape-part-1#/ (accessed on 1 October 2021).

- Merkert, J.; Mueller, M.; Hubl, M. A Survey of the Application of Machine Learning in Decision Support Systems. In Proceedings of the 23rd European Conference on Information Systems (ECIS 2015), Münster, Germany, 26–29 May 2015. [Google Scholar]

- OIV. Resolution CST 1/2008-OIV Guidelines for Sustainable Vitiviniculture: Production, Processing and Packaging of Products. Available online: http://www.oiv.int/public/medias/2089/cst-1-2008-en.pdf (accessed on 5 March 2024).

- Gilinsky, A., Jr.; Newton, S.K.; Vega, R.F. Sustainability in the Global Wine Industry: Concepts and Cases. Agric. Agric. Sci. Procedia 2016, 8, 37–49. [Google Scholar] [CrossRef]

- Ge, L.; Brewster, C.; Spek, J.; Smeenk, A.; Top, J.; van Diepen, F.; Klaase, B.; Graumans, C.; de Ruyter de Wildt, M. Blockchain for Agriculture and Food: Findings from the Pilot Study; Wageningen Economic Research report; No. 2017-112; Wageningen Economic Research: Wageningen, The Nethelands, 2017. [Google Scholar] [CrossRef]

- AlSobeh, A.M.R.; Magableh, A.A. BlockASP: A Framework for AOP-Based Model Checking Blockchain System. IEEE Access 2023, 11, 115062–115075. [Google Scholar] [CrossRef]

- Suciu, G.; Nadrag, C.; Istrate, C.; Vulpe, A.; Ditu, M.C.; Subea, O. Comparative analysis of distributed ledger technologies. In Proceedings of the 2018 Global Wireless Summit (GWS), Chiang Rai, Thailand, 25–28 November 2018; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 2018; pp. 370–373. [Google Scholar]

- Rana, R.L.; Bux, C.; Lombardi, M. Carbon footprint of the globe artichoke supply chain in Southern Italy: From agricultural production to industrial processing. J. Clean. Prod. 2023, 391, 136240. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Govindan, K.; NoorulHaq, A.; Geng, Y. An ISM approach for the barrier analysis in implementing green supply chain management. J. Clean. Prod. 2013, 47, 283–297. [Google Scholar] [CrossRef]

- Unicredit. Industry Book. 2019. Available online: https://www.unicreditgroup.eu/content/dam/unicreditgroup-eu/documents/en/investors/financial-reports/2019/4Q19/2019-Annual-Report-and-Accounts.pdf (accessed on 4 April 2020).

- Rugani, B.; Vázquez-Rowe, I.; Benedetto, G.; Benetto, E. A comprehensive review of carbon footprint analysis as an extended environmental indicator in the wine sectoR. J. Clean. Prod. 2013, 54, 61–77. [Google Scholar] [CrossRef]

- Venkatesh, V.G.; Kang, K.; Wang, B.; Zhong, R.Y.; Zhang, A. System architecture for blockchain based transparency of supply chain social sustainability. Robot. Comput. Integr. Manuf. 2020, 63, 139–144. [Google Scholar] [CrossRef]

- Mao, D.; Hao, Z.; Wang, F.; Li, H. Innovative Blockchain-Based Approach for Sustainable and Credible Environment in Food Trade: A Case Study in Shandong Province, China. Sustainability 2018, 10, 3149. [Google Scholar] [CrossRef]

- Di Vaio, A.; Varriale, L. Blockchain technology in supply chain management for sustainable performance: Evidence from the airport industry. Int. J. Inf. Manag. 2020, 52, 102014. [Google Scholar] [CrossRef]

- Xiong, H.; Dalhaus, T.; Wang, P.; Huang, J. Blockchain Technology for Agriculture: Applications and Rationale. Front. Blockchain 2020, 3, 7. [Google Scholar] [CrossRef]

- Balaji, M.; Arshinder, K. Modeling the causes of food wastage in Indian perishable food supply chain. Resour. Conserv. Recycl. 2016, 114, 153–167. [Google Scholar] [CrossRef]

- Ante, L.; Sandner, P.; Fiedler, I. Blockchain-based ICOs: Pure hype or the dawn of a new era of startup financing? J. Risk Financ. Manag. 2018, 11, 80. [Google Scholar] [CrossRef]

- Chohan, U.W. Initial coin offerings (ICOs): Risks, regulation, and accountability. In Cryptofinance and Mechanisms of Ex-Change; Springer: Berlin/Heidelberg, Germany, 2019; pp. 165–177. [Google Scholar]

- Vishakha, N.S.; Bhushan, B.; Kaushik, I. Blockchain-based Cultivating Ideas for Growth: A New Agronomics Perspective. Blockchain Appl. Secur. IoT Framew. Technol. Shap. Future 2021, 1, 195. [Google Scholar]

- Adamashvili, N.; Fiore, M.; Contò, F.; La Sala, P. Ecosystem for Successful Agriculture. Collaborative Approach as a Driver for Agricultural Development. Eur. Countrys. 2020, 12, 242–256. [Google Scholar] [CrossRef]

- Ogrean, C. Relevance of Big Data for Business and Management. Exploratory Insights (Part I). Stud. Bus. Econ. 2018, 13, 153–163. [Google Scholar] [CrossRef]

- Scholz, T. Platform Cooperativism. Challenging the Corporate Sharing Economy; Rosa Luxemburg Stiftung: New York, NY, USA, 2016. [Google Scholar]

- Chen, H.; Chen, Z.; Lin, F.; Zhuang, P. Effective Management for Blockchain-Based Agri-Food Supply Chains Using Deep Reinforcement Learning. IEEE Access 2021, 9, 36008–36018. [Google Scholar] [CrossRef]

- Feng, Q.; He, D.; Zeadally, S.; Liang, K. BPAS: Blockchain-Assisted Privacy-Preserving Authentication System for Vehicular Ad Hoc Networks. IEEE Trans. Ind. Inform. 2019, 16, 4146–4155. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System; White Paper: Washington, DC, USA, 2008. [Google Scholar]

- Gilbert, H.; Handschuh, H. Security analysis of sha-256 and sisters. In 10th International Workshop on1 Selected Areas in Cryptography (SAC); Springer: Berlin/Heidelberg, Germany, 2003; pp. 175–193. [Google Scholar]

- Lin, Y.-P.; Petway, J.R.; Anthony, J.; Mukhtar, H.; Liao, S.-W.; Chou, C.-F.; Ho, Y.-F. Blockchain: The Evolutionary Next Step for ICT E-Agriculture. Environments 2017, 4, 50. [Google Scholar] [CrossRef]

| Concept | To describe the safety achieved by means of applied technologies in the wine supply chain. |

| Tech. | Intervention |

| BCT | 1. The BCT is used to trace the origin and history of wine bottles. This enables complete transparency and accountability throughout the whole winemaking and distribution process. Using this approach, concerns with product or food safety, such as contamination or recalls, are also identified [38,39,49,67,71,73,74,84,117,124]. 2. BCT is used to generate digital wine authenticity certificates that are used to verify the provenance and legitimacy of a bottle of wine. In addition to reducing the likelihood of falsification and fraud, this offers purchasers more certainty about the quality and authenticity of the wines they purchase [15,30,49,121,122]. 3. In terms of logistics and supply chain management, BCT is used to maintain an electronic record of wine bottles and other goods as they are carried from A to B. The wine’s quality may be affected if, for instance, the temperature varies during delivery, although this is detectable [125]. 4. Blockchain is used to record and keep immutable information on the ingredients and storage temperatures of wine, all of which may impact the safety of the final product [121]. 5. The use of BCT increases consumer trust and confidence in wine safety due to direct interaction between producers and consumers [30,49,119,123]. 6. BCT makes reliable and accurate information available to regulatory agencies and helps them carry out informed and efficient regulations [121,122]. |

| IoT | 1. IoT-enabled sensors monitor the wine’s temperature throughout its entire lifespan. This helps to preserve the wine’s quality and safety throughout storage and transport [46,49]. 2. IoT-enabled sensors are used to monitor wine quality during the manufacturing and storage processes, allowing winemakers to make adjustments in real-time that improve product integrity [46,47,49]. 3. IoT-enabled devices are used to track inventory in wineries and warehouses, simplifying the safe storage and shipment of wine bottles [112]. 4. Information on food safety, such as ingredients and storage temperatures, is kept and transmitted using IoT-enabled devices [38,44,117]. 5. The data recorded by IoT-enabled devices is used to design valuable and high-quality products [38,44,117]. 6. Data records by IoT-enabled devices are useful in disease and outbreak deterrence and risk evaluation, which empowers food safety conclusions and supports decision-making [47]. |

| AI | 1. The quality of the wine is monitored and managed at every step of production using AI-enabled technologies by analyzing data from IoT devices [55,126,127]. 2. AI-enabled systems analyze the data from IoT sensors in vineyards to predict when equipment will need maintenance, therefore lowering the probability of unanticipated malfunctions and accidents [56,124]. 3. AI-enabled systems analyze the data to ensure that the whole production and logistics chain adheres to all relevant safety and regulations [57,126,127]. 4. AI-enabled technology is also used to improve the quality of the final product by predicting the wine’s quality using historical data obtained during production [57,124]. 5. In order to ensure the safety of the final product, AI-enabled systems analyze the data on materials and storage temperatures [59,126,127]. 6. Based on the forecasts from the ML, the macro-control for the production, processing and handling of wine products can be effectively performed [124]. 7. AI reduces the time spent on manual labor, freeing employees to make more valuable contributions to a business [59]. |

| Concept | To describe the environmental protection and/or management within the wine supply chain by the intervention of used technologies. |

| Tech. | Intervention |

| BCT | 1. BCT is used to trace the origin and history of wine bottles which enables transparency and accountability in the wine supply chain that contributes to the implementation of environmentally friendly methods [13,14,39,75,125,138,139]. 2. By tracking wine bottles and other materials across the production and transportation, BCT-enabled supply chain management is used to improve logistics and lower the wine industry’s carbon emission [39,125]. 3. The origin and validity of a bottle of wine may be validated by the use of BCT-based digital authenticity certificates. As a result, the wine supply chain will be sustainable and enhance responsible ecological wine production [14,15,135,136]. 4. BCT is used to record and verify organic and sustainable winemaking credentials [135,136]. 5. A traceability system, with the combination of BCT and IoT, permits the conducting of hazard analysis, which leads to environmental protection [38,136]. |

| IoT | 1. Vineyards are monitored using IoT-enabled devices to gather data on soil conditions, weather conditions, and inputs application and uptake. Using this data, farmers regulate inputs more accurately [47,49]. 2. IoT-enabled devices monitor and control grapes’ power use. It is feasible, for instance, to save energy expenditures by monitoring and regulating wine production tank temperatures using sensors [46,47]. 3. In vineyards, IoT-enabled sensors detect the humidity of the soil, allowing more accurate irrigation system management and reduced water waste [46,47]. 4. Data availability via the IoT-BCT increases transparency and enables the increase of environmental protection/management initiatives [112,117]. 5. IoT devices ensure ethical sourcing and monitoring of the environmental supply chain, reducing barriers and complexity to the green supply chain and social sustainability [44]. |

| AI | 1. With the use of AI-based algorithms, it is possible to predict the optimal harvest time depending on factors such as weather and vine growth. Therefore, the vineyard may become more efficient and produce less food waste [124]. 2. AI may contribute to winery management by increasing efficiency and reducing waste throughout the winemaking process. This can be done by monitoring temperature and acidity throughout fermentation, allowing winemakers to make immediate adjustments to the process for optimal quality control [57,127]. 3. AI might help wineries become more eco-friendly by identifying which production processes and supply networks use the least amount of energy [126]. 4. AI is used to predict the quality of a wine before it is bottled, allowing winemakers to make adjustments and reduce waste [55,124]. |

| Concept | To describe the economic performance achieved by applied technologies in the wine supply chain. |

| Tech. | Intervention |

| BCT | 1. BCT decreases transaction fees, and actors receive fair payments for their products. Wine supply chain actors, mainly farmers, can make mobile payments and credits. 2. Financing is enhanced in the wine supply chain due to transparency and trust brought by using BCT. Small farm owners are able to find investors and improve their business via BCT. 3. Transparency and traceability systems help wine suppliers achieve a better reputation, which, in return, generates income through increased customers [30,79]. 4. Transactions/payments are performed immediately once the products are available. No delay or waste of time by waiting for the payments to be returned. 5. BCT is represented on exchanges and stock markets. Actors are able to benefit from access to stock markets and exchange services. 6. Chain actors are easily trading upcoming contracts at fixed prices for wine. As a result, they will know their cost, and customers will not be surprised by price changes. 7. The ability to track the origin and history of wine bottles allows for total accountability and transparency throughout the whole winemaking and distribution process. There is a correlation between this and an increase in sales and income since consumers’ trust and loyalty to the brand will improve. 8. Using BCT to construct smart contracts that automate monetary transactions and payments between parties may simplify and enhance the wine supply chain’s financing. This ultimately results in improved profits and lower expenses for all concerned parties. 9. BCT enables direct-to-consumer sales via the development of digital marketplaces where buyers and sellers interact without the need for middlemen, therefore saving money. 10. Using BCT to record and verify credentials for ecologically friendly and organic wine production enhances the wine’s value and marketability. |

| IoT | 1. The recorded data by the IoT-enabled devices are used in the planning of the supply chain and permit the best handling of the wine, therefore increasing the price tag of the wine [112,117]. 2. IoT-enabled devices help farmers incur necessary costs by having all records of the chain on file [112,117]. 3. Operating IoT sensors to measure and regulate the flow of water, energy, and fertilizers is one approach to saving money in the vineyard [46,47]. 4. IoT-enabled devices automate vineyard processes like wine fermentation to increase production and reduce costs [112,117]. 5. IoT-enabled devices are used to monitor vineyard and warehouse inventories, therefore enhancing efficiency and reducing needless stockouts and surpluses [46]. |

| AI | 1. AI maintains available products for retailers in a cost-effective way while the stock of retailers can well satisfy the demands of consumers [62,124]. 2. To increase production and profitability, AI is used to analyze data from IoT devices in the wine supply chain in order to anticipate future yields and identify the most efficient use of existing resources [55,124]. 3. Quality control is performed by an AI-enabled system that analyzes Iot devices’ data in real-time to detect and anticipate quality issues like spoilage or contamination. In addition to raising sales and profitability, this helps ensure that buyers obtain only safe and high-quality wine [56,124]. 4. AI-enabled devices are used to anticipate when vineyard machinery and equipment may need service, therefore preventing expensive failures [124]. 5. AI is used to analyze customer data and predict consumer demand, hence enhancing marketing and sales strategies and boosting profitability [60,62,124]. 6. The automation of routine operations and enhanced decision-making are two ways in which AI increases winery output and reduces expenses [56,60,83]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamashvili, N.; Zhizhilashvili, N.; Tricase, C. The Integration of the Internet of Things, Artificial Intelligence, and Blockchain Technology for Advancing the Wine Supply Chain. Computers 2024, 13, 72. https://doi.org/10.3390/computers13030072

Adamashvili N, Zhizhilashvili N, Tricase C. The Integration of the Internet of Things, Artificial Intelligence, and Blockchain Technology for Advancing the Wine Supply Chain. Computers. 2024; 13(3):72. https://doi.org/10.3390/computers13030072

Chicago/Turabian StyleAdamashvili, Nino, Nino Zhizhilashvili, and Caterina Tricase. 2024. "The Integration of the Internet of Things, Artificial Intelligence, and Blockchain Technology for Advancing the Wine Supply Chain" Computers 13, no. 3: 72. https://doi.org/10.3390/computers13030072

APA StyleAdamashvili, N., Zhizhilashvili, N., & Tricase, C. (2024). The Integration of the Internet of Things, Artificial Intelligence, and Blockchain Technology for Advancing the Wine Supply Chain. Computers, 13(3), 72. https://doi.org/10.3390/computers13030072