Linear Actuators in a Haptic Feedback Joystick System for Electric Vehicles

Abstract

1. Introduction

1.1. Literature Background

1.2. Contributions

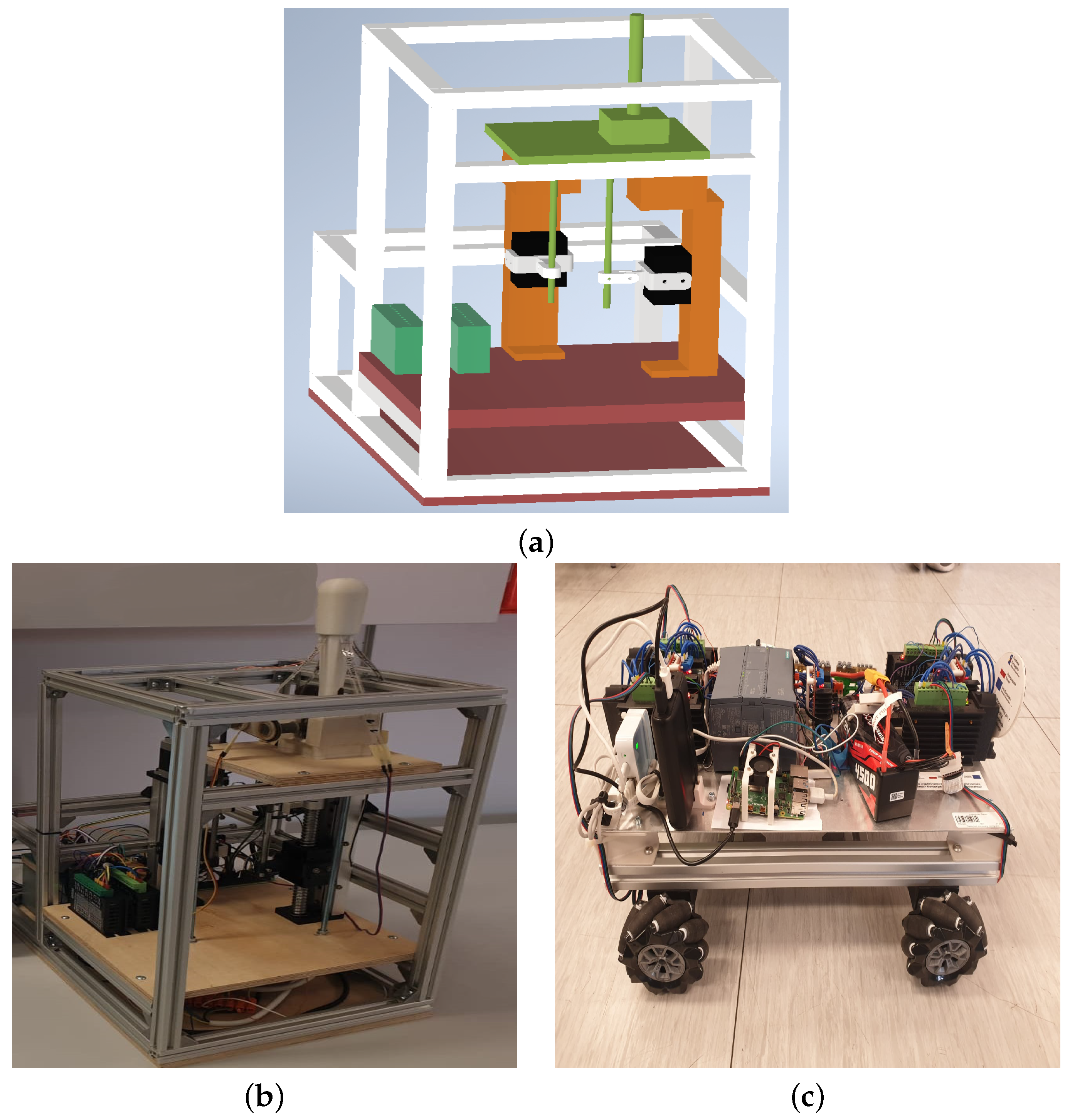

2. Description of the Joystick System and Electric Vehicle

Linear Drives and Stepper Motor

3. Linear Drive Parameters and Control Elements

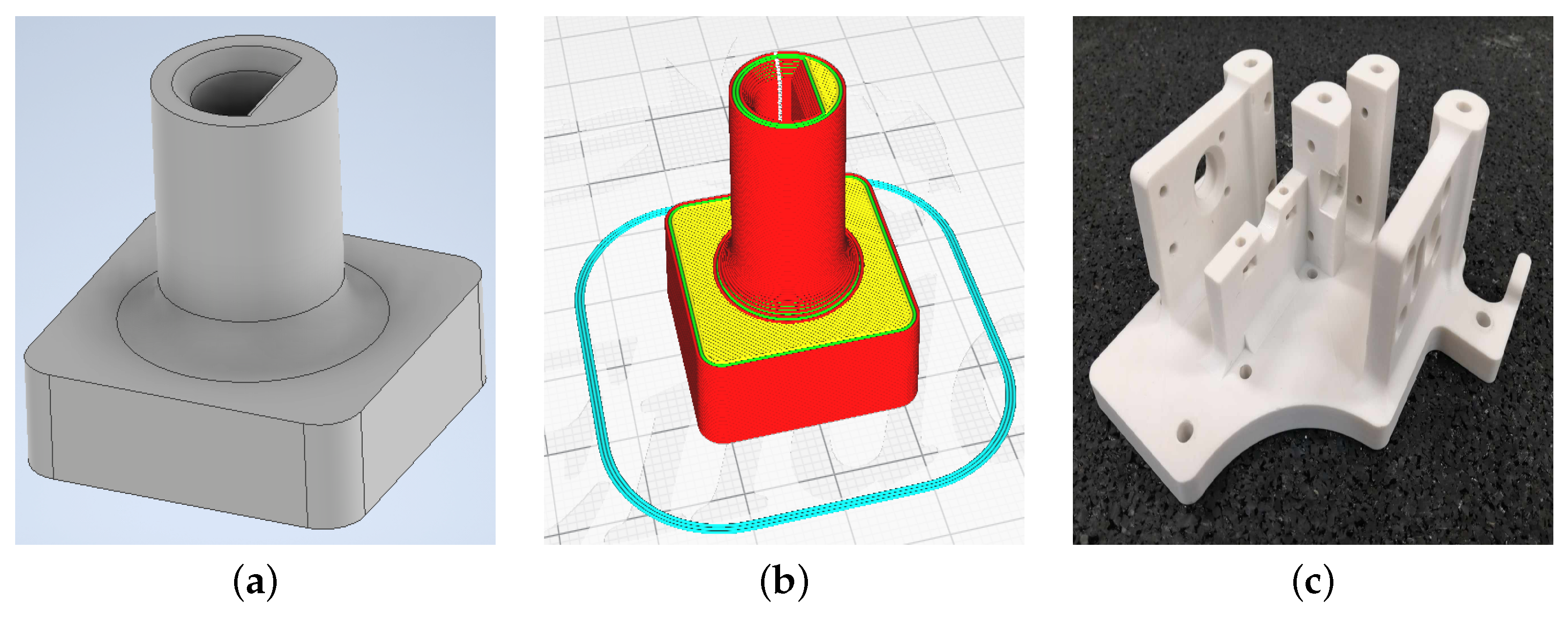

3.1. Joystick Design

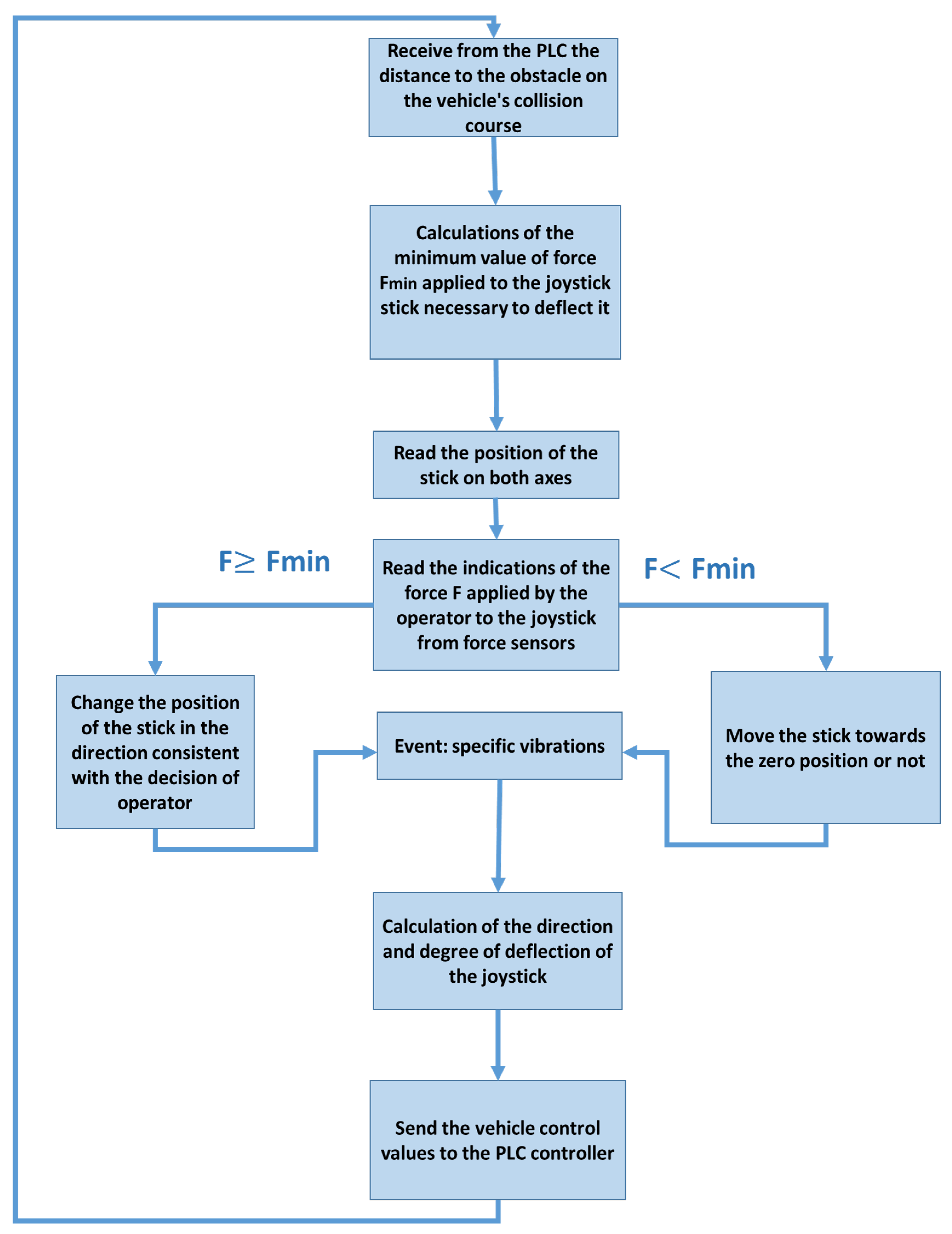

3.2. Joystick Firmware Update: Python Programming Language

- FSR sensor readings using an analog-to-digital converter

- the value of the force applied to the stick in four directions

- initialization of the most important variables

- configuration of some pins of the minicomputer’s input–output module,

- definition of functions, including configuration of the pins of the minicomputer’s input–output module, stick deflection conditions, vibration conditions, and calculation of the joystick’s operating parameters

- data transmission support

3.3. Run Tests

- continuous vibration with intensity of 100%, which is not dependent on the deflection of the joystick because the vehicle is next to the obstacle

- intermittent vibration at 40% intensity when the vehicle is at certain distance from the obstacle, the stick is in the zero position, and the force F applied by the operator is inadequate to deflect the stick and set the vehicle’s speed

4. Experimental Results

Measurements Results

5. Conclusions and Perspectives

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, H.; Jia, F.; Jing, H.; Liu, Z.; Güvenç, L. Coordinated longitudinal and lateral motion control for four wheel independent motor-drive electric vehicle. IEEE Trans. Veh. Technol. 2018, 67, 3782–3790. [Google Scholar] [CrossRef]

- Ding, X.; Wang, Z.; Zhang, L. Hybrid control-based acceleration slip regulation for four-wheel-independent-actuated electric vehicles. IEEE Trans. Transp. Electrif. 2020, 7, 1976–1989. [Google Scholar] [CrossRef]

- Weiskircher, T.; Müller, S. Control performance of a road vehicle with four independent single-wheel electric motors and steer-by-wire system. Veh. Syst. Dyn. 2012, 50, 53–69. [Google Scholar] [CrossRef]

- Ding, X.; Wang, Z.; Zhang, L.; Wang, C. Longitudinal vehicle speed estimation for four-wheel-independently-actuated electric vehicles based on multi-sensor fusion. IEEE Trans. Veh. Technol. 2020, 69, 12797–12806. [Google Scholar] [CrossRef]

- Long, S.; Terakawa, T.; Yogou, M.; Koyano, R.; Komori, M. Kinetic analysis of active omni wheel with barrel-shaped rollers for avoiding slippage and vibration. J. Mech. Robot. 2024, 16, 051002. [Google Scholar] [CrossRef]

- Hijikata, M.; Miyagusuku, R.; Ozaki, K. Omni Wheel Arrangement Evaluation Method Using Velocity Moments. Appl. Sci. 2023, 13, 1584. [Google Scholar] [CrossRef]

- Komori, M.; Matsuda, K.; Terakawa, T.; Takeoka, F.; Nishihara, H.; Ohashi, H. Active omni wheel capable of active motion in arbitrary direction and omnidirectional vehicle. J. Adv. Mech. Des. Syst. Manuf. 2016, 10, JAMDSM0086. [Google Scholar] [CrossRef]

- Macfarlane, A.B.; van Niekerk, T.; Becker, U.; Mercorelli, P. Control system strategy of a modular omnidirectional AGV. In Modeling, Identification, and Control for Cyber-Physical Systems Towards Industry 4.0; Elsevier: Amsterdam, The Netherlands, 2024; pp. 169–197. [Google Scholar]

- Zhao, T.; Qin, P.; Dian, S.; Guo, B. Fractional order sliding mode control for an omni-directional mobile robot based on self-organizing interval type-2 fuzzy neural network. Inf. Sci. 2024, 654, 119819. [Google Scholar] [CrossRef]

- Ismael, O.Y.; Almaged, M.; Abdulla, A.I. Nonlinear Model Predictive Control-based Collision Avoidance for Mobile Robot. J. Robot. Control (JRC) 2024, 5, 142–151. [Google Scholar]

- Borkar, K.K.; Aljrees, T.; Pandey, S.K.; Kumar, A.; Singh, M.K.; Sinha, A.; Singh, K.U.; Sharma, V. Stability Analysis and Navigational Techniques of Wheeled Mobile Robot: A Review. Processes 2023, 11, 3302. [Google Scholar] [CrossRef]

- Samada, S.E.; Puig, V.; Nejjari, F. Robust TS-ANFIS MPC of an autonomous racing electrical vehicle considering the battery state of charge. IEEE/ASME Trans. Mechatronics 2023, 28, 656–667. [Google Scholar] [CrossRef]

- Guevara, L.; Jorquera, F.; Walas, K.; Auat-Cheein, F. Robust control strategy for generalized N-trailer vehicles based on a dual-stage disturbance observer. Control Eng. Pract. 2023, 131, 105382. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Z.; Wang, J. Automated Vehicle Path Following: A Non-Quadratic-Lyapunov-Function-Based Model Reference Adaptive Control Approach With C-Smooth Projection Modification. IEEE Trans. Intell. Transp. Syst. 2022, 23, 21653–21664. [Google Scholar] [CrossRef]

- Zou, Q.; Sun, Q.; Chen, L.; Nie, B.; Li, Q. A comparative analysis of LiDAR SLAM-based indoor navigation for autonomous vehicles. IEEE Trans. Intell. Transp. Syst. 2021, 23, 6907–6921. [Google Scholar] [CrossRef]

- Zheng, K. Autonomous Obstacle Avoidance and Trajectory Planning for Mobile Robot Based on Dual-Loop Trajectory Tracking Control and Improved Artificial Potential Field Method. Actuators 2024, 13, 37. [Google Scholar] [CrossRef]

- Laghmara, H.; Boudali, M.T.; Laurain, T.; Ledy, J.; Orjuela, R.; Lauffenburger, J.P.; Basset, M. Obstacle Avoidance, Path Planning and Control for Autonomous Vehicles. In Proceedings of the 2019 IEEE Intelligent Vehicles Symposium (IV), Paris, France, 9–12 June 2019; pp. 529–534. [Google Scholar] [CrossRef]

- Li, S.; Li, Z.; Yu, Z.; Zhang, B.; Zhang, N. Dynamic Trajectory Planning and Tracking for Autonomous Vehicle with Obstacle Avoidance Based on Model Predictive Control. IEEE Access 2019, 7, 132074–132086. [Google Scholar] [CrossRef]

- Wang, P.; Gao, S.; Li, L.; Sun, B.; Cheng, S. Obstacle avoidance path planning design for autonomous driving vehicles based on an improved artificial potential field algorithm. Energies 2019, 12, 2342. [Google Scholar] [CrossRef]

- Almazrouei, K.; Kamel, I.; Rabie, T. Dynamic obstacle avoidance and path planning through reinforcement learning. Appl. Sci. 2023, 13, 8174. [Google Scholar] [CrossRef]

- Hu, Z.; Su, R.; Zhang, K.; Xu, Z.; Ma, R. Resilient Event-Triggered Model Predictive Control for Adaptive Cruise Control Under Sensor Attacks. IEEE/CAA J. Autom. Sin. 2023, 10, 807–809. [Google Scholar] [CrossRef]

- Hu, Z.; Su, R.; Wang, Y.; Wang, B.; Huang, L.; Lu, Y. Security Enhancement for Longitudinal Vehicle Platooning Under Denial-of-Service Attacks: From Resilient Controller Design Perspective. IFAC-PapersOnLine 2023, 56, 1088–1093. [Google Scholar] [CrossRef]

- Sciuto, G.L.; Kowol, P.; Nowak, P.; Banás, W.; Coco, S.; Capizzi, G. Neural network developed for obstacle avoidance of the four wheeled electric vehicle. In Proceedings of the 2023 30th IEEE International Conference on Electronics, Circuits and Systems (ICECS), Istanbul, Turkey, 4–7 December 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Kowol, P.; Nowak, P.; Banaś, W.; Bagier, P.; Lo Sciuto, G. Haptic Feedback Remote Control System for Electric Mechanical Assembly Vehicle Developed to Avoid Obstacles. J. Intell. Robot. Syst. 2023, 107, 41. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daniel, K.A.; Kowol, P.; Lo Sciuto, G. Linear Actuators in a Haptic Feedback Joystick System for Electric Vehicles. Computers 2024, 13, 48. https://doi.org/10.3390/computers13020048

Daniel KA, Kowol P, Lo Sciuto G. Linear Actuators in a Haptic Feedback Joystick System for Electric Vehicles. Computers. 2024; 13(2):48. https://doi.org/10.3390/computers13020048

Chicago/Turabian StyleDaniel, Kamil Andrzej, Paweł Kowol, and Grazia Lo Sciuto. 2024. "Linear Actuators in a Haptic Feedback Joystick System for Electric Vehicles" Computers 13, no. 2: 48. https://doi.org/10.3390/computers13020048

APA StyleDaniel, K. A., Kowol, P., & Lo Sciuto, G. (2024). Linear Actuators in a Haptic Feedback Joystick System for Electric Vehicles. Computers, 13(2), 48. https://doi.org/10.3390/computers13020048