Digital Twin in the Provision of Power Wheelchairs Context: Support for Technical Phases and Conceptual Model

Abstract

:1. Introduction

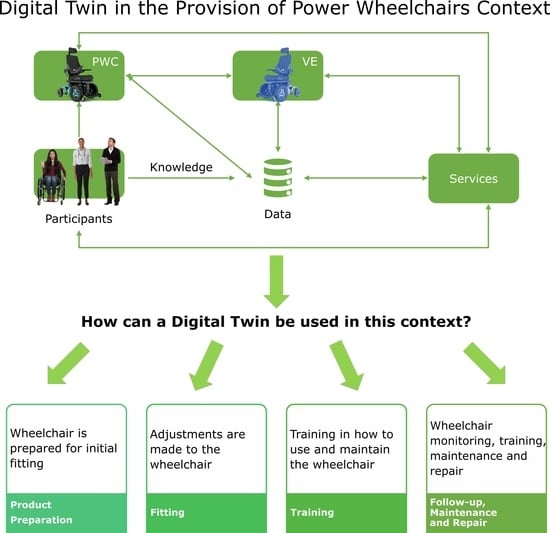

- Main question: Is it possible to use a Digital Twin to mirror a Power Wheelchair, or part of it, to support the technical phases of the wheelchair provision process?

- How can a Digital Twin be used in this context?

- To what extent does a Digital Twin represent a real Power Wheelchair?

2. Digital Twin: Its Elements, Properties, Types, Enabling Technologies, and Tools

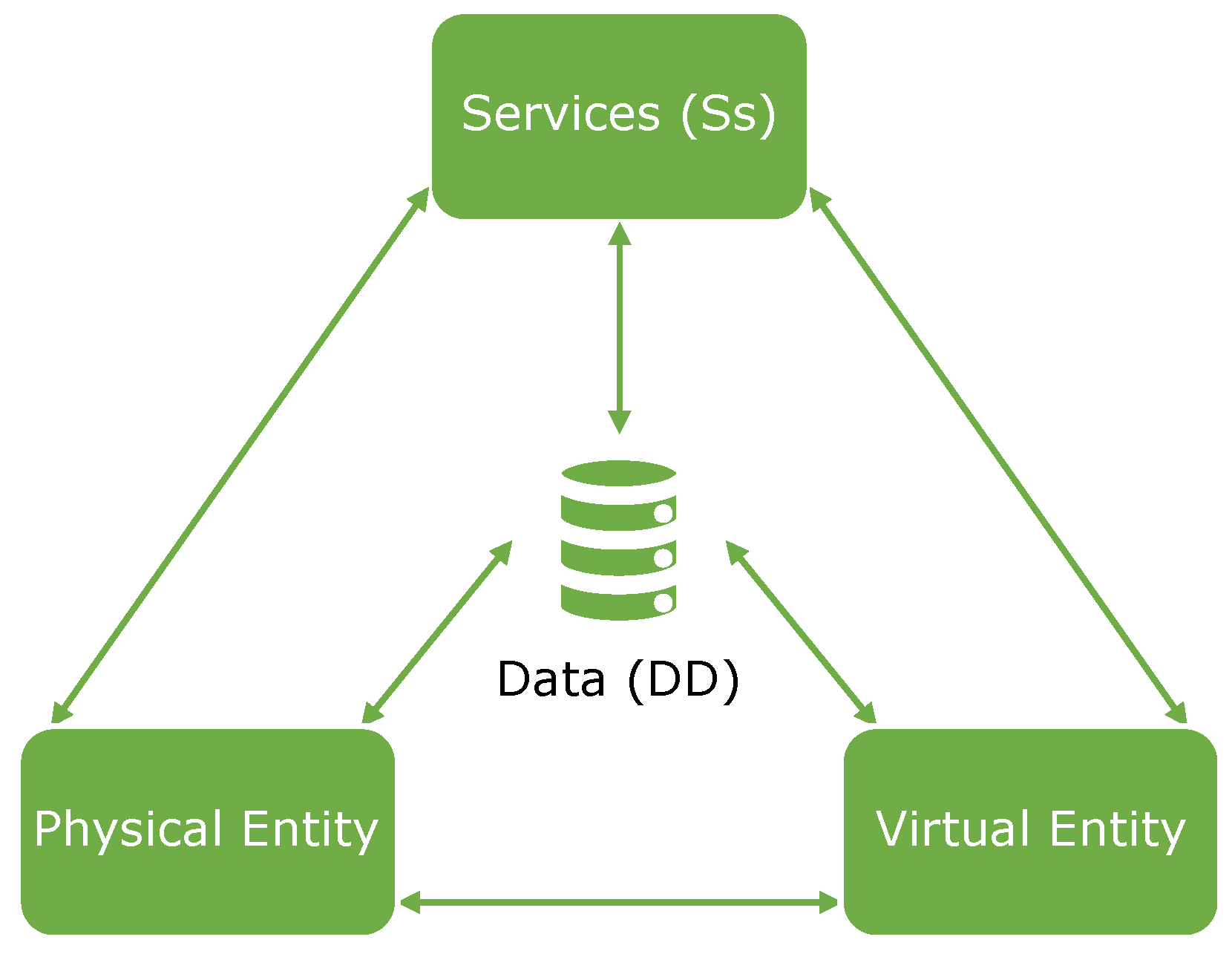

2.1. Dimensions of a Digital Twin Model

2.2. Properties and Types of Digital Twins

2.3. Technologies and Tools to Enable the Digital Twin

2.4. Usage and Advantages of the Digital Twin

- It considers large amounts of data from different sources, characterizing a physical entity, which allows modeling the VE to mirror the PE for the duration of its lifecycle;

- The VE synchronizes with the PE and provides a comparison between real and simulated performance, which can be used to monitor and analyze the PE in real-time, supporting planning, design, maintenance, etc.;

- It can help to optimize the PE, using simulations, but also predictions, evaluating the impact of different scenarios—including unpredictable and undesirable ones—which can be verified and validated before they occur;

- It is capable of performing diagnostics and intelligent control over the PE, with the VE sending instructions when needed;

- It allows remote access for human interaction with the PE, just to mention the most relevant advantages.

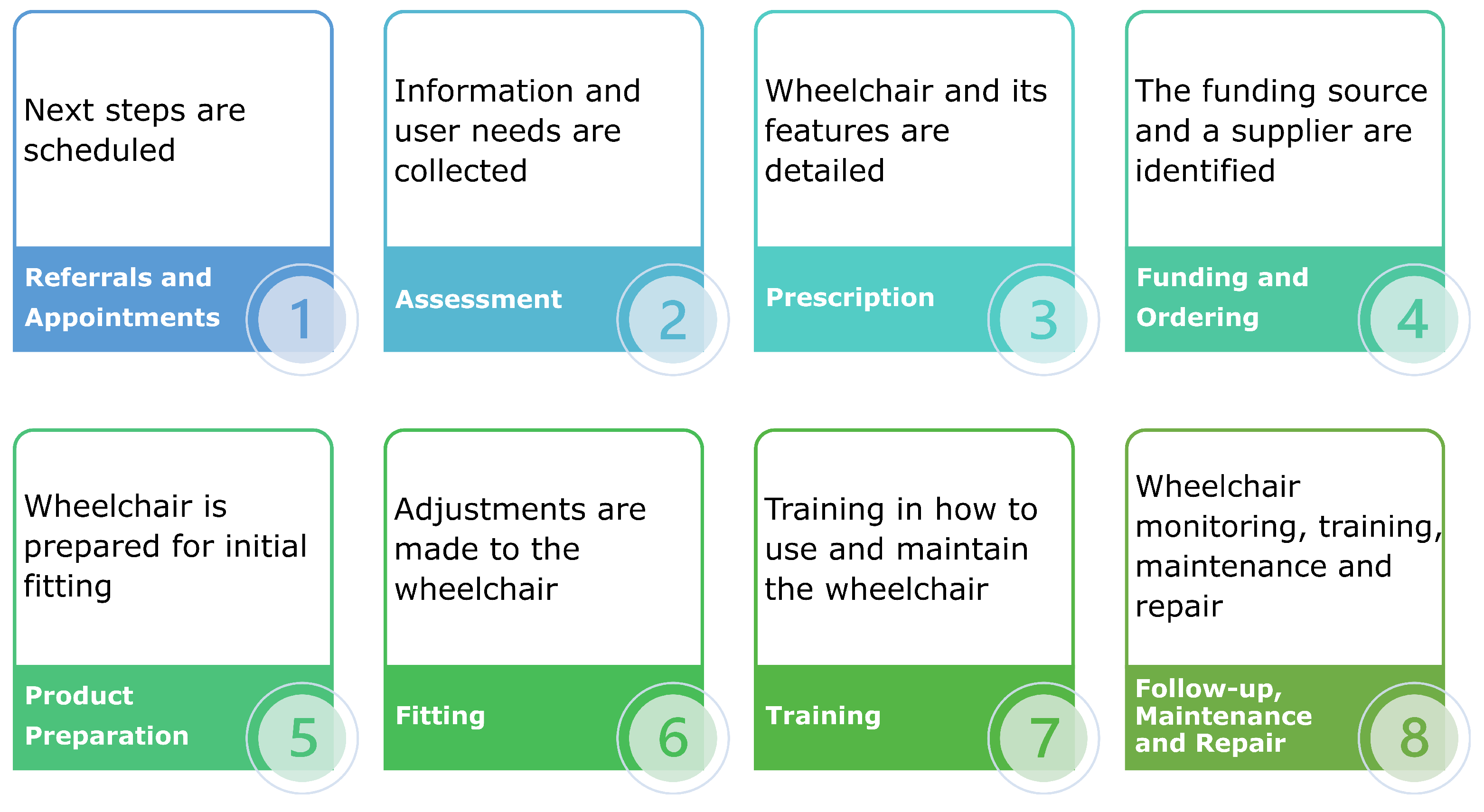

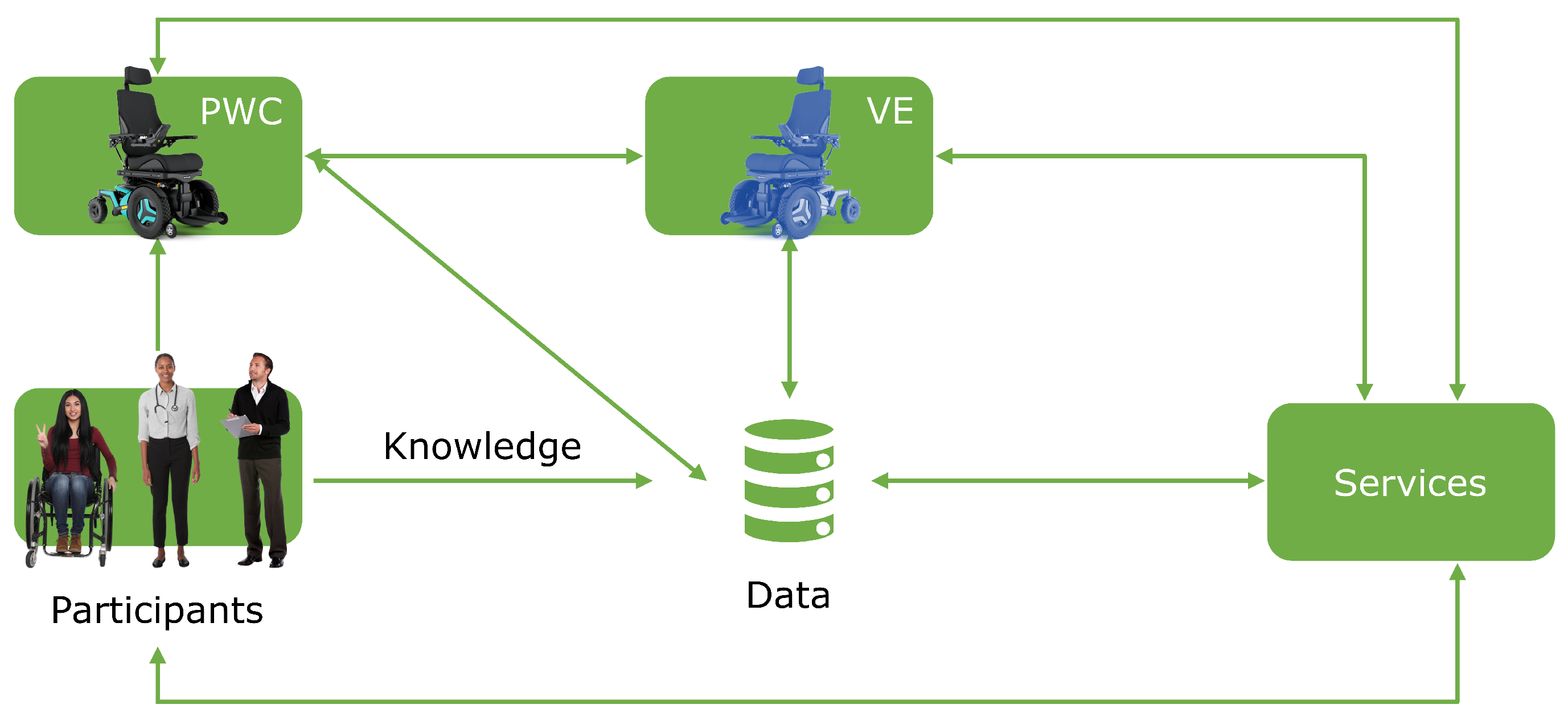

3. Digital Twin Applied in the Provision Process of Power Wheelchairs

- Product preparation and fitting: As part of product preparation and fitting, a PWC DT can help understand how the wheelchair works, support its fitting and adjustments, and assist in planning and testing of various scenarios. The DT can be used specifically by ATPs to justify, design, and validate new or existing PWC features, services, and parts, as well as simulating the health conditions of the PWC, in order to identify and eliminate the causes of problems and undesired situations. The PWC performance can also be predicted with the DT, including the occurrence of unforeseen scenarios.

- Training: The DT’s predictive capability can also be used during training to guide and anticipate potential risks. That is, the DT can guide users with personalized training services, based on their physiological, psychological, and contextual information, from users’ health data, therapists’ assessments, etc.; the DT can also analyze users’ usage data (e.g., location, time, and activity) in order to find out how the PWC is being used and offer accident prevention or mitigation based on this information.

- Follow-up, maintenance, and repair: The DT is able to gather real-time operational data from the PWC, giving insights into possible consequences of its use, showing users what is happening inside their PWCs. Therapists can also use it to guide and monitor users’ rehabilitation activities by tracing their usage patterns and reporting which PWC configurations and functionalities are used. In this way, the rehabilitation process can be better planned and PWC users can engage and follow along. Furthermore, the DT can trigger alerts during follow-up, maintenance, and repair so that a problem can be diagnosed and identify actions that can be taken to improve the performance of the PWC. With the DT, wheelchair repair can be facilitated through remote analysis and real-time PWC intervention.Here are some ways Digital Twins can be used to support the technical phases of wheelchairs provision. A section focused on the VE model and the framework for using the PWC DT follows.

4. Digital Twin of a Power Wheelchair

- Acquisition and analysis of operational data from the PWC in real-time;

- Understanding of the functioning of the PWC, or part of it;

- Evaluation of the PWC’s behavior in the future;

- Planning and testing the impact of the main usage scenarios;

- Improvement of part of the PWC, identifying and eliminating errors;

- Justification and validation of feature changes;

- Diagnosis of problems and identification of actions to improve the PWC’s performance;

- Augmentation of control systems to adjust or optimize the PWC parameters (locally or remotely) and more.

- Enable hardware and software design;

- Eliminate errors early in development;

- Facilitate testing with automated verification and validation techniques;

- Support automatic code generation for target platforms.

5. Discussion

- Design, verify, validate, and deploy Digital Twins using multi-domain modeling tools in a model-driven development approach;

- Model the state models of Digital Twins using an extended Petri net class;

- Implement a framework for the use of Digital Twins in a service-oriented architecture for monitoring, simulation, diagnosis, prognosis, and control of the system in the physical world;

- Define scenarios for the application of Digital Twins in real wheelchairs.

- Promote the well-being and safety of wheelchair users, supporting personalized services (e.g., user training services);

- Increase the engagement of wheelchair users;

- Support real wheelchairs’ adaptation and repair, increasing their safety and reliability, while reducing maintenance costs;

- Offer new mechanisms for ATPs to assist more people, facilitating access to wheelchair analysis and remote intervention with real-time control over physical twins, if necessary;

- Help therapists plan, guide, and monitor users’ rehabilitation activities.

6. Conclusions and Future Work

- Whether a VE model of a Power Wheelchair, or part of it, can be modeled using a non-autonomous high-level Petri net class, in particular;

- Whether a DT can be used in the context of the provision of Power Wheelchairs;

- Whether a DT, modeled in an MDD approach and based on a non-autonomous high-level Petri net class, can be implemented in a framework for Power Wheelchairs’ provision and support, in particular if the framework and the concept of the DT is adding value to the wheelchair provision process.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| API | Application programming interface |

| ATP | Assistive technology professional |

| Cn | Connections |

| DD | Data |

| DT | Digital Twin |

| GPS | Global Positioning System |

| HCP | Healthcare professional |

| I4.0 | Industry 4.0 |

| IoT | Internet of Things |

| LiDAR | Light detection and ranging |

| MDD | Model-driven development |

| NASA | National Aeronautics and Space Administration |

| PE | Physical entity |

| PLM | Product lifecycle management |

| PWC | Power Wheelchair |

| Ss | Services |

| USAF | United States Air Force |

| VE | Virtual Entity |

| WHO | World Health Organization |

| WSN | Wireless sensor network |

References

- World Health Organization; World Bank. World Report on Disability 2011. Available online: https://apps.who.int/iris/handle/10665/44575 (accessed on 8 March 2021).

- Instituto Nacional de Estatística. Censos 2011. Available online: https://censos.ine.pt/xportal/xmain?xpid=CENSOS&xpgid=censos2011_apresentacao (accessed on 6 April 2021).

- World Health Organization. Assistive Technology. Available online: https://www.who.int/news-room/fact-sheets/detail/assistive-technology (accessed on 9 March 2021).

- Watanabe, L. H.R. 2168 Includes Telehealth Options for CRT Clinicians. Available online: https://mobilitymgmt.com/articles/2021/03/29/hr-2168-telehealth-clinicians.aspx (accessed on 19 February 2022).

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Grieves, M.W. Product lifecycle management: The new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71–84. [Google Scholar] [CrossRef]

- Wagg, D.J.; Worden, K.; Barthorpe, R.J.; Gardner, P. Digital Twins: State-of-the-art and future directions for modeling and simulation in engineering dynamics applications. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part B Mech. Eng. 2020, 6. [Google Scholar] [CrossRef]

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems; Kahlen, F.J., Flumerfelt, S., Alves, A., Eds.; Springer: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar] [CrossRef]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. DRAFT Modeling, Simulation, Information Technology & Processing Roadmap, Technology Area 11. Available online: https://www.nasa.gov/pdf/501321main_TA11-MSITP-DRAFT-Nov2010-A1.pdf (accessed on 7 March 2022).

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering Aircraft Structural Life Prediction Using a Digital Twin. Int. J. Aerosp. Eng. 2011, 2011, 154798. [Google Scholar] [CrossRef] [Green Version]

- Gockel, B.T.; Tudor, A.W.; Brandyberry, M.D.; Penmetsa, R.C.; Tuegel, E.J. Challenges with Structural Life Forecasting Using Realistic Mission Profiles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012; American Institute of Aeronautics and Astronautics: Honolulu, Hawaii, 2012. [Google Scholar] [CrossRef]

- Tuegel, E. The Airframe Digital Twin: Some Challenges to Realization. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012; American Institute of Aeronautics and Astronautics: Honolulu, Hawaii, 2012. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012; American Institute of Aeronautics and Astronautics: Honolulu, Hawaii, 2012. [Google Scholar] [CrossRef] [Green Version]

- Psarommatis, F.; May, G. A literature review and design methodology for Digital Twins in the era of zero defect manufacturing. Int. J. Prod. Res. 2022, 1–21. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Nee, A. Five-Dimension Digital Twin Modeling and Its Key Technologies. In Digital Twin Driven Smart Manufacturing; Tao, F., Zhang, M., Nee, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 3; pp. 63–81. [Google Scholar] [CrossRef]

- Minerva, R.; Lee, G.M.; Crespi, N. Digital Twin in the IoT Context: A Survey on Technical Features, Scenarios, and Architectural Models. Proc. IEEE 2020, 108, 1785–1824. [Google Scholar] [CrossRef]

- Aitken, A. Industry 4.0: Demystifying Digital Twins. Available online: https://www.lanner.com/en-us/solutions/digital-twin.html (accessed on 19 February 2022).

- Grieves, M. The Evolution of the Digital Twin: A Visionary Product Concept Brings Big Changes for the Future. IM+io Best & Next Practices aus Digitalisierung. 2018, pp. 66–69. Available online: https://www.im-io.de/worldwide/the-evolution-of-the-digital-twin/ (accessed on 28 September 2021).

- High Value Manufacturing Catapult Visualization. Feasibility of an Immersive Digital Twin. Available online: https://www.amrc.co.uk/files/document/219/1536919984_HVM_CATAPULT_DIGITAL_TWIN_DL.pdf (accessed on 2 March 2022).

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Biesinger, F.; Weyrich, M. The Facets of Digital Twins in Production and the Automotive Industry. In Proceedings of the 2019 23rd International Conference on Mechatronics Technology (ICMT), Salerno, Italy, 23–26 October 2019. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29 Pt A, 36–52. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A. Enabling technologies and tools for Digital Twin. J. Manuf. Syst. 2021, 58 Pt B, 3–21. [Google Scholar] [CrossRef]

- Lim, K.Y.H.; Zheng, P.; Chen, C.H. A state-of-the-Art Survey of Digital Twin: Techniques, Engineering Product Lifecycle Management and Business Innovation Perspectives. J. Intell. Manuf. 2020, 31, 1313–1337. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Nee, A. Background and Concept of Digital Twin. In Digital Twin Driven Smart Manufacturing; Tao, F., Zhang, M., Nee, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Chapter 1; pp. 3–28. [Google Scholar] [CrossRef]

- Pires, F.; Cachada, A.; Barbosa, J.; Moreira, A.P.; Leitão, P. Digital Twin in Industry 4.0: Technologies, Applications and Challenges. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN), Helsinki, Finland, 22–25 July 2019; pp. 721–726. [Google Scholar] [CrossRef]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H.A. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0. Available online: https://www.din.de/blob/76902/e8cac883f42bf28536e7e8165993f1fd/recommendations-for-implementing-industry-4-0-data.pdf (accessed on 2 March 2022).

- Hinduja, H.; Kekkar, S.; Chourasia, S.; Chakrapani, H.B. Industry 4.0: Digital Twin and its Industrial Applications. Int. J. Sci. Eng. Technol. 2020, 8. Available online: https://www.researchgate.net/publication/343713676_Industry_40_Digital_Twin_and_its_Industrial_Applications (accessed on 10 May 2021).

- Yablochnikov, E.I.; Chukichev, A.V.; Timofeeva, O.S.; Abyshev, O.A.; Abaev, G.E.; Colombo, A.W. Development of an industrial cyber-physical platform for small series production using Digital Twins. Philos. Trans. R. Soc. A. 2021, 379. [Google Scholar] [CrossRef]

- Pires, F.; Ahmad, B.; Moreira, A.P.; Leitão, P. Digital Twin based What-if Simulation for Energy Management. In Proceedings of the 2021 4th IEEE International Conference on Industrial Cyber-Physical Systems (ICPS), Victoria, BC, Canada, 10–12 May 2021; pp. 309–314. [Google Scholar] [CrossRef]

- Redelinghuys, A.; Basson, A.; Kruger, K. A Six-Layer Digital Twin Architecture for a Manufacturing Cell. In Service Orientation in Holonic and Multi-Agent Manufacturing. SOHOMA 2018. Studies in Computational Intelligence; Borangiu, T., Trentesaux, D., Thomas, A., Cavalieri, S., Eds.; Springer: Cham, Switzerland, 2019; Volume 803, pp. 412–423. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, A.; Wang, W. A Framework for an Indoor Safety Management System Based on Digital Twin. Sensors 2020, 20, 5771. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of Digital Twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58 Pt B, 346–361. [Google Scholar] [CrossRef]

- Watanabe, L. Telehealth & Remote Services Are More Than Just a Pandemic Stopgap. Available online: https://mobilitymgmt.com/articles/2021/02/17/editor-note-telehealth-remote-services.aspx (accessed on 19 February 2022).

- Armstrong, W.; Borg, J.; Krizack, M.; Lindsley, A.; Mines, K.; Pearlman, J.; Reisinger, K.; Sheldon, S. Guidelines on the Provision of Manual Wheelchairs in Less Resourced Settings; Technical Report; World Health Organization: Geneva, Switzerland, 2008. [Google Scholar] [CrossRef]

- Meyers, B.; Gadeyne, K.; Oakes, B.J.; Bernaerts, M.; Vangheluwe, H.; Denil, J. A Model-Driven Engineering Framework to Support the Functional Safety Process. In Proceedings of the 2019 ACM/IEEE 22nd International Conference on Model Driven Engineering Languages and Systems Companion (MODELS-C), Munich, Germany, 15–20 September 2019; pp. 619–623. [Google Scholar] [CrossRef]

- Kleidermacher, D.; Kleidermacher, M. Secure Embedded Software Development. In Embedded Systems Security; Kleidermacher, D., Kleidermacher, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; Chapter 3; pp. 93–208. [Google Scholar] [CrossRef]

- Murata, T. Petri Nets: Properties, Analysis and Applications. Proc. IEEE 1989, 77, 541–580. [Google Scholar] [CrossRef]

- Girault, C.; Valk, R. Petri Nets for Systems Engineering—A Guide to Modeling, Verification, and Applications, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar] [CrossRef]

- David, R.; Alla, H. Discrete, Continuous, and Hybrid Petri Nets, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Gomes, L.; Barros, J.P. Refining IOPT Petri Nets class for embedded system controller modeling. In Proceedings of the IECON 2018—44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 4720–4725. [Google Scholar] [CrossRef]

- Jensen, K.; Kristensen, L.M. Colored Petri nets: A Graphical Language for Formal Modeling and Validation of Concurrent Systems. Commun. ACM 2015, 58, 61–70. [Google Scholar] [CrossRef]

- Pereira, F.; Gomes, L. The IOPT-Flow modeling framework applied to Power Electronics controllers. IEEE Trans. Ind. Electron. 2017, 64, 2363–2372. [Google Scholar] [CrossRef]

- Jensen, K.; Kristensen, L.M.; Wells, L. Coloured Petri Nets and CPN Tools for modelling and validation of concurrent systems. Int. J. Softw. Tools Technol. Transf. 2007, 9, 213–254. [Google Scholar] [CrossRef]

- Pereira, F.; Moutinho, F.; Gomes, L. IOPT-Tools—Towards cloud design automation of digital controllers with Petri nets. In Proceedings of the 2014 International Conference on Mechatronics and Control (ICMC), Jinzhou, China, 3–5 July 2014; pp. 2414–2419. [Google Scholar] [CrossRef]

- Wisniewski, R.; Bazydlo, G.; Gomes, L.; Costa, A.; Wojnakowski, M. Analysis and Design Automation of Cyber-Physical System with Hippo and IOPT-Tools. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 5843–5848. [Google Scholar] [CrossRef]

- Chénier, F.; Bigras, P.; Aissaoui, R. A new dynamic model of the manual wheelchair for straight and curvilinear propulsion. In Proceedings of the 2011 IEEE International Conference on Rehabilitation Robotics, Zurich, Switzerland, 29 June–1 July 2011; pp. 1–5. [Google Scholar] [CrossRef]

- De La Cruz, C.; Bastos, T.F.; Carelli, R. Adaptive motion control law of a robotic wheelchair. Control. Eng. Pract. 2011, 19, 113–125. [Google Scholar] [CrossRef]

- Palmqvist, M.I. Model Predictive Control for Autonomous Driving of a Truck. Master’s Thesis, KTH Royal Institute of Technology School of Electrical Engineering, Stockholm, Sweden, 2016. Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2%3A930995&dswid=-6957 (accessed on 3 November 2021).

- Zhu, B.; Piao, Q.; Zhao, J.; Guo, L. Integrated chassis control for vehicle rollover prevention with neural network time-to-rollover warning metrics. Adv. Mech. Eng. 2016, 8. [Google Scholar] [CrossRef] [Green Version]

- Ceravolo, E.; Gabellone, M.; Farina, M.; Bascetta, L.; Matteucci, M. Model Predictive Control of an autonomous wheelchair. In IFAC-PapersOnLine—20th IFAC World Congress; Dochain, D., Henrion, D., Peaucelle, D., Eds.; IFAC Hosting by Elsevier Ltd.: Laxenburg, Austria, 2017; Volume 50, pp. 9821–9826. [Google Scholar] [CrossRef]

- Bardaro, G.; Bascetta, L.; Ceravolo, E.; Farina, M.; Gabellone, M.; Matteucci, M. MPC-based control architecture of an autonomous wheelchair for indoor environments. Control. Eng. Pract. 2018, 78, 160–174. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 7176-6:2018-Wheelchairs-Part 6: Determination of Maximum Speed of Electrically Powered Wheelchairs. Available online: https://www.iso.org/standard/70589.html (accessed on 14 March 2022).

- Fürnkranz, J.; Kliegr, T. A Brief Overview of Rule Learning. In Rule Technologies: Foundations, Tools, and Applications. RuleML 2015; Lecture Notes in Computer Science; Bassiliades, N., Gottlob, G., Sadri, F., Paschke, A., Roman, D., Eds.; Springer: Cham, Switzerland, 2015; Volume 9202, pp. 54–69. [Google Scholar] [CrossRef]

- Mobility Management. List of Wheelchairs Companies and Vendors in the Mobility Management Buyer’s Guide. Available online: https://buyersguide.mobilitymgmt.com/category/wheelchairs (accessed on 18 March 2022).

- Sung, J.; Trace, Y.; Peterson, E.W.; Sosnoff, J.J.; Rice, L.A. Falls among full-time wheelchair users with spinal cord injury and multiple sclerosis: A comparison of characteristics of fallers and circumstances of falls. Disabil. Rehabil. 2017, 41, 389–395. [Google Scholar] [CrossRef]

- LUCI. LUCI | Mobility. Available online: https://luci.com (accessed on 17 March 2022).

- Braze Mobility. Braze Mobility—Blind Spot Sensors for Wheelchairs. Available online: https://brazemobility.com (accessed on 17 March 2022).

- Permobil. Permobil Connect Fleet Management. Available online: https://www.permobil.com/en-us/products/power-wheelchairs/functions/fleet-management (accessed on 18 March 2022).

- Lagartinho-Oliveira, C.; Moutinho, F.; Gomes, L. Towards Digital Twin in the Context of Power Wheelchairs Provision and Support. In Technological Innovation for Digitalization and Virtualization. DoCEIS 2022. IFIP Advances in Information and Communication Technology; Camarinha-Matos, L.M., Ed.; Springer International Publishing: Cham, Switzerland, 2022; pp. 95–102. [Google Scholar] [CrossRef]

- Psarommatis, F.; May, G. A standardized approach for measuring the performance and flexibility of Digital Twins. Int. J. Prod. Res. 2022, 1–16. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lagartinho-Oliveira, C.; Moutinho, F.; Gomes, L. Digital Twin in the Provision of Power Wheelchairs Context: Support for Technical Phases and Conceptual Model. Computers 2022, 11, 166. https://doi.org/10.3390/computers11110166

Lagartinho-Oliveira C, Moutinho F, Gomes L. Digital Twin in the Provision of Power Wheelchairs Context: Support for Technical Phases and Conceptual Model. Computers. 2022; 11(11):166. https://doi.org/10.3390/computers11110166

Chicago/Turabian StyleLagartinho-Oliveira, Carolina, Filipe Moutinho, and Luís Gomes. 2022. "Digital Twin in the Provision of Power Wheelchairs Context: Support for Technical Phases and Conceptual Model" Computers 11, no. 11: 166. https://doi.org/10.3390/computers11110166