Effect of Punch Geometry on Stress and Strain Distribution During Contact Lens Demolding

Abstract

1. Introduction

2. Materials and Methods

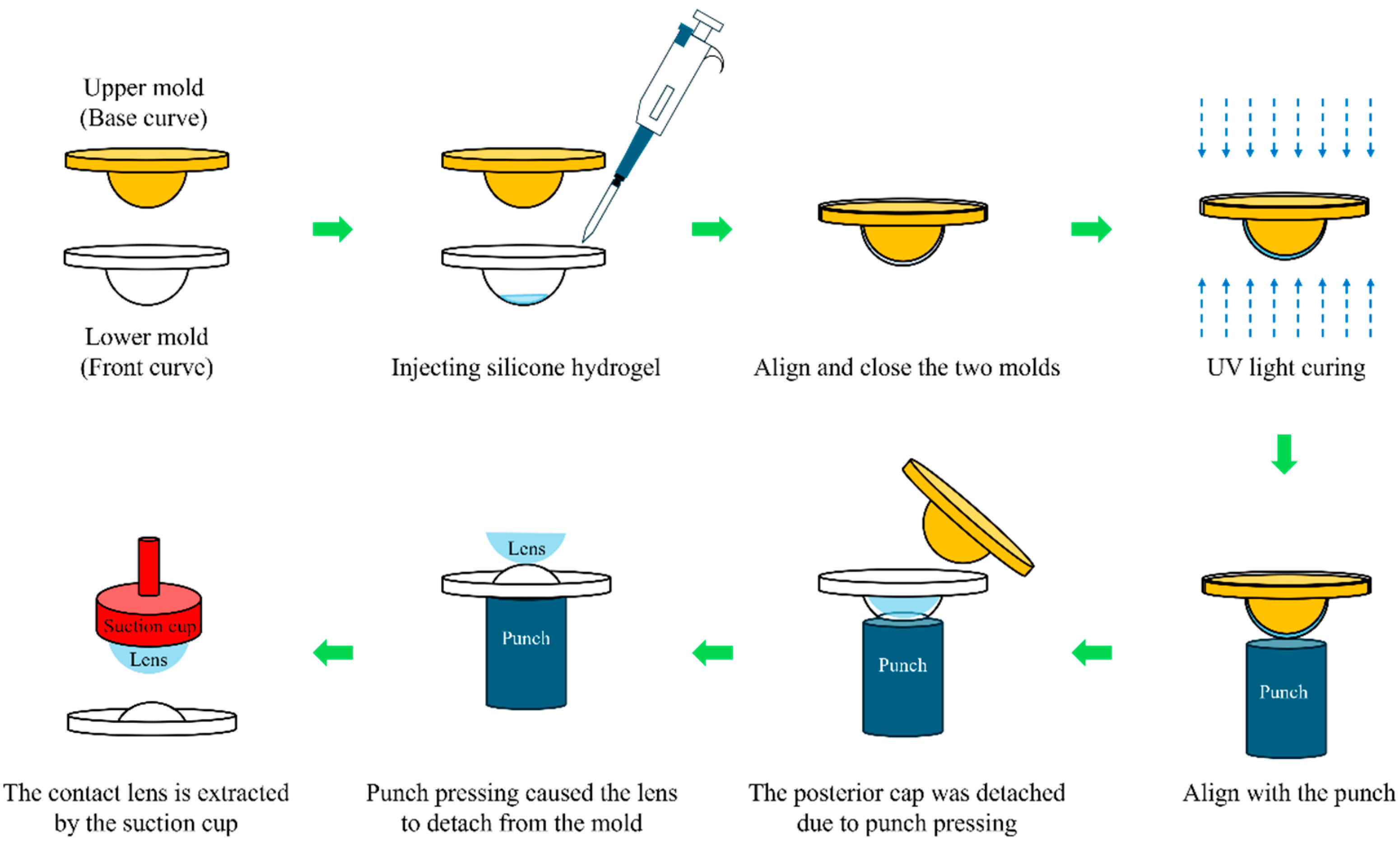

2.1. Punch-Assisted Demolding Test for Contact Lenses

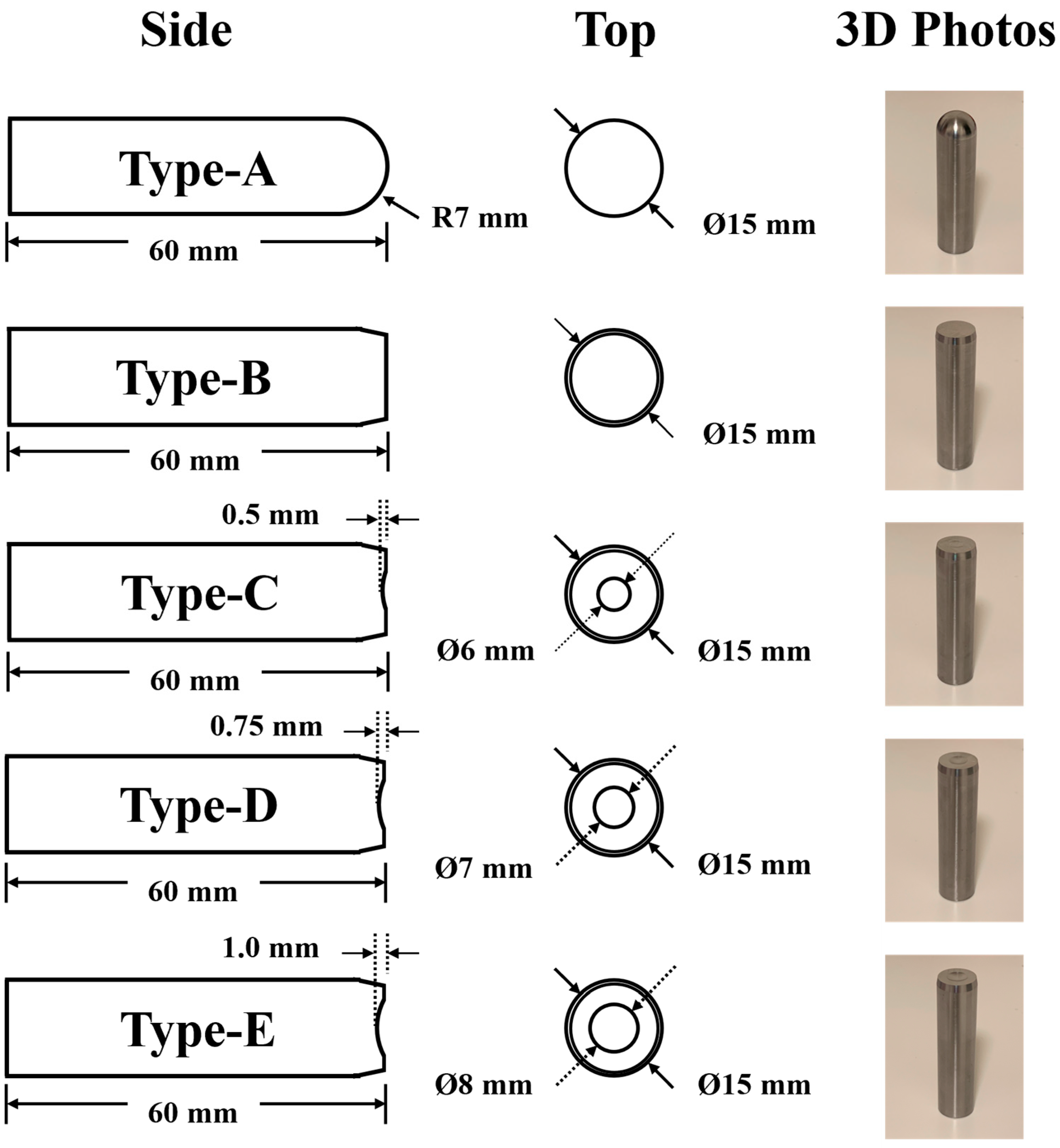

2.2. Development of the FEA Model and Fabrication of the Punch Pin

3. Results and Discussion

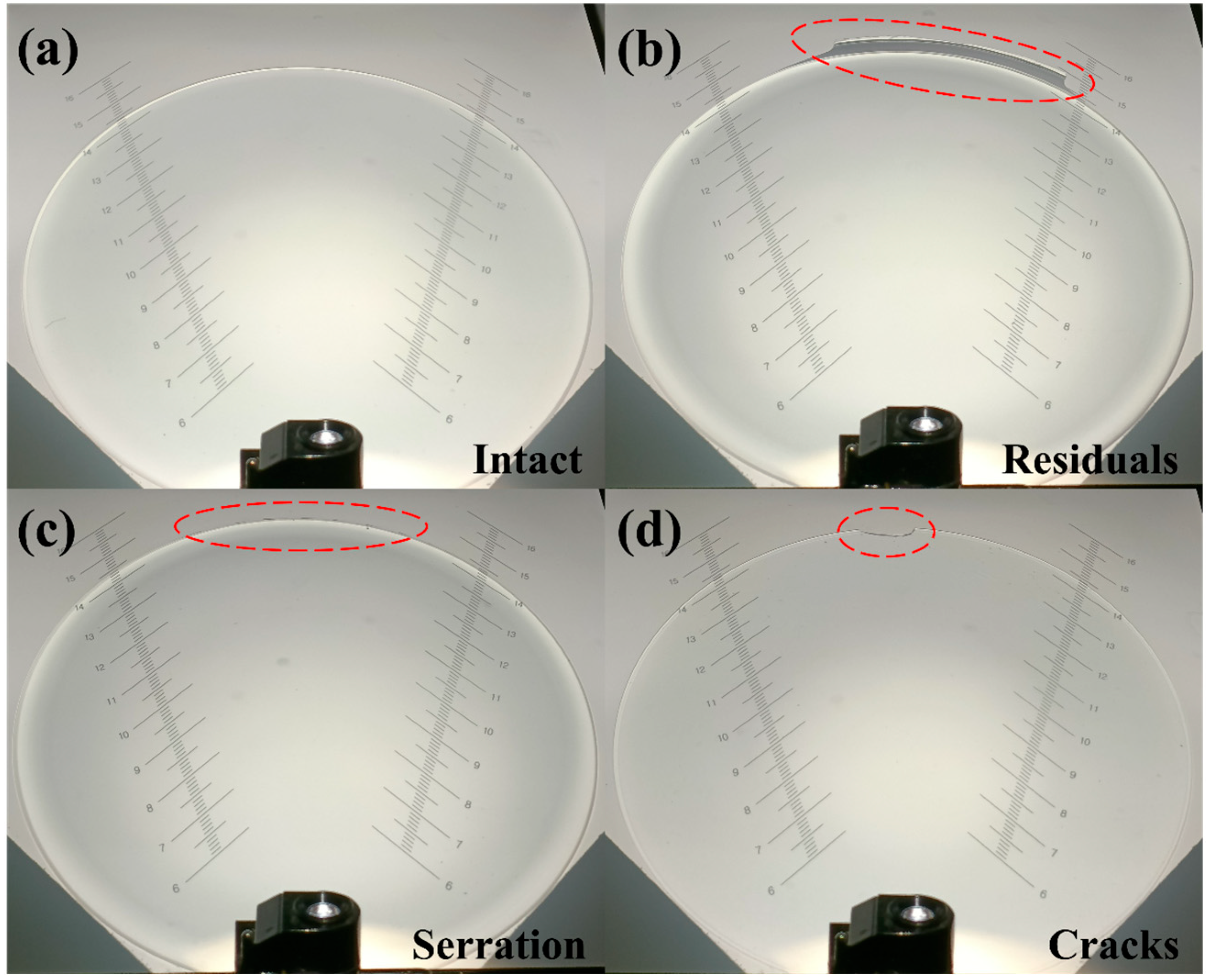

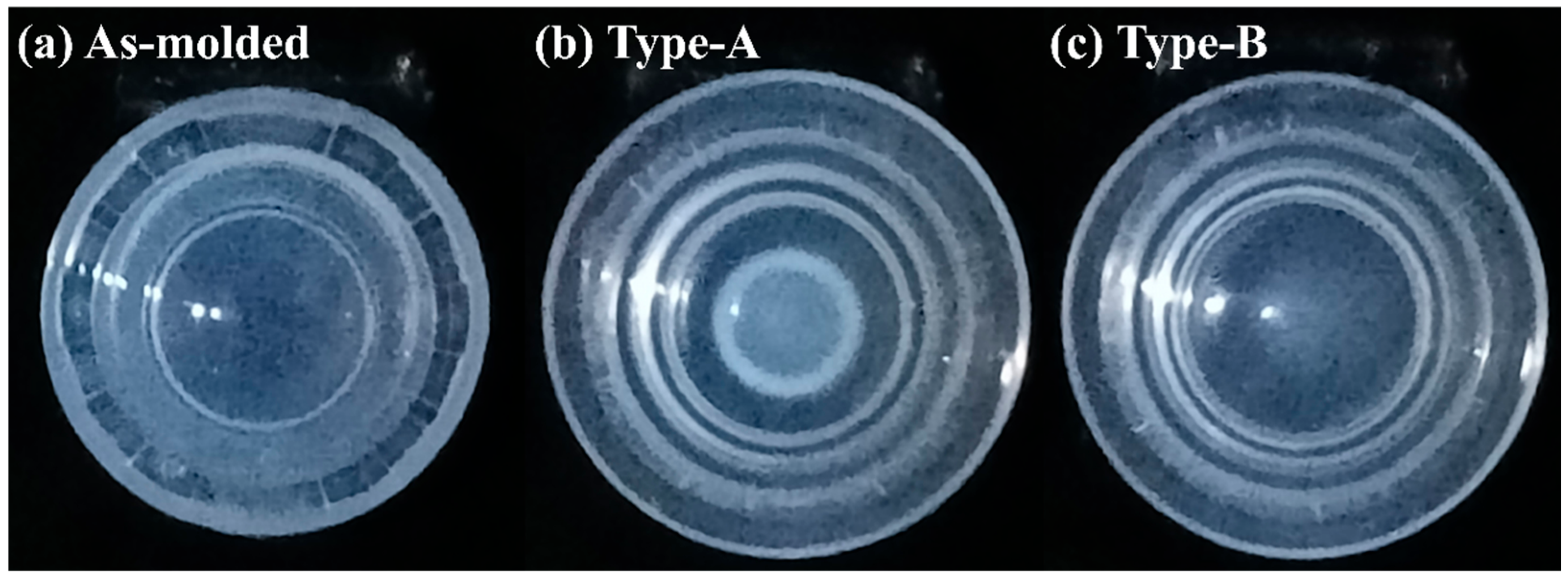

3.1. Experimental and Simulation Analysis of Type A and Type B Punches

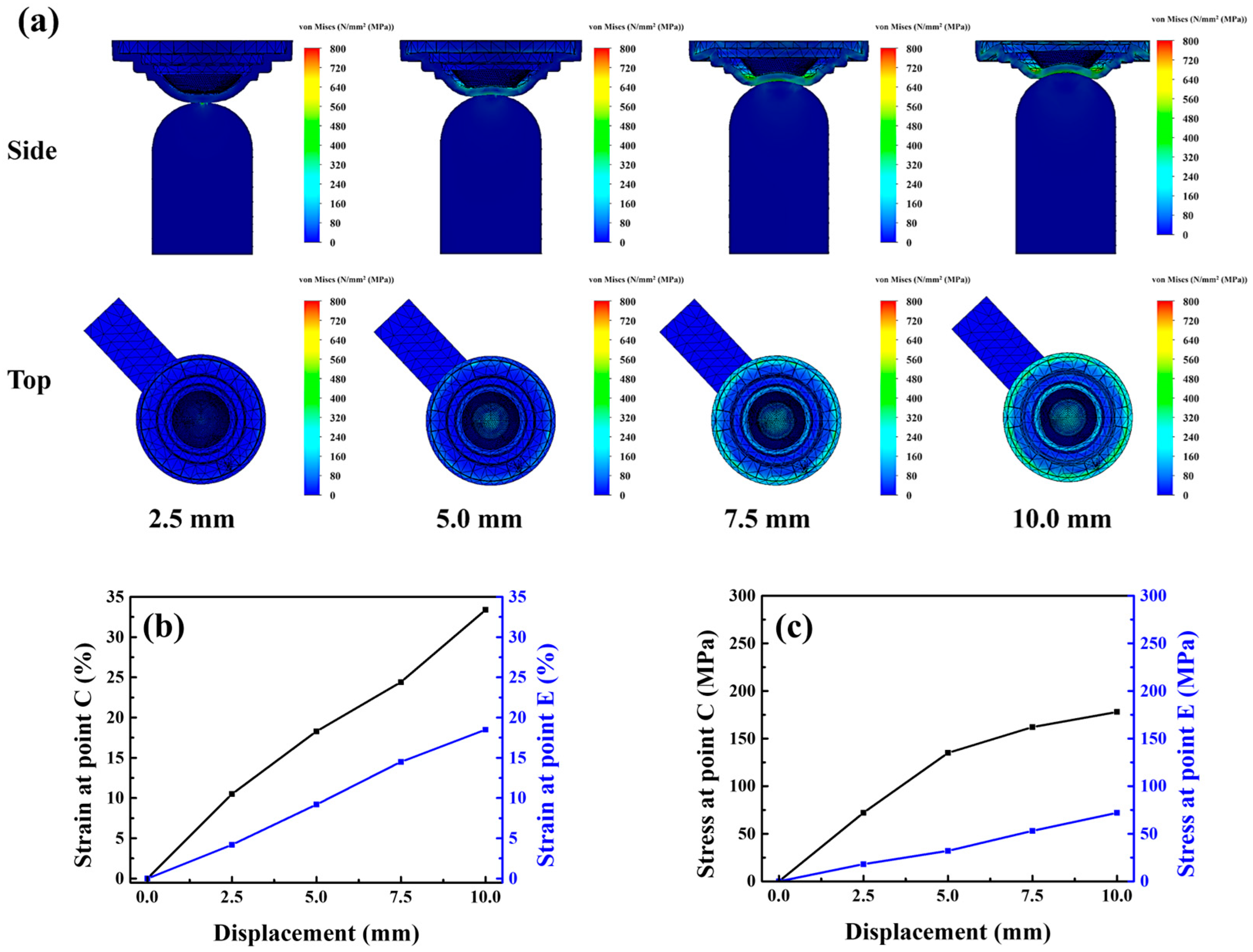

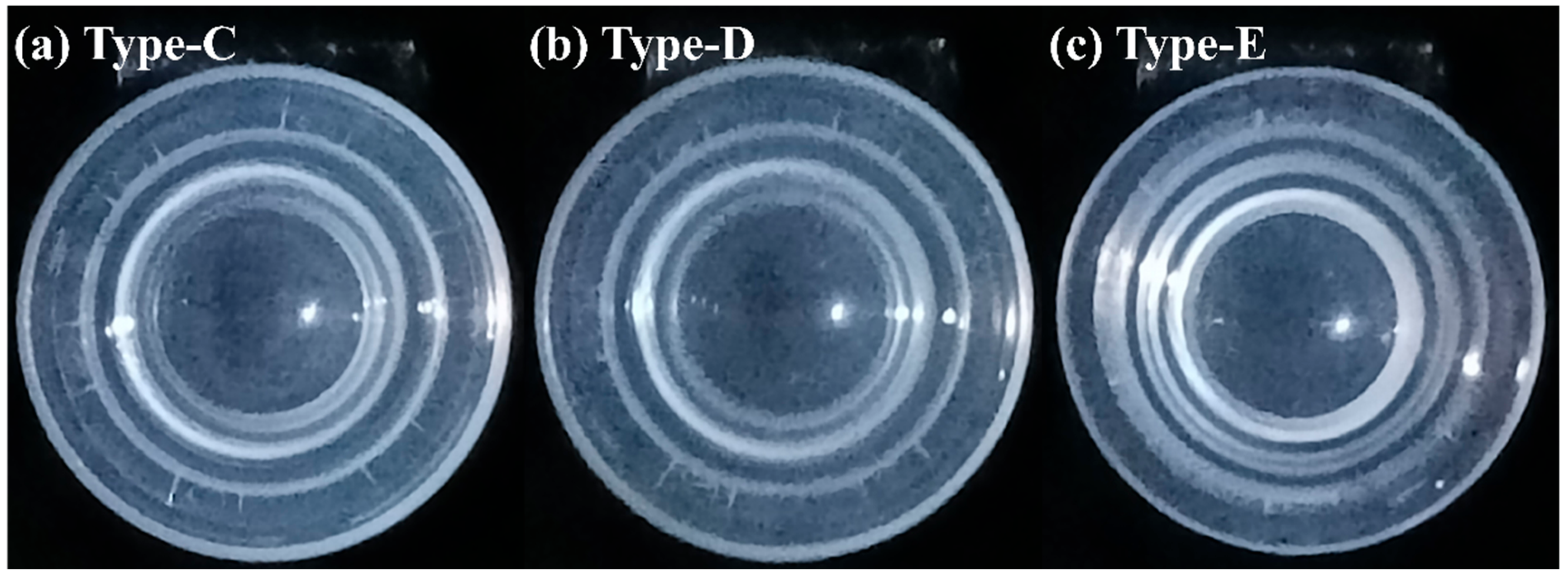

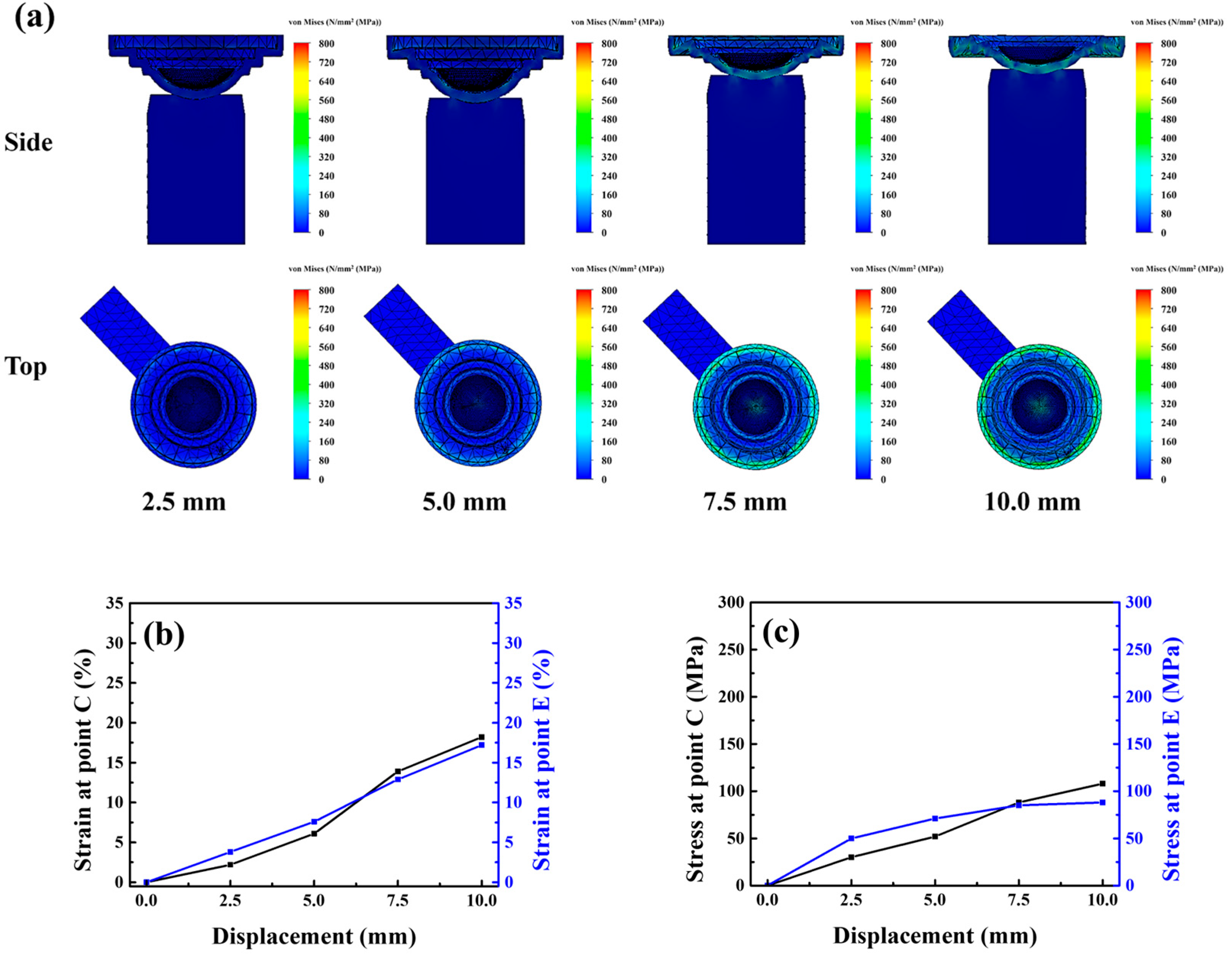

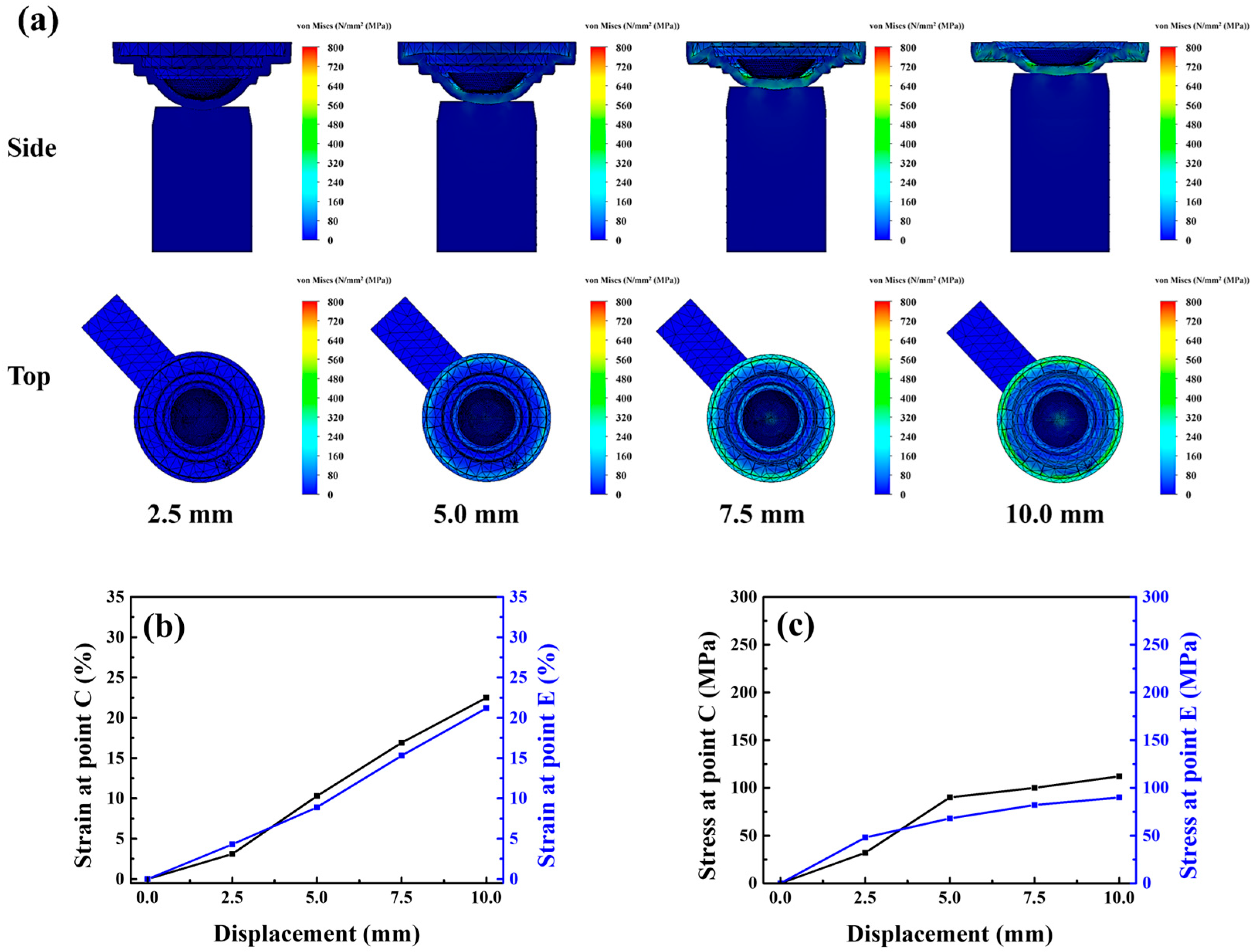

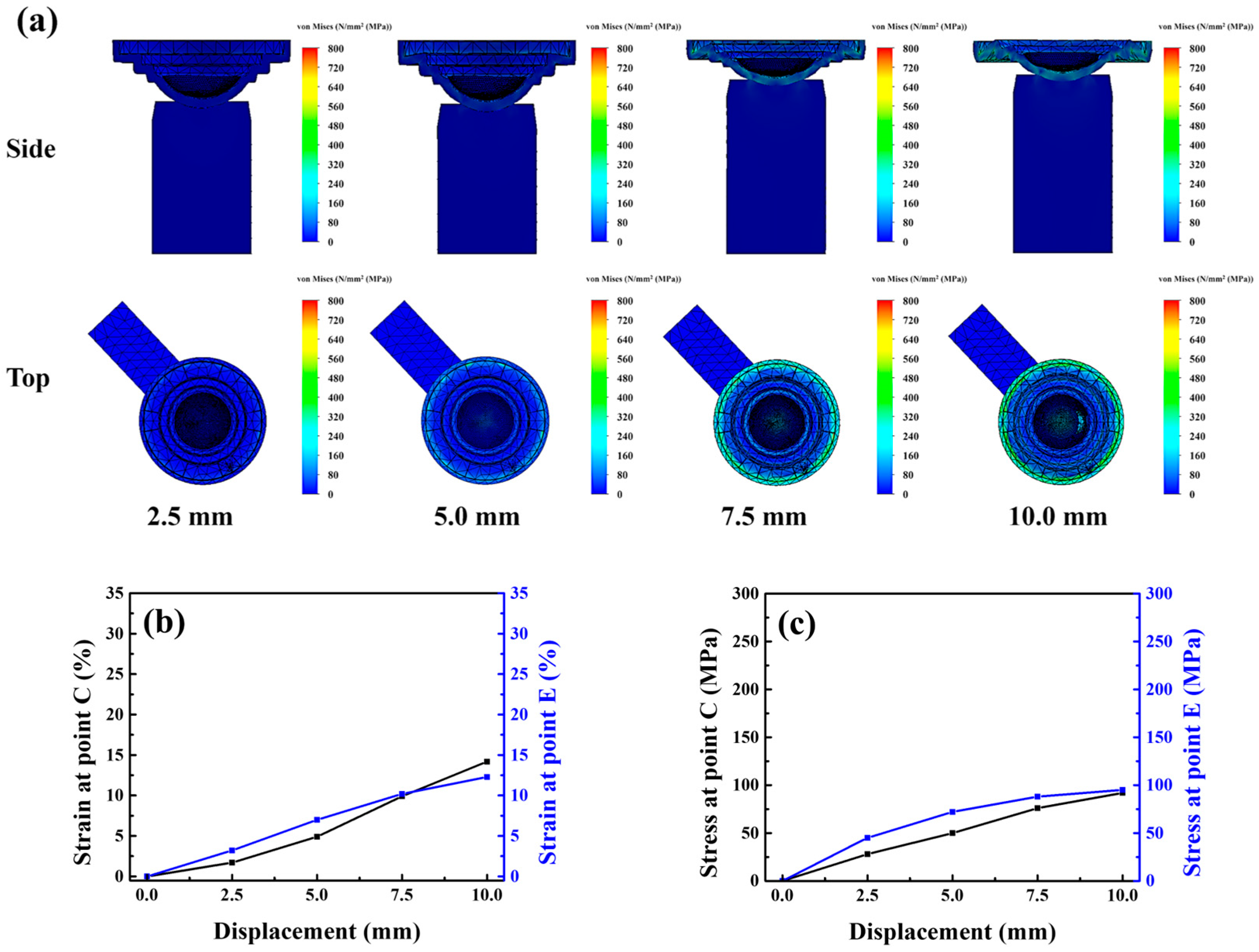

3.2. Experimental and Simulation Analysis of Improved Punch Types (C–E)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chamberlain, P.; Bradley, A.; Arumugam, B.; Hammond, D.; McNally, J.; Logan, N.S.; Jones, D.; Ngo, C.; Peixoto-de-Matos, S.C.; Hunt, C.; et al. Long-term effect of dual-focus contact lenses on myopia progression in children: A 6-year multicenter clinical trial. Optom. Vis. Sci. 2022, 99, 204. [Google Scholar] [CrossRef] [PubMed]

- Lam, C.S.Y.; Tang, W.C.; Zhang, H.Y.; Lee, P.H.; Tse, D.Y.Y.; Qi, H.; Vlasak, N.; To, C.H. Long-term myopia control effect and safety in children wearing DIMS spectacle lenses for 6 years. Sci. Rep. 2023, 13, 5475. [Google Scholar] [CrossRef] [PubMed]

- Whayeb, Y.; Wolffsohn, J.S.; Logan, N.S.; Rubido, J.S. IMI-global trends in myopia management attitudes and strategies in clinical practice—A nine-year review. Contact Lens Anterior Eye 2025, 102492. [Google Scholar] [CrossRef] [PubMed]

- Holden, B.A.; Fricke, T.R.; Wilson, D.A.; Jong, M.; Naidoo, K.S.; Sankaridurg, P.; Wong, T.Y.; Naduvilath, T.J.; Resnikoff, S. Global prevalence of myopia and high myopia and temporal trends from 2000 through 2050. Ophthalmology 2016, 123, 1036–1042. [Google Scholar] [CrossRef] [PubMed]

- Moreddu, R.; Vigolo, D.; Yetisen, A.K. Contact lens technology: From fundamentals to applications. Adv. Healthc. Mater. 2019, 8, 1900368. [Google Scholar] [CrossRef] [PubMed]

- Selinger, R.L.B. History of vision correction: Contact and intraocular lenses. MRS Bull. 1997, 22, 65. [Google Scholar] [CrossRef]

- Brennan, N.A.; Efron, N. Symptomatology of HEMA contact lens wear. Optom. Vis. Sci. 1989, 66, 834. [Google Scholar] [CrossRef] [PubMed]

- Tucker, B.; Kapoor, Y.; Elliott, S. On-line force measurement to monitor contact lens polymerization. Exp. Tech. 2014, 38, 6. [Google Scholar] [CrossRef]

- Haragâș, S.; Negrean, I.; Pop, D.; Buiga, O.; Rusu, F.M. Demolding moment calculation for injected parts with internal trapezoidal thread. Key Eng. Mater. 2016, 699, 104–109. [Google Scholar] [CrossRef]

- Wang, Y.; Weng, C.; Sun, H.; Deng, Z.; Jiang, B. Effect of interfacial interaction on the demolding deformation of injection molded microfluidic chips. Nanomaterials 2022, 12, 3416. [Google Scholar] [CrossRef] [PubMed]

- Lukášk, J.; Fenclová, T.; Tyráčkková, V.; Vacík, J. The surface treatment of polypropylene molds and its effect on the quality of cast contact lenses. J. Appl. Biomater. 1992, 3, 275. [Google Scholar] [CrossRef] [PubMed]

- Sahabudeen, H.; Machatschek, R.; Lendlein, A. Multifunctionality as design principle for contact lens materials. Multifunct. Mater. 2021, 4, 042001. [Google Scholar] [CrossRef]

- Huang, K.M.; Hsu, M.H.; Ramanuel, J.; Chang, C.H.; Wey, M.J. Improvement of product quality using negative clearance grooved punch. Int. J. Adv. Manuf. Technol. 2023, 125, 479–492. [Google Scholar] [CrossRef]

- Zhang, B.; Meng, W.J. Effects of punch geometry and grain size in micron scale compression molding of copper. Mater. Des. 2021, 206, 109807. [Google Scholar] [CrossRef]

- Wojtkowiak, D.; Talaśka, K.; Wilczyński, D.; Górecki, J.; Wałęsa, K. Determination of the effective geometrical features of the piercing punch for polymer composite belts. Int. J. Adv. Manuf. Technol. 2019, 104, 315–332. [Google Scholar] [CrossRef]

- Gaikwad, A.; Desai, S. Molecular dynamics investigation of the deformation mechanism of gold with variations in mold profiles during nanoimprinting. Materials 2021, 14, 2548. [Google Scholar] [CrossRef] [PubMed]

- Zwicke, F.; Elgeti, S. Inverse design based on nonlinear thermoelastic material models applied to injection molding. Finite Elem. Anal. Des. 2019, 165, 65–76. [Google Scholar] [CrossRef]

- Zhang, Y.; You, K.; Fang, F. Pre-compensation of mold in precision glass molding based on mathematical analysis. Micromachines 2020, 11, 1069. [Google Scholar] [CrossRef] [PubMed]

| Material | Elastic Modulus | Poisson’s Ratio | Density |

|---|---|---|---|

| Punch pin (304L stainless steel) | 193 GPa | 0.29 | 8 g/cm3 |

| Polypropylene | 1.5 GPa | 0.42 | 0.9 g/cm3 |

| Punch Pin | Lens | ||||

|---|---|---|---|---|---|

| Deviation | Damage or Edge Serration | Residuals | Failure to Demold | Total Yield | |

| Type-A | 28% | 31% | 2% | 0% | 62% |

| Type-B | 5% | 14% | 10% | 25% | 69% |

| Punch Pin | Lens | ||||

|---|---|---|---|---|---|

| Deviation | Damage or Edge Serration | Residuals | Failure to Demold | Total Yield | |

| Type-C | 13% | 15% | 2% | 0% | 78% |

| Type-D | 6% | 13% | 3% | 0% | 82% |

| Type-E | 5% | 13% | 9% | 6% | 73% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Cheng, C.-M.; Cho, Y.-S.; Cheng, T.-F.; Wang, J.-Y.; Huang, J.-J. Effect of Punch Geometry on Stress and Strain Distribution During Contact Lens Demolding. Micromachines 2026, 17, 10. https://doi.org/10.3390/mi17010010

Cheng C-M, Cho Y-S, Cheng T-F, Wang J-Y, Huang J-J. Effect of Punch Geometry on Stress and Strain Distribution During Contact Lens Demolding. Micromachines. 2026; 17(1):10. https://doi.org/10.3390/mi17010010

Chicago/Turabian StyleCheng, Ching-Mu, Yun-Shao Cho, Tieh-Fei Cheng, Jui-Yu Wang, and Jung-Jie Huang. 2026. "Effect of Punch Geometry on Stress and Strain Distribution During Contact Lens Demolding" Micromachines 17, no. 1: 10. https://doi.org/10.3390/mi17010010

APA StyleCheng, C.-M., Cho, Y.-S., Cheng, T.-F., Wang, J.-Y., & Huang, J.-J. (2026). Effect of Punch Geometry on Stress and Strain Distribution During Contact Lens Demolding. Micromachines, 17(1), 10. https://doi.org/10.3390/mi17010010