Recent Advances in the Design, Modeling, and Control of Flexure-Based Nanopositioning Stages

Abstract

1. Introduction

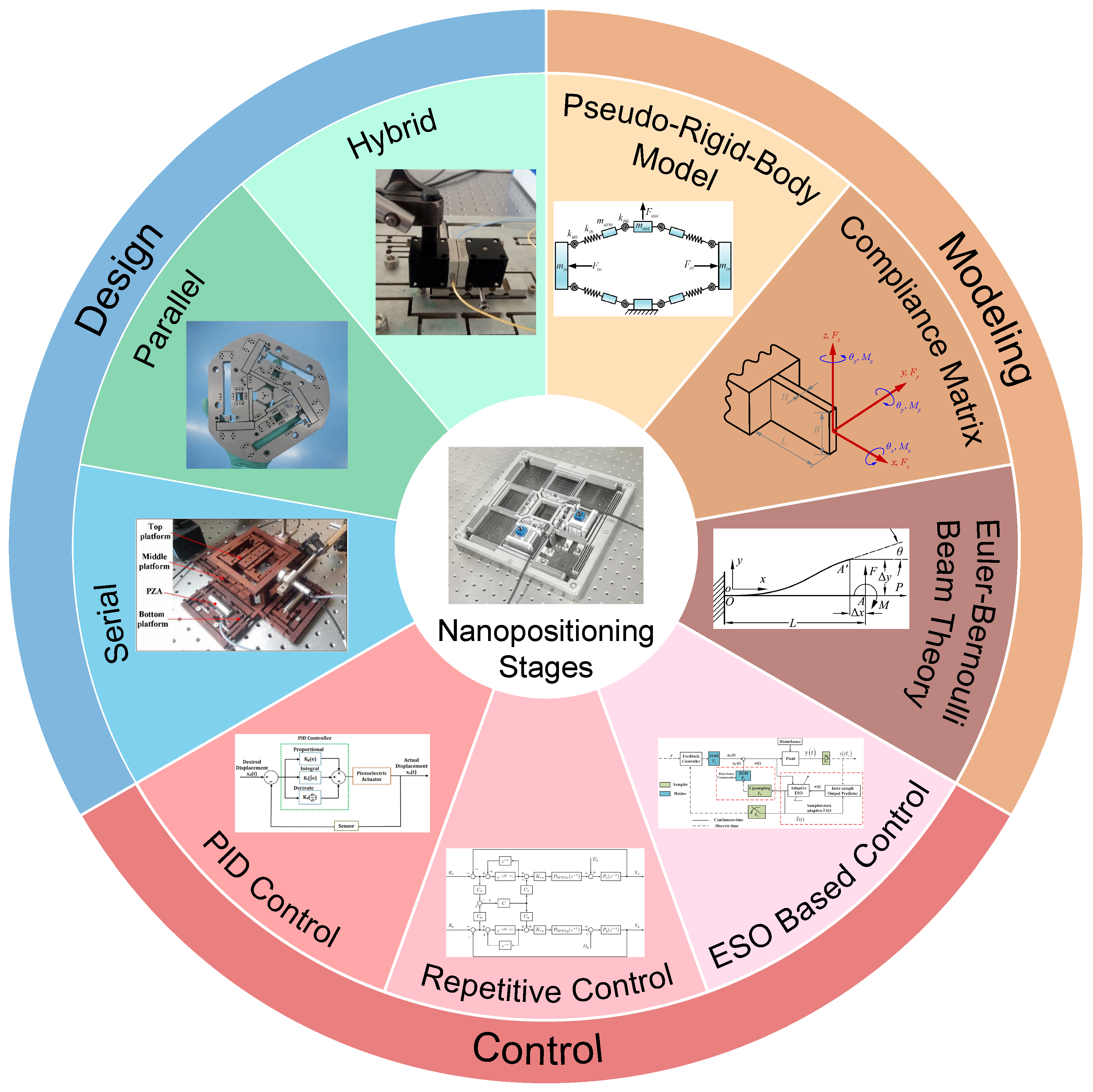

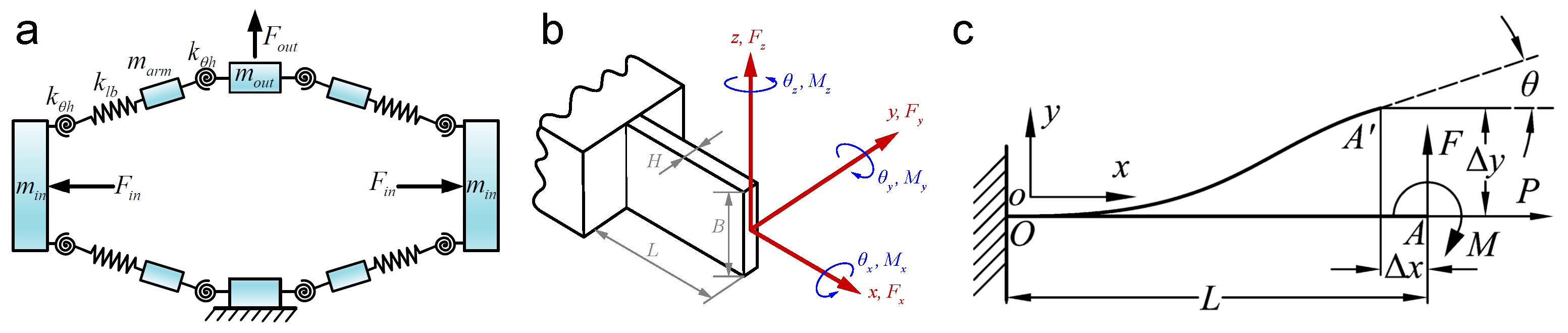

2. Geometric Design of Flexure-Based Stages

2.1. Fundamental Design Principles and Challenges

2.1.1. Motion Decoupling and Parasitic Error Minimization

2.1.2. Stiffness and Range Trade-Offs

2.1.3. Stress Concentration and Fatigue Life

2.2. Structural Topologies for Multi-DOF Systems

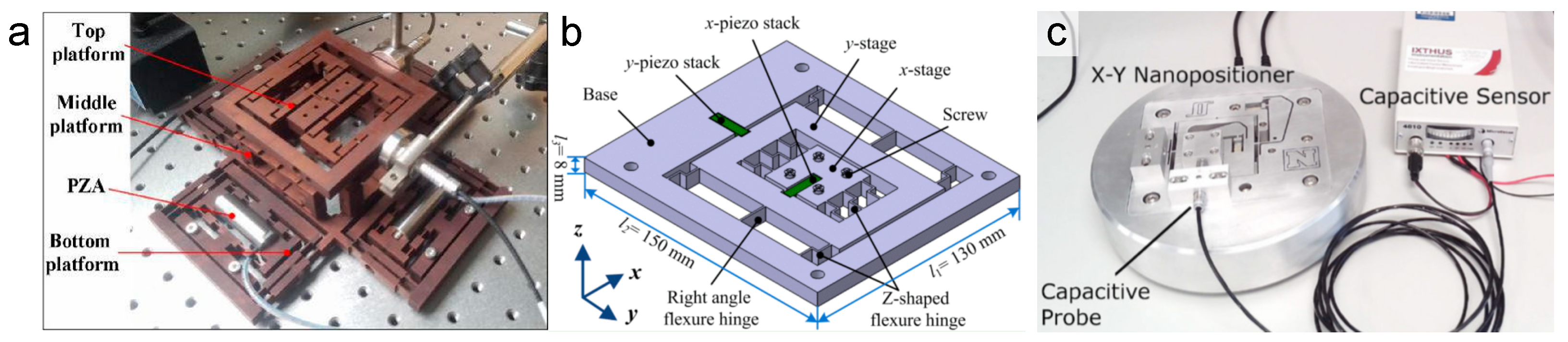

2.2.1. Serial Kinematic Structures

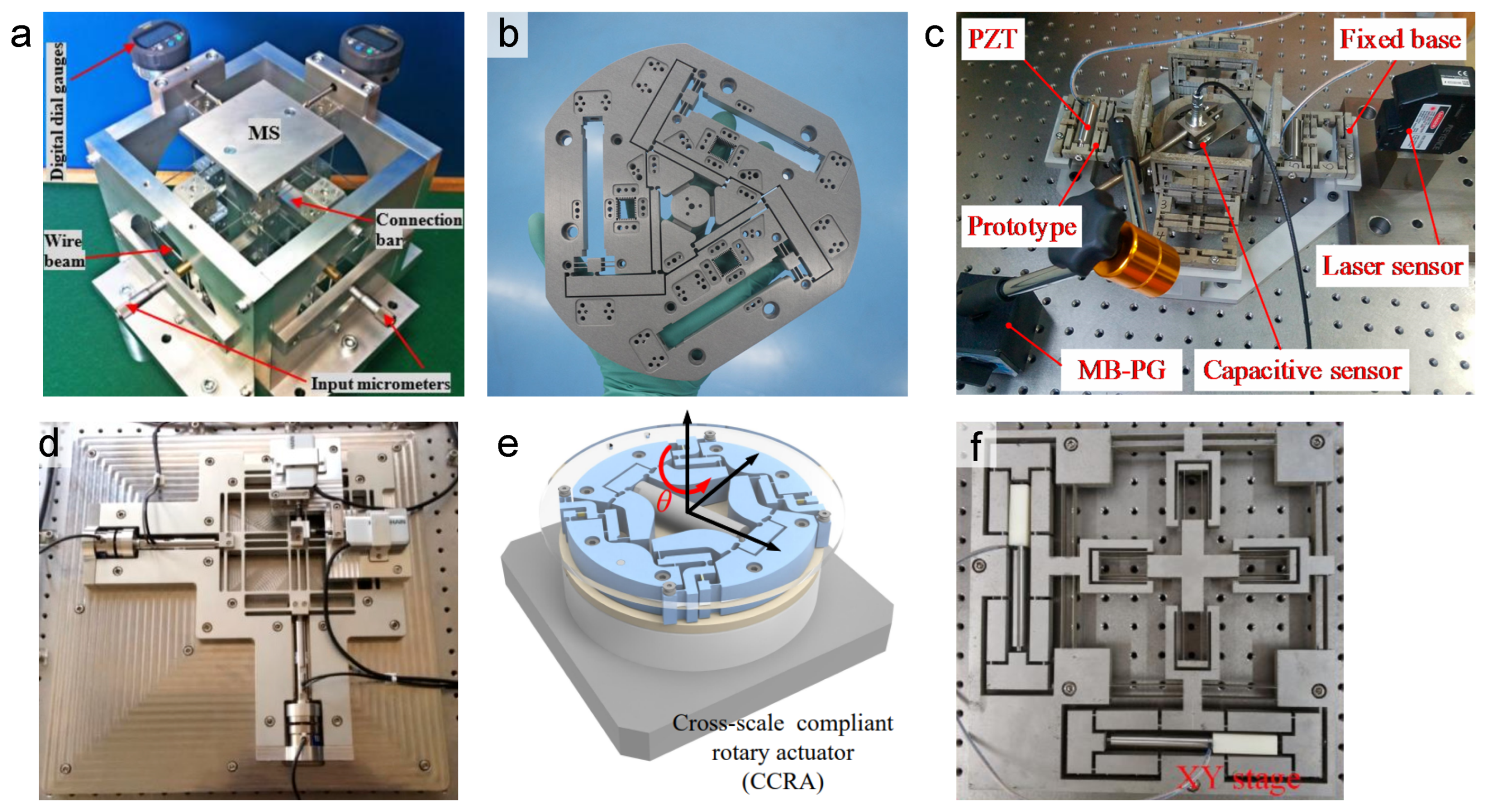

2.2.2. Parallel Kinematic Structures

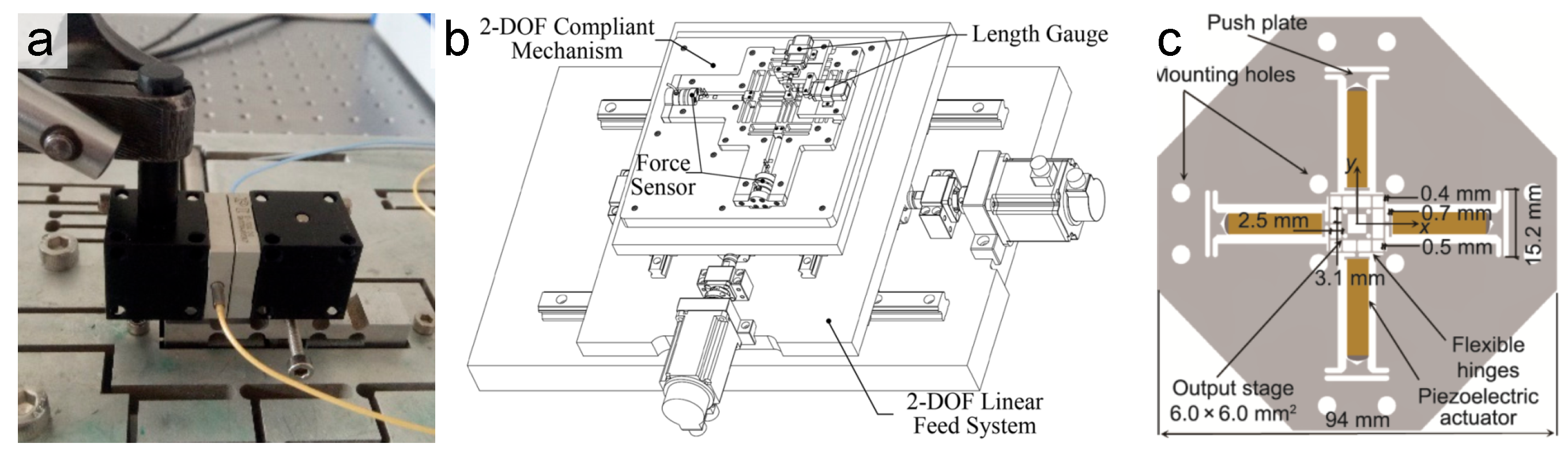

2.2.3. Hybrid Serial–Parallel Configurations

2.2.4. Topology Optimization for Performance Enhancement

2.2.5. Integrated Mechatronic Co-Design for System-Level Performance

2.3. Material Selection and Manufacturing Considerations

2.3.1. Monolithic vs. Assembled Structures

2.3.2. Additive Manufacturing and Its Impact on Design

3. Modeling and Analysis of Flexure-Based Nanopositioning Stages

3.1. Analytical and Semi-Analytical Modeling Techniques

3.1.1. The Pseudo-Rigid-Body Model

3.1.2. Stiffness Matrix (Compliance Matrix) Method

3.1.3. Euler–Bernoulli Beam Theory for Flexure Hinges

3.1.4. Multibody Dynamics Approach

3.1.5. FEA-Based Methods

3.2. Modeling Nonlinearities: Hysteresis and Creep

3.3. Model Validation and System Identification

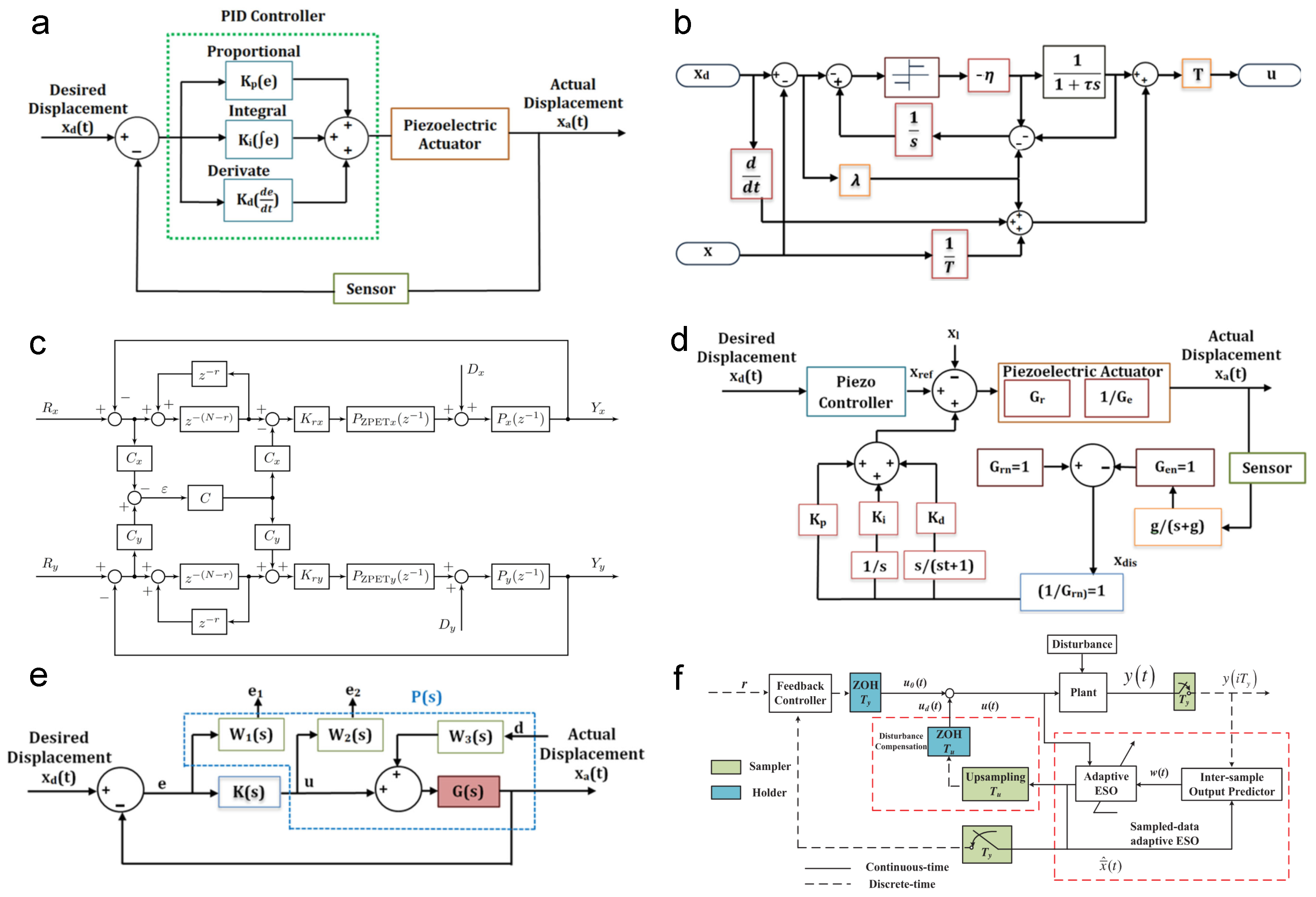

4. Control Strategies

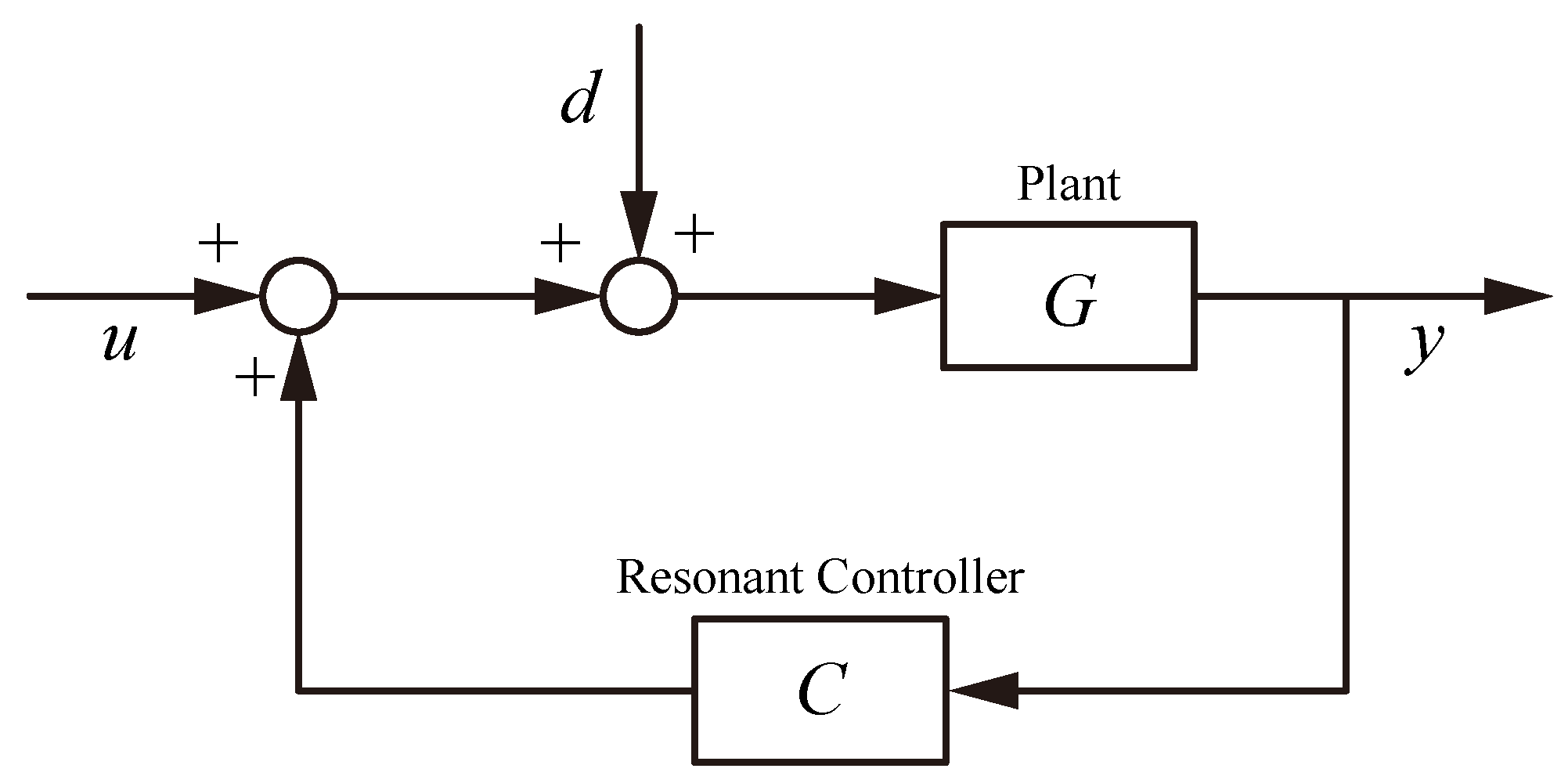

4.1. Active Resonant Control

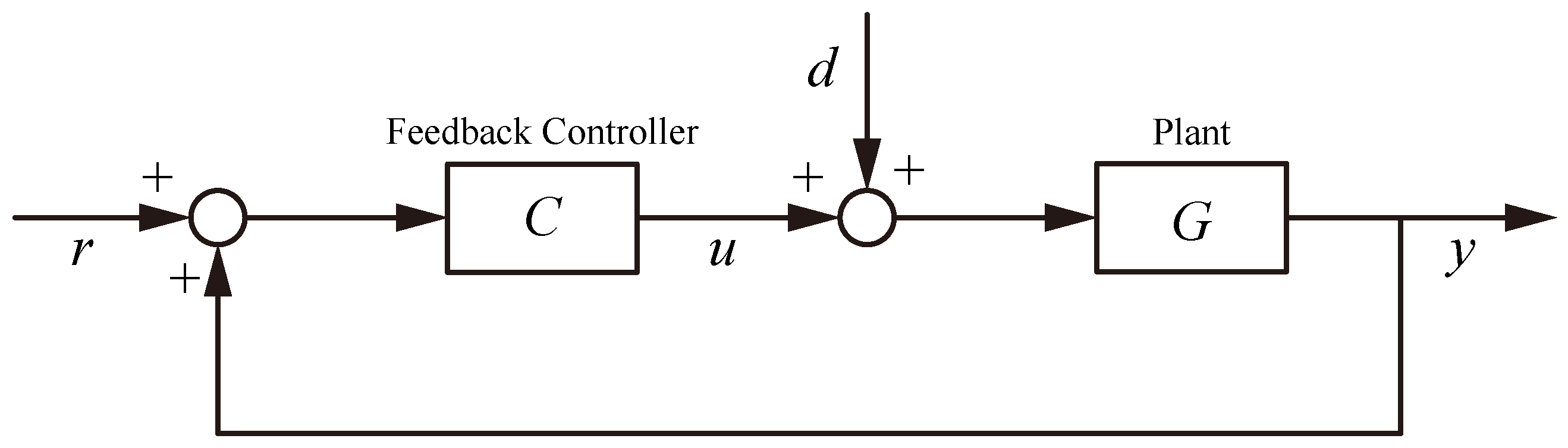

4.2. Tracking Control

4.3. Robust Control

4.4. Adaptive and Learning-Based Control

4.5. Multi-Axis Contour Tracking Control

4.6. Summary

5. Challenges and Future Outlook

5.1. High-Bandwidth Control for Flexure-Based Nanopositioning Stages

5.2. Critical Trade-Offs and Performance Boundaries

5.3. Embracing Data-Driven and AI-Enhanced Methodologies

5.4. Integration and Co-Design as a Path Forward

5.5. Future Horizons

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, R.J.; Xu, P.; Wang, P.Y.; Fan, K.C.; Cheng, R.J.; Huang, Q.X. Development of a micro/nano probing system using double elastic mechanisms. Sensors 2018, 18, 4229. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Zhao, P.; Zhang, W.; Tian, Y.; Hu, G. Design and simulation of a single piezoelectric-driven rotary actuator with double-layer flexible mechanism. Actuators 2023, 12, 231. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, K.; Ma, X.; Jia, L. A compliant leg design combining pantograph structure with leaf springs. Robotica 2024, 42, 332–346. [Google Scholar] [CrossRef]

- Li, H.; Liu, Y.; Wang, Z.; Leng, C.; Zhang, Z.; Hao, G. A constraint-flow based method of synthesizing XYθ compliant parallel mechanisms with decoupled motion and actuation characteristics. Mech. Mach. Theory 2022, 178, 105085. [Google Scholar] [CrossRef]

- Roy, N.K.; Cullinan, M.A. Design and characterization of a two-axis, flexure-based nanopositioning stage with 50 mm travel and reduced higher order modes. Precis. Eng. 2018, 53, 236–247. [Google Scholar] [CrossRef]

- Yang, S.; Chen, P.; Wang, D.; Yu, Y.; Liu, Y. Design and analysis of a 2-DOF actuator with variable stiffness based on leaf springs. J. Bionic Eng. 2022, 19, 1392–1404. [Google Scholar] [CrossRef]

- Wang, B.; Huang, Y.; Wang, Y.; Yan, P.; Pan, Q. Optimal design of micro-nano displacement driving mechanism for obtaining mechanical properties of micro structure. J. Mech. Sci. Technol. 2022, 36, 2287–2297. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, X. Parameters optimization and experiment of a planar parallel 3-DOF nanopositioning system. IEEE Trans. Ind. Electron. 2018, 65, 2388–2397. [Google Scholar] [CrossRef]

- Li, L.; Li, C.X.; Gu, G.; Zhu, L. Modified repetitive control based cross-coupling compensation approach for the piezoelectric tube scanner of atomic force microscopes. IEEE/ASME Trans. Mechatron. 2019, 24, 666–676. [Google Scholar] [CrossRef]

- Jeon, J.W.; Kim, J.M.; Lee, Y.H.; Lee, D.Y. A double-bent planar leaf flexure guide for a nano-scanner: Experimental report. J. Korean Phys. Soc. 2014, 65, 1493–1495. [Google Scholar] [CrossRef]

- Huang, W.W.; Wang, X.; Meng, Y.; Li, L.; Zhang, X.; Ren, M.; Zhu, L.M. Design, modeling and control of high-bandwidth nano-positioning stages for ultra-precise measurement and manufacturing: A survey. Int. J. Extrem. Manuf. 2024, 6, 062007. [Google Scholar] [CrossRef]

- Yang, J.; Yan, P. Design and modeling of spatial parasitic compensation mechanisms supporting triaxial compliant positioning stages. In Proceedings of the 2024 6th International Conference on Reconfigurable Mechanisms and Robots (ReMAR), Chicago, IL, USA, 23–26 June 2024; pp. 72–77. [Google Scholar] [CrossRef]

- Wang, Z.; Qian, B.; Sun, X.; Xu, M.; Liu, G. Design and analysis of a novel compliant tensile testing module based on buckled fixed-guided beam. IEEE Access 2021, 9, 136985–136993. [Google Scholar] [CrossRef]

- Wang, X.; Meng, Y.; Huang, W.W.; Li, L.; Zhu, Z.; Zhu, L. Design, modeling, and test of a normal-stressed electromagnetic actuated compliant nano-positioning stage. Mech. Syst. Signal Process. 2023, 185, 109753. [Google Scholar] [CrossRef]

- Moore, S.I.; Yong, Y.K.; Omidbeike, M.; Fleming, A.J. Serial-kinematic monolithic nanopositioner with in-plane bender actuators. Mechatronics 2021, 75, 102541. [Google Scholar] [CrossRef]

- Song, S.; Shao, S.; Xu, M.; Shao, Y.; Tian, Z.; Feng, B. Piezoelectric inchworm rotary actuator with high driving torque and self-locking ability. Sens. Actuators A Phys. 2018, 282, 174–182. [Google Scholar] [CrossRef]

- Li, J.; Zhao, H.; Shao, M.; Zhou, X.; Huang, H.; Fan, Z. Design and experiment performances of an inchworm type rotary actuator. Rev. Sci. Instrum. 2014, 85, 085004. [Google Scholar] [CrossRef]

- Lu, Y.; Yang, Y.; Xue, Y.; Jiang, J.; Zhang, Q.; Yue, H. A variable stiffness actuator based on leaf springs design, model and analysis. Actuators 2022, 11, 282. [Google Scholar] [CrossRef]

- Liu, Y.; Li, X.; Zhang, Y.; Ge, L.; Guan, Y.; Zhang, Z. Ultra-large scale stitchless AFM: Advancing nanoscale characterization and manipulation with zero stitching error and high throughput. Small 2024, 20, 2303838. [Google Scholar] [CrossRef]

- Wang, X.; Meng, Y.; Xu, Z.; Li, L.; Huang, H.; Zhu, L. Optimizing the scanning throughput of a stick-slip piezoelectric actuator by exploring the scannable trajectory set. IEEE Trans. Ind. Electron. 2024, 72, 5155–5165. [Google Scholar] [CrossRef]

- Wang, X.; Tan, L.; Yu, Q.; Wu, H.; Meng, Y.; Li, L.; Huang, H.; Zhu, L. High-throughput uniform scanning of stick-slip actuators with optimal smooth trajectory. IEEE Trans. Ind. Electron. 2025. early access. [Google Scholar] [CrossRef]

- Zhang, J.J.; Diao, W.D.; Fan, K.; Wang, Z.Q.; Shi, R.Q.; Feng, Z.H. A miniature standing wave linear ultrasonic motor. Sens. Actuators A Phys. 2021, 332, 113113. [Google Scholar] [CrossRef]

- Bian, K.; Zheng, W.; Chen, X.; Zhang, S.; Stöhr, R.; Denisenko, A.; Yang, S.; Wrachtrup, J.; Jiang, Y. A scanning probe microscope compatible with quantum sensing at ambient conditions. Rev. Sci. Instrum. 2024, 95, 053707. [Google Scholar] [CrossRef]

- Wang, L.; Guan, Y.; Liu, Y.; Deng, J.; Liu, J. A compact cantilever-type ultrasonic motor with nanometer resolution design and performance evaluation. IEEE Trans. Ind. Electron. 2021, 68, 734–743. [Google Scholar] [CrossRef]

- Yu, H.; Han, J.; Li, S.; Han, X.; Liu, Y.; Wang, J.; Lin, J. Multi-objective optimization design and performance evaluation of a novel flexure-based tri-axial servo cutting system. J. Manuf. Process. 2022, 84, 1133–1149. [Google Scholar] [CrossRef]

- Tan, L.; Wang, X.; Yu, Q.; Yu, B.; Meng, Y.; Li, L.; Zhang, X.; Zhu, L. An electromagnetic-piezoelectric hybrid actuated nanopositioner for atomic force microscopy. IEEE Trans. Instrum. Meas. 2024, 73, 7503813. [Google Scholar] [CrossRef]

- Xu, Q. Design and development of a compact flexure-based XY precision positioning system with centimeter range. IEEE Trans. Ind. Electron. 2014, 61, 893–903. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z. A large range compliant XY nano-manipulator with active parasitic rotation rejection. Precis. Eng. 2021, 72, 640–652. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Ge, L.; Zhang, Z. A large-stroke reluctance-actuated nanopositioner compliant compensator for enhanced linearity and precision motion control. IEEE/ASME Trans. Mechatron. 2024, 29, 2947–2955. [Google Scholar] [CrossRef]

- Lin, C.; Zheng, S.; Jiang, M. Dynamic analysis and experiment of 6-DOF compliant platform based on bridge-type amplifier. Micromachines 2020, 11, 1024. [Google Scholar] [CrossRef]

- Wang, R.; Wu, H. Design and performance of a spatial 6-RRRR compliant parallel nanopositioning stage. Micromachines 2022, 13, 1889. [Google Scholar] [CrossRef]

- Lv, B.; Wang, G.; Li, B.; Zhou, H.; Hu, Y. Research on a 3-DOF motion device based on the flexible mechanism driven by the piezoelectric actuators. Micromachines 2018, 9, 578. [Google Scholar] [CrossRef]

- Lin, C.; Shen, Z.; Yu, J.; Li, P.; Huo, D. Modelling and analysis of characteristics of a piezoelectric-actuated micro-/nano compliant platform using bond graph approach. Micromachines 2018, 9, 498. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Zhao, J.; Shen, X.; Xiao, Q.; Huang, J.; Wang, Y. Design, modeling, and testing of a novel XY piezo-actuated compliant micro-positioning stage. Micromachines 2019, 10, 581. [Google Scholar] [CrossRef] [PubMed]

- Kanchan, M.; Santhya, M.; Bhat, R.; Naik, N. Application of modeling and control approaches of piezoelectric actuators: A review. Technologies 2023, 11, 155. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, Z. Cross-coupled repetitive control of a compliant nanomanipulator for micro-stereolithography. IEEE Access 2019, 8, 3891–3900. [Google Scholar] [CrossRef]

- Tian, C.; Yan, P. Sampled-data adaptive ESO based composite control for nano-positioning systems. IEEE Access 2020, 8, 6358–6367. [Google Scholar] [CrossRef]

- Chen, F.; Yao, H.; Wei, J.; Zhan, S.; Bi, H. Development and test of a multimode piezomotor with active contact force adjusting. IEEE Trans. Ind. Electron. 2024, 71, 760–768. [Google Scholar] [CrossRef]

- Du, C.; Hoefnagels, J.; Bergers, L.I.J.C.; Geers, M.G.D. A uni-axial nano-displacement micro-tensile test of individual constituents from bulk material. Exp. Mech. 2017, 57, 1249–1263. [Google Scholar] [CrossRef]

- Mackertich-Sengerdy, G.; Campbell, S.D.; Werner, D.H. Tailored compliant mechanisms for reconfigurable electromagnetic devices. Nat. Commun. 2023, 14, 683. [Google Scholar] [CrossRef]

- Yu, H.; Han, J.; Li, S.; Zhao, D.; Wang, J.; Tian, Y.; Lin, J. Hierachical micro/nano structures fabrication by a novel tri-axial piezoelectric servo system. Mater. Des. 2022, 224, 111330. [Google Scholar] [CrossRef]

- Hao, G.; Kong, X. A novel large-range XY compliant parallel manipulator with enhanced out-of-plane stiffness. J. Mech. Des. 2012, 134, 061009. [Google Scholar] [CrossRef]

- Kim, D.; Kang, D.; Shim, J.; Song, I.; Gweon, D. Optimal design of a flexure hinge-based XYZ atomic force microscopy scanner for minimizing Abbe errors. Rev. Sci. Instrum. 2005, 76, 073706. [Google Scholar] [CrossRef]

- Liu, P.; Yan, P.; Özbay, H. Design and trajectory tracking control of a piezoelectric nano-manipulator with actuator saturations. Mech. Syst. Signal Process. 2018, 111, 529–544. [Google Scholar] [CrossRef]

- Chen, Y.; Lai, L.; Zhu, L. Structural design and experimental evaluation of a coarse-fine parallel dual-actuation XY flexure micropositioner with low interference behavior. Rev. Sci. Instrum. 2023, 94, 095006. [Google Scholar] [CrossRef] [PubMed]

- Awtar, S.; Parmar, G. Design of a large range XY nanopositioning system. J. Mech. Robot. 2013, 5, 021008. [Google Scholar] [CrossRef]

- Zhang, Z.; Yan, P.; Hao, G. A large range flexure-based servo system supporting precision additive manufacturing. Engineering 2017, 3, 708–715. [Google Scholar] [CrossRef]

- Wu, P.; Zhao, P.; Li, Z.; Wu, J.; Tan, J. Investigation on the bending mechanism of single-crystal copper under high bending rates via molecular dynamics. Micromachines 2025, 16, 314. [Google Scholar] [CrossRef]

- Li, R. Analytical solution of stiffness for a corner-fillet leaf-spring type flexure hinge with a long fatigue life. Int. J. Mech. Eng. Appl. 2018, 6, 64. [Google Scholar] [CrossRef]

- Li, R.; Yang, Z.; Cai, B.; Chen, G.; Wu, B.; Wei, Y. A compliant guiding mechanism utilizing orthogonally oriented flexures with enhanced stiffness in degrees-of-constraint. Mech. Mach. Theory 2022, 167, 104555. [Google Scholar] [CrossRef]

- Yu, J.; Xie, Y.; Li, Z.; Hao, G. Design and experimental testing of an improved large-range decoupled XY compliant parallel micromanipulator. J. Mech. Robot. 2015, 7, 044503. [Google Scholar] [CrossRef]

- Liu, G.; Liu, P.; Yan, P.; Shi, Y. Design and analysis of an active swing decoupling compliant mechanism with multiple co-directional input branches. J. Mech. Robot. 2024, 16, 021004. [Google Scholar] [CrossRef]

- Ling, M.; Zhao, L.; Wu, S.; Chen, L.; Sun, L. Nonlinear evaluation of a large-stroke coiled L-shape compliant guiding mechanism with constant stiffness. J. Mech. Des. 2024, 146, 063301. [Google Scholar] [CrossRef]

- Yu, J.; Li, Z.; Lu, D.; Zong, G.; Hao, G. Design and analysis of new large-range XY compliant parallel micromanipulators. In Proceedings of the Volume 5A: 38th Mechanisms and Robotics Conference, Buffalo, NY, USA, 17–20 August 2014; p. V05AT08A038. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z. A large range compliant nano-manipulator supporting electron beam lithography. J. Mech. Des. 2022, 144, 043303. [Google Scholar] [CrossRef]

- Ji, C.; Zhang, Z.; Cheng, G.; Kong, M.; Li, R. Design, modeling, and control of a compact and reconfigurable variable stiffness actuator using disc spring. J. Mech. Robot. 2024, 16, 091006. [Google Scholar] [CrossRef]

- Zhu, W.L.; Zhu, Z.; Shi, Y.; Chen, X.; He, Y.; Ehmann, K.F.; Ju, B.F. A novel piezoelectrically actuated 2-DoF compliant micro/nano-positioning stage with multi-level amplification. Rev. Sci. Instrum. 2016, 87, 105006. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Ma, Y.; Wang, F.; Lu, K.; Zhang, D. A novel XYZ micro/nano positioner with an amplifier based on L-shape levers and half-bridge structure. Sens. Actuators A Phys. 2020, 302, 111777. [Google Scholar] [CrossRef]

- Pinskier, J.; Shirinzadeh, B.; Al-Jodah, A. Design and evaluation of a dual-stage, compensated stick-slip actuator for long-range, precision compliant mechanisms. Sens. Actuators A Phys. 2021, 331, 113007. [Google Scholar] [CrossRef]

- Wang, K.; Huang, P.; Liu, Q.; Zhu, L.; Zhu, Z. Generalized element-node complete model and its implementation for the optimal design of a piezo-actuated compliant amplifier. Rev. Sci. Instrum. 2023, 94, 085004. [Google Scholar] [CrossRef]

- Zhu, H.; Pang, C.K.; Teo, T.J. A flexure-based parallel actuation dual-stage system for large-stroke nanopositioning. IEEE Trans. Ind. Electron. 2017, 64, 5553–5563. [Google Scholar] [CrossRef]

- Wang, X.; Li, L.; Meng, Y.; Tan, L.; Huang, W.W.; Zhu, Z.; Jiao, F.; Zhu, L. A normal-stressed electromagnetic-driven stiffness-tunable nanopositioner. IEEE Trans. Ind. Electron. 2024, 71, 15130–15139. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Q. Design, fabrication and testing of a novel symmetrical 3-DOF large-stroke parallel micro/nano-positioning stage. Robot. Comput. Integr. Manuf. 2018, 54, 162–172. [Google Scholar] [CrossRef]

- Cai, K.; Tian, Y.; Wang, F.; Zhang, D.; Shirinzadeh, B. Development of a piezo-driven 3-DOF stage with T-shape flexible hinge mechanism. Robot. Comput. Integr. Manuf. 2016, 37, 125–138. [Google Scholar] [CrossRef]

- Guo, Z.Y.; Zhang, W.C.; Tian, Y.L.; Zhang, Z.Q.; Cao, Y.R.; Lu, X.C.; Zhang, T.G. Design, modeling, and testing of a one degree of freedom manipulator with three-stage amplification mechanism. Rev. Sci. Instrum. 2022, 93, 123705. [Google Scholar] [CrossRef] [PubMed]

- Li, R.J.; Wang, P.Y.; Li, D.D.; Fan, K.C.; Liu, F.F.; Chen, L.J.; Huang, Q.X. Precision manufacturing of patterned beryllium bronze leaf springs via chemical etching. Appl. Sci. 2018, 8, 1476. [Google Scholar] [CrossRef]

- Li, R.J.; Fan, K.C.; Miao, J.W.; Huang, Q.X.; Tao, S.; Gong, E.m. An analogue contact probe using a compact 3D optical sensor for micro/nano coordinate measuring machines. Meas. Sci. Technol. 2014, 25, 094008. [Google Scholar] [CrossRef]

- Jiang, B.; Dong, Y.; Zhang, Z.; Li, X.; Wei, Y.; Guo, Y.; Liu, H. Integrating a physical model with multi-objective optimization for the design of optical angle nano-positioning mechanism. Appl. Sci. 2024, 14, 3756. [Google Scholar] [CrossRef]

- Li, R.; Yang, Z.; Chen, G.; Wu, B. Analytical solutions for nonlinear deflections of corner-fillet leaf-springs. Mech. Mach. Theory 2021, 157, 104182. [Google Scholar] [CrossRef]

- Mei, F.; Bi, S.; Chen, L.; Gao, H. A novel design of planar high-compliance joint in variable stiffness module with multiple uniform stress leaf branches on rigid-flexible integral linkage. Mech. Mach. Theory 2022, 174, 104889. [Google Scholar] [CrossRef]

- Bai, R.; Zhang, H.; Yang, N.; Yu, Z.; Li, B.; Xu, Q.; Chen, G. Optimization of a near-zero-center-shift compliant pivot for large motion range and high bearing stiffness. Mech. Mach. Theory 2025, 216, 106218. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, Q. Survey on recent designs of compliant micro-nano-positioning stages. Actuators 2018, 7, 5. [Google Scholar] [CrossRef]

- Tian, Y.; Huo, Z.; Wang, F.; Liang, C.; Shi, B.; Zhang, D. A novel friction-actuated 2-DOF high precision positioning stage with hybrid decoupling structure. Mech. Mach. Theory 2022, 167, 104511. [Google Scholar] [CrossRef]

- Kim, H.; Gweon, D.G. Development of a compact and long range XYθz nano-positioning stage. Rev. Sci. Instrum. 2012, 83, 085102. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Xie, X.; Tan, R.; Fan, D. Compact design of a novel linear compliant positioning stage with high out-of-plane stiffness and large travel. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 2265–2279. [Google Scholar] [CrossRef]

- Li, J.; Liu, H.; Zhao, H. A compact 2-DOF piezoelectric-driven platform based on “Z-shaped” flexure hinges. Micromachines 2017, 8, 245. [Google Scholar] [CrossRef] [PubMed]

- Altaher, M.; Aphale, S.S. Enhanced positioning bandwidth in nanopositioners via strategic pole placement of the tracking controller. Vibration 2019, 2, 49–63. [Google Scholar] [CrossRef]

- Cai, K.; Tian, Y.; Liu, X.; Zhang, D.; Shang, J.; Shirinzadeh, B. Development and control methodologies for 2-DOF micro/nano positioning stage with high out-of-plane payload capacity. Robot. Comput. Integr. Manuf. 2019, 56, 95–105. [Google Scholar] [CrossRef]

- Kang, D.; Gweon, D. Development of flexure based 6-degrees of freedom parallel nano-positioning system with large displacement. Rev. Sci. Instrum. 2012, 83, 035003. [Google Scholar] [CrossRef]

- Li, Y.; Huang, J.; Tang, H. A compliant parallel XY micromotion stage with complete kinematic decoupling. IEEE Trans. Autom. Sci. Eng. 2012, 9, 538–553. [Google Scholar] [CrossRef]

- Cui, M.; Shang, E.; Jiang, S.; Liu, Y.; Zhang, Z. Design, fabrication and implementation of a high-performance compliant nanopositioner via 3D printing with continuous fiber-reinforced composite. J. Micromechan. Microeng. 2021, 31, 125012. [Google Scholar] [CrossRef]

- Lee, H.J.; Woo, S.; Park, J.; Jeong, J.H.; Kim, M.; Ryu, J.; Gweon, D.G.; Choi, Y.M. Compact compliant parallel XY nano-positioning stage with high dynamic performance, small crosstalk, and small yaw motion. Microsyst. Technol. 2018, 24, 2653–2662. [Google Scholar] [CrossRef]

- Li, P.; Tong, Z.R.; Zhang, W.H. Analytical model establishment and attitude calculation of a parallel leaf-spring carrying mechanism. Mech. Sci. 2022, 13, 311–320. [Google Scholar] [CrossRef]

- Xu, Q. New flexure parallel-kinematic micropositioning system with large workspace. IEEE Trans. Robot. 2012, 28, 478–491. [Google Scholar] [CrossRef]

- Li, H.; Hao, G. Position-space-based design of a symmetric spatial translational compliant mechanism for micro-/nano-manipulation. Micromachines 2018, 9, 189. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Y.; Li, T.; Wang, L.; Chen, F. Systematic design method and experimental validation of a 2-DOF compliant parallel mechanism with excellent input and output decoupling performances. Appl. Sci. 2017, 7, 591. [Google Scholar] [CrossRef]

- Jia, Y.; Cao, J.; Liao, Z.; Wu, W.; Tang, H.; Tian, Y.; Wei, Y. The design and testing of a cross-scale compliant rotary actuator with minimum actuation redundancy and sub-microradian resolution. Actuators 2025, 14, 284. [Google Scholar] [CrossRef]

- Nagel, W.S.; Andersson, S.B.; Clayton, G.M.; Leang, K.K. Low-coupling hybrid parallel-serial-kinematic nanopositioner with nonorthogonal flexure nonlinear design and control. IEEE/ASME Trans. Mechatron. 2022, 27, 3683–3693. [Google Scholar] [CrossRef]

- Wang, X.; Yu, B.; Tan, L.; Meng, Y.; Yu, Q.; Li, L.; Zhu, Z.; Zhu, L. Serial-kinematic hybrid electromagnetic-piezoelectric AFM scanner for high-throughput raster scanning. IEEE Trans. Ind. Electron. 2024, 72, 1003–1013. [Google Scholar] [CrossRef]

- Wang, L.P.; Jiang, Y.; Li, T.M. Analytical compliance modeling of serial flexure-based compliant mechanism under arbitrary applied load. Chin. J. Mech. Eng. 2017, 30, 951–962. [Google Scholar] [CrossRef]

- Sun, H.; Xing, N.; Zou, J.; Rong, Y.; Shi, Y.; Ding, H.; Zhang, H.T. Neural network-based switching output regulation control for high-speed nano-positioning stages. Engineering 2025, in press. [Google Scholar] [CrossRef]

- Guo, Z.; Tian, Y.; Zhang, D.; Wang, T.; Wu, M. A novel stick-slip based linear actuator using bi-directional motion of micropositioner. Mech. Syst. Signal Process. 2019, 128, 37–49. [Google Scholar] [CrossRef]

- Sun, X.; Wang, Z.; Yang, Y. Design and experimental investigation of a novel compliant positioning stage with low-frequency vibration isolation capability. Sens. Actuators A Phys. 2019, 295, 439–449. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, J.; Ding, H. Design and analysis of a novel compliant mechanism with RPR degrees of freedom. Chin. J. Mech. Eng. 2022, 35, 124. [Google Scholar] [CrossRef]

- Huang, S.C.; Dao, T.P. Design and computational optimization of a flexure-based XY positioning platform using FEA-based response surface methodology. Int. J. Precis. Eng. Manuf. 2016, 17, 1035–1048. [Google Scholar] [CrossRef]

- Pham, M.T.; Teo, T.J.; Yeo, S.H.; Wang, P.; Nai, M.L.S. A 3-D printed Ti-6Al-4V 3-DOF compliant parallel mechanism for high precision manipulation. IEEE/ASME Trans. Mechatron. 2017, 22, 2359–2368. [Google Scholar] [CrossRef]

- Chen, W.; Chen, S.; Qu, J.; Chen, W. A large-range compliant remote center of motion stage with input/output decoupling. Precis. Eng. 2018, 51, 468–480. [Google Scholar] [CrossRef]

- Fan, S.; Liu, H.; Fan, D. Design and development of a novel monolithic compliant XY stage with centimeter travel range and high payload capacity. Mech. Sci. 2018, 9, 161–176. [Google Scholar] [CrossRef]

- Xu, P.; Li, R.J.; Shen, Y.; Lin, R.W.; Yao, P.; Cheng, Z.Y.; Zhang, L.S.; Huang, Q.X.; Cheng, F. Nano precision noncontact probing system using tungsten ball tip for high aspect ratio structures with horizontal internal dimensions below 100 µm. IEEE Trans. Instrum. Meas. 2024, 73, 1001810. [Google Scholar] [CrossRef]

- Cai, K.; Tian, Y.; Wang, F.; Zhang, D.; Liu, X.; Shirinzadeh, B. Modeling and tracking control of a novel XYθz stage. Microsyst. Technol. 2017, 23, 3575–3588. [Google Scholar] [CrossRef]

- Cai, K.; Tian, Y.; Wang, F.; Zhang, D.; Liu, X.; Shirinzadeh, B. Design and control of a 6-degree-of-freedom precision positioning system. Robot. Comput. Integr. Manuf. 2017, 44, 77–96. [Google Scholar] [CrossRef]

- Wan, S.; Xu, Q. Design and analysis of a new compliant XY micropositioning stage based on Roberts mechanism. Mech. Mach. Theory 2016, 95, 125–139. [Google Scholar] [CrossRef]

- Wang, S.; Rong, W.; Wang, L.; Pei, Z.; Sun, L. A novel inchworm type piezoelectric rotary actuator with large output torque: Design, analysis and experimental performance. Precis. Eng. 2018, 51, 545–551. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, X.; Yan, P. Large dynamic range tracking of an XY compliant nanomanipulator with cross-axis coupling reduction. Mech. Syst. Signal Process. 2019, 117, 757–770. [Google Scholar] [CrossRef]

- Xu, Q. Design, testing and precision control of a novel long-stroke flexure micropositioning system. Mech. Mach. Theory 2013, 70, 209–224. [Google Scholar] [CrossRef]

- Lee, C.; Stepanick, C.K.; Lee, S.K.; Tarbutton, J.A. Cross-coupling effect of large range XY nanopositioning stage fabricated by stereolithography process. Precis. Eng. 2016, 46, 81–87. [Google Scholar] [CrossRef]

- Wang, Y.; Yan, P. A novel bidirectional complementary-type inchworm actuator with parasitic motion based clamping. Mech. Syst. Signal Process. 2019, 134, 106360. [Google Scholar] [CrossRef]

- Niu, Y.; Chen, X.; Chen, L.; Zhu, Z.; Huang, P. Development of a sinusoidal corrugated dual-axial flexure mechanism for planar nanopositioning. Actuators 2022, 11, 276. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, Y.; Qin, Y. Feedforward and feedback combined control of an XYθ-type micronano mechanism using multilayer feedforward neural network. In Proceedings of the 2023 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), Chengdu, China, 31 July–4 August 2023; pp. 102–107. [Google Scholar] [CrossRef]

- Liu, P.B.; Yan, P.; Zhang, Z.; Leng, T.T. Flexure-hinges guided nano-stage for precision manipulations: Design, modeling and control. Int. J. Precis. Eng. Manuf. 2015, 16, 2245–2254. [Google Scholar] [CrossRef]

- Liu, P.; Yan, P. A new model analysis approach for bridge-type amplifiers supporting nano-stage design. Mech. Mach. Theory 2016, 99, 176–188. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Pan, J.; Yan, Z.; Tan, J. A new nonlinear spatial compliance model method for flexure leaf springs with large width-to-length ratio under large deformation. Micromachines 2022, 13, 1090. [Google Scholar] [CrossRef]

- Wang, R.; Zhou, X.; Meng, H.; Liu, B. A novel type of pseudo-decoupling method for two degree-of-freedom piezoelectrically driven compliant mechanisms based on elliptical parameter compensation. Micromachines 2023, 14, 2043. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, J.; Ding, H.; Zhang, Y. Dynamic modeling and experimental verification of an RPR type compliant parallel mechanism with low orders. Chin. J. Mech. Eng. 2024, 37, 78. [Google Scholar] [CrossRef]

- Wang, L.; Song, Z.; Chen, B.; You, J.; Wu, H. A novel analytical approach for compound bridge-type amplifiers considering the external compound loads and cross-coupling effect. Phys. Scr. 2025, 100, 055005. [Google Scholar] [CrossRef]

- Kim, J.J.; Choi, Y.M.; Ahn, D.; Hwang, B.; Gweon, D.G.; Jeong, J. A millimeter-range flexure-based nano-positioning stage using a self-guided displacement amplification mechanism. Mech. Mach. Theory 2012, 50, 109–120. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, H.C.; Kim, H.Y.; Gweon, D.G. Optimal design and experiment of a three-axis out-of-plane nano positioning stage using a new compact bridge-type displacement amplifier. Rev. Sci. Instrum. 2013, 84, 115103. [Google Scholar] [CrossRef]

- Kim, K.; Ahn, D.; Gweon, D. Optimal design of a 1-rotational DOF flexure joint for a 3-DOF H-type stage. Mechatronics 2012, 22, 24–32. [Google Scholar] [CrossRef]

- Peng, Y.; Ito, S.; Shimizu, Y.; Azuma, T.; Gao, W.; Niwa, E. A Cr-N thin film displacement sensor for precision positioning of a micro-stage. Sens. Actuators A Phys. 2014, 211, 89–97. [Google Scholar] [CrossRef]

- Chen, S.; Ling, M.; Zhang, X. Design and experiment of a millimeter-range and high-frequency compliant mechanism with two output ports. Mech. Mach. Theory 2018, 126, 201–209. [Google Scholar] [CrossRef]

- Gu, S. Development of a piezoelectric hybrid-driven nanopositioner using combined leaf-spring-shaped and C-shaped flexure hinge mechanism. Phys. Scr. 2024, 99, 025407. [Google Scholar] [CrossRef]

- Xie, Y.; Li, Y.; Cheung, C.; Xiao, X.; Chen, X.; Wang, R. Investigation of a compliant precision positioning stage with folding function. Int. J. Adv. Manuf. Technol. 2023, 124, 3343–3358. [Google Scholar] [CrossRef]

- Guo, Z.; Tian, Y.; Tian, J.; Liu, X.; Wang, F.; Zhang, H.; Zhang, D. Probe system design for three dimensional micro/nano scratching machine. Microsyst. Technol. 2017, 23, 2285–2295. [Google Scholar] [CrossRef]

- Wang, R.; Liu, B.; Meng, H.; Zhou, X. Development of a novel type of modularized fast tool servo devices for manufacturing complex optical surfaces. Int. J. Precis. Eng. Manuf. 2024, 26, 635–649. [Google Scholar] [CrossRef]

- Shiou, F.J.; Chen, C.J.; Chiang, C.J.; Liou, K.J.; Liao, S.C.; Liou, H.C. Development of a real-time closed-loop micro-/nano-positioning system embedded with a capacitive sensor. Meas. Sci. Technol. 2010, 21, 054007. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, P.; Zhang, Z. A disturbance observer-based adaptive control approach for flexure beam nano manipulators. ISA Trans. 2016, 60, 206–217. [Google Scholar] [CrossRef]

- Lin, C.Y.; Chen, P.Y. Precision tracking control of a biaxial piezo stage using repetitive control and double-feedforward compensation. Mechatronics 2011, 21, 239–249. [Google Scholar] [CrossRef]

- Gu, G.Y.; Zhu, L.M.; Su, C.Y.; Ding, H.; Fatikow, S. Modeling and control of piezo-actuated nanopositioning stages: A survey. IEEE Trans. Autom. Sci. Eng. 2014, 13, 313–332. [Google Scholar] [CrossRef]

- Das, S.K.; Pota, H.R.; Petersen, I.R. A MIMO double resonant controller design for nanopositioners. IEEE Trans. Nanotechnol. 2014, 14, 224–237. [Google Scholar] [CrossRef]

- Namavar, M.; Fleming, A.J.; Aphale, S.S. Resonance-shifting integral resonant control scheme for increasing the positioning bandwidth of nanopositioners. In Proceedings of the 2013 European Control Conference (ECC), Zurich, Switzerland, 17–19 July 2013; pp. 1317–1322. [Google Scholar] [CrossRef]

- Khodabakhshi, E.; Moheimani, S.R. FPAA-based control of a high-speed flexure-guided AFM nanopositioner. Mechatronics 2024, 104, 103268. [Google Scholar] [CrossRef]

- San-Millan, A.; Aphale, S.S.; Feliu, V. A fast algebraic estimator for system parameter estimation and online controller tuning—A nanopositioning application. IEEE Trans. Ind. Electron. 2019, 66, 4534–4543. [Google Scholar] [CrossRef]

- Fleming, A.J. Nanopositioning system with force feedback for high-performance tracking and vibration control. IEEE/ASME Trans. Mechatron. 2009, 15, 433–447. [Google Scholar] [CrossRef]

- Moheimani, S.; Vautier, B.; Bhikkaji, B. Experimental implementation of extended multivariable PPF control on an active structure. IEEE Trans. Control Syst. Technol. 2006, 14, 443–455. [Google Scholar] [CrossRef]

- Russell, D.; Fleming, A.J.; Aphale, S.S. Simultaneous optimization of damping and tracking controller parameters via selective pole placement for enhanced positioning bandwidth of nanopositioners. J. Dyn. Syst. Meas. Control 2015, 137, 101004. [Google Scholar] [CrossRef]

- MacLean, J.; Aleyaasin, M.; Aphale, S.S. How far should poles be placed? Selecting positive feedback controllers for damping and tracking applications: A complete characterisation. Vibration 2022, 5, 641–658. [Google Scholar] [CrossRef]

- Babarinde, A.K.; Li, L.; Zhu, L.; Aphale, S.S. Experimental validation of the simultaneous damping and tracking controller design strategy for high-bandwidth nanopositioning—A PAVPF approach. IET Control Theory Appl. 2020, 14, 3506–3514. [Google Scholar] [CrossRef]

- Li, L.; Li, C.X.; Gu, G.; Zhu, L.M. Positive acceleration, velocity and position feedback based damping control approach for piezo-actuated nanopositioning stages. Mechatronics 2017, 47, 97–104. [Google Scholar] [CrossRef]

- San-Millan, A.; Feliu-Batlle, V.; Aphale, S.S. Two-degrees-of-freedom PI2D controller for precise nanopositioning in the presence of hardware-induced constant time delay. ISA Trans. 2019, 91, 207–217. [Google Scholar] [CrossRef]

- Babarinde, A.K.; Aphale, S.S. Linear matrix inequality approach to designing damping and tracking control for nanopositioning application. Vibration 2022, 5, 846–859. [Google Scholar] [CrossRef]

- Wang, C.; Gao, Y.; Xu, Y.; Wang, X.; Wang, L. Design and analysis of a novel variable stiffness joint based on leaf springs. Appl. Sci. 2024, 14, 2685. [Google Scholar] [CrossRef]

- Fleming, A.J.; Leang, K.K. Design, Modeling and Control of Nanopositioning Systems; Advances in Industrial Control; Springer International Publishing: Cham, Switzerland, 2014. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Zhang, Z. Design and tracking control of a large-range reluctance-actuated compliant nano-manipulator. In Proceedings of the 19th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Boston, MA, USA, 20–23 August 2023; Volume 7, p. V007T07A016. [Google Scholar] [CrossRef]

- Chen, F.; Zhang, Q.; Dong, W.; Sun, L. Design and test of a compact large-stroke dual-drive linear-motion system. Mech. Syst. Signal Process. 2022, 180, 109438. [Google Scholar] [CrossRef]

- Feng, H.; Pang, A.; Zhou, H. High precision robust control design of piezoelectric nanopositioning platform. Sci. Rep. 2022, 12, 10357. [Google Scholar] [CrossRef]

- Wang, G.; Zhou, Y.; Ni, L.; Aphale, S.S. Robust fractional-order fast terminal sliding mode control with fixed-time reaching law for high-performance nanopositioning. Int. J. Robust Nonlinear Control 2023, 33, 2596–2614. [Google Scholar] [CrossRef]

- Chen, J.; Ni, L.; Liao, X.; Wang, G.; Zhang, L.; Yao, N.; Li, Y.; Aphale, S.S. Hysteresis observer enhanced integral terminal sliding mode control of piezoelectric platform for precision tracking applications. ISA Trans. 2025, 165, 384–394. [Google Scholar] [CrossRef]

- Ahmad, I.; Ali, M.A.; Ko, W. Robust μ-synthesis with Dahl model based feedforward compensator design for piezo-actuated micropositioning stage. IEEE Access 2020, 8, 141799–141813. [Google Scholar] [CrossRef]

- Yang, C.; Youcef-Toumi, K. Principle, implementation, and applications of charge control for piezo-actuated nanopositioners: A comprehensive review. Mech. Syst. Signal Process. 2022, 171, 108885. [Google Scholar] [CrossRef]

- Ling, J.; Feng, Z.; Ming, M.; Xiao, X. Model reference adaptive damping control for a nanopositioning stage with load uncertainties. Rev. Sci. Instrum. 2019, 90, 045101. [Google Scholar] [CrossRef] [PubMed]

- Xu, Q.; Jia, M. Model reference adaptive control with perturbation estimation for a micropositioning system. IEEE Trans. Control Syst. Technol. 2013, 22, 352–359. [Google Scholar] [CrossRef]

- Yang, Z.; Cai, B.; Li, R.; Peng, H.; Bai, Y. A novel micro-positioning stage with large-stroke and adjustable stiffness. In Proceedings of the 45th Mechanisms and Robotics Conference (MR), Virtual, Online, 17–19 August 2021; Volume 8A, p. V08AT08A019. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Q. Reinforcement learning-based adaptive control of a piezo-driven nanopositioning system. IEEE Open J. Ind. Electron. Soc. 2024, 5, 28–40. [Google Scholar] [CrossRef]

- Meng, Y.; Li, L.; Wang, X.; Zhang, X.; Zhu, L. Data-driven based cross-coupling compensation method for the piezoelectric tube scanner of atomic force microscopes. Measurement 2023, 219, 113260. [Google Scholar] [CrossRef]

- Yin, R.; Ren, J. LSTM-inversion-based feedforward–feedback nanopositioning control. Machines 2024, 12, 747. [Google Scholar] [CrossRef]

- Koren, Y.; Lo, C.C. Variable-gain cross-coupling controller for contouring. CIRP Ann. 1991, 40, 371–374. [Google Scholar] [CrossRef]

- Huo, F.; Poo, A.N. Improving contouring accuracy by using generalized cross-coupled control. Int. J. Mach. Tools Manuf. 2012, 63, 49–57. [Google Scholar] [CrossRef]

- Ulu, N.G.; Ulu, E.; Cakmakci, M. Design and analysis of a modular learning based cross-coupled control algorithm for multi-axis precision positioning systems. Int. J. Control Autom. Syst. 2016, 14, 272–281. [Google Scholar] [CrossRef]

- Barton, K.L.; Alleyne, A.G. A cross-coupled iterative learning control design for precision motion control. IEEE Trans. Control Syst. Technol. 2008, 16, 1218–1231. [Google Scholar] [CrossRef]

- Chiu, G.C.; Tomizuka, M. Contouring control of machine tool feed drive systems: A task coordinate frame approach. IEEE Trans. Control Syst. Technol. 2002, 9, 130–139. [Google Scholar] [CrossRef]

- Yao, B.; Hu, C.; Wang, Q. An orthogonal global task coordinate frame for contouring control of biaxial systems. IEEE/ASME Trans. Mechatron. 2011, 17, 622–634. [Google Scholar] [CrossRef]

- Cao, Y.; Zhang, Z. A robust design of time-varying internal model principle-based control for ultra-precision tracking in a direct-drive servo stage. Mechatronics 2024, 103, 103249. [Google Scholar] [CrossRef]

- Tao, Y.D.; Li, H.X.; Zhu, L.M. Hysteresis modeling with frequency-separation-based Gaussian process and its application to sinusoidal scanning for fast imaging of atomic force microscope. Sens. Actuators A Phys. 2020, 311, 112070. [Google Scholar] [CrossRef]

- Li, M.; Zhu, Y.; Yang, K.; Hu, C.; Mu, H. An integrated model-data-based zero-phase error tracking feedforward control strategy with application to an ultraprecision wafer stage. IEEE Trans. Ind. Electron. 2016, 64, 4139–4149. [Google Scholar] [CrossRef]

- Hu, C.; Ou, T.; Zhu, Y.; Zhu, L. GRU-type LARC strategy for precision motion control with accurate tracking error prediction. IEEE Trans. Ind. Electron. 2020, 68, 812–820. [Google Scholar] [CrossRef]

- Meng, Y.; Wang, X.; Huang, W.W.; Li, L.; Hu, C.; Zhang, X.; Zhu, L. Intelligent tracking error prediction and feedforward compensation for nanopositioning stages with high-bandwidth control. IEEE Trans. Ind. Inform. 2022, 19, 6460–6470. [Google Scholar] [CrossRef]

- Lu, K.; Liu, Z.; Chen, C.P.; Zhang, Y. Event-triggered neural control of nonlinear systems with rate-dependent hysteresis input based on a new filter. IEEE Trans. Neural Netw. Learn. Syst. 2019, 31, 1270–1284. [Google Scholar] [CrossRef]

| Reference | Parasitic Rotation (µrad) | Resolution (nm) | Cross-Axis Coupling (%) | Natural Frequency (Hz) | Trajectory Tracking Error (nm) | Experimental Stroke (mm) | Size (mm) |

|---|---|---|---|---|---|---|---|

| [46] | 100 (10 mm × 10 mm) | 20 | 0.6 | 18 | 2250 (5 mm × 5 mm) | 10 | 385 × 385 (with actuators) |

| [104] | N.A. | 30 | N.A. | 20.1 (X-axis) 18.4 (Y-axis) | 74.9 (1 mm × mm) | 2 | 192 × 192 (without actuators) |

| [105] | N.A. | 200 | 1.3 | 29.3 (X-axis) 29.6 (Y-axis) | N.A. | 11.75 (X-axis) 11.66 (Y-axis) | 120 × 120 (without actuators) |

| [5] | N.A. | 106 | 2.87 | 4.1 | N.A. | 54.29 | 443 × 443 (without actuators) |

| [106] | N.A. | N.A. | 1.0 | 55.6 (X-axis) 52.6 (Y-axis) | 3620 (2 mm × 2 mm) | 2 | 127 × 127 (without actuators) |

| [78] | N.A. | 250 | 0.79 (X-axis) 0.98 (Y-axis) | 43.7 (X-axis) 45.3 (Y-axis) | 12300 ( mm × mm) | 2.13 (X-axis) 2.02 (Y-axis) | 280 × 280 (without actuators) |

| [28] | 22.72 (1 mm × 1 mm) | 5 | 0.29 (X-axis) 0.39 (Y-axis) | 57.1 (X-axis) 58.9 (Y-axis) | 88.30 (1 mm × 1 mm) | 2 | 300 × 300 (with actuators) |

| Modeling Method | Theoretical Basis | Accuracy | Computational Cost | Primary Application | Key Limitations |

|---|---|---|---|---|---|

| PRBM | Rigid-body mechanics with torsional springs | Low to Moderate | Very Low | Conceptual design, initial sizing | Inaccurate for large deformations and complex kinematics |

| Compliance Matrix/Beam Theory | Continuum mechanics, differential equations | Moderate to High (for simple geometries) | Low | Analytical analysis of basic flexure elements | Becomes intractable for complex 3D systems |

| Multi-body dynamics | Multi-body dynamics with flexible bodies | High for system-level motion | Moderate | System-level kinematics/dynamics | Contact definition can be complex; depends on input from FEA/analytical models |

| FEA | Numerical solution of PDEs | Very High | Very High | Detailed design validation, stress and modal analysis | Computationally intensive, not suitable for system-level control |

| Control Category | Representative Methods | Core Mechanism/Key Feature | Primary Advantages | Primary Limitations/Challenges | Typical Application Scenarios |

|---|---|---|---|---|---|

| Active Resonant Control | PPF, PVPF, PAVPF, IRC | Introduces positive feedback to reshape the system’s pole-zero distribution, increasing the damping ratio and suppressing mechanical resonance. | Effectively mitigates resonant peaks. Lays the foundation for high-bandwidth operation. PAVPF enables arbitrary pole placement for 3rd-order models. | Requires accurate system identification. Difficult to extend to higher-order or non-minimum phase systems. Controller complexity scales with the number of modes. | Initial damping of flexure mechanism resonances to improve system stability margins. |

| Tracking Control | PID, Loop-Shaping (Lead-Lag, Notch), Feedforward | PID provides error-driven regulation. Loop-shaping modifies frequency response. Feedforward improves response speed and reference tracking. | Simple structure, ease of implementation, and reliable performance. Well-established design methodologies. High steady-state accuracy. | Limited capability in handling significant nonlinearities and unmodeled dynamics. Bandwidth is often limited under high-performance demands. | Point-to-point positioning and trajectory tracking for systems with well-behaved dynamics and low uncertainty. |

| Robust Control | DOB, SMC, , -synthesis, ADRC | Designed to maintain stability and performance under model uncertainties and disturbances. DOB/ADRC estimate and compensate disturbances. SMC is insensitive to parameter variations. /-synthesis provides frequency-domain guarantees. | Strong robustness against parameter variations, external disturbances, and nonlinearities. Formal guarantees of stability. | Increased design complexity. May lead to conservative performance. Higher computational load (e.g., -synthesis). | Applications with significant load variations, unmodeled dynamics, or strong external disturbances. |

| Adaptive & Learning-Based Control | MRAC, ILC, RC, Neural Networks | Controller parameters adjust online to system changes (Adaptive) or performance improves from operational data (Learning). MRAC uses a reference model. ILC/RC learn from repetitive task errors. | Automatically compensates for time-varying dynamics (e.g., load changes). Achieves extremely high repetitive precision through iteration. Data-driven methods avoid the need for precise models. | Complex design with potential stability risks. Learning controllers require repetitive tasks or large datasets. High computational requirements. | Systems with time-varying parameters or repetitive tasks, e.g., AFM scanning, nano-manufacturing. |

| Multi-Axis Contour Tracking Control | CCC, TCF, PDC | Focuses on minimizing the coordinated error between axes (contour error) rather than individual axis tracking error. CCC minimizes contour error directly. TCF decouples error dynamics. PDC uses a position-domain approach. | Explicit minimization of contour error improves coordinated motion accuracy. Adaptable to complex contour geometries. | Increased controller complexity. Higher computational demand. Potential stability challenges from multiple interacting control loops. | Applications requiring precise coordinated motion, e.g., micro/nano-fabrication, complex trajectory scanning. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y. Recent Advances in the Design, Modeling, and Control of Flexure-Based Nanopositioning Stages. Micromachines 2025, 16, 1312. https://doi.org/10.3390/mi16121312

Liu Y. Recent Advances in the Design, Modeling, and Control of Flexure-Based Nanopositioning Stages. Micromachines. 2025; 16(12):1312. https://doi.org/10.3390/mi16121312

Chicago/Turabian StyleLiu, Yijie. 2025. "Recent Advances in the Design, Modeling, and Control of Flexure-Based Nanopositioning Stages" Micromachines 16, no. 12: 1312. https://doi.org/10.3390/mi16121312

APA StyleLiu, Y. (2025). Recent Advances in the Design, Modeling, and Control of Flexure-Based Nanopositioning Stages. Micromachines, 16(12), 1312. https://doi.org/10.3390/mi16121312