A Plantar Pressure Sensing System with Balancing Sensitivity Based on Tailored MWCNTs/PDMS Composites

Abstract

1. Introduction

2. Material Preparation and Characterization

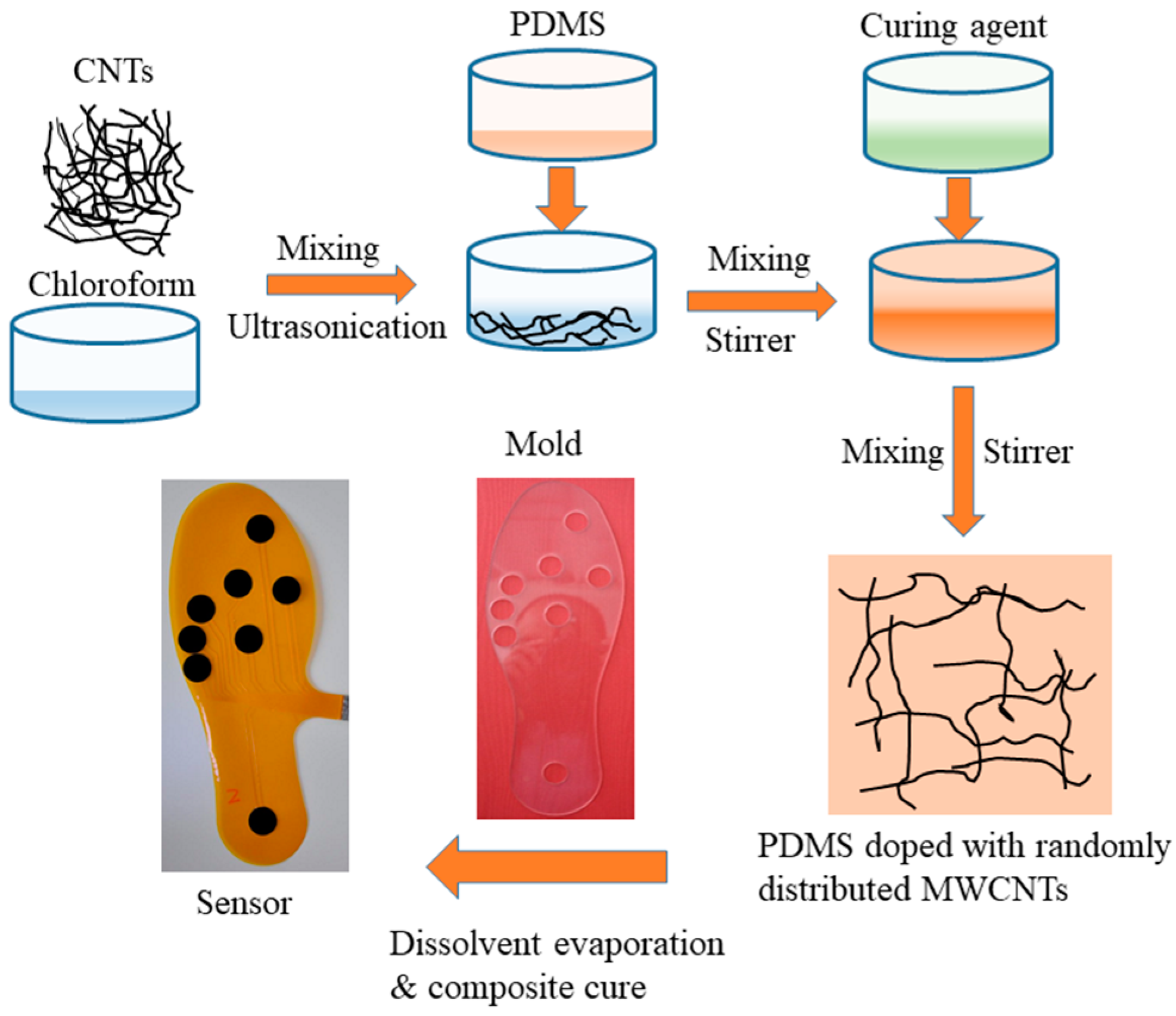

2.1. Material Preparation

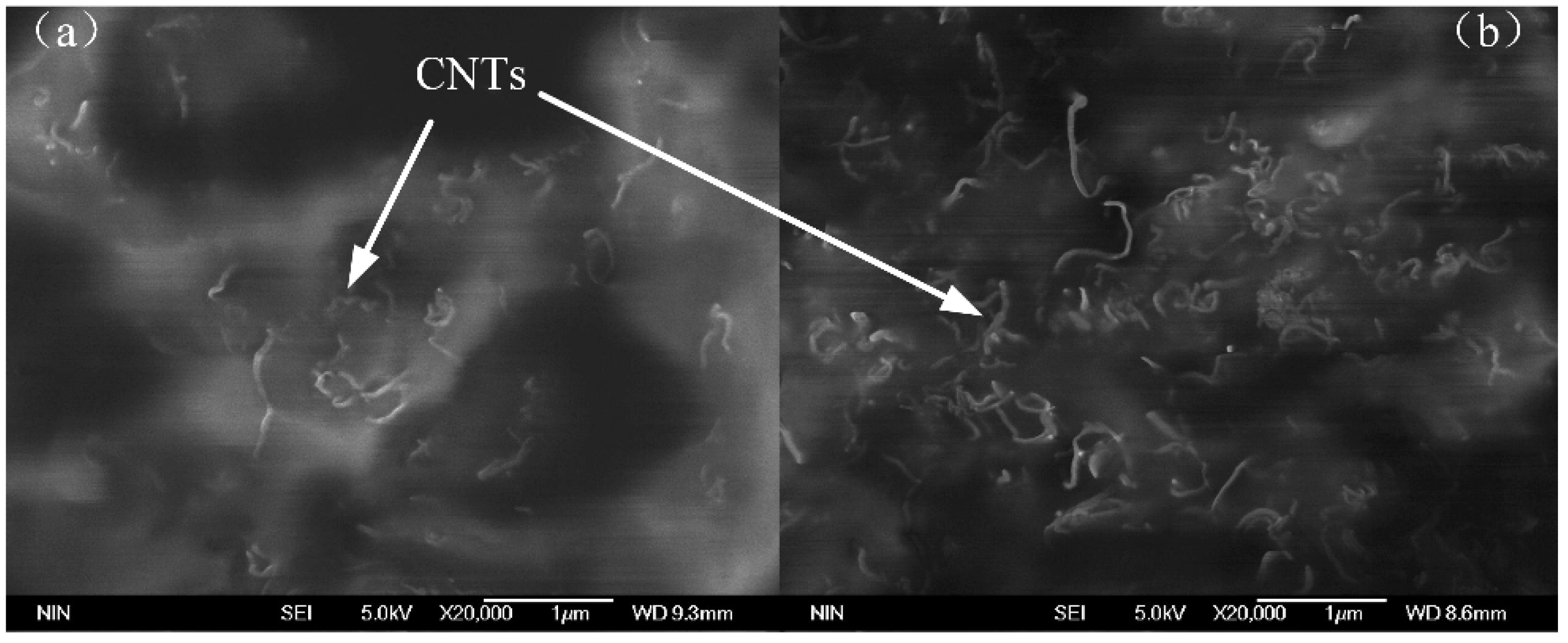

2.2. Material Characterization

2.3. Morphology of the Composite

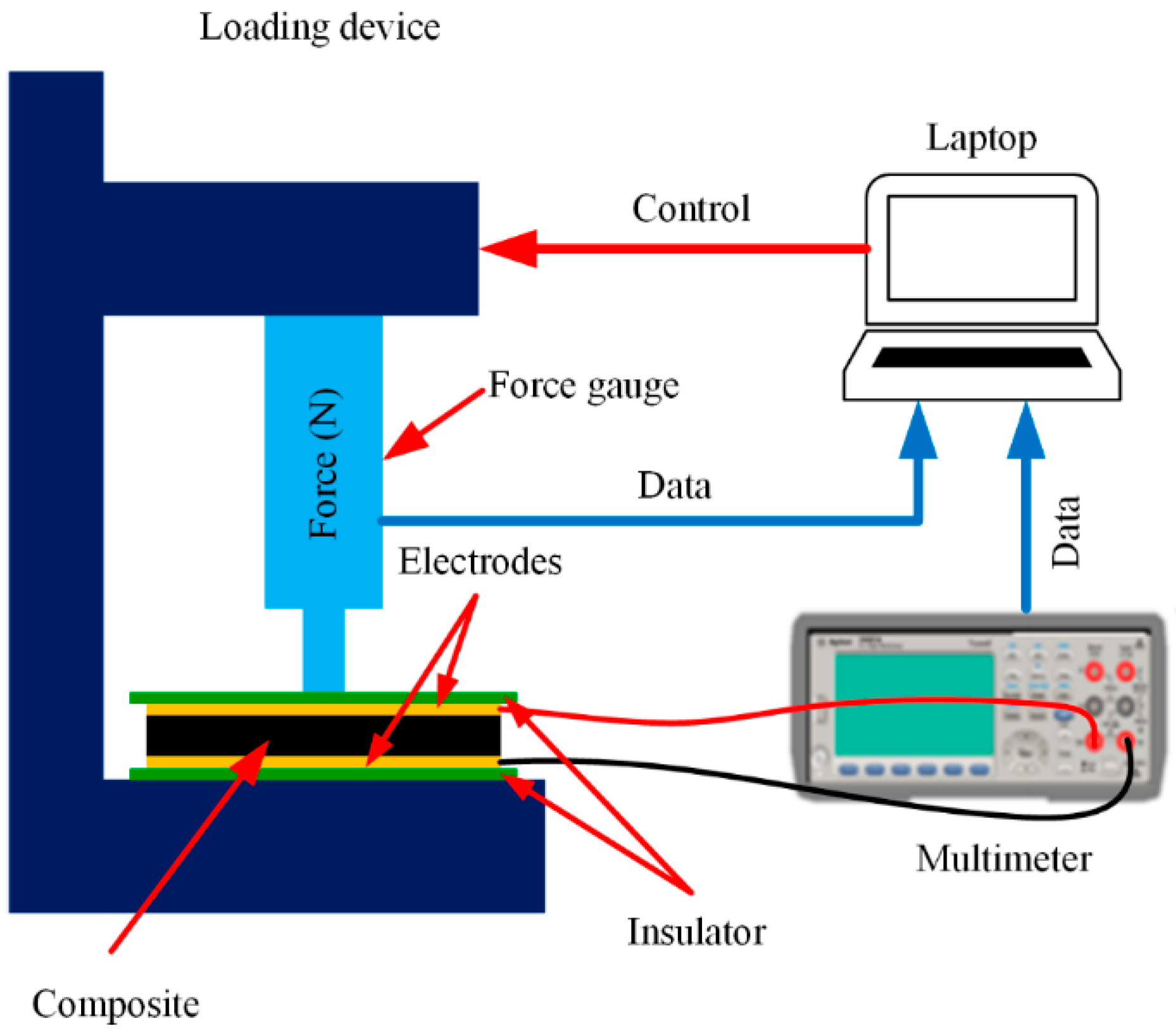

2.4. Electrical and Electromechanical Properties of the Composites

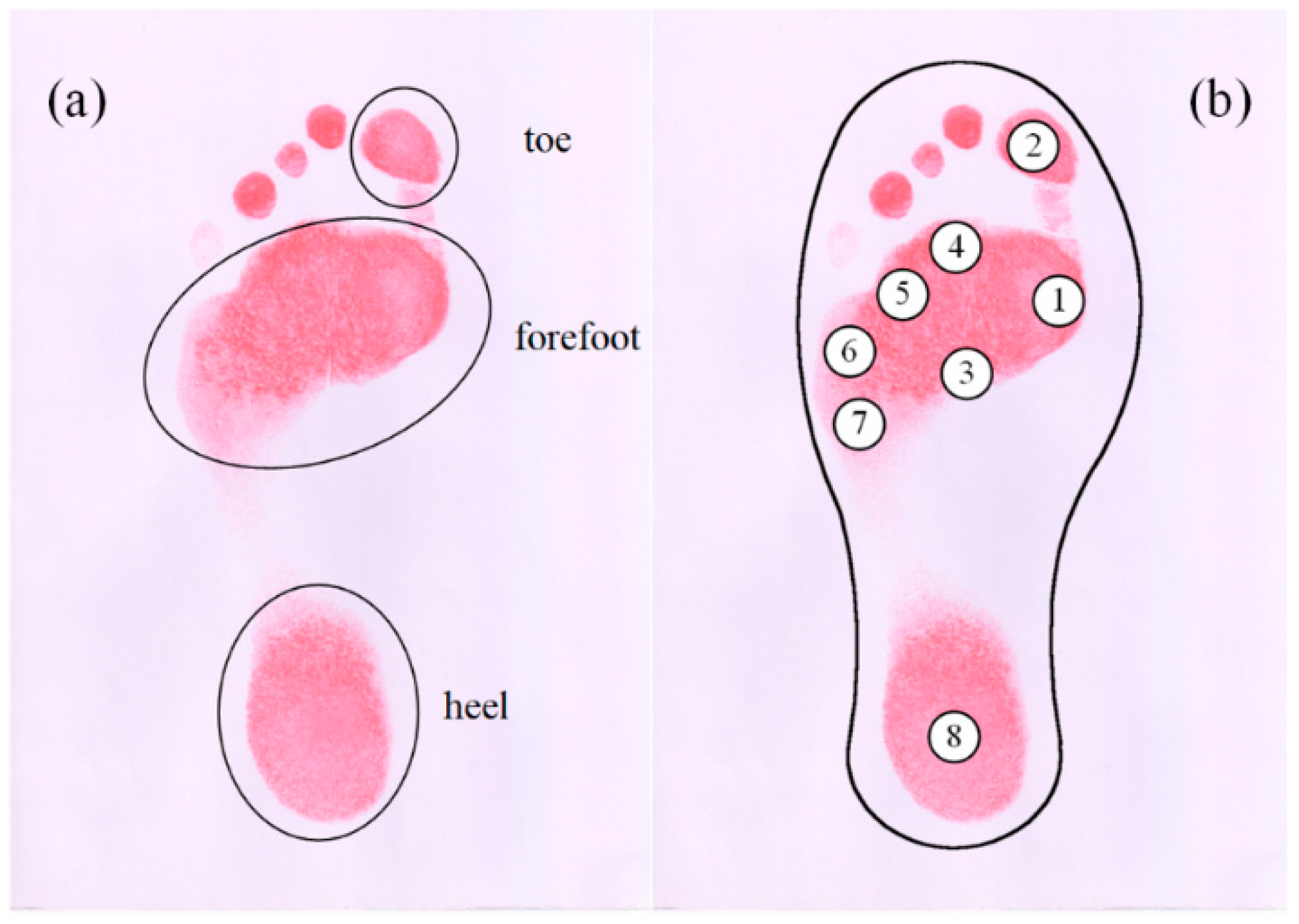

3. Sensor Development

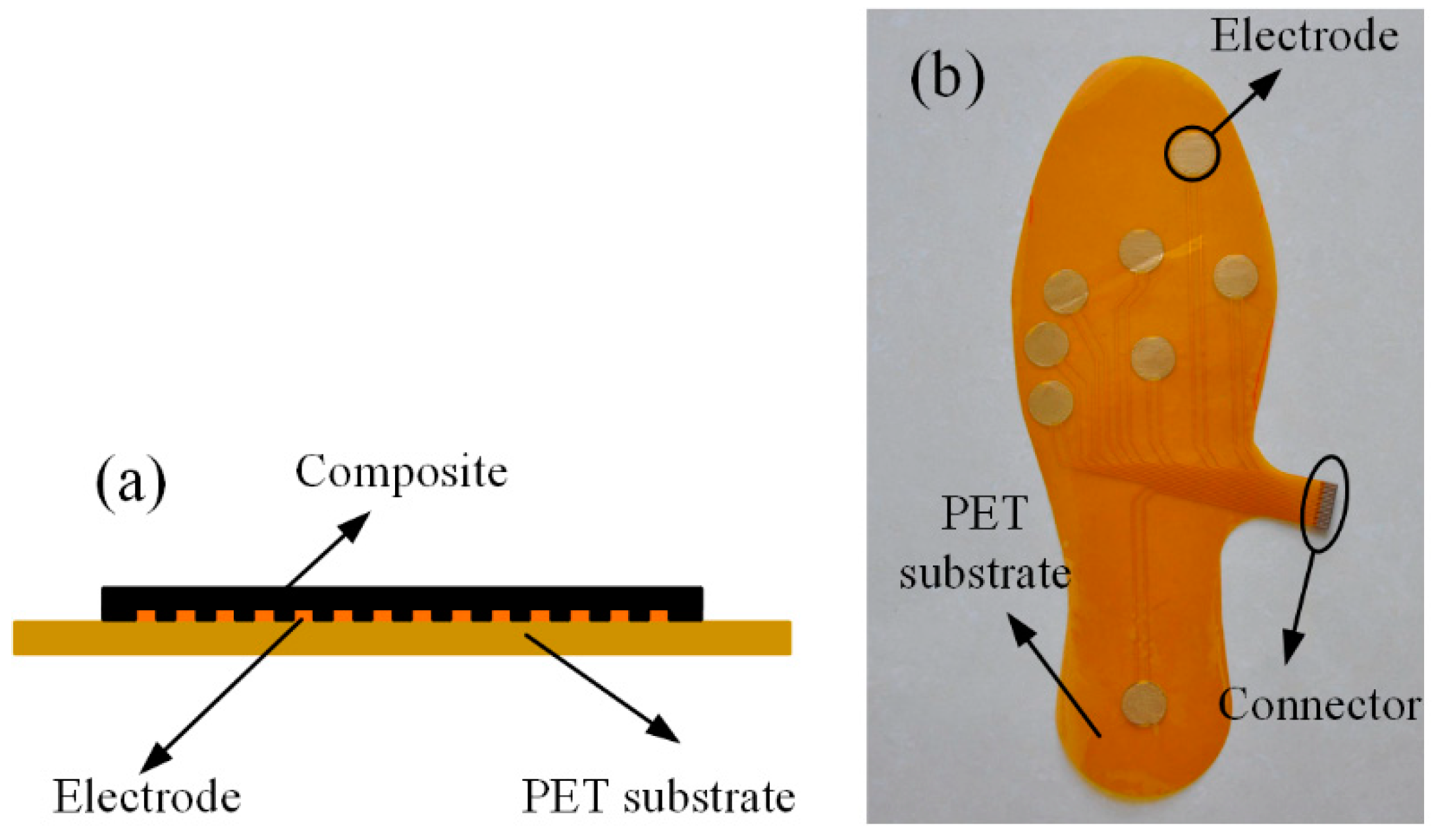

3.1. Sensor Architecture

3.2. Sensor Fabrication

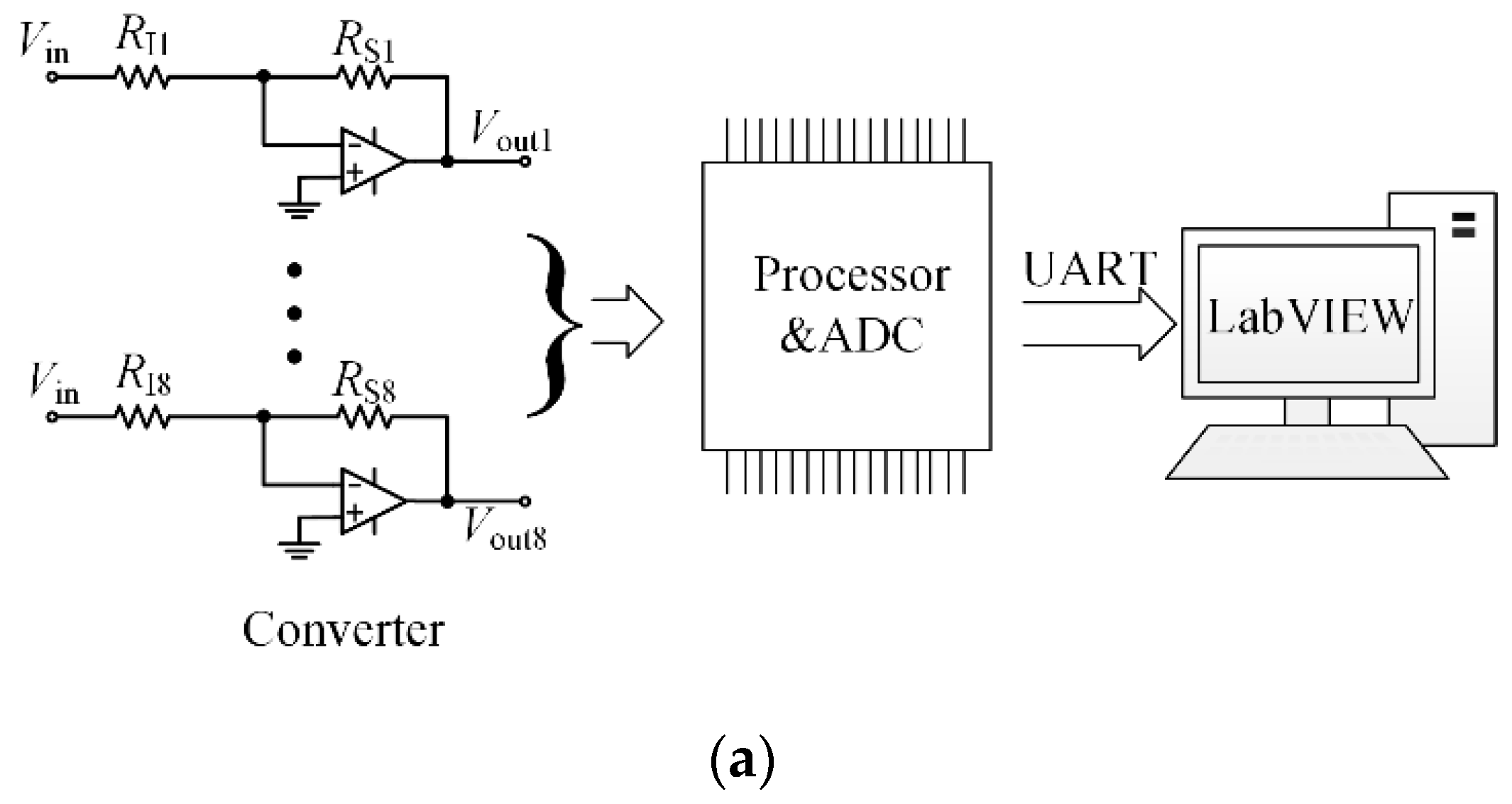

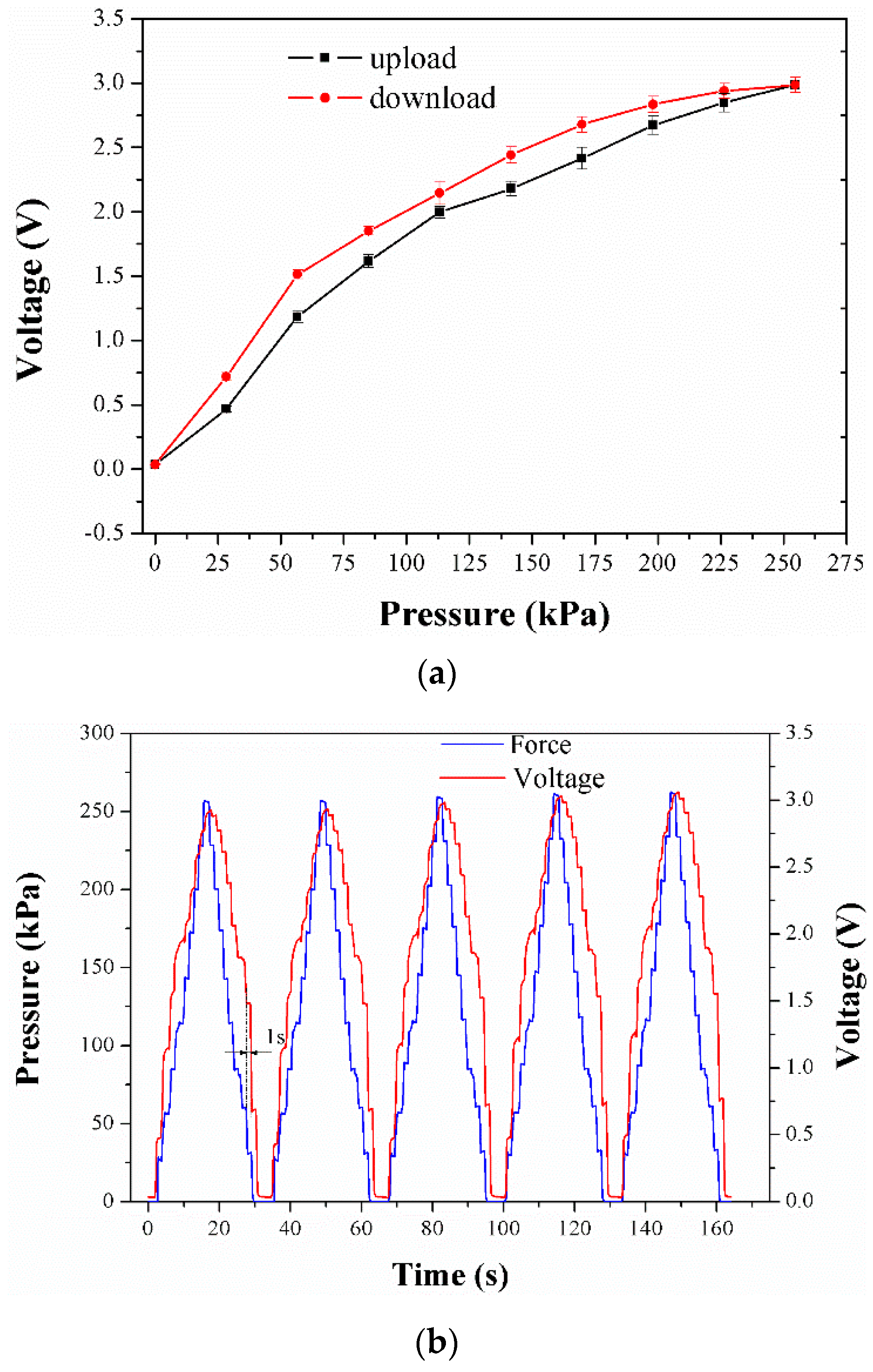

3.3. Signal Processing System

4. Results and Discussion

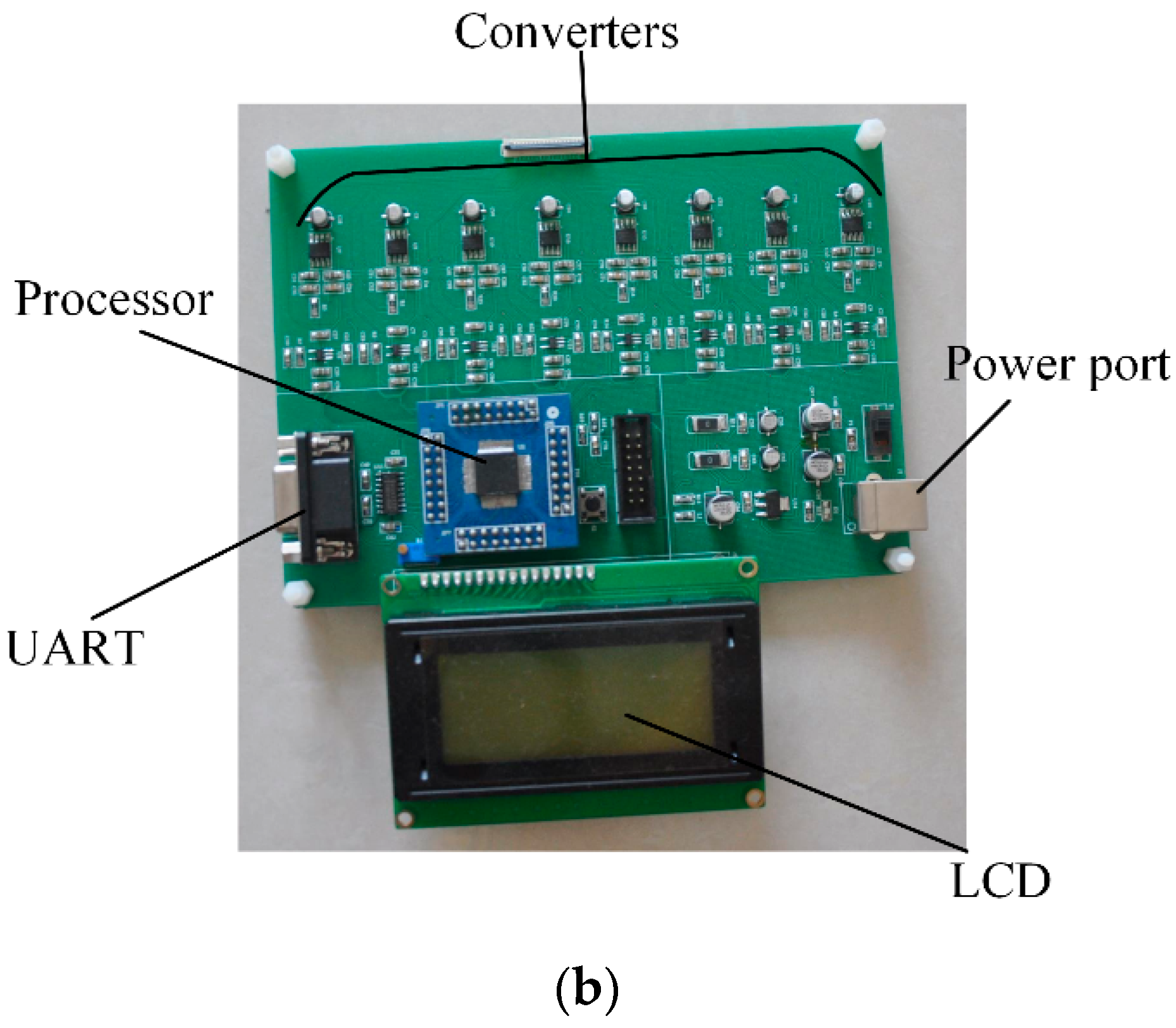

4.1. Characterization of Sensing Elements

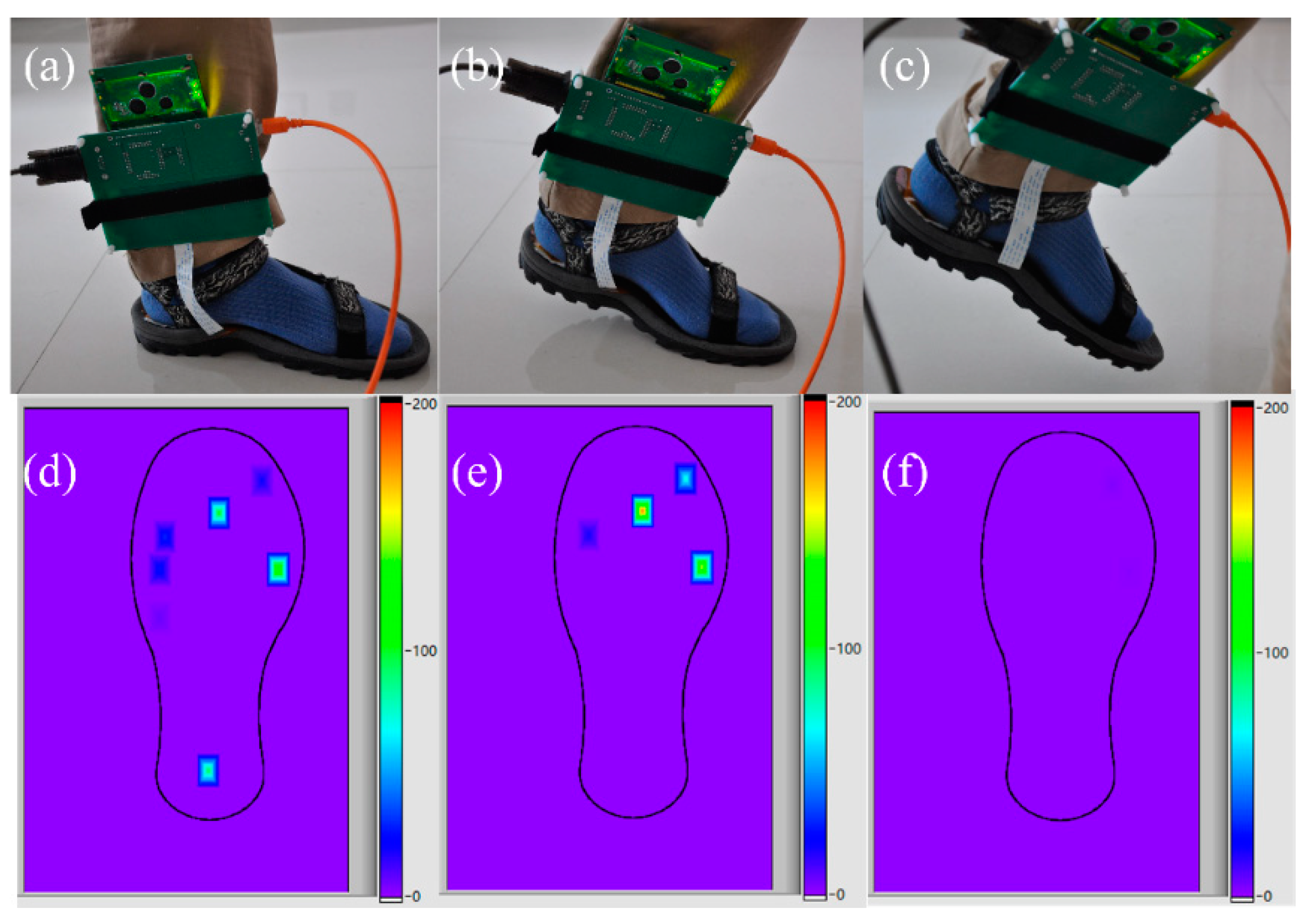

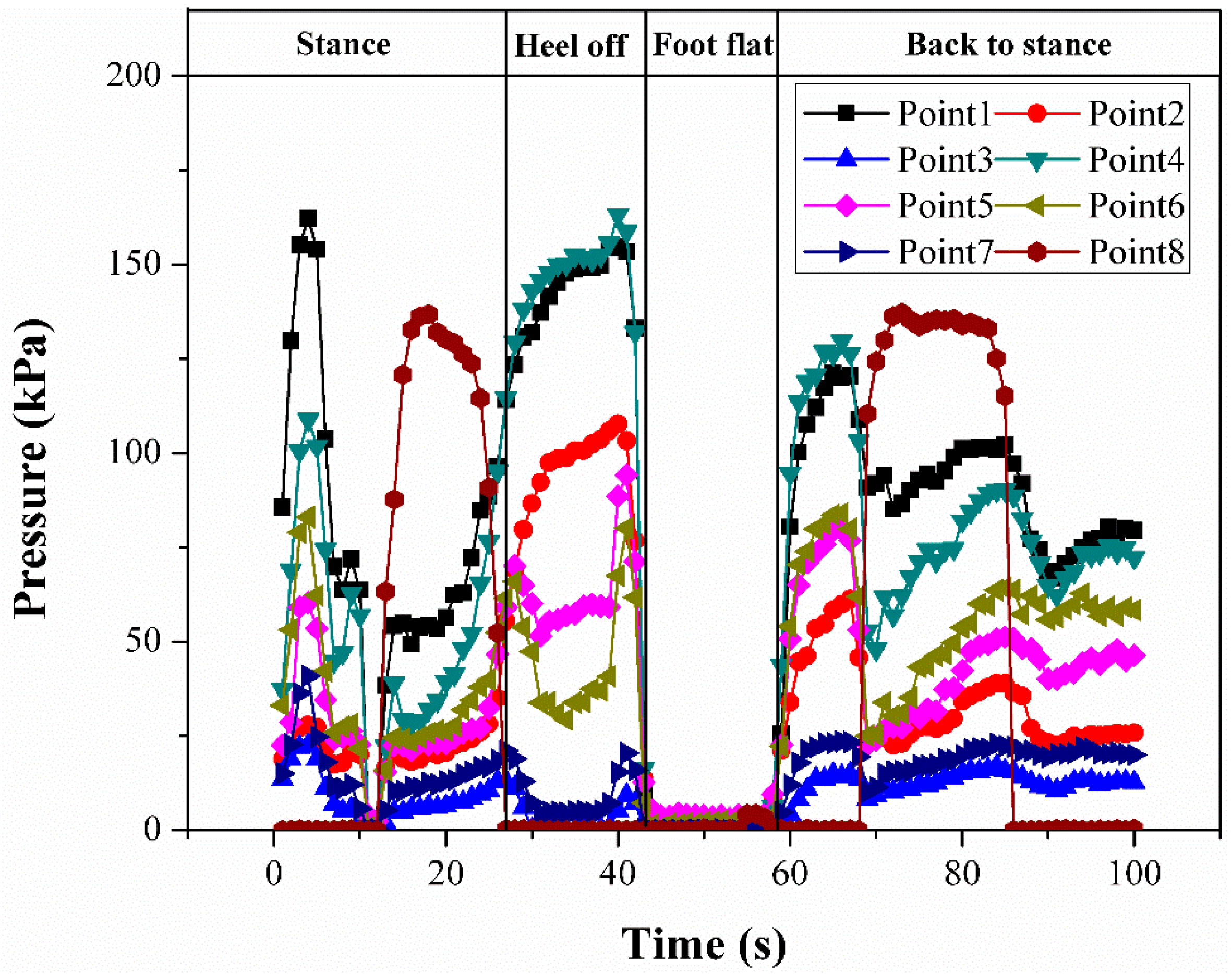

4.2. Application of the Plantar Pressure Sensor

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Qin, L.Y.; Ma, H.; Liao, W.H. Insole plantar pressure systems in the gait analysis of post-stroke rehabilitation. In Proceedings of the 2015 IEEE International Conference on Information and Automation, Lijiang, China, 8–10 August 2015. [Google Scholar]

- Paola, L.D.; Carone, A.; Vasilache, L.; Pattavina, M. Overview on diabetic foot: A dangerous, but still orphan, disease. Eur. Heart J. Suppl. 2015, 17, A64–A68. [Google Scholar] [CrossRef][Green Version]

- Azevedo, R.R.; da Rocha, E.S.; Franco, P.S.; Carpes, F.P. Plantar pressure asymmetry and risk of stress injuries in the foot of young soccer players. Phys. Ther. Sport 2017, 24, 39–43. [Google Scholar] [CrossRef] [PubMed]

- Lam, W.K.; Ng, W.X.; Kong, P.W. Influence of shoe midsole hardness on plantar pressure distribution in four basketball-related movements. Res. Sports Med. 2017, 25, 37–47. [Google Scholar] [CrossRef] [PubMed]

- Hohmann, E.; Reaburn, P.; Tetsworth, K.; Imhoff, A. Plantar Pressures during Long Distance Running: An Investigation of 10 Marathon Runners. J Sports Sci. Med. 2016, 15, 254–262. [Google Scholar] [PubMed]

- Mateos, L.A.; Ortiz, J.; Toxiri, S.; Fernández, J.; Masood, J.; Caldwell, D.G. Exoshoe: A sensory system to measure foot pressure in industrial exoskeleton. In Proceedings of the 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016. [Google Scholar]

- Xie, Z.; Wang, M.; Huang, W.; Wang, M.; Li, J.; Wang, X. A Lower Extremity Exoskeleton System for Walking Assist. In Proceedings of the 8th International Conference on Intelligent Human-Machine Systems and Cybernetics (IHMSC), Hangzhou, China, 27–28 August 2016. [Google Scholar]

- Barkallah, E.; Freulard, J.; Otis, M.J.D.; Ngomo, S.; Ayena, J.C.; Desrosiers, C. Wearable Devices for Classification of Inadequate Posture at Work Using Neural Networks. Sensors 2017, 17, 2003. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, B.; Liang, K.; Wan, Q.; Vanwanseele, B. An optimized design of in-shoe heel lifts reduces plantar pressure of healthy males. Gait Posture 2016, 47, 43–47. [Google Scholar] [CrossRef] [PubMed]

- Kong, K.; Tomizuka, M. A Gait Monitoring System Based on Air Pressure Sensors Embedded in a Shoe. IEEE/ASME Trans. Mechatron. 2009, 14, 358–370. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, Y.; Duan, Z.; Liu, Y. Design and Test of a Soft Plantar Force Measurement System for Gait Detection. Sensors 2012, 12, 16628–16640. [Google Scholar] [CrossRef] [PubMed]

- Gerlach, C.; Krumm, D.; Illing, M.; Lange, J.; Kanoun, O.; Odenwald, S.; Hübler, A. Printed MWCNT-PDMS-Composite Pressure Sensor System for Plantar Pressure Monitoring in Ulcer Prevention. IEEE Sens. J. 2015, 15, 3647–3656. [Google Scholar] [CrossRef]

- Lou, C.; Wang, S.; Liang, T.; Pang, C.; Huang, L.; Run, M.; Liu, X. A Graphene-Based Flexible Pressure Sensor with Applications to Plantar Pressure Measurement and Gait Analysis. Materials 2017, 10, 1068. [Google Scholar] [CrossRef] [PubMed]

- Rsscan Footscan, Rsscan International Website. Available online: http://www.rsscan.com/footscan/ (accessed on 1 August 2018).

- Abdul Razak, A.H.; Zayegh, A.; Begg, R.K.; Wahab, Y. Foot Plantar Pressure Measurement System: A Review. Sensors 2012, 12, 9884–9912. [Google Scholar] [CrossRef] [PubMed]

- Ramirez-Bautista, J.A.; Huerta-Ruelas, J.A.; Chaparro-Cárdenas, S.L.; Hernández-Zavala, A. A Review in Detection and Monitoring Gait Disorders Using In-Shoe Plantar Measurement Systems. IEEE Rev. Biomed. Eng. 2017, 10, 299–309. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Huang, Y.; Cai, X.; Liu, C.; Liu, P. Capacitive wearable tactile sensor based on smart textile substrate with carbon black /silicone rubber composite dielectric. Meas. Sci. Technol. 2016, 27, 045105. [Google Scholar] [CrossRef]

- Chortos, A.; Liu, J.; Bao, Z. Pursuing prosthetic electronic skin. Nat. Mater. 2016, 15, 937–950. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhou, D.; Cao, J. Development of a Skin-Like Tactile Sensor Array for Curved Surface. IEEE Sens. J. 2014, 14, 55–61. [Google Scholar] [CrossRef]

- Tao, L.Q.; Zhang, K.N.; Tian, H.; Liu, Y.; Wang, D.Y.; Chen, Y.Q.; Ren, T.L. Graphene-Paper Pressure Sensor for Detecting Human Motions. ACS Nano 2017, 11, 8790–8795. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Peng, H.; Wang, X.; Chen, X.; Yang, C.; Yang, B.; Liu, J. PDMS/MWCNT-based tactile sensor array with coplanar electrodes for crosstalk suppression. Microsyst. Nanoeng. 2016, 2, 160651–160658. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, L. Piezoresistive effect of a carbon nanotube silicone-matrix composite. Carbon 2014, 71, 319–331. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, Y.; Li, Z.; Wang, Y.; Dai, K.; Zheng, G.; Liu, C.; Shen, C. The effect of filler dimensionality on the electromechanical performance of polydimethylsiloxane based conductive nanocomposites for flexible strain sensors. Compos. Sci. Technol. 2017, 139, 64–73. [Google Scholar] [CrossRef]

- Kwon, S.Y.; Park, Y.K.; Kim, M.S. Piezoresistive properties of multi-walled carbon nanotube–poly (dimethylsiloxane) composites for low-pressure-sensing applications. Nano 2012, 7, 1250005. [Google Scholar] [CrossRef]

- Mitrakos, V.; Hands, P.J.; Cummins, G.; Macintyre, L.; Denison, F.C.; Flynn, D.; Desmulliez, M.P. Nanocomposite-Based Microstructured Piezoresistive Pressure Sensors for Low-Pressure Measurement Range. Micromachines 2018, 9, 43. [Google Scholar] [CrossRef]

- Leardini, A.; Benedetti, M.G.; Berti, L.; Bettinelli, D.; Nativo, R.; Giannini, S. Rear-foot, mid-foot and fore-foot motion during the stance phase of gait. Gait Posture 2007, 25, 453–462. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Zhang, K.; Dai, X.X.; Li, Y.; Guo, J.; Liu, H.; Li, G.H.; Tan, Y.J.; Zeng, J.B.; Guo, Z. Enhanced electrical conductivity and piezoresistive sensing in multi-wall carbon nanotubes/polydimethylsiloxane nanocomposites via the construction of a self-segregated structure. Nanoscale 2017, 9, 11017–11026. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Jiang, R.; Li, G.; Chen, Y.; Tang, Z.; Wang, Y.; Liu, Z.; Jiang, H.; Zhi, C. Flexible dual-mode tactile sensor derived from three-dimensional porous carbon architecture. ACS Appl. Mater. Interfaces 2017, 9, 22685–22693. [Google Scholar] [CrossRef] [PubMed]

- Bae, G.Y.; Pak, S.W.; Kim, D.; Lee, G.; Kim, D.H.; Chung, Y.; Cho, K. Linearly and Highly Pressure-Sensitive Electronic Skin Based on a Bioinspired Hierarchical Structural Array. Adv. Mater. 2016, 28, 5300–5306. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.Q. Development of an Approach for Interface Pressure Measurement and Analysis for Study of Sitting. Master’s Thesis, National University of Singapore, Singapore, 2010. [Google Scholar]

| Purity | Diameter | Length | Ratio | Percolation Threshold | |

|---|---|---|---|---|---|

| Ref [23] | 90% | 5–15 nm | 10–20 μm | 667–4000 | 0.13 vol% |

| Ref [24] | 95% | 15 nm | 40–110 μm | 2667–7333 | 0.045 wt% |

| Ref [25] | 98% | 10 nm | 3–6 μm | 300–600 | 0.625 ± 0.100% w/w |

| This work | 90% | 10–30 nm | 10–30 μm | 333–3000 | <4 wt% |

| E1 | E2 | E3 | E4 | E5 | E6 | E7 | E8 | Ref. [30] | |

|---|---|---|---|---|---|---|---|---|---|

| Linearity (%) | 21.85 | 16.22 | 13.09 | 23.29 | 19.12 | 12.99 | 23.18 | 23.62 | ≤±10 |

| Hysteresis (%) | 12.75 | 11.50 | 13.81 | 8.00 | 18.11 | 8.43 | 8.57 | 22.06 | ≤15 |

| Repeatability (%) | 3.91 | 2.60 | 0.86 | 1.59 | 1.29 | 1.48 | 1.57 | 1.00 | ≤5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Chai, R.; Wang, H.; Ye, X. A Plantar Pressure Sensing System with Balancing Sensitivity Based on Tailored MWCNTs/PDMS Composites. Micromachines 2018, 9, 466. https://doi.org/10.3390/mi9090466

Zhang X, Chai R, Wang H, Ye X. A Plantar Pressure Sensing System with Balancing Sensitivity Based on Tailored MWCNTs/PDMS Composites. Micromachines. 2018; 9(9):466. https://doi.org/10.3390/mi9090466

Chicago/Turabian StyleZhang, Xuefeng, Running Chai, Haitao Wang, and Xiangdong Ye. 2018. "A Plantar Pressure Sensing System with Balancing Sensitivity Based on Tailored MWCNTs/PDMS Composites" Micromachines 9, no. 9: 466. https://doi.org/10.3390/mi9090466

APA StyleZhang, X., Chai, R., Wang, H., & Ye, X. (2018). A Plantar Pressure Sensing System with Balancing Sensitivity Based on Tailored MWCNTs/PDMS Composites. Micromachines, 9(9), 466. https://doi.org/10.3390/mi9090466